Motrec E-242HD Maintance Manual

E-242HD

OPERATOR AND MAINTENANCE MANUAL

SPARE PARTS LISTS INCLUDED

SERIAL NUMBER : 1035396 & UP

Printed in Canada

18/02/2008

One Year Limited Warranty

Effective April 25, 2005, MOTREC, Inc. (MOTREC) hereby warrants to the Original Retail Purchaser (Owner) that any of its

vehicles shall be free from any defect in materials for a period of 90 DAYS while in the possession of such Original Retail

Purchaser. This warranty IS NOT TRANSFERABLE to any subsequent Buyer.

The warranty period is extended to one year or one thousand (1,000) hours, which ever first occurs, on the electric motor,

differential (parts that bathe in oil) and the electronic speed controller. MOTREC makes no warranty or representation with

respect to the internal combustion engine, tires and batteries, since their respective manufacturers cover such parts.

Accessories (light, gage, horn, etc), electrical contacts (switch, solenoid, contactor, relay), diodes & fuses, belts & pulleys,

filters & spark plugs, lubricants, brake linings & shoes, brake drums & discs, seals, seats, trim and other items subject to

wear are not included in this warranty; nor is any item that in MOTREC sole opinion, shows evidence of neglect, misuse,

abuse, collision or alteration.

This warranty shall not apply to normal maintenance requirements as described in the User Manual, and to damages during

shipment. The latter is the carrier's responsibility. No compensation will be allowed for delays.

To initiate warranty coverage on any MOTREC vehicle, the Dealer must complete and return the “Sales/Installation Report”

to MOTREC within 30 days after delivery to the Original Retail Purchaser; or within 90 days after the delivery date to the

Dealer, which ever occurs first. Failure to follow these procedures will result in considering the warranty coverage effective

as of the shipment date from the factory.

The defective vehicle must be returned, at the Owner's expense, to an authorised MOTREC Dealer within 30 days after

failure. The Owner will not be charged for parts and labour required for warranty repairs, which must be performed by an

authorised MOTREC Dealer only. The vehicle will be returned at the owner’s expense. The Warranty Claim Forms must be

completed and returned with the defective part(s) to MOTREC within 30 days after repair was done. No compensation will be

allowed for damages caused by vehicle downtime.

It is the responsibility of the owner of the vehicle to make sure that the driver is properly trained and instructed in the safety

features and operation of the vehicle, including vehicle stability, as required by OSHA and ANSI-B56. Operators shall read,

understand and follow the safety and operating instructions in MOTREC Manual before driving the vehicle. Operators shall

not be permitted to drive the vehicle unless a complete and adequate training has been provided. Driving a vehicle

constitutes a hazard. The driver is responsible for the control of the vehicle while driving and must always evaluate and care

for all peculiar situations that he or she may meet while driving. The driver assumes the inherent hazards related to this

activity. The vehicle is designed for off-road use only. MOTREC disclaims any liability for incidental or consequential

damages, to include, but not be limited to, personal injury or property damage arising from vehicle misuse, lack of

maintenance or any defect in the vehicle.

It is the responsibility of the Owner of the vehicle to make sure that the service technicians are properly trained as required

by OSHA and ANSI-B56. Service technicians shall read, understand and follow instructions in the MOTREC manual before

servicing the vehicle. Only qualified and authorized personnel shall be permitted to maintain, repair, adjust and inspect the

vehicle.

MOTREC prohibits, and disclaims responsibility for, any vehicle modification altering the weight distribution and stability,

increasing the speed or affecting the safety of the vehicle. Such modifications can cause serious personal injury or property

damage for which MOTREC disclaims any responsibility.

For Owners that are located outside North America, the warranty period starts the date of shipment from the factory, and the

defective parts must be returned at the Owner's expense to MOTREC prior to warranty repair.

Table of contents

- 3 -

TABLE OF CONTENTS

INSTRUCTIONS 4

SAFETY WARNINGS FOR OPERATORS 5

OPERATING INSTRUCTIONS 6

MAINTENANCE 7

SAFETY WARNINGS FOR SERVICE TECHNICIANS 8

DECALS AND LABELS 10

PERIODIC MAINTENANCE CHECKLIST 11

ACCELERATOR 12

BELT INSTALLATION AND TENSIONING 13

MECHANICAL BRAKES 14

BATTERY MAINTENANCE 15

BATTERY CHARGER 17

ELECTRICAL TROUBLESHOOTING 18

CURTIS SPEED CONTROLLER 21

WIRING : STANDARD CONFIGURATION 23

DIAGNOSTICS AND TROUBLESHOOTING 24

TROUBLESHOOTING CHART 25

LED DIAGNOSTICS 27

PROGRAMMING PARAMETERS – E-242, E-242HD, E-250 28

CURTIS PMC MOTOR CONTROLLER 29

WIRING : STANDARD CONFIGURATION 31

MAINTENANCE AND ADJUSTMENT 33

SPARE PARTS 35

BODY 36

DIFFERENTIAL 37

MECHANICAL DRUM BRAKES 39

BRAKE CONTROLS 40

STEERING ASSEMBLY 41

STEERING WHEEL 42

MOTOR AND DRIVE 43

REAR AXLE FRAME 44

ELECTRICAL DIAGRAM – SEPEX MAIN CIRCUIT 45

ELECTRICAL DIAGRAM – SERIES MAIN CIRCUIT 46

ACCESSORIES – NO DC/DC CONVERTER 47

BATTERY CONFIGURATIONS - 24V 49

BUILT-IN 25A CHARGER 50

PORTABLE 40A CHARGER 51

PORTABLE 25A CHARGER 52

BUILT-IN/PORTABLE CHARGER MODEL 16370 53

DELTA-Q HF CHARGER 54

MOTREC ILLUSTRATED ACCESSORIES 57

BATTERY DISCHARGE INDICATOR (HOBBS) 59

Instructions

- 4 -

INSTRUCTIONS

Instructions

- 5 -

SAFETY WARNINGS FOR OPERATORS

FAILURE TO OBEY THE FOLLOWING SAFETY RULES MAY RESULT IN SEVERE INJURY.

