Motor Saver 201, 102, 350, 250, 102-A User Manual

...

INSTALLATION INSTRUCTIONS FOR SYMCOM’S

MOTORSAVER MODELS 102, 201, 250, 350

BE SURE POWER IS DISCONNECTED PRIOR TO INSTALLATION!!

FOLLOW NATIONAL, STATE AND LOCAL CODES!

INSTRUCTIONS D’INSTALLATION POUR LE SYMCOM

MOTORSAVER, MODÈLES 102, 201, 250, 350

S’ASSURER QUE LE COURANT EST COUPÉ AVANT L’INSTALLATION!

RESPECTER LES LOIS ET CODES LOCAUX, PROVINCIAUX ET FÉDÉRAUX!

INSTRUCCIONES DE INSTALACIÓN PARA LOS MODELOS

MOTORSAVER 102, 201, 250, 350 DE SYMCOM

ANTES DE LA INSTALACIÓN CERCIÓRESE DE QUE ESTÉ DESCONECTADA LA

ENERGÍA ELÉCTRICA ACATE LOS CÓDIGOS NACIONALES, ESTATALES Y LOCALES

2880 North Plaza Drive, Rapid City, SD 57702 • (800) 843-8848

www.symcominc.com

Manufactured by

Visit our website at www.symcominc.com for our

complete catalog and new product listings!

VOLTAGE MONITORS

MONITEUR DE TENSION

EL MONITOR DEL VOLTAJE

CONNECTIONS

1. Mount the MotorSaver®in a convenient location in or near the motor control panel.If the location is wet

or dusty, the MotorSaver®should be mounted in a NEMA 4 or 12 enclosure.

2. Connect the three lines of the motor’s 3-phase power supply to L1, L2 and L3 on the MotorSaver’s

terminal strip [Pin 3, 4 and 5 on the Model 201] (see Figure 1).

3. Connect the output relay to the circuitry to be controlled (see Figure 1).

SETTINGS

All models are not equipped with the same adjustments. Set the adjustments available on the front of your

particular model.

1. LINE VOLTAGE ADJUSTMENT: Rotate the LINE VOLTAGE ADJUSTMENT to the nominal 3-phase

line voltage feeding the motor to be protected.

2. TIME DELAY RESTART: Rotate the RESTART DELAY to the desired position. The restart delay is the time

between MotorSaver®seeing acceptable power and MotorSaver®closing its output contacts.

For compressor applications, the restart delay should be set for the approximate time it takes for the head

pressure to bleed off of the compressor .For other applications, the restart delay is typically set at 2 seconds.

If the RESTART DELAY is in the MAN (manual) position, the unit will not automatically restar t until it is

turned out of the manual position.

3. TRIP DELAY ADJUSTMENT: Rotate the TRIP DELAY ADJUSTMENT to the desired setting.

The adjustment does not affect the trip delay on phasing faults. Typically, the TRIP DELAY ADJUSTMENT

is set to 4 seconds. In areas where voltage fluctuations are frequent, the TRIP DELAY ADJUSTMENT is

set between 10 and 15 seconds.

4. OTHER OPTIONAL ADJUSTMENTS: If your MotorSa v er®is equipped with another optional adjustment,

rotate the adjustment screw to the desired setting.

POWER-UP

Turn on the power to the motor. The MotorSaver®then goes through its restart delay and the LED will flash

green. After the RESTART DELAY (fixed or adjustable), the MotorSaver®will energize its output contacts

and the RUN LIGHT will turn solid green. If the contacts do not energize and the RUN LIGHT does not turn

solid green, see the TROUBLESHOOTING section.

TROUBLESHOOTING

If the output relay does not energize and the RUN LIGHT does not turn solid green after waiting for the

RESTART DELAY time:

1. Rotate the REST AR T DELAY dial clockwise 1/8 turn, above "2." You may be pointed at "Manual" or close

enough to the Manual reset position that the unit will not automatically restart. If the light does not flash

green, proceed to step 2.

(A) To control a motor : Connect the normally open contact in

series with the magnetic coil of the motor starter as shown.

(B) To sound an alarm: Connect the normally closed

contact in series with the alarm as shown.

Figure 1:Typical Wiring Diagram

RUN

RESTART DELAY

REVERSE PHASE

HIGH / LOW VOLTAGE

UNBALANCE / SINGLE PHASE

GREEN

GREEN

RED

RED

RED

INDICATOR LIGHT

DIAGNOSTICS

WARRANTY

Seller warrants to the buyer that products furnished will be free from defects in material and workmanship, exclusive

of corrosion, for a period of five years from the date of shipment from its factor y, provided said products have been

installed, maintained and operated in conformance with any applicable specifications and recommendations of the

Seller. The sellers liability under this warranty shall be limited to the replacement within the aforesaid time of any defective work or material limited at the Seller’s factor y and shall not be liable for any labor or other repair costs made outside the Seller’s factor y without the written consent of the Seller. The Seller shall be liable for no other damages or

losses. The warranty described in this paragraph shall be IN LIEU OF ANY OTHER WARRANTY EXPRESSED OR

