Order this document by MC33364/D

The MC33364 series are variable frequency SMPS controllers that operate

in the critical conduction mode. They are optimized for low power, high density

power supplies requiring minimum board area, reduced component count,

and low power dissipation. Each narrow body SOIC package provides a small

footprint. Integration of the high voltage startup saves approximately 0.7 W of

power compared to resistor bootstrapped circuits.

Each MC33364 features an on–board reference, UVLO function, a

watchdog timer to initiate output switching, a zero current detector to ensure

critical conduction operation, a current sensing comparator, leading edge

blanking, and a CMOS driver. Protection features include the ability to shut

down switching, and cycle–by–cycle current limiting.

The MC33364D1 is available in a surface mount SO–8 package. It has an

internal 126 kHz frequency clamp. For loads which have a low power

operating condition, the frequency clamp limits the maximum operating

frequency , preventing excessive switching losses and EMI radiation.

The MC33364D2 is available in the SO–8 package without an internal

frequency clamp.

The MC33364D is available in the SO–16 package. It has an internal

126 kHz frequency clamp which is pinned out, so that the designer can

adjust the clamp frequency by connecting appropriate values of resistance.

• Lossless Off–Line Startup

• Leading Edge Blanking for Noise Immunity

• Watchdog T imer to Initiate Switching

• Minimum Number of Support Components

• Shutdown Capability

• Over Temperature Protection

• Optional Frequency Clamp

CRITICAL CONDUCTION

GREENLINE SMPS

CONTROLLER

SEMICONDUCTOR

TECHNICAL DATA

8

1

D1, D2 SUFFIX

PLASTIC PACKAGE

CASE 751

(SO–8)

16

1

D SUFFIX

PLASTIC PACKAGE

CASE 751B

(SO–16)

