Page 1

@M

TO

OLA

M68KVSIG/D2

VME/10

Microcomputer

Installation

Guide

System

QUALITY • PEOPLE • PERFORMANCE

Page 2

Page 3

VME/10

M68KVSIG/D2

MAY

1984

The

infonnation

be

entirely

Furthermore,

to

improve

liability

described

the

rights

I/Qnodule,

arisi

herein;

of

VERSAdos,

in

this

reliable.

Motorola

reliability,

DJ

out

neither

others.

VMElnodule,

MICROCOMPUTER

document

However, no

reserves

function,

of

the

does

SYSTEM

INSTALLATION

has

been

GUIDE

carefully

responsibility

the

right

or

to

design.

application

it

convey any

am

VME/10

are

WARNING

make

changes

Motorola does

or

use

license

trademarks

checked and

is

assumed

to

of

any

under

its

of

is

for

inaccuracies.

any

products

not

product

patent

Motorola

believed

herein

assume any

or

circuit

rights

Inc.

to

or

THIS

FREQUEtCY

CLASS

WITH

EQUIPMENT

AT

MEASURES

EQUIPMENT

ENERGY.

A

COMPUTI~

PART

15

MAY

HIS

<MN

MAY

GENERATES,

THIS

DEVICE

OF

FCC

RULES.

CAUSE

INTERFERENCE,

EXPENSE,

BE

REQUIRFD

WILL

Seco~

USES,

AND

EQUIPMENT

AND

HAS

HOWEVER,

IN

BE

REQUIRED

TO

CORROC'I'

Edition

HAS

BEEN

WHICH

THE

Copyright 1983 by Motorola

First

Edition

May

1983

CAN

RADIATE

BEEN

FOUND

OPERATION

TO

TESTED

CASE

TAKE

TO

OF

THE

WHATEVER

INTERFEREX!E.

Inc.

RADIO

AS

A

COMPLY

THIS

USER,

Page 4

SAFETY SUMMARY

SAFETY DEPENDS ON YOU

The following general safety precautions must be observed during

repair

of

this equipment. Failure to

In this manual violates safety standards

Motorola

safety

the user

the

Inc.

assumes

no

liability

precautions listed below represent warnings

of

the product, should follow these warnings

safe operation

of

the equipment In

GROUND THE INSTRUMENT.

To

minimize shock hazard, the equipment chassis and enclosure must be connected

comply

tor

with these precautions

of

deslgn

manufacture,

1

the customer's failure to

of

certain dangers

your

operating environment.

and

all

all

phases

or

with specific warnings elsewhere

and

Intended use

comply

other

safety precautions necessary for

:;·

of

operatlon

of

the equipment.

with these requirements. The

of

which

we

are aware. You,

to

service. and

1

an electrical

as

ground. The equipment is supplied with a three-conductor ac power cable. The power cable must either

be

plugged into an approved three-contact electrical outlet

adapter, with the grounding wire (green)

power

outlet. The power jack and mating plug

firmly

connected

of

the power cable meet International Electrotechnical

or

used with a three-contact

to

an electrical ground (safety ground) at the

to

two-contact

Commission (IEC) safety standards.

DO

NOT

OPERATE IN AN EXPLOSIVE ATMOSPHERE.

Do

not

operate the equipment in the presence

equipment in such

an

environment constitutes a definite safety hazard.

of

flammable gases

or

fumes. Operation

of

any electrical

KEEP AWAY FROM LIVE CIRCUITS.

Operating personnel must

ments must be made by qualified maintenance personnel. Do

not

remove equipment covers.

Component

not

replacement and internal adjust-

replace components

with

power

cable connected. Under certain conditions, dangerous voltages may exist even with the power cable

removed.

To

avoid injuries, always disconnect power and discharge circuits before

touching

them.

DO

NOT

SERVICE OR ADJUST ALONE.

Do

not

attempt internal service

or

adjustment unless another person, capable

resuscitation, is present.

USE CAUTION WHEN EXPOSING OR HANDLING THE CRT.

Tube

Breakage of the Cathode-Ray

sion).

To

prevent CRT implosion, avoid rough handling

CRT should be done

DO

NOT

SUBSTITUTE PARTS OR MODIFY EQUIPMENT.

Because

of

the danger

unauthorized modification

only

by qualified maintenance personnel using approved safety mask and gloves.

of

introducing

of

(CRT) causes a high-velocity scattering

or

jarring

the

equipment.

additional hazards,

Contact

do

not

Motorola

service and repair to ensure that safety features are maintained.

DANGEROUS PROCEDURE WARNINGS.

Warnings,

manual. Instructions contained in

safety precautions which you deem necessary

such

as

the

example

below,

precede

the

warnings must be followed. You should also

potentially

for

the operation

dangerous

environment.

WARNING

Dangerous voltages, capable

caution when

handling, testing, and adjusting.

of

causing death, are present

of

rendering first aid and

of

glass fragments (implo-

of

the equipment. Handling of the

install substitute parts

or

perform any

Microsystems Warranty and Repair for

procedures

of

the equipment in

in

this

equipment. Use extreme

throughout

employ

your

all other

operating

this

14260 PRINTED

IN

USA (6/811

MPS

300

Page 5

PREFACE

Unless

otherwise

throughout

An

asterisk

significant

is

low.

An

asterisk

significant

on a

high

this

{*)

denotes

{*)

denotes

to

low

specifierl,

manual.

following

that

followin:J

that

transition.

all

the

the

the

the

address

signal

signal

signal

actions

references

name

is

for

true

name

initiaterl

or

for

are

signals

valid

signals

by

which

when

which

that

in

hexadecimal

are

the

are

signal

level

signal

erlge

occur

Page 6

Page 7

TABLE

OF

CONTENTS

CHAPTER

1.1

1.2

1.3

1.4

1.5

CHAPTER

2.1

2.2

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

CHAPTER

3.1

3.2

3.3

3.4

1

2

3

GENERAL

INTRODtJCrION

UNPACK!~

SYSTEM

INFORMATION

•••••••••••••••••••••••••••••••••••••••••••••••

INSTRUcrIONS

EQUIPMENT

SPEX:IFICATIONS

RELATED

VME/10

INTRODUcrION

INSTALLATION

INSTALLATION

OCX::UMENTATION

INSTALLATION

•••••••••••••••••••••••••••••••••••••••••••••••

PROCEDURE

PRO:EDURE 2 •••••••••••••••••••••••••••••••••••

Equipment Supplia:l

Tilt/Swivel

Display

System

Cabling

Display

I/Oroodule

INTRODUcrION

I/Qnodule

VME/10

VME/10

TO

TO

Assenbly

Unit

Unit

Installation

Positionirg

EXPANSION

•••••••••••••••••••••••••••••••••••••••••••••••

EXPANSION

MODEM

PRINTER

•••••••••••••••••••••••••••••••••••••

SUPPLIED

••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••

1

•••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••

Installation

••••••••••••••••••••••••

••••••••••••••••••••••••••••••••

Installation

••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••

CARD

CAGE

CARD

CAGE••••••••••••••••••••••••••••••

INSTALLATION

EQUIPMENT

INSTALLATION

•••••••••••••••••••••••••••••••

INSTALLATION•••••••••••••••••••••••••••••

1-1

1-1

1-1

1-3

1-3

2-1

2-1

2-3

2-4

2-4

2-6

2-8

2-8

3-1

3-1

3-4

3-7

CHAPTER

4.1

4.2

4.2.1

4.2.1.1

4.2.1.2

4.3

4.3.1

4.3.2

4.4

4

VME+I/Qnodule

INTRODUcrION

VME+I/Qnodule

EXPANSION

•••••••••••••••••••••••••••••••••••••••••••••••

EXPANSION

Daisy-Chain Jumpering

VMEmodules

VMEmodules

VMEmodule

VMEmodule

VMEmodule

I/Qnodule

Not

Containing

INSTALLATION

I/O

Cablirg

I/O

Cablirg

INSTALLATION

CARD

CARD

(J6-Jl3)