IMPLIED INCLUDING BUT NOT LIMITED TO ANY IMPLIED W ARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

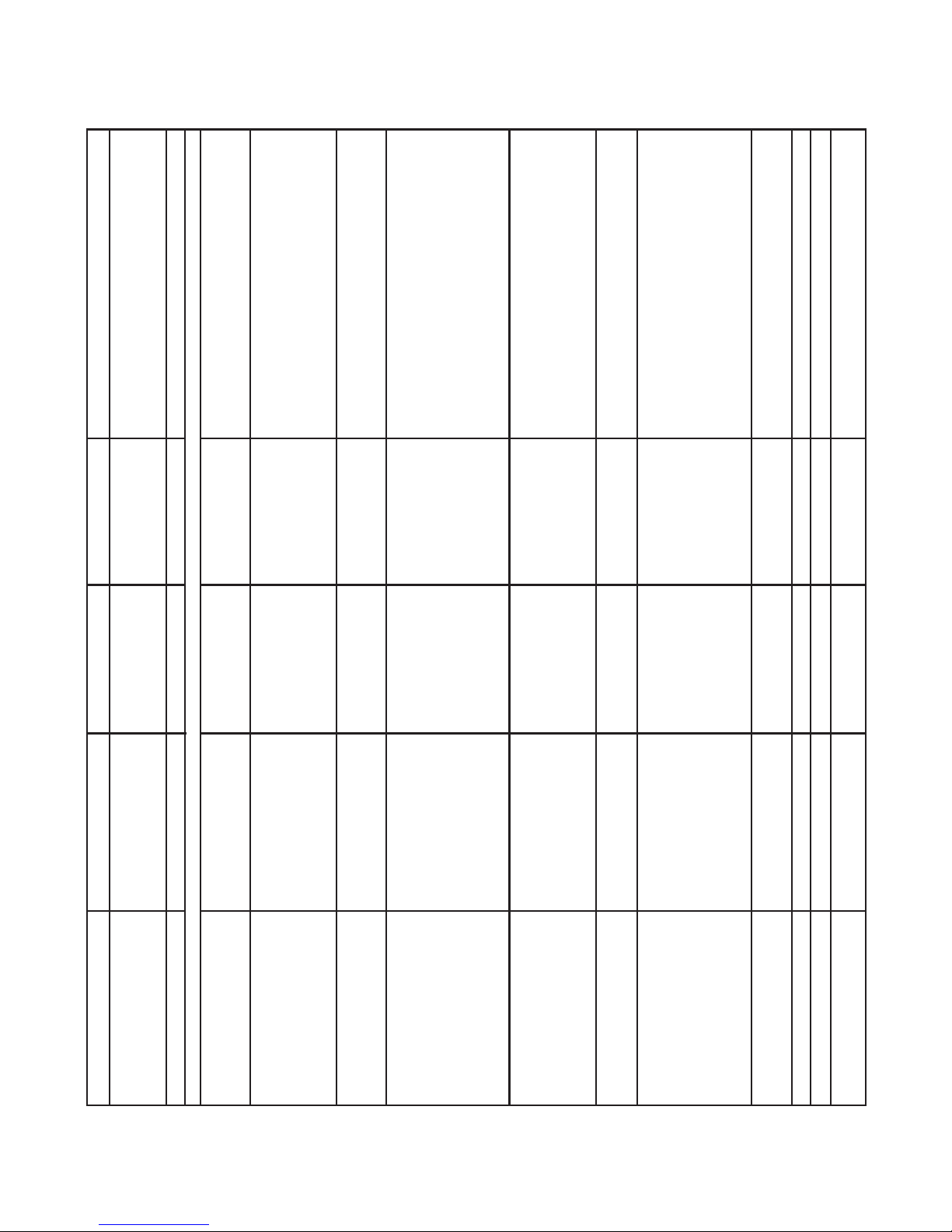

0.150" (3.81)

2.163"

(54.94)

2.913"

(73.99)

4.030" (102.36)

5.250" (133.35)

4.500" (114.30)

.375"

(9.53)

2.900"

(73.66)

SymCom, Inc.

RESTART

DELAY

(SECONDS)

70

2

MAN

150

220

300

C

IND. CONT. EQ

LISTED

784X

U

L

®

IND. CONT. EQ

LISTED

784X

U

L

®

GEN. PURPOSE RATING

10 A at 240 VAC

PILOT DUTY RATING

480 VA at 240 VAC

RUN

LIGHT

MODEL 102

P/N- MS102 - A

220

440

208

416

200

400

190

380

230

460

240

480

LINE VOLTAGE

ADJUST

(VAC)

L1

L2

L3

190-480 VAC, 3Ø, 50/60 HZ

Rapid City, SD

BOTTOM

2.375

(60.331)

1.75

(44.545)

TOP

SIDE

3.15

(80.010)

.5

(12.700)

LINE VOLTAGE ADJUST

190/380

200/400

208/416 220/440

230/460

240/480

RUN LIGHT

(VAC)

DIMENSIONS FOR MODELS 102, 250, 350

DIMENSIONS FOR MODEL 201

SIDE

FRONT

2. Tur n off the 3-phase power. Swap any two leads: L1 and L2; L2 and L3; L3 and L1. You have a 50-50

chance of connecting L1, L2 and L3 up correctly the first time.Turn on the 3-phase power.

