Page 1

MVME197LE

Single Board Computer

User’s Manual

(MVME197LE/D2)

Page 2

Notice

While reasonable efforts have been made to assure the accuracy of this document,

Motorola, Inc. assumes no liability resulting from any omissions in this document, or

from the use of the information obtained therein. Motor ola rese rves the right to revise

this document and to make changes from time to time in the content hereof without

obligation of Motorola to notify any person of such revision or changes.

No part of this material may be reproduced or copied in any tangible medium, or

stored in a retrieval system, or transmitted in any form, or by any means, radio,

electronic, mechanical, photocopying, recording or facsimile, or otherwise, without the

prior written permission of Motorola, Inc.

It is possible that this publication may contain reference to, or information about

Motorola products (machines and programs), programming, or services that are not

announced in your country. Such references or information must not be construed to

mean that Motorola intends to announce such Motorola products, programming, or

services in your country.

Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S.

Government, the following notice shall apply unless otherwise agreed to in writing by

Motorola, Inc.

Use, duplication, or disclosure by the Governm ent is subject to r estrictions as set forth

in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software

clause at DFARS 252.227-7013.

Motorola, Inc.

Computer Group

2900 South Diablo Way

Tempe, Arizona 85282-9602

Page 3

Preface

This document provides general information, hardware preparation and installation

instructions, operating instructions, and a functional description for the MVME197LE

Single Board Computer.

This document is intended for anyone who wants to design OEM systems, supply

additional capability to an existing compatible system, or work in a lab environment

for experimental purposes.

A basic knowledge of computers and digital logic is assumed.

T o use this document, you may wish to become familiar with the publications listed in

the Related Documentation section found in the following pages.

Document Terminology

Throughout this document, a convention has been maintained whereby data and

address parameters are pr eceded by a cha racter which specifies the numeric format, as

follows:

$ dollar specifies a hexadecimal number

% percent specifies a binary number

& ampersand specifies a decimal number

For example, “12” is the decimal number twelve, and “$12” is the decimal number

eighteen. Unless otherwise specified, all address references are in hexadecimal

throughout this document.

An asterisk (*) following the signal name for signals which are level significant denotes

that the signal is true or valid when the signa l is low.

An asterisk (*) following the signal name for signals which are edge significant denotes

that the actions initiated by that signal occur on high to low transition.

In this document, assertion and negation are used to specify forcing a signal to a

particular state. In particular, assert ion and assert refer to a signal that is active or true;

negation and negate indicate a signal that is inactive or false. These terms are used

independently of the voltage level (high or low) that they represent.

Page 4

Data and address sizes are defined as follows:

❏ A byte is eight bits, numbered 0 through 7, with bit 0 being the least

significant.

❏ A two-byte is 16 bits, numbered 0 through 15, with bit 0 being the least

significant. For the MVME197series and other RISC modules, this is called

a half-word.

❏ A four-byte is 32 bits, numbered 0 through 31, with bit 0 being the least

significant. For the MVME197 series and other RISC modules, this is called

a word.

❏ An eight-byte is 64 bits, numbered 0 through 63, with bit 0 being the least

significant. For the MVME197 series and other RISC modules, this is called

a double-word.

Throughout this document, it is assumed that the MPU on the MVME197 module

series is always programmed with big-endian byte orde r ing, as shown below. Any

attempt to use small-endian byte ordering will immediately render the MVME197Bug

debugger unusable.

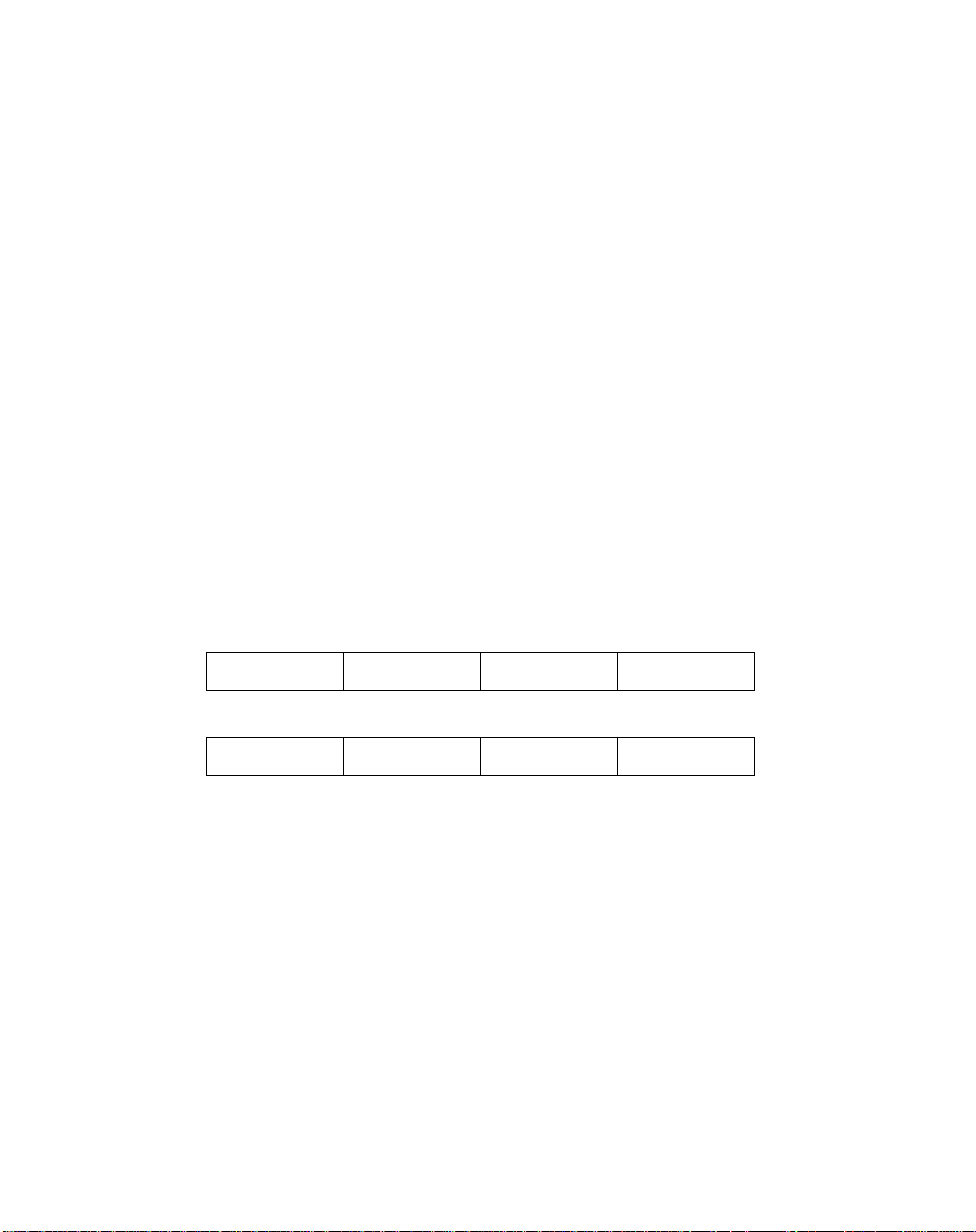

BIT BIT

63 56 55 48 47 40 39 32

ADRO ADR1 ADR2 ADR3

31 24 23 16 15 08 07 00

ADR4 ADR5 ADR6 ADR7

The terms control bit and status bit are used extensively in this document. The term

control bit is used to describe a bit in a register that can be set and cleared under

software control. The term true is used to indicate that a bit is in the state that enables

the function it controls. The term false is used to indicate th at the bit is in the state th at

disables the function it controls. In all tables, the terms 0 and 1 are used to describe the

actual value that should be written to the bit, or the value that it yields when read. The

term status bit is used to describe a bit in a register that r eflects a specific condition. The

status bit can be read by software to determine operational or exception conditions.

Page 5

Related Documentation

The following publications are applicable to the MVME197LE module a nd m ay

provide additional helpful information. If not shipped with this product, they may be

purchased by contacting your Motorola sales office.

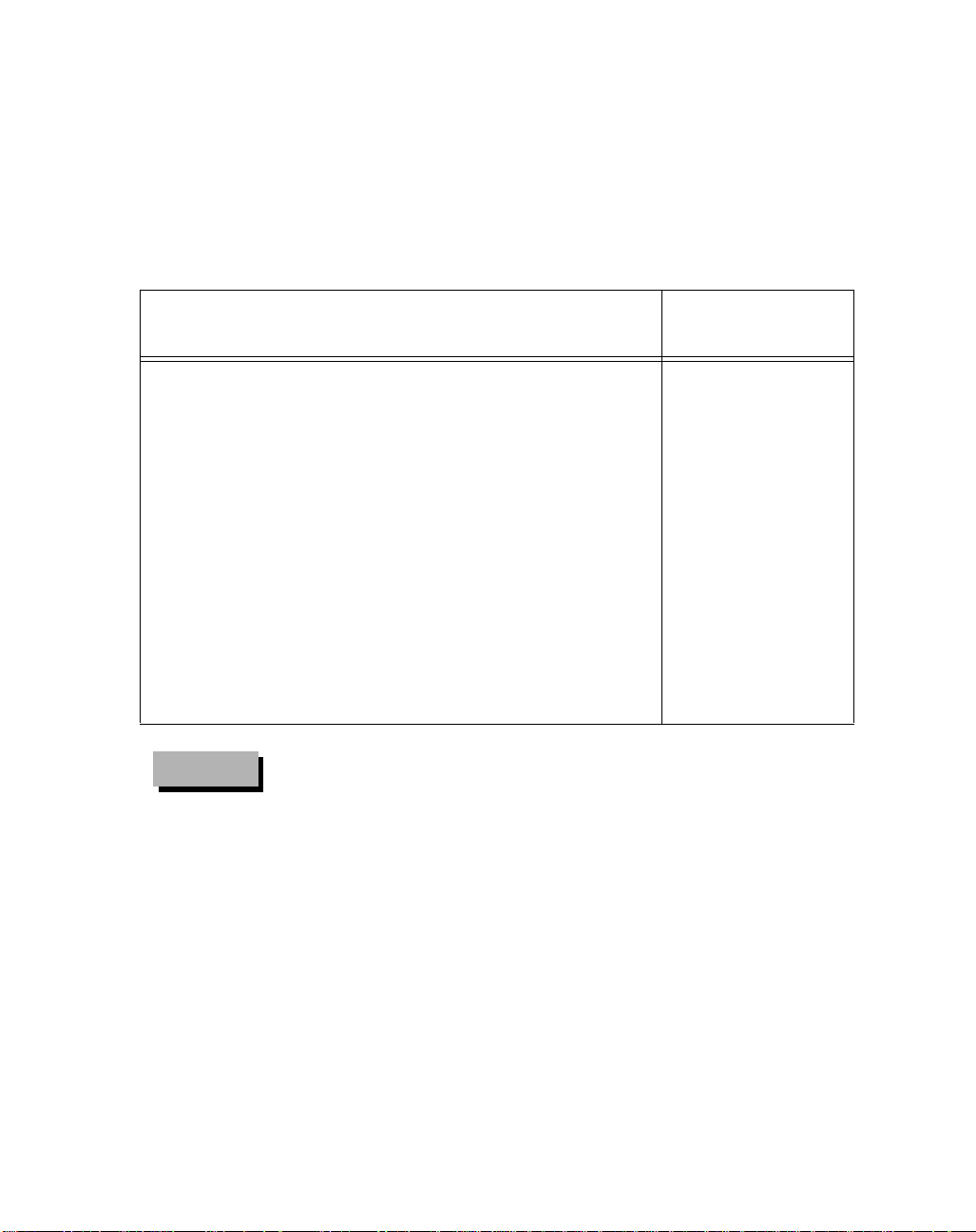

Document Title

MVME197LE, MVME197DP, and MVME197SP Single

Board Computers Programmer’s Reference Guide

MVME197BUG 197Bug Debugging Package User’s Ma nual

MVME197BUG 197Bug Diagnostic Firmware User’s Ma nual

MVME712M Transition Module and P2 A dapter Board

User’s Manual

MVME712-12, MVME712-13, MVME 712A, MVME712A M,

and MVME712B Transition Module and LCP2 Adapter Board

User’s Manual

MC88110 Second Generation RISC Microp rocessor User ’s

Manual

MC68040 Microprocessor User’s Manual

Note

Although not shown in the above list, each Motorola

Computer Group manual publication number is suffixed

with characters which represent the revision level of the

document, such as “/D2” (the second revision of a manual);

a supplement bears the same number as the ma nual but has

a suffix such as “/A1” (the first supplement to the manual).

