Motor Power FLEXI PRO Quick Start Manual

FLEXI PRO Servo Drive

Quick Start Guide

120/240 VAC and 400/480 VAC

Revision 8.1

Firmware Version 1.41.2

DOC-FLEXI PRO-QSG-EN

FLEXI PRO

2 Quick Start Guide

FLEXI PRO

Quick Start Guide 3

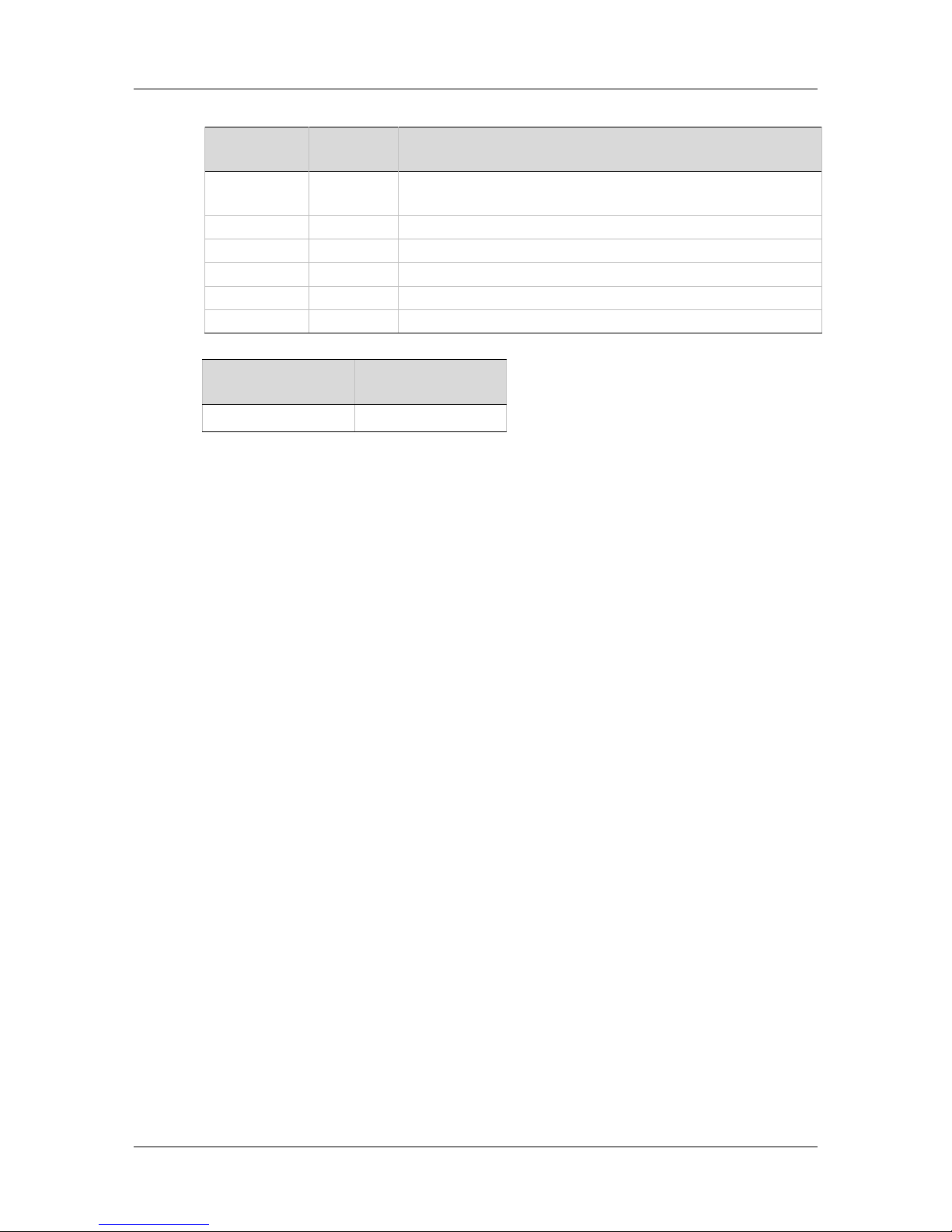

Revision History

Document

Revision

Date Remarks

8.1 May 2016 Added info and diagrams for EB models.

Minor revisions and corrections.

8.0 May 2016 Firmware 1.41.2

7.2 Mar.2015 Firmware 1.15.24

7.1/a/b/c Jan.2015 Updates and corrections.

7.0 Dec.2014 Firmware 1.15.xx

5.7 Jan.2014 Firmware 1.4.5

Firmware

Revision

Software (GUI)

Revision

1.41.2 1.41.2

Note: If an earlier firmware revision is installed in your FLEXI PRO drive,

contact your Account Manager or Technical Support.

Copyright Notice

© 2016 Motor Power Company s.r.l.

All rights reserved. No part of this work may be reproduced or transmitted in any

form or by any means without prior written permission of Motor Power Company.

Disclaimer

This product documentation was accurate and reliable at the time of its release.

