Page 1

Integrated Information S ys tem s Group

8201 E. McDowell Road

Scottsdale, AZ 85252-1417

Exhibit 8 – Users Manual

Card Acceptance Device (CAD+)

Low Power Transceiver Module

FCC ID: ABZMCAD200

Model Nos. T6480A

(and variants)

8.0 Card Acceptance Device (CAD+) Use rs Manual

Exhibit 8

Page 1 of 113 FCC ID: ABZMCAD200

10/10/00

Page 2

MCAD 200

CARD ACCEPTANCE DEVICE (CAD+)

Models

T6479A (Parallel)

T6480A (Serial)

T6481A (Serial)

T6499A (Serial)

T6500A (Serial)

T6501A (Serial)

T6548A (Serial)

Instruction Manual

68P81131E43-O

*6881131e43*

Page 3

MOTOROLA READER WARRANTY

Warranty: Motorola, Inc. (Motorola") warrants its Motorola manufactured smartcard reader or terminal (Prod

uct") to the original purchaser (Buyer") as stated herein, except to the extent the terms herein may be modified by a

written SmartCard Systems Agreement between Motorola and Buyer. Smartcards are not covered by this warranty.

Motorola warrants the Product against material defects in material and workmanship under normal use and service

for a period of One (1) Year from the date of Product shipment. Motorola, at its option, will at no charge either repair

the Product (with new or reconditioned parts), replace it with the same or equivalent product (using new or recondi

tioned parts), or refund the purchase price of the Product during the warranty period provided Buyer notifies Moto

rola within the warranty period in accordance with the terms of this warranty. Repaired or replaced product is war

ranted for the balance of the original applicable warranty period. All replaced parts of the Product shall become the

property of Motorola.

Warranty Exclusions: This warranty does NOT cover:

1. Defects, damage or malfunctions of the Product resulting from:

(a) Use of the Product in other than its normal and customary manner.

(b) Misuse, accident, neglect, environmental or site conditions not conforming to the Product specifications.

(c) Alteration, modification, adjustment, repair or testing of the Product not approved by Motorola.

(d) Equipment not approved by Motorola for use with the Product.

(e) Excessive power conducted or radiated from equipment not approved by Motorola for use with the Prod

uct.

2. Product which has had the serial number removed or made illegible.

3. Normal and customary wear and tear.

4. Fraud, theft or loss resulting from unauthorized use of the Product.

5. Loss of value or data stored in the Product or in other equipment used with the Product.

6. Disclosure of personal or confidential information or data stored in or accessed by the Product.

7. Loss or damage from Product or system downtime.

8. Scratches or other cosmetic damage to Product surfaces that does not affect the operation of the Product.

9. That the software in the Product will meet the purchaser's requirements or that the operation of the software will

be uninterrupted or error-free.

General Provisions: This express warranty is extended by Motorola to the original Buyer purchasing the Product,

and is not assignable or transferable to any other party. This is the complete warranty for the Product. Motorola

assumes no obligations or liability for additions or modifications to this warranty unless made in writing and signed

by an officer of Motorola. Unless made in a separate written agreement(s) between Motorola and Buyer, Motorola

does not warrant the maintenance or service of the Products other than stated herein.

Motorola cannot be responsible in any way for any ancillary equipment not furnished by Motorola which is attached

to or used in connection with the Product, or for operation of the Product with any ancillary equipment, and all such

equipment is expressly excluded from this warranty. Because each system which may use the Product is unique,

Motorola disclaims liability for read range, transaction time, or operation of the system as a whole under this warran

ty other than stated above.

This warranty sets forth the full extent of Motorola's responsibilities regarding the Product. Replacement or refund

of the purchase price, at Motorola's option, is the exclusive remedy. THIS WARRANTY IS GIVEN IN LIEU OF ALL

OTHER EXPRESS WARRANTIES. MOTOROLA DISCLAIMS ALL OTHER WARRANTIES OR CONDITIONS, EX

PRESS OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL MOTOROLA BE LIABLE FOR DAMAGES IN EX

CESS OF THE PURCHASE PRICE OF THE PRODUCT, FOR ANY LOSS OF USE, LOSS OF TIME, INCONVE

NIENCE, COMMERCIAL LOSS, LOST PROFITS OR SAVINGS OR OTHER INCIDENTAL, SPECIAL, INDIRECT OR

CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OR INABILITY TO USE SUCH PRODUCT, TO THE FULL

EXTENT SUCH MAY BE DISCLAIMED BY LAW.

Page 4

Patent and Software Provisions: Motorola will defend, at its own expense, any suit brought against the Buyer to

the extent that it is based on a claim that the Product or its parts infringe a United States patent, and Motorola will pay

those costs and damages finally awarded against the Buyer in any such suit which are attributable to any such

claim, but such defense and payments are conditioned on the following:

(a) that Motorola will be notified promptly in writing by Buyer of any notice of such claim;

(b) that Motorola will have sole control of the defense of such suit and all negotiations for its settlement or compro

mise; and

(c) should the Product or its parts become, or in Motorola's opinion be likely to become, the subject of a claim of

infringement of a United States patent, that Buyer will permit Motorola, at its option and expense, either to

procure for Buyer the right to continue using the Product or its parts or to replace or modify the same so that it

becomes non-infringing or to grant Buyer a credit for the Product or its parts as depreciated and accept its

return. The depreciation will be an equal amount per year over the lifetime of the Product or its parts as estab

lished by Motorola.

Motorola will have no liability with respect to any claim of patent infringement which is based upon the combination

of the Product or its parts furnished hereunder with software, apparatus or devices not furnished by Motorola, nor

will Motorola have any liability for the use of ancillary equipment or software not furnished by Motorola which is

attached to or used in connection with the Product. The foregoing states the entire liability of Motorola with respect

to infringement of patents by the Product or any its parts thereof.

Laws in the United States and other countries preserve for Motorola certain exclusive rights for copyrighted Motoro

la software such as the exclusive rights to reproduce in copies and distribute copies of such Motorola software.

Motorola software may be used in only the Product in which the software was originally embodied and such soft

ware in such Product may not be replaced, copied, distributed, modified in any way, or used to produce any deriva

tive thereof. No other use including, without limitation, alteration, modification, reproduction, distribution, or re

verse engineering of such Motorola software or exercise of rights in such Motorola software is permitted. No license

is granted by implication, estoppel or otherwise under Motorola patent rights or copyrights.

Page 5

FCC Compliance Statement

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions. (1) This

device may not cause harmful interference. And (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the radiated limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

-- Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference. And (2) this device must accept any interference received, including

interference that may cause undesired operation.

The CAD+ was submitted and a grant of authorization received from the FCC as a modular device under the inten

tional radiator requirements of Part 15, Subpart C.

The party that incorporates this device into their product is responsible for verification of the emissions produced by

the final product and must adhere to the limits specified in the Code of Federal Regulation 47, Part 15, Subpart B.

Furthermore, a label must be applied on the exterior of the final product referring to this enclosed module which

states, Contains FCC ID: ABZMCAD200" or Contains Transmitter Module FCC ID: ABZMCAD200".

Notice: When an AC source is used to supply power to the integrated equipment, the final equipment will also

have to verify compliance with the AC line conducted emissions according to FCC Part 15, Subpart B. If unsatisfac

tory emissions are measured at the fundamental frequency of the CAD+ then a Corcom 2VK1L power line filter may

be used to suppress the lineconducted emissions.

Caution: Any changes or modifications not approved by the party responsible for compliance could void the

user's authority to operate the equipment

CE Compliance Statement

The Motorola MCAD200 is in conformity with all essential requirements of the Radio & Telecommunications Termi

nal Equipment Directive (R&TTE 1999/5/EC). This product has been assessed to the following standards:

EN 300 330

ETSI EN 301 489-1

ETSI EN 301 489-3

EN 60950: 1992 Incl Amdt 1-4, 11

This product is marked with CE 0560 , which signifies conformity with Class II product requirements specified in

the R&TTE directive.

Page 6

MCAD 2000

CARD ACCEPTANCE DEVICE (CAD+)

Foreword iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Specifications iv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description

Product Overview page 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Simplified Block Diagram Theory page 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Models

T6479A (Parallel)

T6480A (Serial)

T6481A (Serial)

T6499A (Serial)

T6500A (Serial)

T6501A (Serial)

T6548A (Serial)

chapter

1

Installation

Unpacking and Inspection page 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying Proper Operation page 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning Procedure page 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing CAD into Terminal page 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Final Checkout Procedure page 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

Fault Isolation Procedures page 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Returning Faulty CADs to Motorola page 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Theory of Operation

Functional Theory of Operation page 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

chapter

2

chapter

3

chapter

4

Motorola, Inc. 2000

All Rights Reserved

Printed in U.S.A.

Worldwide Smartcard

Solutions Division

1301 E. Algonquin Road, Schaumburg, IL 60196

68P81131E43-O

October 15, 2000-eDOC

Page 7

Table of Contents

chapter

CAD Protocols and Commands

TerminaltoCAD Command Protocol page 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Answer to Reset (ATR) page 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAD Management Commands page 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Sequences page 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix

Appendix A Performing FLASH Upgrades page A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B CAD Connector PinOuts page B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C Dimensions and Clearances page C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D CAD+ Dip Switch Settings page D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and MOTOROLA are trademarks of Motorola, Inc.

IBM is a registered trademark of International Business Machines, Inc.

5

ii

October 15, 200068P81131E43-O

Page 8

Product Maintenance

Philosophy

Customer Support

Table of Contents

FOREWORD

Due to the high percentage of surfacemount components and multi

layer circuit board design, the maintenance philosophy for this product

is one of Field Replaceable Unit (FRU) substitution. Each Control

Board and Antenna Board matched set is considered a FRU, and when

determined to be faulty, may be quickly and easily replaced with a

known good set to bring the equipment back to normal operation. The

faulty CAD set must then be shipped to the Motorola Radio Support

Center in Rockford, Illinois for further troubleshooting and repair to the

component level.

Scope of Manual

For complete information on ordering FRU replacement modules, or

instructions on how to return faulty modules for repair, contact the

Motorola System Support Center as follows:

Motorola System Support Center

1311 E. Algonquin Road

Schaumburg, IL 60196

1-800-221-7144

FAX 847-576-2172

Int'l 847-576-7300

This manual is intended for use by experienced technicians familiar

with similar types of equipment. In keeping with the maintenance phi

losophy of Field Replaceable Units (FRU), this manual contains func

tional information sufficient to give service personnel an operational

understanding of all FRU modules, allowing faulty FRU modules to be

identified and replaced with known good FRU replacements.

The information in this manual is current as of the printing date.

Changes which occur after the printing date are incorporated by Stan

dard Manual Revisions (SMR). These SMRs are added to the manuals

as the engineering changes are incorporated into the equipment.

October 15, 2000 68P81131E43-O

iii

Page 9

Table of Contents

PERFORMANCE SPECIFICATIONS

Electrical

Required Supply Voltage 9.0 15.0 V dc; ripple less than 50 mV PP

Maximum 320 mA @ 12 V dc (230 mA typical)

Required Supply Current

Maximum Input Power Requirements 3.6 Watts

CAD PowerUp Time Less than 1 second after power applied

Environmental

Operating Temperature 30 C to +70 C (22 F to +158 F)

Storage Temperature 40 C to +85 C (40 F to +185 F)

Cold and Heat Shock 40 C to +85 C (40 F to +185 F) within 2 hour duration

Vibration

Shock

Bump

Electromagnetic Fields Compliant with ISO 105361, 4.2.8

NoteRatings assume recommended tuning with no metal within 10 cm of an

tenna board

Frequency Range:10 Hz to 500 Hz

Vibration Severity:3 gn

Severity: 60 gn

Duration: 11 msec

Severity: 40 gn

Duration: 6 msec

Number of bumps: 4000

Transmitter

Frequency 13.56 MHz .01%

ISO14443 Type A

Rise/Fall Time: 23 sec rise; <1.5 sec fall

ASK Percentage: 100%

Modulation

ISO14443 Type B

Rise/Fall Time: <2 sec rise and fall

ASK Percentage: 8% to 14%

Receiver

Carrier Frequency 13.56 MHz

Subcarrier Frequency 847.5 kHz

ISO14443 Type A

Modified Manchester

Subcarrier Data

ISO14443 Type B

NRZL BPSK

iv

October 15, 200068P81131E43-O

Page 10

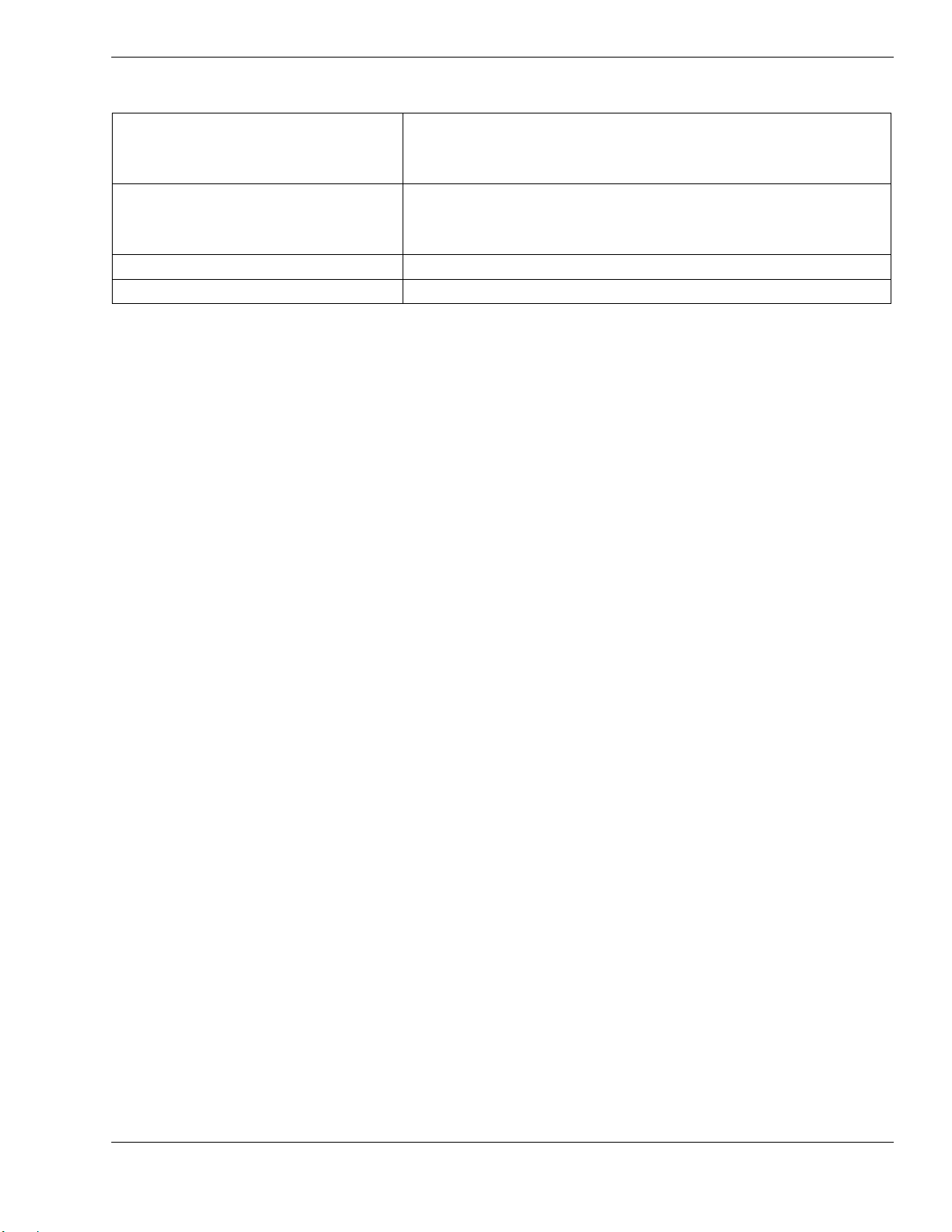

Operational

Serial

CADtoTerminal Communication Protocols

CADtoTerminal Communication Rates

CADtoCard Communication Rate 105.9375 Kbps

CADtoCard Operating Radio Frequency 13.56 MHz

RS232, RS485, and CMOS (depending on model)