It is the responsibility of the owner of this vehicle to train operators to ensure that they understand the operating

characteristics of this vehicle, including training in vehicle stability, and obey the following safety rules and

guidelines. Owner shall comply with OSHA and ANSI/ITSDF B56.8 & B56.9 Standards for vehicle use, safety rules,

operator training and certification. Do not drive this vehicle unless you are a qualified operator.

Do not drive this vehicle under the influence of drugs or alcohol.

Do not drive this vehicle on public roads and highways. This vehicle is designed to be driven in buildings.

The electrical system of this vehicle will make sparks which can ignite inflammable materials. Never use the vehicle

in hazardous areas where there are inflammable materials, explosive dust or fumes in the air.

Have your vehicle inspected regularly by trained personnel, and cease operation if a malfunction occurs.

Do not open battery compartment to prevent battery explosion, acid splashing, severe damage to eyes or skin.

Do not open motor compartment. Keep clear from moving, rotating(wheels, sheaves, etc) or lifting parts.

Never carry more passengers than number allowed for this vehicle. Wait until all occupants are seated and holding on

before moving. Always keep all body parts inside vehicle. Keep both hands on steering wheel.

Do not exceed the vehicle cargo load capacity and gross trailing weight capacity, rated for flat hard even surface.

Different operating conditions such as loose terrain or ramps reduce vehicle capacity.

Avoid loose, unbalanced or top-heavy loads to keep a good stability and prevent overturn. Do not load cargo that can

fall off the vehicle. Do not carry cargo that is longer, wider or higher than this vehicle.

Always depress slowly the accelerator for smooth acceleration. Avoid stunt driving or horseplay.

Avoid sharp turns, always slow down before turning, to prevent vehicle overturn or trailer jack knife. Vehicle is more

sensitive to overturn and jack knife when traveling on inclines or when carrying a heavy load.

Always drive straight up and down the face of an incline, never across the face, to prevent overturn and trailer jack

knife. Drive slower and start applying brakes sooner on inclines to adjust for longer stopping distance.

Use extra care and drive slowly in reverse, in congested areas or on wet or slippery ground.

Keep to the right under normal conditions. Maintain a safe distance from all objects.

Slow down and sound the horn when approaching a corner or other blind intersections.

Before leaving the vehicle, park on a level ground flat surface, turn off all switches, set the forward/reverse switch to

neutral, set the parking brake, remove the key. Do not park the vehicle on an incline.

Before battery charging, park the vehicle in a well ventilated area set for. Do not operate it when charging. To

interrupt a charging cycle, disconnect the AC plug; disconnecting the DC plug or a battery terminal, or operating the

vehicle, could damage the charger and produce a spark, battery explosion and acid splashing.

Use another driver to steer this vehicle while it is towed. Be sure the driver uses brakes when you slow or stop the

towing vehicle. Do not exceed 5 MPH or carry any passenger while towing this vehicle.

Instructions

- 6 -

OPERATING INSTRUCTIONS

It is the responsibility of the owner of this vehicle to ensure that the operator understands the operating

characteristics of this vehicle, and obeys the safety instructions in this manual and ANSI/ITSDF B56.8 & 9

Standards. Do not drive this vehicle unless you are a certified operator as required by OSHA.

BEFORE TURNING ON KEYSWITCH

Set to neutral, set parking brake, check for visible damage, check brake pedal.

AFTER TURNING ON KEYSWITCH

Check safety devices: seat switch, reverse alarm, motion beeper, strobe light, and all other safety devices.

BATTERIES

Never open the battery compartment unless you have received proper training for battery maintenance.

Batteries emit explosive hydrogen gas that can be ignited by a spark or loose terminal. Battery acid causes severe damage to

eyes or skin. Flush the contaminated area immediately with water. Park the vehicle in a well ventilated area for battery

charging. Most battery chargers come with an electronic control that starts when the charger is plugged and stop when the

battery is fully charged. To interrupt the charging cycle, disconnect the AC-plug, do not disconnect the DC plug.

BATTERY DISCHARGE INDICATOR

The green light moves from right to left as batteries are being discharged. When the green light is at the last position on the

left the batteries must be recharged. A flashing light warns the operator that further discharge will damage batteries. See

HOBBS indicator instructions.

EMERGENCY SAFETY DEVICE

The emergency push button or battery disconnect handle, when present, should only be used in case of emergency. Use the

key switch for normal ON/OFF control.

KEYSWITCH

Depress brake pedal and turn the key switch clockwise for on position. Always turn off all switches, set the F/R selector to

neutral, set the parking brake, remove the key before leaving the vehicle.

HORN

Depress the horn button on the steering column or handle bar.

