Datasheet MC33461SQ-43CTR, MC33461SQ-45CTR, MC33461SQ-27CTR, MC33461SQ-28CTR, MC33461SQ-30CTR Datasheet (MOTOROLA)

...

MC33460, MC33461

Under Voltage Detector

Series

The MC33460 and MC33461 series are ultra–low power CMOS

under–voltage detectors with very tight threshold accuracy

specifically designed for accurate monitoring of power supplies. The

devices are optimized for use in battery powered systems where low

quiescent current and small packaging are required. The device

generates an active–low signal whenever the input voltage falls below

the factory set ±2% threshold. Hysteresis is provided to ensure reliable

output switching.

The MC33460/1 series features a highly accurate voltage reference,

a comparator with a precision voltage threshold, and built–in

hysteresis to prevent erratic operation and a choice of output

configurations between Open Drain (MC33460) and complementary

push–pull (MC33461). The products are offered in 9 standard voltage

thresholds ranging from 0.9V to 4.5V. Other threshold voltages from

1.0 to 5.0V are available in 100mV steps. The devices can operate to a

very low input voltage level and are housed in the ultra–miniature

SC–82AB package.

Features

• Available in Open Drain or Push–Pull Output

• Output State Guaranteed to V

• Tight Detector Voltage Accuracy (±2.0%)

• Extended T emperature Operation (–40°C to 85°C)

• Ultra Low Quiescent Current (0.8 µA at V

• Wide Range of Operating Voltage (0.7 V to 10 V)

Applications

• Low Battery Detector

• Power–Fail Indicator

• Microprocessor Reset Generator

• Window Comparator

• Battery Backup Circuit

= 0.8 V

in

= 1.5 V typical)

in

http://onsemi.com

4

1

SC–82AB

SQ SUFFIX

CASE 419C

PIN CONNECTIONS

14

OUT

V

2

in

(Top View)

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 2 of this data sheet.

GND

3

N/C

Nch Open Drain Configuration

V

in

Semiconductor Components Industries, LLC, 1999

November, 1999 – Rev. 2

MC33460

V

ref

Representative Block Diagrams

V

OUT

GND

1 Publication Order Number:

in

MC33461

CMOS Configuration

V

ref

OUT

GND

MC33460/D

MC33460, MC33461

Nch

Oen

Drain

3000 Unit

h

Reel

CMOS

ORDERING INFORMATION

Threshold

Device

MC33460SQ–09ATR 0.9

MC33460SQ–20ATR 2.0 M0

MC33460SQ–27ATR 2.7

MC33460SQ–28ATR 2.8

MC33460SQ–30ATR 3.0

MC33460SQ–32ATR 3.2

MC33460SQ–43ATR 4.3 P3

MC33460SQ–45ATR 4.5 P5

MC33461SQ–09CTR 0.9

MC33461SQ–20CTR 2.0 V0

MC33461SQ–27CTR 2.7 V7

MC33461SQ–28CTR 2.8

MC33461SQ–30CTR 3.0

MC33461SQ–32CTR 3.2 W2

MC33461SQ–43CTR 4.3 X3

MC33461SQ–45CTR 4.5 X5

MAXIMUM RATINGS

Rating Symbol Value Unit

Supply Voltage

Output Voltage (CMOS)

Output Voltage (Nch Open Drain)

Output Current

Power Dissipation

Operating Ambient Temperature

Storage Temperature Range

Lead Temperature (Soldering)

Voltage

Type Marking

p

V

in

V

OUT1

V

OUT2

I

OUT

P

D

T

A

T

stg

T

solder

K9

M7

M8

N0

N2

T9

V8

W0

12

–0.3 to Vin+0.3

–0.3 to 12

70

150

–40 to +85

–40 to +125

260°C, 10 s

Package

(Qty/Reel)

