Page 1

MVME2400-Series

Single Board Computer

Installation and Use

V2400A/IH1

Page 2

Notice

While reasonable efforts have been made to assure the accuracy of this document,

Motorola, Inc. a ssumes n o lia bility r esulti ng from any omissio ns in this docu ment, or from

the use of the information obtained therein. Motorola reserves the right to revise this

document and to ma ke c hanges from time to ti me in t he content hereof witho ut o bligation

of Motorola to notify any person of such revision or changes.

No part of this material may be reproduce d or copied in any tangi ble medium, or stored in

a retrieval system, or transmitted in any form, or by any means, radio, electronic,

mechanical, photocopying, recording or facsimile, or otherwise, without the prior written

permission of Motorola, Inc.

It is possible that this pu blicati on ma y cont ain r eferenc e to, or i nformat ion a bout Mot oro la

products (machines and programs), programming, or services that are not announced in

your country. Such refere nces or informat ion must not be construed to mean that Moto rola

intends to announce such Motorola products, programming, or services in your country.

Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S.

Government, the following notice shall apply unless otherwise agreed to in writing by

Motorola, Inc.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS 252.227-7013.

Motorola, Inc.

Computer Group

2900 South Diablo Way

Tempe, Arizona 85282

Page 3

Preface

The MVME2400-Series VME Processor Module Installation and Use manual provides

information you will need to install and use your MVME2400-series VME processor

module. The MVME2400 VME processor module is based on an MPC750 PowerPC

microprocessor, and features dual PCI Mezzanine Card (PMC) slots with front panel and/

or P2 I/O. The MVME2400 is currently available in the following configurations:

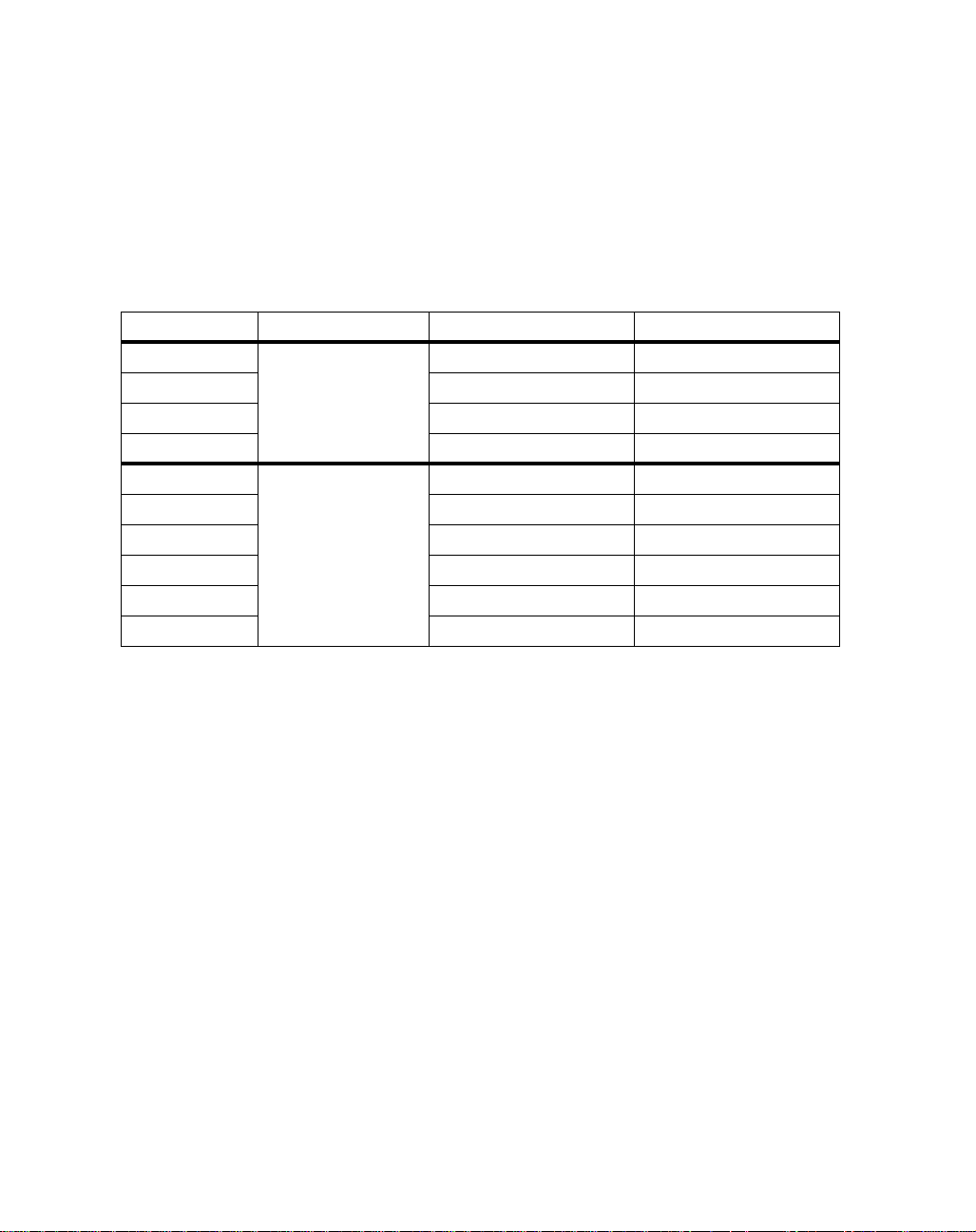

Model MPC Memory Handles

MVME2401-1 MPC750

MVME2401-3 32MB ECC SDRAM 1101 Handles

MVME2402-1 64MB ECC SDRAM Scanbe Handles

MVME2402-3 64MB ECC SDRAM 1101 Handles

MVME2431-1 MPC750

MVME2431-3 32MB ECC SDRAM 1101 Handles

MVME2432-1 64MB ECC SDRAM Scanbe Handles

MVME2432-3 64MB ECC SDRAM 1101-1 Handles

MVME2433-1 128MB ECC SDRAM Scanbe Handles

MVME2433-3 128MB ECC SDRAM 1101-1 Handles

@ 233 MHz

@ 350 MHz

The MVME2400-series module is co mpatible with optional double-widt h or s ingle-width

PCI Mezzanine Cards (PMCs) , and the PMCspan PCI expansion mezzanine module. By

utilizing the two onboard PMC slots and stacking PMCspan(s), the MVME2400 provides

support for up to six PMCs.

32MB ECC SDRAM Scanbe Handles

32MB ECC SDRAM Scanbe Handles

This manual includes hardware preparation and installation instructions for the

MVME2400-series module, information about using the front panel, a functional

description, information about programming the board, using the PPCBug debugging

firmware, and advanc ed debugger topics. Othe r appendices provi de the MVME2400-series

specifications, c onnector pin a ssignments, and a gl ossary of te rms. Additional manuals you

may wish to obtain are listed in Appendix A, Ordering Related Documentation.

The information in this man ual appl ies principally to the MVME2400-se ri es module . The

PMCspan and PMCs are described briefly here but are documented in detail in separate

publications, furni shed with thos e products. Refer to the indi vidual produc t documentation

for complete preparation and installation instructions. These manuals are listed in

Appendix A, Ordering Related Documentation.

Page 4

This manual is intended for anyon e who want s to design OEM systems, supply additiona l

capability to an existi ng compatible syste m, or work in a lab environment for experimental

purposes. A basic knowledge of computers and digital logic is assumed.

Document Terminology

Throughout this manual , a convention i s used which pr ecedes dat a and addres s parameters

by a character identifying the numeric format as follows:

$ Dollar

0x Zero-x

% Percent Specifies a binary number

& Ampersand Specifies a decimal number

Specifies a hexadecimal character

For example, “12” is the deci mal number twelve, and “$12” (hexadeci mal) is the equivalent

of decimal number eighteen. Unless otherwise specified, all address references are in

hexadecimal.

An asterisk (*) following the signal na me for signals which are level-si gnificant denotes

that the signal is true or valid when the signal is low.

An asterisk (*) following the signal na me for signals which are edge-significant denotes

that the actions initiated by that signal occur on high-to-low transition.

In this manual, assertion and negation are used to specify forcing a signal to a particular

state. In particular, assertion and assert refer to a signal that i s acti ve or t rue; negat ion and

negate indicate a sign al tha t is in activ e or fal se. These te rms are u sed i ndepend ently of the

voltage level (high or low) that they represent.

Data and address sizes are defined as follows:

Byte 8 bits, numbered 0 through 7, with bit 0 being the least significant.

Half word 16 bits, numbered 0 through 15 , wit h bit 0 being the least significant.

Word 32 bits, numbered 0 through 31, with bit 0 being the least significant.

Double word 64 bits, numbered 0 through 63, with bit 0 being the least significant.

Page 5

Safety Summary

Safety Depends On You

The following general safety precautions must be observed during all phases of operation, service, and repair of this

equipment. Failure to comply with these prec autions or with spe cific warnings els ewhere in this manua l violates saf ety

standards of design, manufacture, and intended use of the equipment. Motorola, Inc. assumes no liability for the

customer’s failure to comply with these requirements.

The safety precaut ions listed be low represent warnings of ce rtain danger s of which Mot orola is awar e. You, as the

user of the product, should follow these warnings and all other safety precautions necessary for the safe operation of

the equipment in your operating environment.

Ground the Instrument.

To minimize shock hazard, the equipment chassis and enclosure must be connected to an electrical ground. The

equipment is supp lied with a three-c onductor AC power cable. The pow er cabl e must be p lugged in to an appro ved

three-contact electrical outlet. The power jack and mating plug of the power cable meet International Electrotechnical

Commission (IEC) safety standards.

Do Not Operate in an Explosive Atmosphere.

Do not operate the equipment in the presence of flammable gases or fumes. Operation of any electrical equipment in

such an environment constitutes a definite safety hazard .

Keep Away From Live Circuits.

Operating personnel must not remove equipment covers. Only Factory Authorized Service Personnel or other

qualified maint enance personnel m ay remove equip m ent covers for inte rnal subassembl y or component re pl acement

or any internal adjustment. Do not replace components with power cable connected. Under certain conditions,

dangerous voltages may exist even with the power cable removed. To avoid injuries, always disconnect power and

discharge circuit s before touching t h em.

Do Not Service or Adjust Alone.

Do not attempt internal service or adjustment unless another person capable of rendering first aid and resuscitation is

present.

Use Caution When Exposing or Handling the CRT.

Breakage of the Cathode-Ray Tube (CRT) causes a high-velocity scattering of glass fragments (implosion). To

prevent CRT implosion, avoid rough handling or jarring of the equipment. Handling of the CRT should be done only

by qualified mainte nance personnel using approved safety mask a nd gloves.

Do Not Substitute Parts or Modify Equipment.

Because of the dan ger of i ntrodu cing add ition al haza rds, do not ins tall sub stitut e parts or perf orm an y unauth orized

modification of the equipment. Con tact your local Mot or ola representative for service and re pa ir to ensure that safety

features are maintained.

Dangerous Procedure Warnings.

W arn ings , such as th e exa mple be low, precede potentially dangerous pro cedure s thro ughou t this ma nual . Instr uctio ns

contained in the warnings m ust be follow ed. You should also employ all ot her safety precautions w hich you dee m

necessary for the operation of the equipment in your ope r ating environment .

Dangerous voltages, capable of causing death, are present in this

!

WARNING

equipment. Use extreme caution when handling, testing, and

adjusting.

Page 6

This equipment generates, uses, and can radiate electro-magnetic energy. It may

!

WARNING

EN55022 “Limits and Methods of Measurement of Radio Interference Characteristics of Information Technology Equipment”. Tested to Equipment Class B.

EN 50082-1:1997 “Electromagnetic Compatibility -- Generic Immunity Standard, Part 1. Residential, Commercial and Light Indust ry.”

