MOTORSCAN MEMOBIKE 6050 Operating Instructions Manual

1

OPERATING INSTRUCTIONS

TECH SUPPORT

HOTLINE

+1 (888) 665-8804 x1

support@svd.tools

OPERATING INSTRUCTIONS

MS6050EN

Mod. 6050_EN

First Edition

February 2014

A.Cavalca

Release 01

February 2016

A.Cavalca

Release 02

March 2016

A.Cavalca

Any printed or digital reproduction of this manual is forbidden without the authorization of

the copyright holder.

Printing the digital version of this manual is permitted only for the purpose of producing a

back-up copy for the user of the product.

The features and data described in this manual are not binding on the manufacturer. The

right is reserved to make changes or modifications without prior notice or product

replacement.

Product and business names appearing in this manual may or may not be registered

trademarks and are used for identification purposes only. All trademarks are the property

of their respective owners.

MS6050EN

OPERATING INSTRUCTIONS

Dear Customer,

This product is part of the MOTORSCAN® family of products. It is the result of many

years of research and development.

The EOS S.r.l. Motorscan® Division is glad to have you as a customer.

Please contact one of our authorized distributors or our customer service department

for any technical questions.

OPERATING INSTRUCTIONS

MS6050EN

Blank Page

MS6050EN

OPERATING INSTRUCTIONS

INDEX I

INDEX

INDEX ........................................................................................................................................... i

INTRODUCTION ................................................................................................................. 1

INSTALLATION ................................................................................................................... 4

OPERATING INFORMATION ............................................................................................. 4

SYMBOLS ........................................................................................................................... 6

1.0.0 - PRODUCT DESCRIPTION ...................................................................................... 7

1.1.0 - GENERAL ................................................................................................................ 7

1.2.0 - SPECIFICATIONS ................................................................................................... 7

1.3.0 - FRONT / CONNECTIONS VIEW ............................................................................. 8

1.4.0 - KEYBOARD VIEW ................................................................................................... 8

1.5.0 - STANDARD ACCESSORIES ................................................................................. 10

1.6.0 - OPTIONAL ............................................................................................................. 12

2.0.0 - CONNECTING ....................................................................................................... 22

2.1.0 - POWERING THE TOOL......................................................................................... 23

2.2.0 - MOTORCYCLE IDENTIFICATION ......................................................................... 23

2.3.0 - CONNECTING TO THE MOTORCYCLE USING A MASTER/SLAVE CABLE ...... 26

2.4.0 - CONNECTING TO THE MOTORCYCLE USING THE “UNIVERSAL” CABLE ...... 27

2.5.0 - CONNECTING TO THE MOTORCYCLE USING BMW SLAVE CABLE ................ 28

3.0.0 - OPERATION .......................................................................................................... 29

3.1.0 - SETUP MENU ........................................................................................................ 30

3.2.0 - SETTING MENU .................................................................................................... 32

3.2.1 - SCREENSHOT MANAGEMENT ............................................................................ 37

3.2.2 - REPORT ................................................................................................................ 38

3.3.0 - BATTERY INFORMATION SCREEN ..................................................................... 41

3.4.0 - DTC GLOBAL SEARCH ......................................................................................... 45

3.4.1 - DATA LOGGER ..................................................................................................... 48

3.5.0 - SELECTING THE SEARCH MODE FOR SYSTEMS INSTALLED ........................ 53

3.5.1 - MANUAL SEARCH ................................................................................................ 53

3.5.2 - MANUAL SEARCH BY VEHICLE SELECTION ..................................................... 54

3.5.3 - MANUAL SEARCH BY ECU SELECTION ............................................................. 58

3.5.4 - AUTOMATIC SEARCH CONNECTION ................................................................. 61

3.6.0 - ECU MENU ............................................................................................................ 63

3.6.1 - ECU DATA ............................................................................................................. 64

3.6.2 - PARAMETERS ....................................................................................................... 64

3.6.3 - READING STORED FAULTS ................................................................................ 65

3.6.4 - ERASING STORED FAULTS ................................................................................. 67

3.6.5 - DIAGNOSTIC PROCEDURES ................................................................ ............... 68

3.6.6 - CONFIGURATIONS ............................................................................................... 69

4.0.0 - APPENDIX ............................................................................................................. 71

4.1.0 - SCREEN ................................................................................................................ 71

4.1.1 - “START-UP” SCREEN ........................................................................................... 71

4.1.2 - “MENU” SCREEN .................................................................................................. 72

4.1.3 - “PROCEED - EXIT” SCREEN ................................................................................ 73

4.1.4 - “BINARY SELECTION” SCREEN .......................................................................... 73

OPERATING INSTRUCTIONS

MS6050EN

II INDEX

4.1.5 - “MESSAGE” SCREEN ........................................................................................... 74

4.1.6 - “MULTIPLE SELECTION” SCREEN ................................................................ ...... 74

4.1.7 - “PARAMETERS TABLE” SCREEN ........................................................................ 75

4.2.0 - TYPES OF DIAGNOSTICS .................................................................................... 76

4.2.1 - SERIAL COMMUNICATION................................................................................... 76

4.2.2 - BLINKING CODES ................................................................................................. 76

4.2.3 - DISPLAY CODES .................................................................................................. 77

4.2.4 - MANUAL PROCEDURE......................................................................................... 77

MS6050EN

MOD:6050

OPERATING INSTRUCTIONS 1

INTRODUCTION

This manual is an integral part of the product. Read these instructions carefully before using

the tool and keep them in a safe place. EOS S.r.l. Motorscan® Division apologizes for any

errors in the text.