Parallel

ByteWide Parallel Transfer

Serial

9600 bps, 19.2 bps, 38.4 Kbps, 57.6 Kbps, and 115.2 Kbps

Parallel

25,000 bytes per second

Table of Contents

October 15, 2000 68P81131E43-O

v

Page 11

Table of Contents

Notes...

vi

October 15, 200068P81131E43-O

Page 12

Chapter 1 Description

chapter contents

Product Overview

Simplified Block Diagram Theory

2

8

Card Acceptance Device (CAD+)

Technical User's Guide

68P81131E43-O

October 15, 2000

Page 13

Card Acceptance Device (CAD+) Technical User's Guide

PRODUCT OVERVIEW

1

The Motorola Card Acceptance Device (CAD) is an electronic module capable of communicating with

ISO 14443 Type A and Type B compatible smart cards via a radio frequency (RF) interface. This

section provides general information about the application and physical properties of the CAD.

Physical Description

Overview

The CAD, which provides the communications interface between a

terminal and customer smart cards, consists of a Control Board and

an Antenna Board. These two boards are connected together by a

100 mm multiconductor interconnect cable. The CAD is connected

to the terminal via a 16pin connector (parallel models) or a 10pin

connector (serial models) located on the Control Board.

Control Board

The Control Board contains a microprocessor, nonvolatile memory,

and radio frequency transmitting and receiving circuitry. This board

communicates with smart cards via an RF link (provided by the

Antenna Board), and to the terminal via RS232, RS485, or CMOS

(serial models) or a bytewide, proprietary parallel (parallel models)

protocol. Note that serial rates range from 9600 bps to 115.2 kbps,

and parallel rates are up to 25 kbytes/sec.

Typical Application

Antenna Board

The Antenna Board consists of a printed circuit board with copper

traces forming the transmit and receive antenna. The Antenna

Board may be one of several types, varying in dimensions and

construction (some types are attached to a ferrite plate with a metal

back plate serving as a ground plane).

The CAD described in this manual is a device which allows

communications to contactless smart cards by a host or terminal. It

is suitable for applications such as automated fare collection,

access control, electronic purse, and vending machines.

1-2

68P81131E43-O

October 15, 2000

Page 14

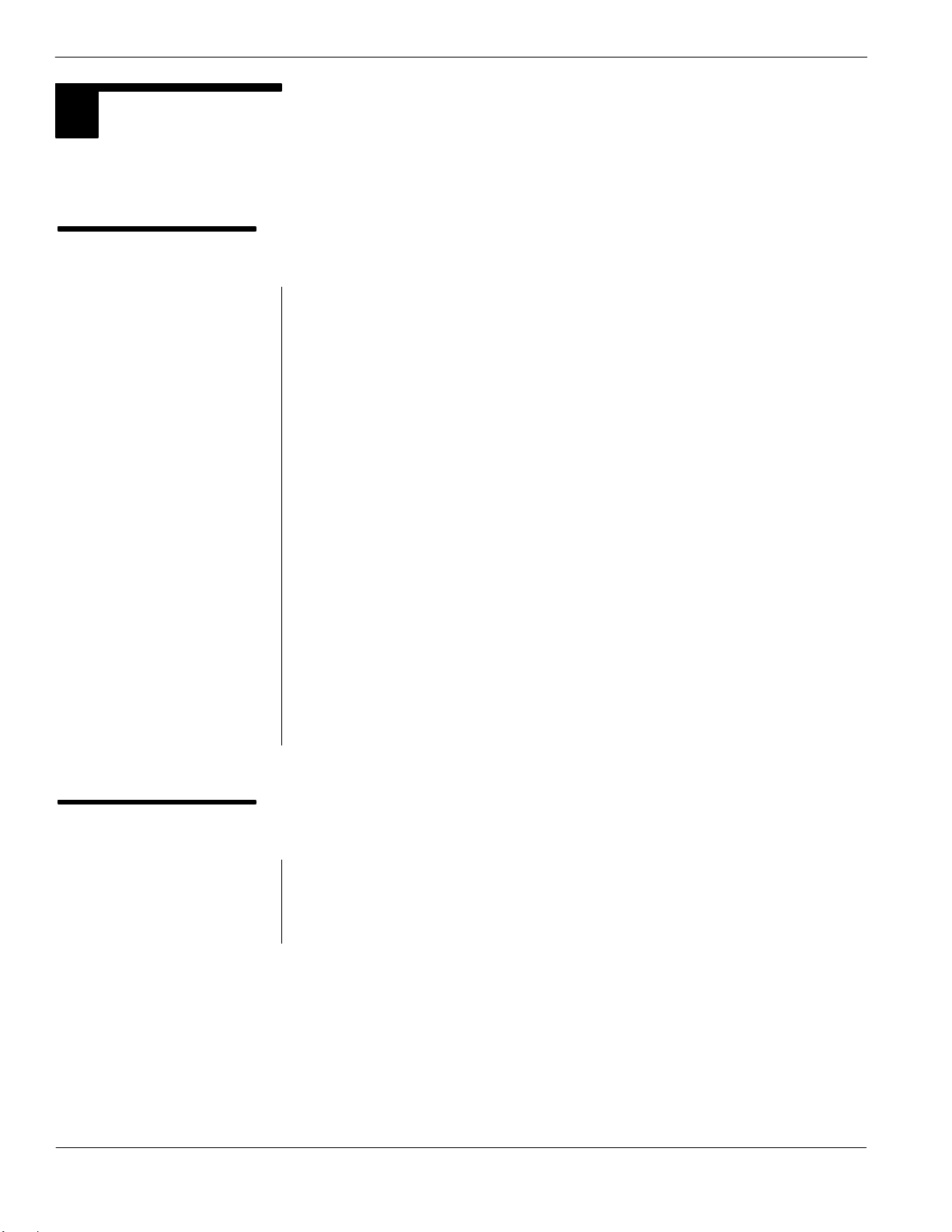

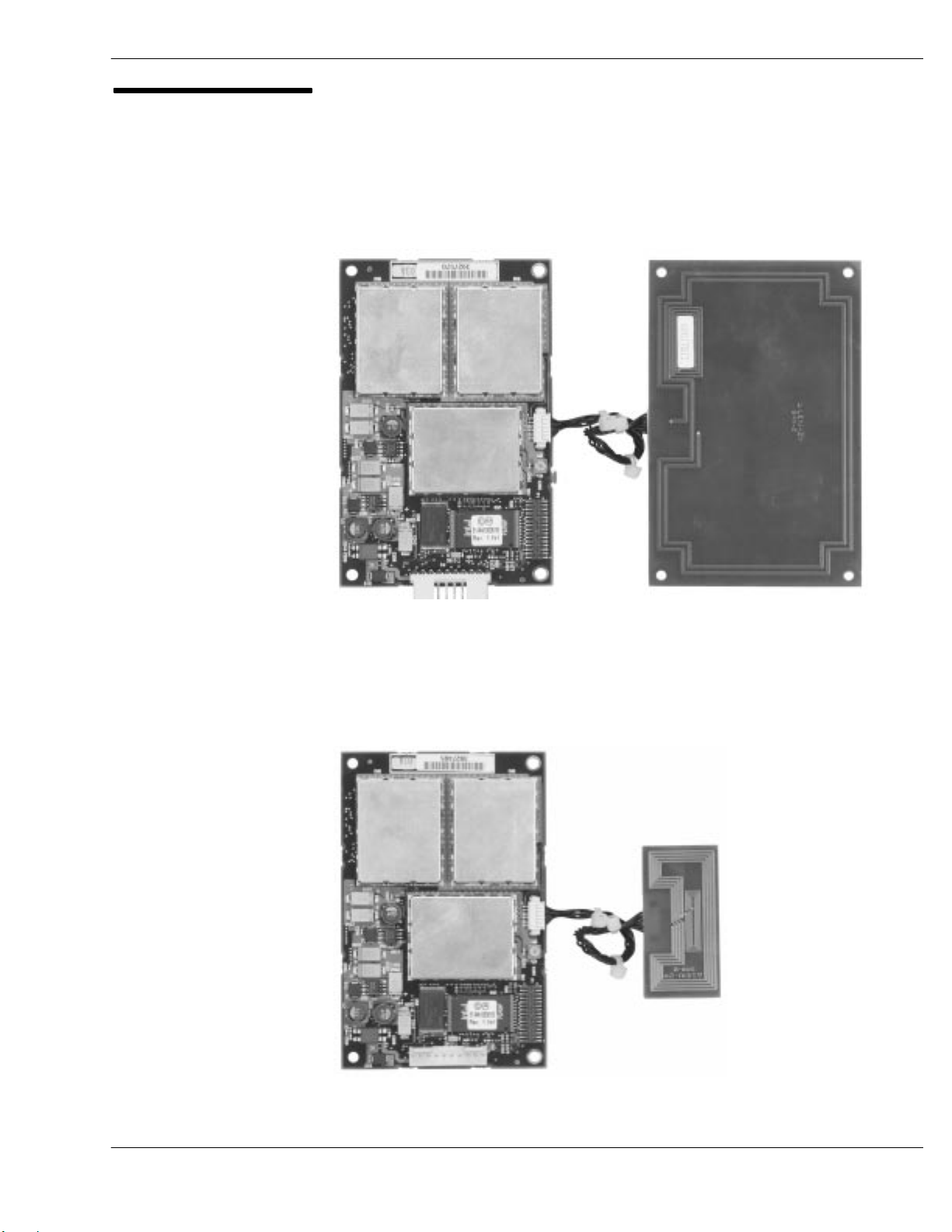

CAD Primary

Components

Chapter 1Description

CONTROL BOARD

ANTENNA BOARD

INTERCONNECT

CABLE

68P81131E43-O

October 15, 2000

1-3

Page 15

Card Acceptance Device (CAD+) Technical User's Guide

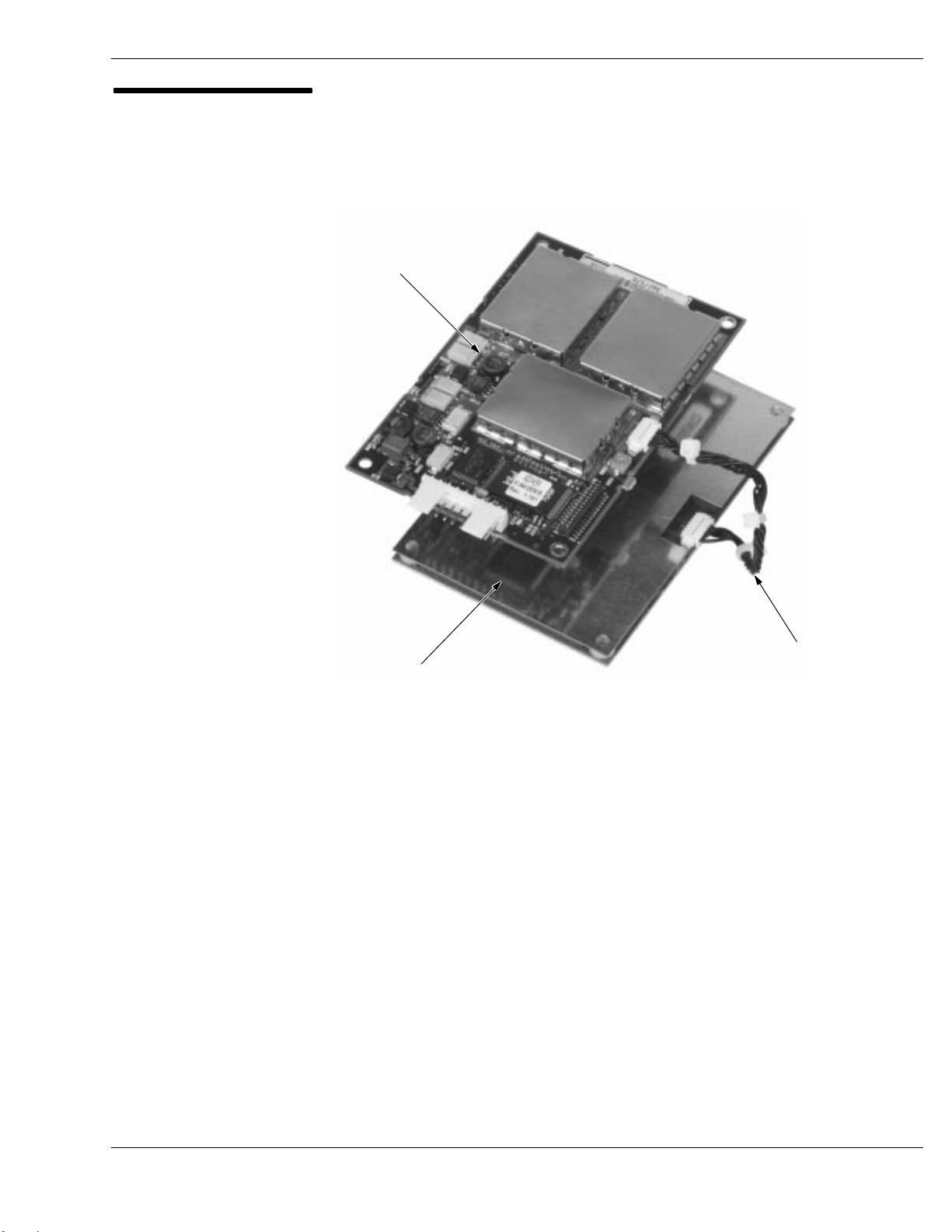

Available Models

The CAD+ is available in several models (shown on the next few

pages). In general, the major differences between the models are

the type of Antenna Board and the type of communications protocol

used to communicate with the terminal.

