SV-520/550 INSTRUCTION MANUAL

SV-520/550

l.Prior

2.Before

3.

4. heck lubri

5.

the u e

may

read it at

in

dicated

Ground

heck that

of

this product, please read the instruc tion

anytime

turn on the

in

ing th

cat

rotational direction

pow

the

contro

machine i always

ing oil

er

l box.

prior

when

be sure to

to op

necessary.

check

neces

erat

ion.

of

the

motor

For safe operation

Manual.

the pow r voltage and

ary

for

safe and norm al operation.

is

correct

prior to operation.

Keep this Instruction

phase

agre ing with the

Rev-5A

Manua

l and the user

nameplat

e that

6. So as to

cl

ose

7. For the following conditions , turn

8.

Repairing

prevent

to

the movi

7.1 or

7.2 To

7.3

7.4

7.5 When lightning and

, re

personal

ng

part

s. l o nev

threading

plug

or

unplug

For

mainten

When machine is not at u e, inspected

modeling

ance

and

injuries

needle

any

and repairing.

adjust

during

er

off

or

r pl

connecto rs from

thunder

ing

works must

operation be carefu l not to allow

try to stop it with external forces.

the

power

acing

occurs

or

disconnect

bobbin.

contro

or

.

only

l box.

adjusted.

be

done by a

the

powe

ppropriately

your

head and hands to

r plug from receptacle.

trained technician s

come

or

specially skilled personnel.

I.

Set

up

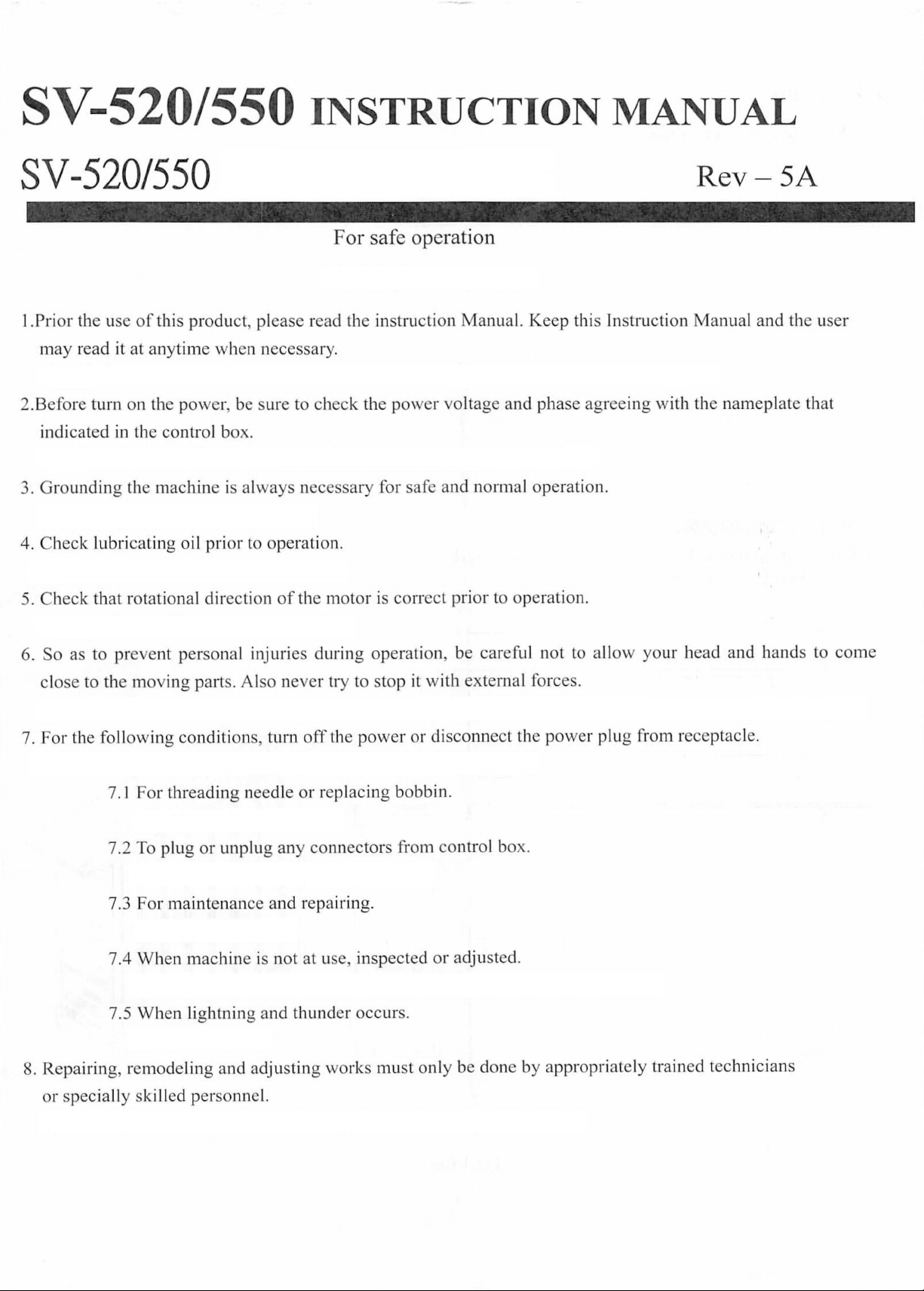

1.For

Dimensions

control

of

box

control

set

up

GTJ

r

box

as shown in Fig. I

lit

J~

-~

@

~

_J

c::=c::=-

---=:J

---=:J

H

301.05

290.75

301.6

328.77

235

- r

-

,

J

"1

7

~

~

=1 -'-

10.25

~1

'-

',;,

{s

I

~

I $n o $1

0 0

en

@ = @

0 0

D

[]