Containirg

IACK/BG

CAGE

CAGE

EQUIPMENT

••••••••••••••••••••••••••

•••••••••••••••••••••••••••

!ACK/BG

Circuitry

Circuitry

•••••••••••••••••••••••••••••••••••••

Method 1

Method 2

•••••••••••••••••••••••••••

•••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••

INSTALLATION

••••••••••••

••••••••••••••••

4-1

4-1

4-1

4-5

4-5

4-8

4-9

4~11

4-17

i

Page 8

LIST

OF

ILLUSTRATIONS

FIGURE

1-1.

2-1.

2-2.

2-3.

2-4.

2-5.

2-6.

2-7.

2-8.

2-9.

2-10.

3-1.

3-2.

3-3.

3-4.

4-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

4-8.

4-9.

Typical

Typical

Display

Control

Control

Control

Control

Display

Display

Display

Display

VME/10

VME/10

Display

Unit

Unit

Unit

Unit

Unit

Unit

Unit

Unit

Unit

with

Microcomputer System

Unit

with

Tilt/Swivel

Chassis

with

Chassis

Chassis

Chassis

Installation

Installation

Installation

Positioning

Tilt/Swivel

Adjustment

Tilt/Swivel

Tilt/Swivel

Tilt/Swivel

Tilt/Swivel

Step 1 ••••••••••••••••••••••••••

Step

Step 3 ••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••

I/Oloodule Expansion Card Cage

I/Omodule Expansion Card Cage

MVME400

MVME410

VME/10

VME+I/Qnodule

MVME923

Typical

Typical

VMEmodule

Present

First

VMEm:>dule

Port 1 Modern

Port 1 Printer

with

VME+I/Omodule

Configuration

Configuration

Expansion Card Cage

Backplane Daisy-Chain

VMElnodule

VMEm:>dule

I/O

Production

Production

I/O

Bus

Arbitration

Bus

Arbitration

Cabling Method 1

Control

Control

Cabling Method 2

Expansion Card Cage

Unit

Unit

•••••••••••••••••••••••

Mechanism

•••••••••••

•••••••••••••••••••••••

Assembly

Assembly

Asserrbly

Position 1 ••••••

Position

Assembly

2

••••••••••••••••••••••••••

••••••••••••

2

Lubrication

•••••••••••••••••

•••••••••••••••••••••••••••••

••••••••••••••••••••••••

••••••••••••••••••••••

•••••••••••••

•••••••••••••••••••••••••

•••••••••••••••••••••••••••••

Bypass••••••••••••••••••

Level

Selection

•••••••••

••••••••••••••••••••••••••••

Chassis

Chassis

••••••••••••••••••••••••••••

I/O

Panel Templet ••

I/O

Panel Templet

••••••

••••

•••

1-2

2-1

2-2

2-3

2-5

2-5

2-6

2-7

2-7

2-7

2-8

3-2

3-3

3-6

3-9

4-2

4-3

4-4

4-6

4-7

4-10

4-13

4-14

4-16

TABLE

1-1.

3-1.

3-2.

VME/10

S~cifications

MVME400

MVME410

Port 1 Printer

LIST

Port 1 Modern

OF

TABLES

•••••••••••••••••••••••••••••••••••••

Configuration

Configuration

••••••••••••••••••••••••

••••••••••••••••••••••

1-3

3-5

3-8

ii

Page 9

OIAPTER

1

1.1

This

INTRODUcrION

installation

I/Omodule expansion

installation

to

as

VME/10)

unpacking

necessary

1.2

UNPACK!~

information

as

instructions,

for

the

user

INSTRUCTIONS

If

request

unpacking arrl

Unpack

all

equipnent

ite:ns

are

from

present.

equipment.

guide

card

cage,

for

shown

equipment

to

shipping

carrier's

shipping

GENERAL

provides

the

in

Figure

general

and

VME+

VME/10

1-1.

supplied

unpack and

cartons

install

are

agent

inspection

cartons.

Save i;acking

INFORMATION

information,

I/Omodule expansion

Microcanputer System

Included

listing,

the

VME/10.

in

arrl equipment

NOTE

damaged

of

Refer

material

upon

be

present

equipement.

to

packing

for

receipt,

storing

VME/10

card

this

during

list

installation,

cage equipment

(hereafter

chapter

specifications

arrl

verify

or

reshipping

referred

are

the

that

the

1.3

SYSTEM

The

VME/10

before

• Keyboard

• Keyboard

•

•

•

• Monitor

• Monitor

• Monitor

• Monitor

•

NOTES:

EQUIPMENT

Microcanputer System

attempting

cable

Control

Chassis

Display

unit

ac power cord (3-wire

unit

data

de

data/de

ac

Tilt/swivel

(1)

14-wire

(2)

3-wire

(3)

16-wire

units).

SUPPLIED

installation.

(6-wire

cable)

chassis

(monochrome/color)

cable

power

power

(1)

cable

power

cord

(2)

cable

(4)

med:lanism

ribbon

cable

cable

(first

shielded

soould

!tans

cable)

(3)

(first

production

ribbon

be

inspectErl

supplied

production

cable

(used

for

are

listed

monochrane

monochrane

with

missing

or

damaged

below:

display

display

units).

monochrane/color

i terns

units).

display

(4)

3-wire

cable

(used

with

color

1-1

display

unit).

Page 10

6-83-1537

FIGURE

1-1.

Typical

VME/10

1-2

Microcanputer

System

Page 11

TWo

types

VME/10.

One

production

chassis

1.4

by

SPE:IFICATI~

of

tilt/swivel

type

units)

the

user.

is

is

provided

mechanisms

mounted on

in a kit

are

the

display

form which

utilized

unit;

in

the

is

mounted on

the

production

other

the

of

type

control

the

(first

unit

Table

1-1

CHARAcrERI

Temperab.lre

Operating

Storage

Relative

Physical

Ieng

Width

Height

lists

the

STIC

humidity

dimensions

th

specifications

TABLE

1-1.

10°

-400

10%

Chassis

22.8

19.0

20.0

required

VME/10

to

40° c

to

60°

to

80%

and

in.

in.

in.

for

the

Specifications

SPOCIFICATION

c

(noncondensing)

monitor

(57.9

(48.3

(50.8

an)

an)

an)

installation

Keyboard

8.3

19.0

2.0

in.

in.

in.

of

the

(21.1

(48.3 cm)

(5.1

VME/10.

cm)

an)

Weight

Power

requirements

Chassis

iooni

tor

1.5

Color

RELATED

monitor

Documentation

•

Input/Output

•

VMEbus

50

+ monochrane

90-132 Vac, 47-63 Hz, 500 W

180-264 Vac, 47-63 Hz,

85-270

60W

D<X!U.MENTATION

applicable

Channel

Specification

to

VME/10

Specification

Manual,

lbs.