EN 61000-4.2 -- Electrostatic Discharge Immunity Test

EN 61000-4.3 -- Radiated, Radio-Frequency Electromagnetic Field, Immunity Test

EN 61000-4.4 -- Electrical Fast Transient/Burst Immunity Test

EN 61000-4.5 -- Surge Immunity Test

EN 61000-4.6 -- Conducted Disturbances Induced by Radio-Frequency Fields -- Immunity

Test

EN 61000-4.11 -- Voltage Dips, Short Interruptions and Voltage Variations Immunity Test

ENV 50204 -- Radiated Electromagnetic Field from Digital Radio Telephones -- Immunity

Test

In accordance with European Community directives, a “Declaration of Conformity” has been

made and is on file at Motorola, Inc. - Computer Group, 27 Mark et Street, Maidenhead, United

Kingdom, Sl6 8AE.

cause or be susceptible to electro-magnetic interference (EMI) if not installed

and used in a cabinet with adequate EMI protection.

If any modifications are made t o the product, the modifier assumes

responsibility for radio frequency interference issues. Changes or modifications

not expressly approved by Motorola Computer Group could void the user’s

authority to operate the equipment.

European Notice: Board products with the CE marking co mply with the EMC

Directive (89/336/EEC). Compliance with this directive implies confor mity to the

following European Norms:

This board product was tested in a representative system to show compliance with the above

mentioned requirements. A proper installation in a CE-marked system will maintain the

required EMC/safety performance.

For minimum RF emissions, it is essen tial that you implement the following conditions:

1. Install shielded cables on all external I/O ports.

2. Connect conductive chassis rails to earth ground to provide a path for connecting shields to

earth ground.

3. Tighten all front panel screws.

The product also fulfills EN60950 (product safety) which is essentially the requirement for the

Low Voltage Directive (73/23/EEC).

Page 7

All Motorola PWBs (printed wiring boards) are manufactured by UL-recognized

manufacturers, with a flammability rating of 94V-0.

The computer programs stored in the Read Only Memory of this device contain material

copyrighted by Motorola Inc., 1995, and may be used only under a license such as those

contained in Motorola’s software licenses.

The software descri bed herein and the docu mentation appea ring herein are fu rnished under

a license agreement and may be used and/or discl osed only in acc ordance wit h the terms of

the agreement.

The software and documentat ion are copyrighted ma terials. Making unauth orized copies is

prohibited by law.

No part of the software or documentation may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any language or computer language, in any

form or by any means without the prior written permission of Motorola, Inc.

Motorola® and the Motorola symbol are registered trademarks of Motorola, Inc.

PowerPC™ is a trademark of International Business Machines Co rporation and is used by

Motorola with permission.

All other products mentioned in this do cument are trademarks or registered trademarks of their

respective holders.

© Copyright Motorola 1999

All Rights Reserved

Printed in the United States of America

February 1999

Page 8

Page 9

Contents

CHAPTER 1 Preparing and Installing the MVME2400-Series Module

Introduction................................................................................................................1-1

MVME240x Description ...........................................................................................1-1

MVME240x Module...........................................................................................1-2

PMCspan Expansion Mezzanine........................................................................1-3

PCI Mezzanine Cards (PMCs)............................................................................1-3

VMEsystem Enclosure .......................................................................................1-4

System Console Terminal...................................................................................1-4

Overview of Start-Up Procedures..............................................................................1-4

Unpacking the MVME240x Hardware......................................................................1-7

Preparing the MVME240x Hardware........................................................................1-7

MVME240x........................................................................................................1-7

Setting the Flash Memory Bank A/Bank B Reset Vector Header (J8) .....1-10

Setting the VMEbus System Controller Selection Header (J9).................1-10

Setting the General-Purpose Software-Readable Header (SRH)

Switch(S3).................................................................................................1-11

PMCs ................................................................................................................1-12

PMCspan...........................................................................................................1-12

System Console Terminal.................................................................................1-12

Installing the MVME240x Hardware ......................................................................1-13

ESD Precautions...............................................................................................1-13

PMCs ................................................................................................................1-13

Primary PMCspan.............................................................................................1-16

Secondary PMCspan.........................................................................................1-18

MVME240x......................................................................................................1-21

Installation Considerations ........................................................... ....................1-23

CHAPTER 2 Operating Instructions

Introduction................................................................................................................2-1

Applying Power.........................................................................................................2-1

MVME240x ...............................................................................................................2-2

Switches..............................................................................................................2-2

ABT (S1) .....................................................................................................2-3

RST (S2)................................................... ...... ...... .......................................2-3

Status Indicators..................................................................................................2-4

ix

Page 10

BFL (DS1).................................................... ...... .........................................2-4

CPU (DS2)..................................................................................................2-4

PMC2 (DS3)................................................................................................2-4

PMC1 (DS4)................................................................................................2-4

10/100 BASET Port............................................................................................2-4

DEBUG Port............................................. ..........................................................2-5

PMC Slots...........................................................................................................2-7

PCI MEZZANINE CARD (PMC Slot 1)....................................................2-7

PCI MEZZANINE CARD (PMC Slot 2)....................................................2-7

PMCspan ...................................................................................................................2-8

CHAPTER 3 Functional Description

Introduction ...............................................................................................................3-1

Features......................................................................................................................3-1

General Description...................................................................................................3-4

Block Diagram...........................................................................................................3-4

MPC750 Processor.............................................................................................3-4

L2 Cache .....................................................................................................3-6

Hawk System Memory Controller (SMC)/PCI Host Bridge (PHB) ASIC........ 3-7

PCI Bus Latency .........................................................................................3-8

PPC Bus Latency.......................................................................................3-10

Assumptions..............................................................................................3-12

Clock Ratios and Operating Frequencies..................................................3-13

PPC60x Originated....................................................................................3-13

PCI Originated ..........................................................................................3-14

SDRAM Memory.............................................................................................3-14

SDRAM Latency.......................................................................................3-15

Flash Memory...................................................................................................3-19

ROM/Flash Performance ..........................................................................3-19

Ethernet Interface.............................................................................................3-22

PCI Mezzanine Card (PMC) Interface............................................................. 3-23

PMC Slot 1 (Single-Width PMC).............................................................3-23

PMC Slot 2 (Single-Width PMC).............................................................3-24

PMC Slots 1 and 2 (Double-Width PMC)................................................3-24

PCI Expansion...........................................................................................3-24

VMEbus Interface ........................................................... .................................3-25

Asynchronous Debug Port................................................................................3-25

PCI-ISA Bridge (PIB) Controller.....................................................................3-26

Real-Time Clock/NVRAM/Timer Function.....................................................3-27

PCI Host Bridge (PHB) ....................................................................................3-27

x

Page 11

Interrupt Controller (MPIC)..............................................................................3-28

Programmable Timers.......................................................................................3-28

Interval Timers ..........................................................................................3-28

16/32-Bit Timers........................................................................................3-29

CHAPTER 4 Programming the MVME240x

Introduction................................................................................................................4-1

Memory Maps.............................................. ........................................ ..... ...... ...........4-1

Processor Bus Memory Map...............................................................................4-2

Default Processor Memory Map..................................................................4-2

PCI Local Bus Memory Map..............................................................................4-3

VMEbus Memory Map.......................................... ...... ..... ..................................4-3

Programming Considerations.....................................................................................4-4

PCI Arbitration ...................................................................................................4-4

Interrupt Handling...............................................................................................4-6

DMA Channels...................................................................................................4-8

Sources of Reset..................................................................................................4-8

Endian Issues....................................................................................................4-10

Processor/Memory Domain....................................... ...... ..........................4-10

PCI Domain...............................................................................................4-10

VMEbus Domain............................................ ...... .....................................4-11

CHAPTER 5 PPCBug

PPCBug Overview.....................................................................................................5-1

PPCBug Basics ..........................................................................................................5-1

Memory Requirements ......................... ..............................................................5-3

PPCBug Implementation....................................................................................5-3

MPU, Hardware, and Firmware Initialization ...........................................................5-3

Using PPCBug ...........................................................................................................5-5

Debugger Commands .........................................................................................5-6

Diagnostic Tests................................................................................................5-10

CHAPTER 6 Modifying the Environment

Overview....................................................................................................................6-1

CNFG - Configure Board Information Block............................................................6-2

ENV - Set Environment.............................................................................................6-3

Configuring the PPCBug Parameters.................................................................6-3

Configuring the VMEbus Interface..................................................................6-13

xi

Page 12

APPENDIX A Ordering Related Documentation

Motorola Computer Group Documents....................................................................A-1

Manufacturers’ Documents......................................................................................A-2

Related Specifications ..............................................................................................A-5

APPENDIX B Specifications

Specifications............................................................................................................B-1

Cooling Requirements..............................................................................................B-3

EMC Regulatory Compliance .................................................................................. B-4

APPENDIX C Connector Pin Assignments

Introduction .............................................................................................................. C-1

Pin Assignments....................................................................................................... C-1

VMEbus Connector - P1 ...................................................................................C-2

VMEbus Connector - P2 ...................................................................................C-4

Serial Port Connector - DEBUG (J2)................................................................ C-6

Ethernet Connector - 10BASET (J3)................................................................. C-6

CPU Debug Connector - J1...............................................................................C-7

PCI Expansion Connector - J6........................................................................C-12

PCI Mezzanine Card Connectors - J11 through J14 ....................................... C-15

PCI Mezzanine Card Connectors - J21 through J24 ........................ ..... .......... C-18

APPENDIX D Troubleshooting the MVME240x

Solving Startup Problems.........................................................................................D-1

Glossary

Abbreviations, Acronyms, and Terms to Know .....................................................GL-1

Index

xii

Page 13

List of Figures

Figure 1-1. MVME240x Switches, LEDs, Headers, Connectors ..............................1-9

Figure 1-2. General-Purpose Software-Readable Header........................................1-11

Figure 1-3. Typical Single-width PMC Module Placement on MVME240x..........1-15

Figure 1-4. PMCspan-002 Installation on an MVME240x .....................................1-17

Figure 1-5. PMCspan-010 Installation onto a PMCspan-002/MVME240x............1-19

Figure 2-1. MVME240x DEBUG Port Configuration ..............................................2-6

Figure 3-1. MVME240x Block Diagram...................................................................3-5

Figure 3-2. Memory Block Diagram .......................................................................3-10

Figure 4-1. VMEbus Master Mapping.......................................................................4-5

Figure 4-2. MVME240x Interrupt Architecture........................................................4-7