with Parallel Connector and 104 x 67 mm Antenna Board

Parallel CAD+ (CMOS Interface)

T6480A

T6479A

with Vertical Connector and 104 x 67 mm Antenna Board

Serial CAD+ (RS485 Interface)

1-4

68P81131E43-O

October 15, 2000

Page 16

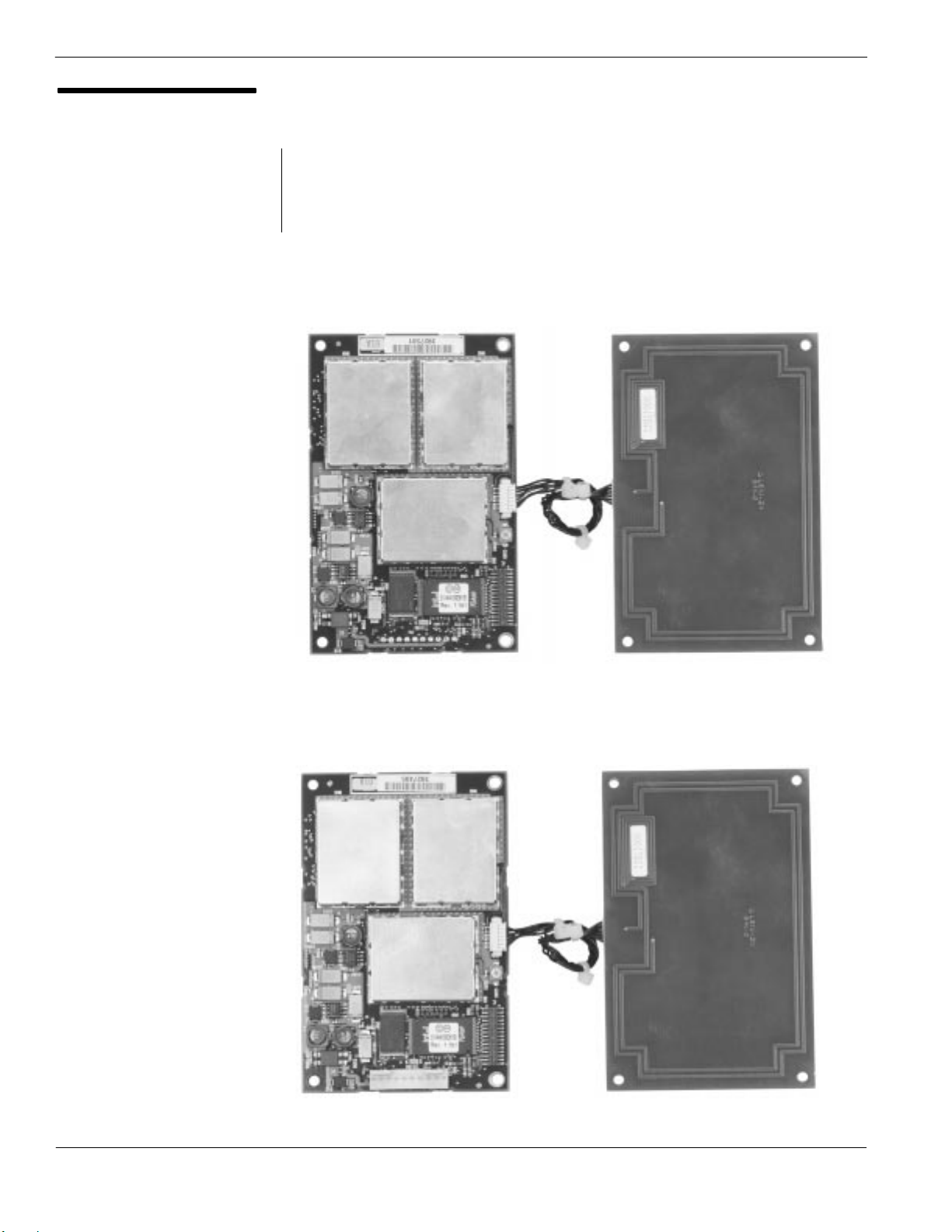

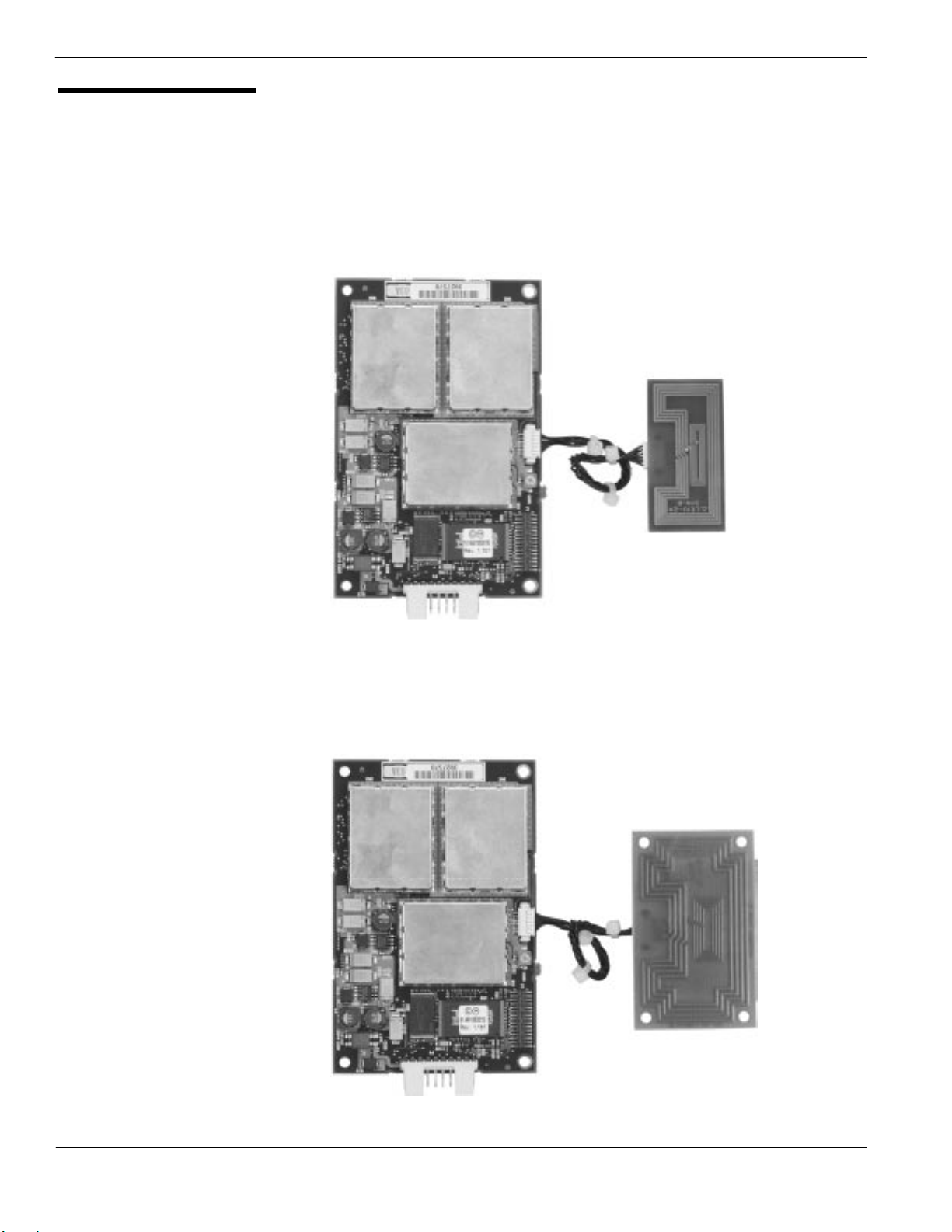

Available Models

(continued)

Chapter 1Description

with Horizontal Connector and 104 x 67 mm Antenna Board

Serial CAD+ (RS485 Interface)

T6481A

with Vertical Connector and 50 x 25 mm Antenna Board

Serial CAD+ (RS485 Interface)

T6499A

68P81131E43-O

October 15, 2000

1-5

Page 17

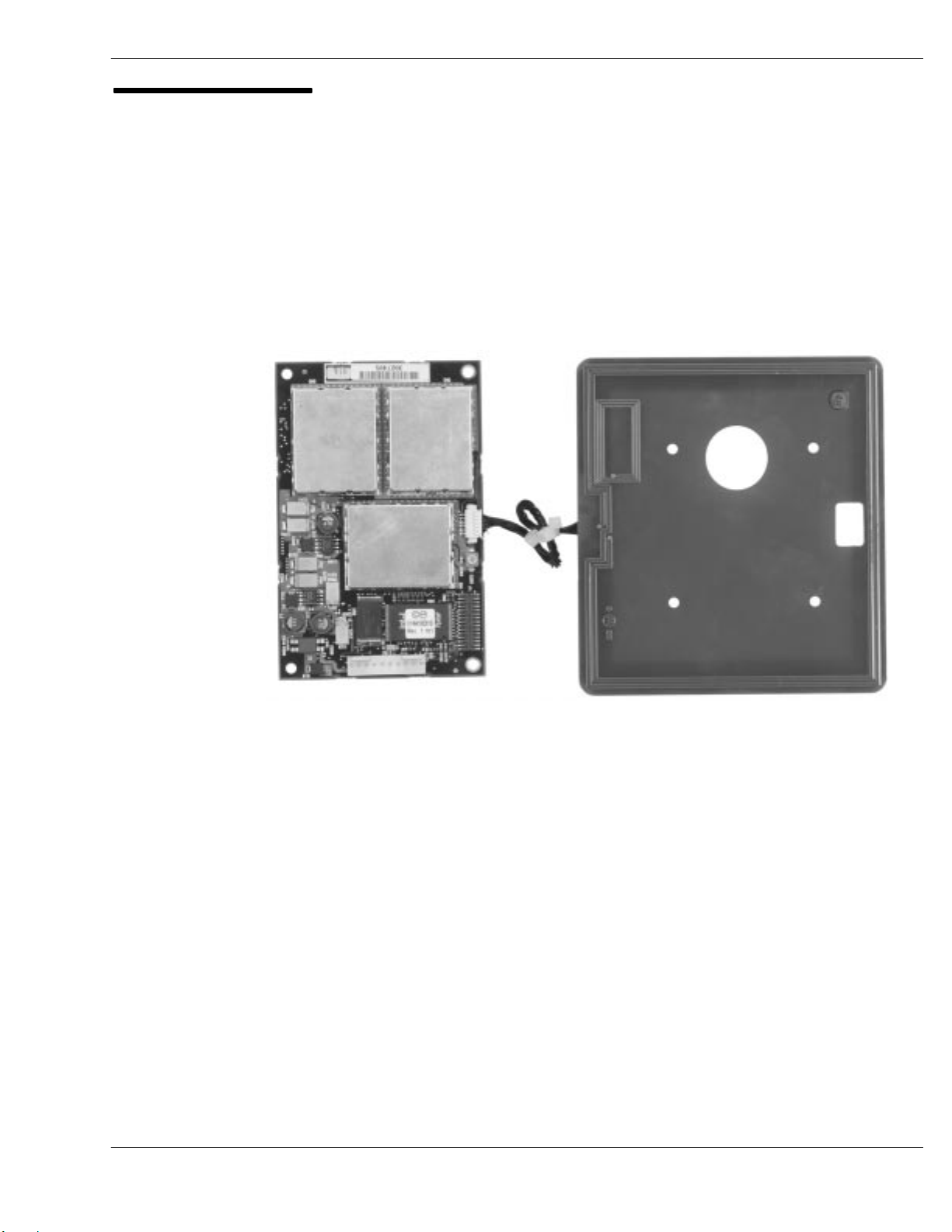

Card Acceptance Device (CAD+) Technical User's Guide

Available Models

(continued)

with Horizontal Connector and 50 x 25 mm Antenna Board

Serial CAD+ (RS485 Interface)

T6500A

with Horizontal Connector and 65 x 40 mm Antenna Board

Serial CAD+ (CMOS Interface)

