MotorVac Cool Smoke EVAP Leak Detection System User Manual

Cool Smoke

Canada & USA Patents: 6,907,771 2,438,448. International Patents Pending

EVAP Leak Detection System

Part No. 500-0100

USER MANUAL

1324 Blundell Rd. Mississauga ON Tel. 905.615.8620 Fax. 905.615.9745 www.motorvac.com

Introduction

Congratulations! You are in possession of the most useful, yet simple to operate Evaporative Emissions

(EVAP) System diagnostic tester available today. This patented Cool Smoke technology creates diagnostic

vapour without the need for high temperature glow plugs or resistance coils. When testing an EVAP system

an inert gas such as nitrogen should be used to reduce the risk associated with introducing air into

a gas tank.

The MotorVac Cool Smoke was specifically developed to OEM specifications for diagnosing vehicle EVAP

system leaks. Additionally, the MotorVac Cool Smoke will also find intake manifold system leaks, exhaust

system leaks and under-dash vacuum system leaks. It will also diagnose many other closed systems where

you may suspect a leak, as well as pinpointing wind and water leaks entering the vehicle’s passenger and

trunk compartments. Its unique design allows the operator to confirm the integrity of the system being tested

by utilizing a metered-air system. If the tool has confirmed a leak in the system being tested, the tool then

introduces a special non-toxic diagnostic marked-vapor (smoke) into the system. To locate the source of

the leak you simply look for the smoke exiting the leak or use the optional UV Phazer NEO™ light to view the

UV deposit left behind, pinpointing the exact location of the leak. (PN: 413025)

Please study this User Guide to become thoroughly familiar with the Cool Smoke.

Thank you for choosing MotorVac.

Sincerely,

The MotorVac Team.

info@motorvac.com www.motorvac.com

Table of Contents

Page

Dual Mode Overview .………….…………………………………………....................................................

Technical Specifications ………………………………………………………………………………………..

Getting to Know the Cool Smoke ….………………………………….……………….………………..........

Cautions & Usage Tips ...……………………………………………..........................................................

Initial Setup …..………………………………………………………………...…………………………….....

Accessories …………………………………………………………………..………………………………....

EVAP System Overview ………………………………………………………………………..…...................

EVAP Test Procedure …………………………………………………………………………..……………....

Leak Verification .....................................................................................................................................

Finding the Leak ....................................................................................................................................

Other Leak Detection Applications .………………………………………………………..………………….

Troubleshooting Chart ………………………………………………………………..………………………...

1

1

2

3

4

5

6

6

7

7

8-12

13

info@motorvac.com www.motorvac.com

Dual Mode Operation

The MotorVac Cool Smoke leak tester utilizes two separate modes for testing:

LEAK TEST MODE: Allows you to quickly determine if a leak exists without smoke.

SMOKE MODE: Quickly finds the leak utilizing both visual-vapour (smoke) and UV dye deposits.

The Cool Smoke fluid is a unique solution that allows for highly visible vapour (smoke) to carry UV dye to leak

points. The UV dye will be deposited at small leak locations where the smoke is forced out a leak.

Your MotorVac Cool Smoke automatically sets the critical pressure that must be maintained during EVAP

testing. You don’t need to set flow rates and you don’t need to be concerned with ambient temperatures or

barometric pressures. The MotorVac Cool Smoke is refillable by the end-user when the smoke-producing

solution is depleted. The smoke it produces, as well as the UV dye, is non-toxic and noncorrosive.

The MotorVac Cool Smoke needs no assembly; it is self-calibrating and requires no maintenance.