s

on 7 inc

Reel

V

V

V

mA

mW

°C

°C

–

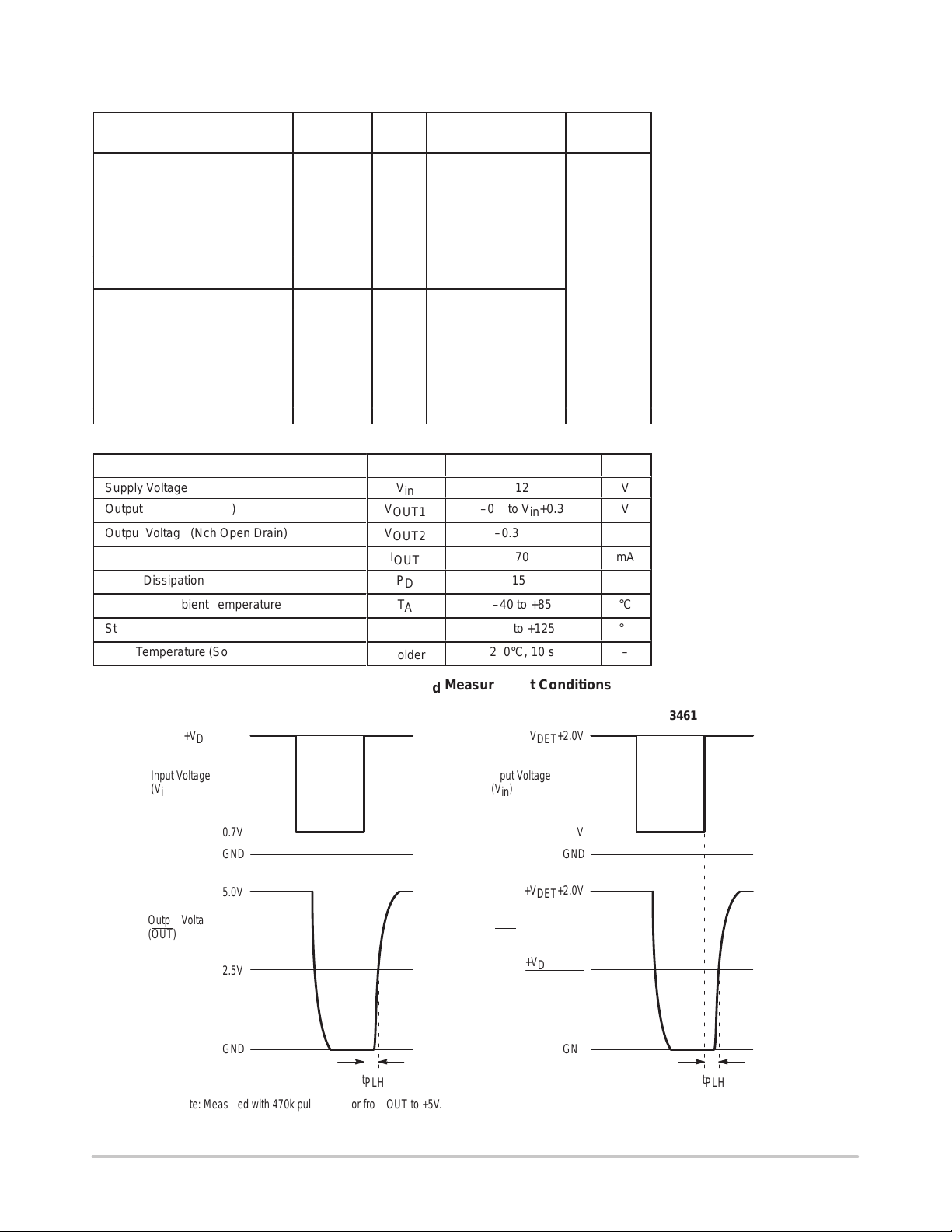

MC33460 MC33461

+V

+2.0V

DET

Input Voltage

(Vin)

0.7V

GND

5.0V

Output Voltage

(OUT

)

2.5V

GND

Note: Measured with 470k pullup resistor from OUT

Figure 1. Tpd Measurement Conditions

+V

+2.0V

DET

Input Voltage

(Vin)

0.7V

GND

+V

+2.0V

DET

Output Voltage

(OUT

)

+V

+2.0V

DET

2

GND

t

PLH

to +5V.