T6501A

1-6

68P81131E43-O

October 15, 2000

Page 18

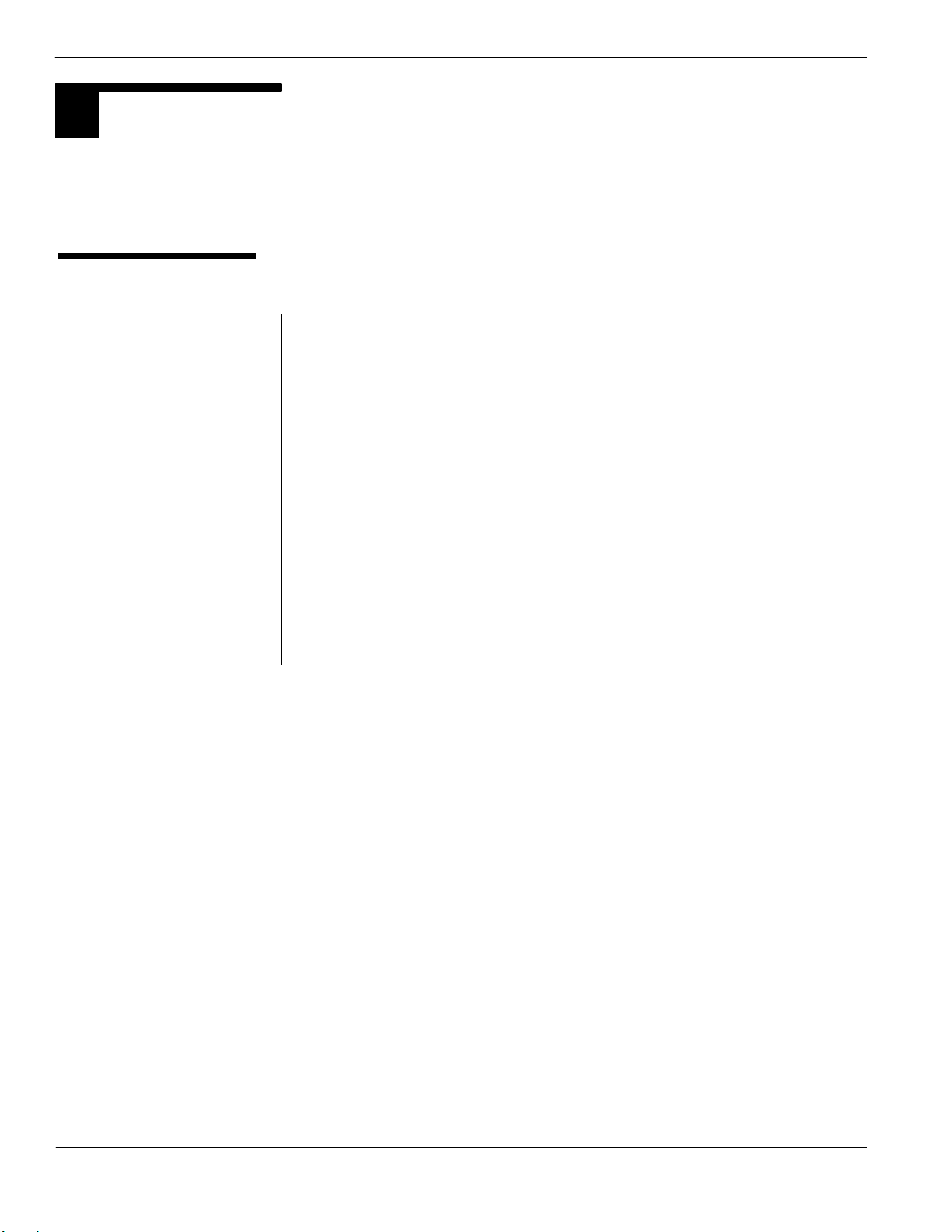

Available Models

(continued)

Chapter 1Description

with Vertical Connector and 100 x 110 mm Antenna Board

Serial CAD+ (RS485 Interface)

T6548A

68P81131E43-O

October 15, 2000

1-7

Page 19

Card Acceptance Device (CAD+) Technical User's Guide

2

The illustration on the facing page shows a simplified block diagram of the CAD. This section is

intended to provide a basic understanding of the CAD circuitry and how it interacts with the terminal

and smart cards. (Refer to Chapter 4 for a more detailed block diagram and circuit descriptions.)

SIMPLIFIED BLOCK DIAGRAM THEORY

Overview of CAD

Operation

The CAD serves as the data communications link between a smart

card and the Terminal in which the CAD is installed (or to which the

CAD is connected). The CAD operations are controlled by the

Terminal. The CAD searches (polls) for smart cards within its range,

notifies theTerminal when valid cards are found, and transfers data

from the Terminal to the card, and from the card back to the

Terminal.

For TerminaltoCard communications, the CAD's Control Board

receives a command from the Terminal to transmit data (received

from the Terminal) to the card. The CAD then transmits the data via

modulated encrypted RF signals to the card.

For CardtoTerminal communications, the CAD's Control Board

detects and demodulates encrypted RF data signals from the smart

card and sends data back to the Terminal. Communications with

the Terminal are made using RS485, RS232, or CMOS (serial

models) or 8bit bytewide parallel (parallel models) protocols.

1-8

68P81131E43-O

October 15, 2000

Page 20

CAD Simplified Block

Diagram

Chapter 1Description

CARD ACCEPTANCE DEVICE (CAD)

TERMINAL

SERIAL OR

PARALLEL DATA

(DEPENDING ON

MODEL)

CONTROL BOARD

MICROPROCESSOR

NONVOLATILE

MEMORY

POWER SUPPLY

CIRCUITRY

+5V

+5V_A

100 MM INTERCONNECT CABLE

ANTENNA BOARD

ANALOG

FRONT

END

(AFE)

68P81131E43-O

October 15, 2000

SMART CARD

1-9

Page 21

Card Acceptance Device (CAD+) Technical User's Guide

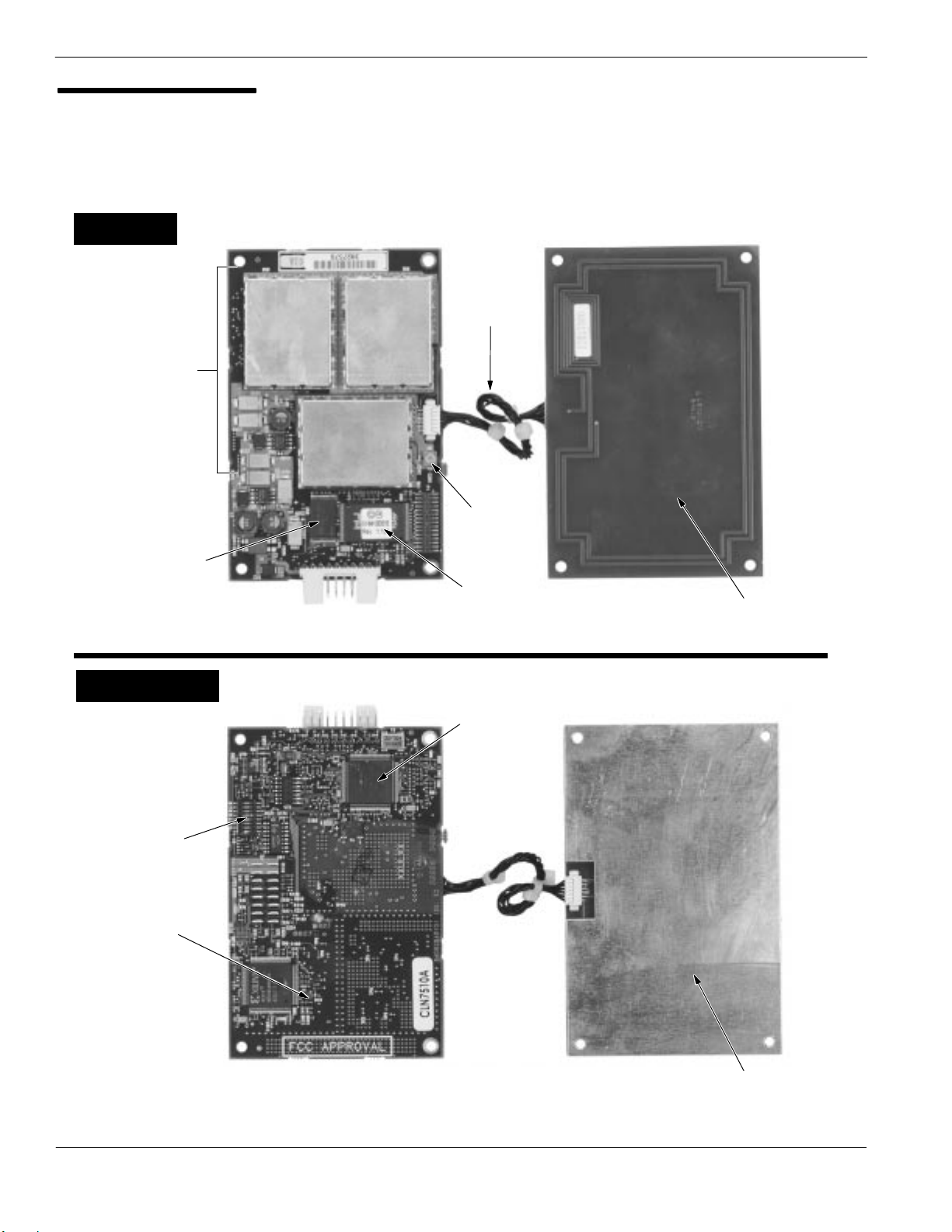

CAD Detailed

Components

The Control Board contains components on both sides of the circuit

board. The Antenna Board contains no components, but rather

printed circuit traces which form the antenna. Refer to the photos

on the next two pages for identification of the components on the

two boards. A typical Parallel CAD

+

and a Serial CAD+ are shown.

1-10

68P81131E43-O

October 15, 2000

Page 22

CAD Detailed

Components

(Typical Parallel CAD+)

Chapter 1Description

TOP VIEW

P/O

ANALOG

FRONT END

(AFE)

BOTTOM VIEW

SRAM

MEMORY

CONTROL BOARD

INTERCONNECT

CABLE

TUNING

CAPACITOR

FLASH

MEMORY

CONTROL BOARD ANTENNA BOARD

MICROPROCESSOR

ANTENNA BOARD

METAL BACK PLATE

(GROUND PLANE)

8POSITION

DIP SWITCH

PARALLEL

CONNECTOR

TO/FROM

TERMINAL

STATUS

(GREEN)

68P81131E43-O

October 15, 2000

LED

ANTENNA CIRCUIT BOARD

(TRACES FORM ANTENNA)

1-11

Page 23

Card Acceptance Device (CAD+) Technical User's Guide

CAD Detailed

Components

(Typical Serial CAD+)

TOP VIEW

P/O

ANALOG

FRONT END

(AFE)

MEMORY

SRAM

CONTROL BOARD ANTENNA BOARD

INTERCONNECT

CABLE

TUNING

CAPACITOR

FLASH

CONNECTS TO

TERMINAL

MEMORY

ANTENNA CIRCUIT BOARD

(TRACES FORM ANTENNA)

BOTTOM VIEW

8POSITION

DIP SWITCH

STATUS

LED

(GREEN)

CONTROL BOARD ANTENNA BOARD

MICROPROCESSOR

METAL BACK PLATE

(GROUND PLANE)

1-12

68P81131E43-O

October 15, 2000

Page 24

Chapter 2 Installation

chapter contents

Unpacking and Inspection

Verifying Proper Operation

Tuning Procedure

Installing CAD Into Terminal

Final Checkout Procedure

2

4

11

20

22

Card Acceptance Device (CAD+)

Technical User's Guide

68P81131E43-O

October 15, 2000

Page 25

Card Acceptance Device (CAD+) Technical User's Guide

UNPACKING AND INSPECTION

1

This section describes the procedures necessary to unpack and take inventory, run a Self Test utility to

verify proper electrical operation, perform a tuning procedure, mechanically install the CAD set into an

external terminal enclosure, and perform a final checkout procedure.

Important!The CAD Control Board contains CMOS and other staticsensitive components. When

handling the CAD, be sure to observe all precautions to prevent damage to the components from static

electricity. These include the use of a grounded antistatic wrist strap and antistatic mats and work

surfaces.

Unpacking and

Inspecting the CAD

Sets

General

Each CAD set (consisting of a Control Board and an Antenna Board) is

tuned and tested at the factory prior to shipment. Each CAD set is

shipped with a 100 mm multiconductor interconnect cable connected

between the Control Board and the Antenna Board.

Remove each CAD set from the packing material and inspect for visual

damage. Report the extent of any damage to the transportation

company and Motorola.

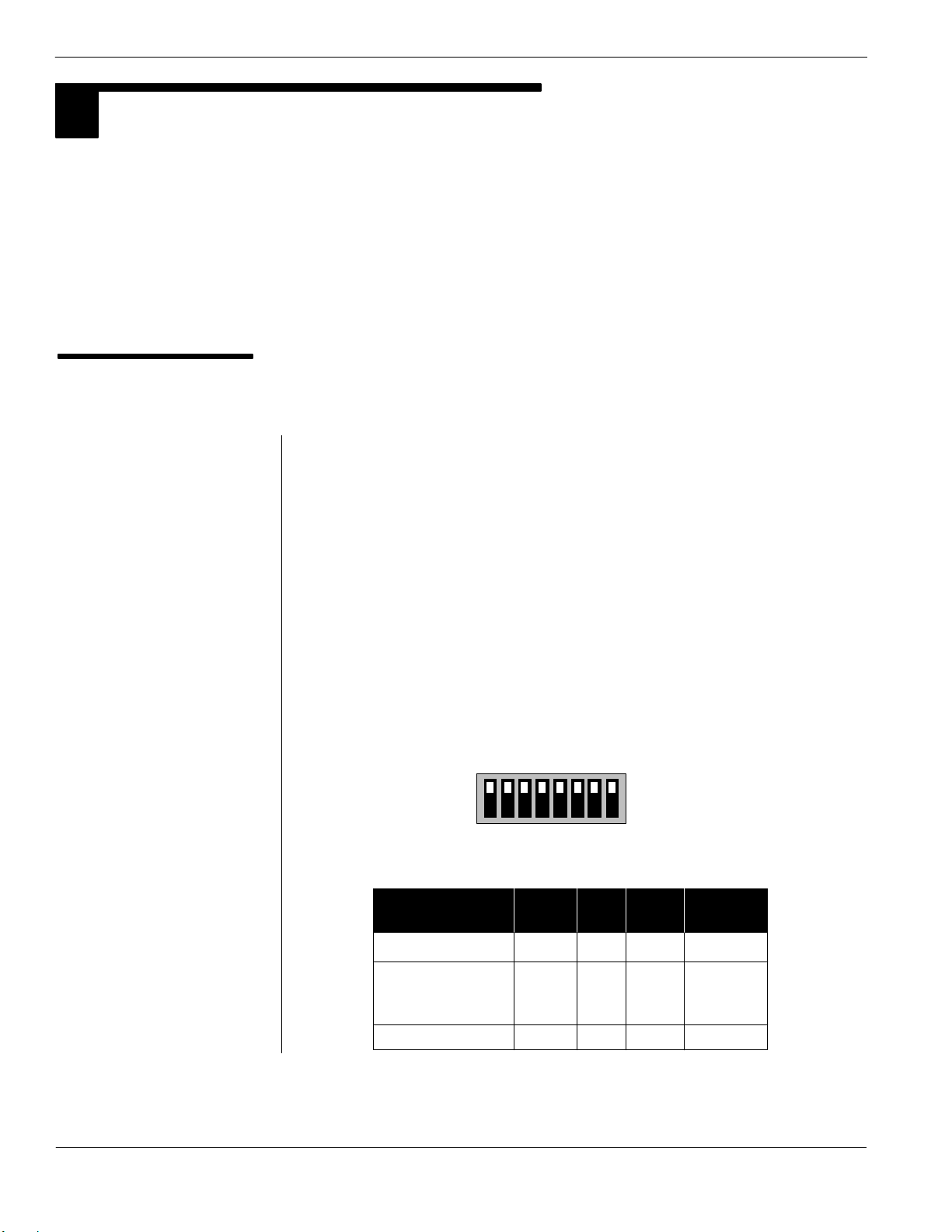

Verifying CAD+ Model Type

Examine the settings on the 8position DIP switch (located on the bottom

of the CAD+ Control Board and compare to the table below to verify the

model type of the CAD+. (Refer to Appendix D for more details on the

DIP switch settings.)