xiii

Page 14

xiv

Page 15

List of T ables

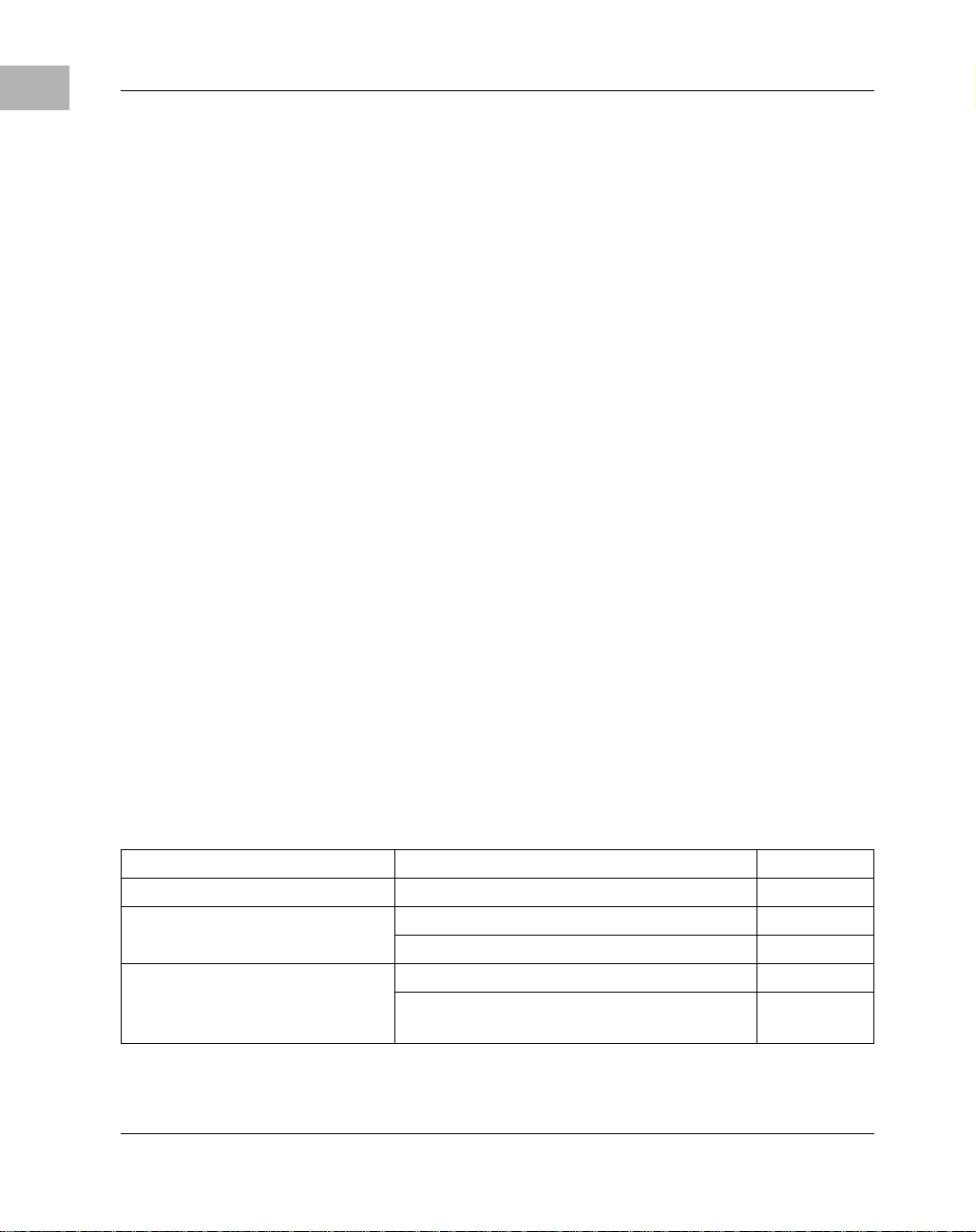

T ab le 1-1. MVME240x Models.................................................................................1-2

T ab le 1-2. PMCspan Models........................ ..............................................................1-3

T ab le 1-3. Start-Up Overview ................................ ...... .............................................1-4

T ab le 3-1. MVME240x Features ................................. ...... .......................................3-1

T ab le 3-2. Power Requirements........................................................... ..... ...... ...........3-6

Table 3-3. PowerPC 60x Bus to PCI Access Timing.................................................3-8

Table 3-4. PCI to ECC Memory Access Timing........................................................3-8

Table 3-1: PowerPC 60x Bus to Dram Access Using 10ns SDRAMs ....................3-11

Table 3-5. PowerPC 60x Bus to FLASH Access Timing for Bank B (16-bit Port).3-14

Table 4-1. Processor Default View of the Memory Map...........................................4-2

T ab le 4-2. PCI Arbitration Assignments........................................ ...... ......................4-6

Table 4-3. Classes of Reset and Effectiveness ..........................................................4-9

T ab le 5-1. Debugger Command s ........................... ...... ...... .......................................5-7

Table 5-2. Diagnostic Test Groups ..........................................................................5-12

Table A-1. Motorola Computer Group Documents................................................. A-1

Table A-2. Manufacturers’ Documents ..................................................................A-2

Table A-3. Related Specifications ..........................................................................A-5

Table B-1. MVME240x Specifications ..................................................................B-1

Table C-1. P1 VMEbus Connector Pin Assignments .............................................C-2

Table C-2. P2 Connector Pin Assignment ..............................................................C-4

Table C-3. DEBUG (J2)Connector Pin Assignments ..............................................C-6

Table C-4. 10/100 BASET (J3) Connector Pin Assignments ..................................C-6

Table C-5. Debug Connector Pin Assignments ......................................................C-7

Table C-6. J18 - PCI Expansion Connector Pin Assignments ..............................C-12

Table C-7. J11 - J12 PMC1 Connector Pin Assignments ......................................C-15

Table C-8. J13 - J14 PMC1 Connector Pin Assignments ......................................C-16

Table C-9. J21 and J22 PMC2 Connector Pin Assignments ..................................C-18

Table C-10. J23 and J24 PMC2 Connector Pin Assignments ................................C-19

Table D-1. Troubleshooting MVME240x Modules ...............................................D-1

xv

Page 16

xvi

Page 17

1Preparing and Installing the

MVME2400-Series Module

Introduction

This chapter provide s a brief description of t he MVME2400-Series VME

Processor Module, and instructions for preparing and installing the

hardware.

In this manual, the name MVME240x refers to all models of the

MVME2400-series boards, unless otherwise specified.

MVME240x Description

The MVME2400-series VM E processor mod ule is a PCI Mezzan ine Card

(PMC) carrier board. It is based on the PowerPC™ 750 microprocessor,

MPC750.

Two front panel cutouts provi de acce ss to PMC I/ O. One doubl e-wid th or

two single-width PMCs can be installed directly on the MVME240x.

Optionally, one or two PMCspan PCI expansion mezzanine modules can

be added to provide the capability of up to four additional PMC modules.

1

Two RJ45 connectors on the front panel provide the interface to

10/100Base-T Ethernet, and to a debug serial port.

The following list is of equipment that is appropriate for use in an

MVME240x system:

❏ PMCspan PCI expansion mezzanine module

❏ Peripheral Component Interconnect (PCI) Mezzanine Cards

(PMC)s

❏ VMEsystem enclosure

❏ System console terminal

❏ Disk drives (and/or other I/O) and controllers

❏ Operating system (and/or application software)

1-1

Page 18

1

Preparing and Installing the MVME2400-Series Module

MVME240x Module

The MVME240x module is a powerful, low-cost embedded VME

controller and i ntelligent PMC carr ier board. The MVME240x is curr ently

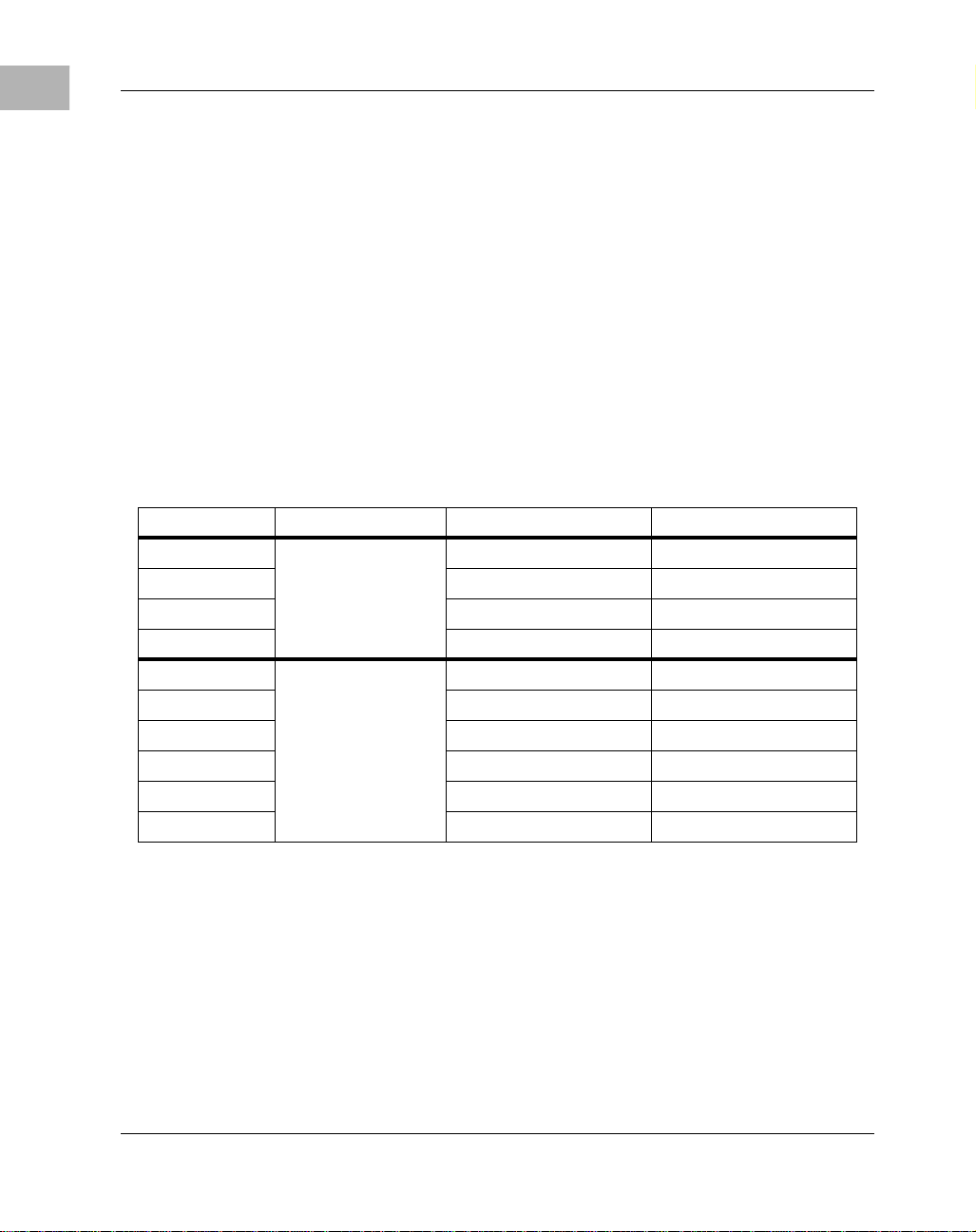

available in the configurations shown in Table 1-1.

The MVME240x includes support circuitry such as ECC SDRAM,

PROM/Flash memory, and bridges to the Industry Standard Architecture

(ISA) bus and the VMEbus. The MVME240x’s PMC carrier architecture

allows flexible configuration options and easy upgrades. It is designed to

support one or two PMCs, plus one or two optional PCI expansion

mezzanine modules that each support up to two PMCs. It oc cupies a single

VMEmodule slot, except when optional PCI expansion mezzanine

modules are also used:

Table 1-1. MVME240x Models

Model MPC Memory Handles

MVME2401-1 MPC750

MVME2401-3 32MB ECC SDRAM 1101 Handles

MVME2402-1 64MB ECC SDRAM Scanbe Handles

MVME2402-3 64MB ECC SDRAM 1101 Handles

MVME2431-1 MPC750

MVME2431-3 32MB ECC SDRAM 1101 Handles

MVME2432-1 64MB ECC SDRAM Scanbe Handles

MVME2432-3 64MB ECC SDRAM 1101-1 Handles

MVME2433-1 128MB ECC SDRAM Scanbe Handles

MVME2433-3 128MB ECC SDRAM 1101-1 Handles

@ 233 MHz

@ 350 MHz

32MB ECC SDRAM Scanbe Handles

32MB ECC SDRAM Scanbe Handles

The MVME240x interfaces t o the VMEbus via th e P1 and P2 connect ors,

which use the new 5-row 160-p in c onne ct ors as specified in the propos ed

VME64 Extension Standard. It also draws +5V, +12V, and -12V power

from the VMEbus backplane through these two con nectors. The +3.3V and

2.5V power, used for the PCI bridge chip and possibly for the PMC

mezzanine, is derived onboard from the +5V power.

1-2 Computer Group Literature Center Web Site

Page 19

Support for two IEEE P1386.1 PCI mezza nine car ds is pro vided vi a eight

64-pin SMT connectors. Front panel openings are provided on the

MVME240x board for the two PMC slots.

In addition, there are 64 pins of I/O from PMC slot 1 and 46 pins of I/O

from PMC slot 2 that are ro uted to P2. The two PMC slo ts may contain two

single-wide PMCs or one double-wide PMC. There are also two RJ45

connectors on the front panel: one for the Ethernet 10BaseT/100BaseTX

interface, and one for the async serial debug port. The front panel also

includes reset and abort switches and status LEDs.