Motor Power Company s.r.l. reserves the right to change the specifications of the

product described in this manual without notice at any time.

Trademarks

All marks in this manual are the property of their respective owners.

Contact Information

Motor Power Company s.r.l.

Via Leonardo Da Vinci , 4

42024 Castelnovo Sotto

Reggio Emilia - Italia

Tel: +39 0522 682710

Fax: +39 0522 683552

Website: www.motorpowerco.com

Technical Support

If you need assistance with the installation and configuration of the FLEXI PRO

drive, contact Motor Power Company Technical Support: info@motorpowerco.it

FLEXI PRO

4 Quick Start Guide

Contents

1 Introduction ................................................................................................... 5

FLEXI PRO Models .............................................................................................. 5

Safety .............................................................................................................. 6

FLEXI PRO Installation Procedure ......................................................................... 6

2 Wiring ............................................................................................................ 7

FLEXI PRO System Wiring ................................................................................... 7

FLEXI PRO Shielding and Bonding ........................................................................ 9

FLEXI PRO Grounding ....................................................................................... 10

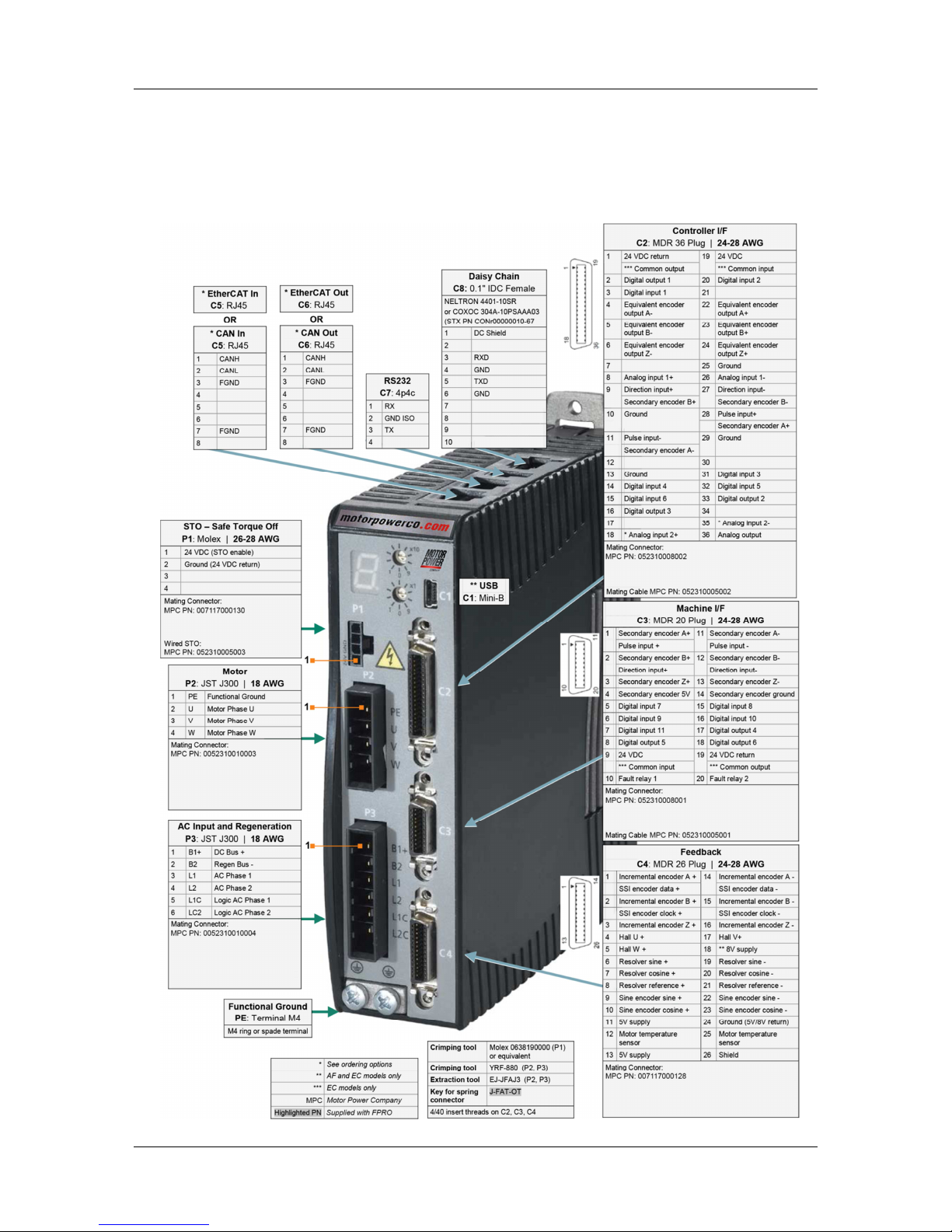

FLEXI PRO Pin Assignments ............................................................................... 11