(23 kg)

Vac

(naninal)

installation

MVMEBS

1-3/1-4

(continuous)

is

Manual,

M68RIOCS

500 W

as

follows:

5

lbs.

(2.3

kg)

Page 12

Page 13

OIAPTER 2

2.1

INTRODUCI'ION

An

area

should

expansion

installation

equiJ;XI\ent

factory.

installed

2.2

This

INSTALLATION

systan

tilt/swivel

shown

in

Figure

be selectErl which

card

cage

procErlures

having

the

The secorrl

on

the

control

PROCEDURE

installation

mechanism

2-1.

to

facilitate

are

tilt/swivel

procedure

unit

installa:l

VME/10

enables

cabling

described.

mechanism

is

chassis

1

procedure

on a

INSTALLATION

access

of

to

peripheral

The

first

installed

for

the

67-W2420B01

by

the

user.

pertains

typical

display

the

on

to

equipment

control

unit

equipment.

procedure

the

display

Tilt/Swivel

unit

by

chassis

Two

is

that

the

types

for

unit

Kit

has

factory

rear

of

VME/10

by

the

to

be

the

as

FIGURE

2-1.

Typical

Display

Unit

2-1

with

Tilt/Swivel

10-83-1800

Mechanism

Page 14

Perform

a.

b.

the

installation

Place

If

display

remove

control

four

procedure

unit

unit

screws

Tension crljustment

as

chassis

in

tilt/swivel

that

is

secure

accanplished

follows:

desirerl

mechanism

tilt/swivel

as

location.

requires

mechanism

illustrated

tension

in

Figure

to

adjustment,

display

2-2.

unit.

c.

Place

d.

Connect one errl

display

connector

chassis

Sane monitor

Other

M3.5 x 0.6

unit/control

e.

Connect monitor

FIGURE

unit

Jl.

connector

data

data

cable

x 10 screws

unit

Some

nnnochrome

2-2.

on

of

the

Connect

J3.

cables

connectors

chassis.

,POwer

Display

top

of

applicable

the

other

utilize

to

cable/cord

nnnitors

Unit

Tilt/Swivel

control

monitor

NOTE

a keyerl

require

secure

to

NOTE

utilize

errl

the

the

unit

of

the

chassis.

data

the

latching

use

cable

display

a

de

power

Adjustment

cable

cable

to

to

connectors.

of

two

phillips

to

the

display

unit.

cable.

the

the

display

control

unit

unit

connect

connector

control

This

unit

Some

with

de

power

one errl

labeled

chassis·connector

monochrane

keyai

connection

of

the

24

Vdc. Connect

monitors

latching

monitor

de

labeled

NOTE

utilize

connectors.

is

automatically

2-2

,POwer

the

24

a

data/de

cable

other

eoo

to

of

Vdc.

power

implemented by

the

the

cable

step

display

cable

d.

to

unit

the

Page 15

f.

Connect one errl

modular

modular RJ

panel.

g.

Connect

RJ

ac

type

type

power

of

the

connector.

connector

cord

into

keyboard

Connect

located

the

control

NOTE

cable

the

on

unit

to

other

the

the

end

control

chassis

keyboard

of

the

cable

unit

power

rear

chassis

mounted

to

either

front

receptacle.

Connect ac power cord

h.

With

the

i.

Refer

publication

instructions.

2.3

The

INSTALLATION

following

information

as

stx>wn

unit

to

in

the

Color

the

control

off

position

to

the

PROCEDURE

installation

to

install

Figure

control

nx>nitors

VME/10

number

the

2-3.

unit

chassis.

utilize

into

unit

(0),

chassis/color

connect

Microcanputer System Overview Manual, Motorola

M68KVSOM,

2

instructions

67-W2420B01

This

tilt/swivel

a 115/220 Vac power

the

color

display

display

the

ac

power

for

VME/10

provide

Tilt/Swivel

kit

is

unit

unit

cord

to

systan

the

user

Kit

on a

designed

cord.

power

power

the

ac

receptacle.

switch

power

power-up and

with

control

to

the

unit

mount

placed

source.

operating

necessary

chassis

the

display

in

FIGURE

2-3.

Control

Unit

Chassis

2-3

with

Tilt/swivel

10-83-1799

Asseni>ly

Page 16

2.3.1

The

Fquipnent Supplied

tilt/swivel

attempting

kit

installation.

should

Parts

be

inspected

supplied

are

for

listed

missing

below.

or

damaged

parts

before

ITEM

NUMBER

1

2

3

2.3.2

The

Tilt/Swivel

user

installation.

a.

Place

b.

Position

Figure

c.

Install

Figure

should

control

2-4.

2-4.

PART

NUMBER

07-W4472B01

03SW994D904

035W993D910

Assembly

read

the

unit

tilt/swivel

two,

iten

Installation

following

chassis

assembly on

number

2,

DESCRIPTION

Assenbly,

Screw, ph

MS x o.8

Screw,

tilt/swivel

il

x 10

phillips,

M3.S x 0.6 x 10

procedure

in

desired

location.

control

phillips

MS x 0.8

1

ips,

canpletely

unit

x 10 screws

QUANTITY

before

chassis

1

4

4

starting

as

shown

as

shown

the

in

in

d.

Position

Figure

e.

Install

screws

f.

Lubricate

lubricant,

recomnended.

g.

Proceed

tilt/swivel

2-S.

the

as

shown

tilt/swivel

such

to

the

ranaining

in

Figure

as

display

assembly on

two,

iten

2-S.

brackets

as

Lubriplate

unit

installation

control

number

shown

in

unit

2,

Figure

number 23-2S

instructions.

chassis

phillips

2-6.

or

as

shown

MS x 0.8

An

al

1 purpose

equivalent,

in

x 10

is

2-4

Page 17

I

I

I

I

I

I

I

t,;.

_______

-------ffi

FRONT

I

I

I

I

I

I

I

I

.

FIGURE

2-4.

Control

Unit Chassis

Tilt/Swivel

Asserrbly

Position

1

FIGURE

2-5.

Control

Unit Chassis

2-5

Tilt/Swivel

Asserrbly

Position

2

Page 18

LUBtltCANT

-----------~~----------

LUBRICANT

2.3.3

Upon

completion

mounten

a.

b.

c.

FIGURE

Display

to

Loosen

the

2-6.

Unit

control

display

bezel.

display

Position

Align screw

Insert

forward

display

as

Control

Installation

of

the

Underside

channels

inserta::I.

This

enables

unit.

display

position

soown

Unit

tilt/swivel

unit

chassis

where

unit

cover

easy

unit

over

unit

in

onto

Figure

Chassis

assembly

(via

of

display

tilt/swivel

screws (two

insertion

over

tilt/swivel

bracket

tilt/swivel

2-8.

Tilt/Swivel

the

NOTE

unit

channel

Assembly

installation,

tilt/swivel

contains

brackets

per

side)

of

the

tilt/swivel

bracket

as

depected

brackets

Lubrication

the

assembly)

two

are

closest

as

shown

in

and

slide

display

as

follows:

to

front

bracket

in

Figure

illustration.

display

unit

monitor

into

the

2-7.

unit

is

While

display

forward

d.

e.