PMCspan Expansion Mezzanine

An optional PCI expansion mezzanine module or PMC carrier board,

PMCspan, provides the capability of adding two additional PMCs. Two

PMCspans can be stacked on an MVME240x, providing four additional

PMC slots, for a total of six slots including the two onboard the

MVME240x. Table 1-2 lists the PMCspan models that are available for

use with the MVME240x.

MVME240x Description

1

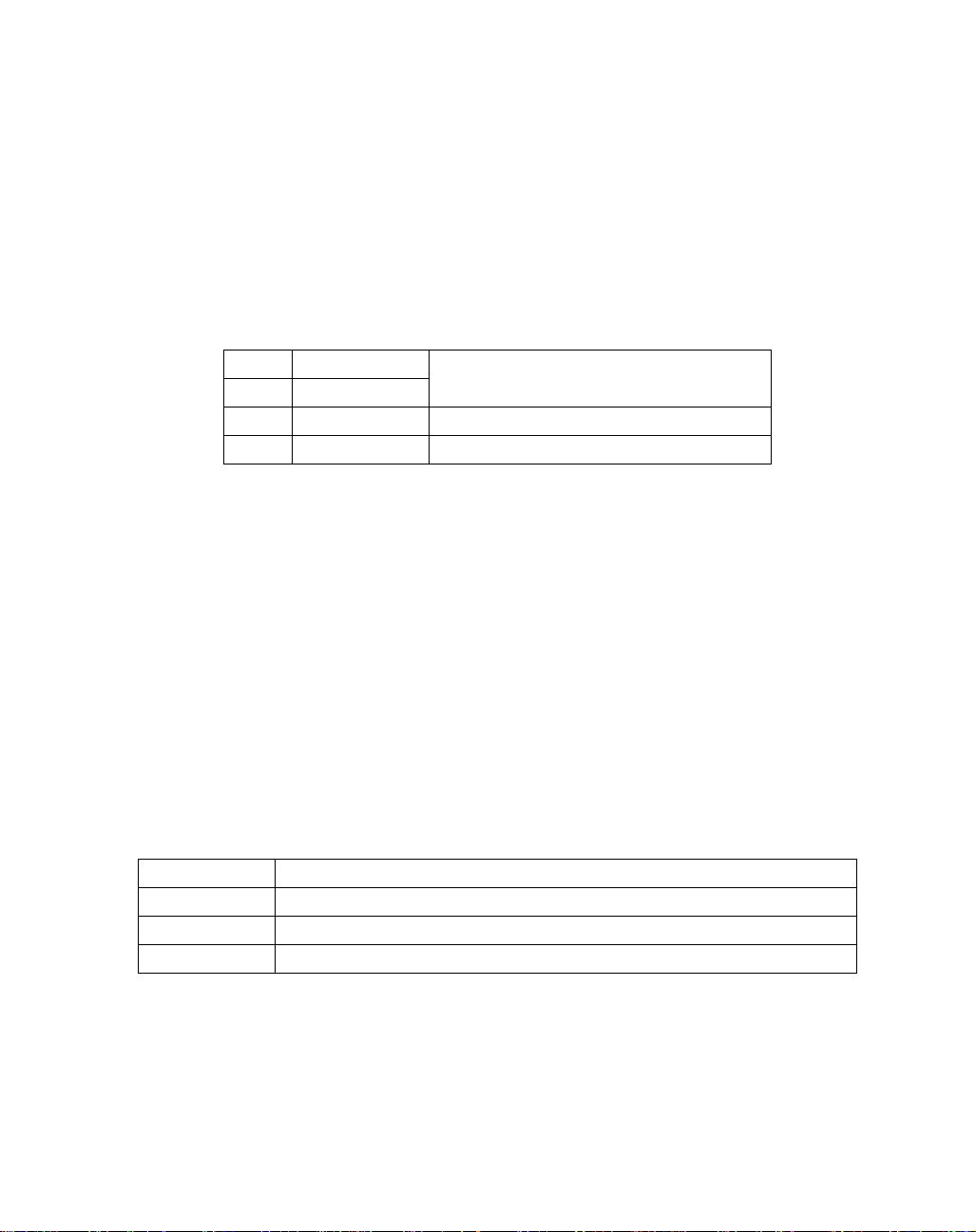

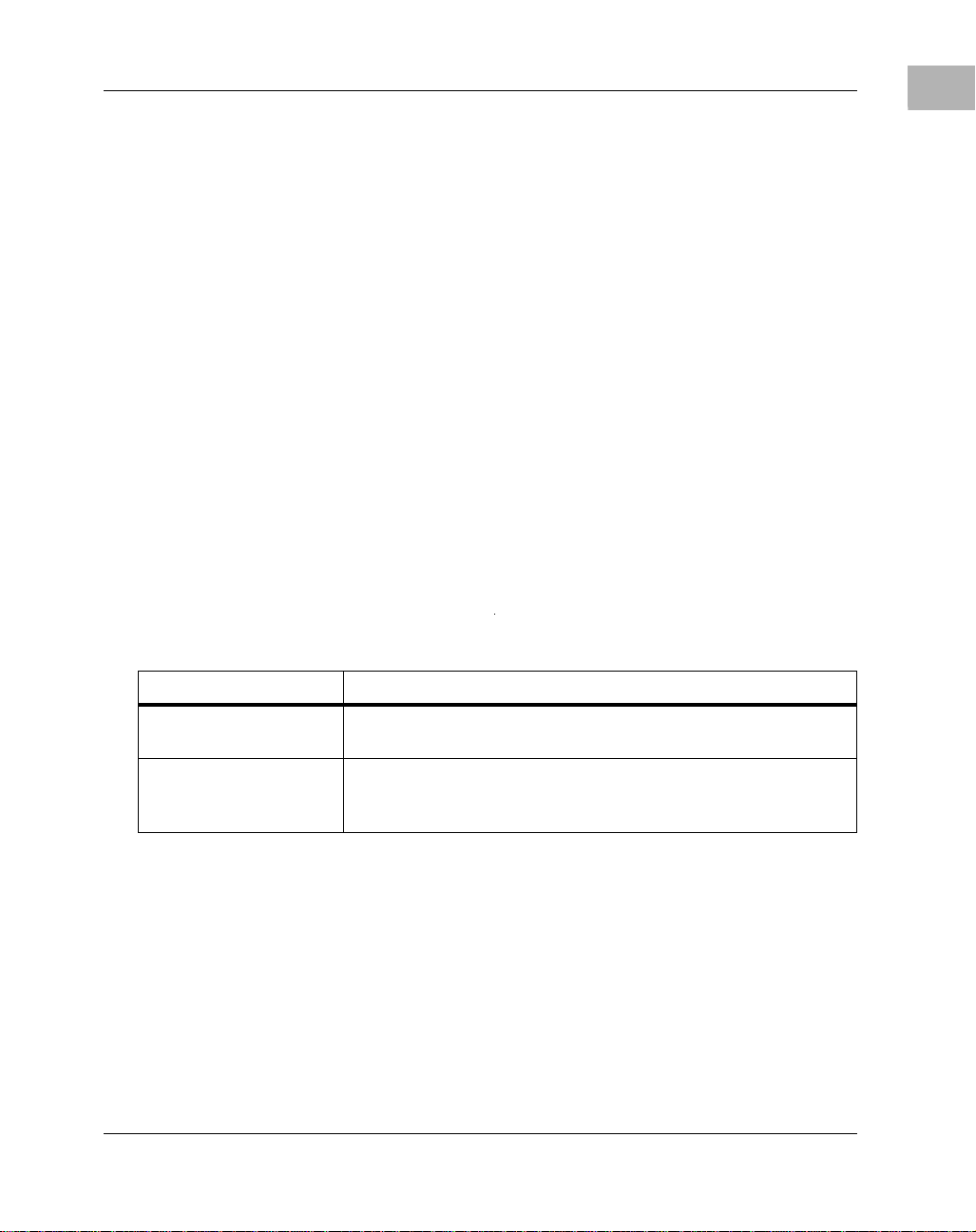

Table 1-2. PMCspan Models

Expansion Module D escript ion

PMCSPAN-002 Primary PCI expansion mezzanine module. Allows two PMC modules

for the MVME240x. Includes 32-bit PCI bridge.

PMCSPAN-010 Secondary PCI expansion mezzanine module. Allows two additional

PMC modules for the MVME240x. Does not include

32-bit PCI bridge; requires a PMCSPAN-002.

PCI Mezzanine Cards (PMCs)

The PMC slots on the MVME240x board are IEEE P1386.1 compliant. P2

I/O-based PMCs that follow the PMC commi ttee recommendat ion for PCI

I/O when using the 5-row VME64 extension connector will be pin-out

compatible with the MVME240x.

http://www.mcg.mot.com/literature 1-3

Page 20

1

Preparing and Installing the MVME2400-Series Module

The MVME240x board supports both front panel I/ O and rear panel P 2 I/O

through either PMC slot 1 o r PMC slot 2. 64 pins o f I/O from slot 1 and 46

pins of I/O from slot 2 are routed directly to P2.

VMEsystem Enclosure

Your MVME240x board must be installed in a VMEsystem chassis with

both P1 and P2 backplane connections. It requires a single slot, except

when PMCspan carrier boards are used. Allow one extra slot for each

PMCspan.

System Console Terminal

In normal operation, connection of a debug console terminal is required

only if you intend to use the MVME240x’s debug firmware, PPCBug,

interactively. An RJ45 connector is provided on the front panel of the

MVME240x for this purpose.

Overview of Start-Up Procedures

The following table li sts the th ings you will need to do bef ore you can use

this board, and tells where to find the information you need to perform

each step. Be sure to read this entire chapter and read all Caution and

What you need to do ... Refer to ... On page ...

Unpack the hardware. Unpacking the MVME240x Hardware 1-7

Set jumpers on the MVME240x

module.

Prepare the PMCs. PMCs 1-13

1-4 Computer Group Literature Center Web Site

Warning notes before beginning.

Table 1-3. Start-Up Overview

Preparing the MVME240x Hardware 1-7

MVME240x 1-7

For additional information on PMCs, refe r to

the PMC manuals provided with these cards.