Motorola

Publication Number

MVME197PG

MVME197BUG

MVME197DIAG

MVME712M

MVME712A

MC88110UM

MC68040UM

Page 6

To further assist your development effort, Motorola has collected user’s manuals for

each of the peripheral controllers used on the MVME197 module series and other

boards from the suppliers. This bundle includes manuals for the following:

68-1X7DS for use with the MVME197 series of Single Board Computers.

NCR 53C710 SCSI Controller Data Manual and Programmer’s Guide

Intel i82596 Ethernet Controller User’s Manual

Cirrus Logic CD2401 Serial Controller User’s Manual

SGS-Thompson MK48T08 NVRAM/TOD Clock Data Sheet

The following non-Motorola publications may also be of interest and may be obtained

from the sources indicated. The VMEbus Specification is contained in ANSI/IEEE

Standard 1014-1987 .

ANSI/IEEE Std 1014-1987 The Institute of Electrical and Electronics

Versatile Backplane Bus: VMEbus Engineers, Incorporated

Publication and Sales Department

345 East 47th Street

New York, New York 10017-2633

Telephone: 1-800-678-4333

ANSI Small Computer System Interface-2 Global Engineering Documents

(SCSI-2), Draft Document X3.131-198X, P.O. Box 19539

Revision 10c Irvine, California 92713-9539

Telephone (714) 979-8135

Page 7

The computer programs stored in the Read Only Memory of this device contain

material copyrighted by Motorola Inc., first published 1991, and may be used only

under license such as the License for Computer Programs (Article 14) contained in

Motorola’s Terms and Conditions of Sale, Rev. 1/79.

®

Motorola

Delta Series, M88000, SYSTEM V/88, VMEmodule, VMEsystem, and 197bug are

trademarks of Motorola, Inc.

Timekeeper and Zeropower are trademarks of Thompson Components.

All other products mentioned in this document are trademarks or registered

trademarks of their respective holders

and the Motorola symbol are registered trademarks of Motorola, Inc.

© Copyright Motorola 1993

All Rights Reserved

Printed in the United States of America

December 1993

!

WARNING

This equipment generates, uses, and can radiate radio

frequency energy and if not installed and used in

accordance with the documentation for this product, may

cause interference to radio communications. It has been

tested and found to comply with the limits for a Class A

Computing Device pursuant to Subpart J of Part 15 of FCC

rules, which are designed to provide reasonable protection

against such interference when operated in a commercial

environment. Operation of this equipment in a residential

area is likely to cause interference in w hich ca se the user, at

the user’s own expense, will be required to take whatever

measures necessary to correct the interference.

Page 8

SAFETY SUMMARY

SAFETY DEPENDS ON YOU

The following general safety precautions must be observed during all phases of operation, service, and repair

of this equipment. Failure to comply with these precautions or with specific warnings elsewhere in this manual

violates safety standards of design, manufacture, and intended use of the equipment. Motorola Inc. assumes

no liability for the customer’s failure to comply with these requirements. The safety precautions listed below

represent warnings of certain dangers of which we are aware. You, as the user of the product, should follow

these warnings and all other saf ety precautio ns necessary for the safe oper ation of the e quipment in you r

operating environment.

GROUND THE INSTRUMENT.

To minimize shock h azard, the equipm ent chassis and e nclosure must be co nnected to an ele ctrical ground. T he

equipment is supplied w ith a three-conduct or ac power cable. The power cable must either be plugged in to an

approved three-contact electrical ou tlet or used w ith a three- contact to two- contact adap ter, with the gr ounding w ire

(green) firmly connected to an electrical ground (safety ground) at the power outlet. The power jack and mating plug

of the power cable meet international Electrotechnical Commission (IEC) safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE.

Do not operate the equipment in the presence of flammable gases or fumes. Operation of any electrical equipment in

such an environment constitutes a definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS.

Operating personnel must not remove equipment covers. Only Factory Authorized Service Personnel or other qualified

maintenance person nel may remove equ ipment covers for internal sub assembly or comp onent replacem ent or any

internal adjustment. D o not replace comp onents with power cab le connected. Unde r certain conditio ns, dangerous

voltages may exist even with th e power cable remo ved. To avoid injuries, alw ays disconnect power and disc harge

circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE.

Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation,

is present.

USE CAUTION WHEN EXPOSING OR HANDLING THE CRT.

Breakage of the Cathode-Ray Tube (CRT) causes a high-velocity scattering of glass fragments (implosion). To prevent

CRT implosion, avoid rough handling or jarring of the equipment. Handling of the CRT should be done only by qualified

maintenance personnel using approved safety mask and gloves.

DO NOT SUBSTITUTE PARTS OR MODIFY EQUIPMENT.

Because of the danger of introduc ing additional hazards, do not install subs titute par ts or perform an y unauthor ized

modification of the equipment. Contact your local Motorola representative for service and repair to ensure that safety

features are maintained.

DANGEROUS PROCEDURE WARNINGS.

Warnings, such as the example below, precede potentially dangerous procedures throughout this manual. Instructions

contained in the war nings must be fo llowed. You shou ld also employ a ll other safety precautions which you deem

necessary for the operation of the equipment in your operating environment.

!

WARNING

Dangerous voltages, capab le of causing de ath, are present in

this equipment. Use extreme caution when handling,

testing, and adjusting.

SPD 15163 R-2 (9/93)

Page 9

Contents

CHAPTER 1 GENERAL INFORMATION

Introduction.............................................................................................................1-1

General Description................................................................................................1-1

Features.....................................................................................................................1-2

Specifications...........................................................................................................1-3

Cooling Requirements.....................................................................................1-4

FCC Compliance..............................................................................................1-5

Equipment Required...............................................................................................1-5

Support Information...............................................................................................1-6

CHAPTER 2 HARDWARE PREPARATION AND INSTALLATION

Introduction.............................................................................................................2-1

Unpacking Instructions..........................................................................................2-1

Hardware Preparation............................................................................................2-1

Configuration Switches...................................................................................2-3

Configuration Switch S1: General Information....................................2-3

Configuration Switch S1: General Purpose Functions

(S1-1 to S1-8)...................................................................................2-4

Configuration Switch S1: System Controller Enable

Function (S1-9)...............................................................................2-4

Configuration Switch S6: Serial Port 4 Clock Select

(S6-1, S6-2)......................................................................................2-5

Connectors ........................................................................................................2-5

Installation Instructions..........................................................................................2-5

MVME197LE Module Installation.................................................................2-6

System Considerations....................................................................................2-7

CHAPTER 3 OPERATING INSTRUCTIONS

Introduction.............................................................................................................3-1

Controls and Indicators..........................................................................................3-1

ABORT Switch S2..................................... ..... ...................................................3-1

RESET Switch S3..............................................................................................3-1

Front Panel Indicators (DS1-DS6)..................................................................3-2

Memory Maps .........................................................................................................3-2

ix

Page 10

Processor Bus Memory Map..........................................................................3-2

Detailed I/O Memory Maps.......................................................................3-5

BBRAM, TOD Clock Memory Map.........................................................3-19

VMEbus Memory Map.....................................................................................3-20

VMEbus Accesses to the Local Peripheral Bus......................................3-20

VMEbus Short I/O Memory Map............................................................3-20

Software Initialization ..............................................................................................3-21

Multi-MPU Programming Considerations....................................................3-21

Local Reset Operation.......................................................................................3-21

CHAPTER 4 FUNCTIONAL DESCRIPTION

Introduction.................................................................................................................4-1

MVME197LE Functional Description......................................................................4-1

Data Bus Structure...............................................................................................4-1

MC88110 MPU .....................................................................................................4-1

BOOT ROM ..........................................................................................................4-3

FLASH Memory...................................................................................................4-3

Onboard DRAM...................................................................................................4-3

Battery Backup RAM and Clock .......................................................................4-3

VMEbus Interface................................................................................................4-4

I/O Interfaces.......................................................................................................4-4

Serial Port Interface ......................................................................................4-4

Printer Interface..................................................... ..... ...... ............................4-5

Ethernet Interface.........................................................................................4-5

SCSI Interface................................................................................................4-6

SCSI Termination .........................................................................................4-6

Peripheral Resources...........................................................................................4-6

Programmable Tick Timers ........................................................................4-6

Watchdog Timer...........................................................................................4-7

Software-Programmable Hardware Interrupts.......................................4-7

Processor Bus Timeout................................................................................4-7

Local Peripheral Bus Timeout....................................................................4-7

Interrupt Sources.................................................................................................4-7

APPENDIX A EIA-232-D INTERCONNECTIONS...............................................A-1

x

Page 11

List of Figures

Figure 2-1. MVME197LE Switches, Connectors, and LED Indicators

Location Diagram...................................................................2-2

Figure 4-1. MVME197LE Block Diagram.............................................................4-2

Figure A-1. Middle-of-the-Road EIA-232-D Configuration.............................A-5

Figure A-2. Minimum EIA-232-D Connection...................................................A-6