Push

properly

Tighten

monitor

display

insertE:rl

display

bezel

unit

to

tension.

slidirg

down

into

unit

obtain

NOTE

display

unit

will

tilt/swivel

as

shown

the

tilt/swivel

cover

screws (two

the

2-6

unit

drop

bracket

in

Figure

desired

forward,

into

channels.

2-9.

assembly.

per

display

the

side)

Display

closest

uni't

tilt

unit

to

is

front

adjustment

now

Page 19

•

•

"

•

FIGURE

FIGURE

2-7.

..

2-8.

Display

Display

Unit

Unit

Installation

Installation

Step

Step

1

~

FIGURE

2-9.

Display

Unit

2-7

Installation

Step

3

Page 20

2.3.4

Upon

System

canpletion

described

Cablirg

in

paragraph

of

Installation

the

display

2.2

unit

installation,

(Installation

Procerlure

system

1),

steps

cabling

d through

is

installed

as

i.

2.3.5

The

display

front

part

pressure

unit

upwards.

Display

unit

of

tilts

Display

loosening/tightening

(two

Unit

the

the

per

Positioning

can

be

positionerl

display

display

unit

tilt

side)

unit

as

unit

adjustment

closest

on

the

shown

in

downward.

NOTE

tension

of

the

display

to

front

control

Figure

Lifting

is

unit

monitor

unit

2-10.

chassis

Slight

uµ.1ards

accanplished

cover

screws

bezel.

by

downward

tilts

by

grasping

the

display

the

thumb

FIGURE

2-10.

Display

2-8

Unit

Positioning

Page 21

OIAPI'ER

3

3.1

This

as

INTRODUCTION

chapter

shown

installation

procerlure

Module.

VME/10

3.

2 I/Qnodule

Figure

The

via

3-2

VME/10.

I/Qnodules.

form

the

I/O Channel

I/Qnodule

describes

in

Figure

procErlures

installs

secorxl

an

MVME410

EXPANSION

illustrates

'!his

Jl

EXPANSION

the

3-1.

utilizing

a

modem

procedure

Dual

CARD

the

card

cage

connectors

via

ribbon

CARD

CAGE

EC.UIPMENT

I/Qnodule expansion

Two

most

camnon

I/Qnodules

to

the

VME/10

installs

Parallel

Port

via

an

a

Centronics-canpatible

Module.

CAGE

I/Qnodule expansion

is

designerl

installerl

cable

to

at

card

connections.

CAUTION

card

VME/10

are

MVME400

card

accept

slot

INSTALLATION

cage

installed

peripheral

also

locations

described.

Dual

cage

up

to

RS-232C

installed

five

(Al) through (AS)

in

the

VME/10

equipnent

The

first

Serial

printer

to

in

"single-wide"

Port

the

the

Unused

VME/10

card

cage

equipnent

EQUIPMENT

IF

BLANK

CAGE

card

UNUSED

slots

overheating

DAMAGE

PANELS

CARD

MAY

RESULT

ARE

NOT

SLOTS.

must always have

due

to

escaping

FROM

OVERHEATING

INSTALLED

blank

cooling

air.

ON

CARD

panels

installed

to

avoid

3-1

Page 22

6-83-1538

FIGURE

3-1.

VME/10

with

I/Qnodule Expansion Card Cage

3-2

Page 23

(TOP)

(A1)

(A2)

(A3)

NOTE:

(A

FIGURE

1)

THRU

3-2.

(A4)

(AS)

(AS)

(FRONT

DENOTE

VIEW)

CARD

SLOT

LOCATIONS.

I/Qnodule Expansion Card Cage

3-3

Page 24

3.3

VME/10

To

connect

jumper

For

specific

MVME400

number

MVME400.

TO

the

headers

Dual

MODEM

VME/10

are

details

RS-232C

The

by

the

The

level

for

MVME400

4.

the

is

This

MVME400.

software-selected.

To

install

the

follows:

a.

Turn

off

INSTALLATION

to a modem,

prepared

as

about

Serial

MVME400

VME/10

configured

is

Dual

VERSAdos

to

established

RS-232C

Baud

MVME400

into

equipment power.

listed

the

jumper

Port

operate

by

the

rate

the

the

MVME400

in

Module

Table 3-1 and

header

User's

Dual

RS-232C

configurations,

Manual, Motorola

NOTE

Serial

SYOOEN

VME/10

operation

comnand

in

the

Port

Module

file.

VME/10

VERSAdos

is

I/Omodule expansion

CAUTION

as

Serial

shown

in

Port

Figure

refer

publication

is

supported

I/O Channel

SYOOEN

file

at

interrupt

specifically

hardware-configured

card

cage,

proceed

Module

3-3.

to

the

and

as

b.

Refer

headers

9,600.

c.

Remove

d.

Secure

e.

Connect

RS-232C

f.

Turn

g.

Refer

publication

the

the

CONNECTING

IN

DAMAGE

to

Table

for

port 1 modem

two

blank

MVME400

modem

type

cable

on

equipment power.

to

the

number

VME/10

desired

VERSAdos

MVME400

MODULES

TO

CDMPONENTS

3-1

and

panels

in

place

device

to

via

the

Systan

M68KSYSGEN,

SYOOEN

configuration.

WHILE

POWER

ON

Figure

operation,

and

insert

with

two

Motorola

MVME400

Generation

for

comnand

IS

THE

MODULE.

3-3

and

interrupt

MVME400

captive

part

front

Facility

details

file

ON

COULD

configure

in

RESULT

level

desired

the

4,

card

screws.

number M68RS232-10,

panel

connector

User's

on

setting

Manual, Motorola

the

(VMESlO.SYSCMD.SA)

MVME400

and baud

slot.

labeled

paraneters

to

jumper

-25,

PORT

reflect

rate

-50

1.

in

3-4

Page 25

HEADER

NUMBER

TABLE

3-1.

MVME400

FUNCTION

Port 1 Modem

Configuration

CONFIGURATION

J2

J3

J4

JS

J6

J7

J8

J9

JlO

Jll

Jl2

Port 2 TxC

select

Port 2 external

2

Port

Interrupt

Base

Port

Port

Port

Baud

Port 1 TxC

internal

level

address

2 crs flow

2

to

modan

2

to

tenninal

rate

port

select

Port 1 external

clock

clock

select

select

control

select

1 and 2

clock

select

select

select

select

select

1-2

No jumpers

1-2,

4-6,

3-4

9-10,

11-12

10-12, 16-18

7-8

5-7,

6-8

No

jumpers

1-2,

3-4,

5-6,

7-8,

9-10, 11-12, 13-14,

15-16, 17-18, 19-20

3-4,

5-6,

9-10, 11-12

1-2

No

jumpers

Jl3

Jl4

Jl5

Jl6

Port 1 internal

Port 1 to

Port 1 to

Port

modem

tenninal

1 crs flow

clock

select

select

control

select

1-2,

3-4

9-10,

1-2,

11-12

3-4,

5-6,

7-8,

9-10, 11-12, 13-14,

15-16,

No

17-18, 19-20

jumpers

5-7,

6-8

3-5

Page 26

FAIL

0

PORT

1

@-..

MVME400

PORT

2

...

2

...

...

...

::

J9

00

...

00

...

00

...

1900

...

20

00

00

00

0 0

J15

00

00

0 0 2 8

0 0

fOO"Hl

J16

____

o_o_~

1920

1920

1 1

2 J

1

0

12

l~u~nl

11

FIGURE

3-3.