Page 21

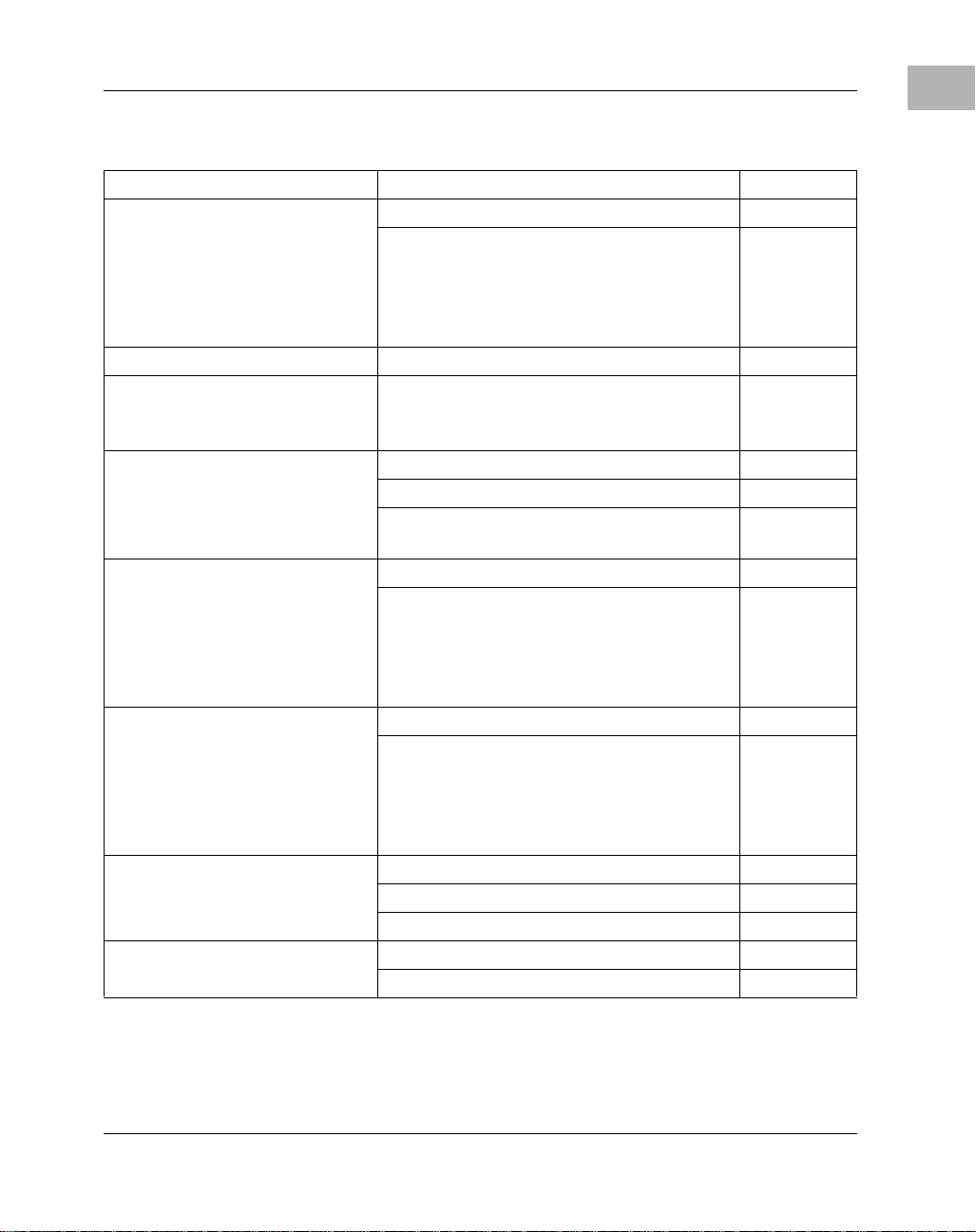

Overview of Start-Up Procedures

Table 1-3. Start-Up Overview (Continued)

What you need to do ... Refer to ... On page ...

Prepare the PMCspan module(s). PMCspan 1-12

For additional information on PMCspan,

refer to the PMCspan PMC Adapter Carrier

Module Installation and Use manual, listed

in Appendix A, Ordering Related

Documentation.

Prepare a console terminal. System Console Terminal 1-12

Prepare any other optional

devices or equipment you will b e

using.

Install the PMCs on the

MVME240x module.

Install the primary PMCspan

module (if used).

Install the secondary PMCspan

module (if used).

Install and connect the

MVME240x module.

Connect a console terminal. MVME240x 1-21

For more information on optional devices

and equipment, refer to the documentation

provided with that equipmen t.

PMCs 1-13

PMC Slots 2-7

For additional information on PMCs, refe r to

the PMC manuals provided with these cards.

Primary PMCspan 1-16

For additional information on PMCspan,

refer to the PMCspan PMC Adapter Carrier

Module Installation and Use manual, listed

in Appendix A, Ordering Related

Documentation.

Secondary PMCspan 1-18

For additional information on PMCspan,

refer to the PMCspan PMC Adapter Carrier

Module Installation and Use manual, listed

in Appendix A, Ordering Related

Documentation.

Installing the MVME240x Hardware 1-13

MVME240x 1-21

Installation Considerations 1-23

Debug Port 2-5

A-1

A-1

A-1

1

http://www.mcg.mot.com/literature 1-5

Page 22

1

Preparing and Installing the MVME2400-Series Module

Table 1-3. Start-Up Overview (Continued)

What you need to do ... Refer to ... On page ...

Connect any other optional

devices or equipment you will b e

using.

Power up the system. Installing the MVME240x Hardware 1-13

Examine the environmental

parameters and make any

changes needed.

Program the MVME240x module

and PMCs as needed for your

applications.

Connector Pin Assignments C-1

For more information on optional devices

and equipment, refer to the documentation

provided with that equipment.

Status Indicators 2-4

If any problems occur, refer to the section

Diagnostic Tests in Chapter 5, PPCBug.

You may also wish to obtain the PPCBug

Diagnostics Manual, listed in Appendix A,

Ordering Related Documentation.

ENV - Set Environment 6-3

You may also wish to obtain the PPCBug

Firmware Package User’s Manual, listed in

Appendix A, Ordering Related

Documentation.

Preparing the MVME240x Hardware 1-7

Programming the MVME240x 4-1

For additional information on PMCs, refe r to

thePMC manuals provided with these cards.

You may also wish to obtain the

MVME2400-Series VME Processor Module

Programmer’s Reference Guide, listed in

Appendix A, Ordering Related

Documentation.

5-10

A-1

A-1

A-1

1-6 Computer Group Literature Center Web Site

Page 23

Unpacking the MVME240x Hardware

Unpacking the MVME240x Hardware

Note If the shipping carton(s) is/are damaged upon receipt, requ est

that the carrier’s agent be present during the unpacking and

inspection of the equipment.

Unpack the equipment from the shipping carton(s). Refer to the packing

list(s) and verify that all items are pres ent. Save the p acking mater ial for

storing and reshipping of equipment.

Avoid touching areas of integrated circuitry; static discharge

!

Caution

can damage these circuits.

Preparing the MVME240x Hardware

1

To produce the desired configuration and ensure proper operation of the

MVME240x, you may need to carry out certain modi fi cat i ons be fore and

after installing the modules.

The following paragraphs discuss the preparation of the MVME240x

hardware components prior to installing them into a chassis and

connecting them.

MVME240

http://www.mcg.mot.com/literature 1-7

x

The MVME240x provides software control over most options; by setting

bits in control registers after installing the MVME24 0x in a system, you

can modify its configurati on. The MVME240x control registe rs are briefly

described in Chapter 4, with additional information in the MVME2400-

Series VME Processor Module Programme r’s Reference Guide as listed in

the table Motorola Computer Group Documents in Appendix A, Order ing

Related Documents.

Page 24

1

Preparing and Installing the MVME2400-Series Module

Some options, however, are not sof tware-programmabl e. Such options are

controlled through manual installation or removal of header jumpers or

interface modules on the MVME240x or the associated modules.

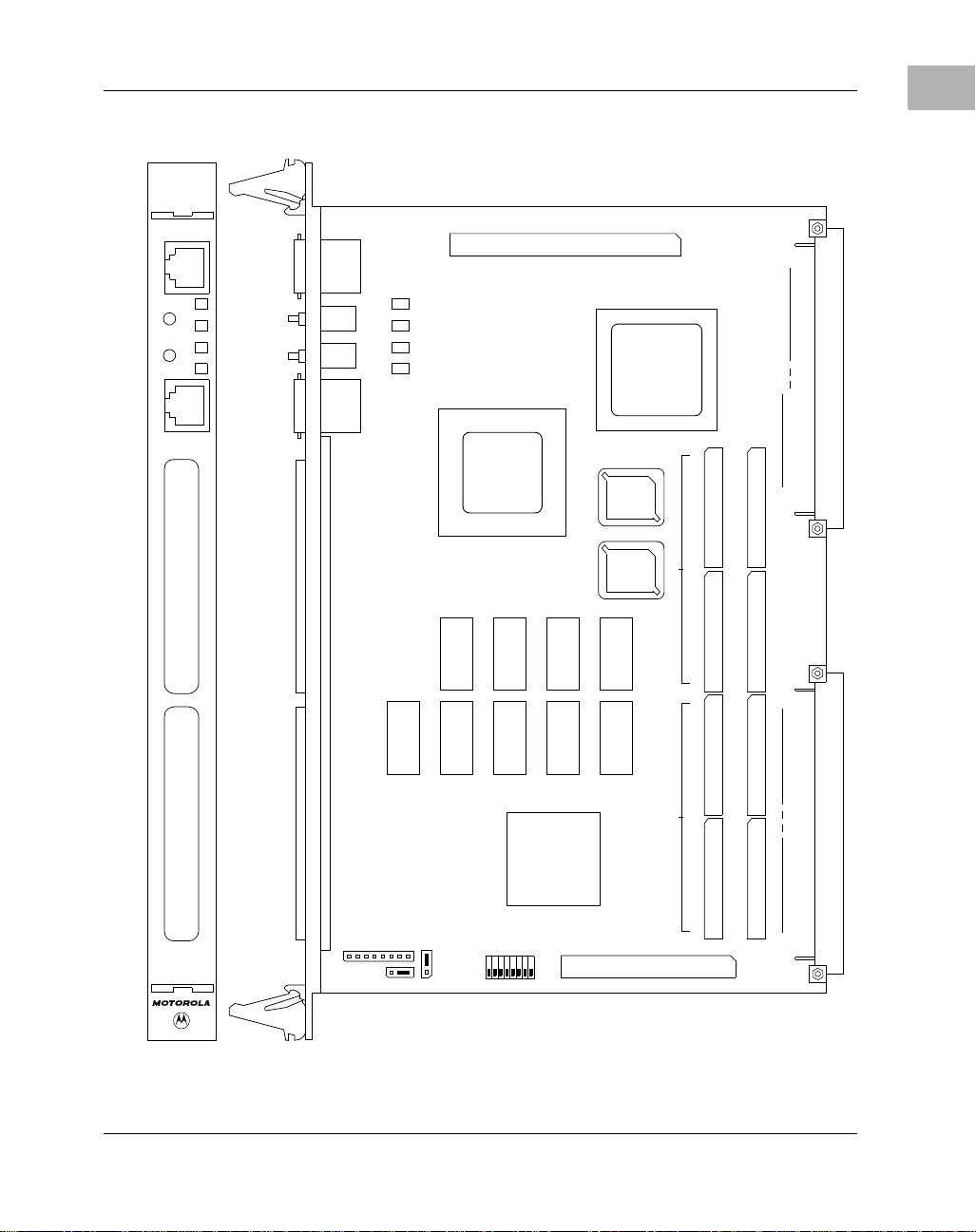

Figure 1-1 illustrates the placement of the switches, jumper headers,

connectors, and LED indicators on the MVME240x. Manually

configurable items on the MVME240x include:

❏ Flash memory bank A/bank B reset vector (J8)

❏ VMEbus system controller selection header (J9)

❏ General-purpose software-readable header (S3)

The MVME240x has been factory tested and is shipped with the

configurations described in the following sections. The MVME240x

factory-installed debug monitor, PPCBug, operates with those factory

settings.

1-8 Computer Group Literature Center Web Site

Page 25

DEBUG

MVME

240X

Preparing the MVME240x Hardware

1

189 190

DEBUG

PORT

J2

J1

12

A1B1C1

D1

ABT

RST

10/100 BASET

PCI MEZZANINE CARD PCI MEZZANINE CARD

BFL

CPU

PMC

ABORT

RESET

ETHERNET

PORT

U19

DS

1

DS

2

DS

3

DS

4

U9

FLASH SOCKETS

U22U17

U21U16

U20U15

U25

U23U18

U10

1

1

264

XU1 XU2

PMC 2 PMC1

63

1

63

1

63

1

J22

J21

63

1

264

J24

J23

63

1

264

J12

J11

63

1

264

J14

J13

P1

264

A32

B32

C32

264

A1B1C1

264

VME BUS

P2

264

SWITCH

S1 S2

SWITCH

J3

63

J5

1

2427 9812

3

8

J9

3

1

J8

S3

1

1 2 3 4 5 6 7 8

113 114

63

J6

12

D32D1D32

C32

B32

A32

Figure 1-1. MVME240x Switches, LEDs, Headers, Connectors

http://www.mcg.mot.com/literature 1-9

Page 26

1

Preparing and Installing the MVME2400-Series Module

Setting the Flash Memory Bank A/Bank B Reset Vector Header (J8)

Bank B consists of 1 MB of 8-bit Flash memory in two 32-pin PLCC 8-bi t

sockets.