xi

Page 12

xii

Page 13

List of Tables

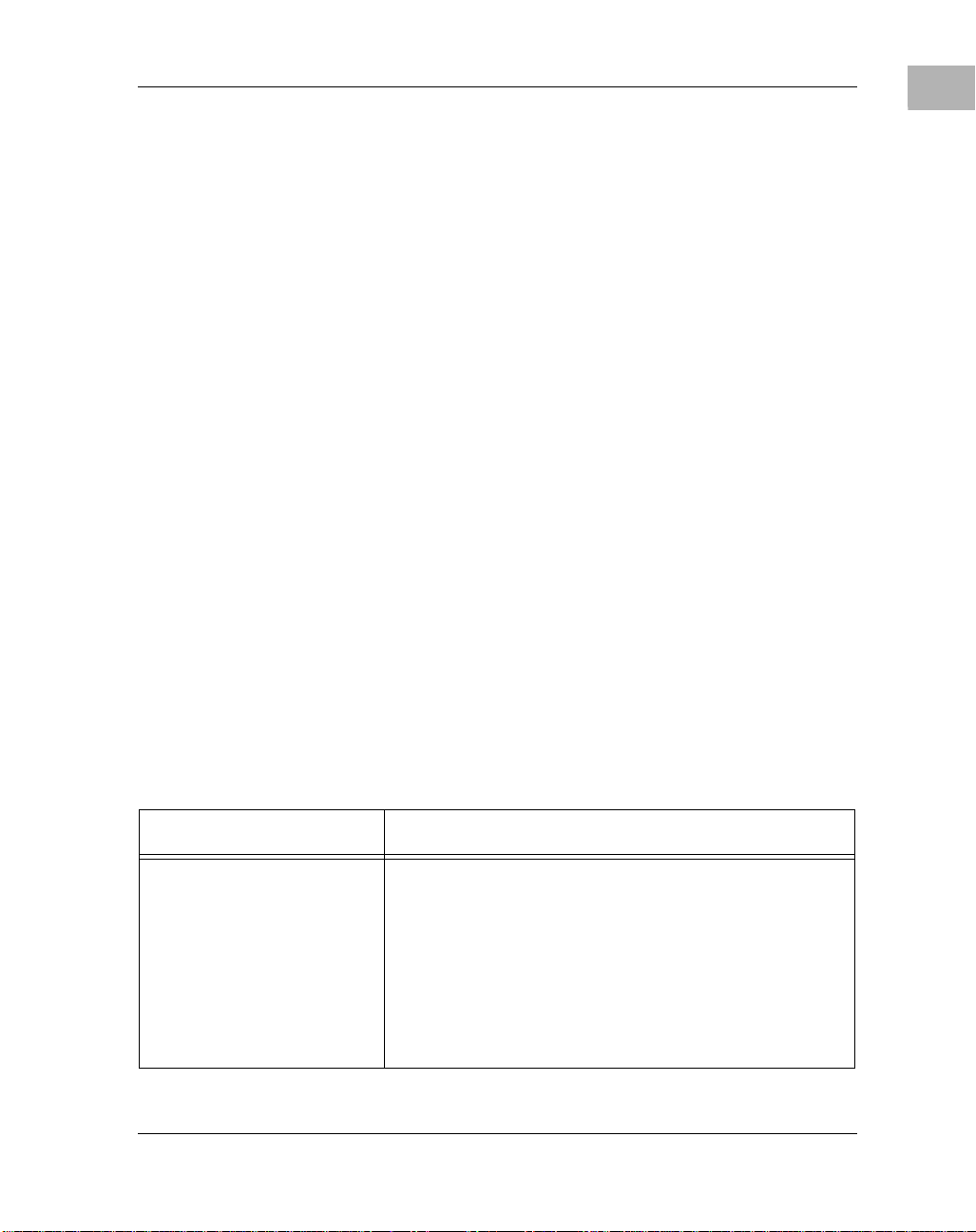

Table 1-1. MVME197LE Specifications.................................................................1-3

Table 3-1. Processor Bus Memory Map................................................................3-3

Table 3-2. Local Devices Memory Map...............................................................3-4

Table 3-3. BusSwitch Register Memory Map .....................................................3-6

Table 3-4. ECDM CSR Register Memory Map ....................................................3-7

Table 3-5. DCAM (I

Table 3-6. VMEchip2 Memory Map......................................................................3-9

Table 3-7. PCCchip2 Memory Map.....................................................................3-13

Table 3-8. Printer Memory Map ..........................................................................3-14

Table 3-9. Cirrus Logic CD2401 Serial Port Memory Map..............................3-15

Table 3-10. 82596CA Ethernet LAN Memory Map...........................................3-16

Table 3-11. 53C710 SCSI Memory Map ..............................................................3-17

Table 3-12. MK48T08 BBRAM, TOD Clock Memory Map..............................3-17

Table 3-13. BBRAM Configuration Area Memory Map ..................................3-18

Table 3-14. TOD Clock Memory Map.................................................................3-18

Table A-1. EIA-232-D Interconnections...............................................................A-2

2

C) Register Memory Map...................................................3-8

xiii

Page 14

xiv

Page 15

GENERAL INFORMATION

Introduction

This user’s manual provides general information, preparation for use and

installation instructions, operating instructions, and a functional description

for the MVME197LE version of the MVME197 series of single board

computers.

General Description

The MVME197LE module is a double-high VMEmodule based on the

MC88110 RISC microprocessor. The MVME197LE has 32/64MB of DRAM,

1MB of FLASH memory, 8KB of static RAM (with battery backup), a time of

day clock (with battery backup), an Ethernet transceiver interface, four serial

ports with EIA-232-D interface, six tick timers, a watchdog timer, 128/256KB

of BOOT ROM, a SCSI bus interface with DMA (Direct Memory Access), a

Centronics printer port, an A16/A24/A32/D8/D16/D32 VMEbus

master/slave interface, and a VMEbus system controller.

Input/Output (I/O) signals are routed through the MVME197LE’s backplane

connector P2. A P2 Adapter Board or LCP2 Adapter board routes the signals

and grounds from connector P2 to an MVME712 series tra nsition module. The

MVME197LE supports the MVME712M, MVME712A, MVME712AM, and

MVME712B transition boards (referred to here as the MVME712X, unless

separately specified). The MVME197LE also supports the MVME712-12 and

MVME712-13 (referred to as the MVME712-XX, unless separately specified).

These transition boards provide configuration headers, seria l port drivers, and

industry standard connectors for the I/O devices.

1

The MVME197LE modules have eight ASICs (Application-Specific Integrated

Circuits) described in the following order: BusSwitch, DCAM, ECDM, PCC2,

and VME2.

The BusSwitch ASIC provides an interface between the processor bus

(MC88110 bus) and the local peripheral bus (MC68040 com patible bu s). Refer

to the MVME197LE block diagram ( Figure 1-1). It provides bus arbitration for

the MC88110 bus and serves as a seven level interrupt handler. It has

programmable map decoders for both busses, as well as write post buffers on

each, two tick timers, and four 32-bit general purpose registers.

MVME197LE/D21-1

Page 16

1

General Information

Note

For the MVME197 series, the term Local Bus, as used in

other MVME1xx Single Board Computer series, is referred

to as the Local Peripheral Bus.

The DCAM (DRAM Controller and Address Multiplexer) ASIC provides the

address multiplexers and RAS/CAS/WRITE control for the DRAM as well as

data control for the ECDM.

The ECDM (Error Correction and Data Multiplexer) ASIC multiplexes

between four data paths on the DRAM array. Since the device handles 16 bits,

four such devices are required on the MVME197LE to accommodate the 64-bit

data bus of the MC88110 microprocessor. Single-bit error correction and

double-bit detection is performed in the ECDM.

The PCCchip2 (Peripheral Channel Controller) ASIC provides two tick timers

and the interface to the LAN chip, the SCSI chip, the serial port chip, the

printer port, and the BBRAM (Battery Backup RAM).

The VMEchip2 ASIC provides a VMEbus interface. The VMEchip2 includes

two tick timers, a watchdog timer, programmable map decoders for the master

and slave interfaces, and a VMEbus to/from the local peripheral bus DMA

controller, a VMEbus to/from the local peripheral bus non-DMA

programmed access interface, a VMEbus interrupter, a VMEbus system

controller, a VMEbus interrupt handler, and a VMEbus requester.

Local peripheral bus to VMEbus transfers can be D8, D16, or D32. VMEchip2

DMA transfers to the VMEbus, however, can be 64 bits wide as Block Transfer

(BLT).

Features

These are some of the major features of the MVME197LE single board

computer:

❏ MC88110 RISC Microprocessor

❏ 32 or 64 megabytes of 64-bit Dynamic Random Access Memory (DRAM)

with error correction

❏ 1 megabyte of FLASH memory

❏ Six status LEDs (FAIL, RUN, SCON, LAN, SCSI, and VME)

❏ 8 kilobytes of Static Random Access Memory (SRAM) and Time of Day

(TOD) clock with Battery Backup RAM (BBRAM)

❏ Two push-button switches (ABORT and RESET)

1-2 User’s Manual

Page 17

Specifications

❏ 128 or 256 kilobytes of BOOT ROM

❏ Six 32-bit tick timers for periodic interrupts

❏ Watchdog timer

❏ Eight software interrupts

❏ I/O

– SCSI Bus interface with Direct Memory Access (DMA)

– Four serial ports with EIA-232-D buffers

– Centronics printer port

– Ethernet transceiver interface

❏ VMEbus interface

– VMEbus system controller functions

– VMEbus interface to local peripheral bus (A24/A32, D8/D16/D32

BLT (D8/D16/D32/D64))(BLT = Block Transfer)

– Local peripheral bus to VMEbus interface (A24/A32, D8/D16/D32

BLT (D16/D32/D64))

– VMEbus interrupter

– VMEbus interrupt handler

– Global CSR for inter-processor communications

– DMA for fast local memory - VMEbus transfers (A16/A24/A32,

D16/D32 BLT (D16/D32/D64))

1

Specifications

The specifications for the MVME197LE are listed in Table 1-1.

Table 1-1. MVME197LE Specifications

Characteristics Specifications

Power requirements

Operating temperature

(refer to the Cooling

Requirements section)

Storage temperature

Relative humidity

MVME197LE/D2 1-3

+5 Vdc (± 2.5% ), 4 A (typical), 5 A (maxim um )

+12 Vdc (± 2.5%), 100 mA (maximum)

-12 Vdc (± 2.5%), 100 mA ( ma ximum)

0° to 55° C at point of entry of forced air

(approximately 490 LFM)

-40° to 85° C

5% to 90% (non-condensing)

Page 18

1

General Information

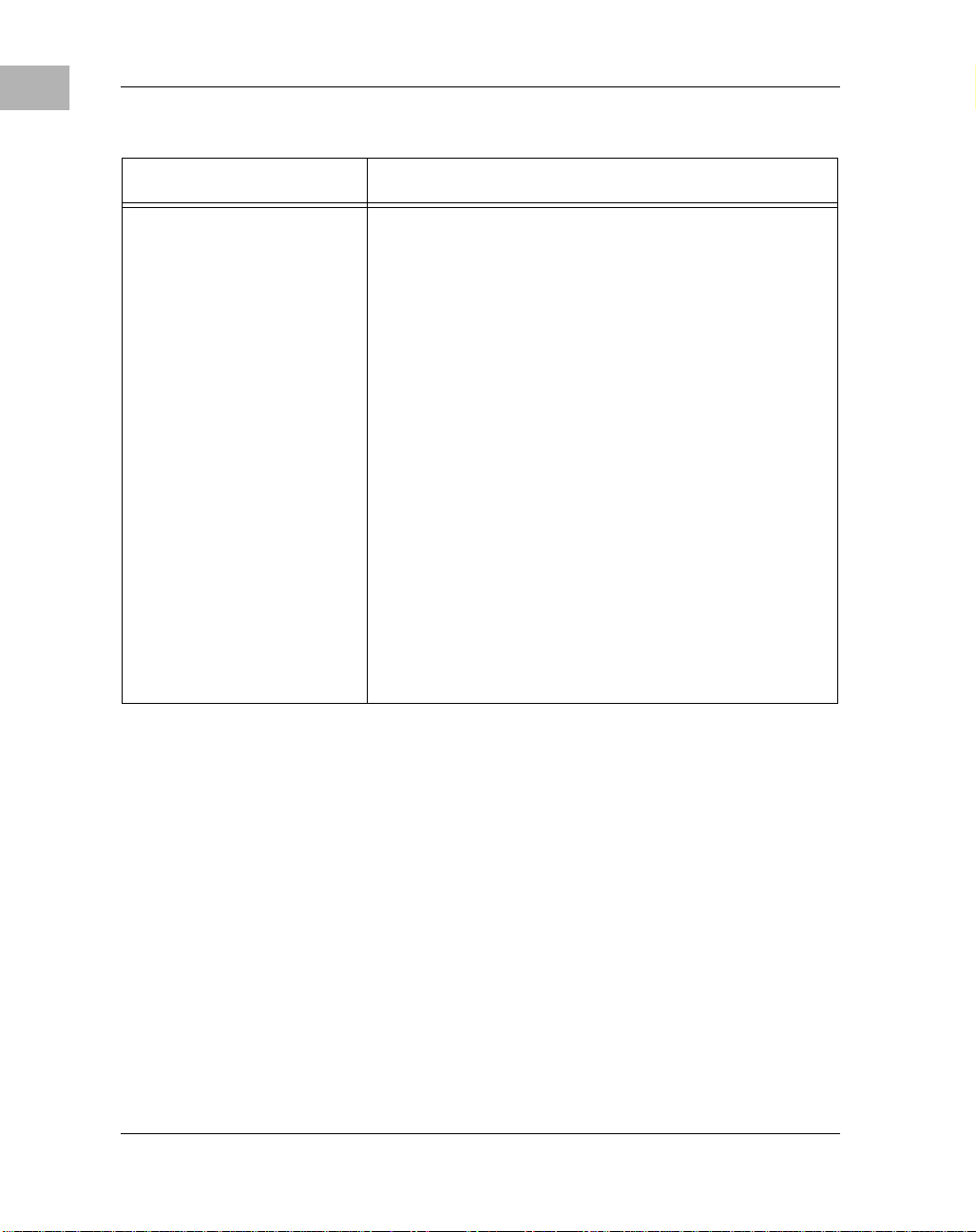

Table 1-1. MVME197LE Specifications (Continued)

Characteristics Specifications

Physical dimensions:

PC board

Height

Width

Thickness

PC board with connectors

and front panel

Height

Width

Thickness

Board connectors:

P1 connector

P2 connector

J1 connector

J2 connector

Cooling Requirements

Double-high VMEboard

9.187 inches (233.35 mm)

6.299 inches (160.00 mm)

0.063 inch (1.60 mm )

10.309 inches (261.85 mm)

7.4 inches (188.00 mm)

0.80 inch (20.32 mm)

A 96-pin connector which provides the interface to the

VMEbus signals.

