MotorVac CarbonClean1000 User Manual

CarbonClean1000

2012 MotorVac, Inc. ZIM11-00474 Rev. 0

Table of Contents

Introduction ..............................................................................................................................3

System Features and Functions ...............................................................................................4

Safety Information.....................................................................................................................6

Safety Before Starting ..............................................................................................................................6

Safety When Connecting/Disconnecting Hoses .......................................................................................7

Safety During Service...............................................................................................................................7

Initial Setup................................................................................................................................8

Service Procedures ...................................................................................................................9

Fuel System Types ...................................................................................................................................9

Manifold Connection..............................................................................................................................11

Vehicle Connection Procedure...............................................................................................................12

Service Procedure With Manifold..........................................................................................................13

Service Procedure With Schrader Port Connection................................................................................16

Service Procedure with Direct Connection.............................................................................................19

Fuel System Diagnostics ........................................................................................................22

Fuel System Pressure Test......................................................................................................................23

Fuel Volume Test ...................................................................................................................................23

Leakdown Test .......................................................................................................................................25

Deadhead Test........................................................................................................................................25

Troubleshooting and Additional Help.....................................................................................26

Appendix A - Maintenance ......................................................................................................27

Maintenance Procedures.........................................................................................................................27

Maintenance Record...............................................................................................................................27

Appendix B - Replacement Parts............................................................................................28

Replacement Parts .................................................................................................................................28

Appendix C - System Accesories ...........................................................................................29

Standard Adaptor Kit..............................................................................................................................29

Deluxe Adaptor Kit ................................................................................................................................31

2012 MotorVac, Inc. ZIM11-00474 Rev. 0

Introduction

Congratulations on your selection of the

product, you are acquiring the most technologically advanced method available for cleaning

harmful fuel system contaminants from gasoline engines.

This is a self-contained cleaning system, designed to connect to any gasoline engine. Once the

unit is connected, it temporarily replaces the regular fuel supply with Fuel System Cleaner and

Engine Decarbonizer which is a proprietary mixture of fuel and a specially formulated Cleaning

Detergent.

With the engine running, the unit pumps the Fuel System Cleaner and Engine Decarbonizer

through the engine's fuel system. As the mixture passes through the vehicle’s fuel system, it

loosens and dissolves accumulated deposits, which then pass harmlessly out through the exhaust

system. Removing contaminants from the combustion chamber creates a more even burn of fuel,

which improves horsepower, increases fuel economy, and reduces exhaust emissions.

It is recommended that you perform the fuel system cleaning procedure on a vehicle every

15,000 miles (24,000 km) to obtain the highest fuel system efficiency.

Please study this Operators Manual to become thoroughly familiar with the CarbonClean 1000

before using it.

MOTORVAC

CarbonClean 1000. By choosing this

IMPORTANT

The Fuel System Cleaner is designed to work

EXCLUSIVELY

with the MotorVac Fuel System Cleaner and Engine Decarbonizer

Use of any other chemical during this process may cause operational

failure of the machine and voids the manufacturer’s warranty.

See warranty card for details.