OFF

ON

12345678

CAD+ Model S1 S2 S3 S4-S8

T6479A On Off Off

T6480A, T6481A,

T6499A, T6500A.

T6548A

Off Off Off Off

Off

2-2

T6501A Off On Off Off

68P81131E43-O

October 15, 2000

Page 26

CAD Set Connected by

Cable

MULTICONDUCTOR

INTERCONNECT

CABLE

Chapter 2Installation

ANTENNA

BOARDCONTROL BOARD

68P81131E43-O

October 15, 2000

2-3

Page 27

Card Acceptance Device (CAD+) Technical User's Guide

VERIFYING PROPER OPERATION

2

Although each CAD set is tested at the factory before shipment, it is recommended that the AutoTest

utility be run on each CAD set prior to installation into a terminal. This ensures that the CAD set is

electrically functional and was not electrically damaged in transit or during unpacking.

The AutoTest utility is part of the CADTools program included with the Model T6439A Parallel CAD

Installation Kit or the Model T6367A Serial CAD Installation Kit (both available from Motorola). The

CADTools program is a Microsoft Windows compatible program that includes a suite of factory test

utilities and a firmware download utility for updating the CAD operating software.

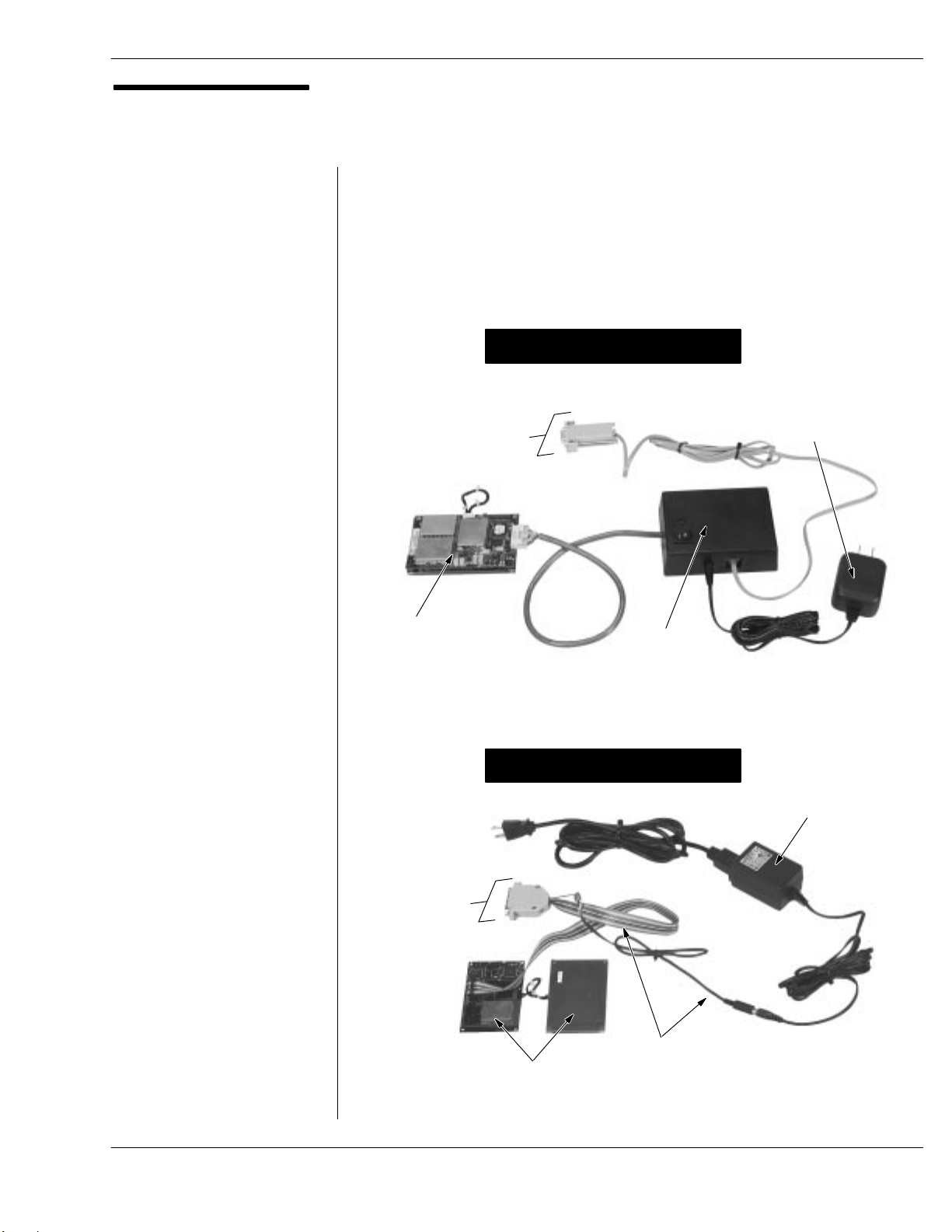

Required Equipment

The following hardware and software is required in order to run the Self

Test Utility on a CAD set.

Model T6367A Serial CAD Installation Kit includes Serial

Converter Box, Power Supply, ISO Antenna Board, and CADTools

Software (version V1.20 or higher required)

or

Model T6439A Parallel CAD Installation Kit includes Test

Cable, Power Supply, ISO Antenna Board, and CADTools Software

(version V1.20 or higher required)

IBM PC or IBMcompatible desktop or laptop computer (Pentium

II class processor running at 200 MHz or greater, Windows 95, 98,

2000, or NT 4.0 operating system)

Installing the CADTools

Software

2-4

The CADTools software is provided on a CDROM (typically). Install the

software by performing the procedures located in the CADTools User's

Guide (supplied with the software in printed and/or electronic format).

68P81131E43-O

October 15, 2000

Page 28

Launching the

CADTools Software

Chapter 2Installation

1. Before launching the CADTools program, the CAD must be

powered and connected to the PC, as shown below. Make these

connections using the cables and power supply provided in the

Model T6367A (Serial) or T6439A (Parallel) CAD Installation Kit.

Serial CAD Connections

+12 V

CONNECTS TO

COM 1 PORT

ON PC

POWER

SUPPLY

Important!Do not attach or

remove the ribbon cable from the

16pin connector on the Control

Board with DC power on (either

from the Terminal or from the DC

Power Supply included with the

Installation kit). Doing so may result

in corrupted Control Board

firmware.

Important!Make sure that the

PC's parallel port is set for

bidirectional. This setting is

usually provided in the PC's BIOS

setup menu (accessed by pressing

a designated key during the PC's

bootup period).

CAD SET

CONNECTS TO

PARALLEL PORT

ON PC

SERIAL

CONVERTER

BOX

Parallel CAD Connections

TEST CABLE

CAD SET

+12 V

POWER

SUPPLY

68P81131E43-O

October 15, 2000

continued on next page

2-5

Page 29

Card Acceptance Device (CAD+) Technical User's Guide

Launching the

CADTools Software

(continued)

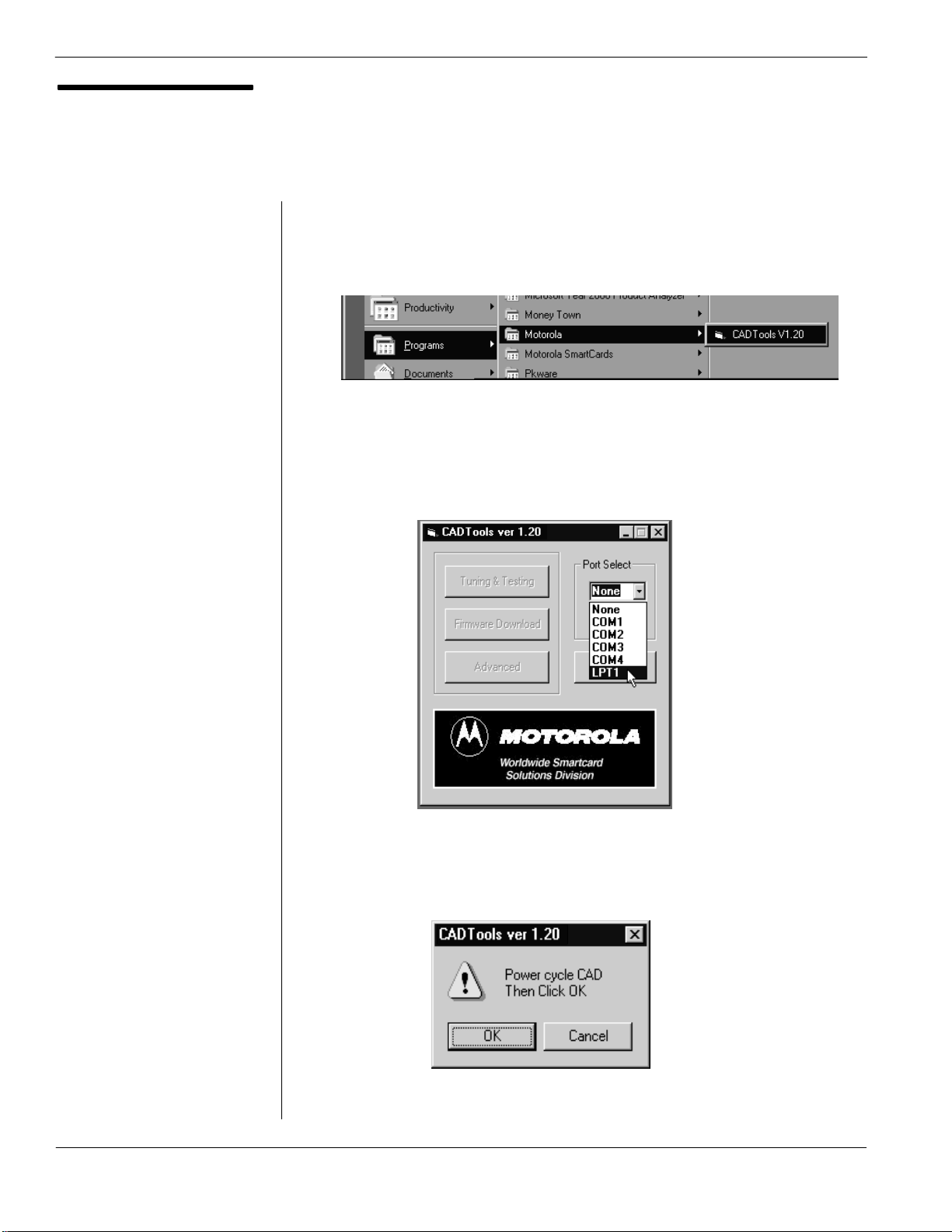

2. Click on the Start button, then select:

Programs ⇒ Motorola ⇒ CADTools

3. The CADTools Main Screen will appear. Click in the Port

Select list box and select COM1 (serial CAD) or LPT1

(parallel CAD). LPT1 is selection is shown below.

