Page 1

MOTOROLA

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

SEMICONDUCTOR TECHNICAL DATA

Surface Mount

Micromachined Accelerometer

The MMA series of silicon capacitive, micromachined accelerometers

features signal conditioning, a 4–pole low pass filter and temperature

compensation. Zero–g offset full scale span and filter cut–off are factory set and

require no external devices. A full system self–test capability verifies system

functionality.

Features

• Integral Signal Conditioning

• Linear Output

• Ratiometric Performance

• 4th Order Bessel Filter Preserves Pulse Shape Integrity

• Calibrated Self–test

• Low Voltage Detect, Clock Monitor, and EPROM Parity Check Status

• Transducer Hermetically Sealed at W afer Level for Superior Reliability

• Robust Design, High Shocks Survivability

T ypical Applications

• Vibration Monitoring and Recording

• Appliance Control

• Mechanical Bearing Monitoring

• Computer Hard Drive Protection

• Computer Mouse and Joysticks

• Virtual Reality Input Devices

• Sports Diagnostic Devices and Systems

Order this document

by MMA2201D/D

MMA2201D

MMA2201D: X AXIS SENSITIVITY

MICROMACHINED

ACCELEROMETER

±40g

16

9

1

8

16 LEAD SOIC

CASE 475–01

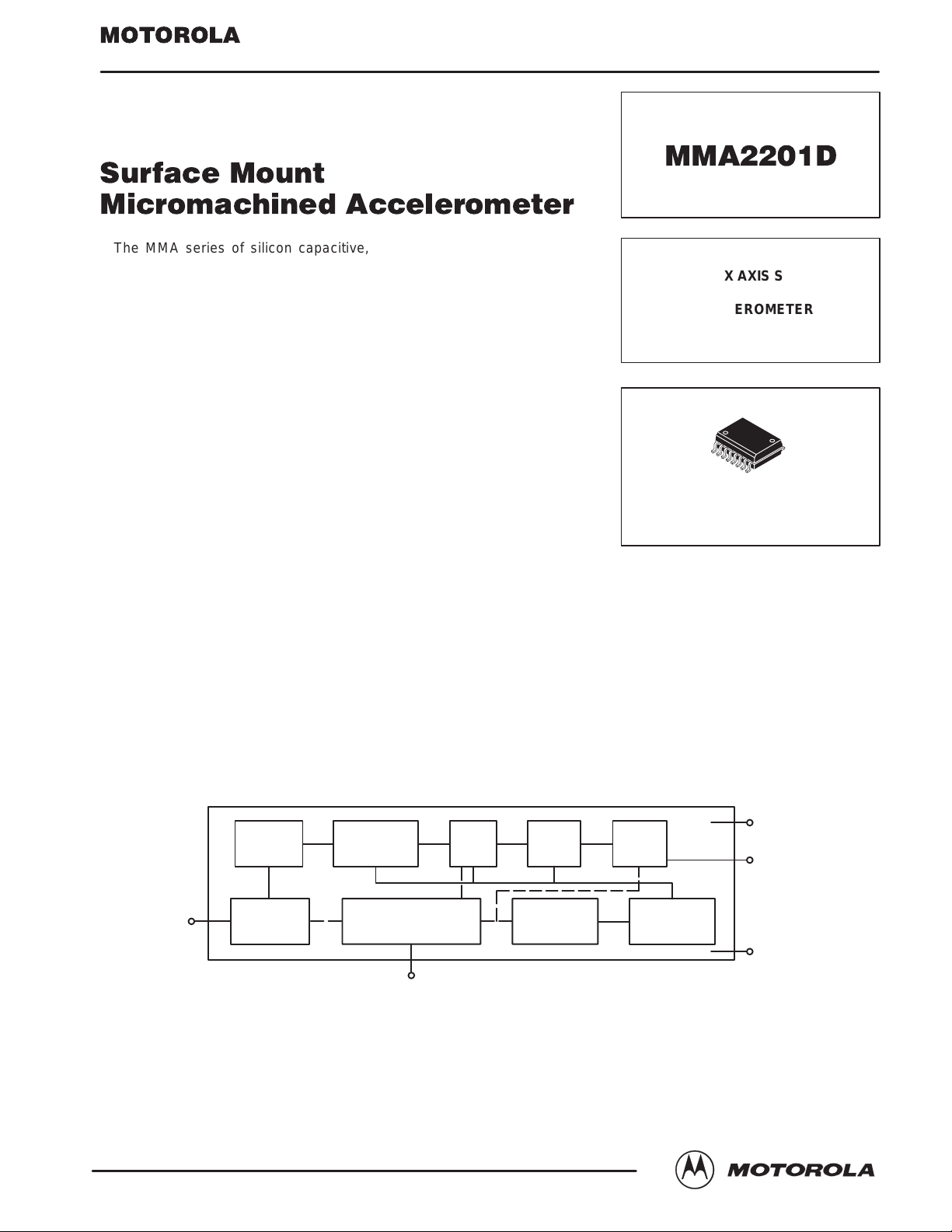

SIMPLIFIED ACCELEROMETER FUNCTIONAL BLOCK DIAGRAM

G–CELL

SENSOR

V

ST

REV 0

Motorola, Inc. 2000

SELF–TEST

Figure 1. Simplified Accelerometer Functional Block Diagram

INTEGRATOR GAIN FILTER

CONTROL LOGIC &

EPROM TRIM CIRCUITS

STATUS

OSCILLATOR

TEMP

COMP

CLOCK GEN.

V

V

V

DD

OUT

SS

1Motorola Sensor Device Data

Page 2

MMA2201D

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

MAXIMUM RATINGS

Powered Acceleration (all axes) G

Unpowered Acceleration (all axes) G

Supply Voltage V

Drop Test

Storage Temperature Range T

NOTES:

(1)

1. Dropped onto concrete surface from any axis.

(Maximum ratings are the limits to which the device can be exposed without causing permanent damage.)

Rating Symbol Value Unit

ELECTRO ST ATIC DISCHARGE (ESD)

WARNING: This device is sensitive to electrostatic

discharge.

Although the Motorola accelerometers contain internal

2kV ESD protection circuitry , extra precaution must be taken

by the user to protect the chip from ESD. A charge of over

500 g

2000 g

–0.3 to +7.0 V

1.2 m

–40 to +105 °C

D

pd

upd

DD

drop

stg

2000 volts can accumulate on the human body or associated

test equipment. A charge of this magnitude can alter the performance or cause failure of the chip. When handling the

accelerometer, proper ESD precautions should be followed

to avoid exposing the device to discharges which may be

detrimental to its performance.