t

PLH

http://onsemi.com

2

MC33460, MC33461

Á

Á

Á

Á

Á

Á

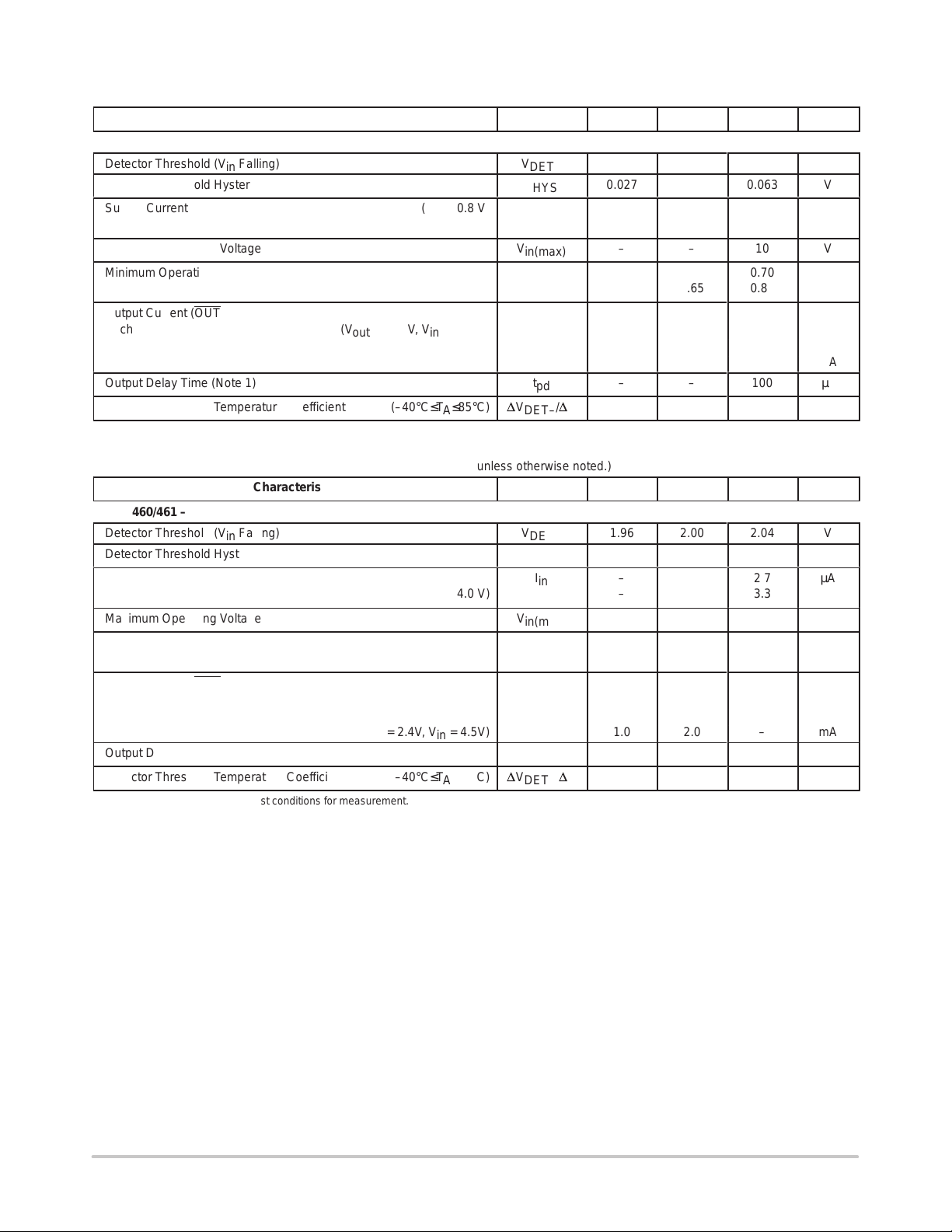

ELECTRICAL CHARACTERISTICS (For all values T

= 25°C, unless otherwise noted.)

A

Characteristic

MC33460/461 – 0.9

Detector Threshold (Vin Falling)

Detector Threshold Hysteresis V

Supply Current (Vin = 0.8 V)

(Vin = 2.9 V)

Maximum Operating Voltage V

Minimum Operating Voltage

(–40°C≤TA≤85°C)

Output Current (OUT)

Nch (V

CMOS Output High (V

= 0.05V, Vin = 0.70V) 0.01 0.05 – mA

out

(V

= 0.50V, Vin = 0.85V) 0.05 0.50 – mA

out

= 2.4V, Vin = 4.5V) 1.0 2.0 – mA

out

Output Delay Time (Note 1)

Detector Threshold Temperature Coefficient (–40°C≤TA≤85°C)

NOTES: 1.Refer to Figure 1 for test conditions for measurement.

ELECTRICAL CHARACTERISTICS (For all values T

= 25°C, unless otherwise noted.)

A

Characteristic

MC33460/461 – 2.0

Detector Threshold (Vin Falling)

Detector Threshold Hysteresis V

Supply Current (Vin = 1.9 V)

ББББББББББББББББ

(Vin = 4.0 V)

Maximum Operating Voltage V

Minimum Operating Voltage

(–40°C≤TA≤85°C)

Output Current (OUT)

Nch (V

CMOS Output High (V

= 0.05V, Vin = 0.70V) 0.01 0.05 – mA

out

(V

= 0.50V, Vin = 1.5V) 1.0 2.0 – mA

out

= 2.4V, Vin = 4.5V) 1.0 2.0 – mA

out

Output Delay Time (Note 1)

Detector Threshold Temperature Coefficient (–40°C≤TA≤85°C)

NOTES: 1.Refer to Figure 1 for test conditions for measurement.