JJ~

t'i

~

Fig.I

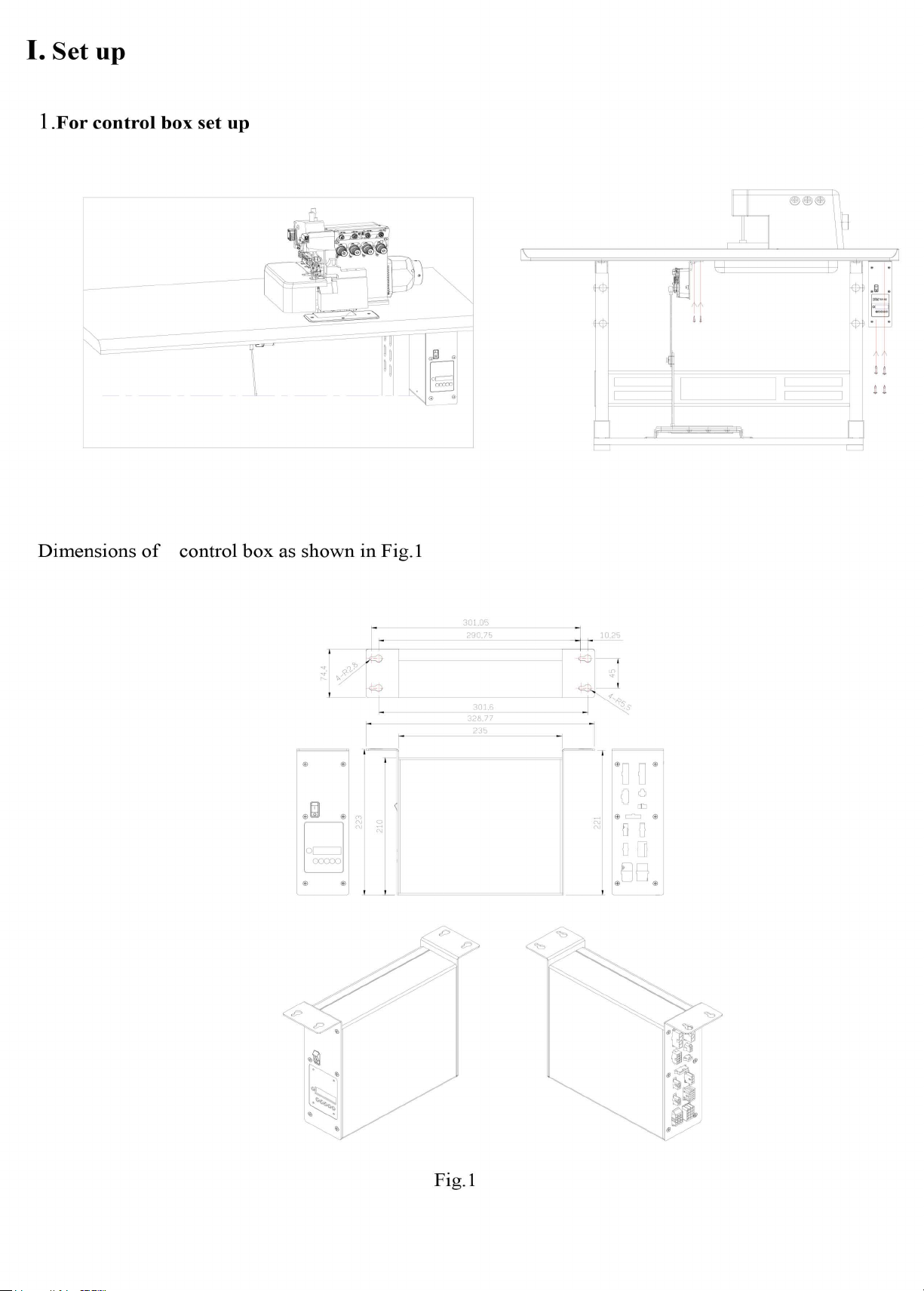

I. Set up

I .For motor & control box set up

Dimensions

of

motor & control box as shown in Fig. I

330

•••••

300.5

(".)

<O

C\J

""'"

If)

C'\i

cO

8

0

0

D

0

()

fl

D

DO

CJ

@

e

Fig.I

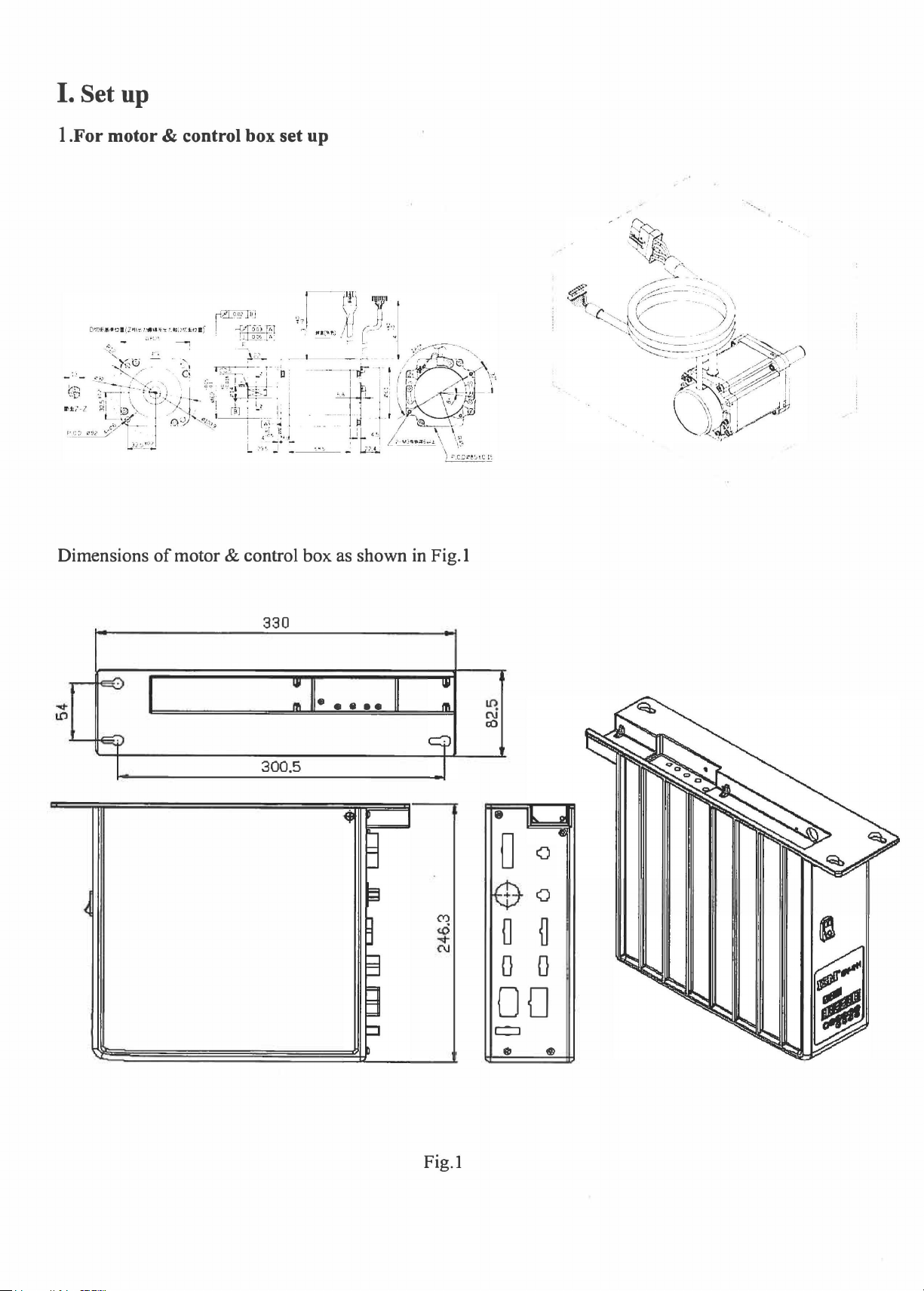

2.

Connector position and function

Circuit boards as Fig. 2 . Table 1 is the explanation for the connectors. Connectors for control box external

output please refer to Fig 3, then according to the machine, connect it to the respective connectors.

-)

CK2~

••

••

••

••

CN3

::

••

••

•

Connector

CN3

CNS

CN4

Fig.2

Option IN_I: pin 5

Option

Option IN_B : pin 9

Option IN_C : pin

IN_A:

pin 7 & 8

• m

CH5~

CN6~

CN

CNS~

7

:

:

rn

ctUJ~

CN

DUI~

CN

l6

9 e •

•

Connectors ' description

CO2

Front cover

Motor encoder connector

Standing operation pedal connector

& 6

&

10

11 & 12

connector

m

.

e e

[;}

..

••

• •

• •

••

CN13

CN14

CN7

CN6

External Panel connector

Speed unit connector

Safety switch connector

Synchronizer connector

CN9

CNll

CN16

CN15

Machine functions' connector

Option

Option

Option

Option

Foot lifter switch

Back tack switch

OPTION D connector

Option

Option

Option

OUT_B:

OUT_E:

OUT_F:

OUT_G:

IN_K: pin 2 & 6

IN_L:

IN M : pin 4 & 6

pin 6 &

pin 2 & 9

pin 1 & 8

pin 7 &

: pin 4 &

:pin5&12

Foot lifter Solenoid connector

pin 3 & 6

Material edge sensor connector

11

13

14

1---i~

3--~--r

0

CNS

CN12

Foot lifter discharge resistor

+12V Power output connector

Table 1

0

1-

2--0{]

3--{]

i

4-osJJ

5---+--

0

Fig.3

See Fig. 3

I .Motor power line connector.