2 Motorola Sensor Device Data

Page 3

MMA2201D

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

OPERATING CHARACTERISTICS

DD

(1)

5.00

5.0

—

38

2.5

0.50 V

50

10

400

—

—

110

2.0

12

—

—

*

2.0

—

—

0.2

—

—

300

—

10

)

110

DD

5.25

6.0

+85

—

2.7

0.56 V

DD

52.5

10.7

440

+1.0

2.8

—

—

14

0.3 x V

DD

V

DD

*

300

10

0.4

—

—

VDD *0.3

100

—

5.0

—

V

mA

°C

g

V

V

mV/g

mV/g/V

Hz

% FSO

mVrms

µV/(Hz

mVpk

g

V

V

µA

ms

V

V

ms

V

pF

Ω

% FSO

kHz

(Unless otherwise noted: –40°C v TA v +85°C, 4.75 v VDD v 5.25, Acceleration = 0g, Loaded output

Characteristic

Operating Range

Supply Voltage

Supply Current

Operating Temperature Range

Acceleration Range

Output Signal

Zero g (VDD = 5.0 V)

Zero g

Sensitivity (TA = 25°C, VDD = 5.0 V)

Sensitivity

Bandwidth Response

Nonlinearity

Noise

RMS (.01–1 kHz)

Power Spectral Density

Clock Noise (without RC load on output)

Self–Test

Output Response

Input Low

Input High

Input Loading

Response Time

(12)(13)

Status

Output Low (I

Output High (I

Minimum Supply Voltage (LVD Trip) V

Clock Monitor Fail Detection Frequency f

Output Stage Performance

Electrical Saturation Recovery Time

Full Scale Output Range (I

Capacitive Load Drive

Output Impedance

Mechanical Characteristics

Transverse Sensitivity

Package Resonance

NOTES:

1. For a loaded output the measurements are observed after an RC filter consisting of a 1 kΩ resistor and a 0.01 µF capacitor to ground.

2. These limits define the range of operation for which the part will meet specification.

3. Within the supply range of 4.75 and 5.25 volts, the device operates as a fully calibrated linear accelerometer. Beyond these supply limits

the device may operate as a linear device but is not guaranteed to be in calibration.

4. The device can measure both + and * acceleration. With no input acceleration the output is at midsupply. For positive acceleration the output

will increase above VDD/2 and for negative acceleration the output will decrease below VDD/2.

5. The device is calibrated at 20g.

6. At clock frequency ^ 70 kHz.

7. The digital input pin has an internal pull–down current source to prevent inadvertent self test initiation due to external board level leakages.

8. Time for the output to reach 90% of its final value after a self–test is initiated.

9. Time for amplifiers to recover after an acceleration signal causing them to saturate.

10. Preserves phase margin (60°) to guarantee output amplifier stability.

11. A measure of the device’ s ability to reject an acceleration applied 90° from the true axis of sensitivity.

12. The Status pin output is not valid following power–up until at least one rising edge has been applied to the self–test pin. The Status pin is

high whenever the self–test input is high.

13. The Status pin output latches high if a Low Voltage Detection or Clock Frequency failure occurs, or the EPROM parity changes to odd. The

Status pin can be reset by a rising edge on self–test, unless a fault condition continues to exist.

(2)

(3)

(7)

(8)

load

load

(4)

= 100 µA)

= 100 µA)

(10)

(11)

OUT

(5)

(6)

(9)

= 200 µA)

Symbol Min Typ Max Unit

V

DD

I

DD

T

A

g

FS

V

OFF

V

OFF,V

S

S

V

f

–3dB

NL

OUT

n

RMS

n

PSD

n

CLK

g

ST

V

IL

V

IH

I

IN

t

ST

V

OL

V

OH

LVD

min

t

DELAY

V

FSO

C

Z

O

V

ZX,YX

f

PKG

L

4.75

4.0

*

40

—

2.3

0.44 V

DD

47.5

9.3

360

*

1.0

—

—

—

10

V

SS

0.7 x V

*

30

—

—

VDD *.8

2.7 3.25 4.0 V

150 — 400 kHz

—

0.3

—

—

—

—

1/2

)

3Motorola Sensor Device Data

Page 4

MMA2201D

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

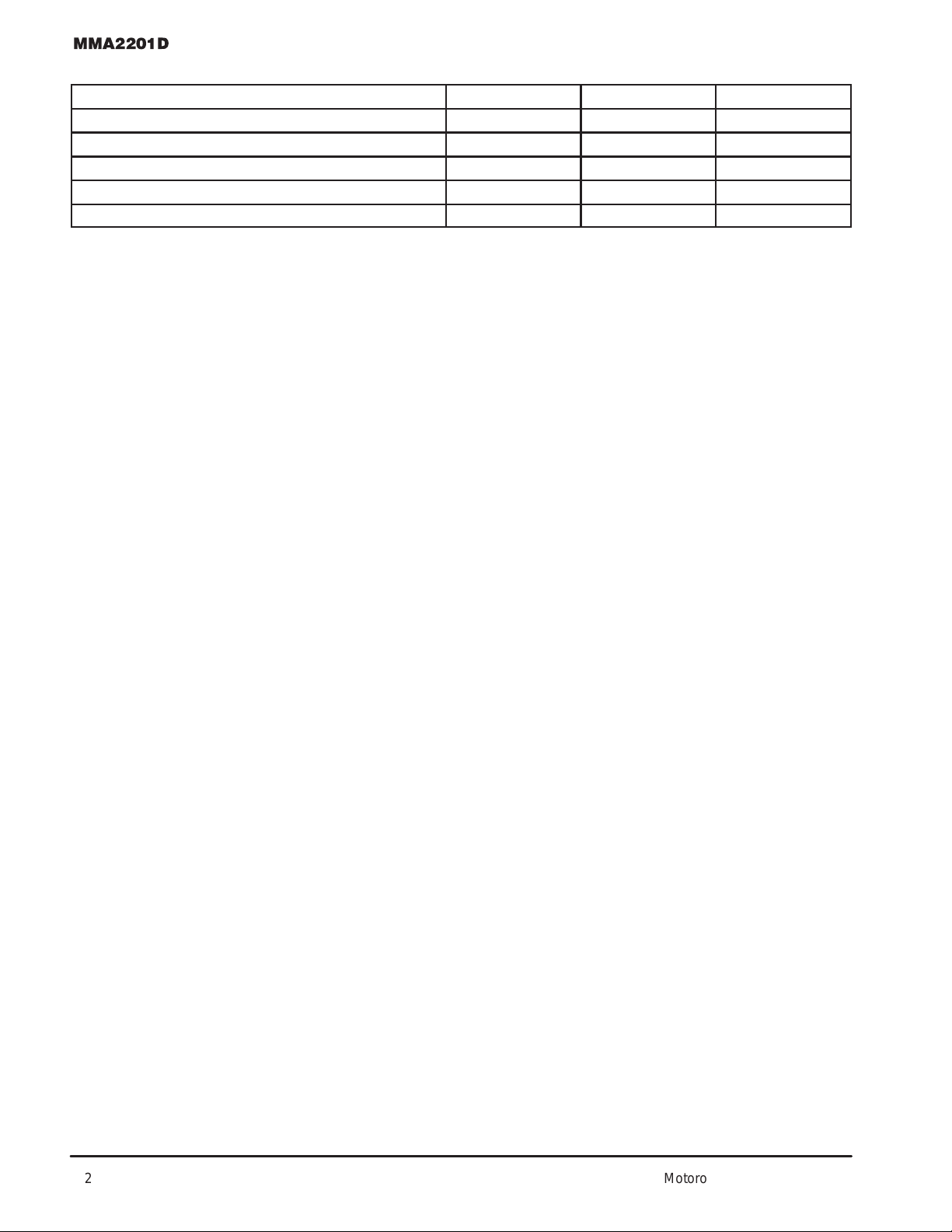

PRINCIPLE OF OPERATION

The Motorola accelerometer is a surface–micromachined

integrated–circuit accelerometer.