3. If the MotorSaver

®

still seems to be malfunctioning, measure the three line-to-line voltages.Calculate

the average of the voltages. If the average voltage is 10% above (high voltage protection standard on

Model 250 only) or 10% below the voltage adjust setpoint, the MotorSaver®is functioning properly,

saving your motor from abnormal power conditions.

4. If the average of the three line voltages is within ±10%, calculate the voltage unbalance using the

NEMA method shown below:

% voltage unbalance = (max. deviation / average of the three voltages) x 100

EXAMPLE: Find the largest deviation from the average voltage and divide it by the average for the

NEMA unbalance.

L1 - L2 = 460VAC, L2 - L3 = 466 VAC, L3 - L1 = 490 VAC

Average = (460 + 466 + 490)/3 = 472

490 is the largest deviation from the average voltage.

Max. deviation = 490 - 472 = 18

% voltage unbalance = (18/472) x 100 = 3.8%

If the percent voltage unbalance is greater than 4.5%, MotorSaver®is functioning properly, saving your

motor from abnormal power conditions.

5. If the percent voltage unbalance is less than 4.5%, contact SymCom at 1-800-843-8848 OR

1-605-348-5580 and we will be happy to help you.

SPECIFICATIONS MODEL 102-A MODEL 201-A MODEL 250-A MODEL 350

Line Voltage Ranges 190 - 480VAC 190 - 480VAC 190 - 480VAC 190 - 240VAC (200V Model)

380 - 480VAC (400V Model)

475 - 600VAC (600V Model)

Frequency 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

Operating Points

Low Voltage

Trip (% of setpoint) 90% 90% 90% 90%

Reset (% of setpoint) 93% 93% 93% 93%

High Voltage

Trip (% of setpoint) N/A (Standard)

Option 9 (110%)

N/A (Standard)

Option 9 (110%)

110% N/A (Standard)

Option 9 (110%)

Reset (% of setpoint) N/A (Standard)

Option 9 (107%)

N/A (Standard)

Option 9 (4 Seconds)

N/A (Standard)

Option 9 (107%)

107% N/A (Standard)

Option 9 (107%)

Voltage Unbalance (NEMA)

Trip (% of setpoint) 6% 6% 6% 6%

Reset (% of setpoint) 4.5% 4.5% 4.5% 4.5%

Trip Delay Time (Nominal)

Low Voltage 4 Seconds (Standard) 4 Seconds 4 Seconds 4 Seconds (Standard)

Option 3 (2 - 30 Seconds)

High Voltage 4 Seconds N/A (Standard)

Options 3 & 9 (2 - 30 Seconds)

N/A (Standard)

Option 9 (4 Seconds)

Unbalance & Phasing Faults 2 Seconds 2 Seconds 2 Seconds 2 Seconds

Restart Delay Time

After a Fault 2 Seconds (Standard)

Option 2 (2 - 300 Seconds)

2 Seconds 2-300 Seconds 2 Seconds (Standard)

Option 2 (2 - 300 Seconds)

From complete power loss 2 Seconds (Standard)

Option 2 (2 - 300 Seconds)

2 Seconds 2-300 Seconds 2 Seconds (Standard)

Option 2 (2 - 300 Seconds)

Manual Reset N/A (Standard)

(Available with option 2)

N/A (Standard) Standard N/A (Standard)

(Available with option 2)

Output Contact Rating

Pilot Duty (SPDT) 480VA @ 240VAC or

10A General Purpose 10A General Purpose

480VA @ 240VAC or

15A Gen. Purp. or 1 hp @ 240VAC (200V Unit)

470VA @ 600VAC (400 or 600V Unit)

2-15A Gen. Purp. or 1 hp @ 240VAC (Option 8)

Pilot Duty (DPDT) 480VA @ 240VAC or

10A General Purpose

2500V for 10 ms 2500V for 10 ms 2500V for 10 ms 2500V for 10 ms

Power Consumption 5 Watts (max.) 5 Watts (max.) 5 Watts (max.) 5 Watts (max.)

Weight 14 oz. 9 oz. 14 oz. 1.5 lbs.

Ambient Operating Temperature

Ambient Storage Temperature

-40 to 70 ºC

-40 to 80 ºC

-40 to 70 ºC

-40 to 80 ºC

-40 to 70 ºC

-40 to 80 ºC

-40 to 70 ºC

-40 to 80 ºC

Internal Transient Protection

Using IEC 1000-4-5:1995

Loading...

Loading...