MVME400

Port 1 Modem

Configuration

20

JS

~~~~~~~

19

2 8

J&

Loo

o •

1

oooe

1 1

Page 27

3.4

VME/10

TO

PRINTER

INSTALLATION

To

connect

Parallel

shown

Port

in

the

Figure

configurations,

Motorola

The

level

for

To

install

publication

MVME410

1.

This

the

MVME410.

the

follows:

a.

Turn

VME/10

Module jmnper

3-4.

refer

to

number

The

MVME410

by

the

VME/10

is

configured

is

established

MVME410

off

equipment power.

CONNECTING

IN

DAMAGE

to

a

Centronics-compatible

headers

For

the

MVME410

MVME410.

Dual

Parallel

VERS.Ados

to

operate

by

into

the

MODULES

TO

COMPONENTS

are

specific

Dual

NOTE

SYSGEN

in

the

VME/10

I/Qnodule

CAUTION

WHILE

POWER

ON

prepared

details

Parallel

Port

Module

co:rrmand

the

VME/10

VERSAdos

expansion

IS

THE

MODULE.

as

ON

printer,

listed

about

Port

is

supported

file.

I/0

SYSGEN

card

COULD

the

in

Table

the

Module

Channel

file

cage,

RESULT

MVME410

3-2

jumper

User's

at

Manual,

interrupt

specifically

proceed

Dual

and

as

header

as

b.

Refer

jumper

c.

Remove

a.

Secure

e.

Connect

to

f.

Turn on equipment power.

g.

Refer

publication

the

the

to

headers

one

MVME410

the

MVME410

to

VME/10

desired

Table

blank

printer

the

number

VERS.Ados

MVME410

3-2

and

for

port 1 printer

panel

in

place

arrl

device

front

panel

System

M68KSYSGEN,

SYSGEN

configuration.

Figure

3-4 and

insert

with

via

two

Motorola

connector

Generation

for

cornnand

configure

operation

MVME410

captive

part

Jl.

Facility

details

file

and

in

desired

screws.

number

User's

on

setting

(VMESlO

the

MVME410

interrupt

card

level

slot.

M68KVMPRTCE

Manual, Motorola

the

parameters

.SYSCMD.SA)

I/Qnodule

1.

type

to

cable

reflect

in

3-7

Page 28

HEADER

NUMBER

TABLE

3-2.

MVME410

FUNCTION

Port 1 Printer

Configuration

CONFIGURATION

J2

J3

J4

JS

J6

J8

J9

JlO

Jll

Jl2

Jl3

Jl4

Jl5

LED

monitor

Port

Port

1 (PlCA2,

1

(PlCA2,

PlPA0-PlPA7)

PlPAO-PlPA7)

Port 1 (PlCB2, PlPBO-PlPB7)

Port

1 (PlCB2,

Port

2

(P2CA2,

Port 2 (P2CA2,

Port

2

(P2CB2,

Port 2 (P2CB2,

Interrupt

Interrupt

Base

address

LED

control

P2PBO-PlPB7)

P2PA0-P2PA7)

P2PAO-P2PA7)

P2PBO-P2PB7)

P2PBO-P2PB7)

select

select

select

direction

direction

direction

direction

direction

direction

direction

direction

No

No

2-4,

2-4,

No

2-3

1-2

1~2

1-2

jurrper

1-2

1-2

1-2

jurrper

8-10

8-10

junper

2-3

3-8

Page 29

@

FAILQ

~~

J1

~;.-

~

s

..

/

~

J16

..............

@-..

MVME410

@

J3

1C!:!)2

J4

J

2

1(

....

ool4

1ra

182

JS

:11~4

J6

1(0

...

ol4

J15

JS

J9

1(EJ2

1(

.... 0 of4

182

J10

1(000014

J11

FIGURE

3-4.

MVME410

Port 1 Printer

Configuration

12 12

.. o ..

o

... 0 ...

0

000000

000000

1

J12

11

1

2 •

(0'0001

~

1 J14 7

J13

11

Page 30

Page 31

CliAPI'ER 4

4.1

INTRODUCI1ION

This

VME/10

are

4.2

Figure

VME/10.

chapter

as

also

provided.

VME+I/Qnodule

4-2

This

VMEhlodules

MVME923

Backplane which

VMEhtodule

Pl

connectors.

JlS

form

addition

the

of

connection.

The

card

five

cage

connectors can

cabling.

VME+I/Qnodule

describes

shown

in

Figure

EXPANSION

illustrates

card

and up

Pl

connectors,

cage

to

Connectors

I/O Channel.

two

connectors

also

provides a connector

EXPANSION

the

4-1.

the

facilitates

four

"single-wide"

contains

and

Jl

The

be

installed

CARD

VME+I/Qnodule

VMEhtodule

CARD

CAGE

VME+I/Qnodule

the

installation

five

two

connectors

connectors

through JS form

I/O Channel

(card

slot

by

the

CAGE

EQUIPMENT

expansion

and I/Qnodule

expansion

I/Onodules.

(Jl4

and

the

VMEbus,

is

extended from

locations

mounting

user

AS

area.

to

INSTALLATION

card

cage

installation

card

of

(Jl

JlS)

cage

up

to

The

card

through JS)

that

and

and

A9)

See

facilitate

installed

installed

five

"double-wide"

cage houses

mate

connectors

the

backplane by

via

Figure

VME1nodule

in

procerlures

in

that

mate

to

I/Qnodule

Jl4

ribbon

4-2.

P2

the

the

the

to

and

the

cable

Up

to

I/O

4.2.1

Vacant

Interrupt

the

Daisy-Chain Jumpering

card

Acknowlerlge

vacant

Daisy-chain

slot

active

headers

(Al)

ca.rd

to

J6

technique.

locations.

are

assigned

to

slot

and

(A4)

signal

slots

should

(!ACK)

slots

have been

jumpering penni

the

last

card

slot

through

Figure

Card

to

, and

assignments

(Ax)

Jl3

slot

slot

headers

are

4-2

(Al)

(A2),

are

(J6-Jl3)

not

and

daisy-chain

ts

the

slot

not

on

the

illustrates

is

not

headers

J9

and

illustrated

exist

Bus

between

Grant

(BG)

jumpererl on

!ACK

and

BG

(AS). Remaining

required

backplane

the

to

be

facilitate

backplane

assignerl a jumper

J7

and

Jll

to

Jl3

to

slot

in

(AS)

Figure

inserterl

signals

signals

vacant

daisy-chain

VMEmodules

in

the

the

to

slots

the

daisy-chain

card

MVME923

propagate

following

jumpered. Jumper

daisy-chain

