Page 1

MVME166

Single Board Computer

Installation Guide

(MVME166IG/D2)

Page 2

Notice

While reasonable efforts have been made to assure the accuracy of this document,

Motorola, Inc. assumes no liability resulting from any omissions in this document, or

from the use of the information obtained therein. Motor ola reserves the right to r evise

this document and to make changes from time to time in the content hereof without

obligation of Motorola to notify any person of such revision or changes.

No part of this material may be reproduced or copied in any tangible medium, or

stored in a retrieval system, or transmitted in any form, or by any means, radio,

electronic, mechanical, photocopying, recording or facsimile, or otherwise, without the

prior written permission of Motorola, Inc.

It is possible that this publication may contain reference to, or information about

Motorola products (machines and programs), programming, or services that are not

announced in your country. Such references or information must not be construed to

mean that Motorola intends to announce such Motorola products, programming, or

services in your country.

Restricted Right Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S.

Government, the following notice shall apply unless otherwise agreed to in writing by

Motorola, Inc.

Use, duplication, or disclosure by the Governm ent is subject to r estrictions as set forth

in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software

clause at DFARS 252.227-7013.

Motorola, Inc.

Computer Group

2900 South Diablo Way

Tempe, Arizona 85282

Page 3

Preface

This manual provides general board level hardware description, hardware preparation

and installation instructions, debugger general information, and using the debugger;

for the MVME166 Single Board Computer.

This manual is intended for anyone who wants to provide OEM systems, supply

additional capability to an existing compatible system, or work in a lab environment

for experimental purposes.

A basic knowledge of computers, and digital logic is assumed.

After using this manual, you may wish to become familiar with the publications listed

in the Related Documentation section in Chapter 1 of this manual. This installation guide

is based on these other documents.

Page 4

The computer programs stored in the Read Only Memory of this device contain

material copyrighted by Motorola Inc., first published 1990, and may be used on ly

under a license such as the License for Computer Programs (Article 14) contained in

Motorola’s Terms and Conditions of Sale, Rev. 1/79.

This equipment generates, uses, and can radiate radio

!

WARNING

Motorola and the Motorola symbol are registered trademarks of Motorola, Inc.

Delta Series, VMEmodule, and VMEsystem are trademarks of Motorola, Inc.

Timekeeper and Zeropower are trademarks of Thompson Components.

All other products mentioned in this document are trademarks or registered

trademarks of their respective holders.

frequency energy and if not installed and used in

accordance with the documentation for this product, may

cause interference to radio communications. It has been

tested and found to comply with the limits for a Class A

Computing Device pursuant to Subpart J of Part 15 of FCC

rules, which are designed to provide reasonable protection

against such interference when operated in a commercial

environment. Operation of this equipment in a residential

area is likely to cause interference in w hich ca se the user, at

the user’s own expense, will be required to take whatever

measures necessary to correct the interference.

©Copyright Motorola 1993, 1994

All Rights Reserved

Printed in the United States of America

April 1994

Page 5

Safety Summary

Safety Depends On You

The following general safety precautions must be observed during all phases of

operation, service, and repair of this equipment. Failure to comply with these

precautions or with specific warnings elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the equipment. Motorola, Inc.

assumes no liability for the customer’s failure to comply with these requirements.

The safety precautions listed below represent warnings of certain dangers of which

Motorola is aware. You, as the user of the product, should follow these warnings and

all other safety precautions necessary for the safe operation of the equipment in your

operating environment.

Ground the Instrument.

T o minimize sho ck hazard, the equipment chassis and enclosure must be connected to

an electrical ground. The equipment is supplied with a three-conductor AC power

cable. The power cable must either be plugged into an approved three-contact

electrical outlet or used with a three-contact to two-contact adapter, with the

grounding wire (green) firmly connected to an electrical ground (safety ground) at the

power outlet. The power jack and mating plug of the power cable meet International

Electrotechnical Commission (IEC) safety sta ndards.

Do Not Operate in an Explosive Atmosphere.

Do not operate the equipment in the presence of flammable gases or fumes. Operation

of any electrical equipment in such an environment constitutes a definite safety hazard.

Keep Away From Live Circuits.

Operating personnel must not remove equipment covers. Only Factory Authorized

Service Personnel or other qualified maintenance personnel may remove equipment

covers for internal subassembly or component replacem ent or any internal adjustment.

Do not replace components with power cable connected. Under certain conditions,

dangerous voltages may exist even with the power cable removed. To avoid injuries,

always disconnect power and discharge circuits before touching them.

Do Not Service or Adjust Alone.

Do not attempt internal service or adjustment unless another person, capable of

rendering first aid and resuscitation, is present.

Page 6

Use Caution When Exposing or Handling the CRT.

Breakage of the Cathode-Ray Tube (CRT) causes a high-velocity scattering of glass

fragments (implosion). To prevent CRT implosion, avoid rough handling or jarring of

the equipment. Handling of the CRT should be done only by qualified maintenance

personnel using approved safety mask and gloves.

Do Not Substitute Parts or Modify Equipment.

Because of the danger of intr oducing additional hazard s, do not install substitute parts

or perform any unauthorized modification of the equipment. Contact your local

Motorola representative for service and repair to ensure that safety features are

maintained.

Dangerous Procedure Warnings.

Warnings, such as the example below, precede potentially dangerous procedures

throughout this manual. Instructions contained in the warnings must be followed. Y ou

should also employ all other safety precautions which yo u deem necessary for the

operation of the equipment in your operating environment.

Dangerous voltages, capable of causing death, a re present in

!

WARNING

this equipment. Use extreme caution when handling,

testing, and adjusting.

Page 7

Contents

CHAPTER 1 BOARD LEVEL HARDWARE DESCRIPTION

Introduction.............................................................................................................1-1

Overview...........................................................................................................1-1

Related Documentation ..................................................................................1-2

Requirements....................................................................................................1-5

Features .............................................................................................................1-5

Specifications....................................................................................................1-6

Manual Terminology .......................................................................................1-6

Block Diagram.........................................................................................................1-8

Functional Description...........................................................................................1-9

Front Panel Switches and Indicators.............................................................1-9

Data Bus Structure.........................................................................................1-10

MC68040 MPU ...............................................................................................1-10

Flash Memory and Download EPROM......................................................1-10

SRAM...............................................................................................................1-11

Onboard DRAM.............................................................................................1-12

Battery Backed Up RAM and Clock............................................................1-13

VMEbus Interface ..........................................................................................1-13

VME Subsystem Bus (VSB) Interface..........................................................1-13

I/O Interfaces .................................................................................................1-13

Serial Port Interface................................................................................1-13

MC68230 Parallel Interface/Timer.......................................................1-14

Parallel Port Interface.............................................................................1-15

Ethernet Interface.............................. ..... ...... ........................................ ...1-15

SCSI Interface..........................................................................................1-16

SCSI Termination....................................................................................1-16

Local Resources..............................................................................................1-16

Programmable Tick Timers...................................................................1-17

Watchdog Timer .....................................................................................1-17

Software-Programmable Hardware Interrupts..................................1-17

Local Bus Timeout..................................................................................1-17

Connectors ......................................................................................................1-17

Memory Maps .......................................................................................................1-18

Local Bus Memory Map................................................................................1-18

Normal Address Range .........................................................................1-18

VMEbus Memory Map..................................................................................1-22

vii

Page 8

VMEbus Accesses to the Local Bus......................................................1-22

VMEbus Short I/O Memory Map............................................................1-22

VSB Memory Map................................. ...... ....................................... ...............1-22

CHAPTER 2 HARDWARE PREPARATION AND INSTALLATION

Introduction.................................................................................................................2-1

Unpacking Instructions..............................................................................................2-1

Hardware Preparation ...............................................................................................2-1

SCSI Terminator Enable Header J2 ...................................................................2-2

General Purpose Readable Jumpers on Header J3 .........................................2-4

System Controller Header J6..............................................................................2-4

SRAM Backup Power Source Select Header J7...............................................2-5

Installation Instructions.............................................................................................2-6

MVME166 Module Installation.........................................................................2-6

System Considerations .......................................................................................2-8

CHAPTER 3 DEBUGGER GENERAL INFORMATION

Overview of M68000 Firmware................................................................................3-1

Description of 166Bug................................................................................................3-1

166Bug Implementation.............................................................................................3-3

Installation and Startup .............................................................................................3-3

BOOTBUG ...................................................................................................................3-7

166BBug Implementation...................................................................................3-7

Execute User Program ........................................................................................3-8

Setup System Parameters...................................................................................3-8

Autoboot ......................................................................................................................3-9

ROMboot....................................................................................................................3-10

Network Boot............................................................................................................3-10

Restarting the System............................................................................................ ...3-11

Reset .................................. ..... ........................................ .....................................3-11

Abort............................................. ..... ........................................ ..........................3-12