3

2012 MotorVac, Inc.

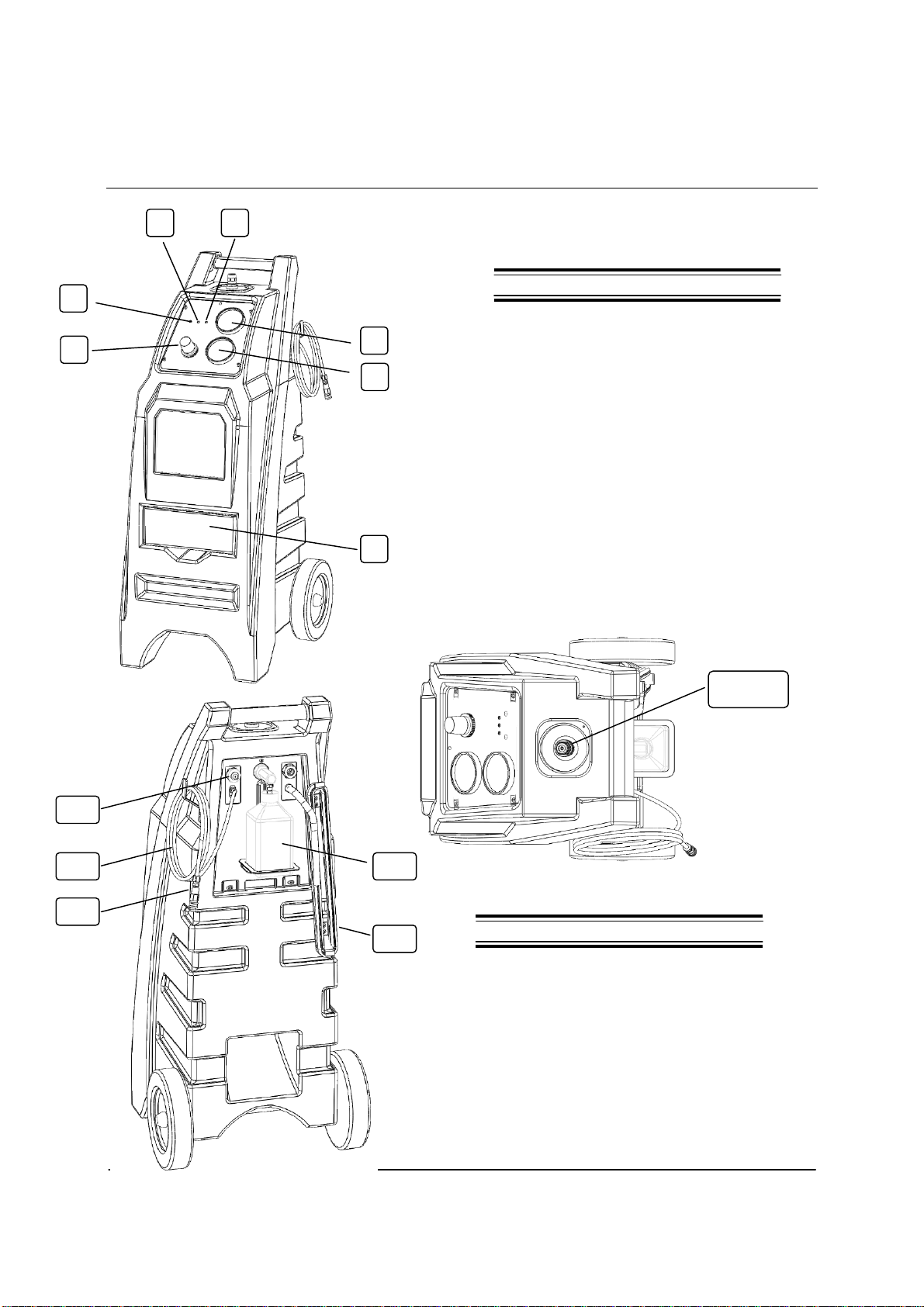

System Features and Functions

1

- Air pressure regulator

1

3 4

5

6

7

11

12

13

15

14

Carbon Clean 1000 Front and Top

2- Power light indicator

3- Ready light indicator

4- Service complete light indicator

5- Fuel pressure gauge

6- Machine pressure gauge

7- Adapter tray

8- Drip cap

9- Inlet port

10- Inlet filter

8, 9, 10

2012 MotorVac, Inc.

4

Carbon Clean 1000 Back

11-

Quick coupler

12-

Service hose

13-

Pressure relief/fuel system flow test

button

14-

Pressure relief/fuel system flow test

bottle

15-

Power cable

Descriptions of the gauges, control switches, and status indicators that make up the control panel are

listed below. Please become familiar with these control panel features and functions before using the unit

1. Air pressure regulator – Used to adjust the system pressure in the cleaning process.

2. Power light indicator – Illuminates when the power cables are connected to a 12VDC power

source.

3. Ready light indicator – Illuminates when there is fluid in the machine indicating it is ready for

the service.

4. Service complete indicator – Illuminates when the service is complete.

5. Fuel Line pressure gauge – Indicates the pressure in the vehicle’s fuel lines.

6. Machine pressure gauge– Indicates the pressure the CarbonClean 1000 is supplying to the

vehicle during a service.

7. Adapter tray – Contains the adapters necessary to connect the CarbonClean 1000 to the

vehicle’s fuel system.