The device consists of a surface micromachined capacitive sensing cell (g–cell) and a CMOS signal conditioning

ASIC contained in a single integrated circuit package. The

sensing element is sealed hermetically at the wafer level

using a bulk micromachined “cap’’ wafer .

The g–cell is a mechanical structure formed from semiconductor materials (polysilicon) using semiconductor processes (masking and etching). It can be modeled as two

stationary plates with a moveable plate in–between. The

center plate can be deflected from its rest position by subjecting the system to an acceleration (Figure 2).

When the center plate deflects, the distance from it to one

fixed plate will increase by the same amount that the distance to the other plate decreases. The change in distance is

a measure of acceleration.

The g–cell plates form two back–to–back capacitors

(Figure 3). As the center plate moves with acceleration, the

distance between the plates changes and each capacitor’s

value will change, (C = Aε/D). Where A is the area of the

plate, ε is the dielectric constant, and D is the distance

between the plates.

The CMOS ASIC uses switched capacitor techniques to

measure the g–cell capacitors and extract the acceleration

data from the difference between the two capacitors. The

ASIC also signal conditions and filters (switched capacitor)

the signal, providing a high level output voltage that is ratiometric and proportional to acceleration.

Acceleration

Self–Test

The sensor provides a self–test feature that allows the

verification of the mechanical and electrical integrity of the

accelerometer at any time before or after installation. This

feature is critical in applications such as automotive airbag

systems where system integrity must be ensured over the life

of the vehicle. A fourth “plate’’ is used in the g–cell as a self–

test plate. When the user applies a logic high input to the

self–test pin, a calibrated potential is applied across the

self–test plate and the moveable plate. The resulting electrostatic force (Fe = 1/2 AV2/d2) causes the center plate to

deflect. The resultant deflection is measured by the accelerometer’s control ASIC and a proportional output voltage

results. This procedure assures that both the mechanical

(g–cell) and electronic sections of the accelerometer are

functioning.

Ratiometricity

Ratiometricity simply means that the output offset voltage

and sensitivity will scale linearly with applied supply voltage.

That is, as you increase supply voltage the sensitivity and

offset increase linearly; as supply voltage decreases, offset

and sensitivity decrease linearly. This is a key feature when

interfacing to a microcontroller or an A/D converter because

it provides system level cancellation of supply induced errors

in the analog to digital conversion process.

Status

Motorola accelerometers include fault detection circuitry

and a fault latch. The Status pin is an output from the fault

latch, OR’d with self–test, and is set high whenever one (or

more) of the following events occur:

• Supply voltage falls below the Low Voltage Detect (LVD)

voltage threshold

• Clock oscillator falls below the clock monitor minimum

frequency

• Parity of the EPROM bits becomes odd in number.

The fault latch can be reset by a rising edge on the self–

test input pin, unless one (or more) of the fault conditions

continues to exist.

Figure 2. Transducer

Physical Model

Figure 3. Equivalent

Circuit Model

SPECIAL FEATURES

Filtering

The Motorola accelerometers contain an onboard 4–pole

switched capacitor filter. A Bessel implementation is used

because it provides a maximally flat delay response (linear

phase) thus preserving pulse shape integrity . Because the filter is realized using switched capacitor techniques, there is

no requirement for external passive components (resistors

and capacitors) to set the cut–off frequency.

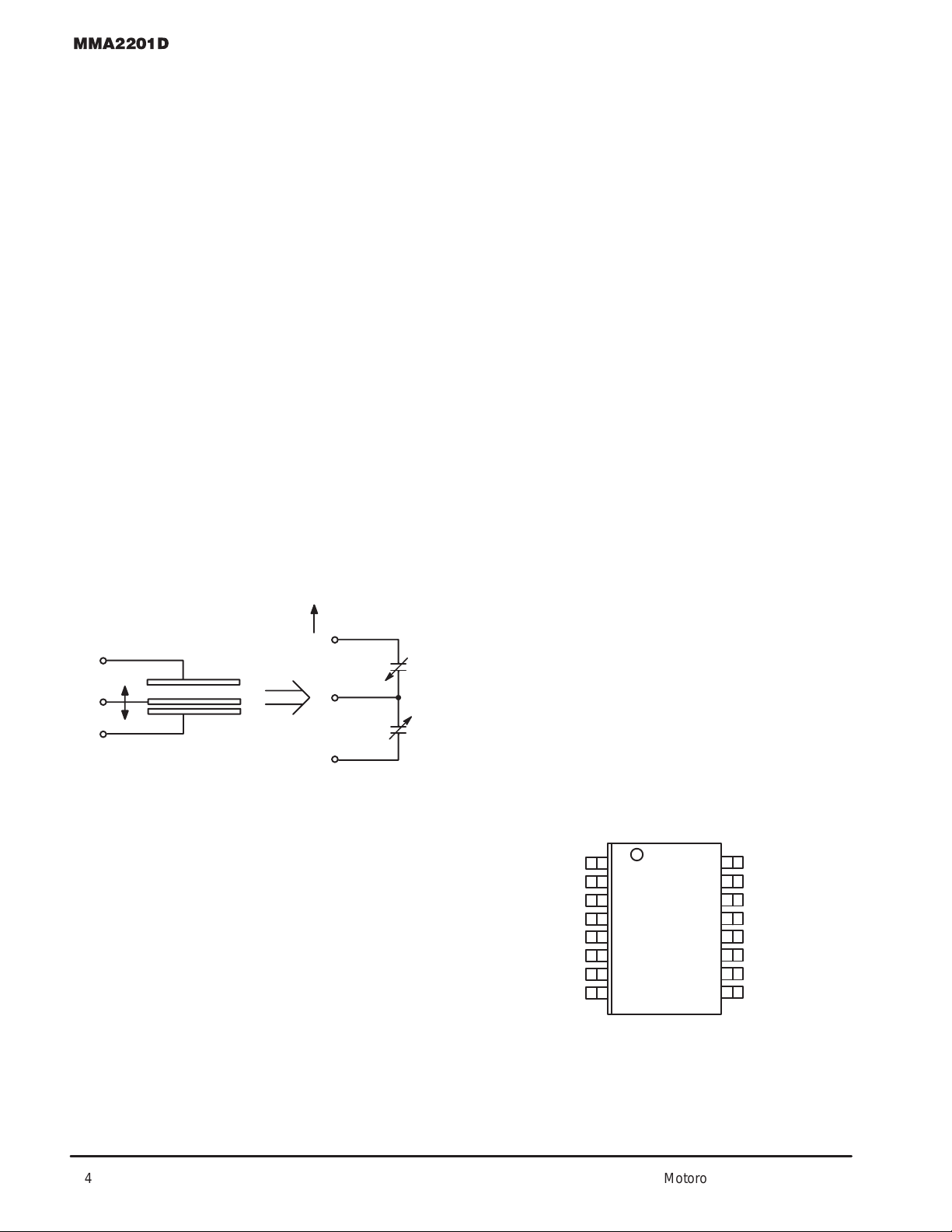

BASIC CONNECTIONS

Pinout Description

V

N/C

N/C

N/C

ST

OUT

N/C

V

SS

V

DD

1

2

3

4

5

6

7

8

4 Motorola Sensor Device Data

16

15

14

13

12

11

10

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

9

Page 5

Pin No. Pin Name Description

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

MMA2201D

PCB Layout

1 thru 3 — No internal connection. Leave

4 ST Logic input pin used to initiate

5 V

6 — No internal connection. Leave

7 V

8 V

9 thru 13 Trim pins Used for factory trim. Leave

14 thru 16 — No internal connection. Leave

V

DD

LOGIC

INPUT

C1

0.1 µF

OUT

SS

DD

4

8

7

ST

V

V

DD

SS

unconnected.

self–test.