Brand names and products mentioned in the document are registered brands of the relevant

owners.

EOS S.r.l. Motorscan® Division is not responsible to third parties for specific, collateral,

accidental, direct, or indirect damage related to, or deriving from the product purchase and use.

Copies of this document and technical information are available from an authorized distributor of

EOS S.r.l. Motorscan® Division.

This document may not be copied or distributed, in part or its entirety, in any form or by any

means, without prior written authorisation from EOS S.r.l. Motorscan® Division.

EOS S.r.l.

Motorscan® Division

Via Monte Aquila, 2 Corcagnano

43124 PARMA – Italy

Tel. +39 0521 631411

www.motorscan.com

sales@motorscan.com

support@motorscan.com

MOD: 6050

MS6050EN

2 OPERATING INSTRUCTIONS

IMPORTANT INFORMATION ABOUT PERSONAL SAFETY

GENERAL SAFETY IN THE WORKSHOP.

DANGER OF SUFFOCATION

GASOLINE ENGINES

Exhaust gases from gasoline vehicles contain Carbon Monoxide, a colorless and odorless

gas which, in case of inhalation, can cause serious physical injury or death. When working

under a vehicle, be very careful. Some components of exhaust gases are heavier than air.

Be careful also when working on LPG-propelled vehicles.

DIESEL ENGINES

The exhaust gas from a diesel engine has a composition that varies according to: type of

engine, of induction, conditions of use, and fuel composition. The diesel exhaust includes

gas (CO, CO2, NO and HC) and particles (soot, sulphates and PAHs). The small carbon

particles forming soot remain suspended in the air and can be breathed in. Small amounts

of toxic components are also present.

SAFETY MEASURES:

Always ensure good ventilation and breathing protection (especially when working under a

vehicle. Always operate the exhaust fan system when working in confined spaces.

DANGER OF CRUSHING

Ensure that the vehicle is locked in place to prevent possible crushing.

SAFETY MEASURES:

Make sure that the vehicle is unable to move by engaging the hand brake and locking the

wheels.

DANGER OF INJURY

Whether engines are at a standstill or operating, there are moving parts (belts, etc.) that can

injure hands and arms. Pay particular attention to electrically operated fans since these may

unexpectedly start up even when the engine itself is off.

SAFETY MEASURES:

Never place hands near moving parts when the engine is on. When working near electrically

operated fans, let the engine cool first and then unplug the fan.

Keep the test instrument connection wires as far as possible away from moving parts of the

engine.

MS6050EN

MOD:6050

OPERATING INSTRUCTIONS 3

DANGER OF BURNS

Some of the components in engines (exhaust gas manifold, etc.) can become very hot, as can

certain sensors. Remember to never touch these parts.

SAFETY MEASURES:

Wear protective gloves. Never allow the test instrument connection wires to rest on or near hot

parts. Never keep the engine running after the tests.

DANGER OF FIRE OR EXPLOSION

When work is being carried out on the fuel system (fuel pump, injectors and carburetor, etc.)

there may be a risk of fire or explosion owing to the fuels used and/or the vapors that these

products form.

SAFETY MEASURES:

Disconnect the ignition system. Allow the engine to cool.

Do not use open flames or anything liable to produce sparks.

Do not smoke.

Collect any spilled fuel.

Operate exhaust fans in closed rooms.

SOUND LEVEL

When working near a vehicle, especially at high engine speed, noise levels can reach 90dB.

Long term exposure to such noise sources can cause hearing damage.

SAFETY MEASURES:

Wear hearing protection.

DANGEROUS VOLTAGE

Work safely on vehicle electrical systems. Do not touch electrically “live” parts of engines. Be

aware of the risk of shock from damaged connections.

SAFETY MEASURES:

Only use the cables supplied with the test instrument. Make sure that the insulation is not

damaged.

Do not touch live parts of the vehicle when testing with the engine running.

Only make test connections with suitable systems (test cables, specific adapter cables).

MOD: 6050

MS6050EN

4 OPERATING INSTRUCTIONS

DANGER OF ASFIXIATION

If subjected to high temperatures (over 250 °C or owing to fire outbreaks), exhaust gas hoses

may release highly toxic gases.

SAFETY MEASURES:

Immediately contact a physician if such gas is inhaled.

Use neoprene or PVC gloves to eliminate combustion residuals.

Fire residuals can be neutralized with a calcium hydroxide solution. This forms calcium fluoride

which can be removed with water.

DANGER OF CORROSION

Acids can harm the skin if not protected.

The residual condensate in gas sampling hoses and the condensate separator unit contains

acids.

Take great care when replacing the oxygen sensor (O2) and the nitric oxide sensor (NO). They

contain highly corrosive substances.