Symbol Min Typ Max Unit

V

D

V

V

DET–

HYS

I

in

in(max)

in(min)

I

OUT

t

pd

DET–

/DT

0.882

0.900

0.918

0.027 0.045 0.063 V

–

–

0.8

1.0

2.4

3.0

– – 10 V

–

–

–

–

0.55

0.65

–

±100

0.70

0.80

100

–

Symbol Min Typ Max Unit

V

DET–

HYS

I

in

ÁÁÁ

in(max)

V

in(min)

I

OUT

t

pd

D

V

/DT

DET–

1.96

2.00

2.04

0.06 0.10 0.14 V

–

ÁÁ

–

0.9

ÁÁ

1.1

2.7

ÁÁ

3.3

– – 10 V

–

–

–

–

0.55

0.65

–

±100

0.70

0.80

100

–

V

µA

V

µs

PPM/°C

V

µA

Á

V

µs

PPM/°C

http://onsemi.com

3

MC33460, MC33461

Á

Á

Á

Á

Á

Á

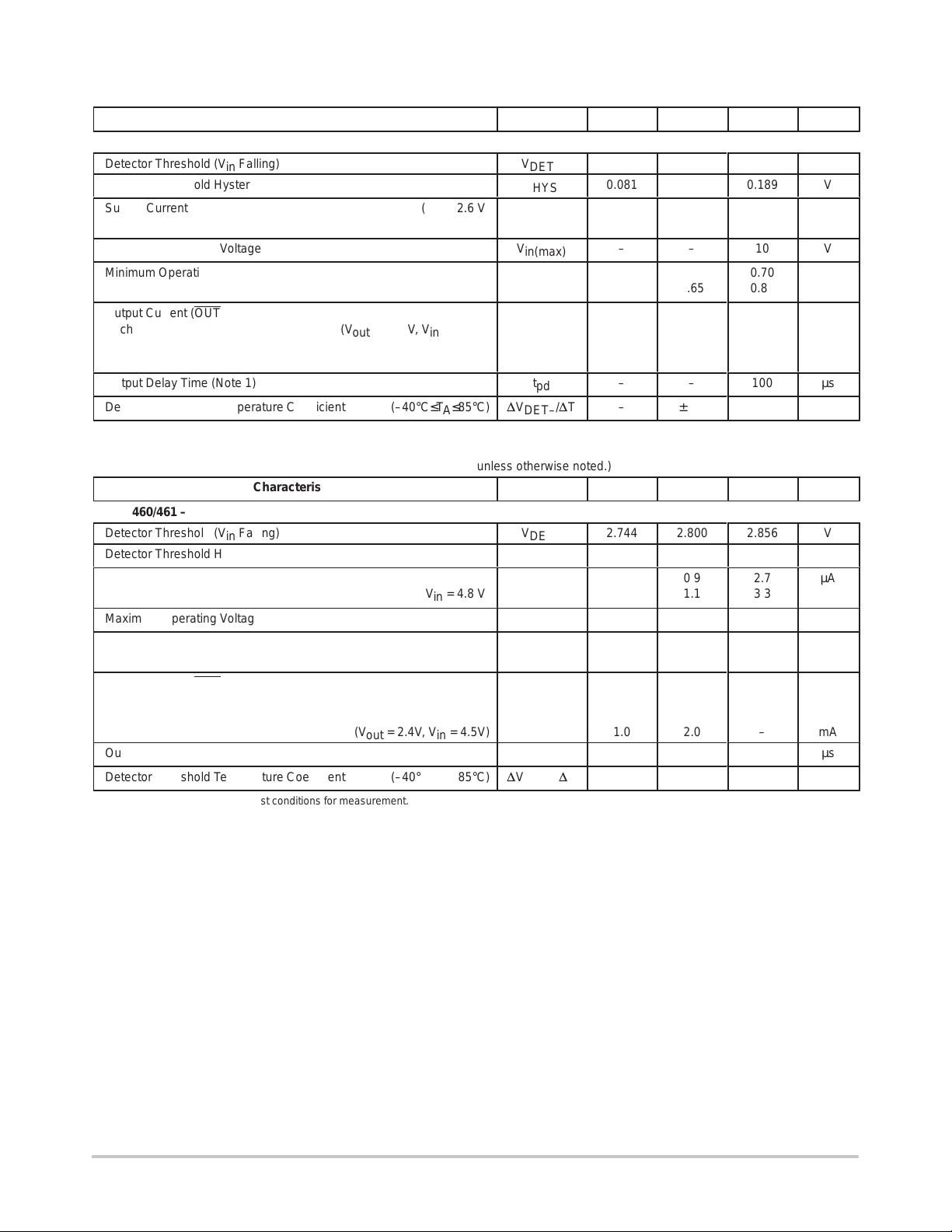

ELECTRICAL CHARACTERISTICS (For all values T

= 25°C, unless otherwise noted.)