PIN CONNECTIONS

ORDERING INFORMATION

Operating

Device

MC33364D1

MC33364D2

MC33364D SO–16

Temperature Range

TJ = –25° to +125°C

Package

SO–8

SO–8

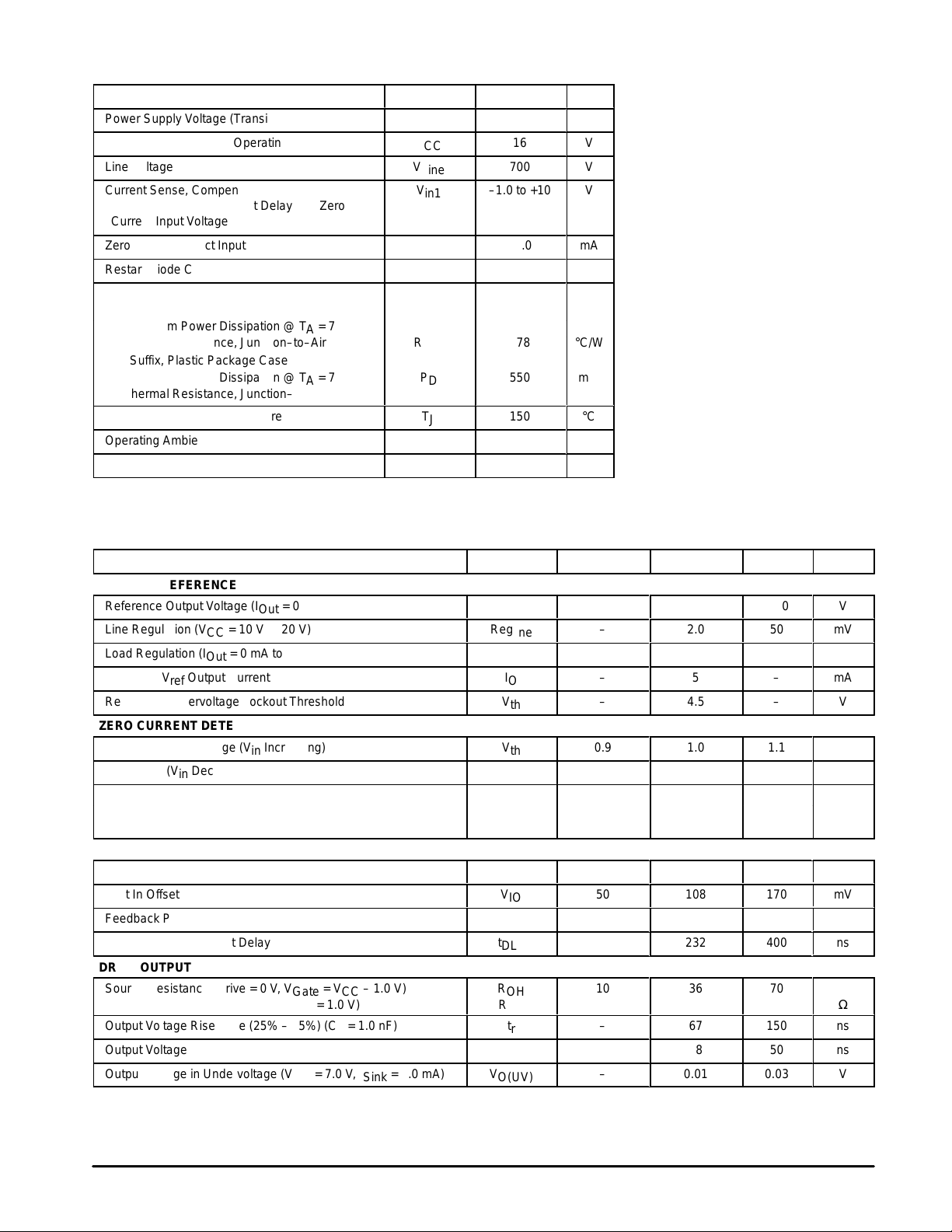

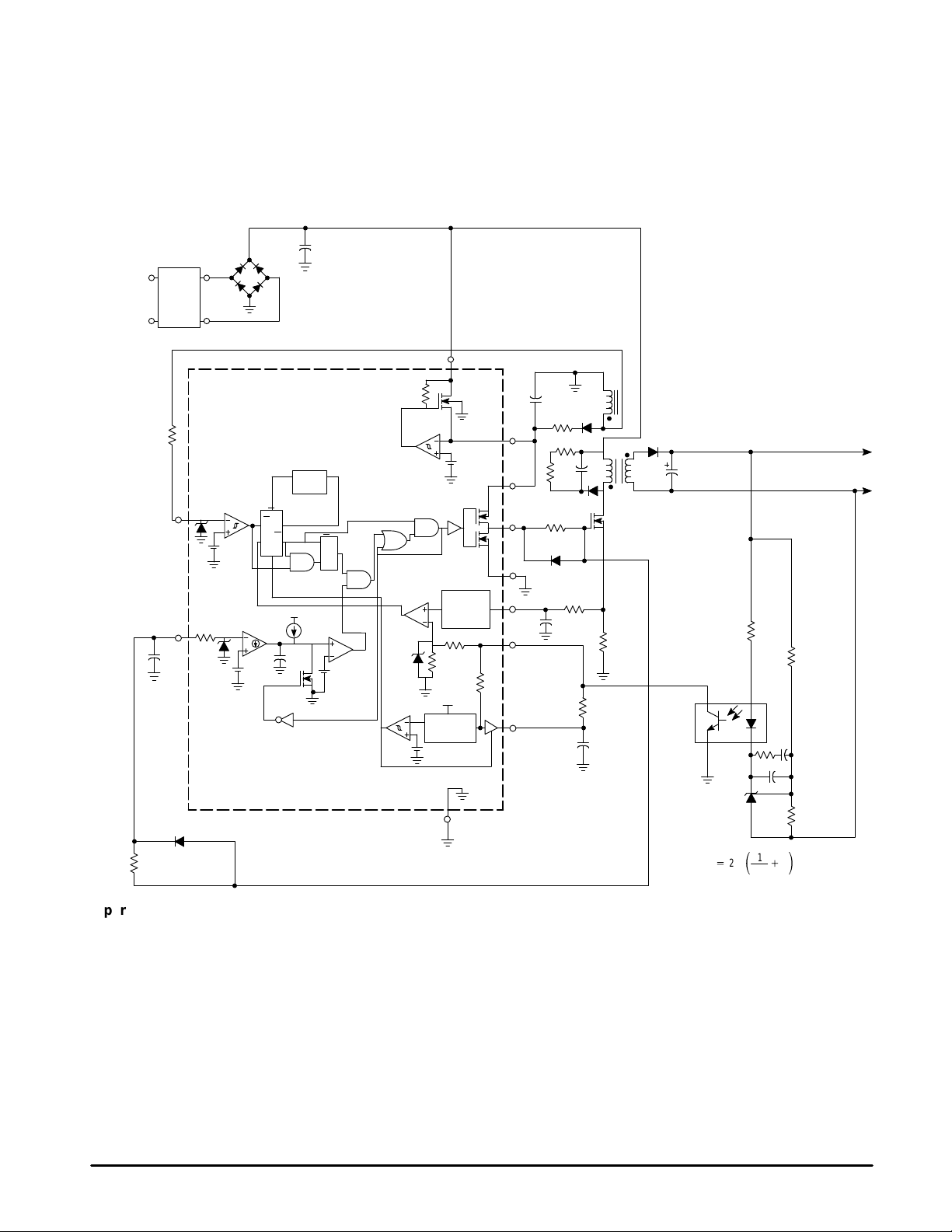

Representative Block Diagram

Restart

Delay

PWM

Comparator

FB

Current

Sense

ZC Det

This document contains information on a new product. Specifications and information herein

are subject to change without notice.

MOTOROLA ANALOG IC DEVICE DATA

Leading

Edge

Blanking

Zero

Current

Detector

This device contains 335 active transistors.

S

R

Q

R

Watchdog

Timer

Thermal

Shutdown

V

ref

UVLO

V

UVLO

Bandgap

Reference

Frequency

Clamp

CC

Line

V

CC

V

ref

Gnd

Gate

Optional

Frequency

Clamp

MC33364D1

MC33364D2

Zero Current

Current Sense

Voltage FB

Zero Current

Current Sense

Voltage FB

Freq Clamp

Motorola, Inc. 1997 Rev 0

18

2

3

V

4

ref

(Top View)

MC33364D

116

N/C

2

3

4

N/C

5

V

6

ref

7

N/C

8

(Top View)

Line

V

7

CC

Gate Drive

6

P Gnd

5

Line

A V

13

CC

P V

12

CC

11

Gate Drive

10

P Gnd

9

A Gnd

1

MAXIMUM RATINGS

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

(TA = 25°C, unless otherwise noted.)