Corrosive liquid may be spilled if a liquid crystal indicator is broken. This liquid should never be

touched, inhaled or swallowed.

SAFETY MEASURES:

In case of contact with the skin, immediately wash the affected area with water and contact a

physician.

Immediately contact a physician if such products are inhaled or swallowed.

GENERAL INFORMATION

INSTALLATION

Never allow the instrument to be exposed to the sun for long periods of time or to allow it to

stand near hot equipment (stoves, heaters, etc.): the maximum operating temperature is 40

°C/105 F.

Do not move the instrument from a hot place to a cold place and vice versa. The formation of

condensation inside the device may damage the electronic circuits.

Protect the instrument from rain or from excessive moisture.

OPERATING INFORMATION

To prevent contamination from toxic gas, it is advisable to use the instrument in a sufficiently

ventilated place or to channel exhaust gases outdoors.

Never pull on the instrument’s cables.

All connections should be made when the vehicle engine in question is off.

Check that all cables are far away from hot parts (over 50 °C/130F) or moving parts.

Disconnect all engine connections before moving the vehicle in question.

MS6050EN

MOD:6050

OPERATING INSTRUCTIONS 5

CLEANING

When necessary, the outer surfaces of the instrument should be cleaned: never use cleaning

products containing spirits, ammonia or gasoline. Only use neutral detergents and a soft,

slightly moistened cloth.

IMPORTANT INFORMATION ABOUT PRODUCT SAFETY

This MOTORSCAN® product provides a high level of protection against the risk of electric

shock.

The installer is responsible for connecting it to a correctly grounded electrical socket. Seek

technical assistance before using an adapter or extension cable. These devices could interfere

with the grounding circuit.

Connection of the appliance to an incorrectly wired electrical outlet could result in electrocution.

Comply with the following rules to protect against the risk of electrocution:

Only connect the instrument to electrical sockets delivering the correct voltage. Contact the

electric utility if you are uncertain as to the outlet voltage.

If the instrument has other wires besides the power cable, these must be connected to their

respective connectors before connecting the power cables to the electrical outlet. Disconnect

the power cables from the sockets before removing other wires.

Strictly comply with the following instructions when servicing:

Always replace fuses with others of equal value (see indications on the label or in this manual).

NEVER open the cover of the instrument: you could risk electrocution. This operation may only

be carried out by a qualified technician and not before having disconnected the power supply

cable.

Deviating from the instructions in this manual or attempting to repair the instrument carries the

risk of electric shock.

Pressing too hard on the display may damage the instrument.

Please contact a service technician if the instrument fails to correctly function after following the

operating instructions.

Check that all installed spare parts have technical characteristics identical to those of the

original parts. Other parts may not possess the same safety characteristics.

Always contact qualified technical personnel if repairs are required.

MOD: 6050

MS6050EN

6 OPERATING INSTRUCTIONS

SYMBOLS

Symbols used in the DEVICE:

ALTERNATING CURRENT

GROUND PROTECTION

CONSULT THE INSTRUCTION MANUAL

RISK OF BURNS

RISK OF ELECTROCUTION

NEVER ATTEMPT TO REMOVE THE COVER

(operation only to be carried out by qualified

technicians)

CE CONFORMITY MARK

It indicates compliance with the relevant European Union

Directives.

Entry to the National Registry of

Manufacturers of Electrical and

Electronic Equipment

n ° IT14010000008257

INFORMATION FOR THE USERS

Pursuant to art.13 of the Law Decree 25 July 2005, n.151

“Implementation of directives 2002/95/CE, 2002/96/CE and

2003/108/CE on the reduction of the use of hazardous

substances in the electrical and electronic equipment and

waste disposal”.

The symbol of the bin with crossed lines on the equipment or

on the packaging indicates that the product at the end of its

useful life has to be collected separately from other waste.

Disposal of the equipment at the end of its life is organized

and managed by the manufacturer. The user wishing to

dispose of the equipment should contact the manufacturer

and comply with the system the latter has adopted for

disposal of the equipment at the end of its life.

Unauthorized disposal of the product by the owner may be

penalized under the relevant laws in force in the country in

question.

MS6050EN

MOD. 6050

OPERATING INSTRUCTIONS 7

1.0 - PRODUCT DESCRIPTION

1.1 - GENERAL

The 6050 is a compact, user-friendly scan tool. This state-of-the-art technology that allows

diagnostics on all types of motorcycle communication protocols.

The tool comes in a handy carrying case, to protect the tool and carry diagnostic cables.