F/R SWITCH

Three positions with neutral at center. Depress the front part of the rocker switch for forward direction. Depress the rear part

of the rocker switch for reverse direction. Always set switch to neutral, turn off all switches, set the parking brake, remove

the key before leaving the vehicle.

ACCELERATOR PEDAL

It is designed for right foot operation only, and controls the speed of the vehicle. Apply slowly.

FOOT BRAKE PEDAL

It is designed for right foot operation only. The brake force is proportional to the pressure on the pedal.

PARKING BRAKE

Pull handbrake lever to apply. Never park the vehicle on an incline. Always turn off all switches, set the F/R selector to

neutral, set the parking brake, remove the key before leaving the vehicle.

Maintenance

- 7 -

MAINTENANCE

Maintenance

- 8 -

SAFETY WARNINGS FOR SERVICE TECHNICIANS

FAILURE TO OBEY THE FOLLOWING SAFETY RULES MAIN RESULT IN SEVERE INJURY.

Owner shall comply with OSHA and ANSI/ITSDF B56.8 & B56.9 Standards for vehicle maintenance.

Only qualified and authorized personnel shall be permitted to maintain, repair, adjust and inspect

carriers, vehicles, tractors, and batteries.

Before any maintenance work, park the vehicle on flat level surface, turn off all switches, remove key,

lift wheels off the ground and secure with jack stands of adequate capacity. Don’t connect charger.

Keep clear from moving parts such as tires, sheaves and motor.

Follow the maintenance instructions applicable to the type of repair, maintenance, or service.

Always wear a face shield and gloves when working around batteries.

Before opening the battery compartment, disconnect the charger, turn off all switches and remove the

key. Batteries emit highly explosive gases which greatly increase when charging; do not disturb

connections or produce sparks around batteries to avoid a battery explosion and acid splashing. Battery

acid causes severe damage to eyes or skin. Flush contaminated area immediately with water.

Use insulated tools to avoid sparks that can cause battery explosion and acid splashing.

Use two counteracting tools, double-wrench technique, when disconnecting or tightening terminals on

the battery and the speed controller to avoid cracking the terminal or battery post welds.

Before cleaning or replacing a battery, charger, speed controller, contactor, relay, diode, or any other

component in the power circuit, always disconnect the charger, turn off all switches, remove the key,

wear a face shield and gloves, identify battery polarity and disconnect battery leads, discharge the

capacitor in the controller with a 10 ohms, 25 W resistor for a few seconds across B+ and B-.

After cleaning, the power must not be reapplied until terminal areas are thoroughly dry.

On EE-Rated vehicles make sure that the control box is sealed, the static strap makes good contact with

the ground, the motor is sealed by bands, the cable protectors are properly installed.

Keep cables and wires clear from mechanical and rubbing action. Make sure that cable insulation is

free from cutting or visible damage. Make sure that EE-Rated cable protectors are properly installed.

Before replacing a fuse or circuit breaker, identify the cause of failure and repair.

Programmable controllers must be programmed using the parameter settings in this service manual,

before connecting the motor, to avoid sudden vehicle movement and accident.

Maintenance

- 9 -

Do not try to increase motor speed by changing parameter settings in the speed controller; it can cause

accident and severe damage to the motor.

SEPEX speed controls are protected by a diode in the power circuit to filter inductive loads in the event

of a sudden power interrupt. Some speed controllers require a diode to filter inductive loads on the KSI

input. Removing the diodes will cause the speed control failure.

Before resuming maintenance operations, inspect safety warnings stickers and replace any if damage is

found and part of the text can’t be read.

Check decals and labels, see “DECAL AND LABELS” page.