A 96-pin connector which provides the interface to the

extended VMEbus signals and other I/O signals.

A 20-pin connector which provides the interface to the

remote reset, abort, the LEDs, and thr ee gen era l purpos e I/O

signals.

A 249-pin connector which provides the interface to the

MC88110 address, data, and control signals to and from the

mezzanine expansion.

The Motorola MVME197LE VMEmodule is specified, designed, an d tested to

operate reliably with an incoming air temp erature range from 0 ° to 55° C (3 2°

to 131° F) with forced air cooling at a velocity typically achievable by using a

100 CFM axial fan. Temperature qualification is performed in a standard

Motorola VMEsystem 3000 chassis. Twenty-five watt load boards are inserted

in two card slots, one on each side, adjacent to the board under test, to simulate

a high power density system configuration. An assembly of three axial fans,

rated at 100 CFM per fan, is placed directly under the VME card cage. The

incoming air temperature is measured between the fan assembly and the card

cage, where the incoming airstream first encounters the module under test.

Test software is executed as the module is subjected to ambient temperature

variations. Case temperatures of critical, high power density integrated

circuits are monitored to ensure component vendors specifications are not

exceeded.

1-4 User’s Manual

Page 19

While the exact amount of airflow required for cooling depends on the

ambient air temperature and the type, number, and location of boards and

other heat sources, adequate cooling can usually be achieved with 10 CFM and

490 LFM flowing over the module. Less airflow is required to cool th e module

in environments having lower maximum ambients. Under more favorable

thermal conditions, it may be possible to operate the module reliably at higher

than 55° C with increased airflow. It is important to note that there are several

factors, in addition to the rated CFM of the air mover, which determine the

actual volume and speed of air flowing over a module.

FCC Compliance

The MVME197LE was tested in an FCC-compliant chassis, and meets the

requirements for Class A equipment. FCC compliance was achieved under the

following conditions:

1. Shielded cables on all external I/O ports.

2. Cable shields are connected to earth ground via metal shell connectors

bonded to a conductive module front panel.

3. Conductive chassis rails connected to earth ground. This provides the path

for connecting shields to earth ground.

4. All chassis and MVME197LE front panel attachment screws are properly

tightened.

Equipment Required

1

For minimum RF emissions , it is essential that the conditions above be

implemented; failure to do so could compromise the FCC compliance of the

equipment containing the module.

Equipment Required

The following equipment is required to make a complete system using the

MVME197LE:

System console terminal

Disk drives and controllers

MVME712 series transition modules (MVME712-12, MVME712-13,

MVME712A, MVME712AM, MVME712B, or MVME712M); P2 or LCP2

Adapter Boards

Operating system

The MVME197Bug debug monitor firmware (197Bug) is provided in the

FLASH memory on the MVME197LE module. It provides over 50 debug,

up/down line load, and disk bootstrap load commands, as well as a set of

onboard diagnostics and a one-line assembler/disassembler. 197Bug includes

MVME197LE/D2 1-5

Page 20

1

General Information

a user interface which accepts commands from the system console terminal.

197Bug can also operate in a System Mode, which includes choices from a

service menu. Refer to the MVME197BUG 197Bug Debugging Package User’s

Manual for more details.

The MVME712 series transition modules provide an interface between the

MVME197LE module and peripheral devices. They connect the MVME197 LE

to EIA-232-D serial devices, Centronics-compatible parallel devices, SCSI

devices, and Ethernet devices. A P2 Adapter Board or LCP2 Adapter Board

and cable is required with the MVME712 series transition modules. Refer to

the MVME712-12, MVME712-13, MVME712A, MVME712AM, and

MVME712B Transition Modules and LCP2 Adapter Board User’s Manual or the

MVME712M Transition Module and P2 Adapter Board User’s Manual for more

details.

Software available for the MVME197LE includes SYSTEM V/88 and real-time

operating systems, programming languages, and other tools and applications.

Contact your local Motorola sales office for more details.

Support Information

Detailed support information such as connector signal decriptions, the module

parts list, and the schematic diagram for the MVME197LE is contained in the

SIMVME197LE Single Board Computer Support Information manual.

This manual may be obtained free of charge by contactin g your local Motorola

sales office.

1-6 User’s Manual

Page 21

HARDWARE PREPARATION

Introduction

This chapter provides unpacking instructions, hardware preparation, and

installation instructions for the MVME197LE VMEmodule. The MVME712X

transition module hardware preparation is provided in separate manuals,

refer to the Related Documentation section found in the preface part of this

User’s Manual.

Unpacking Instructions

Note

Carefully unpack the equipment from the shipping carton. Refer to the

packing list and verify that all items are present. Save the shipping carton and

packing materials for storing or reshipping of the equipment.

Caution

If shipping carton is damaged upon receipt, request that the

carrier’s agent be present during unpacking and inspection

of equipment.

Avoid touching areas of integrated circuit s. Sta tic discha rge

can damage these components.

AND INSTALLATION

2

Inspect the equipment for any shipping damage. If no damage exists, then the

module can be prepared for operation according to the following sections of

this chapter.

Hardware Preparation

To select the desired configuration and ensure proper operation of the

MVME197LE module, certain modifications may be necessary before

installation. These modifications are made through switch settings as

described in the following sections. Many other modifications are done by

setting bits in control registers after the MVME 197LE has been installed in a

system. (The MVME197LE registers are described in the MVME197LE,

MVME197DP, and MVME197SP S ingle Board Computers Programm er’s Reference

Guide as listed in the Related Documentation section of this manual).

MVME197LE/D22-1

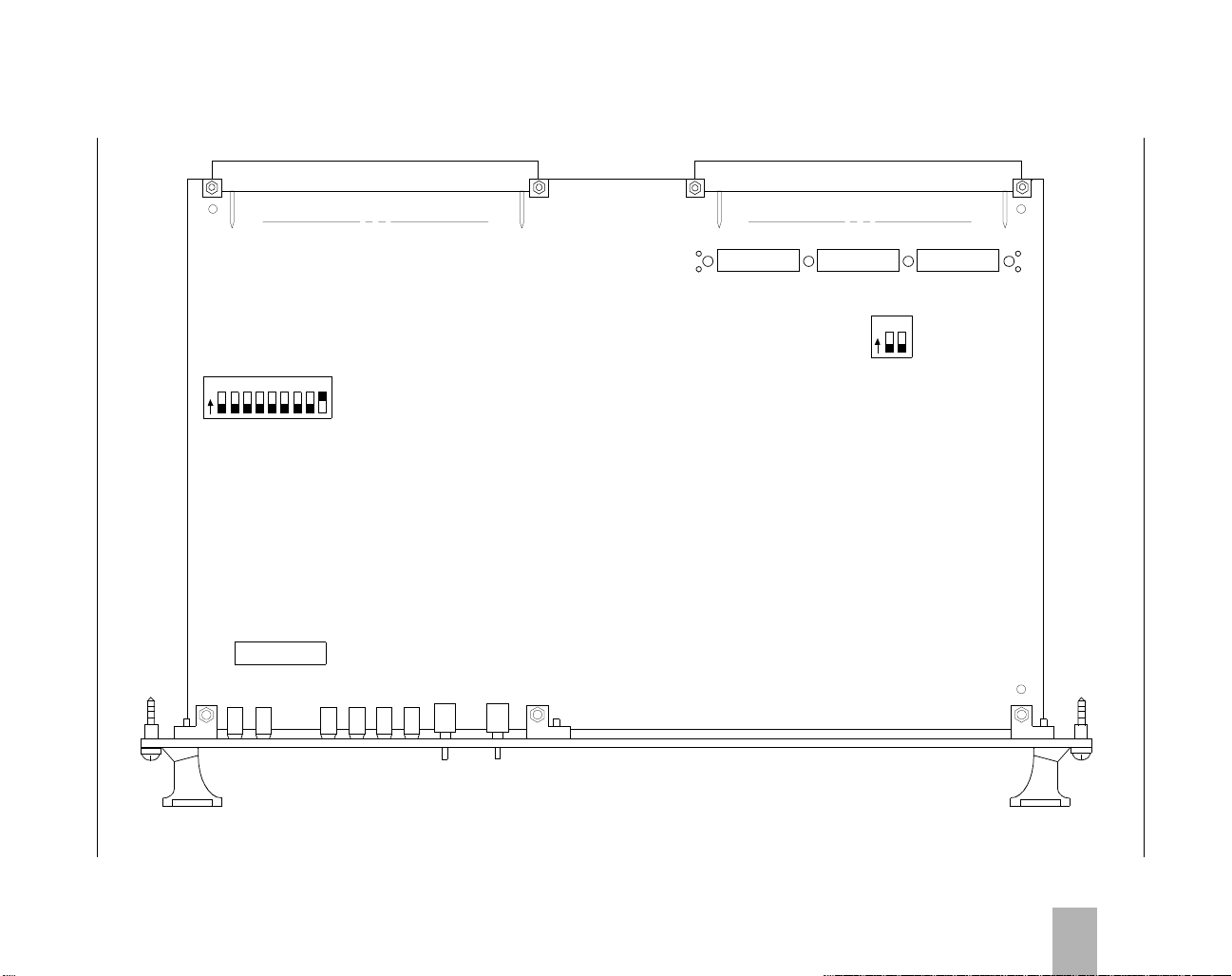

Page 22

Hardware Preparation and Installation

2

2-2 User’s Manual

Page 23

MVME197LE/D2 2-3

VMEbus CONNECTOR P1

VMEbus CONNECTOR P2

P1 P2

A1

B1

C1

A32

B32

C32

A1

B1

C1

1A17

1A1

1A1

2A17

3A1

A32

B32

C32

3A17

12345678

O

N

CONFIGURATION SWITCH S1

GENERAL PURPOSE/SCON

MODULE CONNECTOR J1

REMOTE RESET/ABORT/LEDS

20

19

DS1

FAIL

MVME197LE

S1

DS2

SCON

1E1

1E17

1E1

2E17

3E1

3E17

MEZZANINE CONNECTOR J2

12

O

N

S6

9

2

J1

1

DS4

DS3

LAN

RUN

ABORT

RESET

SWITCH

SWITCH

S2

DS6

DS5

SCSI

VME

S3

S2 S3

CONFIGURATION SWITCH S6

SERIAL PORT 4 CLOCK SELECT

Hardware Preparation

Figure 2-1. MVME197LE Switches, Connectors, and LED Indicators Location Diagram

2

Page 24

Hardware Preparation and Installation

2

Configuration Switches

The location of the switches, connectors, and LED indicators on the

MVME197LE is illustrated in Figure 2-1. The MVME197LE has been factory

tested and is shipped with factory switch settings that are described in the

following sections. The MVME197LE operates with its required and factoryinstalled Debug Monitor, MVME197Bug (197Bug), with these factory switch

setting.