Break....................................... ........................................ .....................................3-12

SYSFAIL* Assertion/Negation........................................................................3-12

MPU Clock Speed Calculation ........................................................................3-13

Memory Requirements ............................................................................................3-13

Terminal Input/Output Control.............................................................................3-14

Disk I/O Support......................................................................................................3-15

Blocks Versus Sectors ........................................................................................3-15

viii

Page 9

Device Probe Function .....................................................................................3-16

Disk I/O via 166Bug Commands................................................................... 3-16

IOI (Input/Output Inquiry).....................................................................3 -16

IOP (Physical I/O to Disk) ..................................................... ...... ............3-16

IOT (I/O Teach).........................................................................................3 -16

IOC (I/O Control)...................................................................................... 3-17

BO (Bootstrap Operating System)........................................................... 3-17

BH (Bootstrap and Halt)...........................................................................3-17

Disk I/O via 166Bug System Calls.................................................................3-17

Default 166Bug Controller and Device Parameters.....................................3-18

Disk I/O Error Codes.......................................................................................3-19

Network I/O Support ............................................................................................. 3-19

Intel 82596 LAN Coprocessor Ethernet Driver.............................................3-19

UDP/IP Protocol Modules..............................................................................3-19

RARP/ARP Protocol Modules........................................................................3-20

BOOTP Protocol Module.................................................................................3-20

TFTP Protocol Module......................................................................................3-20

Network Boot Control Module.......................................................................3-20

Network I/O Error Codes...............................................................................3-20

Multiprocessor Support .......................................................................................... 3-21

Multiprocessor Control Register (MPCR) Method ......................................3-21

GCSR Method.................................................................................................... 3-23

Diagnostic Facilities.................................................................................................3-23

CHAPTER 4 USING THE 166Bug DEBUGGER

Entering Debugger Command Lines ......................................................................4-1

Syntactic Variables .............................................................................................. 4-2

Expression as a Parameter.......................................................................... 4-3

Address as a Parameter .............................................................................. 4-4

Address Formats..........................................................................................4-4

Offset Registers ............................................................................................4-6

Port Numbers ..................................... ...... ....................................... ....................4-8

Entering and Debugging Programs......................................................................... 4-9

Calling System Utilities from User Programs........................................................ 4-9

Preserving the Debugger Operating Environment...............................................4-9

166Bug Vector Table and Workspace.............................................................. 4-10

Hardware Functions.........................................................................................4-10

Exception Vectors Used by 166Bug ................................................................ 4-11

Using 166Bug Target Vector Table.......................................................... 4-12

Creating a New Vector Table...................................................................4-13

ix

Page 10

166Bug Generalized Exception Handler.................................................4-15

Floating Point Support............................................ ...... ........................................ ...4-17

Single Precision Real......................................................... ................................4-18

Double Precision Real.......................................................................................4-18

Extended Precision Real...................................................................................4-18

Packed Decimal Real.........................................................................................4-19

Scientific Notation.............................................................................................4-19

The 166Bug Debugger Command Set....................................................................4-20

APPENDIX A CONFIGURE AND ENVIRONMENT COMMANDS

Configure Board Information Block........................................................................A-1

Set Environment to Bug/Operating System..........................................................A-2

APPENDIX B DISK/TAPE CONTROLLER DATA

Disk/Tape Controller Modules Supported............................................................B-1

Disk/Tape Controller Default Configurations......................................................B-2

IOT Command Parameters for Supported Floppy Types....................................B-5

APPENDIX C NETWORK CONTROLLER DATA

Network Controller Modules Supported...............................................................C-1

x

Page 11

List of Figures

FIGURES

Figure 1-1. MVME166 Block Diagram..................................................................1-8

Figure 2-1. MVME166 Switches, Headers, Connectors, Fuses, and LEDs......2-3

xi

Page 12

xii

Page 13

List of T ables

TABLES

Table 1-1. MVME166 Specifications......................................................................1-6

Table 1-2. Local Bus Memory Map .....................................................................1-19

Table 1-3. Local I/O Devices Memory Map ......................................................1-20

Table 4-1. Debugger Address Parameter Formats..............................................4-5

Table 4-2. Exception Vectors Used by 166Bug...................................................4-11

Table 4-3. Debugger Commands.........................................................................4-20

Table A-1. ENV Command Parameters ..............................................................A-3

xiii

Page 14

xiv

Page 15

BOARD LEVEL

Introduction

This chapter describes the board level hardware features of the MVME166

Single Board Computers. The chapter is organized with a board level

overview and features list in this introduction, followed by a more detailed

hardware functional description. Front panel switches and indicators are

included in the detailed hardware functional description. The chapter closes

with some general memory maps.

All programmable registers in the MVME166 that reside in ASICs are covered

in the MVME166/MVME167/MVME187 Single Board Computers Programmer’s

Reference Guide.

Overview

The MVME166 is based on the MC68040 microprocessor. The MVME166 has

4/8/16/32/64/128/2 56 MB o f ECC-protected D RAM, 1 MB of Flash mem ory

with download EPROM, 128KB of static RAM (with battery backup), 8KB of

static RAM and time of day clock (with battery backup), Ethernet transceiver

interface, four serial ports with TTL inter face, four tick timers, watchdog timer,

SCSI bus interface with DMA, Centronics printer port,

A16/A24/A32/D8/D16/D32/D64 VMEbus master/slave interface, VMEbus

system controller, and a VSB interface.

HARDWARE DESCRIPTION

1

The I/O connection for the MVME166 is provided by two high density

shielded front panel I/O connectors. The SCSI bus is connected through a 68

pin connector. The printer, four serial ports and Ethernet interface are

connected through a 100 pin con n ecto r. The MVME712-10 transition mo dul e

and the MVME712-06/07/09 I/O distribution board set were designed to

support the MVME166 boards. These transition boards provide configuration

headers, serial port drivers and industry standard connectors for the I/O

devices.

The VMEbus interface is provided by an ASIC called the VMEchip2. The

VMEchip2 includes two tick timers, a watchdog timer, programmable map

decoders for the master and slave interfaces, and a VME bus to/from local bus

DMA controller, a VMEbus to/from local bus non-DMA programmed access

interface, a VMEbus interrupter, a VMEbus system controller, a VMEbus

interrupt handler, and a VMEbus requester.

MVME166IG/D21-1

Page 16

1

Board Level Hardware Description

Processor-to-VMEbus transfers can be D8, D16, or D32. VMEchip2 DMA

transfers to the VMEbus, however, can be D16, D32, D16/BLT, D32/BLT, or

D64/MBLT.

The VSBchip2 provides the VSB interface on the MVME166. The VSBchip2

includes programmable map decoders for the master and slave interfaces, a

VSB master interface, a VSB slave interface, a VSB interrupter, a VSB interrupt

handler, a VSB serial requester, a VSB serial arbiter, and a VSB parallel

requester. The VSB is connected to the P2 connector rows A and C on the

MVME166.

The PCCchip2 ASIC provides two tick timers and the interface to the LAN

chip, SCSI chip, serial port chip, printer port, BBRAM, and do wnload EPROM

for Flash memory.

The MCECC memory controller ASIC provides the programmable interface

for the ECC-protected DRAM mezzanine board.

Related Documentation

The MVME166 does not ship with all of the documentation that is available for

the product. The MVME166 instead ships with a start-up installation guide

(the document you are presently reading) that includes all the information

necessary to begin working with these products: installation instructions,

jumper configuration information, memory maps, debugger/monitor

commands, and any other information needed for start-up of the board. The

installation guide is MVME166IG/D for the MVME166.

The following publications are appl icable to the MVME166 and may provide

additional helpful information. They may be purchased by contacting your

local Motorola sales office. Non-Motorola documents may be purchased from

the sources listed.

Document Title

MVME166 Single Board Computer User’s Manual MVME166

MVME166 Single Board Computer Support Information SIMVME166

MVME167Bug Debugging Package User’s Manual MVME167BUG

Debugging Package for Motorola 68K CISC CPUs User’s

Manual

1-2 MVME166 Single Board Computer Installation Guide

Motorola

Publication Number

68KBUG

Page 17

Introduction

1

Single Board Computers SCSI Softw are User’s Manual SBCSCSI

MVME166/MVME167/MVME187 Single Board

Computers Programmer’s Reference Guide

MVME712-06/07/09 I/O Distribution Board Set User’s

Manual

MVME712-10 Transition Module User’s Manual MVME712-10

M68040 Microprocessors User’s Manual M68040UM

Notes

Document Title

Motorola

Publication Number

MVME187PG

MVME712IO

The SIMVME166 manual contains: the connector

interconnect signal information, parts lists, and the

schematics; for the MVME166.