Maintenance

- 10 -

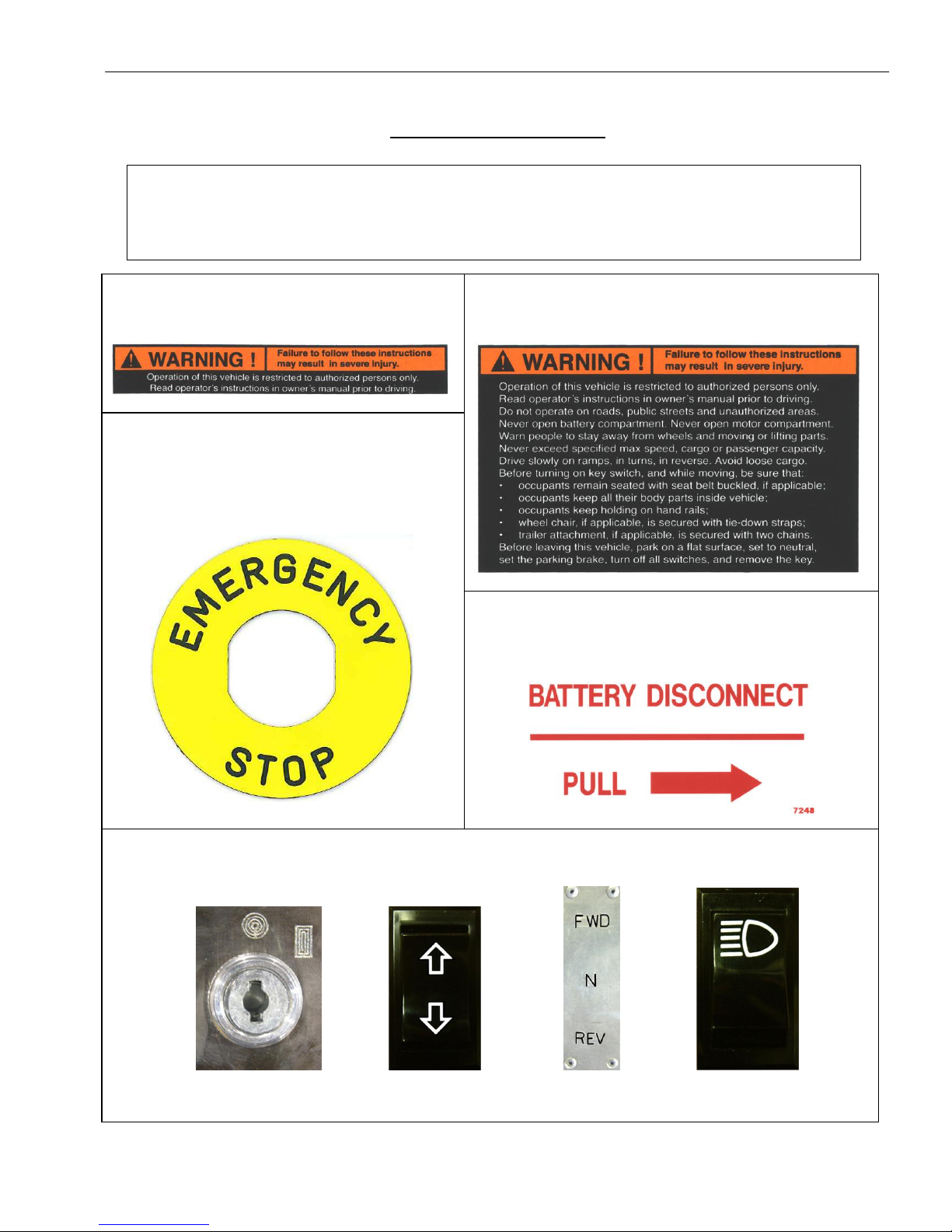

General security warning label:

# 5100000001

When a disconnect handle is installed, this label

is required (located in front of handle):

# 4800012J

When an emergency push button is

installed, this label is required (located

under push button): # 3109800006

DECALS AND LABELS

! CAUTION !

The images included in this section depict the decals/markings installed on the vehicle. It is of

the utmost importance that theses decals/markings remain unaltered and readable. Else, the

sticker or the part baring the marking has to be replaced.

Respectively, key switch markings, forward/reverse selector markings and light switch marking:

# 266211 # 2819321003 # 1269004

Dashboard security warning label:

# 5100000002

Maintenance

- 11 -

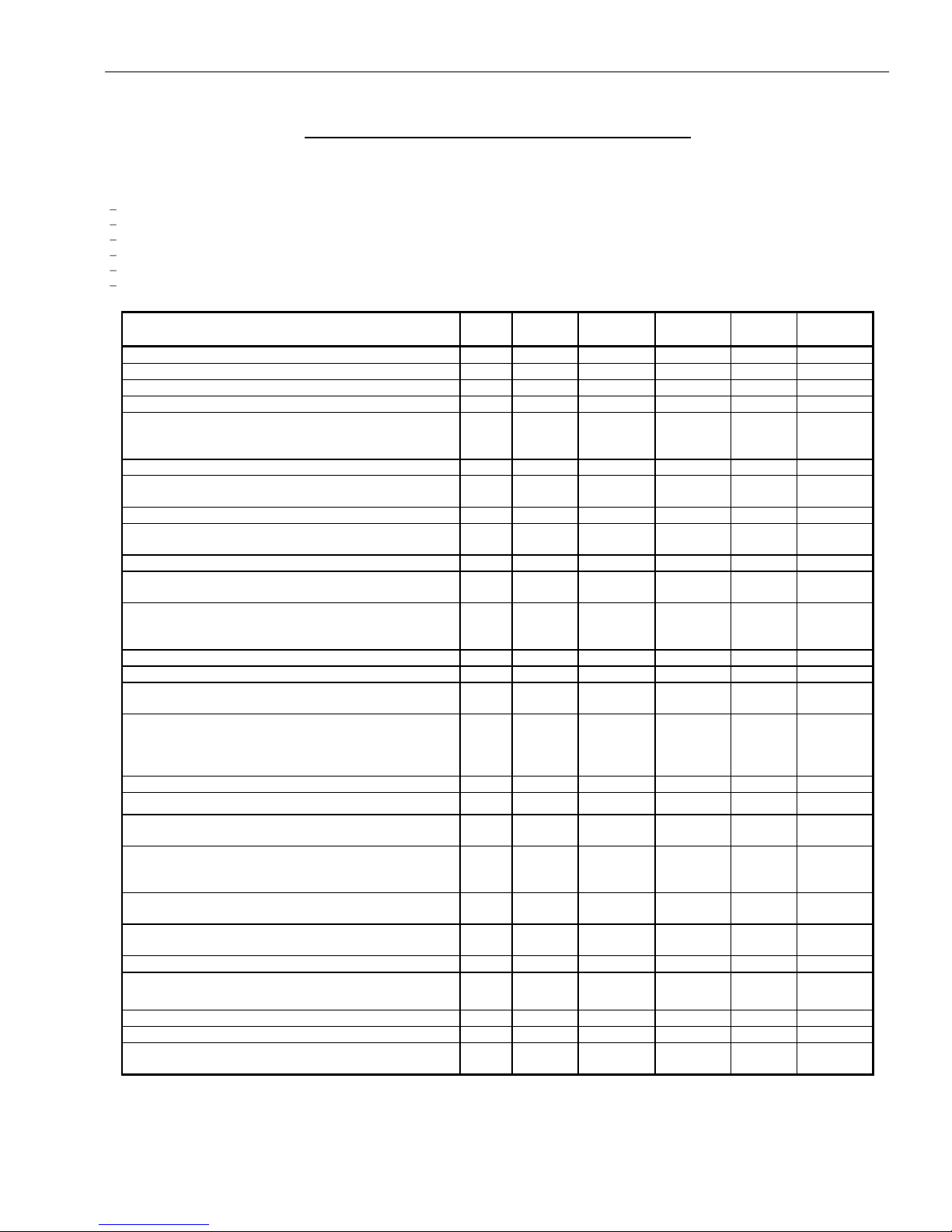

PERIODIC MAINTENANCE CHECKLIST

REVISION 080206

! WARNING !

Maintenance operations must be made by properly trained service technicians.

Keep clear from moving parts such as tires, sheaves and motor.

Check for all EE protections, when applicable, and keep cables and wires clear from mechanical and rubbing action

Batteries contain sulphur acid that can cause severe burns on skin or eyes.

When working around batteries, wear acid proof protective equipment: face shield and gloves.

Use electrically insulated tools to avoid sparks that can cause battery explosion.

Before any maintenance work, park the vehicle on a flat level surface, turn off all switches, remove the key, lift the wheels off the ground and secure

with jack stands of adequate capacity, identify and disconnect battery leads. Don’t connect the charger.

PERIOD

CHECK/PERFORM HOURS

DAY

WEEK

20

MONTH

50

QUART.

200

YEAR

1000

2 YEARS

2000

MECHANICAL DAMAGE, OIL LEAKS

X

REVERSE ALARM, DEADMAN SWITCH

X

STATIC STRAP, min 2” contact with ground

X

TIRE PRESSURE, pressure rating on tire

X

CHECK/FILL BATTERIES, add distilled water to cover

plates. Fill to recommended level after batteries have been

fully charged.

X

WARNING DECALS & MARKINGS

X

EE-Rated CABLE PROTECTORS, SEALED MOTOR,

SEALED CONTROL BOX, STATIC STRAP.

X

MASTER CYLINDER FLUID (DOT 3)

X

BRAKE PEDAL TRAVEL

2” (50 mm) maximum travel

X

STEERING FOR PLAY

X

PARKING BRAKE LEVER

requires 75 lbs. (34 kg) force to apply

X

BELTS AND PULLEYS

-10 lbs (5kg). force for 1/8” (3mm) deflexion;

-pulleys alignment, see procedure.

X

CLEAN/TIGHTEN WIRE TERMINALS

X

WASH BATTERY TOP WITH WATER

X

MOTOR BRUSHES FOR WEAR

-brushes must exceed holders

X

ACCELERATOR ADJUSTMENT

-1/8” (3 mm) travel to activate micro-switch;

-0 to 50 ohms when micro-switch activated;

-4500 to 5500 ohms with pedal down.

X

HYDR. BRAKE LINES FOR LEAK

X

STEERING ASSEMBLY, as instructed

X

BRAKE MECHANICAL LINKAGES

for wear & play

X

BRAKE LININGS FOR WEAR

1/16” (2 mm) minimum lining thickness.

6 mm minimum thickness for brake-pulley lining.

X

LUBRICATE (GREASE EP-2) brake pedal pivots, steering

column, ball joints and kingpins.

X

OIL (SAE 30) LEVEL IN DIFFERENTIAL

Before adding oil, check oil seals for leaks.

X

FRONT WHEEL BEARINGS PLAY

X

TIGHTEN NUTS/BOLTS, electric terminals; drive; steering;

brakes; suspension; body.

X

REPLACE DIFFERENTIAL OIL(SAE 30)

X

CLEAN AND RE-PACK FRONT HUBS

X

SERVICE DIFFERENTIAL, replace the three oil seals,

wheel bearings, oil (SAE 30)