FLEXI PRO-1D5/FLEXI PRO-003 (120/240 VAC) ............................................... 11

FLEXI PRO-4D5/FLEXI PRO-006 (120/240 VAC) ............................................... 13

FLEXI PRO-008/FLEXI PRO-010/FLEXI PRO-013 (120/240 VAC) ......................... 15

FLEXI PRO-020/FLEXI PRO-024 (120/240 VAC) ................................................ 17

FLEXI PRO-003/FLEXI PRO-006 (400/480 VAC) ................................................ 19

FLEXI PRO-012 (400/480 VAC) ...................................................................... 21

Pin Assignments on FLEXI PRO-012 – AP/AF/EC Models .................................... 21

FLEXI PRO-024/FLEXI PRO-030 (400/480 VAC) ................................................ 23

3 Control Board ............................................................................................... 25

Overview ........................................................................................................ 25

Controller Interface .......................................................................................... 25

Controller Interface Wiring ............................................................................ 29

Machine Interface ............................................................................................ 31

Machine Interface Wiring ............................................................................... 32

Motor Feedback ............................................................................................... 34

Feedback Wiring .......................................................................................... 35

Fieldbus Devices .............................................................................................. 38

Host Computer ................................................................................................ 38

Daisy Chain ..................................................................................................... 39

Drive Address Switches ..................................................................................... 39

4 Power Board 120/240 VAC ........................................................................... 40

Safe Torque Off (STO) ...................................................................................... 40

Motor ............................................................................................................. 40

Regeneration Resistor ....................................................................................... 41

AC Input ......................................................................................................... 41

5 Power Board 400/480 VAC ........................................................................... 43

Safe Torque Off (STO) ...................................................................................... 43

Logic Power 24V Input ...................................................................................... 43

AC Input and Regeneration Resistor ................................................................... 44

Brake ............................................................................................................. 44

Motor ............................................................................................................. 44

6 Software ....................................................................................................... 45

Flexi SUITE Installation ..................................................................................... 45

Power Up ........................................................................................................ 45

Drive Configuration .......................................................................................... 45