A

Characteristic

MC33460/461 – 2.7

Detector Threshold (Vin Falling)

Detector Threshold Hysteresis V

Supply Current (Vin = 2.6 V)

(Vin = 4.7 V)

Maximum Operating Voltage V

Minimum Operating Voltage

(–40°C≤TA≤85°C)

Output Current (OUT)

Nch (V

CMOS Output High (V

= 0.05V, Vin = 0.70V) 0.01 0.05 – mA

out

(V

= 0.50V, Vin = 1.5V) 1.0 2.0 – mA

out

= 2.4V, Vin = 4.5V) 1.0 2.0 – mA

out

Output Delay Time (Note 1)

Detector Threshold Temperature Coefficient (–40°C≤TA≤85°C)

NOTES: 1.Refer to Figure 1 for test conditions for measurement.

ELECTRICAL CHARACTERISTICS (For all values T

= 25°C, unless otherwise noted.)

A

Characteristic

MC33460/461 – 2.8

Detector Threshold (Vin Falling)

Detector Threshold Hysteresis V

Supply Current (Vin = 2.7 V)

ББББББББББББББББ

(Vin = 4.8 V)

Maximum Operating Voltage V

Minimum Operating Voltage

(–40°C≤TA≤85°C)

Output Current (OUT)

Nch (V

CMOS Output High (V

= 0.05V, Vin = 0.70V) 0.01 0.05 – mA

out

(V

= 0.50V, Vin = 1.5V) 1.0 2.0 – mA

out

= 2.4V, Vin = 4.5V) 1.0 2.0 – mA

out

Output Delay Time (Note 1)

Detector Threshold Temperature Coefficient (–40°C≤TA≤85°C)

NOTES: 1.Refer to Figure 1 for test conditions for measurement.

Symbol Min Typ Max Unit

V

D

V

V

DET–

HYS

I

in

in(max)

in(min)

I

OUT

t

pd

DET–

/DT

2.646

2.700

2.754

0.081 0.135 0.189 V

–

–

0.9

1.1

2.7

3.3

– – 10 V

–

–

–

–

0.55

0.65

–

±100

0.70

0.80

100

–

Symbol Min Typ Max Unit

V

DET–

HYS

I

in

ÁÁÁ

in(max)

V

in(min)

I

OUT

t

pd

D

V

/DT

DET–

2.744

2.800

2.856

0.084 0.140 0.196 V

–

ÁÁ

–

0.9

ÁÁ

1.1

2.7

ÁÁ

3.3

– – 10 V

–

–

–

–

0.55

0.65

–

±100

0.70

0.80

100

–

V

µA

V

µs

PPM/°C

V

µA

Á

V

µs

PPM/°C

http://onsemi.com

4

MC33460, MC33461

Á

Á

Á

Á

Á

Á

ELECTRICAL CHARACTERISTICS (For all values T

= 25°C, unless otherwise noted.)

A

Characteristic

MC33460/461 – 3.0

Detector Threshold (Vin Falling)

Detector Threshold Hysteresis V

Supply Current (Vin = 2.87 V)

(Vin = 5.0 V)

Maximum Operating Voltage V

Minimum Operating Voltage

(–40°C≤TA≤85°C)

Output Current (OUT)

Nch (V

CMOS Output High (V

= 0.05V, Vin = 0.70V) 0.01 0.05 – mA

out

(V

= 0.50V, Vin = 1.5V) 1.0 2.0 – mA

out

= 2.4V, Vin = 4.5V) 1.0 2.0 – mA

out

Output Delay Time (Note 1)

Detector Threshold Temperature Coefficient (–40°C≤TA≤85°C)

NOTES: 1.Refer to Figure 1 for test conditions for measurement.

ELECTRICAL CHARACTERISTICS (For all values T

= 25°C, unless otherwise noted.)

A

Characteristic

MC33460/461 – 3.2

Detector Threshold (Vin Falling)

Detector Threshold Hysteresis V

Supply Current (Vin = 3.07 V)

ББББББББББББББББ

(Vin = 5.2 V)

Maximum Operating Voltage V

Minimum Operating Voltage

(–40°C≤TA≤85°C)

Output Current (OUT)

Nch (V

CMOS Output High (V

= 0.05V, Vin = 0.70V) 0.01 0.05 – mA

out

(V

= 0.50V, Vin = 1.5V) 1.0 2.0 – mA

out

= 2.4V, Vin = 4.5V) 1.0 2.0 – mA

out

Output Delay Time (Note 1)

Detector Threshold Temperature Coefficient (–40°C≤TA≤85°C)

NOTES: 1.Refer to Figure 1 for test conditions for measurement.