>------le---

0

10

4--0

I .Motor power line connector.

.JJ

1---------l-

0 0

Fig.4 ·

See Fig. 4

11

2. Synchronizer connector

2. Synchronizer connector

3.Operation panel connector

4. Foot lifter solenoid connector

5.Sewing machine function connector

6.Safety switch connector

7.DC 12V 60mA output connector

8.Pedal sensor connector

9.Encoder connector

10.Sewing machine function connector2

3. Operation panel connector

4. Foot lifter solenoid connector

5.Sewing machine function connector

6.Safety switch connector

7 .DC 12V 60mA output connector

8.Pedal sensor connector

9. Encoder connector

10

. Foot lifter switch connector

11.

Sewing machine function connector2

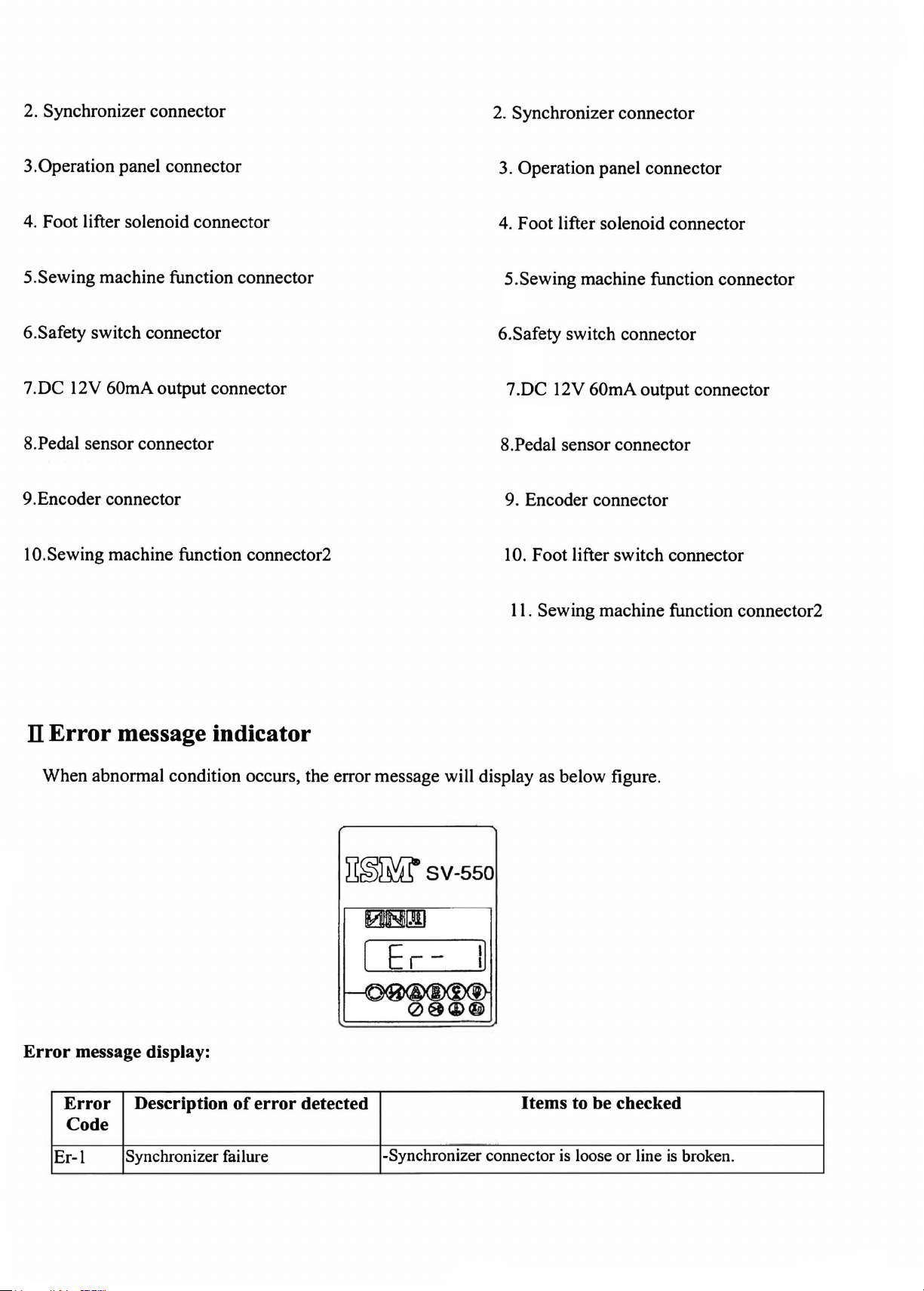

Il Error message indicator

When abnormal condition occurs, the error message will display as below figure.

~~Wsv-550

[ Er -

I]

Error message display:

Error Description

Code

Er-1

Synchronizer failure

of

error detected

-Synchronizer connector

Items to be checked

is

loose

or

line

is

broken.

Er-2

Er-3

Motor

Power

is

not

failure

rotating

-Machine

-Motor

loose.

-IPM

-Voltage is

-Fuse

power

is failed

(F2)

head

either

is

burned

or

line

motor

or

too

high

out.

is locked.

encoder

or

too

line. is

low.

broken,

or

connector

is

Er-4

Er-5

Er-6

Er-7

Er-8

Er-9

Er-10

Er-11

Safety

machine)

Speed

CPU

Material

failed.

Setting

maximum

1PM is failed. -IPM

Solenoid

Synchronizer

switch

unit

error

speed

output

failure( chain stitch

output

edge

speed.

failure

sensor

over

is

down

overload

signal failure

function

the

-Failure in safety

-Safety

-Wrong

-Speed

-Speed

-Connecting

-Noise

(Ex.

-Eeprom

-Parameter

is

-Material

-Connector

Material

-

motor

-Parameter

-Motor

-Motor

-Short

-Solenoid

- Transistor is failed

-Synchronizer

-Setting

switch

setting

unit

connector

unit

is

rod installation is incorrect

interference

High

frequency

damaged

No.42

edge

for material

not

No.

pulley

pulley

overheated

circuit

resistance is too

error

switch

failure

for

parameter

is loose

broken

machine,

wrong

sensor

properly

I setting

diameter

ratio setting

or

connector

for

not

edge

settled

value

is

low

voltage

parameter

connection.

No.35.

welding

setting

properly

sensor

through

is

too

too

small

error

of

1PM

low

is loosen

No5

or

l &

machine)

adjusted

is loose

machine

large

line is broken.