Rating Symbol Value Unit

Power Supply Voltage (Transient)

Power Supply Voltage (Operating)

Line Voltage

Current Sense, Compensation,

Voltage Feedback, Restart Delay and Zero

Current Input Voltage

Zero Current Detect Input

Restart Diode Current

Power Dissipation and Thermal Characteristics

D1 and D2 Suffix, Plastic Package Case 751

Maximum Power Dissipation @ TA = 70°C P

Thermal Resistance, Junction–to–Air R

D Suffix, Plastic Package Case 751B–05

Maximum Power Dissipation @ TA = 70°C P

Thermal Resistance, Junction–to–Air R

Operating Junction Temperature

ББББББББББББ

Operating Ambient Temperature

ББББББББББББ

Storage Temperature Range

ББББББББББББ

NOTE: ESD data available upon request.

V

CC

V

CC

V

Line

V

in1

I

in

I

in

D

θJA

D

θJA

T

J

ÁÁ

T

A

ÁÁ

T

stg

ÁÁ

MC33364

700

–1.0 to +10 V

±5.0

450 mW

178 °C/W

550 mW

145 °C/W

150

ÁÁÁ

–25 to +125

ÁÁÁ

–55 to +150

ÁÁÁ

20

16

5.0

mA

mA

°C

Á

°C

Á

°C

Á

V

V

V

ELECTRICAL CHARACTERISTICS (V

= 12 V, for typical values TA = 25°C, for min/max values TJ = –25 to 125°C)

CC

Characteristic

VOLTAGE REFERENCE

Reference Output Voltage (I

= 0 mA, TJ = 25°C)

Out

Line Regulation (VCC = 10 V to 20 V)

Load Regulation (I

Maximum V

ref

= 0 mA to 5.0 mA)

Out

Output Current

Reference Undervoltage Lockout Threshold

ZERO CURRENT DETECTOR

Input Threshold Voltage (Vin Increasing)

Hysteresis (Vin Decreasing)

Input Clamp Voltage

High State (I

Low State (I

= 3.0 mA) V

DET

= –3.0 mA) V

DET

CURRENT SENSE COMPARATOR

Input Bias Current (VCS = 0 to 2.0 V)

БББББББББББББББ

Built In Offset

БББББББББББББББ

Feedback Pin Input Range

БББББББББББББББ

Feedback Pin to Output Delay

БББББББББББББББ

DRIVE OUTPUT

БББББББББББББББ

Source Resistance (Drive = 0 V, V

Sink Resistance (Drive = VCC, V

= VCC – 1.0 V)

Gate

= 1.0 V) R

Gate

Output Voltage Rise T ime (25% – 75%) (CL = 1.0 nF)

Output Voltage Fall Time (75% – 25%) (CL = 1.0 nF)

Output Voltage in Undervoltage (VCC = 7.0 V, I

Sink

= 1.0 mA)

Symbol Min Typ Max Unit

V

ref

Reg

line

Reg

load

I

O

V

th

V

th

V

H

IH

IL

I

IB

ÁÁÁ

V

IO

ÁÁÁ

V

FB

ÁÁÁ

t

DLY

ÁÁÁ

ÁÁÁ

R

OH

OL

t

r

t

f

V

O(UV)

4.90

–

–

–

–

0.9

–

5.05

2.0

0.3

5

4.5

1.0

200

5.20

50

50

–

–

1.1

–

9.0 10.33 12

–0.5 –0.75 –1.1

–0.5

ÁÁÁ

50

ÁÁÁ

1.1

ÁÁÁ

100

ÁÁÁ

ÁÁÁ

10

0.02

ÁÁÁ

108

ÁÁÁ

1.24

ÁÁÁ

232

ÁÁÁ

ÁÁÁ

36

0.5

ÁÁ

170

ÁÁ

1.4

ÁÁ

400

ÁÁ

ÁÁ

70

5 11 25 Ω

–

–

–

67

28

0.01

150

50

0.03

ÁÁ

ÁÁ

ÁÁ

ÁÁ

ÁÁ

V

mV

mV

mA

V

V

mV

V

µA

mV

V

ns

Ω

ns

ns

V

2

MOTOROLA ANALOG IC DEVICE DATA

MC33364

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

Á

Á

Á

Á

Á

ÁÁÁ

Á

ÁÁÁ

ELECTRICAL CHARACTERISTICS (continued) (V

= 12 V, for typical values TA = 25°C, for min/max values TJ = –25 to 125°C)

CC

Characteristic UnitMaxTypMinSymbol

LEADING EDGE BLANKING

Delay to Current Sense Comparator Input

(VFB = 2.0 V, VCS = 0 V to 4.0 V step, CL = 1.0 nF)

TIMER

Watchdog Timer

UNDERVOLTAGE LOCKOUT

Startup Threshold (VCC Increasing)

БББББББББББББББ

Minimum Operating Voltage After Turn–On (VCC Decreasing)

БББББББББББББББ

FREQUENCY CLAMP

БББББББББББББББ

Internal FC Function (pin open)

БББББББББББББББ

Internal FC Function (pin grounded)