X

Maintenance

- 12 -

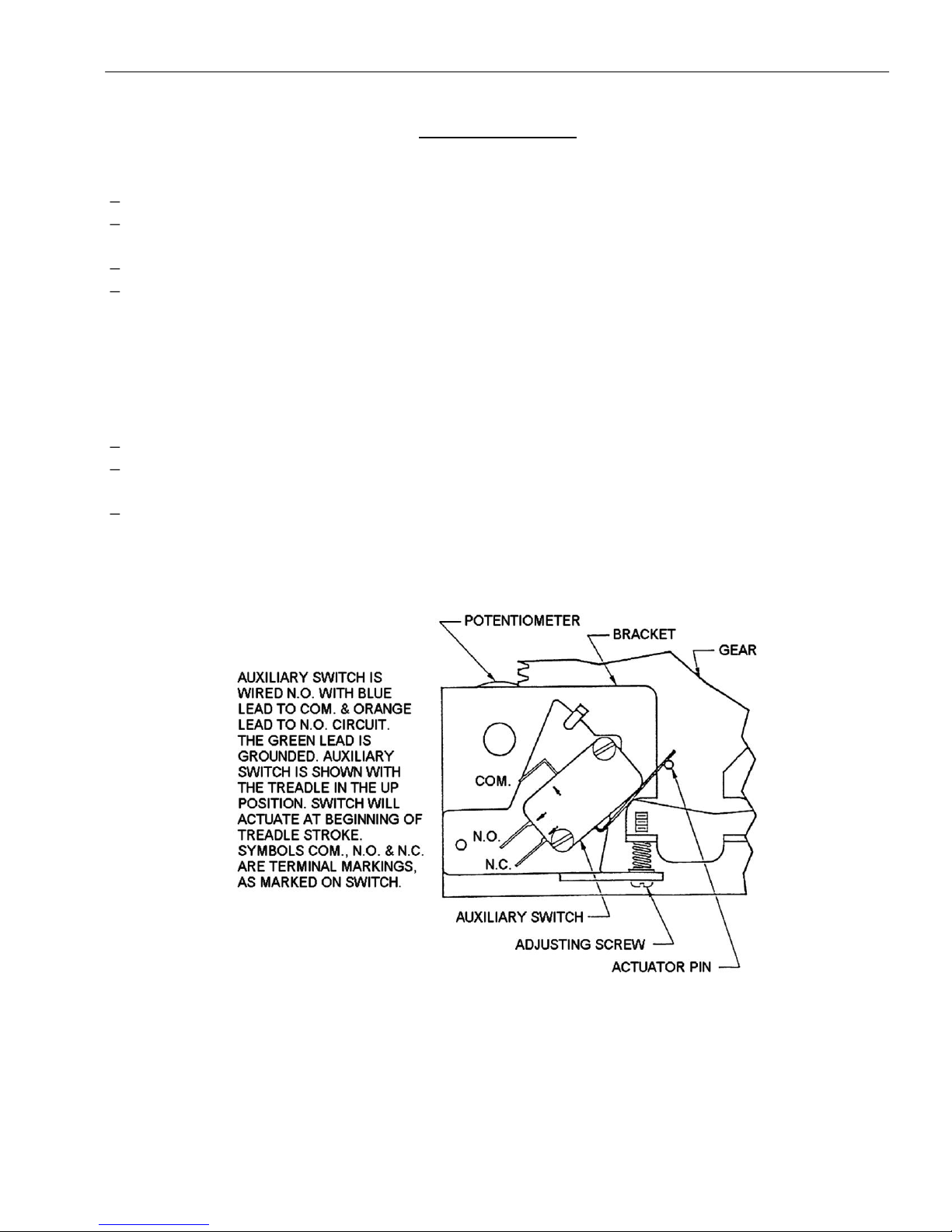

ACCELERATOR

GEAR

Remove the cover.

Backlash between gears must be reduced to a minimum by sliding holder; use locktite 262

to lock the three screws.

When the plastic gear is fully depressed a small backlash must remain between the gears.

When the plastic gear is released its rear portion must not exceed the pedal case.

MICRO-SWITCH

The micro-switch must deactivate the on/off solenoid when the accelerator is released; turn the

adjusting screw (shown on figure below) to adjust the micro-switch height.

POT

Remove the terminals 2 and 3 on PMC to measure resistance signal.

When the micro-switch is activated the signal must be less than 50 ohms. When the front

portion of the pedal is fully depressed the signal must be more than 4600 ohms.

To modify the resistance, turn the adjusting screw to change the micro-switch height (see

figure below).

Proceed with the same verifications after the accelerator cover is on and then connect terminals 2 and 3.