52

Er-12

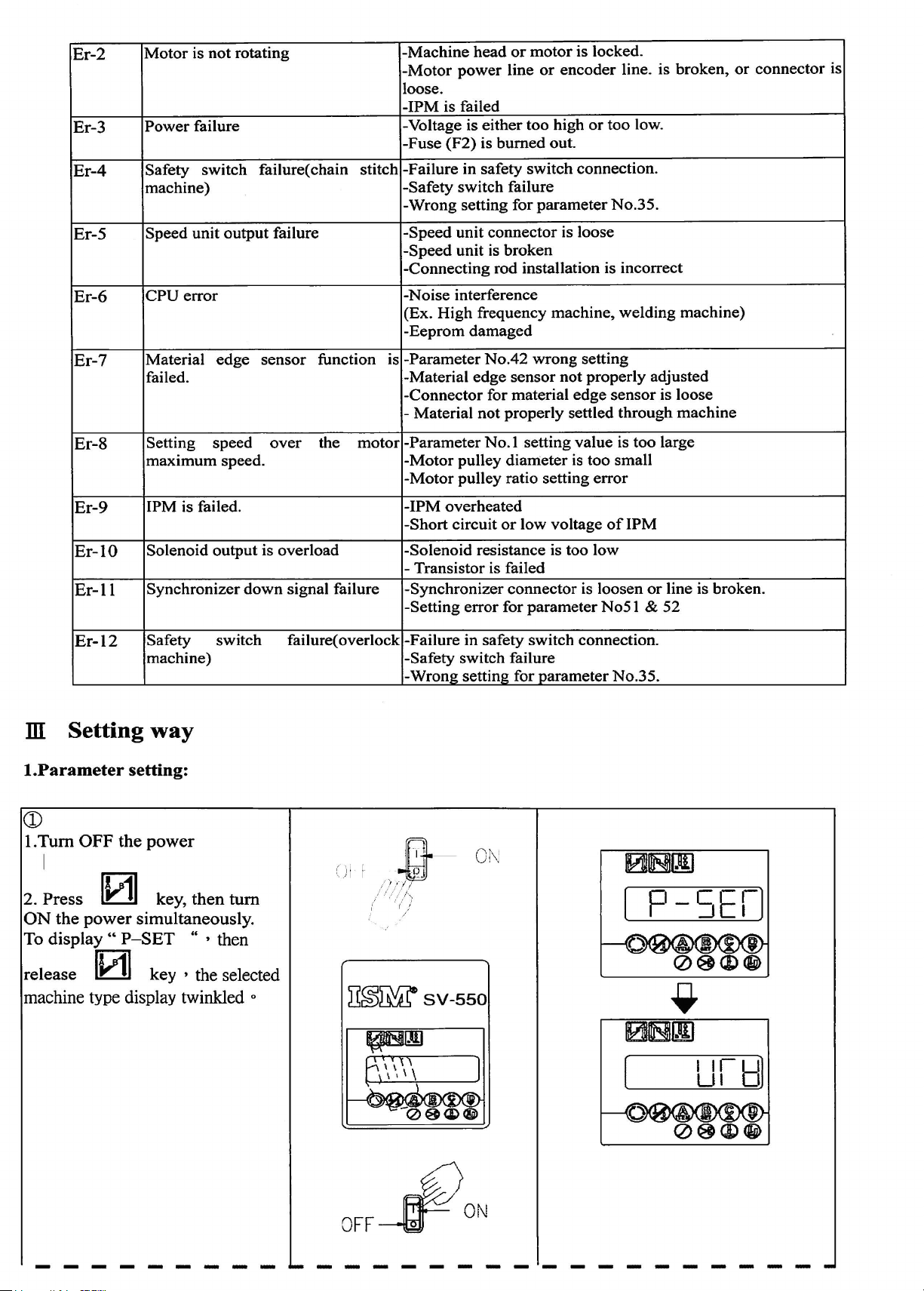

ill Setting

I.Parameter

Safety

machine)

way

setting:

CD

I.

Tum

OFF the

I

2. Press

ON

the power simultaneously.

lv11

To display

release

machine

IWI

type display twinkled

power

key, then

..

P-SET

key , the selected

switch

tum

" , then

0

failure(

overlock

CJ

I I

~~~SV-550

-Failure in safety

-Safety

-Wrong

.

-Gt

1///

/ ' i /·-...

i ( i

/

switch

setting for

-

Of\j

switch

failure

parameter

connection.

No.35.

OFF

PON

----------------------------

®

I. Turn

ON

the power.

2. Press key

until display

release

machine type display twinkled

2.lf

it

is

above, please repeat steps

0exceed

"

P-SET"

[1/1]

not displayed as shown

key , the selected

2 second

' then

®

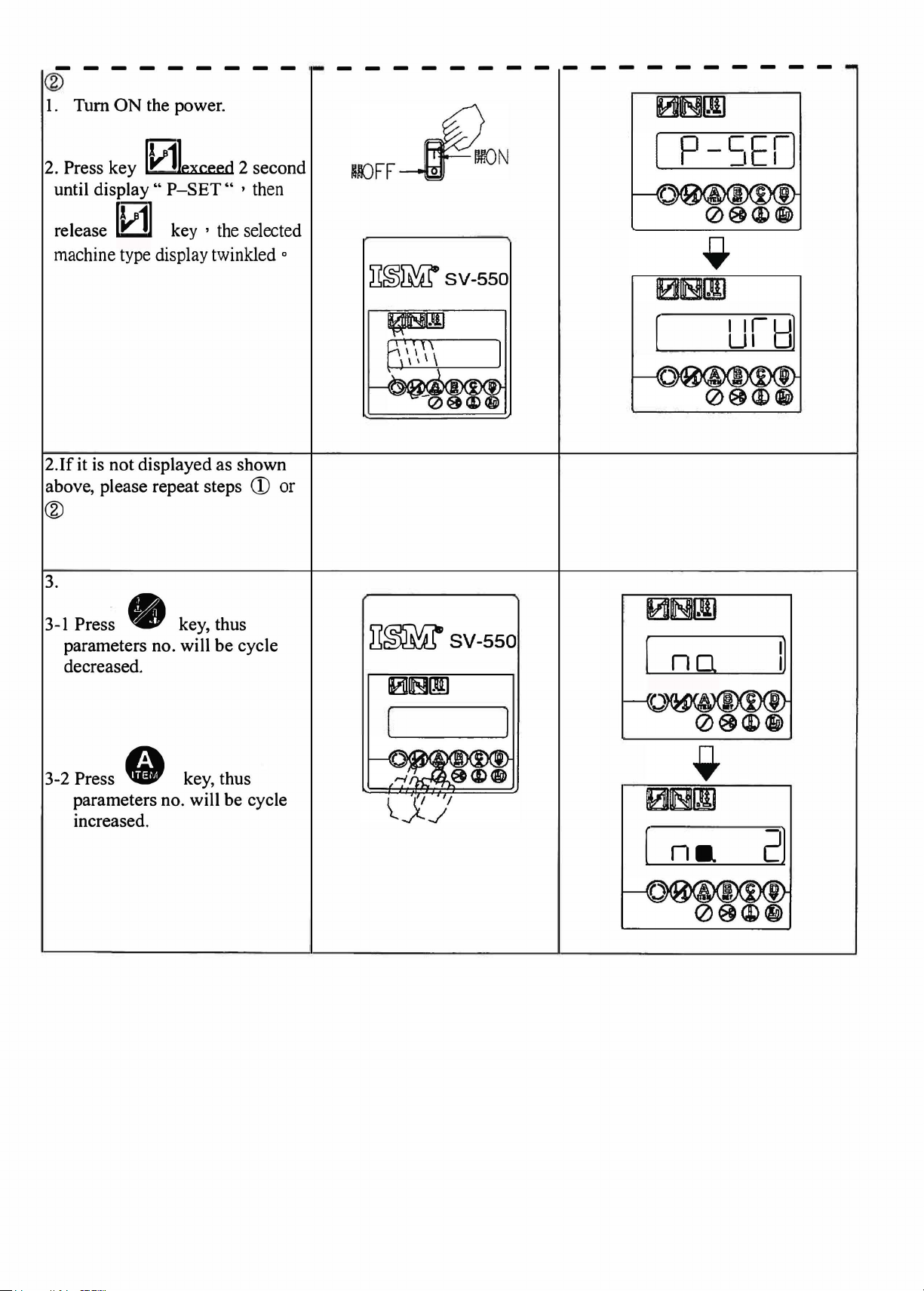

3.

CD

0

~~~SV-550

or

Pres~ • key, thus

3-1

parameters no. will

decreased.