Bank A consists of four 16-bit devices that are populated with 16Mbit

Flash devices (8 MB). A j umper header, J8, associ ated with the f irst set of

four Flash devices provides a total of 64KB of hardware-protected boot

block. Only 32-bit wri tes are sup ported for thi s bank of Fla sh. The address

of the reset vector is jumper-selectable. A jumper must be inst al le d ei the r

between J8 pins 1 and 2 for Bank A factory configuration, or between J8

pins 2 and 3 for Bank B. When the jumper is installed, the SMC (System

Memory Controller) of the Hawk ASIC maps 0xFFF00100 to the Bank B

sockets..

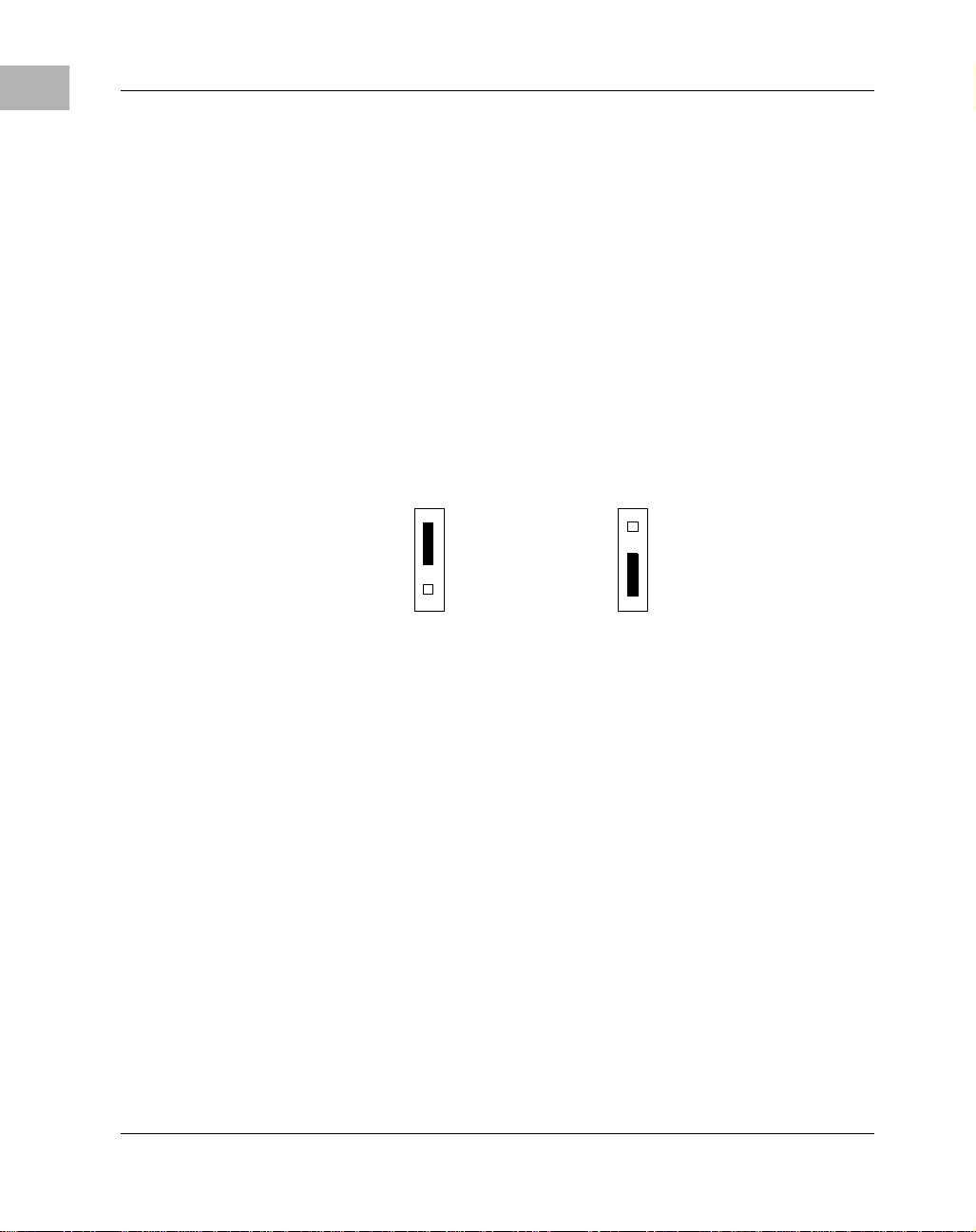

J8

1

2

3

Bank A (factory configuration)

J8

1

2

3

Bank B

Setting the VMEbus System Controller Selection Header (J9)

The MVME240x is factory-configured in automatic sy stem controller

mode; i.e., a jumper is installed across pins 2 and 3 of header J9. This

means that the MVME240x determi nes if it is system co ntr oller at sys tem

power-up or reset by its position on the bus; if it is in slot 1 on the VME

system, it configures itself as the system controller.

Remove the jumper from J9 if you intend to operate the MVME240x as

system controller in all cases.

Install the jumper across pins 1 and 2 if the MVME240x is not to operate

as system controller under any circumstances.

1-10 Computer Group Literature Center Web Site

Page 27

Preparing the MVME240x Hardware

1

J9

1

2

3

Automatic System Controller

(factory configuration)

System Controller Enabled

J9

1

2

3

System Controller Disabled

J9

1

2

3

Setting the General-Purpose Software-Readable Header (SRH) Switch(S3)

Switch S3 is an eight pole single-throw switch with softwa re readable

switch settings. These settings can be read as a register at ISA I/O address

$801 (hexadecimal). Each switch pole can be set to either logic 0 or l ogic

1. A logic 0 means th e switch is in the “ON” position for that particula r bit.

A logic 1 means the switch is i n the “OFF” positi on for t hat par ticu lar bit.

SRH Register Bit 0 is associated with Pin 1 and Pin 16 of the SRH, and

SRH Register Bit 7 i s associated with Pin 8 and Pin 9 of the SRH. The SRH

is a read-only register.

If Motorola’s PowerPC firmware, PPCBug, is being used, it reserves all

bits, SRH0 to SRH7. If it is not being used, the switch can be used for other

applications.

1

12345678

16 16

ON ON

SRH0 = 0

SRH1 = 0

SRH2 = 0

SRH3 = 0

SRH4 = 0

SRH5 = 0

SRH6 = 0

SRH7 = 0

1

12345678

SRH0 = 1

SRH1 = 1

SRH2 = 1

SRH3 = 1

SRH4 = 1

SRH5 = 1

SRH6 = 1

SRH7 = 1

Figure 1-2. General-Purpose Software-Readable Header

http://www.mcg.mot.com/literature 1-11

Page 28

1

Preparing and Installing the MVME2400-Series Module

PMCs

For a discussion of any configurable it ems on the PMCs, refer to the user’s

manual for the particular PMCs.

PMCspan

You will need to use an additional slot in the VME chassis for each

PMCspan expansion module you plan to us e. Before installing a PMCspan

on the MVME240x, you must install t he selecte d PMCs on the PMCspan.

Refer to the PMCspan PMCAdapter Carrier Module Instllation and Use

manual for instructions.

System Console Terminal

Ensure that the switc hes are set in the proper positi on for all bits on switch

S3 of the MVME240x board as shown in Figure 1-2. This is necessary

when the PPCBug firmware is used. Connect the ter minal via a cable to th e

RJ45 DEBUG connector J2. See Table C- 3 for pin sign al assignment s. Set

up the terminal as follows:

– Eight bits per character

– One stop bit per character

– Parity disabled (no parity)

– Baud rate = 9600 baud (default baud rate of the port at power-

up); after power-up, you can reconfigure the baud rate with

PPCBug’s PF command

1-12 Computer Group Literature Center Web Site

Page 29

Installing the MVME240x Hardware

Installing the MVME240x Hardware

The following paragraphs discuss installing PMCs onto the MVME240x,

installing PMCspan modules onto the MVME240x, installing the

MVME240x into a VME chassis, and connecting an optional system

console terminal.

ESD Precautions

Motorola strongly recommends that you use an a ntistatic wrist stra p and a

conductive foam pad when installing or upgrading a system. Electronic

components, such as d isk dr ives, c omputer boards , and memor y modules ,

can be extremely sensitive to Electro-Static Discharge (ESD). After

removing the component fr om th e system or its protective wrapper, place

the component flat o n a grounded, static-free surface (and in the case of a

board, component side up). Do not slide the component over any surface.

If an ESD station is not available, you can avoid damage resulting from

ESD by wearing an antistatic wrist strap (available at electronics stores)

that is attached to an unpainted metal part of the system chassis.

1

PMCs

PCI mezzanine card (PMC) modules mount on top of the MVME240x

module, and/or on a PMCspan. Refer to Figure 1-3 and perform the

following steps to install a PMC on your MVME240x module. This

procedure assumes that you have read the user’s manual that came with

your PMCs.

1. Attach an ESD strap to your wrist . Attach the othe r end of t he ESD

strap to the chassis as a ground. The ESD strap must be secured to

your wrist and to ground throughout the procedure.

2. Perform an operating system shutdown. Turn the AC or DC power

off and remove the AC cord or DC power lines from the system.

Remove chassis or system cover(s) as necessary for access to the

VMEmodules.

http://www.mcg.mot.com/literature 1-13

Page 30

1

Preparing and Installing the MVME2400-Series Module

Inserting or removin g modules with power applied may re sult

!

Caution

!

Warning

!

Caution

in damage to module components.

Dangerous voltages, capable of causing death, are present in

this equipment. Use extreme caution when handling, testing,

and adjusting.

3. If the MVME240x has a lready been installed i n a VMEbus card slot,

carefully remove it. Lay the MVME240x flat, with connectors P1

and P2 facing you.

Avoid touching areas of integrated circuitry; static discharge

can damage these circuits.

4. Remove the PCI filler plate from the selec ted PM C slot in t he fron t

panel of the MVME240x. If inst alling a double-width PMC, remove

the filler plates from b oth PMC slots.

1-14 Computer Group Literature Center Web Site

Page 31

Installing the MVME240x Hardware

2064 9708

1

Figure 1-3. Typical Single-width PMC Module Placement on MVME240x

5. Slide the edge connect or(s) of t he PMC module into t he front pane l

opening(s) from behind and place the PMC module on top of the

MVME240x. The four connectors on the underside of the PMC

module should then connect smoothly with the corresponding

connectors for a single-width PMC (J11/J12/J13/J14 or

J21/J22/J23/J24, all eight for a double-width PMC) on the

MVME240x.

6. Insert the two shor t Phillips scr ews through the hol es at the forwa rd

corners of the PMC module, i nto t he st andoff s on t he MVME240x.

Tighten the screws.

7. If installing two si ngle-width PMCs, repeat the above procedure for

the second PMC.

http://www.mcg.mot.com/literature 1-15

Page 32

1

Preparing and Installing the MVME2400-Series Module

Primary PMCspan

To install a PMCspan-002 PCI expansion module on your MVME240x,

refer to Figure 1-4 and perform the following steps. This procedure

assumes that you have read the user’s manual that was furnished with the

PMCspan, and that you have i nstalled the selected PMCs on the PMCspan

according to the instructions given in the PMCspan and PMC manuals.

1. Attach an ESD strap to your wrist . Attach the othe r end of t he ESD

strap to the chassis as a ground. The ESD strap must be secured to

your wrist and to ground while you are performing the installation

procedure.

2. Perform an operating system shutdown. Turn the AC or DC power

off and remove the AC cord or DC power lines from the system.

Remove chassis or system cover(s) as necessary for access to the

VME module card cage.

Inserting or removin g modules with power applied may re sult

!

Caution

in damage to module components.

Dangerous voltages, capable of causing death, are present in

!

Warning

!

Caution

1-16 Computer Group Literature Center Web Site

this equipment. Use extreme caution when handling, testing,

and adjusting.

3. If the MVME240x has already been installed in the chassis,

carefully remove it from the VMEbus card slot and lay it flat, with

connectors P1 and P2 facing you.

Avoid touching areas of integrated circuitry; static discharge

can damage these circuits.

