CARBONCLEAN

MODEL LE-1

CARBONCLEAN SYSTEM II

OPERATORS MANUAL

MOTORVAC TECHNOLOGIES

MV P/N 100-8135 Rev C 1998

Table of Contents

Introduction ...........................................................................................................................................ii

Overview ...............................................................................................................................................iv

System Features and Functions...................................................................................................... 1-1

Control Panel Features and Functions......................................................................................... 1-2

Safety Information............................................................................................................................. 2-1

Before You Begin .............................................................................................................................. 3-1

First Time Operation..................................................................................................................... 3-1

Mixing Ratios ................................................................................................................................ 3-2

Fuel System Cleaning Procedures.................................................................................................. 4-1

Determining the Vehicle's Fuel System Type............................................................................... 4-1

Carburetor Setup Procedure ........................................................................................................ 4-3

Carburetor Cleaning Procedure.................................................................................................... 4-5

Throttle Body Injection (TBI) Setup Procedure............................................................................. 4-7

Throttle Body Injection (TBI) Cleaning Procedure...................................................................... 4-10

Port Fuel Injection (PFI) Setup Procedure ................................................................................. 4-12

Port Fuel Injection (PFI) Cleaning Procedure............................................................................. 4-15

Continuous Injection System (CIS) Setup Procedure ................................................................ 4-17

Continuous Injection System (CIS) Cleaning Procedure ........................................................... 4-20

Vehicle Diagnostics .......................................................................................................................... 5-1

Fuel System Pressure Test .......................................................................................................... 5-2

Troubleshooting and Additional Help.............................................................................................6-1

Appendix A - Maintenance ...............................................................................................................A-1

Maintenance Procedures.............................................................................................................. A-1

Replacing the LE-1 Fuel Filter ...................................................................................................... A-1

Maintenance Record ....................................................................................................................A-2

Appendix B - System Accessories..................................................................................................B-1

Standard Adaptor Kit .................................................................................................................... B-1

Deluxe Adaptor Kit........................................................................................................................ B-3

Appendix C - Parts ............................................................................................................................C-1

External Parts for the LE-1 ...........................................................................................................C-1

Appendix D - MATERIAL SAFETY DATA SHEET...........................................................................D-1

Material Safety Data Sheet...........................................................................................................D-1

1998 MotorVac Technologies, i

Introduction

Congratulations on your selection of the CARBONCLEAN SYSTEM II. By choosing this product, you

are acquiring the most technologically advanced method available for cleaning harmful fuel system

contaminants from gasoline engines.

The

LE-1 is a self-contained cleaning system, designed to connect to any gasoline engine. Once the unit

is connected, it temporarily replaces the regular fuel supply with a mixture of gasoline and the specially

formulated

With the engine idling, the unit pumps the gasoline/detergent mixture through the engine's fuel system.

As the mixture passes through the vehicles’ fuel system, it loosens and dissolves accumulated deposits,

which then pass harmlessly out through the exhaust system or are removed by the unit fuel filter.

Removing contaminants from the combustion chamber creates a more even burn of fuel, which improves

horsepower, increases fuel economy, and reduces exhaust emissions.

It is recommended that you perform the fuel system cleaning procedure on a vehicle every 12,000 to

16,000 kilometers to obtain the highest fuel system efficiency.

Please study this User Guide to become thoroughly familiar with the

CarbonClean Cleaning Detergent for Gasoline.

LE-1 before using it.

IMPORTANT

The LE-1 Fuel System Cleaner is designed to work

EXCLUSIVELY

with the CarbonClean Cleaning Detergents for Gasoline.

Use of any other chemical during this process may cause operational failure of

the LE-1 and voids the manufacturer’s warranty.

See warranty card for details.

1998 MotorVac Technologies, ii

Introduction

Notes:

1998 MotorVac Technologies, iii

Overview

This manual contains all the information you need to use the LE-1. Please make sure all technicians using

the unit read this manual and have it within easy reach whenever the unit is being used.

The following is a quick reference to the information in this manual:

System Features and Functions

This chapter describes the

Safety Information

Adhere to the safety guidelines in this chapter at all times!

Before You Begin

Follow the instructions in this chapter before using the unit for the first time.

Fuel System Cleaning Procedures

This chapter contains step-by-step setup and cleaning procedures for using the unit with each of

the four fuel system types: Carburetor, Throttle Body Injection (TBI), Port Fuel Injection (PFI),

and Continuous Injection System (CIS).