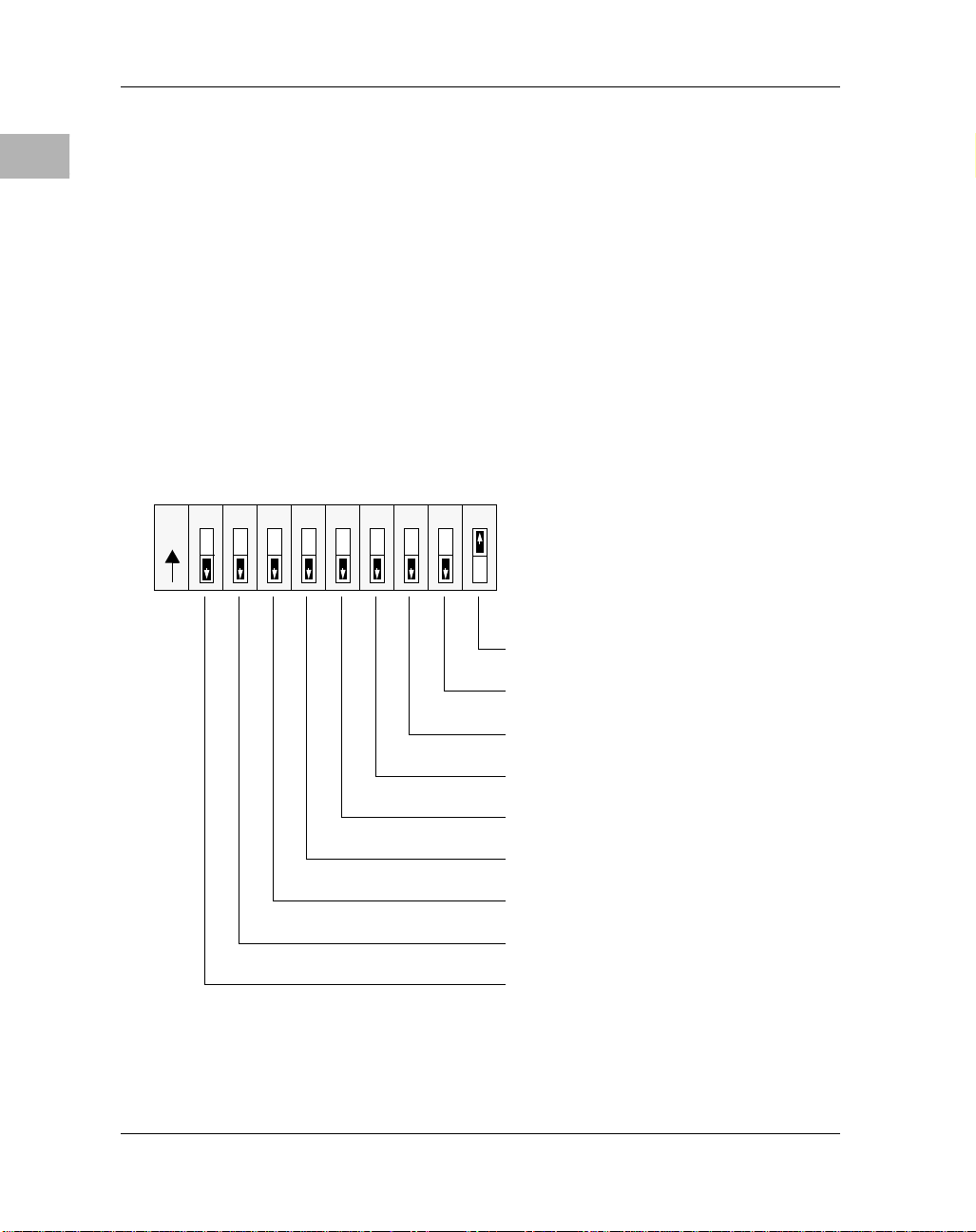

Configuration Switch S1: General Information

Switch S1 is a bank of nine two-way switch segments. The following

illustration shows the factory configuration of switch S1. The bit values are

read as a one when the switch is OFF (open), and as a zero when the switch is

ON (closed). The default value for switch S1 is shown below.

Switch S1

1

O

N

2 3 4 5 6 7 8 9

CLOSED

OPEN

System Controller (SCON)

General Purpose Input 7 (GPI7)

General Purpose Input 6 (GPI6)

General Purpose Input 5 (GPI5)

General Purpose Input 4 (GPI4)

General Purpose Input 3 (GPI3)

General Purpose Input 2 (GPI2)

General Purpose Input 1 (GPI1)

General Purpose Input 0 (GPI0)

(FACTORY CONFIGURATION)

2-4 User’s Manual

Page 25

Hardware Preparation

Configuration Switch S1: General Purpose Functions (S1-1 to S1-8)

The eight General Purpose Input lines (GPI0-GPI7) on the MVME197LE may

be configured with selectable switch segments S1-1 through S1-8. These

switches can be read as a register (at $FFF40088) in the VMEchip2 LCSR. Refer

to the VMEchip2 chapter in the MVME197LE, MVME197DP, an d MVME197SP

Single Board Computers Programmer’s Reference Guide for the status of lines GPI0

through GPI7. Factory configuration is with the general purposes input lines

disabled (open).

Switch S1

1

O

O

N

N

S1-1 to S1-8: OFF -- All Ones (FACTORY CON FIGU RATION )

Configuration Switch S1: System Controller Enable Function (S1-9)

The MVME197LE can be the system controller. The system controller

function is enabled or disabled by configuring selectable switch segment

S1-9. When the MVME197LE is the system controller, the SCON LED is

turned ON. T he VMEchi p2 may b e configu red as a system controller as

illustrated below. Factory configuration is with the system controller

switch enabled (closed).

2 3 4 5 6 7 8 9

CLOSED

OPEN

2

Switch S1

O

O

N

N

S1-9: ON -- MVME197 IS the System Controller

(FACTORY CONF IG URAT ION )

91 2 3 4 5 6 7 8

CLOSED

OPEN

Switch S1

O

N

S1-9: OFF -- MVME197 IS NOT the System Controller

MVME197LE/D2 2-5

91 2 3 4 5 6 7 8

CLOSED

OPEN

Page 26

Hardware Preparation and Installation

2

Configuration Switch S6: Serial Port 4 Clock Select (S6-1, S6-2)

Serial port 4 can be configured to use clock signals provided by the RTXC4 and

TRXC4 signal lines. Switch segments S6-1 and S6-2 on the MVME197LE

configures serial port 4 to drive or receive TRXC4 and RTXC4, respectively.

Factory configuration is with serial port 4 set to receive both signals (open).

The remaining configuration of the clock lines is accomplished by using the

Serial Port 4 Clock Configuration Select header on the MVME712M transition

module. Refer to the MVME712M Transition Module and P2 Adapter Board

User’s Manual for configuration of that header.

Switch S6

1 2

O

N

Receive TRXC4 Receive RTXC4

(FACTORY CONFIGURATION)

Switch S6

1 2

O

N

Drive TRXC4 Drive RTXCC4

CLOSED

OPEN

CLOSED

OPEN

Connectors

The MVME197LE has two 64-position DIN connectors: P1 and P2. Connec tor

P1 rows A, B, C, and connector P2 row B provide the VMEbus interconnection.

Connector P2 rows A and C provide the interconnect to the SCSI bus, the serial

ports, the Ethernet interface, and the Centronics printer. There is a 249-pin

mezzanine connector (J2) with the MC88110 bus interface. This mezzanine

connector is for MVME197LE module expansion. There is also a 20-pin

general purpose connector (J1) which provides the interconnect to the LEDs

and the reset and abort signals. Refer to the SIMVME197LE Single Board

Computer Support Information manual for detailed signal descriptions.

Installation Instructions

The following sections discuss i nsta llation of the MVME197LE into a VME

chassis, and system considerations. Ensure that the BOOT ROM device is

installed. Ensure that all switches are configured as desired.

2-6 User’s Manual

Page 27

Installation Instructions

MVME197LE Module Installation

Now that the MVME197LE module is ready for installation, proceed as

follows:

a. Turn all equipment power OFF and disconnect the power cable from the

power source.

Caution

!

WARNING

b. Remove the chassis cover as instructed in the equipment user’s manual.

c. Remove the filler panel(s) from the appropriate card slot(s) at the front and

Inserting or removing modules while power is applied

could result in damage to module components.

DANGEROUS VOLTAGES, CAPABLE OF CAUSING

DEATH, ARE PRESENT IN THIS EQUIPMENT. USE

EXTREME CAUTION WHEN HANDLING, TESTING,

AND ADJUSTING.

rear of the chassis (if the chassis has a rear card cage). The MVME197LE

module requires power from both P1 and P2. It may be installed in any

double-height unused card slot, if it is not configured as the system

controller. If the MVME197LE is configured as the system controller, it

must be installed in the left-most card slot (slot 1) to correctly initiate the

bus-grant daisy-chain and to have proper operation of the IACK-daisychain driver. The MVME197LE is to be installed in the front of the chassis

and the MVME712X trans ition board whi ch has a double- wide front panel

is to be installed in the rear of the chassis.

2

d. Carefully slide the MVME197LE module in to the card slot. Be sure the

module is seated properly into the P1 and P2 connectors on the backplane.

Do not damage or bend connector pins. Fasten the modu le in the chassis

with screws provided, making good contact with the transverse mounting

rails to minimize RFI emiss ions.

e. Remove the IACK and BG jumpers from the header on the chassis

backplane for the card slot in which the MVME197LE is installed.

f. Connect the P2 Adapter Board and specified cable(s) to the MVME197LE

at P2 on the backplane at the MVME197LE slot, to mate with (optional)

terminals or other peripherals at the EIA-232-D serial ports, parallel port,

SCSI ports, and LAN Ethernet port. Refer to the manuals listed in the

Related Documentati on section for information on installing the P2 Adapter

Board and the MVME712X transition module. (S ome connection diagrams

MVME197LE/D2 2-7

Page 28

Hardware Preparation and Installation

2

are provided in the MVME197LE, MVME197DP, and MVME197SP Single

Board Computers Prog rammer’s Reference Gui de). Some cable(s) are not

provided with the MVME712X module and therefore, are made or

provided by the user. (Motorola recommends using shielded cables for all

connections to peripherals to minimize radiation). Connect the

peripherals to the cable(s). Detailed information on the EIA-232-D signals

supported is found in Appendix A.

g. Install any other required VMEmodules in the system.

h. Replace the chassis cover.

i. Connect the power cable to the ac power source and turn the equipment

power ON.

System Considerations

The MVME197LE needs to draw power from both connectors P1 an d P2 of the

VMEbus backplane. Connector P2 is also used for the upper 16 bits of data for

32-bit transfers, and for the upper 8 address lines for the extend ed addr essing

mode. The MVME197LE may not operate properly without its main board

connected to connectors P1 and P2 of the VMEbus backplane.

Whether the MVME197LE operates as a VMEbus master or as a VMEbus slave,

it is configured for 32 bits of address and for 32 bits of data (A32/D32).