Page 33

P4

Installing the MVME240x Hardware

1

J6

2081 9708

Figure 1-4. PMCspan-002 Installation on an MVME240x

http://www.mcg.mot.com/literature 1-17

Page 34

1

Preparing and Installing the MVME2400-Series Module

4. Attach the four standoffs to the MVME240x module. For each

standoff:

– Insert the threaded end into the standoff hole at each corner of

the VME processor module.

– Thread the locking nuts onto the standoff tips.

– Tighten the nuts with a box- end wrenc h or a pair of needl e nose

pliers.

5. Place the PMCspan on top of the MVME240x module. Align the

mounting holes in each corner to the standoff s, and align PMCspan

connector P4 with MVME240x connector J6.

6. Gently press the PMCs pan an d MVME240 x tog et her , ma kin g sur e

that P4 is fully seated i nto J6.

7. Insert the f our short Phillip s screws t hrough the holes at the c orners

of the PMCspan and into the standoffs on the MVME240x module.

Tighten the screws.

Note The screws have two different head diameters. Use the

screws with the smaller heads on the standoffs next to

VMEbus connectors P1 and P2.

Secondary PMCspan

The PMCspan-010 PCI expansion module mounts on top of a PMCspan002 PCI expansion module. To install a PMCspan-010 on your

MVME240x, refer to Figure 1-5 and perform the following steps. This

procedure assumes that you have re ad the user’s man ual that was f urnished

with the PMCspan, and that you have installed the selected PMCs on the

PMCspan according to the instructions given in the PMCspan and PMC

manuals.

1. Attach an ESD strap to your wrist . Attach the othe r end of t he ESD

strap to the chassis as a ground. The ESD strap must be secured to

your wrist and to ground while you are performing the installation

procedure.

1-18 Computer Group Literature Center Web Site

Page 35

Installing the MVME240x Hardware

P3

1

J3

2065 9708

Figure 1-5. PMCspan-010 Installation onto a PMCspan-002/MVME240x

http://www.mcg.mot.com/literature 1-19

Page 36

1

Preparing and Installing the MVME2400-Series Module

2. Perform an operating system shutdown. Turn the AC or DC power

off and remove the AC cord or DC power lines from the system.

Remove chassis or system cover(s) as necessary for access to the

VME module card cage.

Inserting or removin g modules with power applied may re sult

!

Caution

!

Warning

!

Caution

in damage to module components.

Dangerous voltages, capable of causing death, are present in

this equipment. Use extreme caution when handling, testing,

and adjusting.

3. If the Primary PMC Carrier Module/MVME240x assembly is

already installed in the VME chassis, carefully remove the twoboard assembly fro m the VMEbus card slo ts and lay it fl at, with the

P1 and P2 connectors facing you.

Avoid touching areas of integrated circuitry; static discharge

can damage these circuits.

4. Remove the four short Phillips screws from the standoffs in each

corner of the primary PCI expansion module,

PMCspan-002.

5. Attach the four standoffs to the PMCspan-002.

6. Place the PMCspan-010 on top of the PMCspan-002. Align the

mounting holes in each corner to the standoffs, an d align PMCspan010 connector P3 with PMCspan-002 connector J3.

7. Gently press the two PMCspan modules togethe r, making sur e that

P3 is fully seated in J3.

8. Insert the f our short Phillip s screws t hrough the holes at the c orners

of PMCspan-010 and into the standoffs on the primary PMCspan-

002. Tighten the screws.

Note The screws have two different head diameters. Use the

screws with the smaller heads on the standoffs next to

VMEbus connectors P1 and P2.

1-20 Computer Group Literature Center Web Site

Page 37

Installing the MVME240x Hardware

1

MVME240

!

Caution

!

Warning

x

Before installing the MVME24 0x into your VM E chassis, ensure that the

jumpers on the MVME240x J8, J9, and S3 switch are configur ed, as

previously described. This procedure assumes that you have already

installed the PMCspan( s) if de sired, and any PMCs th at you have selecte d.

Proceed as fo llows to inst all the MVME240x in the VME chassis:

1. Attach an ESD strap to your wrist . Attach the othe r end of t he ESD

strap to the chassis as a ground. The ESD strap must be secured to

your wrist and to ground throughout the procedure.

2. Perform an operating system shutdown:

a. Turn the AC or DC power off and remove the AC cord or DC

power lines from the system.

Inserting or removin g modules with power app lied may result

in damage to module components.

Dangerous voltages, capable of causing death, are present in

this equipment. Use extreme caution when handling, testing,

and adjusting.

b. Remove cha ssis or system cover(s) as necessary for access to t he

VMEmodules.

3. Remove the filler panel from the card slot where you are going to

install the MVME2 40x. If you have inst alled one or more PMCspan

PCI expansion modules onto your MVME240x, you will need to

remove filler panels from one additional card slot for each

PMCspan, above the card slot for the MVME240x.

http://www.mcg.mot.com/literature 1-21

Page 38

1

Preparing and Installing the MVME2400-Series Module

– If you intend to use the MVME240 x as system controller, it must

occupy the leftmost card slot (slot 1). The system controller must

be in slot 1 to correctly in it iat e the bus-grant daisy-chain and to

ensure proper operation of the IACK daisy-chain driver.

– If you do not intend to use the MVME240x a s system contr oller,

it can occupy any unused card slot.

Avoid touching areas of integrated circuitry; static discharge

!

Caution

can damage these circuits.

4. Slide the MVME24 0x (and PMCspans if used) into the selected card

slot(s). Be sure t he m odule or modules is/ are seated properly in the

P1 and P2 connectors on the backplane. Do not damage or bend

connector pins.

5. Secure the MVME240x (and PMCspans i f used) i n the cha ssis wit h

the screws provided, making good contact with the transverse

mounting rails to minimize RF emissions.

Note Some VME backplanes (e.g., those used in Motorola

“Modular Chassis” syst ems) have a n auto-j umpering fe ature

for automatic propag ation of the IACK and BG s ignals. Step

6 does not apply to such backplane designs.

6. On the chassis backplane, remove the

(IACK) and

slot occupied by the MVME240x.

7. If you intend to use PPCBug interacti vely, connect the termin al that

is to be used as the PPCBug system console to the

the front panel of the MVME240x.

In normal operation the host CPU controls MVME240x operation

via the VME bus Universe registers.

1-22 Computer Group Literature Center Web Site

BUS GRANT (BG) jumpers from the header for t he card

INTERRUPT ACKNOWLEDGE

DEBUG port on

Page 39

Installing the MVME240x Hardware

8. Replace the chassis or system cover(s), cable peripherals to the

panel connectors as a ppr opriate, reconnect the s yst em t o the AC or

DC power source, and turn the equipment power on.

1

9. The MVME240x’s green

confidence tests is run, and the debugger prompt

appears.

Installation Considerations

The MVME240x draws power from the VMEbus backpla ne connectors P1

and P2. P2 is also used for the upper 16 bits o f data in 3 2-bit tr ansfers , and

for the upper 8 address lines in extended addressing mode. The

MVME240x may not function properl y wi tho ut its main board connected

to VMEbus backplane connectors P1 and P2.

Whether the MVME240x operates as a VMEbus master or as a VMEbus

slave, it is c onfigured for 3 2 bits of addr ess and 32 bits of dat a (A32/D3 2).

However, it handles A1 6 or A24 devi ces in the address ran ges indicat ed in

Chapter 4. D8 and/or D16 devices in the system must be handled by the

PowerPC processor software. Refer to the memory maps in Chapter 4.

The MVME240x contains shared onboard DRAM whose base address is

software-selectable. Both the onboard processor and off-board VMEbus

devices see this local DRAM at base physical address $00000000, as

programmed by the PPCBug fi rmware. This may be ch anged v ia software

to any other base address. Refer to the MVME240x programmer's

reference guide for more information.

If the MVME240 x tries to access off-board resources in a nonexistent

location and is not system controller, and if the system does not have a

global bus timeout, the MVME240x waits forever for the VMEbus cycle

to complete. This will cause the system to lock up. There is only one

situation in which th e syste m might lack th is gl obal bus timeou t: when t he

MVME240x is not the system cont roller and ther e is no global bus timeout

elsewhere in the system.

Multiple MVME240x boards may be installed in a single VME chassis.

Each must have a unique Universe address, selected by setting jumper s on

its J17 header, as described in Preparing the MVME240x. In general,

hardware multiprocessor features are supported.

CPU LED indicates activity as a set of

PPC1-Bug>

http://www.mcg.mot.com/literature 1-23

Page 40

1

Preparing and Installing the MVME2400-Series Module

Other MPUs on the VMEbus can interrupt, disable, communicate with,

and determine the opera tional status of the proc essor(s). One registe r of the

Universe set incl udes four bits that function as location monitors to all ow

one MVME240x processor to broadcast a sign al to any other MVM E240x

processors. All eight registers are accessible from any local processor as

well as from the V MEbus.

1-24 Computer Group Literature Center Web Site

Page 41

2Operating Instructions

Introduction

This chapter provides information about powering up the MVME240x

system, and functionality of the switches, status indicators, and I/O ports

on the front panels of the MVME240x and PMCspan modules.

Applying Power

After you have verified that all necessary hardware preparation has been

done, that all connections have been made correctly, and that the

installation is complete, you can power up the system. The MPU,

hardware, and firm ware initializa tion process is perf ormed by the PPCBug

firmware power-up or system reset. The fi rmware initializes t he devices on

the MVME240x module in preparation for booting the operating system.

The firmware is shipped from the factory with an appropriate set of

defaults. In most cases the re is no need to modify the firmware

configuration bef ore you boot the opera ting syste m. Refer to Chapter 6 f or

further information about modifying defaults.

2

The following flowchart shows the basic initialization process that takes

place during MVME240x system start-ups.

For further information on PPCbug, refer to Chapter 5, PPCBug; to

Appendix D, Troubleshooting the MVME240x; or to the PPCBug

documentation listed in Appendix A.

2-1

Page 42

Operating Instructions

2

STARTUP

INITIALIZATION

POST

BOOTING

MONITOR

Power-up/reset initialization

Initialize devices on the MVME240x

module/system

Power On Self Test diagnostics

Firmware-configured boot mechanism,

if so configured. Default is no boot.

Interactive, command-driven on-line PowerPC

debugger, when terminal connected.

MVME240

x

The front panel of the MVME240x module is shown on a following page.

Switches

There are two switches (ABT and RST) and four LED (l ight-emitting diode)

status indicators (

panel.

2-2 Computer Group Literature Center Web Site

BFL, CPU, PMC (two)) located on the MVME240x front

Page 43

MVME240x

ABT (S1)

RST (S2)

When activated by software, the Abort switch,

ABT, can generate an

interrupt signal from the base board to the processor at a userprogrammable level. The interrupt is normally used to abort program

execution and return control to the debugger firmware located in the

MVME240x Flash memory. The interrupt signal reaches the processor

module via ISA bus interrup t line IRQ8

∗. The signal is also available from

the general purpose I/O port, which allows software to pol l the Abort switch after

an IRQ8* interrupt and verify that it has been pressed.

The interrupter connect ed to the

ABT switch is an edge-sensitive circuit,

filtered to remove switch bounce.

The Reset switch,

be asserted in the MPC603 or MPC604. It also drives a

RST, resets all onboard devices and cau ses HRESET* to

SYSRESET*

signal if the MVME240x VME proce ssor modu le i s the syst em co ntroller .

The Universe ASIC includes bot h a global and a loca l rese t drive r. When

the Universe operates as the VMEbus system controller, the reset driver

provides a global system reset by asserting the VMEbus signal

SYSRESET*. A SYSRESET* signal may be generated by the RESET

switch, a power-up reset, a watchdog timeout, or by a control bit in the

Miscellaneous Control Register (MISC_CTL) in the Universe ASIC.

SYSRESET* remains asserted for at least 200 ms, as required by the

VMEbus specification.