1.2 - SPECIFICATIONS

CPU

Cortex M3 (96 Mhz)

RAM Memory

32 MB

Flash Memory

2GB

Display

LCD Led 3,5' 320x240

Interfaces

MiniUSB 2.0 Device

Wireless

Bluetooth Class 1

(2)

Audio

1 Speaker

Dimension [mm]

175x112x36

Supply

External 5V

LiPoly battery rechargeable

From vehicle: 8-16V

(1)

Keyboard

9 key keyboard

Vehicle interface

Db26 ISO22900-1 (MVCI)

Internal Multiplexer

MOD. 6050

MS6050EN

8 OPERATING INSTRUCTIONS

1.3 - FRONT / CONNECTIONS VIEW

1 ) LED LIGHT TO ILLUMINATE THE VEHICLE DIAGNOSTC SOCKET

2 ) USB INTERFACE FOR COMPUTER OR POWER SUPPLY CONNECTION

3 ) GRAPHIC DISPLAY

4 ) KEYBOARD

5 ) HD DB26 HD INTERFACE FOR DIAGNOSTIC CABLE CONNECTION

1

2

3

4

5

MS6050EN

MOD. 6050

OPERATING INSTRUCTIONS 9

1.4 - KEYBOARD VIEW

6 ) F1, F2, F3, KEYS : USE FUNCTION KEYS AS INSTRUCTED BY THE SOFTWARE.

7 ) KEYS : TO BROWSE THE SELECTION LIST OR TO MOVE THE CURSOR.

8 ) ENTER – ON/OFF KEY: TO PROCEED TO THE NEXT SCREEN OR TO SELECT A

FUNCTION.

9 ) ESC KEY : RETURN TO THE PREVIOUS SCREEN OR TO INTERRUPT A FUNCTION.

6

9 7 8

MOD. 6050

MS6050EN

10 OPERATING INSTRUCTIONS

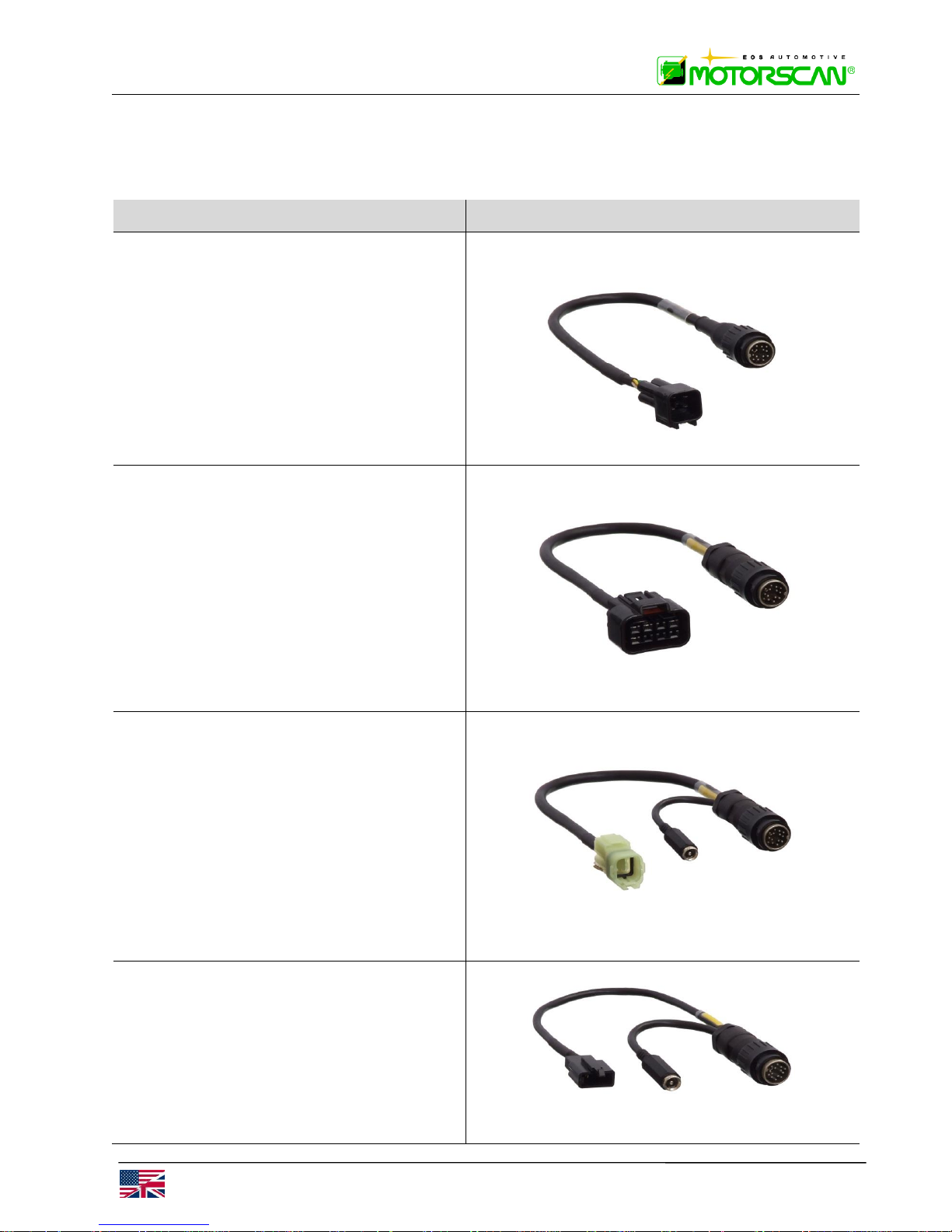

1.5 - STANDARD ACCESSORIES

Next to each motorcycle model in the “Vehicles List” you can find the part number for the cable

required for a particular function.