БББББББББББББББ

Frequency Clamp Input Threshold

БББББББББББББББ

Frequency Clamp Control Current Range

БББББББББББББББ

TOTAL DEVICE

Line Startup Current (V

= 50 V) (VCC = V

Line

th(on)

– 1.0 V)

Restart Delay Time t

Line Pin Leakage (V

Line Startup Current (VCC = 0 V, V

= 575 V) I

Line

= 50 V) I

Line

VCC Dynamic Operating Current (50 kHz, CL = 1.0 nF)

VCC Static Operating Current (VCC = 16 V, V

БББББББББББББББ

ref

= 0)

VCC Pin Leakage (VCC = 11 V)

t

PHL(in/out)

t

DLY

V

th(on)

ÁÁÁ

V

Shutdown

ÁÁÁ

ÁÁÁ

f

max

ÁÁÁ

f

max

ÁÁÁ

V

th(FC)

ÁÁÁ

I

Control

ÁÁÁ

I

Line

DLY

Line

Line

I

CC

ÁÁÁ

ICC

Lkg

–

200

14

ÁÁÁ

6.5

ÁÁÁ

ÁÁÁ

ÁÁÁ90ÁÁÁ

400

ÁÁÁ

ÁÁÁ–ÁÁÁ

ÁÁÁ30ÁÁÁ70ÁÁ

5.0

250

410

15

ÁÁÁ

7.6

ÁÁÁ

ÁÁÁ

126

564

ÁÁÁ

2.0

8.5

700

16

ÁÁ

8.5

ÁÁ

ÁÁ

160

ÁÁ

700

ÁÁ

–

ÁÁ

110

12

100 ms

0.5 32 70 µA

6.0 10 12 mA

1.5

–

ÁÁÁ

300

2.75

3.0

ÁÁÁ

544

4.5

–

ÁÁ

800

ns

µs

V

ÁÁ

V

ÁÁ

ÁÁ

kHz

ÁÁ

kHz

ÁÁ

V

ÁÁ

µA

ÁÁ

mA

mA

ÁÁ

µA

MOTOROLA ANALOG IC DEVICE DATA

3

MC33364

0

5

OUTPUT VOLTAGE (V)