header.

slot

(A3),

Headers

headers

• Backplane jumper

4-3.

requiring

cage

backplane.

from

the

jumpering

jumper

J6

JS and

header

unless

card

last

header

and JlO

Jl2

pin

4-1

Page 32

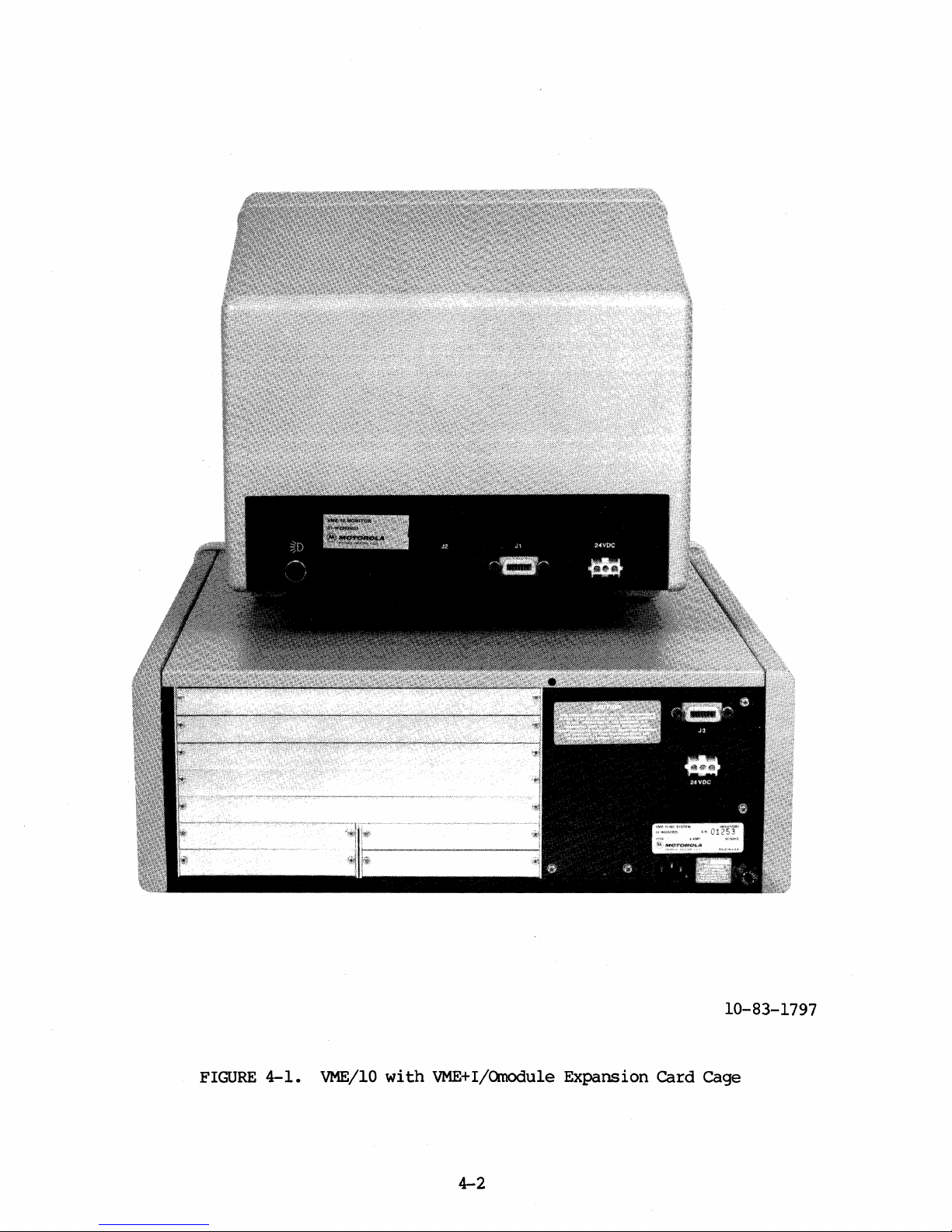

10-83-1797

FIGURE

4-1.

VME/10

with

VME+I/Qnodule Expansion Card Cage

4-2

Page 33

r----------------1

J1

(A1) I I

L----------------~

J6

1 I

.......

· I a

1c::J2

J10

r---------------1

J2

(A2) I I

L---------------~

J7

1 I

........

I a

1c::J2

J11

r---------------1

J3

(A3) I I

L---------------~

JS

1 I·

......

· I a

182

J12

r----------------1

J4

(A4) I I

L---------------~

1 I · · · · · · .. I a

J9

182

J13

t

w

r---------------1

JS

(AS) I I

L---------------~

(A6)

(AS)

J14

(A7) (A9)

J1S

(FRONT VIEW)

NOTE:

(A1) THAU (A9) DENOTE CARD SLOT LOCATIONS.

FIGURE

4-2.

VME+I/Qnodule Expansion Card Cage

Page 34

(A1)

(A2)

(A3)

(A4)

(AS)

J1

J2

J3 J4

JS

J10

J11

J12

J13

IACKIN*

IACKIN*

IACKIN* IACKIN*

A21

A21

A21

A21

A21

IACKOUT*

IA

CK OUT*

IA

CK

OUT*

IACKOUT*

A22

A22

A22

A22 A22

J6

J7

JS

J9

8GOIN* 8GOIN*

1

8GOIN*

8GOIN*

1

84

84

84

84

84

8GOOUT*

8GOOUT*

8GOOUT*

8GOOUT*

~

8S

8S

8S

8S

8S

I

~

8G11N*

8G11N* 8G11N*

8G11N*

86

86

86 86

86

8G10UT*

8G10UT* 8G10UT*

8G10UT*

87

87

87 87

87

8G21N* 8G21N*

8G21N*

8G21N*

88

88

88

88

88

8G20UT*

8G20UT* 8G20UT*

8G20UT*

89

89

89

89

89

8G31N* 8G31N* 8G31N*

8G31N*

810

810

810

810

810

8G30UT*

8G30UT*

8G30UT*

8G30UT*

811

811 811

811 811

FIGURE

4-3.

MVME923

Backplane Daisy-Chain

Page 35

4.2.1.1

not

contain

inserted

a.

b.

VMEmodules

!ACK/BG

into

the

the

applicable

daisy-chain

the

applicable

operation.

Not

Containing

circuitry

card

cage,

card

jumpered,

VMEmodule

(e.g.,

one

slot

or

IACK/BG

MVME200

of

two

jurcper

must

Circuitry.

64K-Byte Dynamic

operations

headers

be

jumpered

If a VMEmodule

must

be

perforrred:

on

the

for

IACK/BG

which does

Memory

Module)

is

backplane must be

signal

bypass

VMEhlodule

4-4.

next

card

4.2.1.2

IACK/BG

cage,

signal

application,

have jurcpers

the

next

Figure

header.

edge

This

bypass method

slot,

VMEmodules

circuitry

the

BG

and

to

the

card

4-5

illustrates

In

connector

without

circuitry

transfer

applicable

installed.

slot,

this

received/transferred

horizontal

next

card

jumpers. Unused

slot

by

IACK/BG

ensures

the

use

of

Containing

IACK/BG

(e.g. , MVME300

must have jumpers

the

unused

card

Installed

thus

defeating

a

typical

figure,

by

BG2*

the

VMF.rnodule

BGO*,

the

placement

of

signal

that

the

bypass method

the

backplane jurcper

Circuitry.

GPIB

BG

slot

Controller)

signals

jumper

jurcpers

the

purpose

VMEmodule

signals

BG

BGl*, arrl

the

vertical

IACK/BG

installed

to

headers

will

of

bus

are

the

circuitry

BG3*

is

illustrated

signals

will

headers.

If a VMErnodule

is

inserted

to

receive

the

next

on

the

bypass

the

all

module

arbitration

only

signals

by

the

signals

jumpers.

propagate

which

into

the

card

slot.

backplane

IACK/BG

IACK/BG

level

permitted

placement

are

bypassed

in

contains

the

selected

For

should

signals

circuitry.

select

Figure

to

the

card

BG

this

not

to

jumper

to

be

of

the

to

the

4-5

Page 36

~

P1

IACKIN*

I

ACK

OUT*

BGOIN*

BGOOUT*

BG11N*

BG10UT*

BG21N*

BG20UT*

BG31N*

..

..

--

-

-..

-..

--

--

--

-

-

~

--

--

~

--

--

--

A21

A22

84

es

86

VMEbus

87

88

89

810

FIGURE

BG30UT*

4-4.

Typical

--

--

~

VMFroodule

4-6

811

Bus

Arbitration

Bypass

Page 37

BUS

ARBITRATION

LEVEL SELECT

JUMPER

HEADER

P1

VMEmodule

BG

CIRCUITRY

LEVEL

LEVEL 1

LEVEL 2

BGOIN*

BGOOUT*

0

BG11N*

BG10UT*

BG21N*

BG20UT*

BG31N*

B4

BS

B6

B7

VMEbus

BS

B9

B10

FIGURE

4-5.

LEVEL 3

Typical

BG30UT*·

VMFJ:nodule

4-7

Bus

Arbitration

B11

Level

Selection

Page 38

4.3

VMElnodule

INSTALLATION

VMF.rnodules

Figure

Unused

4-2.

card

equipment

To

install

follows:

a.

Turn

are

installed

EQUIPMENT

IF

CAGE

cage

slots

overheating

a

VMF.rnodule

off

equipment power.

CONNECrING

RESULT

in

card

CAUTION

BLANK

UNUSED

DAMAGE

PANELS

CARD

MAY

ARE

SLOTS.

must always have

due

to

escaping

into

the

VME+I/Qnodule

CAUTION

MODULES

IN

DAMAGE

TO

slot

cooling

locations

RESULT

NOT

INSTALLED

blank

FROM

panels

air.

expansion

WHILE

CX>MPONENTS

POWER

ON

(Al)

through

OVERHEATING

ON

CARD

installed

IS

THE

ON

card

COULD

MODULE.

cage,

to

(AS).

avoid

proceed

See

VME/10

as

b.

Refer

to

the

applicable

procedures.

c.

Configure

d.

Remove

the

blank

VMEmodule

panel

slot.

e.

If

the

VMEmodule

cabling

f.

Secure

g.

Connect

applicable

installation

VMErnodule

peripheral

VMElnodule

INSTRUCTIONS).

h.

Turn on equipment power.

and

requires

methods

in

place

device

VMEmodule

(via

jumper

insert

VMErnodule

P2

I/O

described