Although not shown in the above list, each Motorola

Computer Group manual publication number is suffixed

with characters which represent the revision level of the

document, such as "/D2" (the second revision of a manual);

a supplement bears the same number as a manual but has a

suffix such as "/D2A1" (the first supplement to the second

edition of the manual).

These manuals may also be ordered in documentation sets as follows:

68-MVME166SET for use with the MVME166.

MVME166/D

MVME167BUG/D

68KBUG/D

SBCSCSI/D

MVME187PG/D

SIMVME166/D

MVME166IG/D2 1-3

Page 18

1

Board Level Hardware Description

To further assist your development effort, Motorola has collected user’s

manuals for each of the peripheral controllers used on the MVME166 f rom the

suppliers. This bundle, which can be ordered as part number 68-1X7DS,

includes manuals for the following:

NCR 53C710 SCSI Controller Data Manual and Programmer’s Guide

Intel i82596 Ethernet Controller User’s Manual

Cirrus Logic CD2401 Serial Controller User’s Manual

SGS-Thompson MK48T08 NVRAM/TOD Clock Data Sheet

The following publications are also available from the sources indicated.

Versatile Backplane Bus: VMEbus, ANSI/IEEE Std 1014-1987, The Institute of

Electrical and Electronics Engineers, Inc., 34 5 East 47th Street, New York, NY

10017 (VMEbus S pecific ation ). (T his is also Mic rop rocess or S yste m Bus for 1 to 4

Byte Data, IEC 821 BUS, Bureau Central de la Commission Electrotechnique

Internationale; 3,rue de Varembé, Geneva, Switzerland.)

IEEE Standard for Multiplexed High-Performance Bus Structure: VSB, ANSI/IEEE

Std 1096-1988, The Institute of Electrical and Electronics Engineers, Inc., 345

East 47th Street, New York, NY 10017 (VS B Specification). (This is also Parallel

Sub-system Bus of the IEC 821 VMEbus, IEC 822 VSB, Bureau Central de la

Commission Electrotechnique Internationale; 3,rue de Varembé, Geneva,

Switzerland.)

ANSI Small Computer System Interface-2 (SCSI-2), Draft Document X3.131-198X,

Revision 10c; Global Engineering Documents, P.O. Box 19539, Irvine, CA

92714.

CL-CD2400/2401 Four-Channel Multi-Protocol Communications Controller Data

Sheet, order number 542400-003; Cirrus Logic, Inc., 3100 West Warren Ave.,

Fremont, CA 94538.

82596CA Local Area Network Coproces sor Data Sheet, order number 290218; and

82596 User’s Manual, order number 296853; Intel Corporation, Literature Sa les,

P.O. Box 58130, Santa Clara, CA 95052-8130.

NCR 53C710 SCSI I/O Processor Data Manual, order number NCR53C710DM;

and NCR 53C710 SCSI I/O Processor Programmer’s Guide, order number

NCR53C710PG; NCR Corporation, Microelectronics Products Division,

Colorado Springs, CO.

TM

MK48T08(B) Timekeeper

RAMs Databook, order number DBSRAM71; SGS-THOMPSON

Microelectronics Group; North & South American Marketing Headquarters,

1000 East Bell Road, Phoenix, AZ 85022-2699.

and 8Kx8 Zeropower TM RAM data sheet in Static

i28F020 F l ash Memory Data Sheet, order number 290245; Intel Literature Sales,

P.O. Box 7641, Mt. Prospect, IL 60056-7641.

1-4 MVME166 Single Board Computer Installation Guide

Page 19

Requirements

These boards are designed to conform to the requirements of the following

documents:

❏ VMEbus Specification (IEEE 1014-87)

❏ EIA-232-D Serial Interface Specification, EIA

❏ SCSI Specification, ANSI

❏ VSB Specification (IEEE 1096-1988)

Features

Features of the MVME166 are listed below.

❏ MC68040 Microprocessor

❏ 4/8/16/32/64/128/256MB of 32-bit DRAM with ECC protect io n

❏ 1 MB of Flash memory and a download EPROM

❏ 128KB SRAM (with battery backup)

❏ Status LEDs for FAIL, STAT, RUN, SCON, LAN, RPWR, SCSI, VME, TPWR and VSB

❏ 8K by 8 RAM and time of day clock with battery backup

❏ RESET and ABORT switches

❏ Four 32-bit tick timers for periodic interrupts

❏ Watchd og timer

❏ Eight software interrupts

❏ I/O

– SCSI Bus interface with DM A

– Four serial ports with TTL buff e rs

– Centronics printer p ort

– Ethernet transceiver interface with DMA

❏ VMEbus interface

– VMEbus system controlle r fun c t ion s

– VMEbus to local bus int e rface (A24/A32,

D8/D16/D32 (D8/D 16/D32/D64BLT) (BLT = Bl oc k Tr an sfe r))

– Local bus to VMEbus interf ac e (A 16 /A24/A32, D8/D16/D32)

–VMEbus interrupter

– VMEbus interrupt handler

– Global CSR for interp rocessor communica ti on s

– DMA for fast local memor y - VME b us t ran sfers (A16/A24/A32,

D16/D32 (D16/D32/D64BLT))

❏ VSB interface

– Local bus to VSB interface (A 16/A24/A32, D8/D16/D 32)

– VSB to local bus interfac e ( A 16/A24/A32, D8/D16 /D32)

– Control and Status Register se t s (Board CSRs accessible from bot h

local bus and VSB; local CSRs acc essible from loca l bus)

(Includes Global CSR for IPC (General Purpose Register s 1 an d 2))

– Local bus interrupter

– VSB interrupter and VSB interrupt handler

– Bidirectional write posting - local bus to VSB and VSB to local bus

– EVSB compatible

Introduction

1

MVME166IG/D2 1-5

Page 20

1

Board Level Hardware Description

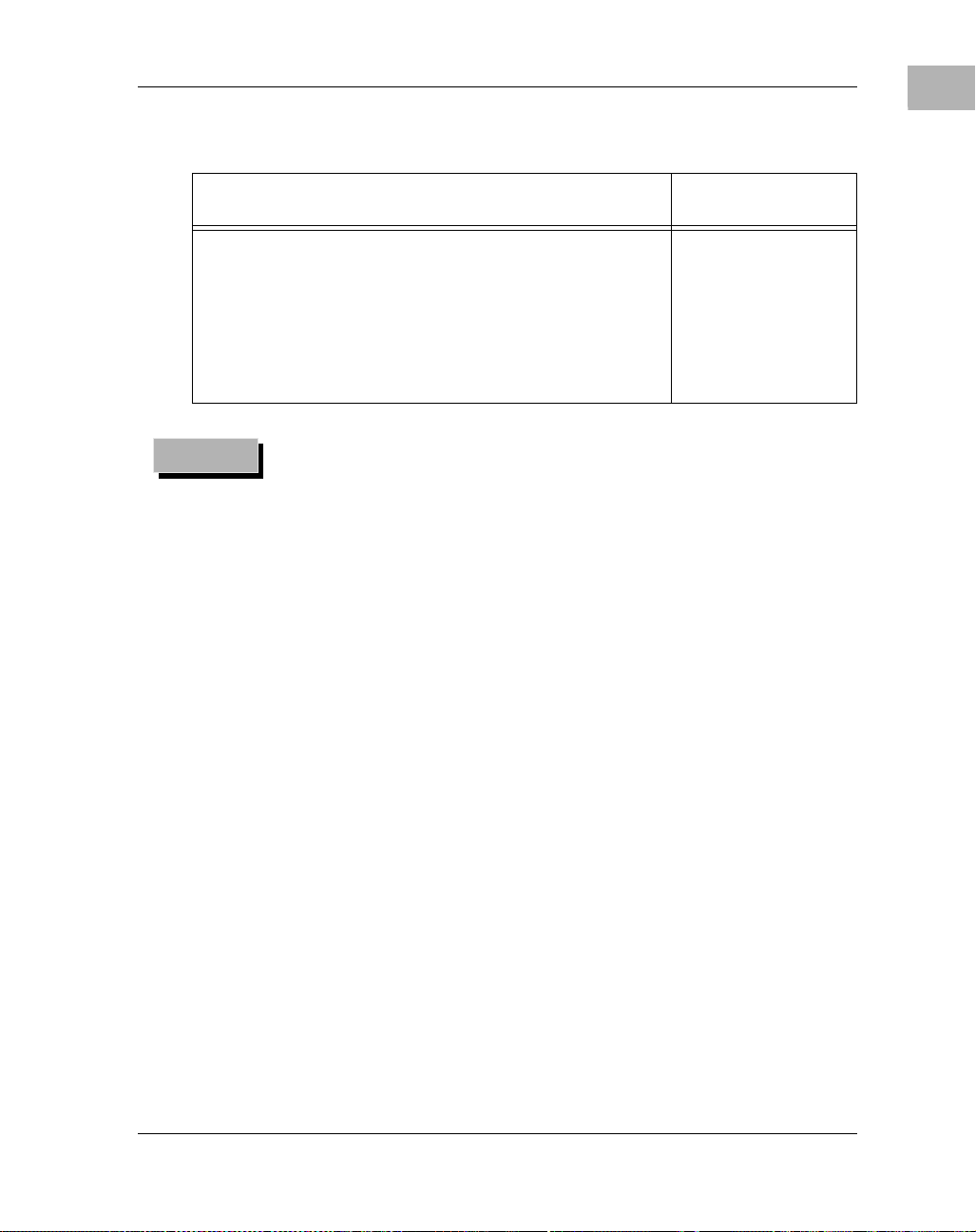

Specifications

General specifications for the MVME166 are listed in Table 1-1.