7 Drive Status (7-Segment Display) ................................................................ 46

FLEXI PRO

Quick Start Guide 5

1 Introduction

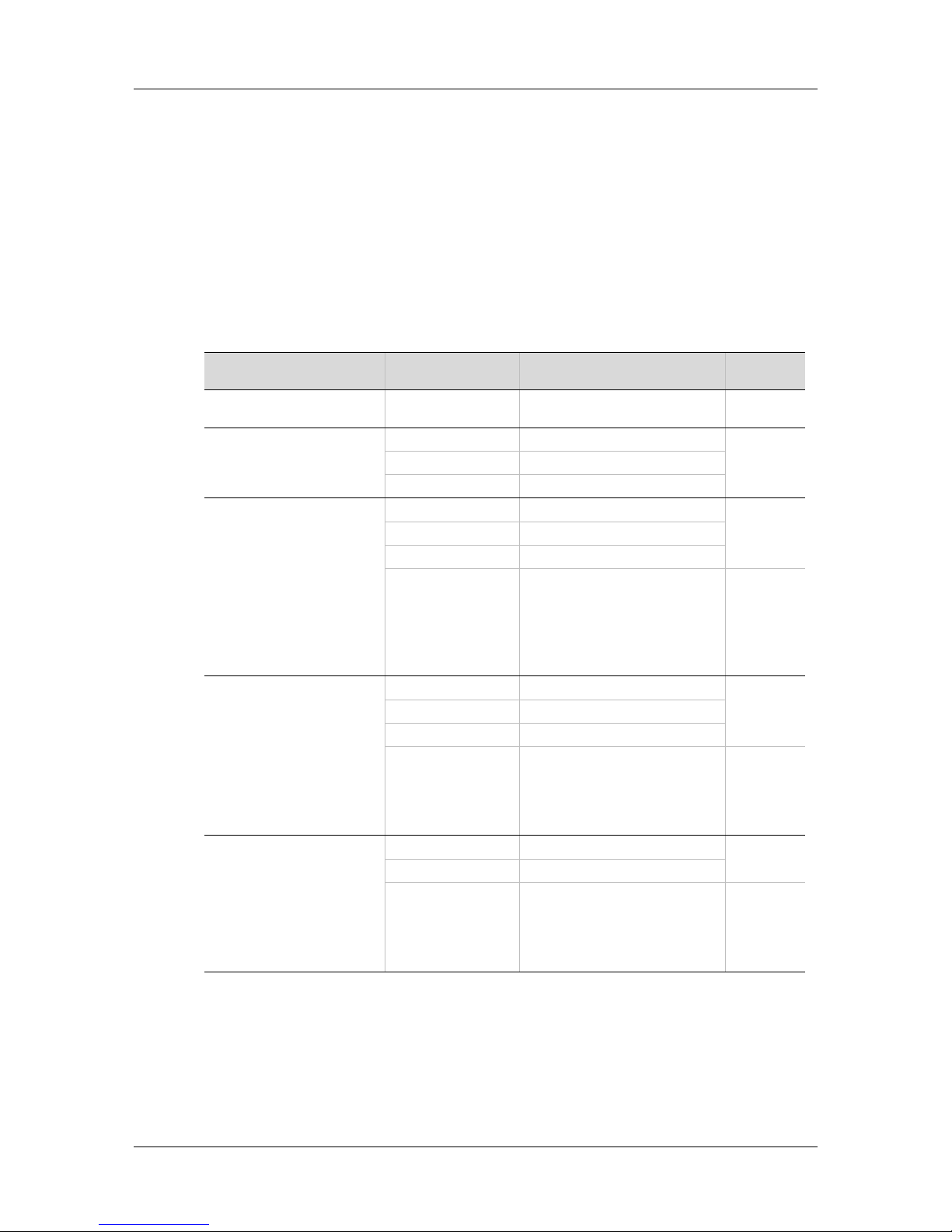

FLEXI PRO Models

The various models in the FLEXI PRO servo drive series are differentiated by means

of the communication methods and protocols they use. The following table

presents the different models and their distinguishing characteristics.

FLEXI PRO Models - Communication and Protocols

FLEXI PRO Model Physical Layer Communication Protocol Program

Language

FLEXI PRO Power Block (PB)* PWM signals PWM signals PMAC

(Delta Tau)

FLEXI PRO (AP)

Standard FLEXI PRO model.

Serial (RS232) ASCII commands VarCom

Analog ±10V

Pulse Train AB signals

FLEXI PRO CAN (AF)

A CAN drive, which uses

CANopen protocol.

Referred to as

FLEXI PRO CANopen drive.

Serial (USB|RS232) ASCII commands VarCom

Analog ±10V

Pulse Train AB signals

CAN Communication: CANopen

CANopen – all 1000h objects

Manufacturer-Specific:

CANopen – all 2000h objects

Standard Servo-Drive (Motion):

CANopen – all 6000h objects

VarCom

CANopen

FLEXI PRO EtherCAT (EC)

An EtherCAT drive, which

uses CANopen over

EtherCAT (CoE) protocol.

Serial (USB|RS232) ASCII commands VarCom

Analog ±10V

Pulse Train AB signals

Ethernet Communication: EtherCAT

Manufacturer-Specific:

CANopen – all 2000h objects

Standard Servo-Drive (Motion):

CANopen – all 6000h objects

VarCom

CANopen

FLEXI PRO EtherCAT

(EB)

An EtherCAT drive, which

uses CANopen over

EtherCAT (CoE) protocol

Serial (USB) ASCII commands VarCom

Analog ±10V

Ethernet Communication: EtherCAT

Manufacturer-Specific:

CANopen – all 2000h objects

Standard Servo-Drive (Motion):

CANopen – all 6000h objects

VarCom

CANopen

* Not included in this Quick Start Guide. Refer to the FLEXI PRO User Manual.

FLEXI PRO

6 Quick Start Guide

Safety

Only qualified persons may perform the installation procedures. You do not need to

be an expert in motion control to install and operate the drive system. However,

you must have a basic understanding of electronics, computers, mechanics, and

safety practices.

The FLEXI PRO utilizes hazardous voltages.

Be sure the drive is properly grounded.

When connecting the FLEXI PRO to other control equipment, be sure to

follow two basic guidelines to prevent damage to the drive:

The FLEXI PRO must be grounded via the earth ground of the main

AC voltage supply.

Any motion controller, PLC or PC that is connected to the FLEXI PRO

must be grounded to the same earth ground as the FLEXI PRO.

Before you install the FLEXI PRO, review the safety instructions in the product

documentation. Failure to follow the safety instructions may result in personal

injury or equipment damage.

FLEXI PRO Installation Procedure

Perform the following steps to install and setup a FLEXI PRO system.