Vehicle Diagnostics

This chapter describes how to use the unit to perform system tests on the vehicle in order to rule

out other fuel system-related problems.

Troubleshooting and Additional Help

Turn to this chapter in the unlikely event you have problems with your

help.

Appendices - Maintenance, Accessories, and Parts

The appendices contain routine maintenance procedures for the

filter, lists of available accessories and replacement parts, and the Material Safety Data Sheets.

LE-1 gauge, control switches, and connections.

LE-1 or need additional

LE-1, such as changing the fuel

1998 MotorVac Technologies, iv

Overview

Notes:

1998 MotorVac Technologies, v

Overview

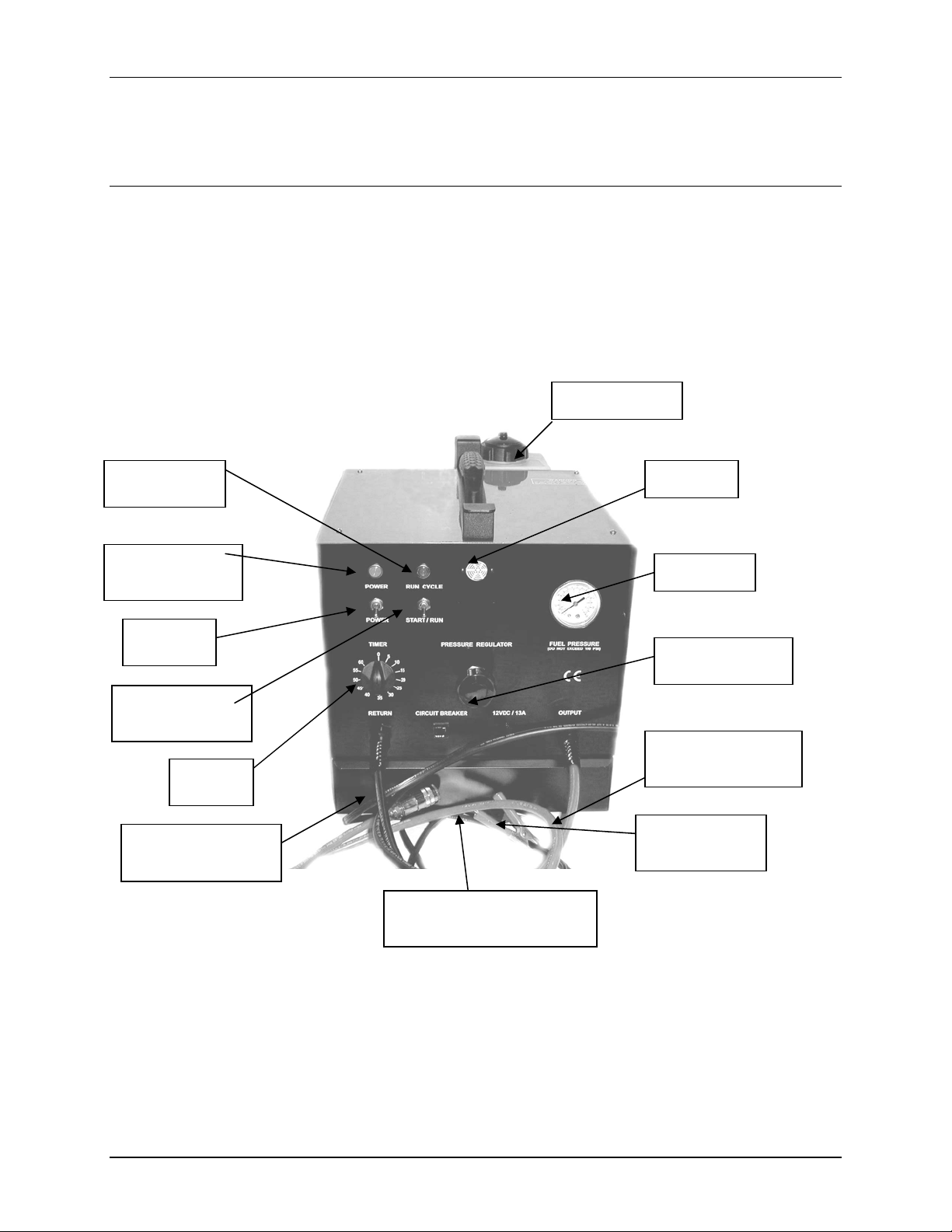

System Features and Functions

The front of the LE-1 cabinet contains the control panel, control switches and status indicators. The fuel

reservior and filter are mounted on the rear of the cabinet.