30

25

20

15

10

5.0

–5.0

16

12

8.0

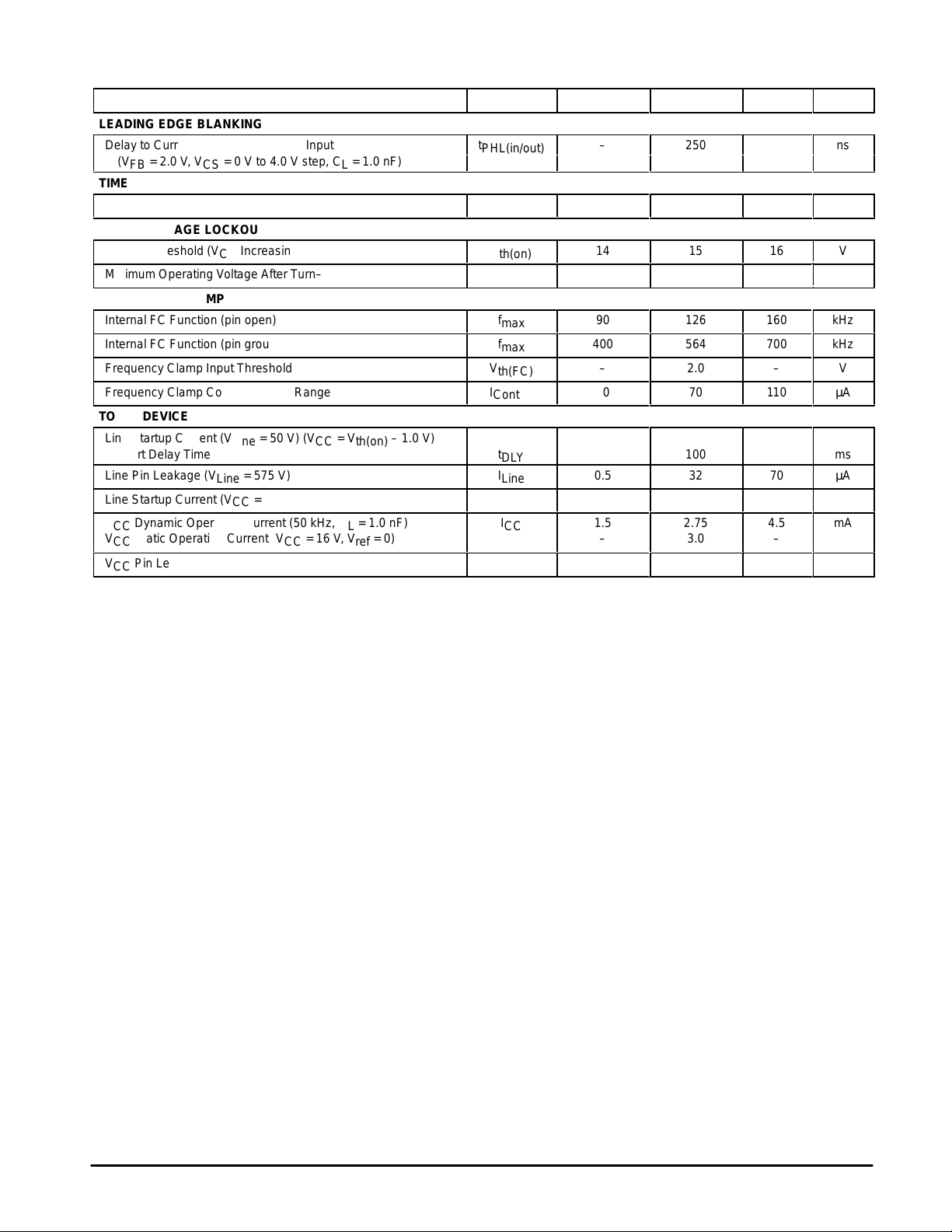

Figure 1. Drive Output Waveform

Figure 2. Watchdog Timer Delay

versus T emperature

VCC = 14 V

CL = 1000 pF

°

C

TA = 25

0

5.0 µs/DIV

Figure 3. Reference V oltage

versus T emperature

VCC = 14 V

µ

, WATCHDOG TIME DELAY ( s)

DLY

t

500

450

400

350

300

–55

6.0

4.0

Circuit of Figure 7

TA = 25

VCC = 14 V

–25 0 25 50 75 100 12

TA, AMBIENT TEMPERATURE (°C)

Figure 4. Supply Current

versus Supply V oltage

°

C

4.0

, VOLTAGE FEEDBACK

FB

V

THRESHOLD CHANGE (mV)

5.0

∆

–4.0

–55

–25 0 25 50 75 125100

TA, AMBIENT TEMPERATURE (°C)

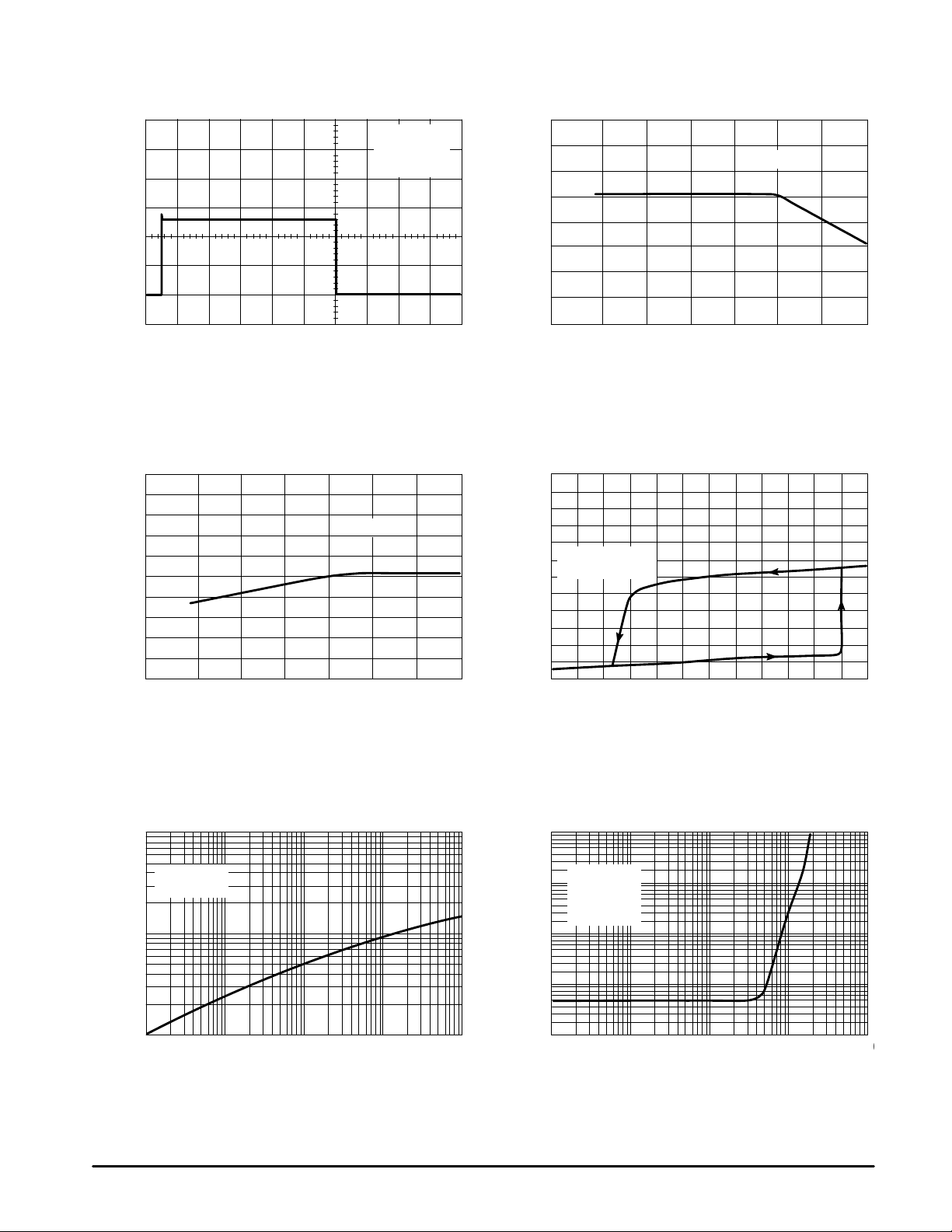

Figure 5. Transient Thermal Resistance

1000

D Suffix

16 Pin SOIC

°

100

, THERMAL RESISTANCE

JA(t)