However, it handles A16 or A24 devices in ce rtain address ran ges. D8 an d/or

D16 devices in the system must be handled by software. Refer to the memory

maps in the MVME197LE, MVME197DP, and MVME197SP Single Board

Computers Programmer ’s Reference Guide.

The MVME197LE contains shared onboard DRAM whose base address is

software-selectable. Both the onboard processor and off-board VMEbus

devices see this local DRAM at base physical address $00000000, as

programmed by the MVME197Bug firmware. This may be changed, by

software, to any other base address. Refer to the MVME197LE, MVME197DP,

and MVME197SP Single Board Computers Programmer’s Reference Guide for

details.

If the MVME197LE tries to access off-board resources in a non-existent

location, and is not the system controller, and if the system does not have a

global bus timeout, the MVME197LE waits forever for the VMEbus cycle to

complete. This would cause the system to hang up. There is only one situation

in which the system might lack this global bus timeout: when the

MVME197LE is not the system controller and there is no global bus timeout

elsewhere in the system.

2-8 User’s Manual

Page 29

Installation Instructions

Multiple MVME197LE modules may be configured into a single VME card

cage. In general, hardware multiprocessor features are supported.

Other MPUs on the VMEbus can interrupt, disable, communicate with and

determine the operational status of the RISC processor(s). One register of the

GCSR set includes four bits which function as location monitors to allow one

MVME197LE processor to broadcast a signal to other MVME197LE

processors, if any. All eight registers are accessible from any local processor as

well as from the VMEbus.

The MVME197LE provides +12 Vdc power to the Ethernet LAN transceiver

interface through a 1 amp fuse (F2) located on the MVME197LE module. If the

Ethernet transceiver fails to operate, check the fuse. When using the

MVME712M transition module, the yellow LED (DS1) on the MVME712M

front panel lights when LAN power is available, indicating that the fuse is

good.

2

MVME197LE/D2 2-9

Page 30

Hardware Preparation and Installation

2

2-10 User’s Manual

Page 31

OPERATING

Introduction

This chapter provides the necessary information to use the MVME197LE

VMEmodule in a system configuration. This includes controls and indicators,

memory maps, and software initialization of the module.

Controls and Indicators

The MVME197LE Single Board Computer has two push-botton switches

(ABORT and RESET) and six LED indicators (FAIL, SCON, RUN, LAN, VME,

and SCSI), all located on the front panel of the module.

ABORT Switch S2

When enabled by software, the front panel ABORT switch (S2) generates an

NMI (Non-Maskable Interrupt) type interrupt at a user-programmable level.

It is normally used to abort program execution and return to the 197Bug

debugger. Refer to the VMEchip2 chapter of the MVME197LE, MVME197D P,

and MVME197SP Single Board Computers Programmer’s Reference Guide for more

information.

INSTRUCTIONS

3

RESET Switch S3

The RESET switch (S3) will reset all the onboard devices and drive the

SYSRESET* signal if the MVME197LE module is the system controller. The

RESET switch (S3) will reset all the onboard devices, with the exception of the

DCAM and ECDM, if the MVME197LE module is not the system controller.

The VMEchip2 generates the SYSREST* signal. The BusSwitch combines the

local reset and the reset switch to generate a loca l board reset. Refer to the Reset

Driver section in the VMEchip2 chapter of the MVME197LE, M VME197DP, and

MVME197SP Single Board Computers Programmer’s Reference Guide for more

information.

The BusSwitch receives the reset switch signal, debounces it and combines

with the reset signal from the VMEchip2 to generate a board reset signal.

The VMEchip2 includes both a global and a local reset driver. When the chip

operates as the VMEbus system controller, the reset driver provides a global

system reset by asserting the VMEbus signal SYSRESET*. A SYSRESET* may

be generated by the RESET switch, a power up reset, a watchdog timeout, or

MVME197LE/D23-1

Page 32

Operating Instructions

by a control bit in the LCSR. SYSRESET* remains asserted for a t least 200 msec,

as required by the VMEbus specification.

Similarly, the VMEchip2 provides an input signal and a control bit to initiate

3

a local reset operation. By setting a cont rol bit, software can maintain a board

in a reset state, disabling a faulty board from participating in normal system

operation.

The local reset driver is enabled even when the VMEchip2 is not the system

controller. A local reset may be generated by the RESET switch, a power up

reset, a watchdog timeout, a VMEbus SYSRESET*, or a contro l bit in the GCSR.

Front Panel Indicators (DS1-DS6)

The six LEDs on the MVME197LE front panel are: FAIL, SCON, RUN, LAN,

VME, and SCSI.

1. The yellow FAIL LED (DS1) is lit when the BRDFAIL signal line is active.

2. The green SCON LED (DS2) is lit when the VMEchip2 is the VMEbus

system controller.

3. The green RUN LED (DS3) is lit when the MC88110 bus MC* pin is low.

4. The green LAN LED (DS4) lights when the LAN chip is the local

peripheral bus master.

5. The green VME LED (DS5) lights when the board is using the VMEbus or

when the board is accessed by the VMEbus.

6. The green SCSI LED (DS6) lights when the SCSI chip is the local peripheral

bus master.

Memory Maps

There are three points of view for the memory maps: 1) the mapping of all

resources as viewed by the Processor Bus (MC88110 bus), 2) the mapping of

onboard/off-board resources as viewed from the Local Peripheral Bus

(MC68040 compatible bus), and 3) the mapping of onboard resources as

viewed by VMEbus Masters (VMEbus memory map).

Processor Bus Memory Map

Care should be taken, since all three maps are programmable. It is

recommended that direct mapping from the Processor Bus to the Local

Peripheral Bus be used.

3-2 User’s Manual

Page 33

Memory Maps

The memory maps of MVME197LE devices are provided in the following

tables. Table 3-1 is the entire map from $00000000 to $FFFFFFFF. Many areas

of the map are user-programmable, and suggested uses are shown in the table.

This is assuming no address translation is used between the processor and

local peripheral bus and between the local peripheral bus and VMEbus. The

cache inhibit function is programmable in the MC88110. The onboard I/O

space must be marked cache inhibit and serialized in its page table. Table 3-2

further defines the map for the local devices.

Table 3-1. Processor Bus Memory Map

3

Address

Range

$00000000 - (DRAMSIZE -1) User Programmable

DRAMSIZE - $FF7FFFFF User Programmable

$FF800000 - $FFBFFFFF Flash M em or y D32 4MB N 5

$FFC00000 - $FFEFFFFF reserved --- 3MB --- 4

$FFF00000 - $FFFEFFFF Local Devices

$FFFF0000 - $FFFFFFFF User Programmable

Notes

1. This area is user-programmable. The suggested use is

shown in the table. The DRAM decoder i s programmed

in the DCAM through the ECDM I

Devices

Accessed

(Onboard DRAM)

(VMEbus)

(Refer to next table)

(VMEbus A16)

Port

Size

D64 DRAMSIZE N 1

D32/D16 3GB ? 2,3

D32-D8 1MB Y ---

D32/D16 64KB ? 1,3

Size

2

CBus interface. The

Software

Cache

Inhibit

Processor Bus to Local Peripheral Bus and the Local

Peripheral Bus to Processor Bus decoders are

programmed in the BusSwitch. The Local Peripheral to

VMEbus (master) and VMEbus to Local Peripheral Bus

(slave) decoders are programmed in the VMEchip2.

2. Size is approximate.

3. Cache inhibit depends on devices in area mapped.

4. This area is not decoded. If these locations are accessed

and the local peripheral bus timer is enabled, the cycle

times out and is terminated by a TEA signal.

5. This area is user programmable via the BusSwitch.

Default size is 4 megabytes.

Notes

MVME197LE/D2 3-3

Page 34

Operating Instructions

The following table focuses on the Local Devices portion of the Memory Map.

Table 3-2. Local Devices Memory Map

3

Address Range Devices Accessed Port Size Size Notes

$FFF00000 - $FFF00FFF BusSwitch D64-D8 4KB 1

$FFF01000 - $FFF01FFF ECDM (DCAM access) --- 4KB 1

$FFF02000 - $FFF02FFF reserved --- 4KB 4

$FFF03000 - $FFF03FFF reserved --- 4KB 4

$FFF04000 - $FFF04FFF reserved --- 4KB 4

$FFF05000 - $FFF05FFF reserved --- 4KB 4

$FFF06000 - $FFF06FFF reserved --- 4KB 4

$FFF07000 - $FFF07FFF User defined --- 4KB 4

$FFF08000 - $FFF3FFFF reserved --- 224KB 4

$FFF40000 - $FFF400FF VMEchip2 (LCSR) D32 256B 1,2,3

$FFF40100 - $FFF401FF VMEchip2 (GCSR) D32-D8 256B 1,2,3

$FFF40200 - $FFF40FFF reserved --- 3.5KB 4,5

$FFF41000 - $FFF41FFF reserved --- 4KB 4

$FFF42000 - $FFF42FFF PCCchip2 D32-D8 4KB 1,2

$FFF43000 - $FFF43FFF reserved --- 4KB 4

$FFF44000 - $FFF44FFF reserved --- 4KB 3

$FFF45000 - $FFF45FFF CD2401 (Serial Comm. Cont.) D16-D8 4KB 1,2

$FFF46000 - $FFF46FFF 82596CA (LAN) D32 4KB 1,2,6

$FFF47000 - $FFF47FFF 53C710 (SCSI) D32/D8 4KB 1,2

$FFF48000 - $FFF4FFFF reserved --- 32KB 4

$FFF50000 - $FFF6FFFF reserved --- 128KB 4

$FFF70000 - $FFF77FFF reserved --- 32KB 4

$FFF78000 - $FFF7FFFF reserved --- 288KB 4

$FFF80000 - $FFFBFFFF DROM (BOOT ROM) --- 256KB 7

$FFFC0000 - $FFFCFFFF MK48T08 (BBRAM,TOD Clk) D32-D8 64KB 1,2

$FFFD0000- $FFFEFFFF reserved --- 128KB 4

Notes

1. For a complete description of the register bits, refer to

the appropriate data sheet for the specific chip. For a

more detailed memory map refer to the detailed

peripheral device memory maps in the MVME197LE,

MVME197DP, and MV ME197SP Sing le Board Comp uters

Programmer’s Reference Guide.

2. Address is the physical address going to the device. It is

after the BusSwitch translation from the MC88110

address to the device seen address.

3-4 User’s Manual

Page 35

3. Writes to the LCSR in the VMEchip2 must be 32 bits.

LCSR writes of 8 o r 16 bits terminate with a TEA signal.

Writes to the GCSR may be 8, 16, or 32 bits. Reads t o the

LCSR and GCSR may be 8, 16, or 32 bits.

4. This area does not return an acknowledge signal. If the

processor bus timeout timer is enabled, the access times

out and is terminated by a TEA signal.

5. Size is approximate.

6. Port commands to the 82596CA must be written as two

16-bit writes: upper word first and lower word second.

7. DROM (BOOT ROM) appears at $0 following a local

peripheral bus reset. Th e D RO M appears at 0 until the

DR0 bit is cleared in the PCCchip2. In additi on, the

ROM0 bit in the BusSwitch must be cleared before

the DRAM is ac cess ed .

Detailed I/O Memory Maps

Memory Maps

3

Tables 3-3 through 3-14 give the detailed memory maps for the BusSwitch

register, the ECDM CSR register, the DCAM (I

register, the PCCchip2 register, the printer register, the CD2401 Serial Port

register, the Ethernet LAN register, the SCSI Controller register, and the

BBRAM/TOD Clock register.