with

(if

two

required)

user's

user's

headers)

cabling,

captive

manual

in

in

paragraph

screws.

to

for

as

required.

desired

perform

VMF.module

manual (Chapter

hardware

"double-wide"

one

of

the

4.3.l

or

as

2,

4.3.2.

described

INSTALLATION

preparation

card

two

I/O

in

4-8

Page 39

4.3.1

VMEh\odule

I/O Cabling Method 1

This

an

installation

unused

illustrates

a.

Remove

of

b.

Connect

applicable

c.

Configure

d.

Install

e.

Secure

f.

Secure

cable

card

this

desired

I/O

cable

the

I/O

card

metric

VMEmodule

VMFroodule

modified

assembly)

method

slot

in

cabling

card

assembly

other

VMEmodule

cable

cage

screws

the

VM~odule

in

blank

in

enables

the

VMEmodule

VME+

I/Omodule

method and

cage blank

to

blank

end

of

the

P2

connector.

assembly J2

if

desired.

to

secure

(via

in

desired

place

with

panel

place

with

P2

I/O

expansion

is

installed

panel

and

panel.

I/O

cable

NOTE

connector

Use

assembly (J2

can

two

connector

jurrper

headers)

"double-wide"

two

captive

(containing

two screws

cabling

card

as

follows:

install

be

mounted

peripheral

M2.5 x 0.45

to

card

as

card

cage.

required.

slot.

screws.

peripheral

(previously

to

be

routed

cage.

connector

connector

to

x 8

connector

removed).

through

Figure

end)

end

of

to

4-6

end

the

I/O

4-9

Page 40

FIGURE

4_6

•

VMEmodule

I/O

4-10

Ca

.

bllng

Method 1

Page 41

4.3.2

VMF.lnodule

I/O

Cabling Method 2

This

rear

I/O

installation

of

the

panel.

disassembly,

reassembly.

The

control

a.

Disconnect system

b.

Remove

c.

Remove

d.

Remove

two

pan~head

e.

Remove

seven pan-head

metood

VME+I/Om:>dule

This

unit

I/O

chassis

cabling

cable

ac

AC

J?Cl'lER

ELECl'RICAL

all

external

display

control

unit

unit

screws

control

unit

screws).

enables

VMEmodule

expansion

method

asserri::>ly

is

disassembled

power.

MUST

SHOCKS

cables

from

control

chassis

per

side).

chassis

card

is

cage,

accanplished

installation,

as

WARNING

BE

REMOVED

TO

MAINTENANCE

from

control

unit

side

top

covers.

cover.

P2

I/O

under

follows:

unit

chassis.

(Accanplished by

(Accanplished by

cabling

the

by

arrl

TO

to

blower

the

control

control

AVOID

PERSONNEL.

chassis.

be

routed

fan,

unit

unit

the

the

fran

to

the

chassis

chassis

removal

removal

the

rear

of

of

f.

Remove

two

g.

On

connector

quick

h.

On

type

pan-head

control

flat-head

'!WO

MODULAR

FRONT

FROM

present

disconnect

first

production

connectors

screws.)

unit

screws

PANEL

CABLE

production

wiring

connectors.)

from

chassis

per

side.)

RJ

TYPE

OR

CDNNEX::TOR

HARNESS

CDNNEcrORS

TO

units,

from

cable

units,

front

front

panel.

CAUTION

WIRING

AVOID

disconnect

harness.

ranove

panel.

(Accanplished by

SHOOLD

SHOOLD

CDNNEcrOR

BE

REMOVED

BE

DISCDNNOCTID

WIRING

front

(Accanplished by

connector

bracket

(Accanplished by

DAMAGE.

panel

arrl

the

the

removal

FROM

modular RJ

cable

both

modular RJ

removal

of

type

harness

of

two

4-11

Page 42

The

Systan

gain

access

follows:

a.

Control

for

Disconnect

locations:

Module

the

cable

Jl,

I/O

P2,

(SCM)

cable

assembly

Jl2,

is

now

assembly

connectors

Jl3,

and

NOTE

removed

fran

installation.

Jl4.

the

at

control

The

SCM

following

unit

is

SCM

chassis

removed

connector

to

as

b.

Remove

the

c.

SCM

forward on

The

control

connector

in

the

production

is

used

second

panel

is

a.

type

Remove

pan-head screws and

b.

Remove

of

Sa1

removal

(with

unit

en:3

of

on

present

whidl

removed

I/O panel

J3

connector

Observe

Pl2

(including

of

bracket

the

chassis

the

of

production

is

as

orientation

red

wire

three

SCM.

rear

I/O

cable

the

VME/10.

usErl

follows:

fran

must mate

bracket

flat-head

assembly)

I/O

assembly.

control

on

first

chassis.

associated

connector

from

chassis

mounting hardware.)

of

connectors

with

assembly)

screws

is

panel

The

is

first

unit

production

flat

I/O

Jl2

arrl

Jl2

pin

1.

fran

per

removed from

now

removed

Two

types

type,

chassis.

chassis.

side.)

of

as

illustrated

Figure

control

the

to

I/O

unit

(Accanplished by

washers,

panel.

lock

washers,

(Accanplished by

Pl2.

chassis

mount

panels

4-8

chassis.

the

(Accanplished by

by

pulling

the

peripheral

are

utilized

in

Figure

illustrates

removal

arrl

nuts.)

the

4-7,

the

The

I/O

of

four

removal

c.

If

applicable,

(Accanplished

an:3

pushing

d.

Install

pmel.

by

in

on

peripheral

Refer

to

remove

24VDC

squeezing

the

connector.)

connector

Figures 4-7

both

errl

or

connector

fr

an

chassis

upper and lower connector

of

the

I/O

4-8

for

applicable

cable

assembly

I/O

4-12

to

panel

I/O

locking

chassis

tanplet.

panel.

tabs

I/O

Page 43

0

r---------

---

(P2)

1/0 CONNECTOR

MOUNTING

AREA

0

J3

L

____________

0 0