JUNCTION–TO–AIR ( C/W)

θ

R

10

0.01

0.1 1.0 10 100

t, TIME (s)

2.0

, SUPPLY CURRENT (mA)

CC

I

0

4.0

1000

µ

100

10

1.0

, PROGRAMMED DEAD TIME ( sec)

d

T

0.1

0.1

6.0 8.0 10 12 14 16

VCC, SUPPLY VOLTAGE (V)

Figure 6. Dead Time

versus Input Current

D Suffix

16 Pin SOIC

°

C

TA = 25

VCC = 14 V

1.0 10 100 100

Iin, CURRENT SOURCED INTO PIN 8 (µA)

4

MOTOROLA ANALOG IC DEVICE DATA

MC33364

FUNCTIONAL DESCRIPTION

INTRODUCTION

With the goal of reducing the size and cost of off–line

power supplies, there is an ever increasing demand for an

economical method of obtaining a regulated galvanically

isolated dc output voltage using a control which operates

Figure 7. Functional Block Diagram

C5

10

D3

1N4006

92 to

270 Vac

EMI

Filter

1N4006

D2

D1

1N4006

1N4006

D4

MC33364

R2

22 k

1.5 V

UVLO

UVLO

+

Leading

Blanking

44 K

14 K

V

CC

5.0 V

Reference

Zero Current

Frequency

Clamp

C2

0.01

D9

1N4148

R13

100

4.0 K

10 V

Zero

Current

Detect

0.3/

0.25 V

2.0 V

RQ

Timer

R

Q

R

Q

S

En

5.0 V

10 pF

3.0

R

S

µ

Q

A

2.0 V

Line

+

15/7.6

Edge

5.0 k

A Gnd

directly from the ac line. This data sheet describes a

monolithic control IC that was specifically designed for power

supply control with a minimal number of external

components. It offers the designer a simple cost effective

solution to obtain the benefits of off–line power regulation.

T1

En

C3

V

CC

P V

Gate Drive

P Gnd

Current

Sense

Voltage FB

V

ref

1N4934

20

+

D5

CC

R1 56

R5 47 k

R6

47 K

470 R4

D7

1N4148

R12 100

C9 .01

C4

.001

R3

1.2 K

C10

0.1

D6

MURS160T3

Q1

MTD1N60

R7

2.2

D8

MBRS340T3

C5

300

U3

MOC8102

VO+

5

39 k

U2

TL431

2.5

R9

R8

430

R10

14 k

1

24

C7

10

2

R10

R11

C8

330 pF

1

R11

10 k

Ǔ

)

1

3

ǒ

6.0 V

2 Amp

Operating Description

The MC33364 contains many of the building blocks and

protection features that are employed in modern high

performance current mode power supply controllers.

Referring to the block diagram in Figure 7, note that this

device does not contain an oscillator. A description of each of

the functional blocks is given below.

Zero Current Detector

The MC33364 operates as a critical conduction current

mode controller, whereby output switch conduction is

initiated by the Zero Current Detector and terminated when

the peak inductor current reaches the input threshold level.

The Zero Current Detector initiates the next on–time by

MOTOROLA ANALOG IC DEVICE DATA

setting the RS Latch at the instant the inductor current

reaches zero. This critical conduction mode of operation has

two significant benefits. First, since the MOSFET cannot

turn–on until the inductor current reaches zero, the output

rectifier’s reverse recovery time becomes less critical

allowing the use of an inexpensive rectifier. Second, since

there are no deadtime gaps between cycles, the ac line

current is continuous thus limiting the peak switch to twice

the average input current

The Zero Current Detector indirectly senses the inductor

current by monitoring when the auxiliary winding voltage falls

below 0.25 V . To prevent false tripping, 50 mV of hysteresis is

provided. The Zero Current Detector input is internally

5

MC33364

protected by two clamps. The upper 0.7 V clamp prevents

input overvoltage breakdown while the lower –0.7 V clamp

prevents substrate injection. An external resistor must be

used in series with the auxiliary winding to limit the current

through the clamps to 5.0 mA or less.

Current Sense Comparator and RS Latch

The Current Sense Comparator RS Latch configuration

used ensures that only a single pulse appears at the Drive

Output during a given cycle. The inductor current is

converted to a voltage by inserting a ground–referenced

sense resistor in series with the source of output switch. This

voltage is monitored by the Current Sense Input and

compared to the divided down feedback voltage. The internal

feedback voltage divider is limited to 1.5 V maximum.

Therefore the maximum peak switch current is:

I

pk(max)

The Current Sense Input to Drive Output propagation

delay is typically 232 nS.

Timer

A watchdog timer function was added to the IC to eliminate

the need for an external oscillator when used in stand alone

applications. The Timer provides a means to automatically

start or restart the preconverter if the Drive Output has been

off for more than 410 microseconds after the inductor current

reaches zero.

Undervoltage Lockout

The MC33364 has a 5.0 V internal reference brought out

to Pin 6 (D Suffix) or Pin 4 (D1 and D2 Suffixes) and capable

of sourcing 10 mA typically . It also contains an Under V oltage

Lockout (UVLO) circuit which suppresses the Gate output at

Pin 1 1 if the VCC supply voltage drops below 7.6 V typical.