Symbol Min Typ Max Unit

V

D

V

V

DET–

HYS

I

in

in(max)

in(min)

I

OUT

t

pd

DET–

/DT

2.94

3.00

3.06

0.09 0.15 0.21 V

–

–

1.0

1.2

3.0

3.6

– – 10 V

–

–

–

–

0.55

0.65

–

±100

0.70

0.80

100

–

Symbol Min Typ Max Unit

V

DET–

HYS

I

in

ÁÁÁ

in(max)

V

in(min)

I

OUT

t

pd

D

V

/DT

DET–

3.136

3.200

3.264

0.096 0.160 0.224 V

–

ÁÁ

–

1.0

ÁÁ

1.2

3.0

ÁÁ

3.6

– – 10 V

–

–

–

–

0.55

0.65

–

±100

0.70

0.80

100

–

V

µA

V

µs

PPM/°C

V

µA

Á

V

µs

PPM/°C

http://onsemi.com

5

MC33460, MC33461

Á

Á

Á

Á

Á

Á

ELECTRICAL CHARACTERISTICS (For all values T

= 25°C, unless otherwise noted.)

A

Characteristic

MC33460/461 – 4.3

Detector Threshold (Vin Falling)

Detector Threshold Hysteresis V

Supply Current (Vin = 4.14 V)

(Vin = 6.3 V)

Maximum Operating Voltage V

Minimum Operating Voltage

(–40°C≤TA≤85°C)

Output Current (OUT)

Nch (V

CMOS Output High (V

= 0.05V, Vin = 0.70V) 0.01 0.05 – mA

out

(V

= 0.50V, Vin = 1.5V) 1.0 2.0 – mA

out

= 2.4V, Vin = 4.5V) 1.0 2.0 – mA

out

Output Delay Time (Note 1)

Detector Threshold Temperature Coefficient (–40°C≤TA≤85°C)

NOTES: 1.Refer to Figure 1 for test conditions for measurement.

ELECTRICAL CHARACTERISTICS (For all values T

= 25°C, unless otherwise noted.)

A

Characteristic

MC33460/461 – 4.5

Detector Threshold (Vin Falling)

Detector Threshold Hysteresis V

Supply Current (Vin = 4.34 V)

ББББББББББББББББ

(Vin = 6.5 V)

Maximum Operating Voltage V

Minimum Operating Voltage

(–40°C≤TA≤85°C)

Output Current (OUT)

Nch (V

CMOS Output High (V

= 0.05V, Vin = 0.70V) 0.01 0.05 – mA

out

(V

= 0.50V, Vin = 1.5V) 1.0 2.0 – mA

out

= 6.9V, Vin = 8.0V) 1.5 3.0 – mA

out

Output Delay Time (Note 1)

Detector Threshold Temperature Coefficient (–40°C≤TA≤85°C)

NOTES: 1.Refer to Figure 1 for test conditions for measurement.

Symbol Min Typ Max Unit

V

D

V

V

DET–

HYS

I

in

in(max)

in(min)

I

OUT

t

pd

DET–

/DT

4.214

4.300

4.386

0.129 0.215 0.301 V

–

–

1.1

1.3

3.3

3.9

– – 10 V

–

–

–

–

0.55

0.65

–

±100

0.70

0.80

100

–

Symbol Min Typ Max Unit

V

DET–

HYS

I

in

ÁÁÁ

in(max)

V

in(min)

I

OUT

t

pd

D

V

/DT

DET–

4.410

4.500

4.590

0.135 0.225 0.315 V

–

ÁÁ

–

1.1

ÁÁ

1.3

3.3

ÁÁ

3.3

– – 10 V

–

–

–

–

0.55

0.65

–

±100

0.70

0.80

100

–

V

µA

V

µs

PPM/°C

V

µA

Á

V

µs

PPM/°C

http://onsemi.com

6

MC33460, MC33461

TYPICAL CHARACTERISTICS

MC33461–0.9

2.5

TA = 85°C

µ

2.0

1.5

1.0

, SUPPLY CURRENT ( A)

in

I

0.5

0

0

2.0 4.0 6.0 8.0 10

INPUT VOLTAGE, Vin (V)

25°C

–40°C

MC33461–2.7

, DETECTOR THRESHOLD (V)

V

0.98

0.96

0.94

0.92

0.90

0.88

DET

0.86

0.84

1.0

V

V

HYS

–40 –20 0 20 100

–60

V

TEMPERATURE, TA (°C)

DET+(Vin

DET–(Vin

rising)

falling)