Output voltage of the accelerome-

ter.

unconnected.

The power supply ground.

The power supply input.

unconnected.

unconnected.

V

OUT

6

R1

1 kΩ

5

C2

0.01 µF

MMA2201D

STATUS

OUTPUT

SIGNAL

Figure 4. SOIC Accelerometer with Recommended

Connection Diagram

P1STATUS

MICROCONTROLLER

0.1 µF

P0

A/D IN

V

RH

V

SS

C

0.1 µF

V

DD

ST

V

OUT

V

SS

ACCELEROMETER

V

DD

1 kΩ

C

0.1 µF

POWER SUPPLY

R

C

0.01 µF

C

Figure 5. Recommend PCB Layout for Interfacing

Accelerometer to Microcontroller

NOTES:

• Use a 0.1 µF capacitor on VDD to decouple the power

source.

• Physical coupling distance of the accelerometer to the

microcontroller should be minimal.

• Place a ground plane beneath the accelerometer to reduce

noise, the ground plane should be attached to all of the

open ended terminals shown in Figure 5.

• Use an RC filter of 1 kΩ and 0.01 µF on the output of the

accelerometer to minimize clock noise (from the switched

capacitor filter circuit).

• PCB layout of power and ground should not couple power

supply noise.

• Accelerometer and microcontroller should not be a high

current path.

• A/D sampling rate and any external power supply switching

frequency should be selected such that they do not interfere with the internal accelerometer sampling frequency.

This will prevent aliasing errors.

5Motorola Sensor Device Data

Page 6

MMA2201D

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

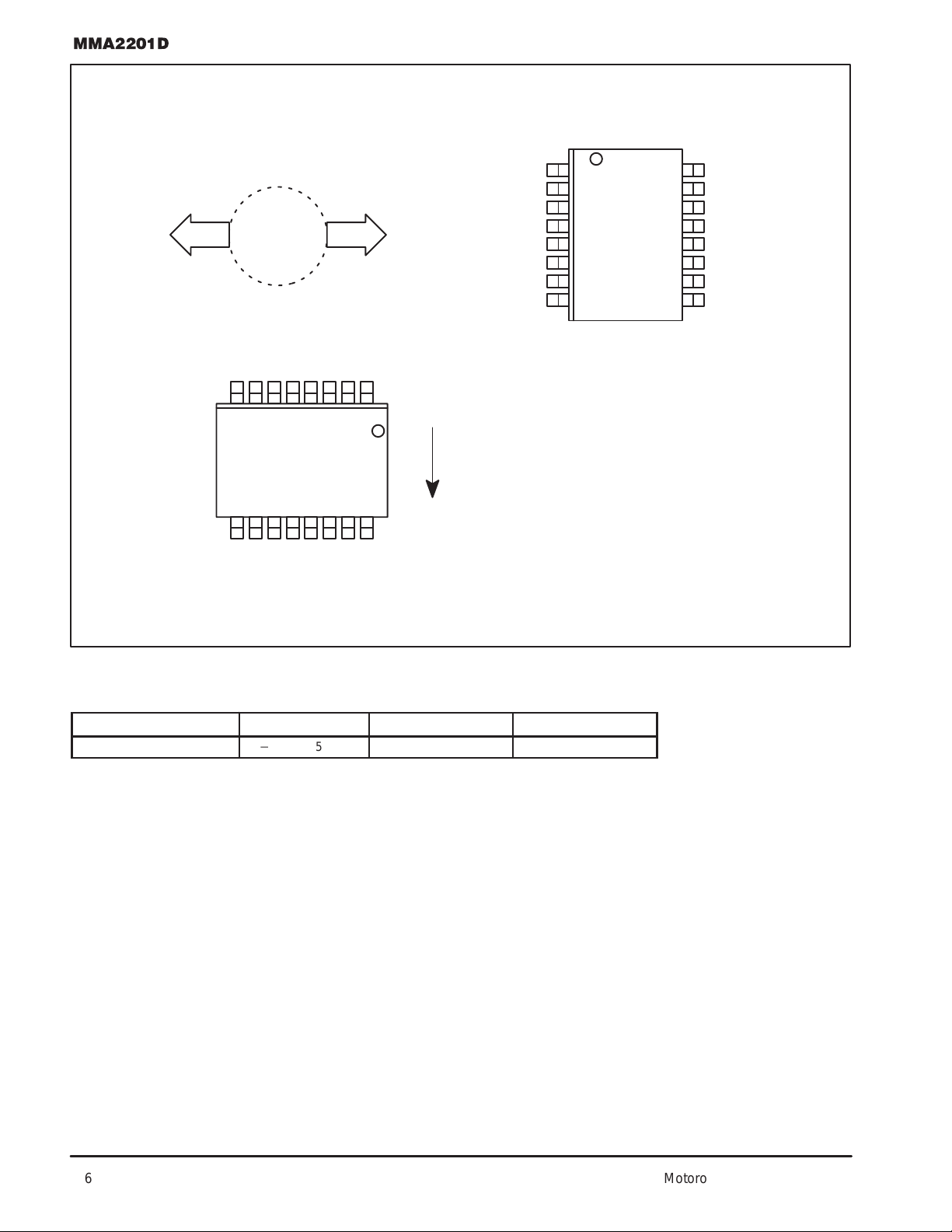

Positive Acceleration Sensing Direction

AXIS

ORIENTATION

–X +X

(ACCELERATION

FORCE

VECTOR)

87654321

10 11 12 13 14 15 16

9

* When positioned as shown, the Earth’s gravity will result in a positive 1g output

N/C

N/C

N/C

SELF TEST

X

OUT

N/C

V

SS

V

DD

N/C pins are recommended to be left FLOATING

Direction of Earth’s gravity field.*

1

2

3

4

5

6

7

8

16–Pin SOIC Package

16

15

14

13

12

11

10

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

9

ORDERING INFORMATION

Device Temperature Range Case No. Package

MMA2201D

*

40 to +85°C Case 475–01 SOIC–16

6 Motorola Sensor Device Data

Page 7

P ACKAGE DIMENSIONS

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

MMA2201D

–T–

SEATING

PLANE

–A–

16 9

–B–

18

D 16 PL

0.13 (0.005) B

M

M

A

T

C

K

G

P

8 PL

0.13 (0.005) B

M

M

T

R

K

J

F

CASE 475–01

ISSUE A

16 LEAD SOIC

A

X 45

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION.

M

M

_

M

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006) PER

SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.13 (0.005) TOTAL IN

EXCESS OF D DIMENSION AT MAXIMUM

MATERIAL CONDITION.