Table 1-1. MVME166 Specifications

Characteristics Specifications

Power requirements

(excluding external LAN

transceiver)

(at 33 MHz with 32 MB

ECC memory)

Operating temperature 0° to 55° C at point of entry of forced air

Storage temperature -40° to +85° C

Relative humidity 5% to 90% (non-condensing)

Physical dimensions

PC board with mezzanine

module only

Height

Depth

Thickness

PC boards with connectors

and front panel

Height

Depth

Thickness

+5 Vdc (± 5%), 5.0 A (typical), 6.5 A (max.)

(includes transition modules)

+12 Vdc (± 5%), 100 mA (max.) (1.0 A

(max.) with offboard LAN transceiver)

-12 Vdc (± 5%), 100 mA (max.)

(approximately 490 LFM)

Double-high VMEboard

9.187 inches (233.35 mm)

6.299 inches (160.00 mm)

0.662 inches (16.77 mm)

10.309 inches ( 261.85 mm)

7.4 inches (188 mm)

0.80 inches (20.32 mm)

Manual Terminology

Throughout this manual, a convention is used which precedes data and

address parameters by a character identifying the numeric format as follows:

$ dollar specifies a hexadecimal character

% percent specifies a binary number

& ampersand specifies a decimal number

For example, "12" is the decimal number twelve, and "$12" is the decimal

number eighteen.

Unless otherwise specified, all address references are in hexadecimal.

An asterisk (*) following the signal name for signals which are level significant

denotes that the signal is true or valid when the signal is low.

1-6 MVME166 Single Board Computer Installation Guide

Page 21

Introduction

An asterisk (*) following the signal name for signals which are edge significant

denotes that the actions initiated by that signal occur on high to low transition.

In this manual, assertion and negation are used to specify forcing a signal to a

particular state. In particular, assertion and assert refer to a signal that is active

or true; negation and negate indicate a signal that is inactive or false. These

terms are used independently of the voltage level (high or low) that they

represent.

Data and address sizes are defined as follows:

❏ A byte is eight bits, numbered 0 through 7, with bit 0 being the least

significant.

❏ A two-byte is 16 bits, numbered 0 through 15, with bit 0 being the least

significant. For the MVME166 and other CISC modules, this is called a

word.

❏ A four-byte is 32 bits, numbered 0 through 31, with bit 0 being the least

significant. For the MVME166 and other CISC modules, this is called a

longword.

The terms control bit and status bit are used extensively in this document. The

term control bit is used to describe a bit in a register that can be set and cleared

under software control. The term true is used to indicate that a bit is in the

state that enables the function it controls. The term false is used to indicate that

the bit is in the state that disables the function it controls. In all tables, the

terms 0 and 1 are used to describe the actual value that should be written to

the bit, or the value that it yields when read. The term status bit is used to

describe a bit in a register that reflects a specific condition. The sta tus bit can

be read by software to determine operational or exception conditions.

1

MVME166IG/D2 1-7

Page 22

1

Board Level Hardware Description

Block Diagram

Figure 1-1 is a general block diagram of the MVME166.

MC68040

DRAM

82596CA

LAN

ETHERNET

VMEchip2

53C710

SCSI

FLASH

MK48T08

BBRAM

& CLOCK

CD2401

SCC

SERIAL IO

PCCchip2

VSBchip2

VSBVMEbus

PRINTER

PORT

DOWNLOAD

EPROM

128KB

STATIC

RAM

bd078 9304

Figure 1-1. MVME166 Block Diagram

1-8 MVME166 Single Board Computer Installation Guide

Page 23

Functional Description

This section contains a functional description of the majo r blocks on the

MVME166 Single Board Computers.

Front Panel Switches and Indicators

There are switches and LEDs on the front panel of the MVME166. The

switches are RESET and ABORT. The RESET switch resets all onboard devices

and drives SYSRESET* if the board is system controller. The RESET switch

may be disabled by software.

When enabled by software, the ABORT switch generates an interrupt at a userprogrammable level. It is normally used to abort program execution and

return to the debugger.

There are ten LEDs on the MVME166 front panel: FAIL, STAT, RUN, SCON,

LAN, RPWR, SCSI, VME, TPWR and VSB.

The red FAIL LED (part of DS1) lights when the BRDFAIL signal line is active.

The MC68040 status lines are decoded, on the MVME166, to drive the yellow

STAT (status) LED (part of DS1). In this case, a halt condition from the

processor lights the LED.

The green RUN LED (part of DS2) lights when the local bus TIP* signal line is

low. This indicates one of the local bus masters is executing a local bus cycle.

The green SCON LED (part of DS2) lights when the VMEchip2 in the

MVME166 is the VMEbus system controller.

The green LAN LED (part of DS3) lights when the LAN chip is local bus

master.

The MVME166 supplies +5V, +12V, and -12V power to the transition board

through fuses. There is one fuse for each voltage. The green RPWR (remote

power) LED (part of DS3) lights when all three voltages are available to the

transition board interface.

The green SCSI LED (part of DS4) lights when the SCSI chip is local bus master.

The green VME LED (part of DS4) lights when the board is using the VMEbus

(VMEbus AS* is asserted by the VMEchip2) or when the board is accessed by

the VMEbus (VMEchip2 is the local bus master).

The MVME166 supplies +5V to the SCSI bus for terminator power through a

fuse. The green TPWR (terminator power) LED (part of DS5) lights when

TERMPWR is available to the SCSI bus. SCSI bus TERMPWR may be supplied

by other devices on the SCSI bus.

The green VSB LED (part of DS5) lights when the MVME166 is using the VSB

(VSB PAS* is asserted by the VSBchip2) or when the MVME166 is accessed by

the VSB (VSBchip2 is the local bus master).

Functional Description

1

MVME166IG/D2 1-9

Page 24

1

Board Level Hardware Description

Data Bus Structure

The local data bus on the MVME166 is a 32-bit synchronous bus that is based

on the MC68040 bus, and supports burst transfers and snooping. Th e various

local bus master and slave devices use the local bus to communicate. The local

bus is arbitrated by priority type arbiter and the priority of the local bus

masters from highest to lowest is: 82596CA LAN, CD2401 serial (through the

PCCchip2), 53C710 SCSI, VSB, VMEbus, and MPU. In the general case, any

master can access any slave; however, not all combinations pass the common

sense test. Refer to the MVME166/MVME167/MVME187 Single Board

Computers Programmer’s Reference Guide and to the user’s guide for each device

to determine its port size, data bus connection, and any restrictions that apply

when accessing the device.

MC68040 MPU

The MC68040 processor is u sed o n t h e MVME1 66. The MC68040 has on-chip

instruction and data caches and a floating point processor. Refer to the

M68040 user’s manual for more information.

Flash Memory and Download EPROM

The MVME166 includes four 28F020 Flash memory devices and a download

EPROM. These parts replace the four EPROM sockets used on the

MVME167/187. The Flash parts are programmable on the MVME166 board

and the programming code is provided in the download EPROM. The Flash

devices provide 1 MB of ROM at address $FF800000-$FF8FFFFF. The

download EPROM provides 128 KB of ROM at $FFF80000-$FFF9FFFF. The

download EPROM is mapped to local bus address 0 following a local bus reset.

This allows the MC68040 to access the stack pointer and execution address

following a reset. The download EPROM appears at 0 until the DR0 bit is

cleared in the PCCchip2 chip. The Flash devices are controlled by the

VMEchip2 and the download EPROM is controlled by the PCCchip2. The PC0

bit in the MC68230 PI/T chip must be low to enable writes to Flash.

The EPROM contains the BootBug product (166BBug). Because Flash memory

can be electronically erased, the EPROM firmware is a subset of the regular

debugger product. It contains enough functionality from the debugger to

permit downloading of object code (via VMEbus, serial port, SCSI bus, or the

network) and reprogramming of the Flash memory.

A jumper on the MVME166 (J3, pins 7 and 8) controls the operation of the

BootBug. If the jumper is in place, the BootBug (which always executes at

power-up and reset) passes execution to the full debugger contained in Flash

memory. If the jumper is removed, execution continues (with diminished

functionality) in the BootBug.