40 60 80

2.0

µ

1.5

1.0

, SUPPLY CURRENT ( A)

in

I

0.5

0

0

2.0 4.0 6.0 8.0 10

INPUT VOLTAGE, Vin (V)

TA = 85°C

25°C

–40°C

, DETECTOR THRESHOLD (V)

V

DET

2.9

2.8

2.7

2.6

2.5

V

V

HYS

–40 –20 0 20 10040 60 80

–60

V

TEMPERATURE, TA (°C)

DET+(Vin

DET–(Vin

rising)

falling)

MC33461–4.5

2.0

µ

1.5

1.0

, SUPPLY CURRENT ( A)

in

I

0.5

0

0

2.0 4.0 6.0 8.0 10

INPUT VOLTAGE, Vin (V)

TA = 85°C

25°C

–40°C

, DETECTOR THRESHOLD (V)

V

DET

4.8

4.7

4.6

4.5

4.4

V

V

HYS

V

–60

–40 –20 0 20 10040 60 80

TEMPERATURE, TA (°C)

DET+(Vin

DET–(Vin

rising)

falling)

Figure 2. Supply Current vs. Input Voltage

Figure 3. Detector Threshold Hysteresis vs. T emperature

http://onsemi.com

7

MC33460, MC33461

MC33461–0.9

m

, OUTPUT CURRENT ( A)

OUT

I

OUT

I , OUTPUT CURRENT (mA)

700

600

500

400

300

200

100

300

TA = 25°C

250

Vin = 0.85 V

TA = 25°C

0

0

0.2 0.4 0.80.6

V

, OUTPUT VOLTAGE (V)

OUT

m

OUT

I , OUTPUT CURRENT ( A)

200

150

100

Vin = 0.8 V

0.7 V0.7 V

50

0

0

0.02 0.04 0.10.06 0.08

V

, OUTPUT VOLTAGE (V)

OUT

MC33461–2.7

20

18

16

14

12

10

8

6

4

2

0

0

TA = 25°C

V

0.5 1.0

, OUTPUT VOLTAGE (V)

OUT

Vin = 2.5 V

2.0 V

1.5 V

m

OUT

I , OUTPUT CURRENT ( A)

300

250

200

150

100

TA = 25°C

Vin = 0.8 V

0.7 V

50

0

0

0.02 0.04 0.06 0.08 0.1

V

, OUTPUT VOLTAGE (V)

OUT

, OUTPUT CURRENT (mA)

OUT

I

MC33461–4.5

40

TA = 25°C

30

3.5 V

20

10

0

0

V

OUT

3.0 V

2.5 V

0.5 1

, OUTPUT VOLTAGE (V)

Vin = 4.5 V

4.0 V

2.0 V

1.5 V

Figure 4. Nch Output Current versus V

m

OUT

I , OUTPUT CURRENT ( A)

300

250

200

150

100

TA = 25°C

Vin = 0.8 V

0.7 V

50

0

0

0.02 0.04 0.10.06 0.08

V

, OUTPUT VOLTAGE (V)

OUT

in

http://onsemi.com

8

MC33460, MC33461

MC33461–2.7MC33461–0.9

m

, OUTPUT CURRENT ( A)

OUT

I

1.4

1.2

1.0

0.8

0.6

0.4

0.2

OUT

I , OUTPUT CURRENT (mA)

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

TA = 25°C

0

12 734

Vin, INPUT VOLTAGE (V)

V

OUT

= Vin – 2.1 V

1.5 V

1.0 V

0.5 V

56

TA = 25°C

V

= Vin – 0.7 V

OUT

0.5 V

0

0

24 86

Vin, INPUT VOLTAGE (V)

MC33461–4.5

4.5

OUT

I , OUTPUT CURRENT (mA)

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

TA = 25°C

V

= Vin – 2.1 V

OUT

1.5 V

1.0 V

0.5 V

0

210

468

Vin, INPUT VOLTAGE (V)

, OUTPUT VOLTAGE (V)

OUT

V

Figure 5. Output Current High versus Input Voltage

6

5

4

3

2

1

0

0

TA = –40°C

25°C

85°C

0.5 1 1.5 2 42.5 3 3.5

INPUT VOLTAGE, Vin (V)

Figure 6. T ypical Output Voltage versus Input Voltage

, OUTPUT VOLTAGE (V)

OUT

V

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

MC33461–2.7MC33460–2.7

85°C

25°C

TA = –40°C

0

0.5 1 1.5 2 42.5 3 3.5

INPUT VOLTAGE, Vin (V)

http://onsemi.com

9

MC33460, MC33461

MC33460–2.7MC33460–0.9

, OUTPUT DELAY TIME (ms)