DESCRIPTION and PART NUMBER

PICTURE

Carrying case

Code: 22ST5600KP3*A

Scan tool

Part number: SL6050

AC/DC power supply

Part number: 2303W5V1AUSB

MS6050EN

MOD. 6050

OPERATING INSTRUCTIONS 11

DESCRIPTION and PART NUMBER

PICTURE

USB/Power cable

Part number: 116000004

Master Cable

Part number: 520

Required for the use of the slave cables.

Battery power cable

Part number: 051

“Universal” Cable

Applications: Aprilia2, Benelli, BMW5,

Cagiva2, Harley Davidson3, Honda1,

Hyosung, Kawasaki5, Kymco, Malaguti2,

Mondial, Polaris5, Suzuki4, Sym, Triumph5,

Yamaha.

Part number: 522

1

Only blinking code and Hiss systems

2

Except Marelli systems

3

Only Marelli systems

4

Only display code systems

5

Except CAN-BUS systems

MOD. 6050

MS6050EN

12 OPERATING INSTRUCTIONS

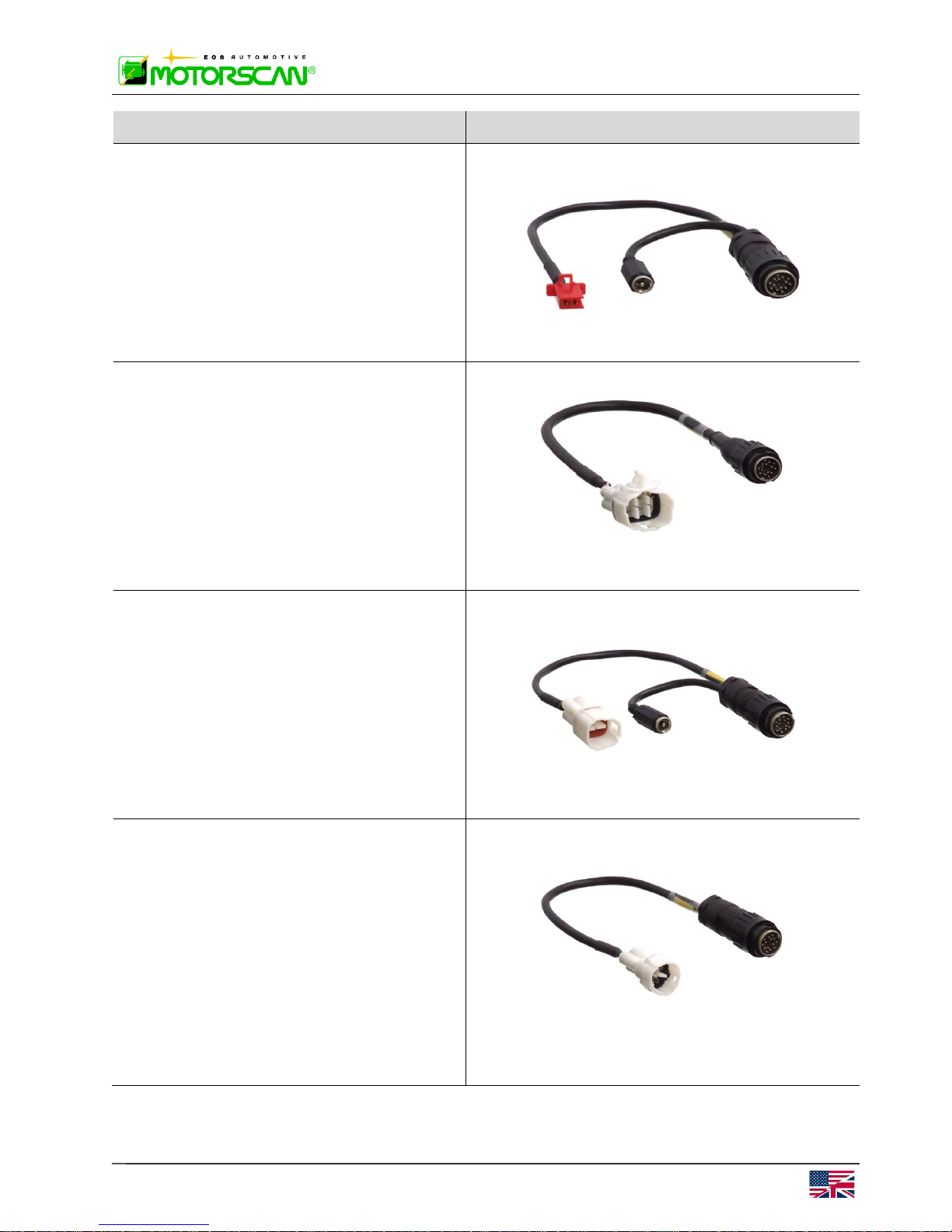

1.6 - OPTIONAL

The part number for the cable required for a particular function is next to each motorcycle model

in the “Vehicles List”. Exact cables included vary by kit. Consult distributor.