FLUID TANK

RUN

POWER ‘ON’

INCICATOR

POWER

START-RUN

SWITCH

TIMER

RETURN HOSE

black

ADAPTER STORAGE

DRAWER

ALARM

GAUGE

PRESSURE

OUTPUT HOSE

red

BATTERY

LEADS

1998 MotorVac Technologies, vi

Overview

LE-1 Features and Functions

Descriptions of the gauge, control switches, and status indicators that make up the control panel are listed

below. Please become familiar with these control panel features and functions before using the unit.

Adjust Time Knob

Start/Run Switch

Run Cycle Light

Fuel Pressure Gauge

Pressure Adjust

Regulator

Warning Alarm

Power Switch

Output Hose (red)

Return Hose (black)

Fuel Filter

Battery Cables

Sets or re-sets the system run time in one-minute increments, from 1

to 60 minutes.

Starts the cleaning cycle.

Illuminates when the run cycle is under way.

Displays output pressure of the unit’s output hose, or system

pressure of the vehicle being serviced.

Used to adjust the system pressure during the cleaning process. Turn

clockwise to close (increase the pressure); counterclockwise to open

(decrease the pressure).

Sounds when the run cycle is complete or when a pressure loss

occurs.

Shuts off power to the unit.

Connects to the input side of the vehicle's engine fuel system.

Connects to the return side of the vehicle's engine fuel system.

Filters out contaminants that become removed during the cleaning

process. See Appendix A for replacement information

Positive (red) and negative (black) battery connections (11-15

VOLTS DC)

1998 MotorVac Technologies, vii

Overview

Safety Information and Precautions

/!\ DANGER

Vehicle exhaust gases contain Carbon Monoxide, which is a colorless and odorless lethal gas.

Only run engines in well-ventilated areas and avoid breathing exhaust gases.

Extended breathing of exhaust gases will cause serious injury or death.

/!\ WARNING

Exhaust gases, moving parts, hot surfaces, and potent chemicals are present during the use of the fuel

system cleaner.

Read and understand the operator’s manual before using the fuel system cleaner.

When using chemicals always refer to the MSDS sheets and manufacturer’s instructions for the

proper procedure to handle emergency medical treatment, cleanup, handling, and storage

requirements.

Improper use of the fuel system cleaner or exposure to exhaust gases or cleaning chemicals can cause

injury.

Flammable fuel chemical and vapors can ignite.

Avoid exposure to flames, sparks, hot engine parts, and other ignition sources.

Always keep fully charge fire extinguisher nearby. The extinguisher should have a class B rating

and be suitable for gasoline, chemical, and electrical fires.

Cleanup any fuel or chemical spills immediately.

Dispose of contaminated cleanup material according to governing environmental laws.

Never look directly into the air induction plenum or carburetor throat when the engine is

operating.

Always plug or cap any open fuel lines during service.

Keep Cleaner and Detergent container closed except when filling reservoir.

Explosion or flame or exposure to flammable liquid and vapors can cause injury.

Flammable liquid can splash out of reservoir when pump is on and/or unit is being moved.

Always keep Reservoir Cap secure except when filling reservoir.

Explosion or flame can cause injury.

Many fuel systems maintain residual pressure in fuel lines even after the engine has been turned off.

Wear safety goggles.

Wear chemical resistant gloves when connecting or disconnecting fitting and adaptors.

Obtain ZERO psi before connecting or disconnecting any fuel lines or adaptors.

Explosion or flame or exposure to flammable liquid and vapors can cause injury.

1998 MotorVac Technologies, viii

Overview

Chemicals can cause harmful byproducts.

Use only approved chemicals (refer to operator’s manual).

Do not swallow or ingest any chemicals.

Use with adequate ventilation. Avoid breathing vapors.

Do not store chemicals on the machine.

Improper use of chemicals can cause injury.

Over exposure can have harmful effect on eyes, skin, respiratory system and possible unconsciousness

and asphyxiation.

Improperly blocked vehicles can move.

Set the parking brake and chock the wheels.

Moving vehicles can cause injury.

Moving engine parts.

The engine cooling fan will cycle on and off depending on the coolant temperature and could operate

without the engine running.

Wear safety goggles.

Always keep objects, clothing, and hands away from the cooling fans and engine parts.

Moving engine parts can cause injury.