FIGURE

4-7.

Present

Production

_J

Control

Unit

Chassis

I/O

Panel

0

Tanplet

4-13

Page 44

0

r---------

( 112)

1/0

CONNECTOR

MOUNTING

AREA

0

J3

24VDC

L

____________

0 0

FIGURE

4-8.

First

Production Control

_..

Unit

Chassis

0

I/O Panel Templet

4-14

Page 45

The

as

follows:

I/O

cable

a.

Route I/O

assembly

cable

is

now

installed

assenbly

as

shown

into

in

CAUTION

the

control

Figure

4-9.

unit

chassis.

Proceed

The

b.

I/O

cable

filter.

c.

Connect

VME+I/Qnodule

screws.

d.

Reinstall

e.

If

applicable,

f.

Reinstall

not

blocking

control

a.

mates

b.

Reinstall

unit

Reinstall

with

BLOCKAGE

IN

EQUIPMENT

CF

assembly must

the

J2

connector

expansion

J3

connector

reinstall

I/O

panel

air

chassis

SCM

card

SCM

Jl,

to

flow

is

(with

cage

P2,

BLCMER

DAMAGE

be

FAN

DUE

routed

errl

card

to

chassis

24VDC

control

fran

cage

connector

unit

blower

reassembled

bracket

connector

Jl2,

asserrbly)

XJl.)

Jl3,

COOL!~

TO

under

of

using

I/O

chassis.

fan.

as

follows:

arrl

Jl4

COULD

OVERHEAT!~.

the

the

blower

I/O

two

RESULT

cable

M2.5

panel.

to

chassis

Ensure

to

chassis.

cabling.

fan

assembly

x

0.45

I/O

panel.

that

(SCM

arrl

over

I/O

Pl

the

to

x 8

metric

cabling

connector

EMI

the

is

c.

Reconnect modular

modular

d.

Reinstall

e.

Reinstall

f.

Reinstall

VME1nodule,

and

installed.

Observe

Pl2

RJ

type

front

top

chassis

utilizing

Refer

orientation

red

wire

RJ

connectors

panel

cover

to

side

the

I/O

to

paragraph

must mate

type

connector

to

to

chassis.

chassis.

covers.

cable

assembly

4.3.

NOTE

of

connectors

with

wiring

front

panel.

4-15

Jl2

just

Jl2

and

pin

1.

to

cable

installed,

Pl2.

harness

can

now

or

reinstall

be

prepared

Page 46

(FRONT)

TYPICAL

P2

RIBBON CABLE

ROUTING

I I I I

'--------...I

J1

VME

+ l/Omodule

EXPANSION

CARD CAGE

(REAR)

L-------...1

J2

r

I

I

I

I

I

.._

__

1/0

v

PANEL

'-----------"'

FAN

EMI

FILTER

FIGURE

4-9.

VMDnodule

4-16

I/O

Cabli~

Method 2

Page 47

4.4

I/Qnodule

INSTALIATION

I/Qnodules

Figure

When

Serial

slots

MVME400

4-2.

inserting

Port

for

are

•

Install

card

•

Install

card

are

installed

Both

Chapter 3 are

expansion

"double-wide"

Module)

sp:!cific

requirErl,

both

slots

(A6)

both

slot

(AS) which

EQUIPMENT

BLANK

UNUSED

in

I/Oloc>dule

card

into

this

I/Qnodule

the

user

I/Qnodules

am

(AS)

I/Omodules

is

DAMAGE

PANELS

CARD

card

slot

NOTE

installation

also

applicable

cage.

front

card

panel

cage,

installations

has

two

options

in

card

slots

•

in

card

slots

a "double-wide"

CAUTION

MAY

RESULT

ARE

NOT

INSTALLED

SLOTS.

locations

procErlures

to

I/Qnodules

described

the

VME+I/Qnodule

(e.g.,

considerations

must

be

made. For an example,

available

(A7)

and (A9),

(A6)

am

(AS),

VMEmodule

FROM

OVERHEAT!~

ON

(A6)

about

•

card

CARD

through

in

MVME400

sacrificing

therefore

therefore

slot.

IF

CAGE

(A9}.

dual

RS-232C

if

sacrificing

sacrificing

See

card

two

Unused

VME/10

To

install

a.

b.

c.

d.

e.

f.

card

cage

equi!lllent

a I/Omodule

Turn

Refer

off

equipment power.

to

the

procedures.

Configure

Remove

blank

slot.

Secure

Connect

I/Omodule

peripheral

I/Omodule

card

slots

overheating

into

<DNNECI'ING

RESULT

IN

DAMAGE

applicable

the

I/Oroodule

panel

user's

arrl

in

place

manual (Chapter

must always have

due

to

escaping

the

VME+I/Omodule

CAUTION

MODULES

I/Omodule

(via

device

WHILE

TO

<DMPONENTS

j~r

insert

with

two

to

user's

I/Qnodule

captive

I/Omodule

2,

blank

cooling

card

POWER

ON

cage

IS

THE

air.

ON

panels

MODULE.

manual

headers)

as

in

desired

screws.

as

INSTALIATION

installed

proceed

as

follows:

COULD

for

hardware

requirErl.

"single-wide"

described

in

INSTRUCI'IONS).

to

avoid

preparation

card

applicable

g.

Turn on equipment power.

4-17/4-lS

Page 48

Page 49

SUGGESTION/PROBLEM

REPORT

QUALITY • PEOPLE • PERFORMANCE

Motorola welcomes your comments on its products and publications. Please use this form.

To:

Motorola Inc.

Microsystems

2900

S.

Diablo

Way

Tempe, Arizona 85282

Publications Manager

Mai

Id

rop DW164

_

Manual:---------------

Product:

Attention:

______________

Please Print

_______________

Name

Company

Street----------------

City

For Additional Motorola Publications

Literature Distribution Center

616 West 24th Street

Tempe, AZ 85282

(602) 994-6561

_____________

________________

~

_

Title---------------Division---------------

Mail Drop

_

State

Four Phase/Motorola Customer Support, Tempe Operations

(800) 528-1908

(602) 438-3100

_____

_________

Phone

______

Zip

____

®MOTOROLA

_

_

Page 50

lil\

0

ltllOTOROLA

Semiconductor

P.O.

BOX 20912 •PHOENIX, ARIZONA 85036

Products

Inc.

•A

SUBSIDIARY

OF

MOTOROLA INC.

17602 PRINTED IN USA (4/84)

MPS

4M

Loading...

Loading...