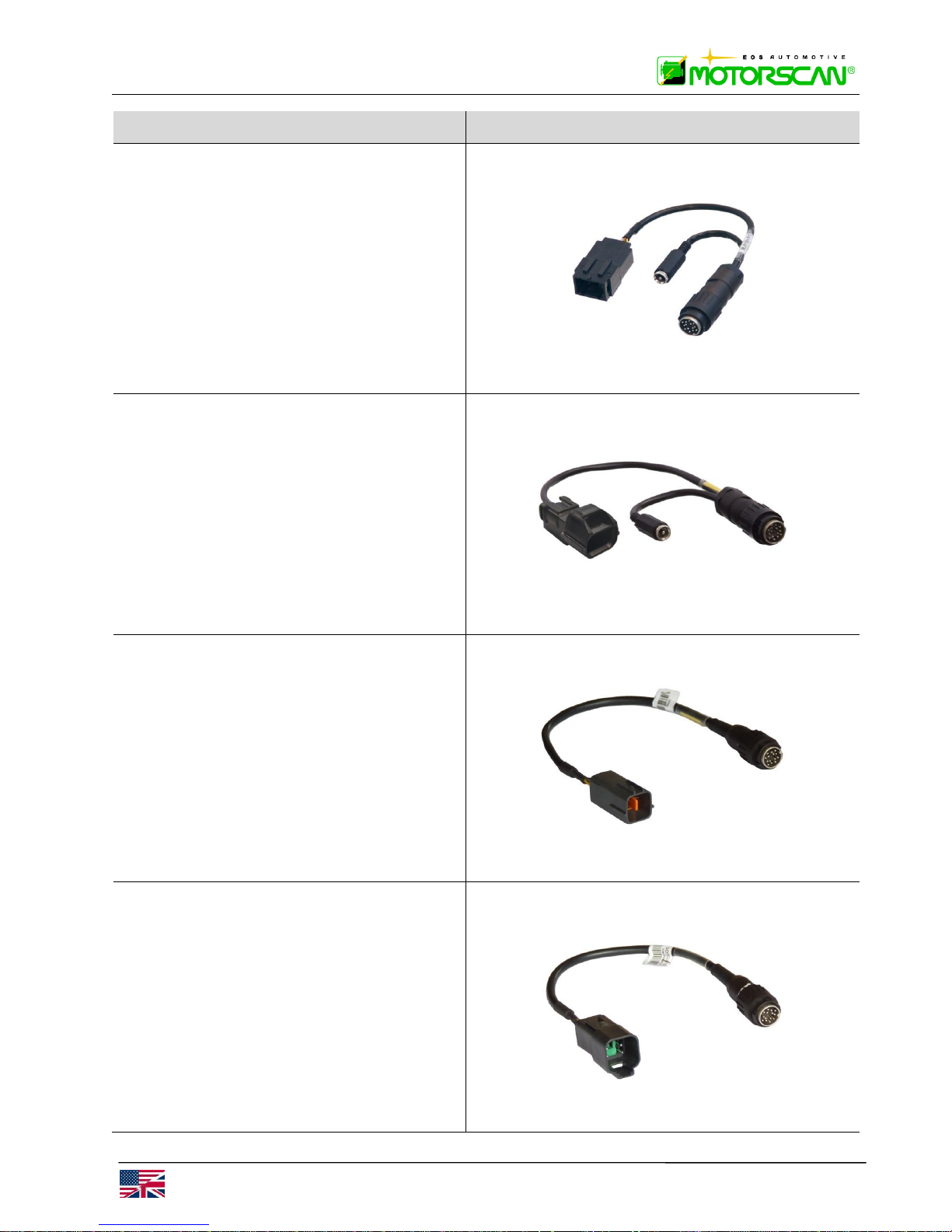

DESCRIPTION and PART N°.

PICTURE

KAWASAKI 4 Pin Slave Cable

Part number: 458

KAWASAKI 8 Pin Slave Cable

Part number: 459

HONDA 4 Pin Slave Cable

Part number: 460

WARNING: do not use on MV Agusta systems.

HONDA 3 Pin Slave Cable

Applications: Honda with blinking code

systems.

Part number: 461

WARNING: do not use on Aprilia/Ditech systems.