1. Mount the FLEXI PRO.

2. Make all electrical connections:

Controller I/Os and/or Machine I/Os

Motor feedback

Fieldbus devices, if required

Safe torque off (STO), or bypass using jumpers

Motor

Regeneration resistor, if required

Motor brake, if required

AC input voltage

3. Set the drive address using the rotary switches.

4. Connect the drive to the host computer.

5. Power up the drive and the computer.

6. Install Flexi SUITE software.

7. Using Flexi SUITE, configure and test the drive.

FLEXI PRO

Quick Start Guide 7

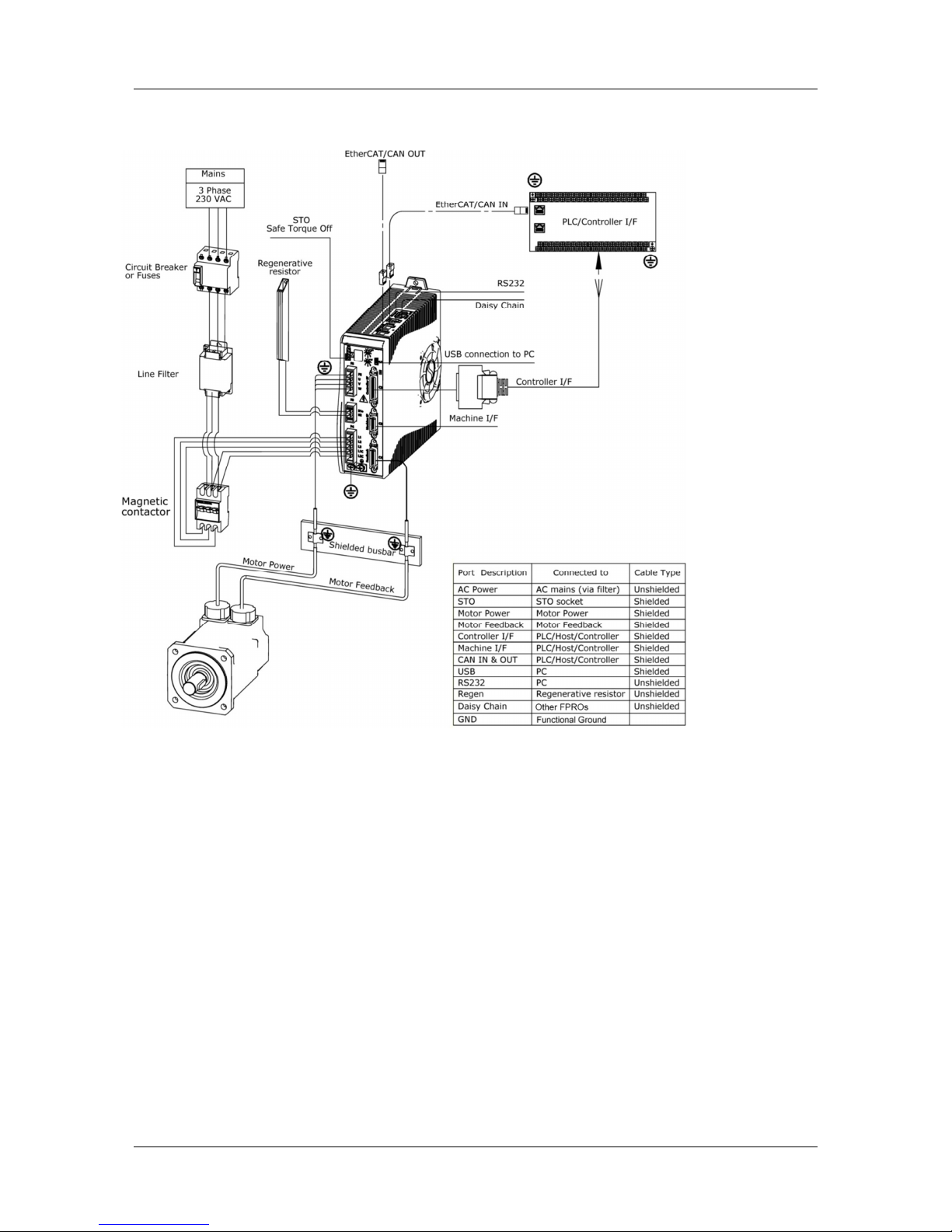

2 Wiring

FLEXI PRO System Wiring

Example of Servo System Wiring, (120/240 VAC) 1-Phase

FLEXI PRO

8 Quick Start Guide

Example of Servo System Wiring, (400/480 VAC) 3-Phase

FLEXI PRO

Quick Start Guide 9

FLEXI PRO Shielding and Bonding

FLEXI PRO

10 Quick Start Guide

FLEXI PRO Grounding

FLEXI PRO

Quick Start Guide 11

FLEXI PRO Pin Assignments

FLEXI PRO-1D5/FLEXI PRO-003 (120/240 VAC)