2-6

4. The following screen may appear, prompting you to power

cycle the CAD. Disconnect, then reconnect the black DC

power connector to power cycle the CAD. Then click on OK.

continued on next page

68P81131E43-O

October 15, 2000

Page 30

Launching the

CADTools Software

(continued)

Chapter 2Installation

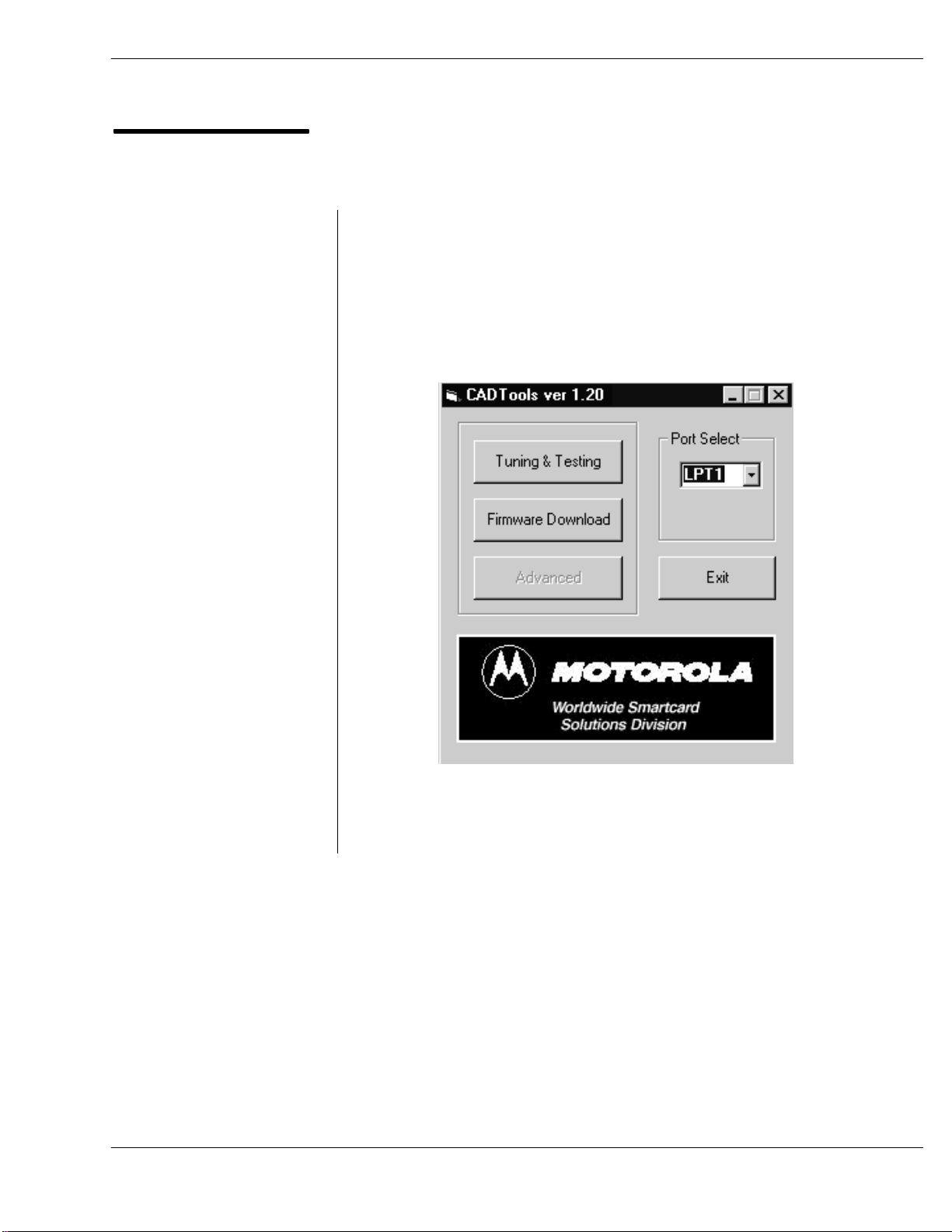

5. The CADTools main screen will appear. It is from this screen that

you can access the Tuning & Testing tool (used to run selftest

diagnostics and perform field tuning) and the Firmware

Download utility (used to download CAD operating software from

the PC into FLASH memory in the CAD Control Board).

68P81131E43-O

October 15, 2000

End of this Procedure

2-7

Page 31

Card Acceptance Device (CAD+) Technical User's Guide

THIS PAGE INTENTIONALLY LEFT BLANK

2-8

68P81131E43-O

October 15, 2000

Page 32

Running the SelfTest

Utility

Chapter 2Installation

1. With the CAD connected to the PC and the CADTools program

running (refer to Launching the CADTools Software on page 2-5),

click on the Tuning & Testing button.

1

2. The following CADTools Tuning & Testing main screen will

appear.

continued on next page

68P81131E43-O

October 15, 2000

2-9

Page 33

Card Acceptance Device (CAD+) Technical User's Guide

Running the Self Test

Utility

(Continued)

3. Click on the Reset CAD button to cause the CAD set to perform

a reboot process. When complete, the Reset command sent

message will be displayed.

Reset command successful

3

4. Click on the AutoTest button to initiate the selftest routine. The

results will be displayed as shown below. Verify that all test

results are OK.

AutoTests Result:

– Flash Checksum: OK

– FPGA load: OK

– UART loopback test: OK

– SRAM test: OK

4

2-10

End of this Procedure

68P81131E43-O

October 15, 2000

Page 34

Chapter 2Installation

TUNING PROCEDURE

3

Introduction

Each CAD set is tuned at the factory for maximum operating range with minimal power. However, in some

cases it may be necessary to tune the CAD set again when it is installed in the terminal due to

characteristics of the terminal (such as metal or metallic paint near the Antenna Board) which can affect

the operating range or reliability. It may also be required to tune the CAD set again if a terminal (such

as a batterypowered terminal) requires minimal power draw from the CAD and a nominal operating

range.

CAD Tuning Guidelines

If the CAD set requires tuning due to Terminal characteristics such as metal or metallic paint near the

Antenna Board (which can affect operating range or reliability), it is recommended that the CAD be

installed into the Terminal first and then tuned. This may require some special adapters (e.g., to connect

the CAD to the PC).

However, there may be situations where tuning the CAD while installed in the Terminal is not possible

(e.g., access to the tuning capacitor is not possible while installed in the Terminal housing). In these

cases, a special tuning fixture" may have to be constructed to simulate the CAD installed in the Terminal

housing while also providing access to the tuning capacitor. The fixture must be constructed so as to

simulate any metal shielding in the Terminal, as well as the precise distance between a presented smart

card and the Antenna Board. For further assistance in constructing a tuning fixture, consult with the

Motorola System Support Center.

If, instead, the Terminal has little or no effect on the CAD performance and the CAD needs to be adjusted,

this can be done prior to installation in the Terminal. In cases such as this, tuning may be performed on

a test bench with the distance between the Antenna Board and the Terminal card presentation target

simulated. The tuning procedure beginning on page 2-12 describes this method.

NoteTo perform the tuning procedure, you will use the CADTools program. This software application

was used previously to perform the SelfTest utility to verify that the CAD is electrically functional. Refer

to page 2-4 for instructions on installing this software application on your PC.

Required Equipment

The following hardware and software is required in order to perform the

tuning procedure on a CAD set.

Model T6367A Serial CAD Installation Kit includes Serial

Converter Box, Power Supply, ISO Antenna Board, and CADTools

Software (version V1.20 or higher required)

or

Model T6439A Parallel CAD Installation Kit includes Test

Cable, Power Supply, ISO Antenna Board, and CADTools Software

(version V1.20 or higher required)

IBM PC or IBMcompatible desktop or laptop computer (Pentium

II class processor running at 200 MHz or greater, Windows 95, 98,

2000, or NT 4.0 operating system)

Oscilloscope (Tek TDS420A, or equivalent)

68P81131E43-O

October 15, 2000

2-11

Page 35

Card Acceptance Device (CAD+) Technical User's Guide

Tuning the CAD

1. Place the Control Board and the Antenna Board on a grounded

antistatic mat as shown below. Because of the metallic content

of the antistatic mat, the CAD Antenna Board must be raised

approximately 5 cm above the mat by using a nonmetallic

spacer (e.g., a few pads of paper).

2. Refer to the photos on page 2-5 to connect the Parallel CAD+

or Serial CAD+ to DC power and the PC. However, make sure

you perform the following substeps in order:

Connect the test cable (supplied in the Installation Kit) to the

CAD and the PC.

Plug the power supply line cord into an AC outlet.

Connect the DC connector from the power supply to the DC

connector on the test cable. The green LED on the Control

Board should light within approximately 1 second.

ANTENNA

BOARD RAISED 5

CM ABOVE MAT

2-12

continued on next page

68P81131E43-O

October 15, 2000

Page 36

Tuning the CAD

(continued)

Chapter 2Installation

3. Place a nonmetallic spacer (e.g., small pad of paper) on top of

the Antenna Board. Note that the pad must be the same

thickness as the distance from the reader surface (target" spot

on the outside of the particular Terminal housing) to the top of

the Antenna Board (where it will be mounted in the Terminal).

PAD OF

PAPER

(OR SIMILAR)

ANTENNA

BOARD

(SHIELDED SIDE)

continued on next page

68P81131E43-O

October 15, 2000

2-13

Page 37

Card Acceptance Device (CAD+) Technical User's Guide

Tuning the CAD

(continued)

4. Attach the scope probe to the ISO Antenna wires and position

the antenna on the spacer, centered over the Antenna Board.

While monitoring the waveform on the oscilloscope, move the

antenna around until you achieve the maximum Vpp reading

(approximately 5 to 10 Vpp). Secure the ISO Antenna in place

using electrical tape or equivalent.

ISO ANTENNA

ATTACH SCOPE PROBE

CONNECTED TO

OSCILLOSCOPE TO

THESE LEADS

2-14

SECURE ANTENNA

USING TAPE

continued on next page

68P81131E43-O

October 15, 2000

Page 38

Tuning the CAD

(continued)

NoteThe Frequency and RSSI

tuning parameters are not used

(and are not adjustable) for CAD+

models.

Chapter 2Installation

5. Launch the CADTools program (described on page 2-5) and

click on the Tuning & Testing button to access the CADTools

Tuning & Testing main screen. The current settings from the CAD

will be retrieved and displayed, as shown below.

6. Locate the tuning capacitor on the CAD Control Board and

adjust it using a plastic tuning tool to achieve the maximum Vpp

reading on the oscilloscope.

Tuning

Capacitor

continued on next page

68P81131E43-O

October 15, 2000

2-15

Page 39

Card Acceptance Device (CAD+) Technical User's Guide

Tuning the CAD

(continued)

7. Click on the up/down arrows in the Antenna adjustment box to

set the RF power to the approximate desired level, as indicated

by the waveform on the oscilloscope. Set to a value of 30 for

minimal power and operating range (as required by some

portable terminals) or a starting value of 220 for maximum

operating range. To adjust for maximum range, continue to

adjust the Antenna value up or down as necessary to obtain the

maximum Vpp reading (not to exceed 10.9 Vpp).

NoteThe table below shows the various CAD+ models and the

Vpp reading you should be able to obtain.

Write down the Vpp reading (label as V max) for use in later

steps. (Always adjust the Antenna value at least one digit from

its starting value to ensure a proper reading on the

oscilloscope.)

Important!Do not place a SmartCard near the antenna board

while making this adjustment.

Maximize

Vpp Reading

(10.9 Vpp max)

Antenna

Board

Size

100 x 110 mm 7.5 Vpp

104 x 67 mm 10.9 Vpp (Note 1)

65 x 40 mm 8.0 Vpp

50 x 25 mm 2.8 Vpp

Note 1Maximum allowable Vpp for any Antenna Board is

10.9 Vpp. Do not exceed this voltage.

Nominal Obtainable Vpp

(max RF power 1 cm

from Antenna)

8. Click on the up/down arrows in the Modulation adjustment box

(to increment/decrement the value one step at at time) to set the

value at a starting value of 165. Change the value (click up once,

then down once) to ensure a proper reading on the oscilloscope.

This value represents an approximate 11% modulation level.

Write down the Vpp reading for use in the next step.

Important!Do not place a SmartCard near the antenna board

while making this adjustment.

2-16

continued on next page

68P81131E43-O

October 15, 2000

Page 40

Tuning the CAD

(continued)

NoteYou can calculate the

Amplitude Modulation percentage

using the following formula:

Chapter 2Installation

9. In the table below, locate the V max voltage (from Step 7) in the

left column and compare the V min voltage (from Step 8) to the

V min values in the corresponding row. The V min voltage from

Step 8 should be between the V min (9%) and V min (13%)

range. If it is not within the range, click on the up/down arrows in

the Modulation adjustment box until the peakpeak voltage of the

CAD is closer to the V min (11%) value.

%AM = 100 *

(V max - V min)

(V max + V min)

V max V min (9%) V min (11%) V min (13%)

11 9.183 8.820 8.469

10.9 9.100 8.740 8.392

10.8 9.017 8.659 8.315

10.7 8.933 8.579 8.238

10.6 8.850 8.499 8.161

10.5 8.766 8.419 8.084

10.4 8.683 8.339 8.007

10.3 8.599 8.259 7.930

10.2 8.516 8.178 7.853

10.1 8.432 8.098 7.776

10 8.349 8.018 7.699

9.9 8.265 7.938 7.622

9.8 8.182 7.858 7.545

9.7 8.098 7.777 7.468

9.6 8.015 7.697 7.391

9.5 7.931 7.617 7.314

9.4 7.848 7.537 7.237

9.3 7.764 7.457 7.160

9.2 7.681 7.377 7.083

9.1 7.597 7.296 7.006

9 7.514 7.216 6.929

8.9 7.430 7.136 6.852

8.8 7.347 7.056 6.775

8.7 7.263 6.976 6.698

8.6 7.180 6.895 6.621

8.5 7.096 6.815 6.544

8.4 7.013 6.735 6.467

8.3 6.929 6.655 6.390

8.2 6.846 6.575 6.313

8.1 6.762 6.495 6.236

8 6.679 6.414 6.159

7.9 6.595 6.334 6.082

7.8 6.512 6.254 6.005

7.7 6.428 6.174 5.928

7.6 6.345 6.094 5.851

7.5 6.261 6.014 5.774

7.4 6.178 5.933 5.697

7.3 6.094 5.853 5.620

7.2 6.011 5.773 5.543

7.1 5.928 5.693 5.466

7 5.844 5.613 5.389

6.9 5.761 5.532 5.312

6.8 5.677 5.452 5.235

6.7 5.594 5.372 5.158

6.6 5.510 5.292 5.081

6.5 5.427 5.212 5.004

6.4 5.343 5.132 4.927

Table Continues on Next Page

68P81131E43-O

October 15, 2000

2-17

Page 41

Card Acceptance Device (CAD+) Technical User's Guide

Tuning the CAD

(continued)

V max V min (9%) V min (11%) V min (13%)

6.3 5.260 5.051 4.850

6.2 5.176 4.971 4.773

6.1 5.093 4.891 4.696

6 5.009 4.811 4.619

5.9 4.926 4.731 4.542

5.8 4.842 4.650 4.465

5.7 4.759 4.570 4.388

5.6 4.675 4.490 4.312

5.5 4.592 4.410 4.235

5.4 4.508 4.330 4.158

5.3 4.425 4.250 4.081

5.2 4.341 4.169 4.004

5.1 4.258 4.089 3.927

5 4.174 4.009 3.850

10. To adjust for operating range, remove the ISO antenna and place

a nonmetallic spacer with the depth of the desired operating

range on the Antenna Board (or Terminal target area if CAD is

installed in the Terminal) and place an initialized compatible

SmartCard on top of the spacer. For example, if the desired

operating range is 5 cm, then place an additional 5 cm spacer

on the Antenna Board (or Terminal target area) and place the

SmartCard on top of it.

NoteThe operating range of a card and CAD depends upon

three primary factors: card type, Antenna Board size, and the RF

power level from the CAD. When adjusting RF power for

operating range, use the following table to determine the typical

maximum range with a given Motorola SmartCard and Antenna

Board. (Note that the ranges shown below are measured from the

surface of the Antenna Board.)