MS6050EN

MOD. 6050

OPERATING INSTRUCTIONS 13

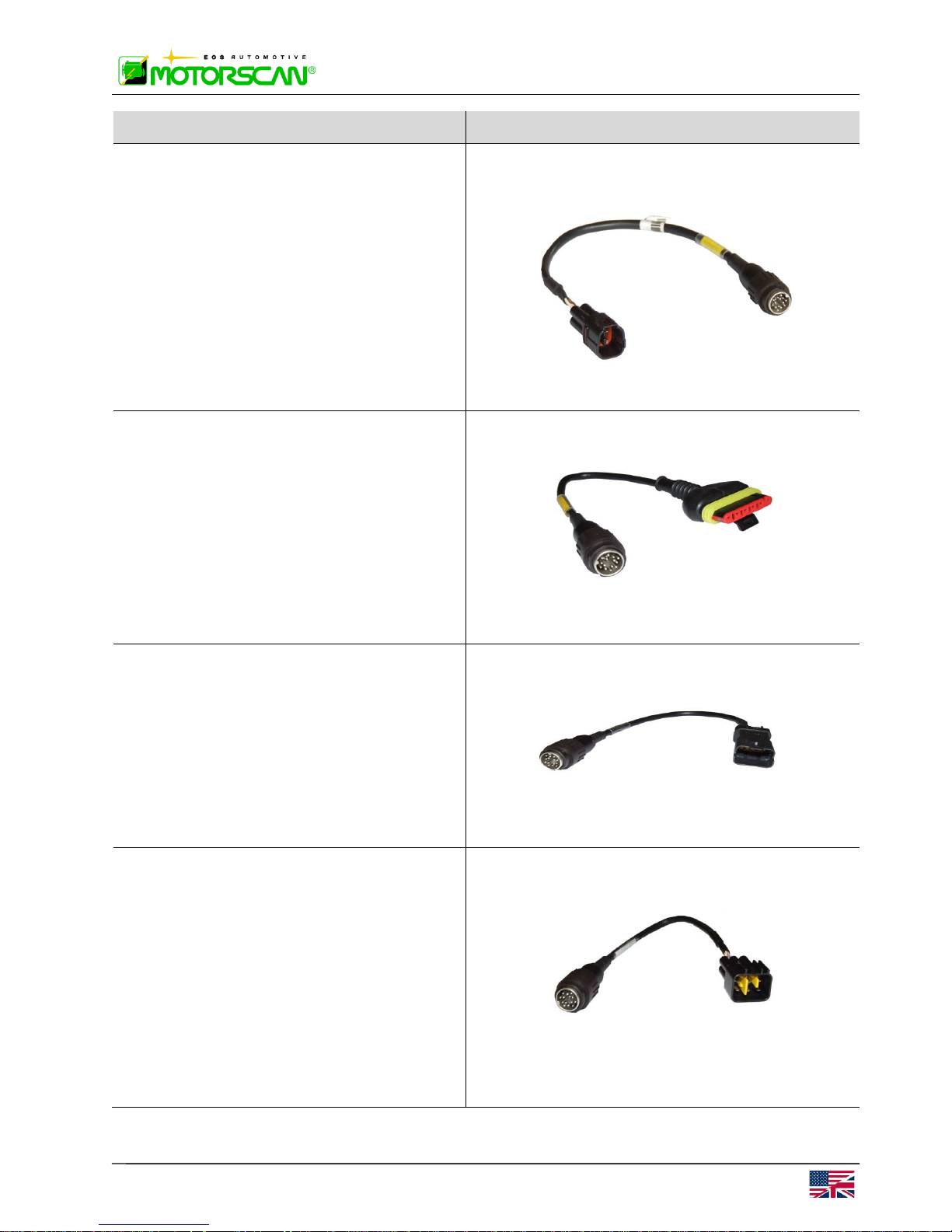

DESCRIPTION and PART N°.

PICTURE

HONDA 2 Pin Slave Cable

Applications: Honda HISS systems.

Part number: 462

SUZUKI 6 Pin Slave Cable

Part number: 463

SUZUKI 4 Pin Slave Cable

Part number: 464

YAMAHA 3 Pin Slave Cable

Applications: Malaguti1 and Yamaha.