2

C) register, the VMEchip2

MVME197LE/D2 3-5

Page 36

Operating Instructions

Table 3-3. BusSwitch Register Memory Map

BusSwitch Base Address = $FFF00000

Offset

3

63 56 55 48 47 32 31 16 15 0

CHIPID CHIPREV GCSR IODATA IODIR

0

8

10

18

20

28

30

38

40

48

50

58

60

68

70

78

80

88

90

PSAR1 PEAR1 PSAR2 PEAR2

PSAR3 PEAR3 PSAR4 PEAR4

PTR1 PTSR1 PTR2 PTSR2

PTR3 PTSR3 PTR4 PTSR4

SSAR1 SEAR1 SSAR2 SEAR2

SSAR3 SEAR3 SSAR4 SEAR4

STR1 STSR1 STR2 STSR2

STR3 STSR3 STR4 STSR4

PAR1 PAR2 PAR3 PAR4 SAR1 SAR2 SAR3 SAR4

BTIMER PADJUST PCOUNT PAL

WPPA WPTPA WPPAT

ROMCR TCTRL1 TCTRL2 LEVEL MASK ISEL0 ISEL1

ABORT CPINT TINT1 TINT2 WPINT PALINT XINT VBASE

TCOMP1 TCOUNT1

TCOMP2 TCOUNT2

GPR1 GPR2

GPR3 GPR4

XCTAGS

100

108

110

118

3-6 User’s Manual

XCCR VECTOR1

VECTOR2 VECTOR3

VECTOR4 VECTOR5

VECTOR6 VECTOR7

Page 37

Memory Maps

3

MVME197LE/D2 3-7

Page 38

3

3-8 User’s Manual

Operating Instructions

Table 3-4. ECDM CSR Register Memory Map

Sub-System Me mory C SR Base Address = $FF F01000

Offset/Register:

ECDM0 ECDM1 ECDM2 ECDM3

ADDR/REGISTER ADDR/REGISTER ADDR/REGISTER ADDR/REGISTER ADDR/REGISTER ADDR/REGISTER ADDR/REGISTER ADDR/REGISTER

00 / MEMCON0 01 / ECDMID0 02 / MEMCON1 03 / ECDMID1 04 / MEMCON2 05 / ECDMID2 06 / MEMCON3 07 / ECDMID3

08 / SYNSTAT0 0 9 / E R STAT0 0A / SYNS TAT1 0 B / E R STAT1 0C / SYNSTAT2 0D / ERSTAT2 0E / SYNSTAT3 0F / ER STAT3

10 / I2CON0 11 / I2STAT0 12 / I2CON1 13 / I2STAT1 14 / I2CON2 15 / I2STAT2 16 / I2CON3 17 / I2STAT3

18 / I2DATA0 19 / I2ADDR0 1A / I2DATA1 1B / I2ADDR1 1C / I2DATA2 1 D / I2ADDR2 1E / I2DATA3 1F / I2ADDR3

D64 D56 D55 D48 D47 D40 D39 D32 D31 D24 D23 D16 D15 D8 D7 D0

ECDM register ma p of four ECDM device s in a 64-bit sy stem. The byte offset add ress is shown next to each reg ister.

Page 39

Memory Maps

Table 3-5. DCAM (I2C) Register Memory Map

DCAM (I2C) Base Address = $C0 (default)

Offset

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

00 00 ID Register

01 01 Version Register

02 02 SL31 SL30 SL29 SL28 SL27 SL26 SL25 DISRAM

03 03 SH31 SH30 SH29 S H28 SH27 SH26 SH25 SCRUB1TIME

04 04 CASCLKSL CASCLK2 CASCLK1 PGMODE ONEBANK DRAMSIZ3 DRAMSIZ2 DRAMSIZ1

05 05 REF7 REF6 REF5 REF4 REF3 REF2 REF1 REF0

06 06 REFTAIL4 REFTAIL3 REFTAIL2 REFTAIL1 REF11 REF10 REF9 REF8

07 07 NOT USED NOT USED RDTAIL5 RDTAIL4 RDTAIL3 RDTAIL2 RDTAIL1 RTCLKSL

08 08 READACK7 READACK6 READACK5 READACK4 READACK3 READACK2 READACK1 INTRRUPT

09 09 NOT USED READOE 6 READOE5 READOE4 READOE3 READOE2 READOE1 NOT USED

0A 10 FECCKSL BREADOE6 BREADOE5 BREADOE4 BREADOE3 BREADOE2 BREADOE1 PCGCLKSL

0B 11 PCHG7 PCHG6 PCHG5 PCHG4 PCHG3 PCHG2 PCHG1 PCHG0

0C 12 SL ECDM5 SLECDM4 SLECDM3 SLECDM2 FLECDM4 FLECDM3 FLECDM2 FLECDM1

0D 13 NOT USED ERAMOE6 ERAMOE5 ERAMOE4 ERAMOE3 ERAMOE2 ERAMOE1 ROECLKSL

0D 14 NOT USED RMWRMOE6 RMWRMOE5 RMWRMOE4 RMWRMOE3 RMWRMOE2 RMWRMOE1 RMWOE5

0F 15 CSRTAIL7 CSRTAIL6 CSRTAIL5 CSRTAIL4 CSRTAIL3 CSRTAIL2 CSRTAIL1 NOT USED

10 16 BWRTTL4 BWRTTL3 BWRTTL2 BWRTTL1 RMWOE4 RMWOE3 RMWOE2 RMWOE1

11 17 SECCLKSL RMWOCKSL BWRITE5 BWRITE4 BWRITE3 BWRITE2 BWRITE1 WRCLKSEL

12 18 NOT USED NOT USED RMW5 RMW4 RMW3 RMW2 RMW1 NOT USED

13 19 RMWTAIL7 RMWTAIL6 RMWTAIL5 RMWTAIL4 RMWTAIL3 RMWTAIL2 RMWTAIL1 RMWTLCSL

14 20 CBRDOE3 CBRDOE2 CBRDOE1 NOT USED C R EADOE3 CREADOE2 CREADOE1 BWRTCSL

15 21 SC9 SC8 SC7 SC6 SC5 SC4 SC3 SC2

16 22 SC17 SC16 SC15 SC14 SC13 S C12 SC11 SC10

17 23 SC25 SC24 SC23 SC22 SC21 S C20 SC19 SC18

18 24 NOT USED SC32 SC31 SC30 SC29 SC28 SC27 SC26

19 25 NOT USED NOT USED NOT USED CBTAIL4 CBTAIL3 CBTAIL2 CBTAIL1 CBTLCKSL

1A 26 CSR7 CSR6 CSR5 CSR4 NOT USED NOT USED NOT USED NOT USED

1B 27 CSR15 CSR14 CSR13 CSR12 CSR11 CSR10 CSR9 CSR8

1C 28 CSR23 CSR22 CSR21 CSR20 CSR19 CSR18 CSR17 CSR16

1D 29 CSR31 CSR30 CSR29 CSR28 CSR27 CSR26 CSR25 CSR24

1E 30 NOT USED NOT USED BRDTAIL5 BRDTAIL4 BRDTAIL3 BRDTAIL2 BRDTAIL1 NOT USED

1F 31

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

3

DCAM registers are only accessible/addressable on the DRAM sub-system I2Cbus through

the ECDM I

2

C interface.

MVME197LE/D2 3-9

Page 40

Operating Instructions

3

3-10 User’s Manual

Page 41

MVME197LE/D2 3-11

Table 3-6. VMEchip2 Memory Map

(Sheet 1 of 4)

VMEchip2 LCSR Base Address = $FFF40000

OFFSET:

D31 D30 D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

00

04

08 VMEbus SLAVE ADDRESS TRANSLATION ADDRESS 1 VMEbus SLAVE ADDRESS TRANSLATION SELECT 1

0C

10

14

18 LOCAL BUS SLAVE ENDING ADDRESS 2 LOCAL BUS SLAVE STARTING ADDRESS 2

1C

20 LOCAL BUS SLAVE ENDING ADDRESS 4 LOCAL BUS SLAVE STARTING ADDRESS 4

24

(LB)

(LB)

D16

WP

28

EN

EN

2C

(VB) GCSR GROUP ADDRESS

D31 D30 D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

LB = Local Bus

(LB) = Local Bus Slave

LV = Local Bus to VMEbus

VMEbus SLAVE ENDING ADDRESS 1 VMEbus SLAVE STARTING ADDRESS 1

VMEbus SLAVE ENDING ADDRESS 2 VMEbus SLAVE STARTING ADDRESS 2

VMEbus SLAVE ADDRESS TRANSLATION ADDRESS 2 VMEbus SLAVE ADDRESS TRANSLATION SELECT 2

(VB)

(VB)

(VB)

(VB)

(VB)

(VB)

(VB)

(VB)

(VB)

SNP

WP

SUP

USR

A32

A24

2

2

2

2

LOCAL BUS SLAVE ENDING ADDRESS 1 LOCAL BUS SLAVE STARTING ADDRESS 1

LOCAL BUS SLAVE ENDING ADDRESS 3 LOCAL BUS SLAVE STARTING ADDRESS 3

LOCAL BUS SLAVE ADDRESS TRANSLAT ION ADDRESS 4 LOCAL BUS SLAVE ADDRESS TRANSLAT ION SELECT 4

(LB)

(LB) AM 4

D16

EN

(LB)

WP

EN

(VB) GCSR

BOARD

ADDRESS

D64

2

2

2

(LB) AM 3

LB

EN4LBEN3LBEN2LBEN1LBI2

BLK

(VB)

PGM

DAT

2

2

2

(LB)

(LB)

D16

WP

EN

EN

LB

LB

I2

EN

WP

LB

I2

I2

SU

PD

(LB) AM 2

LB

I1

EN

D16

(VB)

(VB)

(VB)

(VB)

(VB)

WP

EN

1

A32

1

ROM BANK B

SPEED

(VB)

A24

(XX)

SNP

WP

SUP

1

LB

LB

I1

I1

WP

USR

1

1

(LB)

(LB)

D16

EN

LB

ROM

I1

SIZE

SU

(XX)

VB = VMEbus

(VB) = VMEbus Slave

(XX) = Not Used on the MVME197 Series

(VB)

(VB)

D64

BLK

1

1

1

(LB) AM 1

ROM BANK A

(VB)

PGM

1

SPEED

(XX)

(VB)

DAT

1

Memory Maps

3

Page 42

Operating Instructions

3

3-12 User’s Manual

Page 43

MVME197LE/D2 3-13

Table 3-6. VMEchip2 Memory Map (Continued)

(Sheet 2 of 4)

VMEchip2 LCSR Base Address = $FFF40000

OFFSET:

D31 D30 D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

30

34

38

3C

40 DMAC BYTE COUNTER

44

INTERRUPT

48

1

SIGNAL

IRQ

CLR

4C

IRQ

STAT

VMEbus

INTERRUPT

LEVEL

VB

DMAC

TO

TIME OFF

50 TICK TIMER 1 COMPARE

54

58 TICK TIMER 2 COMPARE

5C

SCON SYS

60

FAIL

BRD

FAIL

STAT

PURS

STAT

CLR

PURS

STAT

BRD

FAIL

OUT

RST

SW

EN

SYS

RSTWDCLR

64

D31 D30 D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

LB = Local Bus

(LB) = Local Bus Slave

LV = Local Bus to VMEbus

ROM0

(XX)

VMEbus INTERRUPT VECTOR

TIME ON

WD

WD

CLR

CNT

TO

STAT

STAT

DMAC TB

SNP MODE

DMAC

WD

BDF

EN

SPRAM

SPEED

(XX)

DMAC LOCAL BUS ADDRESS COUNTER

DMAC VMEbus ADDRESS COUNTER

DMAC TABLE ADDRESS COUNTER

WD

SYS

LRST

ROBN

(XX)