DIM MIN MAX MIN MAX

A 10.15 10.45 0.400 0.411

B 7.40 7.60 0.292 0.299

C 3.30 3.55 0.130 0.140

D 0.35 0.49 0.014 0.019

F 0.76 1.14 0.030 0.045

G 1.27 BSC 0.050 BSC

J 0.25 0.32 0.010 0.012

K 0.10 0.25 0.004 0.009

M 0 7 0 7

____

P 10.16 10.67 0.400 0.420

R 0.25 0.75 0.010 0.029

INCHESMILLIMETERS

7Motorola Sensor Device Data

Page 8

MMA2201D

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or

guarantee regarding the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the

application or use of any product or circuit, and specifically disclaims any and all liability , including without limitation consequential or incidental

damages. “Typical” parameters which may be provided in Motorola data sheets and/or specifications can and do vary in dif ferent applications

and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer application

by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of others. Motorola products are

not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where

personal injury or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application,

Buyer shall indemnify and hold Motorola and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs,

damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated

with such unintended or unauthorized use, even if such claim alleges that Motorola was negligent regarding the design or manufacture of the

part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal Opportunity/Affirmative Action Employer.

8 Motorola Sensor Device Data

◊

MMA2201D/D

Page 9

美国 MOTOROLA 压力传感器

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

美国 MOTOROLA 公司的 MPX 系列硅压力传感器,主要以气压测量为主,适合用于医疗器械,气体压力控制等领域,输出数字信号。其测量方式可分为:

表压(GP)、绝压(A、AP)、差压(D、DP)型。在宽温度范围工作时需外加补偿网络和信号调整电路。具体型号分类而定

名称:MPX2010DP

名称:MPX5700DP MPX5700GP

名称:MPX2100AP

名称:MPX5500DP

名称:MPX5010DP

名称:MPX5100AP

名称:MPX4115AP

名称:MPX5050DP

名称:MPX2200A

名称:MPX2200AP

名称:MPXH6115A6U

名称:MPX4250DP

Page 10

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

名称:MPX4115A

名称:MPX2053GP

名称:MPX2202DP

名称:MPXY8300A6U 压力传感器

名称:MPX2102AP

名称:触力型压力传感器 FSG15N1A

名称:硅压力传感器 MPXH6115A

名称:压力传感器 FPM07

名称:MPX5700DP 硅压力传感器

名称:轮胎压力传感器 TP015

名称:MPX53GP 硅压力传感器

名称:轮胎压力传感器 NPP301

Page 11

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

名称:Freescale 压力传感器 MPX2010DP

商斯达实业传感器与智能控制分公司专门从事各种进口传感器的营销工作,代理多家欧美知名公司的产品。涉及压力、温度、湿度、电流、液位、

磁阻、霍尔、流量、称重、光纤、倾角、扭矩、气体、光电、位移、触力、红外、速度、加速度等多种产品。广泛应用于航空航天、医疗器械(如

血压计)、工业控制、冶金化工、汽车制造、教育科研等领域。

商斯达实业代理的品牌产品主要有:

压 力:Kulite、ACSI、Honeywell、Entran、Gems、Dwyer、SSI、Smi、Senstronics、Intersema、Motorola、 NAIS、E+H、Fujikura、Dytran、

APM

称重测力:Transcell、HBM、Interface、Thamesside、Philips、Entran

温 湿 度:Honeywell、Dwyer

流 量:Gems、Dwyer、Honeywell、Folwline、WorldMagnetics

液 位:Honeywell、Siccom、Gems、Dwyer、Kulite、SSI

加 速 度:Entran、Silicondesigns、Dytran

压力开关:ACSI、Gems、Dwyer、台湾矽微

航空器材:TexTech 隔音材料、Honeywell 薄膜加热片、DigirayX 射线探伤仪

仪 表:Honeywell、Transcell、东辉、上润、AD、东崎

商斯达实业 除代理上述产品外,还有几条传感器生产线,一条压力传感器组装线,可为用户提供各种用途的、特殊要求的配套产品。同时还和国

内众多同行建立了友好交流的合作关系。商斯达实业地处深圳,信息资源集中,技术力量雄厚,与国内外有着广泛的联系,本着互利互惠、让利

与长期合作者的原则,以成为企业 "理想的战略伙伴" 为已任,深受业界好评。商斯达实业期待着与您开展更友好、更广泛、更深入的合作!

飞思卡尔 > 传感器

Page 12

MMA7260Q 是一款三轴 (XYZ-Axis) 向低重力加速度传感器,提供 1.5g、2g、4g 和 6g 的可选灵敏度。MMA7260Q

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

能够用于各种多功能应用,具备感应坠落、倾斜、移动、定位、撞击和震动的功能。它的封装尺寸很小,只需较

小的板卡空间,另外还提供快速启动和休眠模式,这些特性使 MMA7260Q 成为采用电池供电的电子产品的理想之选,

包括 PDA、手机、3D 游戏和数码相机等。 更多

重点汽车应用

轮胎压力监控系统 (中文)

轮胎压力监控系统(TPMS) 在线座谈 (中文)

重点产品

加速度(Low-g)传感器

MMA7260Q 低重力加速度(low-g)传感器 (中文)

MMA6200xxQ 低重力加速度(low-g)传感器 (中文)

集成压力传感器

MPXAZ 或 MPXHZ 封装的集成压力传感器特别适用于汽车应用

MPXA6115A 高温精确集成压力传感器 (中文)

MPXAZ6115A 媒体耐抗的高温精确集成压力传感器 (中文)

MPXH6115A 高温精确集成压力传感器 (中文)

MP3H6115A 高温精确集成压力传感器 (中文)

MPXHZ6115A 媒体耐抗的高温精确集成压力传感器 (中文)

MPXH6250A 集成压力传感器 (中文)

MPXH6300A 压力传感器 (中文)

MPXH6400A 集成压力传感器 (中文)

美国 motorola/freescale 气压传感器

MPX10D MPX10DP MPX10GP MPX10GS MPXV10GC6U MPXV10GC7U MPX12D MPX12DP MPX12GP MPX2010D MPX2010DP MPX2010GP MPXT2010G7U MPX2050D

MPX2050DP MPX2050GP MPX2050GVP MPX2050GS MPX2050GSX MPX2050GVSX MPX2053D MPX2053DP MPX2053GP MPX2100A MPX2100DP MPX2100AP MPX2100AS

MPX2100ASX MPX2102A MPX2102D MPX2102DP MPX2102AP MPX2102GP MPX2102GVP MPX2200A MPX2200D MPX2200DP MPX2200AP MPX2200GP MPX2200A

MPX2200D MPX2200DP MP2200AP MPX2200GP MPX21002A MPX2102D MPX2102DP MPX2102AP MPX2102GP MPX2102GVP MPX2200A MPX2200D MPX2200DP

MPX2200AP MPX2200GP MPX2201GP MPX2300DT1 MPX4080D MPX4100A MPXA4100A6U MPX4100AP MPXA4100A6U MPX4100AS MPX4101A MPXA4101AC6U

MPX4105A MPX4115A MPXA4115A6U MPX4115AP MPXA4115AC6U MPX4115AS MPX4200A MPX4200AP MPX4200SA MPX4200ASX MPX4250A MPX4250AP MPX4250A6U

MPXA4250A6T1 MPXA4250AC6U MPXA4250AC6T1 MPX4250D MPX4250GP MPX4250DP MPX5010D MPX5010DP MPX5010GP MPX5010GS MPX5010GSX MPXV5010G6U

MPXV5010G7U MPXV5010GC6U/T1 MPXV5010GC7U MPX5050D MPX5050DP MPX5050GP MPX5100A MPX5100D MPX5100DP MPX5100AP MPX5100GP MPX5100GVP