Antenna

Card Operating Range ( 1 cm)

Board

Size MV Series MM Series

100 x 110 mm 7 cm 10 cm

104 x 67 mm 6 cm 9 cm

65 x 40 mm 3 cm 6 cm

50 x 25 mm 2 cm 4 cm

2-18

continued on next page

68P81131E43-O

October 15, 2000

Page 42

Tuning the CAD

(continued)

Chapter 2Installation

11. Click on the RF Loopback Test button and verify the status

shows % of the CAD requests read. If the percentage is 100%,

then proceed to Step 12. Otherwise, increase the RF power by

clicking a few times on the up arrow in the Antenna box. Recheck

the percentage of success by clicking the RF Loopback Test

button again. Repeat this procedure until the status shows 100%

or a maximum is obtained. Proceed to Step 13.

RF Loopback Test

completed successfully

RF Loopback Test:

OK

100% of the CAD requests read

11

12. If the initial success rate is 100%, then continue to adjust the RF

power level down (by clicking on the down arrow in the Antenna

box) a bit and click on the RF Loopback Test button until the

percentage is just less than 100%. Then adjust up a bit until it

shows 100% again. This minimizes the CAD current draw for the

operating range desired.

13. Click on the Save as Defaults button to store the adjustment

settings in FLASH memory on the CAD Control Board.

68P81131E43-O

October 15, 2000

End of this Procedure

2-19

Page 43

Card Acceptance Device (CAD+) Technical User's Guide

INSTALLING CAD INTO TERMINAL

4

The information in this section describes the typical mounting methods for installing a CAD set into a

Terminal.

NoteRefer to Appendix B for pinout details of the CAD connectors, and Appendix C for physical

dimensions and clearances.

Mounting Methods

Introduction

The CAD may be mounted in one of two ways:

Stacked

Separated

Each of these mounting methods is described below.

Stacked" Mounting Method

The Control Board and the Antenna Board have been designed so that

they may be stacked as shown on the facing page. The mounting holes

line up with each other, and may be used with screws and spacers to

secure the CAD to the terminal chassis.

Note that the two boards may be stacked so that the metal shields on the

Control Board are either touching or not touching the metallic surface of

the Antenna Board.

Separated" Mounting Method

The 100 mm cable allows the Control Board and the Antenna Board to

be separated to accommodate various mounting scenarios, as shown

on the facing page.

Other Things You Should Know

The nonmetallic side of the Antenna Board must face towards the

card reading surface of the terminal.

The Antenna Board should be mounted as close as possible to the

Reader target area.

The Antenna Board should be located at least 15 mm (in all

directions) from any metallic materials.

Route the multiconductor interconnect cable away from any

metallic materials. Also, dress and secure cable to prevent

movement.

2-20

68P81131E43-O

October 15, 2000

Page 44

Mounting Methods

Stacked" Mounting Method

CONTROL BOARD

(CONNECTOR SIDE UP)

Chapter 2Installation

ANTENNA BOARD

(METALLIC SIDE UP)

Separated" Mounting Method

68P81131E43-O

October 15, 2000

CONTROL BOARD

ANTENNA BOARD

(NONMETALLIC SIDE FACES TOWARD

CARD READING SURFACE)

2-21

Page 45

Card Acceptance Device (CAD+) Technical User's Guide

5

Once the CAD has been tuned and installed into the terminal, a final checkout procedure must be

performed to ensure that the CAD can communicate with a compatible SmartCard. Once this final

checkout has been performed, the terminal may be placed into service.

FINAL CHECKOUT PROCEDURE

Required Equipment

The following hardware and software is required to perform the final

checkout procedure:

Compatible SmartCard (e.g., Model MV4000D)

Powered terminal with CAD installed

Performing the Final

Checkout Procedure

Place an active SmartCard (one that has been initialized and

personalized for use with the particular terminal application) within

reading distance and verify that the desired results are achieved. For

example, for a transit application, the terminal should generate a receipt

ticket (or some other verification, such as a `'beep" or light, that the

transaction was successful).

2-22

68P81131E43-O

October 15, 2000

Page 46

Chapter 3 Troubleshooting

chapter contents

Fault Isolation Procedures

Returning Faulty CADs to Motorola

2

4

Card Acceptance Device (CAD+)

Technical User's Guide

68P81131E43-O

October 15, 2000

Page 47

Card Acceptance Device (CAD+) Technical User's Guide

FAULT ISOLATION PROCEDURES

1

There are four basic techniques for isolating the CAD as the source of a faulty terminal:

Verify dc power from the terminal (+12 V dc)

Observe LED Indicator on the Control Board

Perform the Self Test diagnostics checkout procedure

Perform the Tuning Procedure

Verify DC Power

With the terminal turned on, the CAD should be receiving

+12 V dc on the following pins:

Parallel CAD+ Pins 1 and 2 of the 16pin parallel

connector located on the Control Board (use pin 3 or

4 as ground)

Verify LED Indicator

Serial CAD+ Pin 3 of the 10pin serial connector

located on the Control Board (use pin 2 as ground)

Verify that the voltage is present using a digital voltmeter. If the

dc voltage is not present:

Make sure the cable from the terminal is securely attached

to the 16pin (parallel) or 10pin (serial) connector on the

Control Board.

Troubleshoot the terminal to determine source of faulty

+12 V dc.

A green LED is provided on the Control Board to provide a visual

indication that the Control board has received dc power and has

successfully performed its startup routine. If this LED is not lit

after applying power:

3-2

Verify +12 V dc power from the terminal (see above)

Reload the CAD operating software into FLASH memory

(refer to Appendix A in this manual)

68P81131E43-O

October 15, 2000

Page 48

Perform the Self Test

Checkout Procedure

Perform the CAD Tuning

Procedure

Chapter 3Troubleshooting

Run the Self Test Utility as described in Chapter 2.

Perform the CAD tuning procedure as described in Chapter 2.

68P81131E43-O

October 15, 2000

3-3

Page 49

Card Acceptance Device (CAD+) Technical User's Guide

RETURNING FAULTY CADS TO MOTOROLA

2

If you have performed the troubleshooting procedures on page 32 and have determined that the CAD

is faulty, the entire CAD (Control Board, Antenna Board, and interconnect cable) must be returned to

Motorola. The faulty CAD will be either repaired or replaced by Motorola service personnel. Contact

the Motorola System Support Center at the contact numbers in the Foreword in this manual for

shipping instructions.

3-4

68P81131E43-O

October 15, 2000

Page 50

Chapter 4 Functional Theory of Operation

chapter contents

Functional Theory of Operation

2

Card Acceptance Device (CAD+)

Technical User's Guide

68P81131E43-O

October 15, 2000

Page 51

Card Acceptance Device (CAD+) Technical User's Guide

1

The following theory of operation describes the operation of the CAD circuitry at a functional level. The information

is presented to give the service technician a basic understanding of the functions performed by the CAD in order

to facilitate fault isolation. Refer to Figure 1 for a block diagram of the CAD.

FUNCTIONAL THEORY OF OPERATION

Microprocessor Circuitry

Overview

The CAD uses a Motorola ColdFire MCF5204 microprocessor (P)

which serves as the main controller for the CAD. The microprocessor,

running at a clock speed of 18.432 MHz (generated by an external

clock circuit) controls the operation of the CAD as determined by the

CAD software contained in the FLASH memory.

Address and Data Buses

The P is equipped with a 32bit address bus used to access the

memory (FLASH and SRAM) and provide control (via memory map

ping) for other circuitry in the CAD. A 16bit data bus is used to transfer

data to/from the P, memory, and the AFE.

Reset Circuit

A Low +5V Detect circuit monitors the level of the +5V supply voltage

and generates a reset signal if it falls below a threshold level. The reset

signal is sent to the P, the I/O Register, the AFE, and FLASH memory.

A hardware reset can also be initiated from both the Serial and Parallel

connectors by applying a low active pulse (1 sec minimum) on the

EXTERNAL_RST# line of either connector.

NonVolatile Memory Circuitry

4-2

FLASH Memory

The CAD software resides in a 256k x 16 FLASH memory IC. The

FLASH memory is accessed by the P via the 32bit Address Bus and

the 16bit Data Bus.

SRAM Memory

To supplement the P's internal 512 bytes of internal SRAM, a 32k x 8

SRAM IC is provided.

68P81131E43-O

October 15, 2000

Page 52

AFE Circuitry

Supply Voltages Circuitry

Chapter 4Functional Theory of Operation

The Analog Front End (AFE) circuitry operates under control of the P

to provide a number of functions, as follows:

Controls the power output to the antenna

Modulates TX data and sends to card (via Antenna Board)

Receives (via Antenna Board) RX data from card and provides

demodulation

The CAD Control Board contains onboard regulators and filtering cir

cuitry to generate the various voltages required by the CAD circuitry.

+12 V from the terminal (via connector P8) is used as the source to

generate +5V and +5V_A supply voltages. Also, the variable PA_PWR

supply voltage is generated and fed to the Power Amplifier (p/o AFE)

to control the RF output power of the CAD.

Antenna Board

Serial Interface Circuitry

The Antenna Board consists of a printed circuit board (with traces that

form the antenna), a ferrite plate (which magnetically shields the anten

na from the Control Board), and a metal back plate (which electrically

shields the antenna from the Control Board). The Antenna Board is

connected to the Control Board by a 6wire cable.

The CAD+ Control Board supports a variety of serial protocols

(RS485, RS232, and CMOS). In order to accomplish this, the Serial

Interface Logic Circuitry routes the desired transmit and receive data

to/from the 10pin Serial Connector as determined by the settings on

an 8position DIP switch located on the board.

68P81131E43-O

October 15, 2000

4-3

Page 53

Card Acceptance Device (CAD+) Technical User's Guide

MICROPROCESSOR CIRCUITRY

+5V

+5V

18.432 MHz

OSCILLATOR

CIRCUITRY

+5V

LOW +5V

DETECT

CLK

MICROPROCESSOR

RESET

EXTERNAL_RST#

RESET

ADDRESS

DATA

TO OTHER

DEVICES

ADDRESS BUS

RS232_TXD

RS232_RXD RS232_RXD

+5V

CS05

AFE_CONTROL

A0-A20

D0-D15

CAD_STRB#

CAD_STRB#

CAD_STRB#

FROM

AFE

RESET

ADDRESS BUS

DATA BUS

I/O

REGISTER

D8-D13

RS232_TXD

AFE_CONTROLS

EXTERNAL_

RST#

SERIAL

CONNECTOR

P/O P4

1

CABLE FROM

D

TO

AFE

A

B

MATES WITH

TERMINAL

NON-VOLATILE MEMORY

+5V

FLASH

A1-A20

RESET

256K X 16

D0-D15

SRAM MEMORY

+5V

SRAM

32K X 8

A0-A14

D8-D15

Figure 1. Card Access Device (CAD) Functional Block Diagram (1 of 3)

4-4

CONNECTOR

CAD W/R#

CAD_ACK#

CAD_STRB#

EXTERNAL_RST#

D0-D7

PARALLEL

P/O P8

14

16

13

15

5

12

MATES WITH

CABLE FROM

TERMINAL

68P81131E43-O

October 15, 2000

Page 54

AFE CIRCUITRY

Chapter 4Functional Theory of Operation

FROM

A

B

+5V_A

AFE_CONTROLS

P

PA_PWR

+5V

CAD READY

INDICATOR

ANTENNA

TO

P

AFE_CONTROL

A0-A3

D8-D15

RESET

ANALOG

FRONT END

(AFE)

ANTENNA_COIL

RECEIVE SIGNAL

6WIRE

CABLE

P6

5

6

3

4

2

1

BOARD

MATES WITH

CABLE FROM

TERMINAL

MATES WITH

CABLE FROM

TERMINAL

PARALLEL

CONNECTOR

P/O P8

+12V

1

2

3

4

SERIAL

CONNECTOR

P/O P4

+12V

3

2

9

SUPPLY VOLTAGES CIRCUITRY

+5V

REGULATOR

Figure 1.Card Access Device (CAD) Functional Block Diagram (2 of 3)

ADJUSTABLE

REGULATOR

FILTER

CIRCUITRY

FILTER

CIRCUITRY

+5V

+5V_A

PA_PWR

68P81131E43-O

October 15, 2000

4-5

Page 55

Card Acceptance Device (CAD+) Technical User's Guide

SERIAL INTERFACE CIRCUITRY

D

RS232_TXD

RS232_RXD

SERIAL INTERFACE

LOGIC CIRCUITRY

(See Note Below)

A

B

C

A

B

C

RS485

RS232

TXA

TXB

RXA

RXB

TXB

RXB

SERIAL

CONNECTOR

P/O P4

7

6

CABLE FROM

5

4

SERIAL

CONNECTOR

P/O P4

8

10

MATES WITH

TERMINAL

MATES WITH

CABLE FROM

TERMINAL

NOTESelection of RS232, RS485, or CMOS Serial Interface is accomplished

by DIP Switch Settings, as follows:

SW1 SW2 SW3 Type of Serial Interface Selected

OFF OFF x RS485 (Selection A Above)

OFF ON ON RS232 (Selection B Above)

OFF ON OFF CMOS (Selection C Above)

Figure 1.Card Access Device (CAD) Functional Block Diagram (3 of 3)

4-6

CMOS

TXB

RXB

SERIAL

CONNECTOR

P/O P4

8

10

68P81131E43-O

October 15, 2000

MATES WITH

CABLE FROM

TERMINAL

Page 56

Chapter 5 CAD Protocols and Commands

chapter contents

TerminaltoCAD Command Protocol

Answer to Reset (ATR)

CAD Management Commands

Command Sequences

2

6

9

28

Card Acceptance Device (CAD+)

Technical User's Guide

68P81131E43-O

October 15, 2000

Page 57

Card Acceptance Device (CAD+) Technical User's Guide

TERMINALTOCAD COMMAND PROTOCOL

1

This section defines the structure of commands initiated by the terminal for transmission control and for

specific control in asynchronous halfduplex transmission protocols. Block protocol type ISO 78163 T=1

is used.

The command structure (shown below) consists of the following blocks:

prologue field

information field

epilogue field

The prologue and epilogue fields are mandatory, and must be sent in every case. The information field

is optional. The number of bytes of the information field is indicated by length (LEN) byte (part of the

prologue field).