Restart Delay

A restart delay function is provided to allow hiccup mode

fault protection in case of a short circuit condition and to

prevent the SMPS from repeatedly trying to restart after the

input line voltage has been removed. When power is first

applied, the VCC bypass capacitor is charged through a

constant current source. The Restart Delay turns off the high

voltage startup MOSFET when VCC reaches the startup

threshold level. The Restart Delay turns on the high voltage

MOSFET after VCC has dropped below 4.5 V.

If the SMPS output is short circuited, the transformer

winding, which provides the VCC voltage to the MC33364, will

be unable to sustain VCC. The restart delay prevents the high

voltage startup transistor within the IC from maintaining the

voltage on the VCC pin bootstrap capacitor. After VCC drops

below the UVLO threshold in the SMPS, the SMPS switching

transistors are held off for the time programmed by the restart

delay circuit. In this manner, the SMPS switching transistor is

operated at a very low duty cyle, preventing destruction. If

the short circuit fault is removed, the power supply system

will turn on by itself in a normal startup mode after the restart

delay has timed out

+

1.5 V

R

Sense

Figure 8. Frequency Clamp Circuit

5.0 V

µ

A

10 pF

3.0

0 = Disable

FC Output

to PWM latch

2.0 V

Frequency

Clamp

4.0 k

2.0 V

Gate

Drive

Signal

Output Switching Frequency Clamp

In normal operation, the MC33364 operates the flyback

transformer primary inductance in the critical mode. That is,

the inductor current ramps to a peak value, ramps down to

zero, then immediately begins ramping positive again. The

peak current is programmed by the current sense resistance

value. If the output load is reduced from full load to a standby

load or no load condition, the switching frequency can

increase to hundreds of kilohertz. Because regulatory

agency EMI limits for allowed conducted current decreases

as the switching frequency increases beyond 150 kHz, this

may be an undesireable operating condition. The Output

Switching Frequency Clamp remedies this situation to

minimize EMI generated in this operating region. The internal

frequency clamp circuit in the MC33364D1 and MC33364D

programs a minimum off time, forcing discontinuous mode

operation and limiting the operating frequency to less than

126 kHz. The MC33364D2 does NOT contain a frequency

clamp circuit. The Output Switching Frequency Clamp

function in the MC33364D can be disabled by connecting the

FC input, Pin 8, to ground. The clamp frequency can be set

externally by sinking or sourcing a current into the pin of up to

100 microamperes.

Output

The IC contains a CMOS output driver specifically

designed for direct drive of power MOSFETs. The Drive

Output is capable of up to ±1500 mA peak current with a

typical rise and fall time of 50 nS with a 1.0 nF load. Additional

internal circuitry has been added to keep the Drive Output in

a sinking mode whenever the Undervoltage Lockout is

active. This characteristic eliminates the need for an external

gate pull–down resistor. The totem–pole output has been

optimized to minimize cross–conduction current during high

speed operation.

Design Example

Design an off–line Flyback converter according to the

following requirements:

Output Power: 12 W

Output: 6.0 V @ 2 Amperes

Input voltage range: 90 Vac – 270 Vac, 50/60 Hz

The operation for the circuit shown in Figure 9 is as

follows: the rectifier bridge D1–D4 and the capacitor C1

convert the ac line voltage to dc. This voltage supplies the

primary winding of the transformer T1 and the startup circuit

6

MOTOROLA ANALOG IC DEVICE DATA

MC33364

in U1 through Pin 8. The primary current loop is closed by the

transformer’s primary winding, the TMOS switch Q1 and the

current sense resistor R7. The switch Q1 is driven from Pin 6

of U1 through the resistor R4 and the diode D7. The resistor

R4 smooths the switch–on of Q1. The diode D7 ensures a

fast switching–off. The resistors R5, R6, diode D6 and

capacitor C4 create a clamping network that protects Q1

from spikes on the primary winding. The network consisting

of capacitor C3, diode D5 and resistor R1 provides a V

supply voltage for U1 from the auxiliary winding of the

transformer. The resistor R1 makes VCC more stable and

resistant to noise. The resistor R2 reduces the current flow

through the internal clamping and protection zener diode of

the Zero Crossing Detector (ZCD) within U1. C3 is the

decoupling capacitor of the supply voltage. The resistor R3

provides bias current for the optoisolator’s transistor. The

diode D8 and the capacitor C5 rectify and filter the output

voltage. The device U2 drives the primary side through the

optoisolator to make the output voltage stable. The output

voltage information is delivered to U2 by a resistive divider

that consists of resistors R10 and R11. The resistor R9 and

the capacitors C7, C8 provide frequency compensation of the

feedback loop.

Since the critical conduction mode converter is a variable

frequency system, the MC33364 has a built–in special block

to reduce switching frequency in the no load condition. This

block is named the ”frequency clamp” block. MC33364 used

in the design example has an internal frequency clamp set to

126 kHz. However, optional versions with a disabled or

variable frequency clamp are available. The frequency clamp

works as follows: the clamp controls the part of the switching

cycle when the MOSFET switch is turned off. If this ”off–time”

(determined by the reset time of the transformer’s core) is too

short, then the frequency clamp does not allow the switch to

turn–on again until the defined frequency clamp time is

reached (i.e., the frequency clamp will insert a dead time).