MPX5100AS MPX5100GS MPX5100GVS MPX5100ASX MPX5100GSX MPX5100GVSX MPX53D MPX53GP MPX5500D MPX5500DP MPX5700D MPX5700A MPX5700DP

MPX5700GP MPX5700AP MPX5700GS MPX5700AS MPX5999D MPXA6115A6U MPXA6115AC6U MPXA6115A MPXA6115A6T1 MPXA6115AC6T1 MPXAZ4100A6U

MPXAZ4100A MPXAZ4100A6T1 MPXAZ4100AC6U MPXAZ4100AC6T1 MPXAZ4115A6U MPXZ4115A MPXAZ4115A6T1 MPXAX4115AC6U MPXAZ4115AC6T1 MPXC2011DT1

MPXM2010D MPXM2010DT1 MPXM2010GS MPXM2010GST1 MPXM2053D MPXM2053DT1 MPXM2053GS MPXM2053GST1 MPXV4006GC6U MPXV4006G6U MPXV4115V6U

MPXV4115V6T1 MPXV4115VC6U MPXV5004GC6U/T1 MPXV5004G6U/T1 MPXV5004GC7U MPXV5004G7U MPXY8010 MPXY8020 MPXY8030 MPXY8040 MMA6200xxQ

低重力加速度(low-g)传感器

MPXA6115A 高温精确集成压力传感器 MPXAZ6115A 耐抗高温压力传感器 MPXH6115A 高温精确集成压力传感器

MP3H6115A 高温精确集成压力传感器 MPXHZ6115A 媒体耐抗的高温精确集成压力传感器 MPXH6250A 集成压力传感器 MPXH6300A 压力传感器

MPXH6400A 集成压力传感器 等汽车用压力传感器

Page 13

详情请致电我公司或上我公司网站查询

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

美国 motorola 压力传感器

MPX2010 MPX2100 MPX4080D MPX5050 MPX4105A MPX4200

MPX4250D MPX2050 MPX5999D MPX5100 MPX5010 MPX10

MPX4115A MPX4250A

MPX(毫伏输出)选型指南:(D:差压、A:绝压、P:含包装、MPX7000 系列适合电池供电)

型号 压力范围 KPa

MPX10D/DP 10 20 35 50 3.5 75 查看

MPX50D/DP 50 45 60 90 1.2 200 查看

MPX100D/DP/A/AP 100 45 60 90 0.6 200 查看

MPX200D/DP/A/AP 200 45 60 90 0.3 400 查看

MPX700D/DP 700 45 60 90 0.086 2800 查看

MPX2010D/DP 10 24 25 26 2.5 700 查看

MPX2050D/DP 50 38.5 40 41.5 0.8 200 查看

MPX2100D/DP/A/AP 100 38.5 40 41.5 0.4 400 查看

MPX2200D/DP/A/AP 200 38.5 40 41.5 0.2 400 查看

MPX2700D 700 38.5 40 41.5 0.057 2800 查看

MPX7050D/DP 50 38.5 40 41.5 0.8 200 查看

MPX7100D/DP/A/AP 100 38.5 40 41.5 0.4 400 查看

满量程输出,mV

灵敏度 mV/psi 过压 psi,Max 价格<元> 详细资料

Min. Typ. Max.

MPX7200D/DP/A/AP 200 38.5 40 41.5 0.2 400 查看

MPX(标准输出)选型指南

MPX4100A/AP 15-102 4618 4700 4782 54 400 查看

MPX4250A 20-250 4622 4690 4762 20 400 查看

MPX5010D/DP 10 4275 4500 4725 450 75 查看

MPX5050D/DP 50 4388 4500 4613 90 200 查看

MPX5100D/DP 100 4388 4500 4613 45 400 查看

MPX5100A/AP 15-115 4388 4500 4613 45 400 查看

MPX5500D/DP 500 4388 4500 4613 9.0 3500 查看

MPX5700D/DP 700 4388 4500 4613 6.0 2800 查看

MPX5999D/DP 1000 4388 4500 4613 5.0 2800 查看

Page 14

Freescale

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

加速度传感器(low g)

型 号

MMA6260Q

MMA6261Q

MMA6262Q

MMA6263Q

MMA2260D

MMA1260D

MMA1270D

MMA1250D

MMA1220D

MMA6231Q

MMA6233Q

型 号

MMA3201D

Acceleration(g) sensing axis sensitivity(mg/v) Rolloff frequency(hz) vdd(v) zero g output package

1.5/1.5 X-Y 800/800 50 3.3 1.65 16pin QFN

1.5/1.5 X-Y 800/800 300 3.3 1.65 16pin QFN

1.5/1.5 X-Y 800/800 150 3.3 1.65 16pin QFN

1.5/1.5 X-Y 800/800 900 3.3 1.65 16pin QFN

1.5 X 1200 50 5.0 2.5 16pin SOIC

1.5 Z 1200 50 5.0 2.5 16pin SOIC

2.5 Z 750 50 5.0 2.5 16pin SOIC

5.0 Z 400 50 5.0 2.5 16pin SOIC

8.0 Z 250 250 5.0 2.5 16pin SOIC

10/10 X-Y 120/120 300 3.3 1.65 16pin QFN

10/10 X-Y 120/120 900 3.3 1.65 16pin QFN

Freescale

Acceleration(g) sensing axis sensitivity(mg/v) Rolloff frequency(hz) vdd(v) zero g output package

40/40 X-Y 50/50 400 5.0 2.5 20pin SOIC

加速度传感器(Medium g)

MMA2201D

MMA2202D

MMA3222D

MMA3204D

MMA3202D

MMA2204D

MMA1213D

MMA1210D

型 号

MMA1211D

MMA2301D

MMA1212D

MMA2300D

MMA1200D

40 X 50 400 5.0 2.5 16pin SOIC

50 X 40 400 5.0 2.5 16pin SOIC

50/30 X-Y 40/66.67 400 5.0 2.5 20pin SOIC

100/30 X-Y 20/66.67 400 5.0 2.5 20pin SOIC

100/50 X-Y 50/100 400 5.0 2.5 20pin SOIC

100 X 20 400 5.0 2.5 16pin SOIC

50 Z 40 400 5.0 2.5 16pin SOIC

100 Z 20 400 5.0 2.5 16pin SOIC

Freescale

Acceleration(g) sensing axis sensitivity(mg/v) Rolloff frequency(hz) vdd(v) zero g output package

150 Z 13 400 5.0 2.5 16pin SOIC

200 X 10 400 5.0 2.5 16pin SOIC

200 Z 10 400 5.0 2.5 16pin SOIC

250 X 8.0 400 5.0 2.5 16pin SOIC

250 Z 8.0 400 5.0 2.5 16pin SOIC

加速度传感器(High g)

Freescale

集成压力传感器

Page 15

型 号

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

最大 压力

psi

最大 压力

kpa

最大 压力

in H2O

最大 压力

cm H2O

最大 压力

mm Hg

过压 (kpa)

量程 电压

vdc

灵敏 mV/Kpa

精度 0~85

(% of VFSS)