8. Drip cap – Stops contaminants from entering the inlet filter when not in use.

9. Inlet port – Accepts can and transfers the fuel system cleaner and engine decarbonizer into the

CarbonClean 1000.

10. Inlet filter – Filters debris from entering the machine and vehicle’s fuel system.

11. Quick coupler – Connects the CarbonClean 1000 to the appropriate adapter.

12. Service hose – Transfers fluid from CarbonClean 1000 to vehicle.

13. Pressure relief/fuel system flow test button – Use to relieve pressure before disconnecting the

CarbonClean 1000 from the vehicle and to perform fuel pump diagnostic flow test.

14. Pressure relief/fuel system flow test bottle – Collects fluid when relieving pressure and

performing a flow test on the vehicle’s fuel system.

15.

Power cable – Connect to vehicle’s battery before performing a service.

.

5

2012 MotorVac, Inc.

Safety Information

Please become familiar with all safety procedures described in this chapter.

IMPORTANT

Failure to observe these precautions, or the

improper use of equipment, could result in

property damage or serious injury.

Follow the safety procedures in this chapter each

time the unit used.

Safety Before Starting

Follow these safety procedures before starting any service with the unit.

Ventilate the Work Area.

To avoid breathing harmful fumes and exhaust, make sure the unit is always used in a well ventilated

area, away from all flames, sparks, and other ignition sources.

Keep a Fire Extinguisher On Hand.

Keep an approved fire extinguisher within easy reach.

Check Oil and Coolant Levels.

Check engine oil and coolant levels and add oil or coolant if necessary.

Check Polarity.

Always use proper polarity on battery posts. When connecting the unit to a battery, connect the positive

(

red

) battery lead to the positive (+) battery terminal. Connect the negative (

battery terminal (11-15 VOLTS DC).

Avoid Open Flames and Sparks.

Keep lighted cigarettes, open flames, or other ignition sources away from the battery.

Use Caution at All Times.

Use safety goggles and keep hands, hair, loose clothing, and jewelry away from the battery, fan blades,

belts, and other moving parts of the vehicle engine.

Ensure Vehicle is safe

Before beginning a service ensure the vehicle is in satisfactory condition (i.e. broken or loose fuel lines,

ignition wires, battery cables, electrical wires, fuses and relays.)

Relieve Fuel Tank Pressure.

Before performing any fuel system service remove or loosen the fuel filler cap to the vehicle to relieve

fuel tank pressure.

black

) lead to the negative (-)

2012 MotorVac, Inc.

6

7

Safety When Connecting/Disconnecting Hoses

Fuel systems maintain residual pressure in fuel lines even after the engine has been turned off.

Use caution when opening any fuel line.

Avoid Spills.

To avoid fuel spills, wrap a clean shop cloth around fittings when connecting or disconnecting any hoses

or adapters.

Remove Ignition Sources.

Remove all ignition sources such as lit cigarettes, matches, etc., when working with fuels and detergents.

Safety During Service

Follow these safety instructions whenever the unit is being operated.

Consult Manufacturers Service Manual

Use manufacturer’s service manual for test procedures and fuel system specifications (i.e. fuel pressure).

Clean Spills Immediately.

Clean up all gasoline or detergent spills immediately and make sure to use a proper container for disposal.

Check All Fittings.

Check all fittings and fuel lines for leaks before, during, and after performing a cleaning service.

Secure Fuel Lines.

Keep fuel lines away from hot manifolds and all moving components.

2012 MotorVac, Inc.

Initial Setup

Hardware Required

• Air hose nipple

• 9/16” (15mm) and 1” (26mm) wrenches

Air Line Inlet Port

Apply Teflon tape or pipe thread sealant to the threads of the

air hose nipple. Screw the air hose nipple into the inlet port

and tighten.