Maintenance

- 13 -

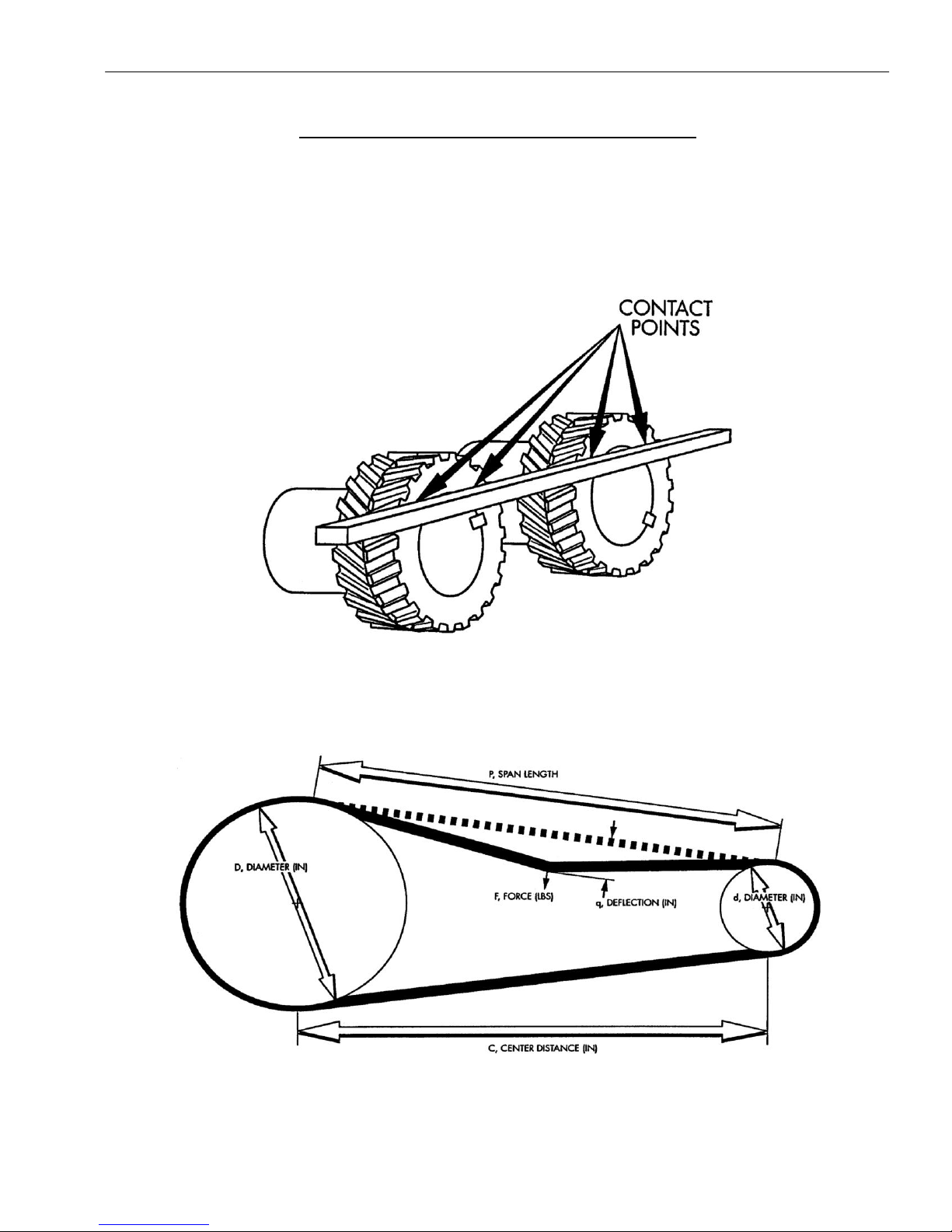

BELT INSTALLATION AND TENSIONING

INSTALLATION

Adjust the sprockets using a straight edge. Slide up the edge on the larger pulley until it contacts the

smaller pulley. Properly adjusted pulleys will provide three points of contact. Properly aligned pulleys

will provide four points of contact. Tighten setscrews and recheck alignment.

TENSIONING

Check the force F required to provide a deflection of 1/8 in. If the measured force is less than 15 lbs

then lengthen centre distance C.

Maintenance

- 14 -

MECHANICAL BRAKES

Revision 2008-02-06

REPLACING THE BRAKE SHOES ON SELF ADJUSTING DRUM BRAKES:

raise the vehicle until the rear tires lift-off the floor and install two jack stands on rear;

remove drums;

replace brakes shoes and springs if linings are 1/16” (2mm) thick or less

disassemble and clean the adjusting screw assembly;

check brake lever and replace lever and pin if there is wear in the pivot;

replace all spring parts;

apply Hi-Temp grease on mechanisms and install the adjusting screw assembly;

check pulling rods, make sure that they are of the same length;

install drums and make sure that there is no contact with brake shoes;

depress and release the brake pedal until the brakes are adjusted;

drive the vehicle to check brakes.

ADDITIONAL INORMATION FOR MANUALLY ADJUSTED DRUM BRAKES.

Before any brake adjustment, check the brake levers on the inboard side of the backing plates. The

levers must be equally pulled . Adjust pulling rods if necessary. The shoes are adjusted by turning the

stud (17mm key) located on the inboard side of the backing plate. Turning the stud clockwise will

reduce the drum to shoe clearance. Properly adjusted shoes will equally brake the rear wheels. Avoid

Shoe contact with drum when the pedal is released.

PARKING BRAKE

Replace cables and stoppers if cable play exceeds 1/8” (4mm).

To install new cables and stoppers:

-insert the new cable through the hand lever end;

-pull the cable out from the brake assembly or brake pedal end;

-insert the stopper on the cable and leave a maximum play of 1mm;

-for a two-cable system, make sure that cable length is the same at hand lever end;

-tighten ¼-ncx3/4 grade-5 bolt in stopper at 8 LbFt (11NM) torque;

-cable must extend 1.5” (4cm) out of the cable stopper, cut cable excess.

Once cable play has been checked and/or adjusted, turn the knob on the brake lever until a force of 75 Lbs

or 34 kg is required on the handle to set the parking brake.

Maintenance

- 15 -

BATTERY MAINTENANCE

! WARNING !

It is the responsibility of the owner of this vehicle to ensure that the service technicians are

properly trained, read and obey the safety rules and guidelines in this manual (ANSI B56).

Maintenance operations must be made by properly trained service technicians only.

Before any maintenance work, park the vehicle on a flat level surface, turn off all the

switches, set to neutral, remove the key, lift the wheels off the ground and secure with jack

stands of adequate capacity.

Keep charger disconnected while doing any maintenance work.

Always wear a face shield and scarf when working around batteries.

Battery emits highly explosive gases; do not produce sparks to avoid battery explosion and

acid splashing. Battery acid causes severe damage to eyes or skin. Flush contaminated area

immediately with water.

Use insulated tools to avoid sparks that can cause battery explosion and acid splashing.

Use two counteracting tools, double-wrench technique, when disconnecting or tightening

battery posts.

Before cleaning or replacing a battery, discharge the capacitor in the controller with a 10

ohms, 25 W resistor for a few seconds across B+ and B-, identify battery polarity and

disconnect battery leads.

After cleaning, the power must not be reapplied until terminal areas are thoroughly dry.

BATTERY LEADS AND CONNECTORS

Check for loose connections, damaged cables, acid spill, loose terminal posts, quarterly.

BATTERY POST CORROSION

If corrosion is present on battery posts, remove the cable connectors, use a wire brush to remove

particles, and then clean them with a cloth that has been moistened with ammonia.