1-10 MVME166 Single Board Computer Installation Guide

Page 25

SRAM

Functional Description

1

Before you perform any SCSI, VMEbus, or Ethernet I/O with the MVME166,

it may be necessary to define some parameters (e.g., SCSI ID, Ethernet address,

VMEbus mapping). For details on configuring the MVME166, refer to the

setup command description in Chapter 3 in this manual, and in the

MVME167Bug Debugging Package User’s Manual .

The boards include 128KB of 32-bit wide static RAM with onboard battery

backup that supports 8-, 16-, and 32-bit wide accesses. The SRAM allows the

debugger to operate and limited diagnostics to be executed without the

DRAM mezzanine. The SRAM is controlled by the VMEchip2, and the a ccess

time is programmable. The boards are populated with 100 ns SRAMs.

The SRAM is also battery backed up on the MVME166. The battery backup

function is provided by a Dall as DS1210S. The DS12 10S supports primary and

secondary power sources. When the main board power fails, th e DS1210S

selects the source with the highest voltage. If one source should fail, the

DS1210S switches to the redundant source. Each time the board is powered,

the DS1210S checks power sources and if the voltage of the backup sources is

less than two volts, the second memory cycle is blocked. This allows software

to provide an early warning to avoid data loss. Because the DS1210S may

block the second access, the software should do at least two accesses before

relying on the data.

The MVME166 provides jumpers that allow either power source of the

DS1210S to be connected to the VMEbus +5 V STDBY pin or one cell of the

onboard battery. For example, the primary system backup source may be a

battery connected to the VMEbus +5 V STDBY pin and the secondary source

may be the onboard battery. If the system source should fail or the board is

removed from the chassis, the onboard battery takes over.

Caution

The onboard power source is a RAYOVAC FB1225 battery which has two

BR1225 type lithium cells and is socketed for easy removal and replacement.

A small capacitor is provided to allow the battery to be quickly replaced

without data loss. The lifetime of the battery is very d ependent on the ambient

temperature of the board and the power-on duty cycle. The lithium battery

supplied on the MVME166 should p rovide at least two years of backup t i me

MVME166IG/D2 1-11

For proper operation of the SRAM, some jumper

combination must be installed on the Backup Power Source

Select Header. If one of the jumpers is used to select the

battery, the battery must be installed on the MVME166. The

SRAM may malfunction if inputs to the DS1210S are left

unconnected.

Page 26

1

Board Level Hardware Description

with the board powered off and the board at 40° C. If the pow er-on duty cycle

is 50% (the board is powered on half of the time), the battery lifetime is four

years. At lower ambient temperatures the backup time is greatly extended

and may approach the shelf life of the battery. When a board is stored, the

battery should be disconnected to prolong battery life. This is especially

important at high ambient temperatures. The MVME166 is shipped with the

batteries disconnected.

The power leads from the battery are exposed on the solder side of the board,

therefore the board should not be placed on a conductive surface or stored in

a conductive bag unless the battery is removed.

Caution

❏ Do not short circuit.

❏ Do not disassemble, deform, or apply excessive pressure.

❏ Do not heat or incinerate.

❏ Do not apply solder directly.

❏ Do not use different models, or new and old batteries together.

❏ Do not charge.

❏ Always check proper polarity.

Lithium batteries incorporate inflammable materials such

as lithium and organic solvents. If lithium batteries are

mistreated or handled incorrectly, they may burst open and

ignite, possibly resulting in injury and/or fire. When

dealing with lithium batteries, carefully follow the

precautions listed below in order to prevent accidents.

To remove the battery from the module, carefully pull the battery from the

socket.

Before installing a new battery, ensure that the battery pins are clean. Note the

battery polarity and press the battery into the socket. When the battery is in

the socket, no soldering is required.

Onboard DRAM

The MVME166 onboard DRAM is located on a mezzanine board. The

mezzanine boards are available in different sizes and with ECC protection.

Mezzanine board sizes are 4, 8, 16, 32, 64, or 128MB, and two mezzanine

boards may be stacked to provide 256MB of onboard RAM. The main board

and a single mezzanine board together take one slot. The stacked

configuration requires two VMEboard slots. The DRAM is four-way

interleaved to efficiently support cache burst cycles.

1-12 MVME166 Single Board Computer Installation Guide

Page 27

The DRAM map decoder can be programmed to a ccommo date dif ferent base

address(es) and sizes of mezzanine boards. The onboard DRAM is disabled

by a local bus reset and must be programmed before the DRAM can be

accessed. Refer to the MCECC in the MVME166/MV ME167/ MVME187 S ing le

Board Computers Programmer’s Reference Guide for detailed programming

information. Most DRAM devices require some number of access cycles

before the DRAMs are fully operational. Normally this requirement is met by

the onboard refresh circuitry and normal DRAM installation. However,

software should insure a minimum of 10 initialization cycles are performed to

each bank of RAM.

Battery Backed Up RAM and Clock

The MK48T08 RAM and clock chip is used on the MVME166. This chip

provides a time of day clock, oscillator, crystal, power fail detection, memory

write protection, 8KB of RAM, and a battery in one 28-pin package. The clock

provides seconds, minutes, hours, day, date, month, and year in BCD 24-hour

format. Corrections for 28-, 29- (leap year), and 30-day months are

automatically made. No interrupts are generated by the clock. The MK48T08

is an 8 bit device; however, the interface provided by the PCCchip2 supports

8-, 16-, and 32-bit accesses to the MK48T08. Refer to the MK48T08 data sheet

for detailed programming information.

VMEbus Inte rface

Functional Description

1

The local bus to VMEbus interface, the VMEbus to local bus interface, and the

local-VMEbus DMA controller functions on the MVME166 are provided by

the VMEchip2. The VMEchip2 can also provide the VMEbus system controller

functions.

VME Subsystem Bus (VSB) Interface

The local bus to VSB interface and the VSB to local bus interface are pro vided

by the VSBchip2, only on the MVME166 board. The VSB uses the P2 connector

of the MVME166.

I/O Interfaces

The MVME166 provides onboard I/O for many system applications. The I/O

functions include serial ports, printer port, Ethernet transceiver interface, and

SCSI mass storage interface.

Serial Port Interface

The CD2401 serial controller chip (SCC) is used to implement the four serial

ports. The serial ports support the standard baud rates (110 to 38.4K baud).

The four serial ports on the MVME166 are functionally the same. All serial

ports are full function asynchronous or synchronous ports. They can operate

MVME166IG/D2 1-13

Page 28

1

Board Level Hardware Description

at synchronous bit rates up to 64 k bits per second. They use RXD, CTS, DCD,

TXD, RTS, DTR, and DSR. They also interface to the synchronous clock signal

lines. Additional control signals are provided for each serial port by the

MC68230. These include local loopback control, self test control, and ring

indicator. The ring indicator signal can be programmed to generate a local bus

interrupt. Refer t o th e MC68230 section for addit i o nal i n fo rmat io n. Note that

the usable functionality of the serial ports depends on the transition module

used.

All four serial ports on the MVME166 use a TTL interface to the transition

board. This allows the interface specific drivers to be located on the transition

board. This allows more flexibility in configuring the serial ports for different

interfaces like EIA-232-D or V.35. An external I/O transition module such as

the MVME712-10 should be used to provide configuration headers, interface

drivers, and industry-standard connectors.

The interface provided by the PCCchip2 allows the 16-bit CD2401 to appear at

contiguous addresses; however, accesses to the CD2401 must be 8 or 16 bits.

32-bit accesses are not permitted. Refer to the CD2401 data sheet for detailed

programming information.

The CD2401 supports DMA operations to local memory. Because the CD2401

does not support a retry operation necessary to break VMEbus or VSB dual

port lockup conditions, the CD2401 DMA controllers should not be

programmed to access the VMEbus or VSB. The hardware does not restrict the

CD2401 to onboard DRAM.

MC68230 Parallel Interface/Timer

The MVME166 provides an MC68230 parallel interface/timer (PI/T) chip.

When the MVME166 is used with the MVME712-10 transition module or the

MVME712-06/07/09 I/O distribution board set, the MC68230 is used to

provide additional control lines for the serial ports. These include local

loopback, self test, and ring indicator. The ring indicator signals can be

programmed to generate local bus interrupts. Refer to the MVME712-10

transition module manual for more information.

The base address of the MC68230 is $FFF45E00, and because it is an 8-bit

device it appears only at odd addresses. Space for the MC68230 was created

by dividing the area occupied by redundant copies of the CD2401 registers

into eight segments. The CD2401 is still addressed at $FFF45000 to $FFF451FF.

Addresses $FFF45200 to $FFF45BFF are reserved, and if accessed on an

MVME166 cause a local bus timeout error, if the local bus timer is enabled.