3-2 Press

parameters no. will be cycle

increased.

• key, thus

be

cycle

il~SV-550

101B[J]

[

(

no

na

I]

2)

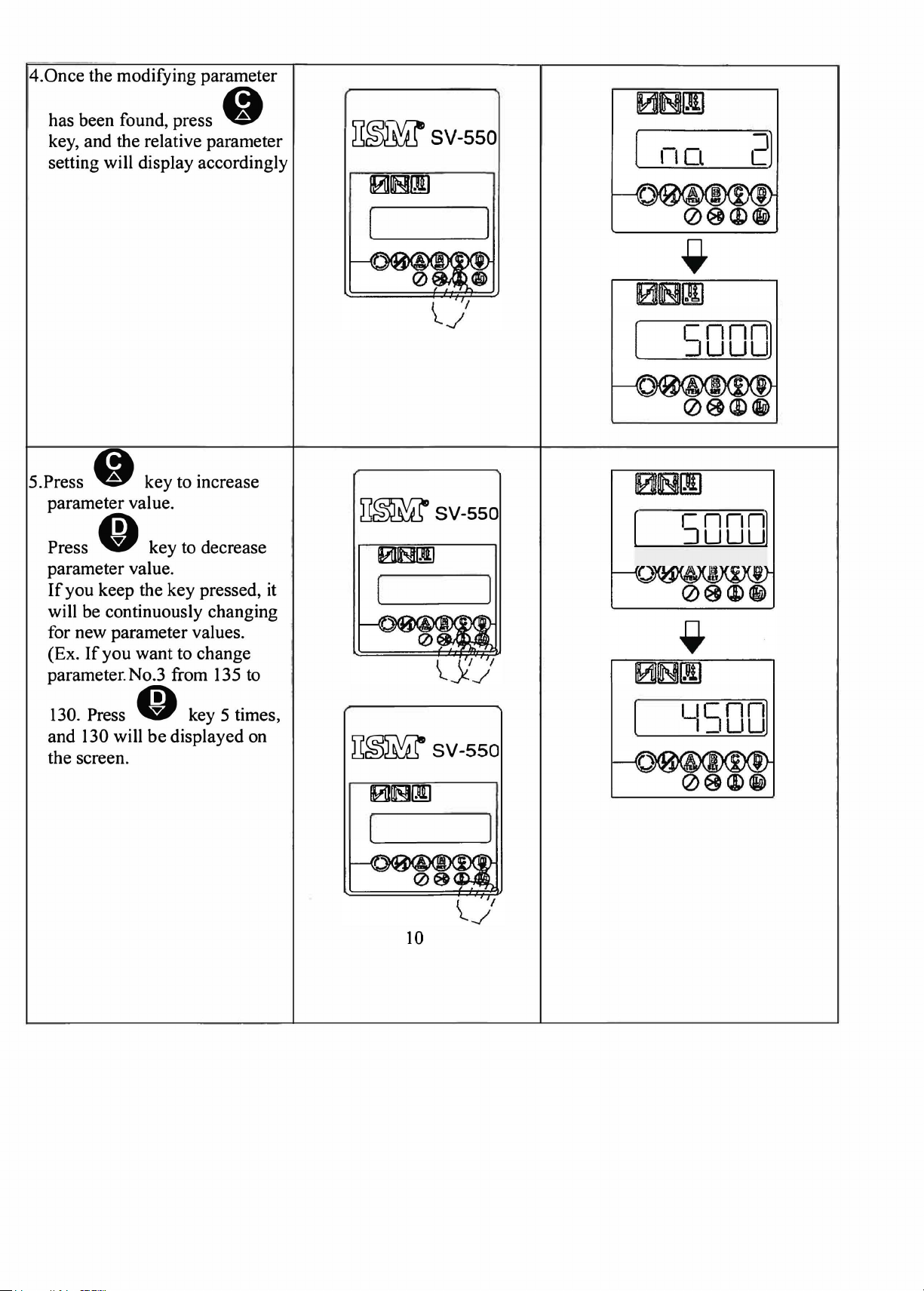

4.Once

the modifying parameter

has been found, press •

key, and the relative parameter

setting will display accordingly

~~SV-550

2)

101ms![IJ

5.Press • key to increase

parameter value.

Press

parameter value.

If

will be continuously changing

for new parameter values.

(Ex.

parameter.No.3 from 135 to

130. Press

and 130 will

the screen.

• key to decrease

you keep the key pressed,

If

you

want to change

O key 5 times,

be

displayed on

it

D~sv-sso

ims!~

~~SV-550

[

(

[

5000)

50001

'~SOD]

0~111

10

6.Pressing • key can selec~

for the next parameter no.

repeat steps 4-6 to modify

parameter value.

7 .Once all specified value has

~~SV-550

0~

r1c1

----

- f

-,i,

been changed, press

to save.

performed, the specified value

will

8.Tum

re-start the power, thus it will

operate according to

parameter values

not

OFF

If

this procedure is

be

updated.

the

power

Okey

then

new

not

ra·-.

w-i:

-~~

--·

=~

,,__J

I\ .

D~~SV-550

I

2.Motor pulley ratio measurement :

I.Tum

OFF

the power.

J'·

"'

·-;.

~.'

; I ,

1· ,

•.

2.Press O key, then turn ON

the power. Release • key.

If

the display

3.

is

not as shown

above, please repeat steps 1-2.

~~SV-550

------

~r"WLlw=•

-'<Y

0 s

111.JI'~

~

t ) \ I I \

\

-

,1UIJ-

j~

'F~'

I

__

II

---

-

'

4.

If

the pedal is forwardly

pressed, the motor will rotate 7

turns at positioning speed. After

the motor stops, the motor

pulley ratio will be displayed.

(Sewing machine

360°=motor?

degrees). The step 4 can be

repeated

to

confirm.

'

-... -.

-~~

=-~

-::.~ --~~

--

--.-·--·

I I

...

-·_: --.

c::-:_----\

.J

_../-.·::,

-

_,;,;;..

____

.-

---

·

' .

::::

--

--

: \ .

-;-

I J

-,

--~ c): n; I

-'/ ,/

..

~.

1.-~ I

' . . . . .

~

~-

J

..

__

5.Press @ key to save.

procedure is not performed, it

will remain as the old values.

6.Turn

ON

power

the power, It will operate

then re-turn

OFF

the

according to new pulley ratio

values.

If

this

~~SV-550

0~

-

,-

.~

y y '

;

,.

..

,,

..

,'

,..'

',/

tr@r-"i~-=x

~71°'~~5fft~

A{ -lJc If -

~-

...

'•'

'\

'

..

··

..:..

-,

c I

CCI

- -

--~

D~~SV-550

--

Ii

·'

3.Select the machine type :

I.Tum

2.Press

OFF

the power.

G key

simultaneously, then turn

the power, until rESET

displayed then release the key.

ON

~~SV-550

~eoo

- - -- - -----

_

Cc

_ I

C

I,_

!=

. 1

' j't

I !