P

t

0.001

100

1.0

0.1

0.01

10

0.0001

t

PLH

t

PHL

0.001 0.1

C

, LOAD CAPACITANCE (mF)

OUT

0.01

Figure 7. Output Delay Time versus Load Capacitance

K

L

J

Pin 1

, OUTPUT DELAY TIME (ms)

0.01

P

t

0.001

D

A

B

C

USER DIRECTION OF FEED

100

1.0

0.1

E

10

0.0001

t

PLH

t

PHL

0.001 0.1

C

, LOAD CAPACITANCE (mF)

OUT

A 2.2mm

F

G

H

B 2.6mm

C 4.0±0.1mm

D 4.0±0.1mm

E 2.0±0.05mm

F 1.75±0.1mm

G 3.5±0.05mm

H 8.0±0.3mm

J 1.5+0.1mm

K 0.2±0.1mm

L 1.6mm Max

0.01

178mm

21±0.8mm

Figure 8. T aping Specifications

2±0.5mm

Figure 9. Reel Dimensions

14.4mm MAX

13.0±0.2mm

60mm

8.4+2.0mm

http://onsemi.com

10

MC33460, MC33461

INFORMATION FOR USING THE SC–82AB SURFACE MOUNT PACKAGE

MINIMUM RECOMMENDED FOOTPRINT FOR SURFACE MOUNTED APPLICATIONS

Surface mount board layout is a critical portion of the total

design. The footprint for the semiconductor packages must

be the correct size to insure proper solder connection

0.60 0.60

0.80

0.60

0.80

SC–82AB

SOLDERING PRECAUTIONS

The melting temperature of solder is higher than the rated

temperature of the device. When the entire device is heated

to a high temperature, failure to complete soldering within

a short time could result in device failure. Therefore, the

following items should always be observed in order to

minimize the thermal stress to which the devices are

subjected.

• Always preheat the device.

• The delta temperature between the preheat and

soldering should be 100°C or less.*

• When preheating and soldering, the temperature of the

leads and the case must not exceed the maximum

temperature ratings as shown on the data sheet. When

using infrared heating with the reflow soldering

method, the difference shall be a maximum of 10°C.

interface between the board and the package. With the

correct pad geometry, the packages will self align when

subjected to a solder reflow process.

1.90

0.80

1.30

mm

• The soldering temperature and time shall not exceed

260°C for more than 10 seconds.

• When shifting from preheating to soldering, the

maximum temperature gradient shall be 5°C or less.

• After soldering has been completed, the device should

be allowed to cool naturally for at least three minutes.

Gradual cooling should be used as the use of forced

cooling will increase the temperature gradient and

result in latent failure due to mechanical stress.

• Mechanical stress or shock should not be applied

during cooling.

* Soldering a device without preheating can cause

excessive thermal shock and stress which can result in

damage to the device.

http://onsemi.com

11

MC33460, MC33461

PACKAGE DIMENSIONS

(SC–82AB)

SQ SUFFIX

PLASTIC PACKAGE

CASE 419C–01

ISSUE O

D3 PL

4

S

12

A

NOTES:

G

C

N

3

B

F

L

K

H

J

0.05 (0.002)

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

DIM MIN MAX MIN MAX

A 1.8 2.2 0.071 0.087

B 1.15 1.45 0.045 0.057

C 0.8 1.1 0.031 0.043

D 0.2 0.4 0.008 0.016

F 0.3 0.5 0.012 0.020

G 1.1 1.5 0.043 0.059

H 0.0 0.1 0.000 0.004

J 0.10 0.26 0.004 0.010

K 0.1 ––– 0.004 –––

L 0.05 BSC 0.002 BSC

N 0.7 REF 0.028 REF

S 1.8 2.4 0.07 0.09

INCHESMILLIMETERS

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

North America Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor — European Support

German Phone: 303–308–7140 (Mon–Fri 2:30pm to 5:00pm Munich Time)

German Email: ONlit–german@hibbertco.com

French Phone: 303–308–7141 (Mon–Fri 2:30pm to 5:00pm T oulouse T ime)

French Email: ONlit–french@hibbertco.com

English Phone: 303–308–7142 (Mon–Fri 1:30pm to 5:00pm UK Time)

English Email: ONlit@hibbertco.com

http://onsemi.com

ASIA/PACIFIC: LDC for ON Semiconductor — Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong T ime)

T oll Free from Hong Kong 800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–8549

Phone: 81–3–5487–8345

Email: r14153@onsemi.com

Fax Response Line: 303–675–2167

800–344–3810 Toll Free USA/Canada

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local Sales Representative.

MC33460/D

12

Loading...

Loading...