The address range from $FFF45C00 to $FFF45DFF always returns a local bus

timeout error if the local bus timer is enabled. The CD2401 appears

redundantly from $FFF45200 to $FFF45FFF on the MVME167/187.

1-14 MVME166 Single Board Computer Installation Guide

Page 29

The presence of the MC68230 can be determined by reading address

$FFF45C00. If a timeout error occurs, then the board is an MVME166 and and

the MC68230 is present. If a timeout does not occur, then the board is an

MVME167/187 and the MC68230 is not present. The local bus timeout timer

in the VMEchip2 must be enabled for this test.

The MC68230 may be used for general purpose I/O when the MVME166 is not

used with the MVME712 family of transition modules. Because the outputs

are unbuffered and unprotected, these signals should be used with caution.

The port A signal lines PA<7..0> are connected to the front panel connector J9.

The port A signal lines can be programmed as inputs or outputs. The port B

signal lines PB<3..0> are connected to the port H signal lines H<4..1> and the

front panel connector J9. This allows these four lines to be inputs or outputs

or receive interrupts. The port B signal line PB<7> is also connected to the front

panel connector J9. When used with the MVME712 family of transition

modules, the PB<7> signal line is used to read the configuration of the serial

ports. Timer interrupts from the MC68230 are not supported on the

MVME166. The MC68230 is conn ected t o a 1 0 MHz cl ock . The P C0 bi t in the

MC68230 PI/T chip must be low to enable writes to Flash memory.

Parallel Port Interface

The PCCchip2 provides an 8-bit bidirectional parallel port. All eight bits of the

port must be either inputs or outputs (no individual selection). In addition to

the 8 bits of data, there are two control pins and five status pins. Each of the

status pins can generate an interrupt to the MPU in any of the following

programmable conditions: high level, low level, high-to-low transition, or

low-to-high transition. This port may be used as a Centronics-compatible

parallel printer port or as a general parallel I/O port.

Functional Description

1

When used as a parallel printer port, the five status pins function as: Printer

Acknowledge (ACK), Printer Fault (FAULT*), Printer Busy (BSY), Printer

Select (SELECT), and Printer Paper Error (PE); while the control pins act as

Printer Strobe (STROBE*), and Input Prime (INP*).

The PCCchip2 provides an auto-strobe feature similar to that of the MVME147

PCC. In auto-strobe mode, after a write to the Printer Data Register, the

PCCchip2 automatically asserts the STROBE* pin for a selected time specified

by the Printer Fast Strobe control bit. In manual mode, the Printer Strobe

control bit directly controls the state of the STROBE* pin.

Ethernet Interface

The 82596CA is used to implement the Ethernet transceiver interface. The

82596CA accesses local RAM using DMA operations to perform its norm al

functions. Because the 82596CA has small internal buffers and the VMEbus

has an undefined latency period, buffer overrun may occur if the DMA is

programmed to access the VMEbus. Therefore, the 82596CA should not be

programmed to access the VMEbus or VSB.

MVME166IG/D2 1-15

Page 30

1

Board Level Hardware Description

Every MVME166 is assigned an Ethernet Station Address. The address is

$08003E2XXXXX where XXXXX is the unique 5-nibble number assigned to the

board (i.e., every MVME166 has a different value for XXXXX).

Each module has an Ethernet Station Address displayed on a label attached to

the VMEbus P2 connector. In addition, the six bytes including the Ethernet

address are stored in the configuration area of the BBRAM. That is,

08003E2XXXXX is stored in the BBRAM. At an address of $FFFC1F2C, the

upper four bytes (08003E2X) can be read. At an address of $FFFC1F30, the

lower two bytes (XXXX) can be read. The MVME166 debugger has the

capability to retrieve or set the Ethernet address. So does the MVME166

BootBug.

If the data in the BBRAM is lost, the user should use the number on the

VMEbus P2 connector label to restore it.

The Ethernet transceiver interface is located on the MVME166 main module,

and the industry standard connector is located on the MVME712X transition

module.

Support functions for the 82596CA are provided by the PCCchip2. Refer to the

82596CA user’s guide for detailed programming information.

SCSI Interface

The MVME166 provides for mass storage subsystems through the industrystandard SCSI bus. These subsystems may include hard and floppy disk

drives, streaming tape drives, and other mass storage devices. The SCSI

interface is implemented using the NCR 53C710 SCSI I/O controller.

Support functions for the 53C710 are provided by the PCCchip2. Refer to the

53C710 user’s guide for detailed programming information.

SCSI Termination

The individual configuring the system must ensure that the SCSI bus is

properly terminated at both ends. On the MVME166, the SCSI bus termination

is provided on the main board. The terminators are enabled/disabled by a

jumper. If the SCSI bus ends at the MVME166, the SCSI terminators must be

enabled by installing the jumper. Refer to the jumper configuration tables in

Chapter 2.

Local Resources

The MVME166 includes many resources for the local processor. These include

tick timers, software programmable hardware interrupts, watchdog timer,

and local bus timeout.

1-16 MVME166 Single Board Computer Installation Guide

Page 31

Programmable Tick Timers

Four 32-bit programmable tick timers with 1 µs resolution are provided, two

in the VMEchip2 and two in the PCCchip2. The tick timers can be

programmed to generate periodic interrupts to the processor.

Watchdog Timer

A watchdog timer function is provided in the VMEchip2. When the watchdog

timer is enabled, it must be reset by software within the programmed time or

it times out. The watchdog timer can be programmed to generate a SYSRESET

signal, local reset signal, or board fail signal if it times out.

Software-Programmable Hardware Interrupts

Eight software-programmable hardware interrupts are provided by the

VMEchip2. These interrupts allow software to create a hardware interrupt.

Local Bus Timeout

The MVME166 provides a timeout function fo r the local bus. When the time r

is enabled and a local bus access times out, a Transfer Error Acknowledge

(TEA) signal is sent to the local bus master. The timeout value is selectable by

software for 8 µsec, 64 µsec, 256 µsec, or infinite. The local bus timer does not

operate during VMEbus or VSB bound cycles. VMEbus bound cycles are

timed by the VMEbus access timer and the VMEbus global timer. VSB bound

cycles are timed by the VSB access timer, the VSB transfer timer, and if its serial

arbiter is enabled, by the VSB arbitration timer.

Functional Description

1

Connectors

The MVME166 has two 96-position DIN connectors: P1 and P2. P1 rows A, B,

C, and P2 row B provide the VMEbus interconnection. P2 rows A and C, on

the MVME166, provide the connection to the VSB. The MVME166 has a 20-pin

connector mounted behind the front panel. When the MVME166 board is

enclosed in a chassis and the front panel is not visible, this connector allows

the reset, abort and LED functions to be extended to the control panel of the

system, where they are visible. The MVME166 has a 68-pin mini D ribbon

shielded connector for the SCSI bus interface. The MVME166 has a 100-pin

mini D ribbon shielded connector for the serial ports, Ethernet, and printer.

MVME166IG/D2 1-17

Page 32

1

Board Level Hardware Description

Memory Maps

There are two points of view for memory maps: 1) the mapping of all resources

as viewed by local bus masters (local bus memory map), 2) the mapping of

onboard resources as viewed by externa masters (VMEbus memory map or

VSB memory map).

Local Bus Memory Map

The local bus memory map is split into different address spaces by the transfer

type (TT) signals. The local resources respond to the normal access and

interrupt acknowledge codes.

Normal Address Range

The memory map of devices that respond to the normal address range is

shown in the following tables. The normal address range is defined by the

Transfer Type (TT) signals on the local bus. On the MVME166, Transfer Types

0, 1, and 2 define the normal address range.

Table 1-2 is the entire map from $00000000 to $FFFFFFFF. Many areas of the

map are user-programmable, and suggested uses are shown in the table. The

cache inhibit function is programmable in the MMUs. The onboard I/O space

must be marked cache inhibit and serialized in its page table.

Table 1-3 further defines the map for the local I/O devices.

1-18 MVME166 Single Board Computer Installation Guide

Page 33

Memory Maps

Table 1-2. Local Bus Memory Map

Software

Address Range Devices Accessed Port Size Size

$00000000 - DRAMSIZE User Programmable

(Onboard DRAM)

DRAMSIZE - $FF7FFFFF User Programmable

(VMEbus or VSB)

$FF800000 - $FF8FFFFF FLASH D32 1MB N 1

$FFC00000 - $FFDFFFFF reserved -- 2MB -- 5

$FFE00000 - $FFE1FFFF SRAM D32 128KB N - $FFE20000 - $FFEFFFFF SRAM (repeated) D32 896KB N -$FFF00000 - $FFFEFFFF Local I/O Devices

(Refer to next table)

$FFFF0000 - $FFFFFFFF User Programmable

(VMEbus A16)

D32 DRAMSIZE N 1, 2

D32/D16 3GB ? 3, 4

D32-D8 1MB Y 3

D32/D16 64KB ? 2, 4

Cache

Inhibit

Notes

NOTES:

1. There is 1MB of FLASH in this 4MB map area. Download

EPROM on the MVME166 appears at $00000000 - ROMSIZE

following a local bus reset. The Download EPROM appears

at 0 until the DR0 bit is cleared in the PCCchip2. The DR0 bit

is located at address $FFF42000 bit 15. The EPROM must be

disabled at 0 before the DRAM is enabled. The VMEchip2,

VSBchip2, and DRAM map decoders are disabled by a local

bus reset.