典型压力

A D G V

MPX4080

MPX4100

MPX4101

MPXA6115A

MPX4105

MPX4115

MPXH6115A

MPX4200

MPX4250

MPXH6250

MPXV4006

MPXV5004

MPX5010

11.6 80 321 815 600 400 4.3 54 ±3.0 •

15.2 105 422 1070 788 400 4.6 54 ±1.8

14.8 102 410 1040 765 400 4.6 54 ±1.8

16.7 115 462 1150 863 400 4.5 45.9 ±1.5

15.2 105 422 1070 788 400 4.6 51 ±1.8

16.7

16.7

16.7 115 462 1150 863 400 4.6 45.9 ±1.5

29 200 803 2040 1500 400 4.5 26 ±1.5

36

36

36 250 1000 2550 1880 400 4.7 19 ±1.5

0.87 6.0 24 61 45 10 4.6 766 ±5.0

0.57 4.0 16 40 29 10 3.9 1000 ±2.5

1.45 10 40 102 75 75 4.5 450 ±5.0

115

115

250

250

462

462

1000

1000

1174

1174

2550

2550

863

863

1880

1880

400

400

400

400

4.6

4.0

4.7

4.7

46

38

20

19

±1.5

±1.5

±1.5

±1.4

•

•

•

•

•

•

•

•

• •

•

• •

• •

• •

•

MPX5050

MPX5100

MPX5500

MPX5700

MPX5999

MPXh6300

MPXH6400

型 号

MPX2010

MPX2053

MPX2102

7.25 50 201 510 375 200 4.5 90 ±2.5

14.5

16.7

72.5 500 2000 5100 3750 2000 4.5 9.0 ±2.5

102 700 2810 7140 5250 2800 4.5 6.0 ±2.5

150 1000 4150 10546 7757 4000 4.5 5.0 ±2.5

44 300 1200 3060 2250 400 4.7 16 ±1.8

60 400 1600 4000 3000 500 4.7 12 ±1.5

最大压力

psi

1.45 10 40 102 75 75 ±1.0 25 2.5 -1.0 1.0 • •

7.0 50 201 510 375 200 ±1.0 40 0.8 -0.6 0.4

14.5

14.5

100

115

最大压力

kpa

100

100

401

462

最大压力

in H2O

400

400

1020

1174

最大压力

cm H2O

1020

750

863

Freescale

最大压力

mm Hg

750

750

400

400

4.5

4.5

带补偿压力传感器

过压

(kpa)

200 200

零位

偏差

mv

±2.0 ±

1.0

量程电压

mv

40

40

灵敏

mV/Kpa

0.4

0.4

45

45

线性%量程

最小

-1.0

-0.6

±2.5

±2.5

• • •

• • •

• •

• • •

•

•

•

线性%量程

最大

A D G V

• •

•

•

1.0

0.4

典型压力

•

Page 16

MPX2202

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

29

29

200

200

800

800

2040

1500

1500

400 400

±1.0 ±

1.0

40

40

0.2

0.2

-1.0

-0.6

1.0

0.4

•

•

•

MPX2050

MPX2100

MPX2200

型号

MPX10

MPX12

MPX53

7.0 50 201 510 375 200 ±1.0 40 0.8 -0.3 -0.3

最大

压力

1020

2040

过压

(kpa)

750

750

1500

1500

Freescale

零位

量程

偏差

电压

mv

mv

Freescale

200 200

400 400

±2.0 ±

1.0

±1.0 ±

1.0

40

40

40

40

无补偿压力传感器

线性 %

小

线性 %

量程 最

大

灵敏

mV/Kpa

量程 最

胎压监测传感器

0.4

0.4

0.2

0.2

-1.0

-0.3

-1.0

-0.3

A D G V

-1.0

-0.3

-1.0

-0.3

典型压力

• •

• •

14.5

14.5

29

29

最大

压力

psi

1.45 10 40 102 75 75 20 35 3.5 -1.0 1.0 • •

1.45 10 40 102 75 75 20 55 3.5 -1.0 1.0

7.0 50 200 510 375 200 20 60 1.2 -0.6 0.4

最大

压力

kpa

100

100

200

200

最大

压力

in h2o

最大

压力

cm h2o

400

400

800

800

mm Hg

• •

• •

• •

•

•

型 号

MPXY8020A

MPXY8021A

MPXY8040A

最大 压

力 psi

130.5 900 9.0 8-BIT 5.0 ±25kpa ±20kpa ±4° C 2.1-3.6

最大 压

力 kpa

92.4 637.5 6.4 8-BIT 2.5 ±15kpa ±7.5kpa ±4° C

92.4 637.5 6.4 8-BIT 2.5 ±20kpa ±7.5kpa ±4° C 2.1-3.6

最大 压

力 BAR

量程 输

出

灵敏

kpa/count

最大压力

精度

-20° C

最大压力

精度

+25 ° C-+70° C

最大温度

精度

+25° C

工作电压 v

2.1-3.6

单位换算

单 位 千 帕 mm Hg millibars inchesH2O PSI

典型压力

A D G V

•

•

•

1 大气压 101.325 760.00 1013.25 406.795 14.696

Page 17

1 千帕 1.00000

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

1 mm Hg 0.133322 1.00000 1.33322 0.535257 0.0193368

1 millibar 0.100000 0.750062 1.00000 0.401475 0.0145038

1 inch H2o 0.249081 1.86826 2.49081 1.00000 0.0361

1 PSI 6.89473 51.7148 68.9473 27.6807 1.00000

1 hectoPascal 0.100000 0.75006 1.00000 0.401475 0.0145038

1 cm H2O 0.09806 0.7355 9.8x10*7 0.3937 0.014223

7.50062

10.0000 4.01475 0.145038

压力传感器型号解析(MPXA2XXXAPXT1)

M PX A 2 XXX A P X

无 -UNIBODY

AH- SSOP

M -

标准

品

S-

定制

品

P,X-

测试

品

A/V- SOP

AZ -SMALL OUTLINE MEDIA

RESISTANT PACKAGE

压

C-CHIP

力

HZ-SUPER SMALL OUTLINE

传

MEDIA RESISTANT

感

M-M PAK

器

Y-SUPER SMALL OUTLINE

PACKAGE(TPM)

无-无补偿

2-温度补偿校 正

3-open

4--温度补偿校正信

号

自动校准

5- 温度补偿校正信号

6-高温

7-CMOS

8-胎压检测

最大压力

(kpa)

mpx2300

(mmHg)

A-绝对压

力

G-表压

D-差压

V-真空

C-AXIXL PORT(SMALL

OUTLINE PACKAGE)

P-PORTED

SINGLE PORT

(AP,GP,GVP)

DUAL PORT(DP)

S-STOVEPIPE

PORT(UNIBODY)

SX-AXIAL PORT

(UNIBODY)

NONE-NO LEADFORM

0-OPEN

1-2 (CONSULT FACTORY)

3-5 OPEN

6-7 SOP ONLY

(6=GULL WING/SURFACE MOUNT)

(7= 87 DEGREES/DIP)