Hot surfaces are present during and after running the engine.

Do not contact hot surfaces such as, manifolds, pipes, mufflers, catalytic converters, or radiators

and hoses.

Hot surfaces can cause injury.

Catalytic converters become extremely hot.

Do not park a converter-equipped vehicle over dry grass, leaves, paper, or any other flammable

material.

Do not touch a catalytic converter until the engine has been off for at least 45 minutes.

For tests allowing unburned hydrocarbons or service involving operation of an overly rich

condition, minimize the time of rich operation, monitor the catalytic converter temperature, and

allow at least two minutes of operation at normal mixture subsequent to testing or service for

converter cooling.

Catalytic converters can cause burns.

Cracked fan blade can become airborne.

Examine fan blades for cracks. If found, do not service the vehicle.

Flying objects can cause injury.

Batteries produce explosive gases and can explode.

Wear safety goggles when working on or near batteries.

Use in a well-ventilated area.

Keep sparks and flames away from the battery and never lay tools, equipment, or other

conductive objects on the battery.

1998 MotorVac Technologies, ix

Overview

When tools or equipment is connected to the battery, make sure the equipment power switch is

off. Connect the positive lead of the equipment to the positive lead battery first; connect the

negative lead of the equipment to a solid ground point as far from the battery as possible.

Keep battery acid away from skin or eyes. In case of eye contact, flush with clean water for 15

minutes and get medical attention.

Battery explosion and ignited gases can cause injury.

1998 MotorVac Technologies, x

Overview

Before You Begin

First Time Operation

NOTE

The following process is used to flush factory

testing fluids out of your new machine, and is

only necessary before the first time you use the

unit.

1. Verify that the LE-1’s fuel filter is connected and securely in place in the rear of the cabinet.

2. Check the output/return hoses, battery connections, and all external components for damage.

3. Turn the Pressure Adjust regulator on the unit control panel counterclockwise until it is

completely open.

4. Attach the unit to the vehicle's battery by connecting the red battery clip to the positive (+)

battery terminal and the black battery clip to a solid ground point as far from the battery as

possible. Turn on the LE-1 power switch.

5. Fill the LE-1’s reservoir with clean gasoline

6. Connect the LE-1’s output (red) hose and return (black) hose together by using the

#060-1400 adaptors and securing them with a clamp. Follow the procedures below to flush fuel

through the system:

• Set the Timer knob for five minutes.

• Press and hold the Start/Run switch for five minutes.

• Release the Start/Run switch.

7. Disconnect the output and return lines.

8. Connect the #060-1400 adaptor to the output hose, then drain the gasoline from the LE-1’s

reservoir using the following procedure:

• Set the Timer knob for five minutes.

• Direct the output (red) hose into an appropriate container.

• Press and hold the Start/Run switch until the fuel from the unit has been emptied into the

container.

1998 MotorVac Technologies, xi

until the tank level indicates 1/4 tank.

Overview

• Release the Start/Run switch.

• Dispose of the fuel in an environmentally approved method.

9. The LE-1’s reservoir is now completely drained of fuel. Follow the steps below before

performing the first cleaning service:

Mixing Ratios

Using a separate container or the LE-1’s reservoir, follow the chart below to mix the proper amounts of

CarbonClean Cleaning Detergent for Gasoline and fuel for the cleaning process.

NOTE

The proper ratio is 1 oz. (30 ml.) per cylinder to 3 oz. (90 ml.) gasoline.

DETERGENT / GASOLINE RATIO

3 cylinders = 3 oz. (90 ml.) detergent to 9 oz. (270 ml.) gasoline, (360 TOTAL)

4 cylinders = 4 oz. (120 ml.) detergent to 12 oz. (360 ml.) gasoline, (480 TOTAL)

5 cylinders = 5 oz. (150 ml.) detergent to 15 oz. (450 ml.) gasoline, (600 TOTAL)

6 cylinders = 6 oz. (180 ml.) detergent to 18 oz. (540 ml.) gasoline, (720 TOTAL)

8 cylinders = 8 oz. (240 ml.) detergent to 24 oz. (720 ml.) gasoline, (960 TOTAL)

10 cylinders = 10 oz. (300 ml.) detergent to 30 oz. (900 ml.) gasoline, (1200 TOTAL)

12 cylinders = 12 oz. (360 ml.) detergent to 36 oz. (1080 ml.) gasoline, (1440 TOTAL)

1998 MotorVac Technologies, xii

Loading...

Loading...