1

2. This area is user-programmable. The suggested use is shown

in the table. The DRAM decoder is programmed in the

MCECC chip, and the local-to-VMEbus decoders are

programmed in the VMEchip2. The local-to-VSB decoders

are programmed in the VSBchip2.

3. Size is approximate.

4. Cache inhibit depends on devices in area mapped.

5. This area is not decoded. If these locations are accessed and

the local bus timer is enabled, the cycle times out and is

terminated by a TEA signal.

MVME166IG/D2 1-19

Page 34

1

Board Level Hardware Description

The following table focuses on the Local I/O D ev ices portion of the local bus

Main Memory Map.

Table 1-3. Local I/O Devices Memory Map

Address Range Devices Accessed Port Size Size Notes

$FFF00000 - $FFF3FFFF reserved -- 256KB 5

$FFF40000 - $FFF400FF VMEchip2 (LCSR) D32 256B 1,4

$FFF40100 - $FFF401FF VMEchip2 (GCSR) D32-D8 256B 1,4

$FFF40200 - $FFF40FFF reserved -- 3.5KB 5,7

$FFF41000 - $FFF41FFF VSBchip2 D32-D8 4KB 1,10

$FFF42000 - $FFF42FFF PCCchip2 D32-D8 4KB 1

$FFF43000 - $FFF430FF MCECC #1 D8 256B 1

$FFF43100 - $FFF431FF MCECC #2 D8 256B 1

$FFF43200 - $FFF43FFF MCECCs (repeated) -- 3.5KB 1,7

$FFF44000 - $FFF44FFF reserved -- 4KB 5

$FFF45000 - $FFF451FF CD2401 (Serial Comm. Cont.) D16-D8 512B 1,9

$FFF45200 - $FFF45DFF reserved -- 3KB 7,9

$FFF45E00 - $FFF45FFF MC6823 0 -- 512B 1,9

$FFF46000 - $FFF46FFF 82596CA (LAN) D32 4KB 1,8

$FFF47000 - $FFF47FFF 53C710 (SCSI) D32/D8 4K B 1

$FFF48000 - $FFF4FFFF reserved -- 32KB 5

$FFF50000 - $FFF6FFFF reserved -- 128KB 5

$FFF70000 - $FFF76FFF reserved -- 28KB 6

$FFF77000 - $FFF77FFF reserved -- 4KB 2

$FFF78000 - $FFF7EFFF reserved -- 28KB 6

$FFF7F000 - $FFF7FFFF reserved -- 4KB 2

$FFF80000 - $FFF9FFFF Download EPROM -- 128KB 11

$FFFA0000 - $FFFBFFFF reserved -- 128KB 5

$FFFC0000 - $FFFCFFFF MK48T08 (BBRAM, TOD Clock) D32-D8 64KB 1

$FFFD0000 - $FFFDFFFF reserved -- 64KB 5

$FFFE0000 - $FFFEFFFF reserved -- 64KB 2

NOTES:

1. For a complete description of the register bits, refer to the

MVME166/MVME167/MVME187 Single Board Computers

Programmer’s Reference Guide or to the data sheet for the

specific chip.

1-20 MVME166 Single Board Computer Installation Guide

Page 35

Memory Maps

2. On the MVME166 this area does not return an acknowledge

signal. If the local bus timer on the MVME166 is enabled, the

access times out and is terminated by a TEA signal.

On the MVME187 this area is used.

3. Byte reads should be used to read the interrupt vector. These

locations do not respond when an interrupt is not pending. If

the local bus timer is enabled, the access times out and is

terminated by a TEA signal.

4. Writes to the LCSR in the VMEchip2 must be 32 bits. LCSR

writes of 8 or 16 bits terminate with a TEA signal. Writes to

the GCSR may be 8, 16 or 32 bits. Reads to the LCSR and

GCSR may be 8, 16 or 32 bits.

5. This area does not return an acknowledge signal. If the local

bus timer is enabled, the access times out and is terminated by

a TEA signal.

6. This area does return an acknowledge signal.

7. Size is approximate.

8. Port commands to the 82596 CA must be wri tten as t wo 16-bit

writes: upper word first and lower word second.

1

9. The MC68230 is included only on the MVME166. The area

from $FFF45200 to $FFF45DFF does not return an

acknowledge on the MVME166. If the local bus timer is

enabled, the access times out and is terminated by a TEA

signal.

10. The VSBchip2 is included only on the MVME166.

11. The Download EPROM is only on the MVME166.

MVME166IG/D2 1-21

Page 36

1

Board Level Hardware Description

VMEbus Memory Map

This section describes the mapping of local resources as viewed by VMEbus

masters. Default addresses for the slave, master, and GCSR address decoders

are provided by the ENV command. Refer to Appendix A.

VMEbus Accesses to the Local Bus

The VMEchip2 includes a user-programmable map decoder for the VMEbus

to local bus interface. The map decoder allows you to program the starting

and ending address and the modifiers the MVME166 responds to.

VMEbus Short I/O Memory Map

The VMEchip2 includes a user-programmable map decoder for the GCSR.

The GCSR map decoder allows you to program the starting address of the

GCSR in the VMEbus short I/O space.

VSB Memory Map

This section describes the mapping of local resources as viewed by VSB

masters. The VSBchip2, on the MVME166, includes a user-programmable

map decoder for the VSB to local bus interface. This map deco der allows VSB

masters access to devices on the local bus. Default addresses for the slave,

master, and address decoders are provided by the ENV command. Refer to

Appendix A.

1-22 MVME166 Single Board Computer Installation Guide

Page 37

HARDW ARE PREPARATION

Introduction

This chapter provides unpacking instructions, hardware preparation, and

installation instructions for the MVME166. Hardware preparation and

installation for the MVME712 series transition modules is described in a

separate manual. Refer to the Related Documentation section in Chapter 1.

Unpacking Instructions

Note

Unpack equipment from shipping carton. Refer to packing list and verify that

all items are present. Save packing material for storing and reshipping of

equipment.

Caution

If the shipping carton is damaged upon receipt, request

carrier’s agent be present during unpacking and inspection

of equipment.

Avoid touching areas of integrated circuitry; static discharge

can damage circuits.

AND INSTALLA TION

2

Hardware Preparation

To select the desired configuration and ensure proper operation of the

MVME166, certain option modifications may be necessary before installation.

The MVME166 provides software control for most of these options. Some

options can not be done in software, so are done by jumpers on headers. Most

other modifications are done by setting bit s in control registers after the

MVME166 has been installed in a system. (The MVME166 registers are

described in the MVME166/MVME167/MVME187 Single Board Computers

Programmer’s Reference Guide as listed in Related Documentation in Chapter 1.)

MVME166IG/D22-1

Page 38

Hardware Preparation and Installation

2

connectors, and LED indicators on the MVME166. The MVME166 has been

factory tested and is shipped with the factory jumper settings described in the

following sections. The MVME166 operates with its required and factoryinstalled Debug Monitor, MVME166Bug (166Bug), with these factory jumper

settings. Settings can be changed for the following headers:

❏ SCSI terminator selection (J2)

❏ General purpose readable register (J3)

❏ System controller selection (J6)

❏ SRAM backup power source selection (J7)

SCSI Terminator Enable Header J2

The MVME166 provides terminators for the SCSI bus. The SCSI terminators

are enabled/disabled by jumpers on header J2. The SCSI terminators may be

configured as follows.