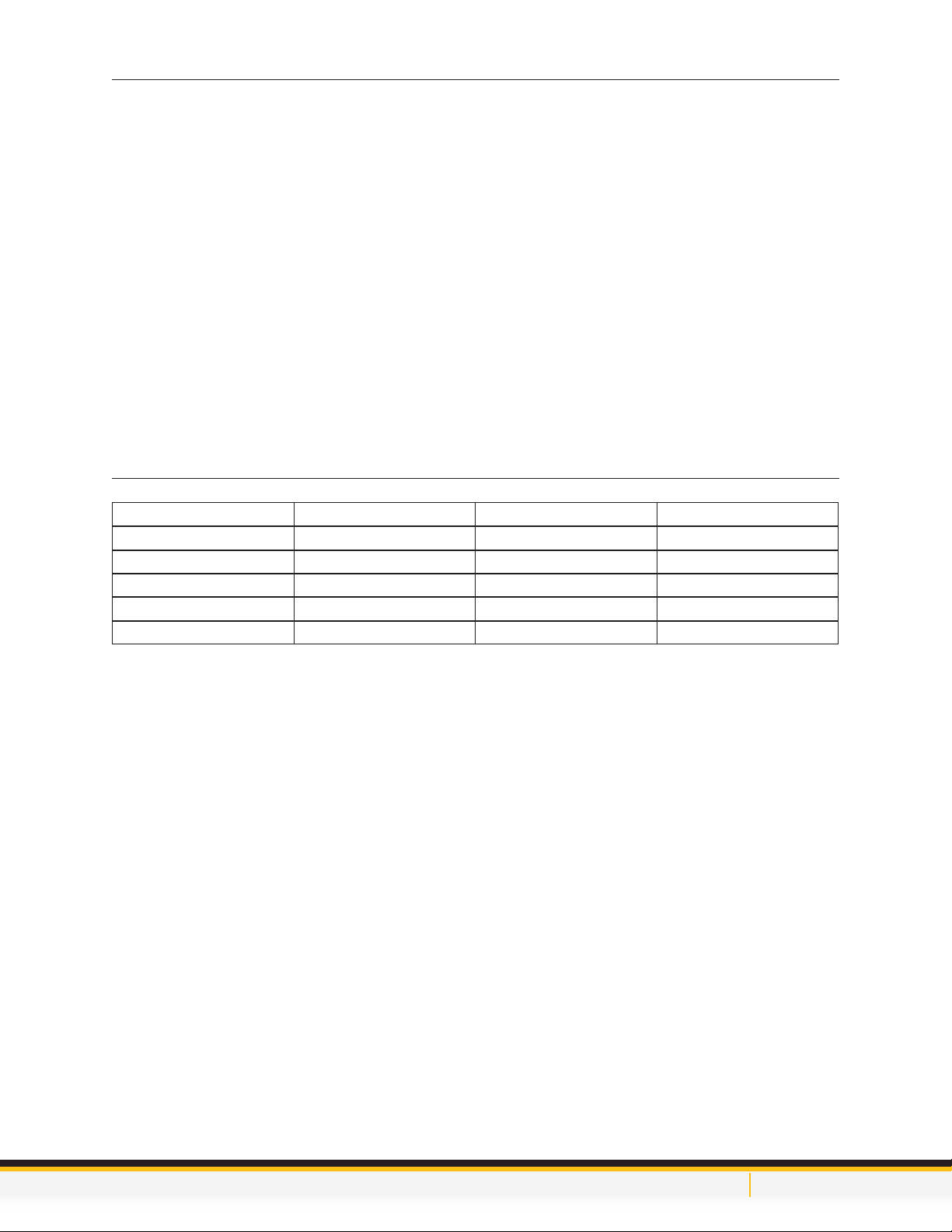

Technical Specifications

Height 12.25 in (31 cm) Current Usage 0.75 A

Width 13.75 in (35 cm) Inlet pressure required 80-150 psi (5.5-10.3 bar)

Depth 11 in (28 cm) Output pressure 13 in H20 (0.03 bar)

Weight 15 lbs (6.8 kg) Output volume 0.14 SCFM (3.9 L/min)

Ship Weight 18.5 lbs (8.4 kg) Smoke outlet line 10 ft (3 m)

Power Supply 12 VDC Power Cord 10 ft (3 m)