3.If

it is not displayed as shown

above, please repeat steps 1-2.

4.Use A, B,

password. And enter

to confirm.

C,

D key to i

in

r•

1/1

~~~SV-550

~~~SV-550

~~

l~l1tLn

I

11_1_

I

I_I

:

IFf

5.If

the password is correct, the 1

sewing machine head choice

will be displayed.

password is incorrect, the

"PW-ER" will be displayed.

Please repeat step 4.

If

the

st

r~,zt~tif

' --

---

-·

-- -

--

.J

6.Press key to select

machine type, then

~~SV-550

,

___

·1

_

press.

Tum

7.

OFF the power, then

ON

the power again. It will

operate according to the

manual's instruction initial

value.

key .

tum

01E!III

~~SV-550

10IBIII

.....

,,..--·

....

'

·- - ·

l~

t~~Jtt~

·--------

~~~SV-550

0~

- -

··

l

;:....,

_

_)

5.Historical error message display

1.

Turn OFF the power.

THi

,

;

i.

'~H! r

-

/.'/

/·

•1,

/,/ ,

tt

'

'·

2.

Press O key, then tum ON

the power simultaneously and

display "ERROR"

~~SV

-550

~

{ '; ,'i,

., .....

. : .J --~

C n

..

;-

-··~ .

2.1 Release

display recent error message.

3.Press key to cycle display

recent 6 error messages.

O key and will

~~~SV-550

\.

__

,/

Er

I

I

6.Pedal sensor neutral point setting mode

I .Tum OFF the power

;-:._:-;'

I

J

~

'''

.

' p

2.

Speed unit (Pedal sensor) pedal

sensor in the neutral point.

Press

the

display "OFSET".

3. Release

display

was stored in EEPROM.

4. Once pressed

the pedal sensor again.

