MotorVac BrakeVac-II User Manual

BrakeVac-II

Brake Fluid Service System

Part No. 500-8100/500-8105

USER MANUAL

500-8100 (Serial Numbers 8100-1200 and up)

500-8105 (Serial Numbers 8105-0700 and up)

1324 Blundell Rd. Mississauga ON Tel. 905.615.8620 Fax. 905.615.9745 www.motorvac.com

Introduction

Congratulations you now own the cleanest, most efcient and user-friendly brake uid service machine available

today. Your new electric pressure brake bleeder is designed specically for modern hydraulic brake and clutch

systems. It is advised that only professional technicians perform brake system service.

The MotorVac BRAKEVAC-II equipment has been designed for use on all hydraulic brake and clutch systems

especially Anti-Lock Braking Systems. The simplicity of our pressure bleeder makes it very user friendly and eliminates the need for hands-on training.

The large capacity reservoir allows for a single service on any vehicle. The uid should be drained and kept in a

sealed container between vehicle services as the onboard storage is not air-tight.

The MotorVac BRAKEVAC-II System allows years of clean, safe, one-man operation brake services.

Thank you for choosing MotorVac.

Sincerely,

The MotorVac Team.

info@motorvac.com www.motorvac.com

Table of Contents

Page

Why should the Brake system be Flushed? .………….....…………………………...................................

System Features ………………………………………………............…….………................................…

Safety Information & Precautions ………………………………………………............…….…….......……

Brake Flush Service Procedure ………………………………………………............…….………..........…

Adjusting the pressure regulator ………………………………………………............…….…….........……

Automatic low uid level warning system and shut off …………………………............…….…….....……

Emptying the tank after each use …………………..............…………………………….....…….…………

Tips for hydraulic brake bleeding ………………………………………………............…….…........………

Suction hose lter assembly………………………………………………............…….……................……

BrakeVac - System Accessories ………………………………………………............…….………........…

Parts ………………………………………………............…….………................….................................

1

1-2

3

3-4

4

4

4

5

5

6-8

9

info@motorvac.com www.motorvac.com

Why should the Brake system be Flushed?

Brake uid is hygroscopic meaning it can absorb moisture from the air resulting in a dangerous reduction

of its boiling point. Water contaminated brake uid under repeated working pressure boils and creates air

bubbles. Under severe conditions, this can result in complete brake system failure.

Water contaminated brake uid causes electrolysis to occur inside the brake system. The oxygen contained

in the water droplets cause oxidation. Electrolysis and oxidation corrodes the hydraulic master cylinder and

wheel cylinders, and steel brake lines from the inside. Pressure bleeding has been proven the most effective

method in ushing and bleeding hydraulic brake systems. Flushing the brake system and replacing the dirty

and contaminated brake uid with fresh brake uid can often avoid expensive repairs.

System Features

Front view

Pressure switch

Pressure gauge

Black new uid hose

Vacuum switch

Drain Tank SwitchPressure Regulator

Circuit BreakerClean uid tank

Clear vacuum hoseFluid level ‘window’

12 volt DC power cord

Storage drawers

for adapters

1

info@motorvac.com www.motorvac.com

System Features

Back view

A

C

E

F

B G H

D

J

I

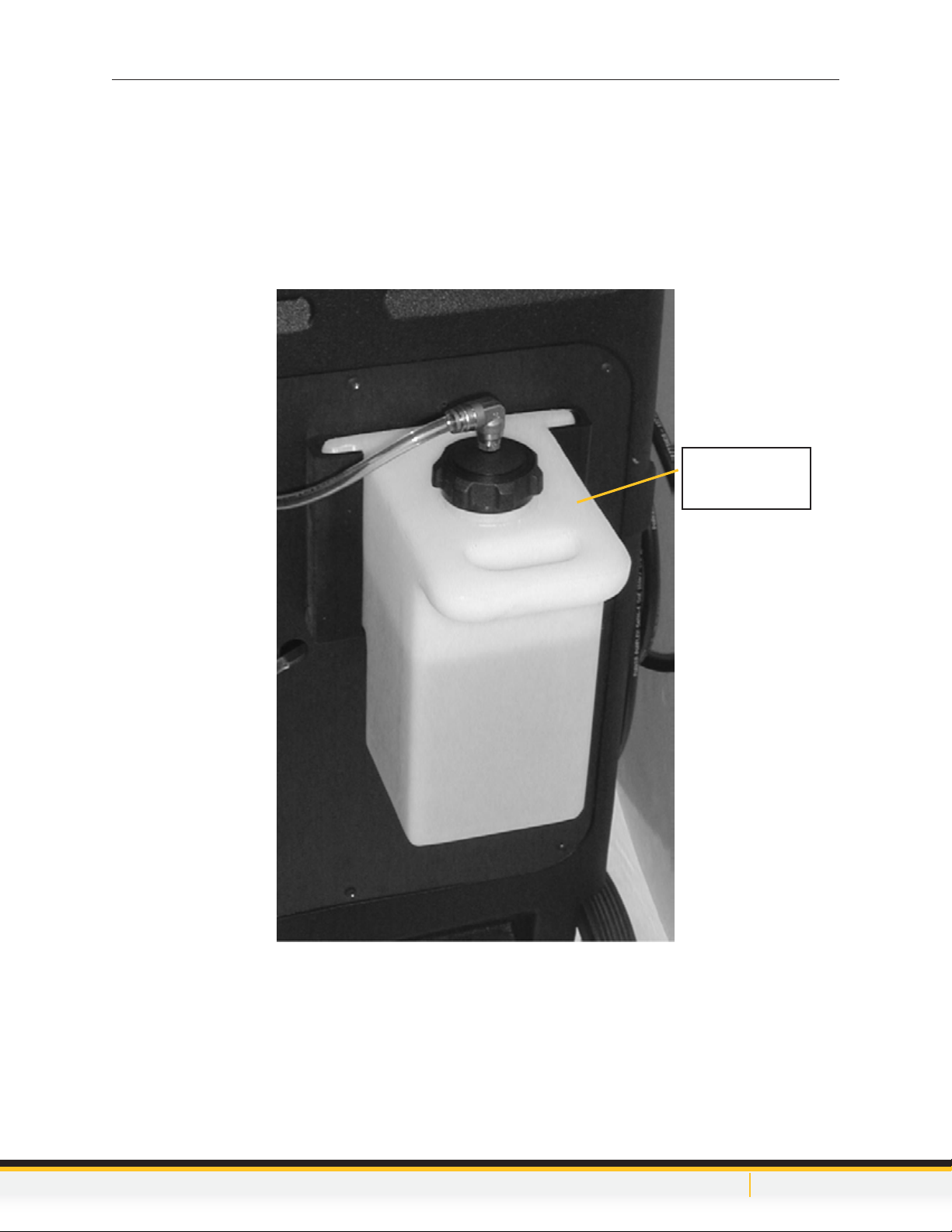

Waste (used)

uid capture

tank

2

info@motorvac.com www.motorvac.com

Loading...

Loading...