2

Similarly, the Universe ASIC sup pli es an inpu t si gnal and a control bit to

initiate a local reset oper ation. By sett ing a control bit, software can

maintain a board in a reset state, disabling a faulty board from participating

in normal system operation. The local reset driver is enabled even when

the Universe ASIC i s not syst em controll er. Local rese ts may be g enerated

by the

RST switch, a power-up reset, a watchdog timeout, a VMEbus

SYSRESET*, or a control bit in the MISC_CTL register.

http://www.mcg.mot.com/literature 2-3

Page 44

Operating Instructions

2

Status Indicators

There are four LED (light-emitting diode) status

indicators located on the MVME240x front panel.:

CPU

, PMC2, and PMC1.

BFL (DS1)

The yellow

the BRDFAIL* signal line is active.

BFL,

BFL LED indicates board f ai lu re; l ig hts whe n

MVME

DEBUG

ABT

RST

10/100 BASET

240x

BFL

CPU

PMC

CPU (DS2)

The green

CPU LED indicates CPU activity; lights when

the DBB* (Data Bus Busy) signal line on the processor

bus is active.

PMC2 (DS3)

The top green

PMC LED indicates PCI activity; lights

PCI MEZZANINE CARD PCI MEZZANINE CARD

when the PCI bus grant to PMC2 signal line on the PCI

bus is active. This ind icates that a PMC installed on slot 2

is active.

PMC1 (DS4)

The bottom green

PMC LED indicates PCI activity; lights

when the PCI bus grant to PMC1 signal line on the PCI

bus is active. This ind icates that a PMC installed on slot 1

is active.

10/100 BASET Port

The RJ45 port on the front panel of the MVME240x

labeled

10BaseT/100Base TX interf ace, implemented with a DEC

21140/21143 device.

2-4 Computer Group Literature Center Web Site

10/100 BASET supplies the Ethernet LAN

Page 45

MVME240x

DEBUG Port

The RJ45 port labeled DEBUG on the front panel of the MVME240x

supplies the MVME240x serial communications interface, implemented

via a UART PC16550 controller chip from National Semiconductor. It is

asynchronous only. This se ri al port is configured for EIA-232- D DT E, as

shown in Figure 2-1.

The

to serve as the firmware console for the factory installed debugger,

PPCBug. The port is configured as follows:

After power-up, the baud rate of the

using the debugger’s Port Format (PF) command . Refer to Chapters 5 and

6 for information about PPCBug.

2

DEBUG port may be used for connect ing a terminal to the MVME2 40x

❏ 8 bits per character

❏ 1 stop bit per character

❏ Parity disabled (no parity)

❏ Baud rate = 9600 baud (default baud rate at power-up)

DEBUG port can be reconfigured by

http://www.mcg.mot.com/literature 2-5

Page 46

Operating Instructions

2

SOUT

RTS*

DTR*

SIN

CTS*

DCD*

PC16550

MVME240x

4

2

8

5

7

1

3

6

Debug

RJ45

Figure 2-1. MVME240x DEBUG Port Configuration

2-6 Computer Group Literature Center Web Site

Page 47

MVME240x

PMC Slots

Two openings located on the front panel provide I/O

expansion by allowing access to one or two 4-port singlewide or one 8-port double-wide PCI Mezzanine Card

(PMC), connected to the PMC connectors on the

MVME240x. For pin assignments f or the PMC connect ors,

refer to Appendix C.

Do not attempt to instal l any PMC boards without performing

!

Warning

PCI MEZZANINE CARD (PMC Slot 1)

an operating system shutdown and following the procedures

given in the user’s manual for the particular PMC.

The right-most (lower) opening labeled

CARD on the MVME240x front panel provides front panel

I/O access to a PMC that is connected to the 64-pin

connectors J11 through J14 on the MVME240x module.

Connector J14 allows rear panel P2 I/O.

This slot is MVME240x Port 1.

PCI MEZZANINE

2

PMC2

PMC1

PCI MEZZANINE CARD PCI MEZZANINE CARD

PCI MEZZANINE CARD (PMC Slot 2)

The left-most (upper)opening labeled

CARD

on the MVME240x front panel prov ides front panel

PCI MEZZANINE

I/O access to a PMC that is connected to the 64-pin

connectors J21 through J24 on the MVME240x module.

Connector J24 allows rear panel P2 I/O.

This slot is MVME240x Port 2.

http://www.mcg.mot.com/literature 2-7

Page 48

Operating Instructions

2

PMCspan

A PMCspan front panel is pictured on the previous page. The front panel

is the same for all PMCspan models.

There are two PMC slots, labeled

either two single-wide PMCs or one double-wide PMC.

The PMCspan board has two sets of three 32-bit connectors for PMC

interface to a secondary PCI bus and a user-specific I/O. It also has a P1

connector and a 5-row P2 connector for power and VMEbus I/O.

The PMCspan has two green LEDs on its front panel, one for each PMC

slot, labeled

individual LED is illuminated whenever a PMC has been granted bus

mastership of the secondary PCI bus.

The right-most (l ower) opening l abeled

panel is Port 1.

The left-most (upper)opening labeled

panel is Port 2.

PCI MEZZANINE CARD, which support

PMC2 and PMC1. Both LEDs are illuminated du ring rese t. An

PCI MEZZANINE CARD on the front

PCI MEZZANINE CARD on the front

2-8 Computer Group Literature Center Web Site

Page 49

3Functional Description

Introduction

This chapter descr ibes the MVME240x VME process or module on a block

diagram level. The General Description provides an overview of the

MVME240x, followed by a detailed description of several blocks of

circuitry. Figure 3-1 shows a block diagram of the overall board

architecture.

Detailed descriptions of other MVME240x blocks, including

programmable registe rs in the ASICs and peripheral c hips, can be f ound in

the MVME2400-Series VME Processor Module Programmer’s Reference

Guide (part number V2400A/PG). Refer to it for a functional description

of the MVME240x in greater depth.

Features

3

The following table summarizes the features of the MVME240x VME

processor module.

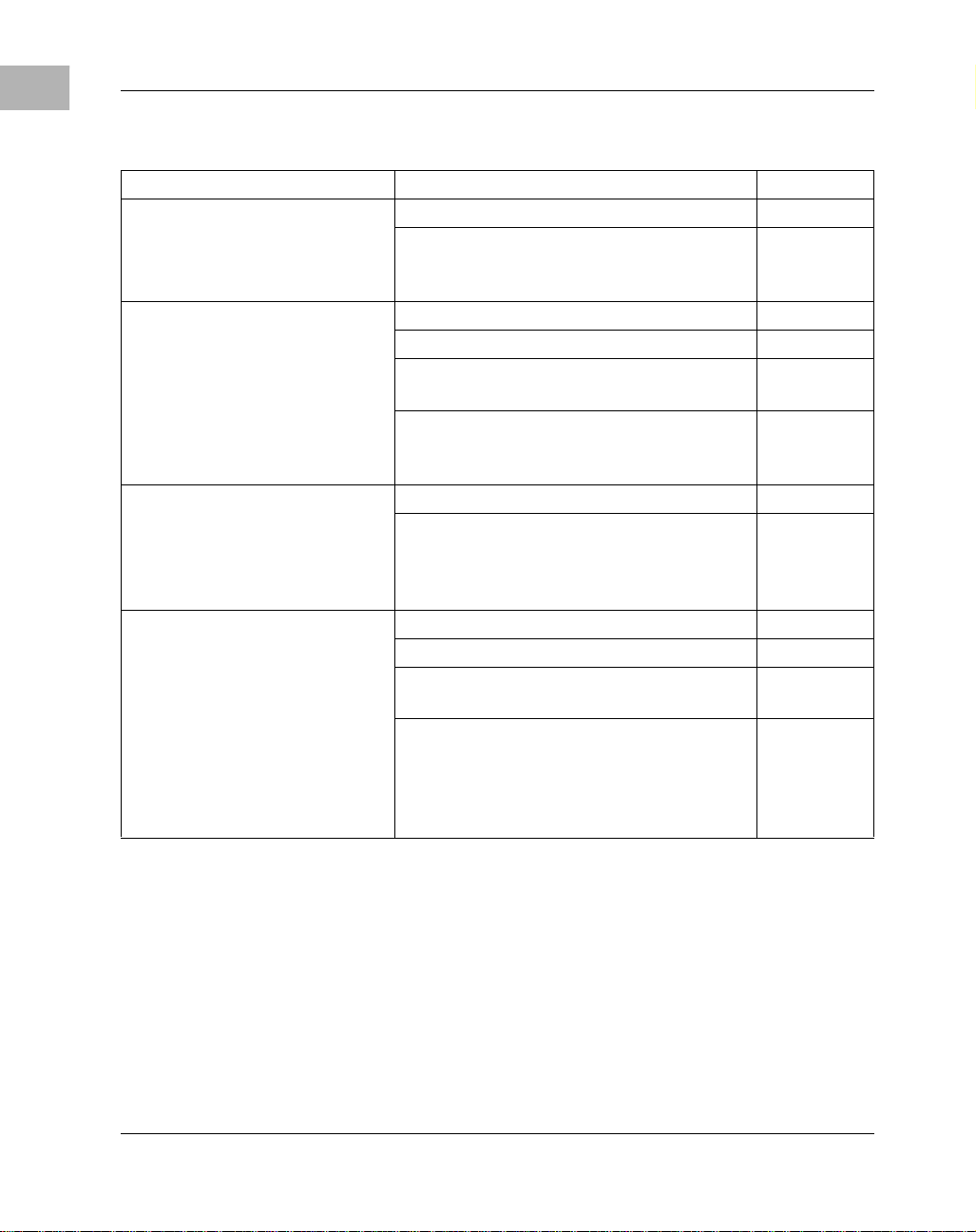

Table 3-1. MVME240x Features

Feature Description

233 MHZ MPC750 PowerPC

Microprocessor

Form factor 6U VMEbus

SDRAM

L2 Cache

(MVME2401 - 2402 models)

350 MHZ MPC750 PowerPC

(MVME2431 - 2434 models)

Double-Bit-Error detect, Single-Bit-Error correct across 72 bits 32MB,

64MB, or 128MB SDRAM

Build-option for 1MB back side L2 Cache using l ate write or burstmode SRAMS

TM

processor

TM

processor

3-1

Page 50

Functional Descr iption

Feature Description

Table 3-1. MVME240x Features (Continued)

3

Flash memory

Memory Controller Hawk’s SMC (System Memory Controller)

PCI Host Bridge Hawk’s PHB (PCI Host Bridge)

Interrupt Controller Hawk’s MPIC (Multi-Processor Interrupt Controller)

PCI Interface 32/64-bit Data, 33MHz operation

Real-time clock

Peripheral Support

Switches Reset

Status LEDs Four: Board fail (BFL), CPU, PMC (one for PMC slot 2, one for slot 1)

Timers

VME I/O VMEbus P2 connector

PCI interface

Sockets for 1 MB

8 MB Soldered on-board

8KB NVRAM with RTC and battery backup (SGS-Thomson

M48T559)

One 16550-compatible async serial port routed to front panel RJ45

10BaseT/100BaseTX Ethernet interface routed to front panel RJ45

(RST) and Abort (ABT)

One 16-bit timer in W83C553 ISA bridge; four 32-bit timers in MPIC

device

Watchdog timer provided in SGS-Thomson M48T59

Two IEEE P1386.1 PCI Mezzanine Card (PMC) slots for one doublewidth or two single-width PMCs

Front panel and/or VMEbus P2 I/O on both PMC slots

One 114-pin Mi ct or conn ector for optional PMCspan expan sion module

3-2 Computer Group Literature Center Web Site

Page 51

Table 3-1. MVME240x Features (Continued)

Feature Description

Features

VMEbus interface

VMEbus system controller functions

64-bit PCI (Universe 2)

VMEbus-to-local-bus interface (A32/A24/A16, D64 (MBLT)

D32//D16/D08 Master and Slave

Local-bus-to-VMEbus interface (A16/A24/A32, D8/D16/D32)

VMEbus interrupter

VMEbus interrupt handler

Global Control/Status Register (GCSR) for interprocessor

communications

DMA for fast local memory/VMEbus transfers (A16/A24/A32,

D16/D32/D64)

3

http://www.mcg.mot.com/literature 3-3

Page 52