(USE a 1” wrench to hold assembly to prevent from

turning)

Air hose

inlet port

2012 MotorVac, Inc.

8

Service Procedure

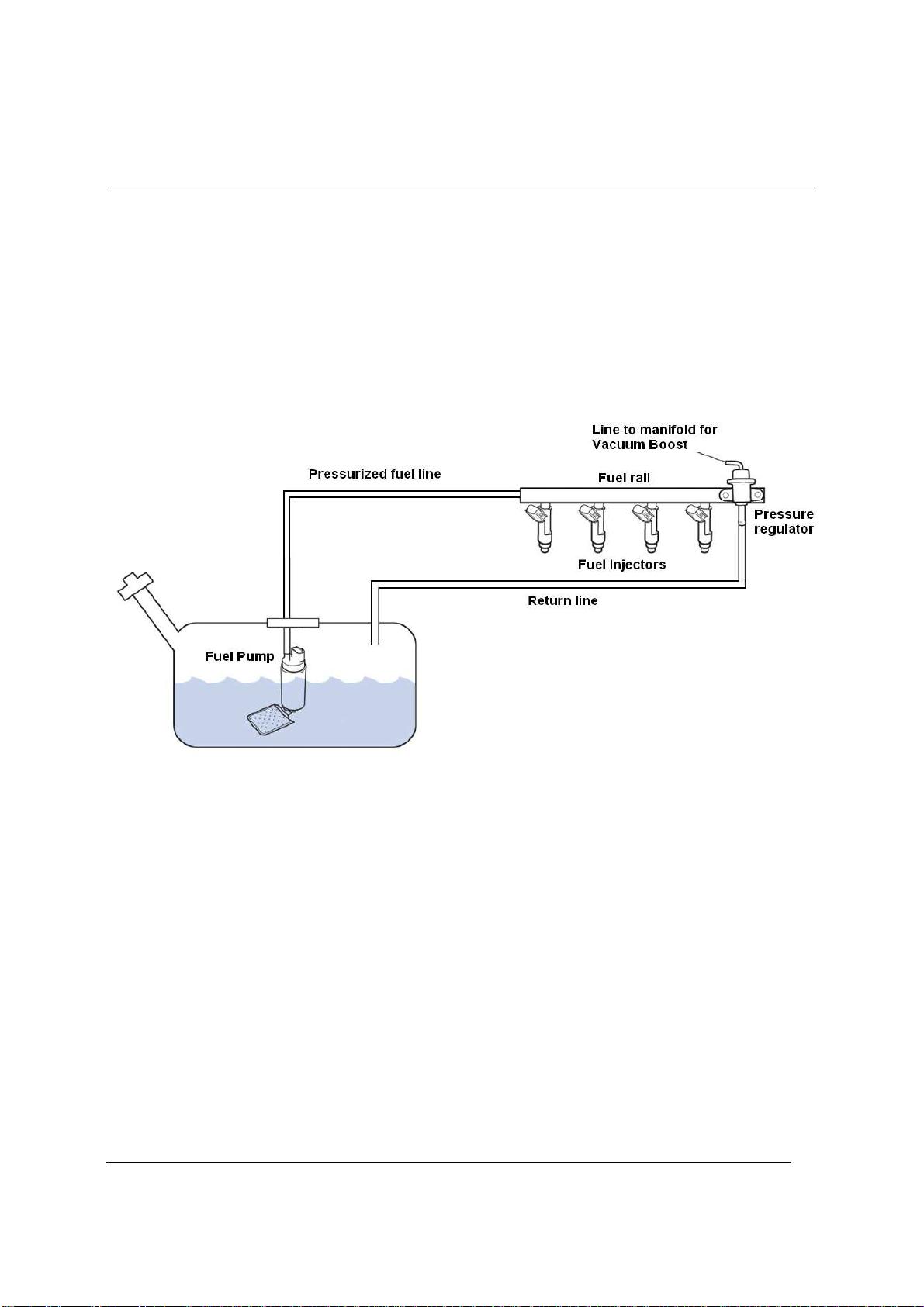

Fuel System Types

Before beginning an exchange determine if the vehicle being serviced has a return or

returnless fuel system.

Return Systems

A return system has 2 fuel lines, one from the fuel tank to the fuel rail and one returning

to the fuel tank. A regulator maintains the correct fuel rail pressure by returning any

excess fuel back to the tank.

NOTE: The fuel pump must be disabled for return fuel systems as dead heading

the pump can cause damage to the pump or fuel system.

9

2012 MotorVac, Inc.

Loading...

Loading...