value between 1340-1790, press

• key, then tum ON

power-simultaneously and

• key, and will

the pedal sensor value that

• key, read

If

the

~~~SV-550

"-J

• key to save the value.

5.

If

always displays "ERROR" that

means the pedal sensor neutral

point offset is too much. The

pedal sensor mechanical neutral

point must be adjusted then repeat

step 4.

IV SV-520/550 series Control box parameter list:

No

1

Sewing machine maximum speed

'

2 ,

Sewing

Sewing machine positioning speed

3

Sewing

4

5

The

' Soft start speed

6

7 Soft start stitches

Condensed sewing speed / End auto back

8

tack soeed

End condensed stitches' number

9

10

Stitches' number that between condensed

sewing and trimming

machine medium speed

machine trimming speed

speed

of

start auto back tack

Item

200spm

200spm

I00spm -250spm

I00spm -250spm

500spm

250spm

0

500

0

0

- 8000spm

-

-

-

19

stitches

-

- 2500spm

99 stitches

-

19

stitches

-

8000spm

2500spm

2000spm

Ranl!e

Remarks

50 rpm/step

50spm

I

I step

lspm

/ step

lspm / step

I0spm

/step

I0spm /step

I0spm

/step

Foot lifter type

11

12

Foot

lifter control mode PFL: Pedal controls foot lifter.

Delay time after foot lifter is

13

Confirming time for foot lifter acting level

14

15

Foot lifter duty

down

SOL: Solenoid type

AIR: Pneumatic type

TAFL: auto foot lifts after trimming

AFL: Auto foot lifting after positioning

TFL: Pedal controls foot lifter after trimming

SFL: Auto foot lifting (Material edge sensor

control)

AFL2: Auto foot lifting after trimming.

even pedal forward)

100 - 2500 ms

1000 ms

-

10

0

- 99%

(It's

as

output

effective

10

ms/

step

10

ms/

step

1 % / step

Foot

16

lifter ful I duty output time

100

-

1000 ms

10

ms/

step

Thread trimming mode

17

OFF : No thread trimming

I

Thread trimming delaying time 0

18

19

Thread trimming acting time 0

20

Thread wiping delaying time 0

LOCK : lockstitch

LU2 : LU2220 thread trimming

LUI : LU1520 thread trimming

LU:Other LU machine thread trimming

US639 : US63900 thread trimming

UT : Needle up trimming

AIR:Needle up trimming (AIR BLOW)

UT2:Needle down trimming (trimming

& wiping together)

200ms

-

lOOOms

-

300ms

-

thread trimming

10

10

10

ms/

ms/

ms/

step

step

step

Thread wiping acting time

21

22

23

24

25

26

27

28

Foot lifter delaying time

Thread wiping output control 0 : No output thread wiping

Motor rotating direction

A_ code back tacking compensation 0

B _ code back tacking compensation

C _ code back tacking compensation

The curve slope

rotating speed

of

pedal stroke vs. motor 0

0

2500

2500

no·

no·

no·

4

ms

ms

-

0

-

I : Output thread wiping

2 : Output thread wiping when foot

lifter active

CCW : Counterclockwise

CW : Clockwise

-

0

-

0

-

-

Bigger value means smaller curve slope

10

ms/

10

ms/

5

• /step

5

• /step

5 • /step

step

step

I

I

29

18S

Motor

type

select

Slowdown speed select at auto

turning point

backtack

6535 : 650 W / 3500 rpm

5535 : 550 W / 3500 rpm

5560 : 550 W / 6000 rpm

5550 : 550 W / 5000 rpm

6560 : 650 W / 6000 rpm

4550 : 450 W / 5000 rpm

5070 : 500 W / 7000 rpm

3570 : 350 W / 7000 rpm

3570 < 5070 < 4550 < 6560 < 5550 < 5560 < 5535 <

6535

0

.....,

3

30

The pedal stroke adjustment for motor 150 - 90

rotating (Pedal

neutral=

40, LOI lighting)

31

Pedal stroke adjusts for motor accelerating 70

32

Pedal stroke adjusts for foot lifter acting

33

Pedal stroke adjusts for start thread 3 - 30

trimming

34

Standing type pedal operating choice

Safety switch type

35

In auto test mode, motor running time I 00

36

adjustment

-

110

10 -35

OFF:

Normal speed pedal unit

PK70:

For JUKI standing operation

PK70 type

PKSW: Standing pedal operation, the

speed is fixed (low speed

PK71 : For YHH standing operation

PK71 type

N.O:

Normal open switch

N.C:

Normal close switch

- 20000

ms

& high speed)

100

ms/

step

In auto test mode, motor stopping time I 00

37

adjustment

Back tacking switch function

38

- 20000

BTSW : Control back tacking solenoid

NDUP : Control back tacking solenoid when motor

runs, and as needle up switch when motor stops

DSIN : Control back tacking solenoid when motor

runs, non-continuously inching during motor stops

CNIN : Control back tacking solenoid when motor

runs, continuously inching during motor stops

IRFSS

both during sewing and stopping

: Reverse feed stitching function is effective

UPBT : Control back tacking solenoid only in up

position

SHOT : Control back tacking solenoid, No.74 decide

the output pulse width.

ms

100

ms

I step

FLIP : Control back tacking solenoid,

by flip-flop type output

Stitches' number in reverse feed stitching

39

Trimming function in the reverse feed OFF: Ineffective

40

stitching ON: Effective

-

19

0

stitches

41

Execute auto thread trimming after end fixed

stitches' number sewing process

42

Material edge sensor function OFF: Ineffective

Material edge sensor stitches' number

43

44 Use material edge sensor to process

trimming function

45

Auto needle up positioning when power on OFF: Ineffective

OFF: Ineffective

ON: Effective

ON: Effective

O

0:

I : Auto trimming after execute the step-I stitches.

2 : Auto trimming after execute the step-2 stitches.

3 : Auto trimming after execute the step-3 stitches.

4 : Auto trimming after execute the step-4 stitches.

ON: Effective

--

250 stitches

No

such function.

46

47

48

49

50 The

51

52

53

Backtack switch protect time

To lock the pedal forward

finish trimming process ON: Effective

Sewing machine reversed revolution

function after thread trimming processed ON: Effective

Sewing machine reversed revolution angles 0

after thread trimming processed

delaying

trimming

reversed revolution.

Virtual needle down positioning function

The angles between virtual needle

positioning point and needle up signal

The needle positioning function

sewing

time

but before sewing machine

function before

after finished thread 0

down

of

starting

--

3 0 seconds

0

OFF: Ineffective

OFF: Ineffective

--

250°

--

2500 ms

OFF: Ineffective

ON: Effective

0

--

250°

OFF: Ineffective

ON: Effective

1 ° / step

10

ms/

l°

/ step

step

54

The needle

sewing

55

The starting angle

(count from the needle down position and

only effective

56

The continuous angles

(count from the needle down position and

only effective

positioning angles

of

trimming action

in

LU

trimming mode)

of

trimming action

in

LU

trimming mode)

of

starting

0

--

250°

0

--

250°

0

--

250°

1 ° / step

1 ° / step

1 ° / step

57 The

58

59

60

61

tension

(count from the needle down position and

only effective in LU trimming mode)

The tension release continuous acting angles 0

(only effective in LU trimming mode)

The tension release continuous acting time

( count from the needle up position and only

effective

The function choice

The function selection for Option IN_B

release

in

LU trimming mode)

starts

of

Option IN_ A

acting

,..._,

angles 0

250°

,..._,

250°

0

,.._,

1250

ms

OFF : No function

DSCT: Cancel thread trimming for one time

DSBT: Cancel auto back tacking for one time

DSCN : Cancel condensed stitching for single time

NDUP : Needle up switch

l°

/ step

1 ° / step

5

ms

I step

(it's

only effective

when No.34=OFF)

62

Option IN_P 0 : Stop switch

The function selection for option

(only SV-520 effective)

63 Motor stop before executes EBT

Motor stops time before executes EBT

64

(only effective when No.63=ON)

65

Breaking thresfold 130-250

JN

_ P

HALF : Half stitch inching

ONE : One stitch inching

1

: Stop switch (flip-flop type) • output OUT_E

active

when

2 : Cancel automatic backtack switch • output OUT_E

when active

OFF : ineffective

ON:

20

effective

,..._,

1500

ms

10

ms/

step

66 Slight breaking action time 10-50ms

67

Slight breaking speed

200-l 700rpm

68 Slight breaking function OFF: Ineffective

ON: Effective

The Option OUT_A acts stitches'

69

after material edge sensor on

number

0

,..._,

99 stitches

The Option OUT_A delays stitches' number 0

70

after material edge sensor

The acts stitches' number after the Option 0

71

OUT_A delays stitches' number

edge sensor

off

off

& material

.......

99 stitches

,.._,

99

stitches

The Option OUT_B acts stitches' number O

72

I after material edge sensor on

The Option OUT_B delays stitches' number O

73

after material edge sensor

74

The Option OUT _B acts time

The Option OUT_C acts stitches' number

75

after material edge sensor on

The Option OUT_C delays stitches' number 0

76

after material edge sensor

The Option OUT_D acts stitches'

77

after material edge sensor on

78

The Option OUT _D delays stitches' number 0

after material edge sensor

off

off

off

number

0

O

O

,.._

,.._

.......

---

.......

.......

---

99

stitches

99 stitches

250

ms

99

stitches

99

stitches

99

stitches

99

stitches

79

The function choice

80

The function choice

80

The function choice

0:

of

Option OUT_A

of

Option OUT_B

of

Option OUT_B 3 : Depend on the setting stitches' number output

No output

I : Depend on the setting stitches' number output

Depend on the setting stitches'

2 :

when foot lifter acts

No

3:

0:

I : Depend on the setting stitches' number output

(Pedal control speed)

2 : Depend on the setting stitches' number output

(material edge sensor starts

speed)

(material edge sensor ends

speed)

output when motor stop

No

output

& during motor medium

& during motor medium

number output

81

The

function

choice

of

Option

OUT_

C

0:

No

output

I :

Depend

(Pedal control speed)

2 :

Depend

(material

speed)

on

on

edge

the

the

setting

setting

sensor

stitches'

stitches'

ends & during

number

number

motor

output

output

medium

82

83

84

3 : Auto

without pedal press