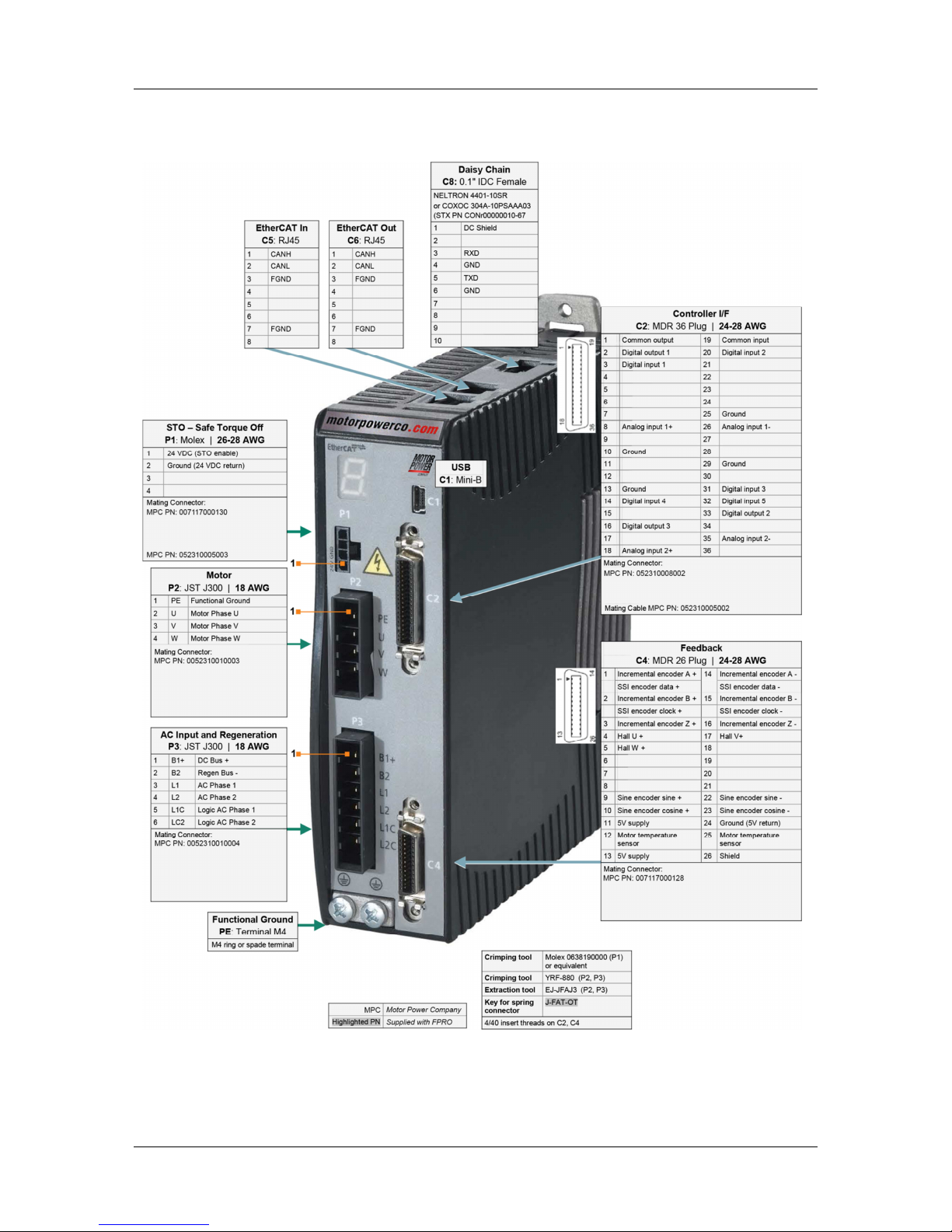

Pin Assignments on FLEXI PRO-1D5/FLEXI PRO-003 – AP/AF/EC Models

FLEXI PRO

12 Quick Start Guide

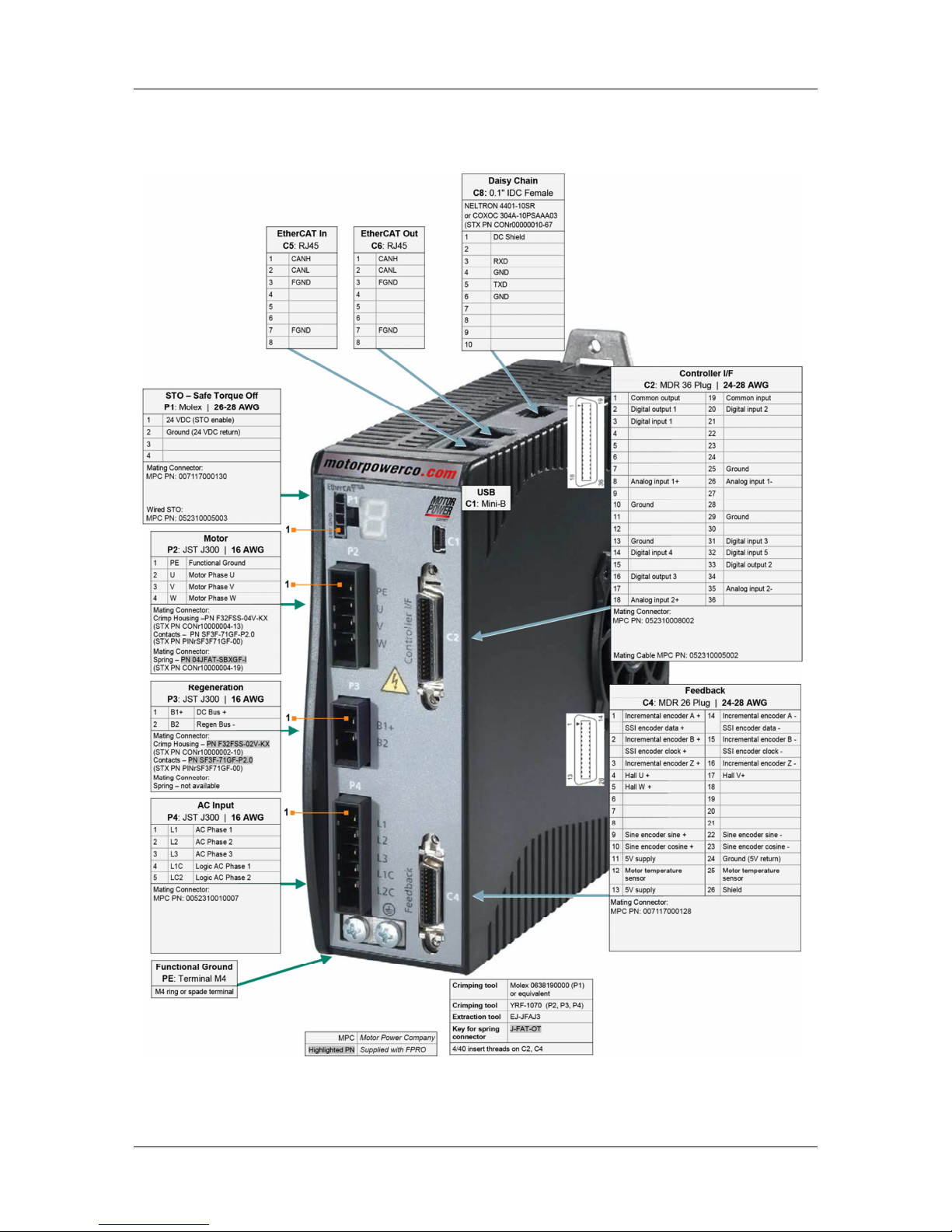

Pin Assignments on FLEXI PRO-1D5/FLEXI PRO-003 – EB Models

FLEXI PRO

Quick Start Guide 13

FLEXI PRO-4D5/FLEXI PRO-006 (120/240 VAC)

Pin Assignments on FLEXI PRO-4D5/FLEXI PRO-006 – AP/AF/EC Models

FLEXI PRO

14 Quick Start Guide

Pin Assignments on FLEXI PRO-4D5/FLEXI PRO-006 – EB Models

FLEXI PRO

Quick Start Guide 15

FLEXI PRO-008/FLEXI PRO-010/FLEXI PRO-013 (120/240 VAC)