Command Structure

Prologue Field Information Field Epilogue Field

NAD PCB LEN Inf EDC

1 Byte 1 Byte 1 Byte 0 to 254 Bytes 2 Bytes

Prologue Field

NAD

The NAD byte in the Prologue field contains the block's target

(DAD) and source (SAD) node addresses, as shown below.

NAD Byte Structure

b8 b7 b6 b5 b4 b3 b2 b1 Meaning

x xx x ---- DAD (Destination Node Address)

----xxxx SAD (Source Node Address)

5-2

68P81131E43-O

October 15, 2000

Page 58

Prologue Field

(continued)

Chapter 5CAD Protocols and Commands

PCB

The PCB byte in the Prologue field serves to control and

supervise the transmission protocol. The PCB byte encodes first

and foremost the block type, as well as supplementary data

needed in this context. The PCB byte information for an Iblock,

an Rblock, and an Sblock are shown below.

PCB Byte Information for an IBlock

b8 b7 b6 b5 b4 b3 b2 b1 Meaning

0 ------- b8=0, Signals Iblock

0 N(S) - 00000 b7=N(S), Send sequence number

0-x00000 b6= Chaining (more data)

PCB Byte Information for an RBlock

b8 b7 b6 b5 b4 b3 b2 b1 Meaning

1 00----- b8=1, Signals Rblock

1 0 0 N(R) ---- b5=N(R), Sequence Number

1 0 0 N(R) 0000 b4b1=0, No errors

1 0 0 N(R) 0001 b4b1=1, EDC or parity error

1 0 0 N(R) 0010 b4b1=2, Other errors

1 0 0 N(R) 0011 b4b1=3, Timeout error

PCB Byte Information for an SBlock

b8 b7 b6 b5 b4 b3 b2 b1 Meaning

1 1------ b8=1 & b7=1, Signals Sblock

1 1000000 RESYNCH req = C0

1 1100000 RESYNCH ans = E0

1 1000010 Abort request = C2

1 1100010 Abort response = E2

1 1000011 WTX request = C3

1 1100011 WTX response = E3

11xxxxxx RFU values used for the CAD manage

ment

68P81131E43-O

October 15, 2000

5-3

Page 59

Card Acceptance Device (CAD+) Technical User's Guide

Information Field (INF)

The presence of INF is optional. When present, INF conveys

either application data in Iblocks for cards, miscellaneous data

for the CAD or nonapplication control and status information in

Sblocks.

In an Sblock, this field is used for the management of the CAD.

The CAD does not support the exhaustive list of SBlocks defined

in ISO 7816-3 T=1. However, the CAD supports Motorola

proprietary definition of SBlocks as commands for

management.

Rblocks do not contain an INF field.

Epilogue Field

This field contains the error detection code (EDC) of the

transmitted block. The protocol definition permits this to be either

an LRC or a CRC. The LRC is calculated as the exclusive OR

(XOR) of all the bytes starting with the NAD through the last byte

of the information field, and is typically referred to simply as the

checksum. For CRC see ISO 3309. The CAD uses the CRC.

5-4

68P81131E43-O

October 15, 2000

Page 60

Chapter 5CAD Protocols and Commands

THIS PAGE INTENTIONALLY LEFT BLANK

68P81131E43-O

October 15, 2000

5-5

Page 61

Card Acceptance Device (CAD+) Technical User's Guide

ANSWER TO RESET (ATR)

2

After cycling the power supply or software reboot, the CAD sends out an ATR. For serial transmission,

the ATR is sent at 9.6 Kbps and then the CAD switches to its programmed baud rate (from 9.6 Kbps to

230.4 Kbps). For parallel transmission, the rate is synchronous. The ATR is a data string, up to 33

bytes long, which contains various data relevant to the transmission protocol and to the card. The

ATR's data string and data elements are defined and described in detail in ISO/IEC 7816-3.

ATR Format

The basic ATR format consists of:

TS one byte, the initial character; specifies the con

ventions to code data bytes in all subsequent charac

ters. There are two possible values of TS (ten consec

utive bits from start to end and corresponding hexade

cimal value). The CAD uses direct convention:

(Z)AZZAZZZAAZ(Z) where logic level ONE is Z (LSB

is first). It equals to "3B" when decoded by direct con

vention.

T0 one byte, the format character; serves to indi

cate the subsequent "interface character" a bit field is

used, from b5 to b8. It further contains the number of

subsequent "historical characters," from b1 to b4.

T0 Byte Information

b8 b7 b6 b5 b4 b3 b2 b1 Meaning

---1 ---- TA1 is transmitted

--1 ----- TB1 is transmitted

- 1------ TC1 is transmitted

1 ------- TD1 is transmitted

----xxxx Number of historical characters

5-6

68P81131E43-O

October 15, 2000

Page 62

ATR Format (continued)

Chapter 5CAD Protocols and Commands

The four least significant bits of any interface byte TDi indicates

a protocol type T, specifying rules to be used to process

transmission protocols. When TD

used. TA

TB1 TC1 and TB2 are the global interface bytes. These

1

is not transmitted, T=0 is

1

global interface bytes shall be interpreted in order to process any

transmission protocol correctly.

The interface characters specify all transmission parameters of

the current protocol. They are constructed from the bytes TAi,

, TCi, and TDi (i =1, 2, 3...). TAi, TBi and TCi indicate the

TB

i

protocol parameters. Their interpretation depends on the

protocol type indicated by T in TD

. TDi indicates the protocol

i-1

type T, as defined in [1] Section 6.1.4.3, and the presence of

subsequent interface characters. The ATR transmission of these

bytes is optional and may be omitted if appropriate.

TDi Byte Information

b8 b7 b6 b5 b4 b3 b2 b1 Meaning

---1 ---- TA

--1 ----- TB

- 1------ TC

1 ------- TD

----xxxx Protocol type for subsequent transmis

When TDi is not transmitted, the default value of TA

TC

is null, indicating that no further interface characters TA

i+1

TB

i+1

TC

i+1

TD

will be transmitted. TA1 to TC3 convey

i+1

is transmitted

i+1

is transmitted

i+1

is transmitted

i+1

is transmitted

i+1

sion

i+1

TB

i+1

i+1

information that shall be used during exchanges between the

terminal and the CAD subsequent to the Answer to Reset. They

indicate the values of the transmission control parameters F, D,

I, P, and N, and the IFSC, block waiting time integer (BWI), and

character waiting time integer (CWI) applicable to T=1 as defined

in ISO/IEC 7816-3. The information contained in TA

to TC1 and

1

TC2 shall apply to all subsequent exchanges.

68P81131E43-O

October 15, 2000

The historical characters, T1 T2 -TK, maximum 15 characters.

It designates general information, for example, the CAD firmware

version.

The value of check character TCK shall be such that the

exclusive-ORing of all bytes from byte T0 to the last byte before

the TCK.

5-7

Page 63

Card Acceptance Device (CAD+) Technical User's Guide

ATR Format (continued)

The structure of the ATR is the initial character TS followed by a

variable number of subsequent characters in the following order:

the format character T0, optionally the interface characters TAi,

TBi, TCi, TDi and optionally the historical characters T1 T2 - TK

and, conditionally, the check character TCK.

Charac

ter

TS 3B Indicates direct convention

T0 F3 F = (1111)

TA

1

TB

1

TC

1

TD

1

TA

2

TD

2

TA

3

TB

3

TC

3

T1

T2

T3

TCK XX LRC used for Check character

ATR Data Information

Value Meaning

, TA1, TB1, TC1, and TD1 present;

bin

3 indicates the number of historical bytes present

71 Most significant half byte (b8 to b5): Default Baud

Rate (0...7)

Least significant half byte (b4 to b1): Di = 1

00 Vpp is not required

FF Indicates amount of extra guard time required

(FF = no guard time)

91 9 = (1001)

, TB2 and TC2 absent; TA2 and TD

bin

present;

1 indicates that T=1 is to be used

81 specific mode" ; [6]

8 = (1000)

, b8 = 1 mode change not allowed

bin

1 indicates that T=1 is to be used

71 7 = (0111)

, TA3, TB3, TC3 present; TD3 absent

bin

1 indicates that T=1 is to be used

FF IFSI = FF, which indicates initial value (255 bytes) for

information field size for the CAD

01 b8-b5 = 0 BWI minimum

b4-b1 = 0 CWI minimum

00 01 = CRC in use

XX

XX

11

Version Number of CAD Firmware (MSB)

Version Number of CAD Firmware (LSB)

NAD used by the CAD

2

5-8

68P81131E43-O

October 15, 2000

Page 64

CAD MANAGEMENT COMMANDS

3

Commands in proprietary SBlocks supported by the CAD are:

RF POWER CONTROL: control of the RF field parameters (page 5-10)

SLEEP: put the CAD in low power mode (page 5-12)

DOWNLOADING: put the CAD in downloading mode (page 5-14)

ERROR REPORT: the CAD indicates an Hardware error (page 5-16)

POLL: put the CAD in card registration mode (page 5-18)

ANSWER TO POLL: the CAD sends the parameters of a card detected (page 5-20)

DETECT CARD: put the CAD in card detection mode (page 5-22)

CARD PRESENCE: the CAD sends to the terminal the result of the DETECT CARD com

mand. (page 5-24)

REBOOT: forces the CAD to reset (page 5-25)

BREAK CHARACTER: forces the CAD to reset (page 5-26)

Chapter 5CAD Protocols and Commands

Commands issued from the Terminal to the CAD are called Requests."

Commands issued from the CAD to the Terminal are called Responses."

68P81131E43-O

October 15, 2000

5-9

Page 65

Card Acceptance Device (CAD+) Technical User's Guide

RF POWER

CONTROL

RF POWER CONTROL request

Description

This command allows the terminal to control the RF field power. The four options

of the PCON byte can turn on the 13.56MHz carrier, turn off the carrier, increase

the power of the RF field and to decrease the power of the RF field.

Direction

Terminal to CAD

Size

6 Bytes

Format

See below

RF POWER CONTROL Request Format

NAD PCB LEN PCON CRC1 CRC2

0x11 0xC5 1 (see below) (see below) (see below)

PCON Values Meaning CRC1 Values CRC2 Values

0x00 Power On 0x3B 0x09

0x01 Power Off 0xB2 0x18

0x02 Decrease Power 0x29 0x2A

0x03 Increase Power 0xA0 0x3B

Other Values Forbidden

5-10

68P81131E43-O

October 15, 2000

Page 66

RF POWER

CONTROL

(continued)

Chapter 5CAD Protocols and Commands

RF POWER CONTROL response

Description

The response frame is an acknowledgement of the previous command,

indicating that the command was properly received and has been executed.

Direction

CAD to Terminal

Size

5 Bytes

Format

See below

RF POWER CONTROL Response Format

NAD PCB LEN CRC1 CRC2

0x11 0xE5 0 0xA4 0x8E

68P81131E43-O

October 15, 2000

5-11

Page 67

Card Acceptance Device (CAD+) Technical User's Guide

SLEEP

SLEEP request

Description

This command switches the CAD board to a lowpower mode. It sequentially

turns off the RF power, stops watchdog timer, unmask only the UART (serial

CAD) or STROBE (parallel CAD) interrupt and switches to the STOP mode of the

ColdFire. While no interrupt from the UART (or STROBE) is received (any frame

from the terminal), the CAD stays in this mode. Any UART (or STROBE) interrupt

wakes the CAD processor core, turns on the RF power and switches to the state

of frame reception.

Direction

Terminal to CAD

Size

5 Bytes

Format

See below

SLEEP Request Format

NAD PCB LEN CRC1 CRC2

0x11 0xC8 0 0xEF 0x1D

SLEEP response

Description

The response frame is an acknowledgment of the previous command that

indicates that the command was properly received and is ready to be executed.

This response is sent before the CAD switches to SLEEP state.

Direction

CAD to Terminal

Size

5 Bytes

5-12

Format

See below

SLEEP Response Format

NAD PCB LEN CRC1 CRC2

0x11 0xE8 0 0xDC 0x3E

68P81131E43-O

October 15, 2000

Page 68

Chapter 5CAD Protocols and Commands

THIS PAGE INTENTIONALLY LEFT BLANK

68P81131E43-O

October 15, 2000

5-13

Page 69

Card Acceptance Device (CAD+) Technical User's Guide

DOWNLOADING

DOWNLOADING request

Description

This command makes the CAD switch to downloading mode. It is only accepted

as the first command after the CAD reboots. The code of the Parameters 1 & 2,

processor and FPGA can be downloaded by selecting the TARGET byte 0x00.

This command must be sent both at the beginning and at the end of the

downloading sequence. At the end of the downloading sequence, this

command confirms that the downloading sequence is correctly complete and

provokes the reset of the CAD processor. The TARGET field of this last block

must be identical to the TARGET field of the previous DOWNLOADING

command.

Direction

Terminal to CAD

Size

6 Bytes

Format

See below

DOWNLOADING Request Format

NAD PCB LEN TARGET CRC1 CRC2

0x11 0xC6 1 (see below) (see below) (see below)

TARGET

Values

0x00 Parameters 12, MCU, and

0x01 All FLASH Code

Note: This is the recommended

Other Values RFU RFU RFU

Meaning CRC1 Values CRC2 Values

0x5F 0xE6

FPGA Code

0xD6 0xF7

(including Boot Block)

download mode

5-14

68P81131E43-O

October 15, 2000

Page 70

DOWNLOADING

(continued)

Chapter 5CAD Protocols and Commands

DOWNLOADING response

Description

The response frame is an acknowledgment of the previous command that

indicates that the command was properly received and is ready to be executed.

Direction

CAD to Terminal

Size

5 Bytes

Format

See below

DOWNLOADING Response Format

NAD PCB LEN CRC1 CRC2

0x11 0xE6 0 0xCC 0xA4

68P81131E43-O

October 15, 2000

5-15

Page 71

Card Acceptance Device (CAD+) Technical User's Guide

ERROR REPORT

ERROR REPORT request

Description

The Terminal sends this command to the CAD to determine if the CAD software

has detected any error during the test sequence at boot up. It is recommended

that the Terminal always issue this command immediately after the CAD boots

and has sent an ATR to ensure the CAD is working properly before further