1

info@motorvac.com www.motorvac.com

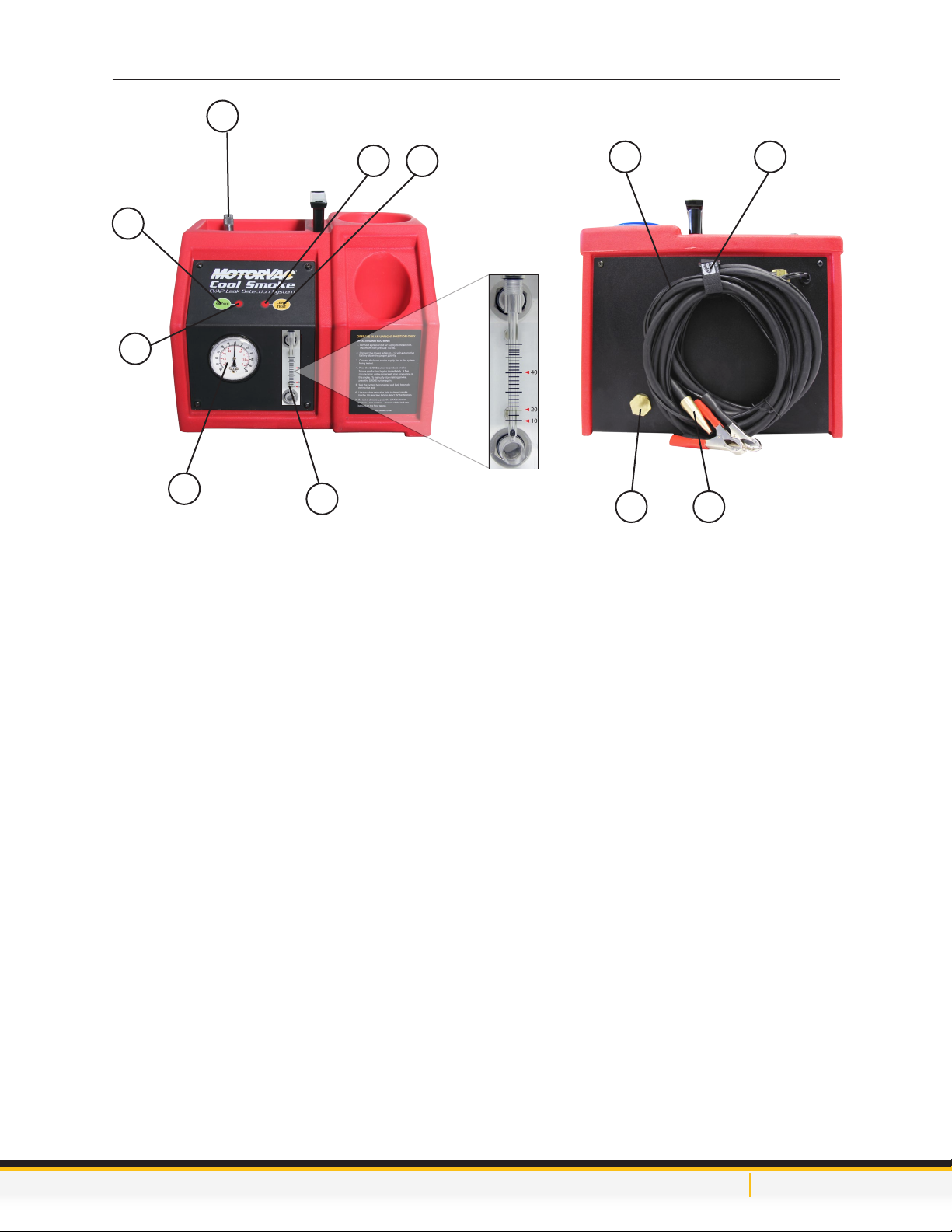

Getting to Know the Cool Smoke

1

2

3

6

7

Component description:

54

Leak size in

*

thousandths

of an inch

10

8

9

11

1. SMOKE SOLUTION DIPSTICK: Measure fluid level with dipstick fully installed. Keep fluid level in

hatched area on the dipstick. The unit is filled through the dipstick tube.

CAUTION: DO NOT OVERFILL THE UNIT.

2. SMOKE BUTTON: Press to activate smoke creating mode, press again to cancel smoke creating

mode. Note: The unit will automatically stop creating smoke after 5 minutes.

3. SMOKE LED: Turns on when the unit is in smoke creating mode.

4. LEAK LED: Turns on when unit is in leak testing mode.

5. LEAK TEST BUTTON: Press to activate leak mode. Press again to cancel leak mode.

6. COMPOUND PRESSURE/VACUUM GAUGE: Can be used to verify leaks by pressure of vacuum

decay in the system. To find the size of the leak the flow meter must be used.

7. FLOW METER: When the unit is in leak detection mode the level that the ball settles to indicates the

size of the leak in the system. If the ball is at the bottom of the gauge there is no leak.

8. COMPRESSED GAS INLET: Connect appropriate male quick coupler to supply the Cool Smoke with

compressed inert gas if testing an EVAP system or compressed air for general smoke purposes.

9. SMOKE HOSE: Used to connect the Cool Smoke to the system being tested in either smoke or leak

mode.

10. POWER CABLES: Connect to 12-volt DC power.

11. WIRE AND HOSE STRAP: Use this to safely store both the power cables and smoke hose when the

unit is not in use.

2

info@motorvac.com www.motorvac.com

Cautions and Usage Tips

To prevent personal injury and / or damage to vehicle or equipment:

• Many automotive manufacturers require the use of nitrogen to be used while testing the EVAP system.

This is because a high heat source or spark could ignite fuel vapours mixed with air. The Cool Smoke

does not use potentially hazardous high temperature glow plugs or resistance coils to create smoke.

However nitrogen should be used to reduce the ignition risk if other potential ignition sources are nearby.

The Cool Smoke can perform it’s functions using clean and dry conventional shop air.

• Use this equipment in the manner specified by the manufacturer.

• Understand operating procedures / Follow all safety precautions.

• Correctly connect power supply to battery and chassis ground. Top-off smoke-producing solution

throughout the year.

• Use only Cool Smoke Smoke Solution No. 400-1054. Altering the solution, hoses, cables or any other

replacement parts will void the warranty; may cause tester malfunction; may cause damage to

the vehicle, to property or may cause personal injury.

• To view the dye deposit, use the optional UV Phazer NEO™ light. (PN: 413025)

• Wear yellow glasses that are provided with the UV light to view dye.

• Do not use with running vehicle engine.

• Do not perform test near source of spark or ignition.

• Never leave the tester’s hoses or power cables connected to the vehicle for extended periods of time if

tests aren’t being performed.

• The 12V DC battery source you use to power the tester must be in good condition and fully charged.

• Wear eye protection that meets OSHA standards.

• Tester input pressure must be 80-150 psi (5.5-10.3 bar)

Store and operate the tester in upright position.

TIPS:

• Whenever possible allow the system to vent as far away from where the smoke is being

introduced. This will purge the air and fill the system with smoke. Once the system is filled with smoke

close the vent and allow the system to be pressurized.

• When testing an engine’s intake or exhaust system for leaks, it is recommended that the engine be cold.

Small leaks may be sealed due to thermal expansion.

3

info@motorvac.com www.motorvac.com

Loading...

Loading...