MODE

DMAC

VMEbus

GLOBAL

TIMEOUT

TICK TIMER 1 COUNTER

TICK TIMER 2 COUNTER

WD

WD

RST

EN

EN

PRESCALER COUNTER

VB = VMEbus

(VB) = VMEbus Slave

(XX) = Not Used on the MVME197 Series

LV

INTE

VMEbus

ACCESS

TIMEOUT

LV

DHBLVDWB

DMAC LB

SNP

MODE

DMAC

INTERRUPT

COUNTER

TIMEOUT

OVERFLOW

COUNTER 2

LV

FAIRLVRWDLVREQUEST

DMAC

DMAC

DMAC

VME

LB

TVME

INC

INC

MPU

MPU

CLR

LB

EN

LOCAL

BUS

PERR

WATCHDOG TIMEOUT PRESCALER ADJUST

CLR

OVF

2

LEVEL

DMAC

D16

MPU

MPU

LB

OB

COC2CNT

EN

DMAC

DMACENDMAC

HALT

DMAC

DMAC

BLK

TR

MPU

DMAC

LB

LB

TO

2

DMAC

FAIR

DMAC

LB

OB

DMAC

LB

TO

DMAC

RELM

DMAC

LB

ERR

CLR

OVF

1

TBL

DMACAMDMACAMDMACAMDMACAMDMACAMDMAC

BLK

TR

DMAC

LB

LB

EN

PERR

OVERFLOW

COUNTER 1

DMAC

REQUEST

LEVEL

DMAC

VME

ERR

COC1CNT

AM

DMAC

DONE

EN

1

Memory Maps

3

Page 44

Operating Instructions

3

3-14 User’s Manual

Page 45

MVME197LE/D2 3-15

Table 3-6. VMEchip2 Memory Map (Continued)

(Sheet 3 of 4)

VMEchip2 LCSR Base Address = $FFF40000

OFFSET:

D31 D30 D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

AC

AB

SYS

MWP

PE

IRQ1

TIC

TIC

VME

DMAC

GCSR

GCSR

GCSR

GCSR

GCSR

GCSR

LB

LB

LB

LB

LB

LB

LB

LB

FAIL

SW

FAIL

ERR

IRQ

EDGE

TIM2

TIM1

IACK

IRQ

SIG3

SIG2

SIG1

SIG0

LM1

LM0

SW7

SW6

SW5

SW4

SW3

68

IRQ

IRQ

IRQ

EN

IRQ

IRQ

6C

31

IRQ

EN

EN

IRQ

IRQ

30

29

70

CLR

CLR

CLR

IRQ

30

29

ACFAIL

IRQ LEVEL

VMEbus

ACKNOWLEDGE

IRQ LEVEL

SW7

IRQ LEVEL

SPARE

IRQ LEVEL

CLR

IRQ

7C

74

78

80

84

88

IRQ

31

VECTOR BASE

IRQ

REGISTER 0

D31 D30 D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

LB = Local Bus

(LB) = Local Bus Slave

LV = Local Bus to VMEbus

IRQ

IRQ

IRQ

EN

EN

EN

IRQ

IRQ

27

CLR

27

VECTOR BASE

REGISTER 1

26

IRQ

26

IRQ LEVEL

IRQ LEVEL

IRQ LEVEL

IRQ LEVEL

IRQ

CLR

IRQ

ABORT

DMAC

SW6

VMEbus

IRQ7

28

CLR

IRQ

28

IRQ

EN

EN

IRQ

IRQ

25

24

CLR

CLR

IRQ

IRQ

25

24

MST

IRQ

IRQ

IRQ

IRQ

IRQ

IRQ

IRQ

IRQ

IRQ

EN

EN

EN

EN

EN

EN

EN

IRQ

IRQ

IRQ

IRQ

23

22

21

CLR

CLR

22

SYSFAIL

IRQ LEVEL

IRQ LEVEL

IRQ LEVEL

VMEbus

IRQ LEVEL

IRQ

21

GCSR

SIG 3

SW5

IRQ6

AC

FAIL

LEVEL

CLR

IRQ

ABORT

LEVEL

IRQ

23

SYS

FAIL

EN

LEVEL

IRQ

20

19

CLR

CLR

IRQ

IRQ

20

19

GENERAL

PURPOSE

I/O ENABLE

IRQ

18

17

CLR

IRQ

18

17

MASTER WRITE

POST ERROR

IRQ LEVEL

GCSR

SIG 2

IRQ LEVEL

SW4

IRQ LEVEL

VMEbus

IRQ5

IRQ LEVEL

CLR

IRQ

IRQ

EN

IRQ

16

SET

IRQ

CLR

IRQ

16

EN

15

15

15

IRQ

EN

EN

IRQ

IRQ

14

13

SET

SET

IRQ

IRQ

14

13

CLR

CLR

IRQ

IRQ

14

13

PARITY ERROR

IRQ LEVEL

GCSR

SIG 1

IRQ LEVEL

SW3

IRQ LEVEL

VMEbus

IRQ4

IRQ LEVEL

GENERAL

PURPOSE

I/O OUTPUT

SET

IRQ

CLR

IRQ

VB = VMEbus

(VB) = VMEbus Slave

(XX) = Not Used on the MVME197 Series

SW2

IRQ

IRQ

12

12

12

IRQ

SET

IRQ

CLR

IRQ

EN

11

11

11

IRQ

EN

IRQ

10

SET

IRQ

10

CLR

IRQ

10

EDGE-SENSITIVE

IRQ LEVEL

GCSR

IRQ LEVEL

IRQ LEVEL

VMEbus

IRQ LEVEL

GENERAL

PURPOSE

I/O INPUT

EN

IRQ

SW1

IRQ

EN

IRQ

SET

IRQ

CLR

IRQ

IRQ1

SIG 0

SW2

IRQ3

SPARE VME

SW0

IRQ

EN

IRQ

9

8

SET

IRQ

9

8

CLR

IRQ

9

8

IRQ

EN

7

IRQ7

IRQ

EN

IRQ

6

TICK TIMER 2

IRQ LEVEL

IRQ LEVEL

IRQ LEVEL

IRQ LEVEL

VME

VME

VME

IRQ6

IRQ5

IRQ

EN

IRQ

5

GCSR

LM 1

SW1

VMEbus

IRQ2

GENERAL PURPOSE INPUT

VME

IRQ4

IRQ3

IRQ

IRQ

IRQ

EN

EN

IRQ

IRQ

IRQ

4

3

EN

2

TICK TIMER 1

VME

IRQ2

IRQ

EN

IRQ

1

IRQ LEVEL

GCSR

LM 0

IRQ LEVEL

SW0

IRQ LEVEL

VMEbus

IRQ1

IRQ LEVEL

VME

IRQ1

IRQ

EN

IRQ

0

Memory Maps

3

Page 46

Operating Instructions

3

3-16 User’s Manual

Page 47

MVME197LE/D2 3-17

Table 3-6. VMEchip2 Memory Map (Continued)

(Sheet 4 of 4)

VMEchip2 GCSR Base Address = $FFF40100

L V D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

00

LM3 LM2 LM1 LM0 SIG3 SIG2 SIG1 SIG0 RST ISF BF SCON

42

84

C6

10 8

14 A

18 C

1C E

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

NOTES: L = Local Bus Offset.

CHIP REVISION CHIP ID

GENERAL PURPOSE CONTROL AND STAT US REGISTER 0

GENERAL PURPOSE CONTROL AND STAT US REGISTER 1

GENERAL PURPOSE CONTROL AND STAT US REGISTER 2

GENERAL PURPOSE CONTROL AND STAT US REGISTER 3

GENERAL PURPOSE CONTROL AND STAT US REGISTER 4

GENERAL PURPOSE CONTROL AND STAT US REGISTER 5

V = VMEbus Offset.

SYS

FL

Memory Maps

3

Page 48

Operating Instructions

3

3-18 User’s Manual

Page 49

MVME197LE/D2 3-19

Table 3-7. PCCchip2 Memory Map

PCCchip2 LCSR Base Address = $FFF42000

OFFSET:

D31 D30 D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

00

04

08

0C

10

14

GPI

GPI

PLTY

E/L*

18

1C

CHIP ID CHIP REVISION DR0

PRESCALER COUNT PRESCALER CLOCK ADJUST

GPI

GPI

GPI

INT

IEN

ICLR

SCC

SCC

RTRY

PAR

ERR

ERR

GPI

IRQ LEVEL GPI GIOE GPO

SCC

SCC

EXT

ERR

LTO

ERR

SCC

SCLR

SCC

MDM

SCC

MDM

SCC

MDM

SCC MODEM

IRQ LEVEL

TIC TIMER 1 COMPARE

TIC TIMER 1 COUNTER

TIC TIMER 2 COMPARE

TIC TIMER 2 COUNTER

OVERFLOW

COUNTER 2

TIC2

INT

SCC

TX

IRQ

20

24 SCC TRANSMIT PIACK SCC RECEIVE PIACK

LAN

LAN

LAN

LAN

LAN

28

2C

PRTR

PRTR

PRTR

ACK

30

ACK

E/L*

PRTR

BSY

E/L*

ACK

PRTR

BSY

PLTY

PRTR

BSY

34

PLTY

PAR

ERR

ERR

SCSI

SCSI

PAR

ERR

ACK

IEN

BSY

IEN

PRTR

ACK

ICLR

PRTR

BSY

ICLR

ERR

PRTR

INT

PRTR

INT

EXT

EXT

IRQ LEVEL

IRQ LEVEL

LTO

ERR

SCSI

LTO

ERR

PRTR ACK

PRTR BSY

LAN

SCLR

SCSI

SCLR

PRTR

FLT

PLTY

PRTR

FLT

E/L*

PRTR

FLT

INT

PRTR

FLT

IEN

PRTR

FLT

ICLR

PRTR FAULT

IRQ LEVEL

PLTY

PRTR

SEL

PLTY

PRTR

ANY

LAN

E/L*

INT

PRTR

PRTR

PRTR

SEL

SEL

E/L*

INT

INT

PRTR

38 CHIP SPEED PRINTER DATA

3C

D31 D30 D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

TIC2

IEN

SCC

TX

IEN

LAN

IEN

SEL

IEN

ACK

TIC2

ICLR

SCC

TX

AVEC

LAN

ICLR

PRTR

SEL

ICLR

PRTR

FLT

CPU

MSTR

040

INT

EN

CLR

COUN

OVF

EN

2

TIC TIMER 2

IRQ LEVEL

SCC TRANSMIT

IRQ LEVEL

LAN

IRQ LEVEL

PRTR SEL

IRQ LEVEL

PRTR

PRTRPEPRTR

SEL

INTERRUPT

IPL LEVEL

FAST

BRAM VECTOR BASE

COUN

2

EN

BSY

OVERFLOW

COUNTER 1

2

SCC

SC1

LAN

SC1

PRTR

PLTY

TIC1

TIC1

INT

SCC

SCC

IRQ

LAN

ERR

INT

SCSI

IRQ

PRTR

PE

PE

INT

SCC

SCC MODEM PIACK

LAN

ERR

SCSI

PRTR

PRTR

DAT

ENBL

SC2

LAN

SC2

PRTR

PE

E/L*

CLR

OVF

1

TIC1

ICLR

SCC

AVEC

LAN

ERR

ICLR

PRTR

PE

ICLR

PRTR

INP

TIC TIMER 1

SCC RECEIVE

PRTR

STB

INTERRUPT

MASK LEVEL

IEN

IEN

IEN

IEN

PE

IEN

COUN

EN

1

IRQ LEVEL

IRQ LEVEL

LAN ERR

IRQ LEVEL

SCSI INT

IRQ LEVEL

PRTR PE

IRQ LEVEL

PRTR

FAST

ASTB

COUN

EN

PRTR