The

function

The

control solenoid

material

edge

choice

sensor

of

Option

output

OUT_D

cycle

choice

0:

No

I :

Depend

2 :

Depend

when

3 :

Depend

number

motor

of

O : Option OUT_A

1 : Option OUT_B

2 : Option OUT_C

3:

None

The

priority

on

& pressing pedal forward pressing pedal

between

material

edge

sensor

O :

The

I : Pedal condition is

material

sewing

output

material

edge

the

on

the

on

foot lifter acts

on

the

output

stops)

sensor

setting stitches

setting stitches'

the

setting

setting

(keeps acting

edge

on

stitches'

stitches'

sensor

immediate

number

even

must

output

number

be

acted

effective

output

before

when

85

Cancel

when

the

thread

pedal is heeled. is heeled

trimming

function

choice

2 : Pressing pedal is prior.

OFF

: With

ON : Cancel

is heeled.

effective.

the

the

thread

thread

And

trimming

trimming

just

function

function

the

foot lifting function is

when

when

pedal

pedal

Special function choice

86

No

special function

0 :

I : LB2 enable, MTJ=OFF

2 : LB2 enable, MTJ=

3 :

BAF

function

521

4 : LUI

5:

CAI

6 : SAS I function

7 : BASF function

8 : Manual one- shot function

9 : Automatic one-shot function

10

: edge sensor with re-cycle function

11:

auto sewing when use PKSW

jy

12:

13:

FW740 function

function

function

tunction

ON

No

87

88

89

90

91

synchronizer operation mode

The speed margin

positioning

Decelerating speed slope choice

Motor static brake function

Motor rotation signal control

of

executing needle

14: FW730 function

OFF : ineffective .

ON : effective

80

,._

160

1

,._

8

(The bigger value means the longer time of

decelerating.)

0 : No such function

"'

1

powerful braking force.)

OFF : No output

TL

TL2 :

TL3 : TL solenoid control by edge sensor

20 (The bigger value means the more

I : TL solenoid outputs when motor rotates.

TL

solenoid outputs when motor rotates & foot

lifter acts.

1 /

step

TIA : TL solenoid control by edge sensor and Interval

stitch

TL5 :

TL

solenoid control by Interval stitch

92

Forward output the motor rotation signal

0

-----

1250

ms

5

ms/

step

93

Current limit table boost

up

......

0

20

94

95

96

97

98

99

100

101

Reverse

stitching.

Check the speed control unit condition

function when

Alarm signal output function.

Auto function setting. OFF: Ineffective

(Only effective in BAFS machine)

Motor

(Only effective in BAFS machine)

BLOWER-B

(Only effective in BAFS machine)

I

BLOWER-B

(Only effective in BAFS machine)

In motor running,

control

angles when

power

delays starting time. 0

delays output time.

output time.

FLSW

FLL

output acted stitches'

machine starts 0 --250°

on. ON: Effective

key

input to

number

OFF: Ineffective

OFF: Ineffective

ON

: Effective

ON: Effective

....,

9900 ms

0

......

9900

ms

--...

9900

00

ms

stitches

0

0

- 5

1 ° / step

100

ms

/ step

100

ms/

step

ms/

100

2 stitches/ step

step

102

103

Material edge sensor begins acting, Option

OUT_E delay acting stitches number

Material edge sensor ends acting, Option

OUT_E

104 Option

105

106

107

108

Foot lifter protecting time

Folder auto function setting

(Only effective in TCF machine)

Folder auto function delays stitches ' number 0

(Only effective in

Motor's braking force when positioning

continuously act stitches number

OUT

_E function choice

TCF

machine)

- 99 stitches

0

0

- 99 stitches

OFF : No

ON : Depend on setting stitches'

0

-

OFF: Ineffective

ON: Effective

- 99 stitches

- S

0

60

seconds

output

number output

1 seconds / step

109

110

111

Quick Needle positioning function

Motor positioning stopping force 0

ER-2 checking time 0

OFF: Ineffective

ON: Effective

,.._,

5

5 seconds

-

1 seconds / step

112

ATC auto function setting

(Only effective in ATC

machin~)

OFF: Ineffective

ON: Effective

113

114

115

116

117

118

119

Material edge sensor begins acting;Option

OUT_F delay acting stitches' number

Material edge sensor ends acting, Option

OUT_F continuously act stitches' number

Option OUT_F function choice OFF :

Control Option OUT_C

function by Option IN_D

Start condensed stitching stitches' number

During motor

stitches' number (YU2F & YU3F machine is

effective)

Auto FOLDER function (YU2F & YU3F

machine is effective)

rotates,

solenoid

FOLDER0

auto

0

-

0

- 99 stitches

ON: Depend on setting stitches'

OFF: Ineffective

output

ON: Effective

0

-

-

OFF: Ineffective

ON: Effective

99

stitches

No

output

99 stitches

99 stitches

number output

120

121

122

123

124

125

126

127

D _ code back tacking compensation

C2 _

code

back tacking compensation

A2 _ code back tacking compensation

BI_

code back tacking compensation 0

WA_ code back tacking compensation 0

WB_

code back tacking compensation 0

Position subroutine executive timr

Forward stitches to decelerate speed

in

SBT

no·

0

-

no·

0

-

no·

0

-

no·

-

720

-

-

0

-

0

-

.

no·

lOOms

2

5 • /step

5 • /step

5 • /step

5 • /step

' /step

5

5

• /step

128

Special function choice

OFF:

ineffective

I: When tlsw active , change the foot lifter control

modetoTFL

2:

Option

3:

Four

4: Start backtack last trip modify mode

5: Special display for DINO

16:

7: Slow down the speed at auto backtack turning point

8.Tension release enable (chain stitch)

OUT_Adelay

-step

selection for edge sensor stitches

Edge sensor re-effective after chain-off thread

suction (only effective in

off

function

M03

machine)

129

130

131

132

133

134

135

136

137

Differential control function

Up position adjustment

Stitch number for one-shot function 0

The delay time for DST function

The

acting time for DST function

Stop position

active

UTL delaying time

UTL acting ti

De

lay

ti

me

stitch

when material edge sensor

me

between

UTL

an

condensi

d

ng

OFF: Ineffective

ON: Effective

- 50 ° - 50 °

..._,

250

..._

0

300ms

....,

0

2500

ms

OFF:

Depend on simple control panel

setting

UP : Up position

DOWN :

0

0

0

....,

......,

......,

Down

200ms

2000 ms

200

ms

pos

ition

I

IO

IO

10

IO

10

O

I step

ms

ms/

ms

ms/

ms

I step

step

/step

step

I step

138

139

140

141

142

Option OUT_C delay acting stitches

(only effective

Option OUT_ C acting stitches

(only effective in PT2 machine)

Motor protecting functi

Cumulate times for motor protecting function

Forward stitches to decelerate speed

in

PT2 machine)

on

in

EBT

O

......,

99 stitches

O - 99 stitches

OFF: Ineffective

ON: Effective

100

......,

5000 hours 50 hours / step

0

---

2

143

Stitches counter for

ATC

machine

0

---

1000

4 stitches/ step

144

145

146

147

148

149

In auto test

adjustment

In auto test mode, motor stop mode selection

Motor stop

Inching switch (on display panel)operation NDUP : Needle up switch

mode

Quick needle positioning check level

Soft start mode 0 : First stitching after trimming

mode, motor running

at

the end

of

start back-tacking OFF · ineffective

level

60

""

250

TRIM : trimming active

Fl.ON : foot lifter active

STOP : motor stop

ON:

HALF :

ONE : One stitch inching

500""

effective

Half

stitch inching

lOOOspm

I : After the start back-tacking

IO/ step

50

I step

150

151

152

153

154

155

156

157

158

159

Motor automatic stop function

Times for automatic stop the motor

Speed loop gain adjustment

Virtual needle up positioning function(only OFF : Ineffective

for direct drive motor)

Decelerating speed slope choice for fixed

stitches sewing

The safety range

Dotted line function OFF: Ineffective

Delay

time

Active angle for dotted line function

Step-2 for

number

of

UP position

before dotted line function

material edge sensor stitches' 0

OFF: Ineffective

ON: Effective clear

0

100

5

100

1000

---

250

hours

ms

360

stitches

°

---

0

---

ON: Effective

- 4

0

0

---

ON: Effective

0

,._

200

,._

The cumulate time

after power tum

off

1

hour/

step

is

160

161

Step-3

number

Step-4 for material edge sensor stitches'

number

material edge sensor stitches'

for

0

---

250

stitches

,._

250

0

stitches

162

Execute auto foot lifter after

stitches' number sewing process

end

OFF: Ineffective

fixed

ON: Effective

163

164

165

166

167

168

169

170

171

Fast cutter function

Stitches between UTL

Option OUT

Control the speed for material edge sensor

stitches' number

(only

machine)

Forward decelerating angle for quick needle 0

positioning

Interval

suction

Suction active stitch for intermediate suction 0

Stop up position before foot lifter active

Chain-off thread suction active time when 0

manual cutter switch active

_A

effective

stitch between both intermediate

and

trimming

delay Off time

in SAF , YU2F •

YU3F

OFF: Ineffective

ON: Effective

0

99

-

0

9000

-

0 :

1 :

2 :

-

0 - 250 stitches

- 250 stitches

OFF: Ineffective

ON: Effective

- 9900

ms

pedal control speed

medium speed

Auto sewing without pedal press

200°

ms

100

ms/

step

172

173

174

175

176

177

178

179

180

181

Manual blower function

Blower start active angle

Blower stop active angle

Blower start active angle

Tension

active

Tension

active

Edge sensor ty

Foot lifter

material ON: Effective

Prevent special parameter be modified OFF: Ineffective

Compensation

C code

release delay time when blower 0

release active time

pe

select OFF : light on.

active when edge sensor detect

stitch in end back tacking

when blower

OFF: Ineffective

ON: Effective

0 - 250 °

100 - 250 °

0

19 stitches

-

100

-

0 -

ON:

OFF: Ineffective

ON: Effective

0 - 3 stitches

ms

150

ms

dark on

182

183

184

Material edge sensor detects stitches

ER-9 detect counter

Manual motor pulley ratio measure

3 stitches

0

-

6

3

-

OFF: not execute

ON: executed

I

Loading...

Loading...