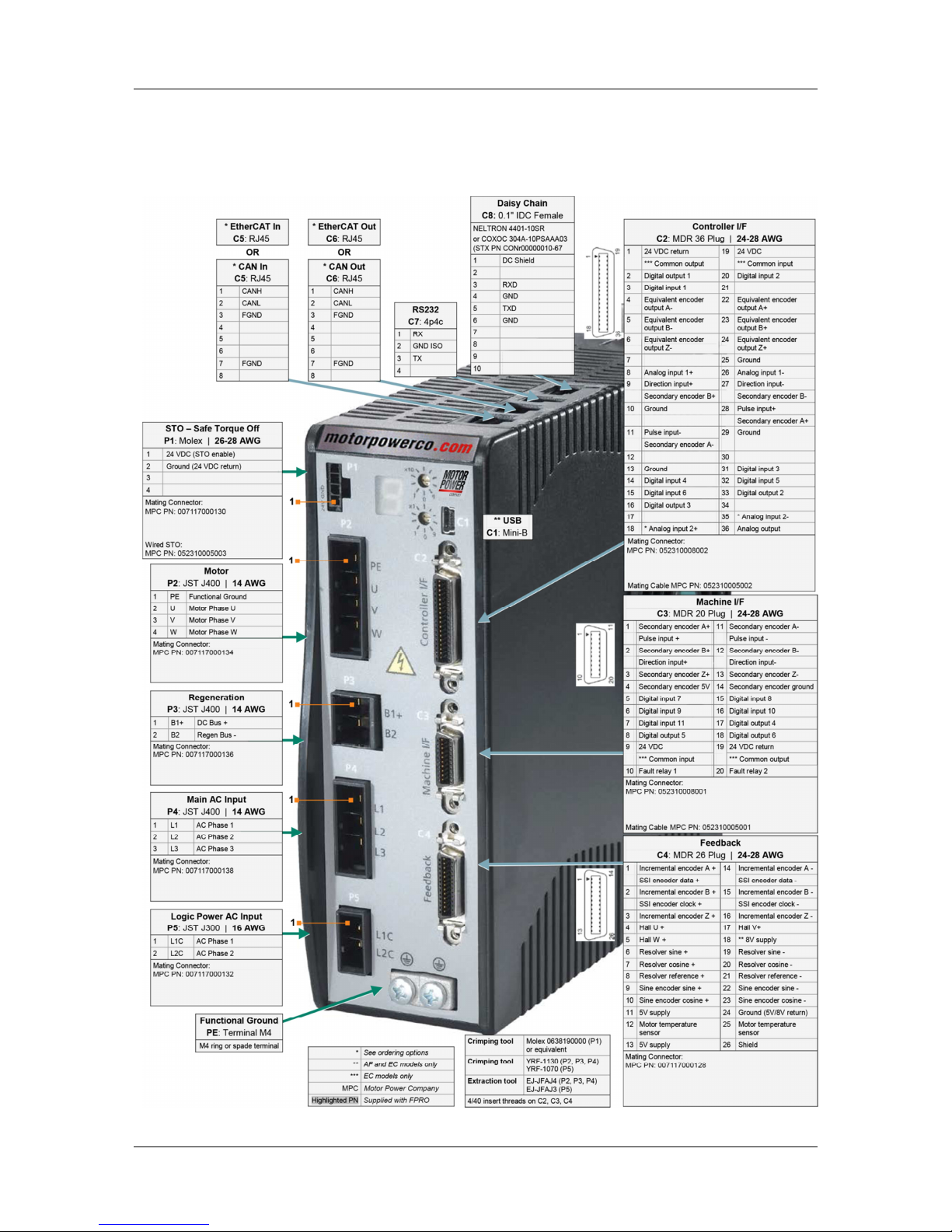

Pin Assignments on FLEXI PRO-008/FLEXI PRO-010/FLEXI PRO-013 – AP/AF/EC Models

FLEXI PRO

16 Quick Start Guide

Pin Assignments on FLEXI PRO-008/FLEXI PRO-010/FLEXI PRO-013 – EB Models

FLEXI PRO

Quick Start Guide 17

FLEXI PRO-020/FLEXI PRO-024 (120/240 VAC)

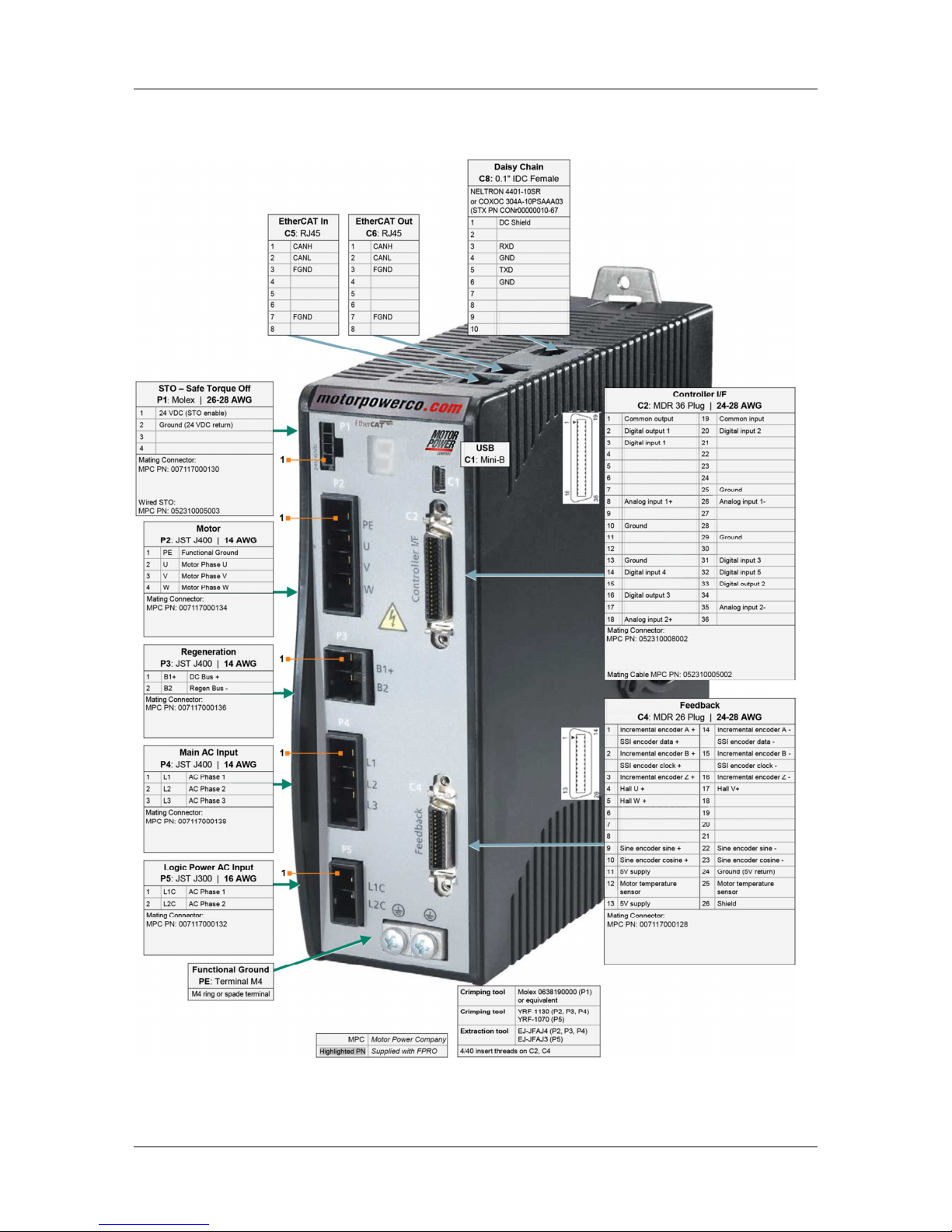

Pin Assignments on FLEXI PRO-020/FLEXI PRO-024 – AP/AF/EC Models

Loading...

Loading...