Part number: 475

1

Only Yamaha EFI systems

MOD. 6050

MS6050EN

14 OPERATING INSTRUCTIONS

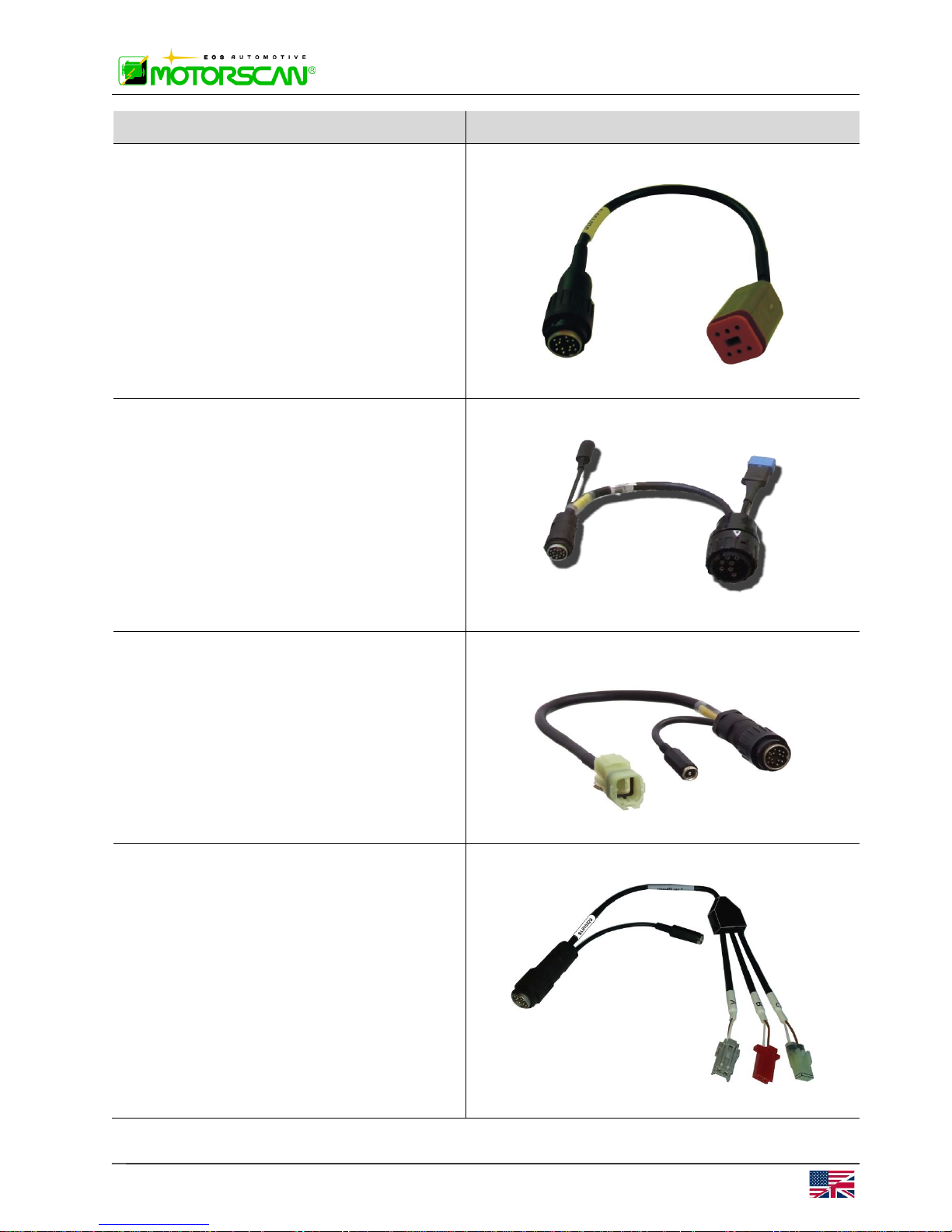

DESCRIPTION and PART N°.

PICTURE

CAGIVA 10 Pin Slave Cable

Part number: 476

BMW Slave Cable

Part number: 525

Harley-Davidson Slave Cable

Applications: Harley-Davidson2 and Buell

Part number: 480

2

Except CAN -BUS systems

OBDII Slave Cable

Applications: Triumph

Part number: 481

MS6050EN

MOD. 6050

OPERATING INSTRUCTIONS 15

DESCRIPTION and PART N°.

PICTURE

Packard Slave Cable

Applications: Aprilia1, Bimota1, Cagiva1,

Derbi, Ducati, Garelli, Gas Gas, Gilera,

KVN Motor, Laverda, Malaguti1, Moto

Guzzi, Moto Morini, MV Agusta1, Piaggio,

Sherco, Vespa, Voxan

Part number: 499

1

Only Marelli systems

APRILIA/DITECH Slave Cable

Applications: Aprilia Ditech system.

Part number: 483

WARNING: do not use on Honda systems.

KTM Slave Cable

Applications: KTM and Husaberg system.

Part number: 489

APRILIA/SAGEM Slave Cable

Applications: Aprilia Sagem system.

Part number: 490

MOD. 6050

MS6050EN

16 OPERATING INSTRUCTIONS

DESCRIPTION and PART N°.

PICTURE

PEUGEOT Slave Cable

Part number: 491

KYMCO Slave Cable

Part number: 493

KAWASAKI 4 Pin/2007 Slave Cable

Part number: 500

BRP Slave Cable

Part number: 501

MS6050EN

MOD. 6050

OPERATING INSTRUCTIONS 17

DESCRIPTION and PART N°.

PICTURE

KAWASAKI REG. INJ. Slave Cable

Part number: 502

BENELLI 6 Pin Slave Cable

Part number: 505

DUCATI CAN 4 Pin Slave Cable

Part number: 508

KAWASAKI 6 Pin Slave Cable

Part number: 509

MOD. 6050

MS6050EN

18 OPERATING INSTRUCTIONS

DESCRIPTION and PART N°.

PICTURE

KAWASAKI MY 2010 6 Pin Slave Cable

Part number: 510

SYM 3 Pin Slave Cable

Part number: 512

POLARIS 8 Pin Slave Cable

Part number: 516

WALBRO SYSTEM Slave Cable

Applications: Aprilia and Bimota with

Walbro systems.

Part number: 518

MS6050EN

MOD. 6050

OPERATING INSTRUCTIONS 19

DESCRIPTION and PART N°.

PICTURE

HARLEY-DAVIDSON CAN 6 Pin Slave

Cable

Applications: Harley-Davidson with CANBUS systems.

Part number: 519

BMW Slave Cable

Part number 525

MV AGUSTA CAN 4 Pin Slave Cable

Applications: MV Agusta with CAN-BUS

systems.

Part number: 526

WARNING: do not use on HONDA

systems.

HONDA HISS 2 Pin Slave Cable

Applications: Honda HISS systems.

Part number: 528

Loading...

Loading...