ELECTROLYTE LEVEL

Does not apply to sealed battery.

Disconnect battery connectors on roll-out or lift-out installations.

Make sure the battery roll-out tray is provided with stops before rolling out.

Fill with distilled water.

Daily charged batteries normally require watering once a week. Under watering leads to a

shortened battery life. Over watering leads to battery corrosion. Be careful not to overfill any cell to

avoid electrolyte to be forced out while charging.

Fill each cell to plate level with distillated or de-ionized water, before battery charging. When the

battery is charged, the fluid expands and can seep out if overfilled. Refill each cell after full charge,

when the fluid has expanded to its maximum level.

Reinstall battery caps before charging.

Maintenance

- 16 -

BATTERY MOUNTING

A loose battery increases damaging effects of vibrations and is more prone to short out.

BATTERY DISCHARGE LIMIT

Discharging below a 20% state of charge cuts down the battery life and the number of cycles available.

At 20% state of charge, specific gravity of 6V battery should be 1180; and 1220 for industrial battery.

CHARGING AREA

Always charge battery in a well ventilated area set for and approved for charging.

Never leave a charger connected for more than 20 hours.

FREQUENCY OF CHARGE

When a battery is discharged to its 20% state of charge, it is best to charge immediately.

Batteries require a low current equalization charge (min 4 hours) at least every week, to equalize

battery cells, improve battery performance and life in number of cycles.

Never leave a charger connected for more than 20 hours.

STORAGE

Keep the battery from getting cold, it would loose its capacity.

Let the battery warm up before charging.

Charge batteries in “stored” vehicles every month.

DEFECTIVE BATTERY

Check specific gravity of each cell; if a cell is shorted, voltage drop may occur only when there is

current.

Maintenance

- 17 -

BATTERY CHARGER

! WARNING !

Always unplug the AC and DC electrical cords before attempting any repairs to the charger.

CHARGER DOES NOT TURN ON:

Dc cord of portable chargers must be disconnected from batteries after every charge to restart;

Check dc fuse links;

Check battery voltage at the battery connector;

Check ac outlet and cordset;

Replace electronic control ;

RELAY CLOSES AND TRANSFORMER HUMS BUT AMMETER DOES NOT REGISTER:

Check dc fuse links;

Check the continuity of the dc output cord, ammeter, diodes and all connections in the dc

circuit;

Check diodes;

Check capacitor(rapidely increasing resistance);

SINGLE CHARGER FUSE BLOWS:

Disconnect and check diodes;

BOTH FUSE LINKS BLOW:

Check the battery pack and battery connector polarity;

Disconnect and check diodes.

CHARGER OUTPUT IS LOW:

Disconnect and check diodes;

Can be caused by a transformer failure.

AMMETER READS 30 AMPS FOR MORE THAN 30 MINUTES:

Check the battery pack;

CHARGER DOES NOT TURN OFF:

Check specific gravity in each battery cell;

As much as 16 hours may be required to properly charge heavely discharged new or cold

batteries;

Replace electronic control.

AC LINE FUSE OR CIRCUIT BREAKER BLOWS:

Check ac cordset;

Check ac line fuse rating;

Replace electronic control;

Can be caused by a transformer failure.

Maintenance

- 18 -

ELECTRICAL TROUBLESHOOTING

! WARNING !

Maintenance work must be performed by trained service technicians only.

It is the responsibility of the owner of this vehicle to ensure that the services technicians are properly

trained, understand and obey the safety rules and guidelines (ANSI B56).

All service technicians must read and understand the maintenance warning section in this manual.

! WARNING !

Before any maintenance work, park the vehicle on a flat level surface, turn off all switches, remove the

key, lift the wheels off the ground, secure with jack stands of adequate capacity, disconnect charger.

Always wear safety glasses.

Batteries emit highly explosive gases that can be ignited by a spark. Before disconnecting a high

current terminal, turn off all switches, disconnect battery charger, disconnect batteries.

Keep clear from moving parts such as tires, sheaves and motor.

PMC SELF DIAGNOSTIC

If your PMC comes with a status led, use the flashing code to help troubleshooting.

BATTERY VOLTAGE

Make sure batteries are securely connected. Measure voltage between + and - terminals. We will call

this value B+ or full battery voltage.

ACCESSORIES NOT WORKING

Check the fuses on the batteries and the DC/DC converter.

Check voltage across + and – terminals on the battery gage; if not B+, check wiring.

Turn the key switch ON, check voltage between output terminal on the key switch and the -

terminal on the battery gage; if not B+, replace the key switch.

Check voltage across DC/DC converter output terminals; if not 12-Volt, replace the converter.

Depress the accessory switch, check voltage across accessory terminals. If not 12-Volt, replace the

switch. If 12-Volt, replace the accessory.

FORWARD ONLY

On a SEPEX motor control, check the reverse signal input on the controller.

On a series wound motor control, a bad reverse contactor is the most probable cause of the problem.

Switch to reverse and check voltage on the reverse control wire. If not B+, replace the F/R switch. If

B+, turn off the key switch, disconnect batteries, disconnect power terminals on the F/R contactors,

check the resistance across N.C. power terminals of the reverse contactor. If not 0 ohm, change the

reverse contactor. If 0 ohms, switch to forward and check the resistance across the forward N.O. power

terminals. If not 0 ohms, change the forward contactor.

Loading...

Loading...