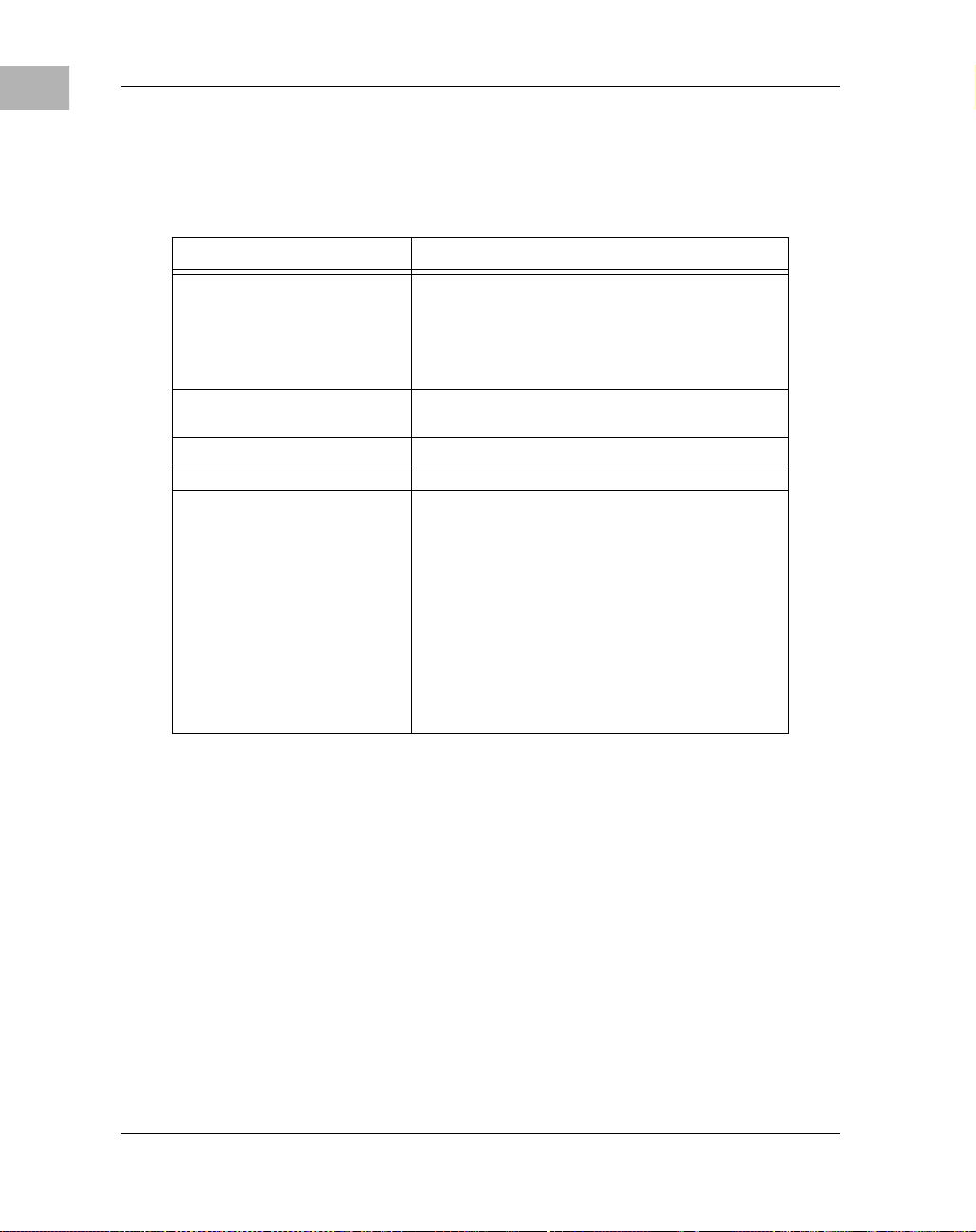

Figure 2-1 illustrates the placement of the switches, jumper headers,

J2

1

Onboard SCSI Bus Terminator Enabled

(Factory Configuration)

2

Onboard SCSI Bus Terminator Disabled

J2

1

2

2-2 MVME166 Single Board Computer Installation Guide

Page 39

MVME

166 LGA

Hardware Preparation

2

STATFAIL

RUN SCON

LAN RPWR

SCSI VME

TPWR VSB

ABORT

RESET

A1B1C1

DS1

DS2

DS3

DS4

12

J2

DS5

F1

S1 S2

F2

343368

67

SCSI

PRIMARY SIDE

I/O

J8

36

35

2

1

100

495099

J9

1

5

J7

2

6

J3

15

16

1

2

2

1

J6

MEZZANINE BOARD

C32

B32

P1

A32

F3 F4

A1B1C1

P2

22

2

51

1

C32

B32

A32

1381 9404

Figure 2-1. MVME166 Switches, Headers, Connectors, Fuses, and LEDs

MVME166IG/D2 2-3

Page 40

Hardware Preparation and Installation

J6

2

General Purpose Readable Jumpers on Heade r J3

Each MVME166 may be configured with readable jumpers. These jumpers can

be read as a register (at $FFF40088) in the VMEchip2 LCSR. The bit values are

read as a one when the jumper is off, and as a zero when the jumper is on.

J3

GPIO0

GPIO1

GPIO2

GPIO3

GPIO4

GPIO5

GPIO6

12

78

15

All Zeros

(Factory Configuration)

16GPIO7

IN = Normal Debugger

OUT = BootBug

System Controller Header J6

The MVME166 can operate as VMEbus system controller. The system

controller function is enabled/disabled by jumpers on header J6. When the

MVME166 is functioning as system controller, the SCON LED is turned on.

The VMEchip2 can be configured as a system controller as follows.

J6

1

1

2

System Controller

(Factory Configuration)

Not System Controller

2

2-4 MVME166 Single Board Computer Installation Guide

Page 41

Hardware Preparation

SRAM Backup Power Source Select Header J7

Header J7 is used to select the power source used to backup the SRAM on the

MVME166.

J7

1

5

Primary Source OnboardBattery

Secondary Source Onboard Battery

2

6

J7

1

5

Primary Source VMEbus +5V STBY

Secondary Source Onboard Battery

2

6

Primary Source VMEbus +5V STBY

Secondary Source VMEbus +5V STBY

Secondary Source VMEbus +5V STBY

1

5

(Factory Configuration)

1

5

Primary Source Onboard Battery

2

J7

2

6

J7

2

6

Caution

Do not remove all jumpers from J7. This may disable the

SRAM.

If the battery is removed, jumpers must be installed on J7,

between pins 1 to 3 and pins 2 to 4, as shown in the F actory

Configuration drawing above.

MVME166IG/D2 2-5

Page 42

Hardware Preparation and Installation

2

Installation Instructions

The following sections discuss the installation of the MVME166 in a VME

chassis, and describe system considerations relevant to the in stallation.

Ensure that an EPROM device is installed as needed. The factory

configuration provides for one EPROM (installed for 166BBug, the BootBug

firmware subset of the MVME166Bug debug monitor contained in Flash

memory) in socket U12. Ensure that all header jumpers are configured as

desired.

MVME166 Module Installation

Now that the MVME166 module is ready for installation, proceed as follows:

a. T urn all equipment power OFF and disconnect power cable from ac power

source.

Caution

!

WARNING

Inserting or removing modules while power is applied

could result in damage to module components.

DANGEROUS VOLTAGES, CAPABLE OF CAUSING

DEATH, ARE PRESENT IN THIS EQUIPMENT. USE

EXTREME CAUTION WHEN HANDLING, TESTING,

AND ADJUSTING.

b. Remove chassis cover as instructed in the equipment user’s manual.

c. Remove the filler panel(s) from the appropriate car d slot(s) at the front and

(if the chassis has a rear card cage that you intend to use) rear of the

chassis.

The MVME166 module requires power from both P1 and P2. It may be

installed in any double-height unused card slot, if it is not configured as

system controller. If the MVME166 is configured as system controller, it

must be installed in the leftmost card slot (slot 1) to correctly initiate the

bus-grant daisy-chain and to have proper operation of the IACK-daisychain driver.

2-6 MVME166 Single Board Computer Installation Guide

Page 43

Installation Instructions

The MVME166 is to be installed in the front of the chassis. The MVME712

module(s) is/are to be installed either in the front or the rear of the chassis,

depending on the I/O option you select:

Through the front panel I/O connector via cable to the MVME712-10

transition module, which may be mounted either in the forward card cage

alongside the MVME166 (recommended) or in the rear transition module

area.

Through the front panel I/O and SCSI connectors via cable to the

MVME712-06/07/09 I/O distribution board set, which likewise may be

mounted either in the forward card cage alongside the MVME166 or in th e

rear transition module area.

If you opt for front mounting of the transition module(s), the MVM E 166

should be located at their left if possible to make use of the cabling slots

provided in its front panel. You may need to shift the placement of other

modules in the forward card cage to allow space for the double- or triplewide MVME166/MVME712 combination.

d. Carefully slide the MVME166 module into the card slot. Be sure the

module is seated properly in the P1 and P2 connectors on the backplane.

Do not damage or bend connector pins. Fasten the module in the chassis

with the screws provided, making good contact with the transverse

mounting rails to mini mize RFI emissions.

e. On the chassis backplane, remove the IACK and BG jumpers from the

header for the card slot occupied by the MVME166.

f. Connect the transition module(s) and specified cable(s) to the MVME166

(at the I/O connector on the MVME166 front panel, according to

configuration) to mate with (optional) terminals or other pe ripherals at the

serial ports, parallel port, SCSI ports, and LAN Ethernet port. Connect the

peripherals to the cable(s).