T1

NONE-TRAYS

T1-TAPE AND REEL

1 INDICATES PART

ORIENTATION IN TAPE

U-RAIL

Page 18

SUNST AR商斯达实业集团是集研发、生产、工程、销售、代理经销 、技术咨询、信息服务等为一体的高

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

科技企业,是专业高科技电子产品生产厂家,是具有 10 多年历史的专业电子元器件供应商,是中国最早和

最大的仓储式连锁规模经营大型综合电子零部件代理分销商之一,是一家专业代理和分銷世界各大品牌IC

芯片和電子元器件的连锁经营綜合性国际公司。在香港、北京、深圳、上海、西安、成都等全国主要电子

市场设有直属分公司和产品展示展销窗口门市部专卖店及代理分销商,已在全国范围内建成强大统一的供

货和代理分销网络。 我们专业代理经销、开发生产电子元器件、集成电路、传感器、微波光电元器件、工

控机/DOC/DOM电子盘、专用电路、单片机开发、MCU/DSP/ARM/FPGA软件硬件、二极管、三极管、模

块等,是您可靠的一站式现货配套供应商、方案提供商、部件功能模块开发配套商。专业以现代信息产业

(计算机、通讯及传感器)三大支柱之一的传感器为主营业务,专业经营各类传感器的代理、销售生产、

网络信息、科技图书资料及配套产品设计、工程开发。我们的专业网站——中国传感器科技信息网(全球

传感器数据库) www.SENSOR-IC.COM 服务于全球高科技生产商及贸易商,

术交流平台。

变送器、执行器、自动控制产品厂商介绍产品到 中国,共同开拓市场。本网站是关于各种传感器-变送器-

仪器仪表及工业自动化大型专业网站,深入到工业控制、系统工程计 测计量、自动化、安防报警、消费电

子等众多领域,把最新的传感器-变送器-仪器仪表买卖信息,最新技术供求,最新采购商,行业动态,发展方

向,最新的技术应用和市场资讯及时的传递给广大科技开发、科学研究、产品设计人员。本网站已成功为

石油、化工、电力、医药、生物、航空、航天、国防、能源、冶金、电子、工业、农业、交通、汽车、矿

山、煤炭、纺织、信息、通信、IT、安防、环保、印刷、科研、气象、仪器仪表等领域从事科学研究、产

品设计、开发、生产制造的科技人员、管理人员 、和采购人员提供满意服务。 我公司专业开发生产、代

理、经销、销售各种传感器、变送器、敏感元器件、开关、执行器、仪器仪表、自动化控制系统: 专门从

事设计、生产、销售各种传感器、变送器、各种测控仪表、热工仪表、现场控制器、计算机控制系统、数

据采集系统、各类环境监控系统、专用控制系统应用软件以及嵌入式系统开发及应用等工作。如热敏电阻、

压敏电阻、温度传感器、温度变送器、湿度传感器、 湿度变送器、气体传感器、 气体变送器、压力传感

器、 压力变送、称重传感器、物(液)位传感器、物(液)位变送器、流量传感器、 流量变送器、电流

(压)传感器、溶氧传感器、霍尔传感器 、图像传感器、超声波传感器、位移传感器、速度传感器、加速

度传感器、扭距传感器、红外传感器、紫外传感器、 火焰传感器、激光传感器、振动传感器、轴角传感器、

光电传感器、接近传感器、干簧管传感器、继电器传感器、微型电泵、磁敏(阻)传感器 、压力开关、接

近开关、光电开关、色标传感器、光纤传感器、齿轮测速传感器、 时间继电器、计数器、计米器、温控仪、

固态继电器、调压模块、电磁铁、电压表、电流表等特殊传感器 。 同时承接传感器应用电路、产品设计

和自动化工程项目。

欢迎各厂商互通有无、交换信息、交换链接、发布寻求代理信息。欢迎国外高科技传感器、

为企业科技产品开发提供技

欢迎索取免费详细资料、设计指南和光盘 ;产品凡多,未能尽录,欢迎来电查询。

更多产品请看本公司产品专用销售网站:

商斯达中国传感器科技信息网:http://www.sensor-ic.com/

商斯达工控安防网:http://www.pc-ps.net/

商斯达电子 元器件网:http://www.sunstare.com/

商斯达微波光电产品网:HTTP://www.rfoe.net/

商斯达消费电子产品网://www.icasic.com/

商斯达军工产品网:http://www.junpinic.com/

商斯达实业科技产品网://www.sunstars.cn/传感器销售热线:

地址:深圳市福田区福华路福庆街鸿图大厦

电话:0755-83607652 83376489 83376549 83370250 83370251 82

传真:0755-83376182 (0)13902971329 MSN: SUNS8888@hotmail.com

邮编:518033 E-mail:szss20@163.com QQ: 195847376

深圳赛格展销部:深圳华强北路赛格电子市场

技术支持: 0755-83394033 13501568376

1602 室

500323

2583 号 电话:0755-83665529

Page 19

SUNSTAR 商斯达实业集团是集研发、生产、工程、销售、代理经销 、技术咨询、信息服务等

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

为一体的高科技企业,是专业高科技电子产品生产厂家,是具有 10 多年历史的专业电子元器件

供应商,是中国最早和最大的仓储式连锁规模经营大型综合电子零部件代理分销商之一,是一家

专业代理和分銷世界各大品牌 IC 芯片和電子元器件的连锁经营綜合性国际公司,专业经营进口、

国产名厂名牌电子元件,型号、种类齐全。在香港、北京、深圳、上海、西安、成都等全国主要

电子市场设有直属分公司和产品展示展销窗口门市部专卖店及代理分销商,已在全国范围内建成

强大统一的供货和代理分销网络。 我们专业代理经销、开发生产电子元器件、集成电路、传感

器、微波光电元器件、工控机/DOC/DOM 电子盘、专用电路、单片机开发、MCU/DSP/ARM/FPGA

软件硬件、二极管、三极管、模块等,是您可靠的一站式现货配套供应商、方案提供商、部件功

能模块开发配套商。商斯达实业公司拥有庞大的资料库,有数位毕业于著名高校——有中国电子

工业摇篮之称的西安电子科技大学(西军电)并长期从事国防尖端科技研究的高级工程师为您精

挑细选、量身订做各种高科技电子元器件,并解决各种技术问题。

更多产品请看本公司产品专用销售网站:

商斯达中国传感器科技信息网:http://www.sensor-ic.com/

商斯达工控安防网:http://www.pc-ps.net/

商斯达电子元器件网:http://www.sunstare.com/

商斯达微波光电产品网:HTTP://www.rfoe.net/

商斯达消费电子产品网://www.icasic.com/

商斯达实业科技产品网://www.sunstars.cn/

传感器销售热线:

地址:深圳市福田区福华路福庆街鸿图大厦 1602 室

电话:0755-83370250 83376489 83376549 83607652 83370251 82500323

传真:0755-83376182 (0)13902971329 MSN: SUNS8888@hotmail.com

邮编:518033 E-mail:szss20@163.com QQ: 195847376

深圳赛格展销部:深圳华强北路赛格电子市场 2583 号 电话:0755-83665529 25059422

技术支持: 0755-83394033 13501568376

欢迎索取免费详细资料、设计指南和光盘 ;产品凡多,未能尽录,欢迎来电查询。

北京分公司:北京海淀区知春路 132 号中发电子大厦 3097 号

TEL:010-81159046 82615020 13501189838 FAX:010-62543996

上海分公司:上海市北京东路 668 号上海賽格电子市场 2B35 号

TEL:021-28311762 56703037 13701955389 FAX:021-56703037

西安分公司:西安高新开发区 20 所(中国电子科技集团导航技术研究所)

西安劳动南路 88 号电子商城二楼 D23 号

TEL:029-81022619 13072977981 FAX:029-88789382

Loading...

Loading...