There are several advantages of the MC33364’s startup

circuit. The startup circuit includes a special high voltage

switch that controls the path between the rectified line

voltage and the VCC supply capacitor to charge that capacitor

by a limited current when the power is applied to the input.

After a few switching cycles the IC is supplied from the

transformer’s auxiliary winding. After VCC reaches the

undervoltage lockout threshold value, the startup switch is

turned off by the undervoltage and the overvoltage control

circuit. Because the power supply can be shorted on the

output, causing the auxiliary voltage to be zero, the MC33364

will periodically start its startup block. This mode is named

”hiccup mode”. During this mode the temperature of the chip

rises but remains protected by the thermal shutdown block.

During the power supply’s normal operation, the high voltage

internal MOSFET is turned off, preventing wasted power , and

thereby , allowing greater circuit efficiency.

Since a bridge rectifier is used, the resulting minimum and

maximum dc input voltages can be calculated:

V

in(min)

V

in(max)

Ǹ

dc+2

Ǹ

dc+2

xV

xV

in(min)

in(max)

ac

ac

Ǹ

+ǒ2

Ǹ

+ǒ2

Ǔ

(

90 Vac)+

Ǔ

(

270 Vac)+

CC

127 V

382 V

The maximum average input current is:

P

Iin+

where n = estimated circuit efficiency.

A TMOS switch with 600 V avalanche breakdown voltage

is used. The voltage on the switch’s drain consists of the

input voltage and the flyback voltage of the transformer’s

primary winding. There is a ringing on the rising edge’s top of

the flyback voltage due to the leakage inductance of the

transformer. This ringing is clamped by the RCD network.

Design this clamped wave for an amplitude of 50 V. Add

another 50 V to allow a safety margin for the MOSFET. Then

a suitable value of the flyback voltage may be calculated:

V

flbk

Since this value is very close to the V

V

flbk

The V

ē

max

The maximum input primary peak current:

I

ppk

Choose the desired minimum frequency f

to be 70 kHz.

After reviewing the core sizing information provided by a

core manufacturer, a EE core of size about 20 mm was

chosen. Siemens’ N67 magnetic material is used, which

corresponds to a Philips 3C85 or TDK PC40 material.

The primary inductance value is given by:

Lp+

The manufacturer recommends for that magnetic core a

maximum operating flux density of:

B

max

The cross–sectional area Ac of the EF20 core is:

Ac+

The operating flux density is given by:

B

max

From this equation the number of turns of the primary

winding can be derived:

np+

out

ƪ

nV

+

600 V*382 V*100 V+118 V

+

flbk

+

V

2I

+

[

ē

ē

max V

ǒ

I

ppk

+

33.5 mm

+

LpI

B

maxAc

ƫ

in(min)

V

TMOS

V

in(min)

value of the duty cycle is given by:

V

flbk

)

flbk

in

+

]

max

in(min)

ǒ

Ǔ

f

min

0.2 T

2

LpI

ppk

NpA

c

ppk

12 W

+

[

0.8(127 V

*

V

in(max)

+

127 V

V

in(min)

0.2(0.118 A

+

0.5

+

(

0.472 A)(70 kHz

Ǔ

+

0.118 A

)]

*

100 V

in(min)

127 V

[

127 V)127 V

)

+

0.472 A

0.5(127 V

)

+

, set:

+

]

of operation

min

+

1.92 mH

)

0.5

MOTOROLA ANALOG IC DEVICE DATA

7

MC33364

The AL factor is determined by:

ǒ

L

L

AL+

core with an AL of 100 nH is selected. The desired number of

turns of the primary winding is:

np+

(assuming a Schottky rectifier is used):

ns+

p

n2p

From the manufacturer‘s catalogue recommendation the

L

p

ǒ

Ǔ

A

L

The number of turns needed by the 6.0 V secondary is

ǒ

Vs)

ƪ

The auxiliary winding to power the control IC is 16 V and its

number of turns is given by:

naux

C1

where the minimum ripple frequency is 2 times the 50 Hz line

frequency and t

haversine cycle, is assumed to be half the cycle period.

calculations for the value of the output filter capacitors will be

done at the lowest frequency, since the ripple voltage will be

greatest at this frequency. The approximate equation for the

output capacitance value is given by:

C5

one uses the peak current in the predesign consideration.

Since within the IC there is a limitation of the voltage for the

current sensing, which is set to 1.2 V, the design of the

current sense resistor is simply given by:

R7

secondary, connected to the primary side via an optoisolator,

the MOC8102.

(V

+

The approximate value of rectifier capacitance needed is:

t

(Iin)

off

+

V

ripple

Because we have a variable frequency system, all the

I

+

(f

min

Determining the value of the current sense resistor (R7),

V

cs

+

I

ppk

The error amplifier function is provided by a TL431 on the

B

p

maxAc

+

ǒ

L

ƪ

p

ǒ

+

1ń2

ƪ

+

ǒ

Ǔ

V

1–ēmaxǓn

fwd

ē

maxǒV

in(min)

ǒ

+

)

V

aux

ƪ

ē

max(V

(16 V)0.9 V)(1*0.5)139

+

(5 m sec)(0.118 A)

+

, the discharge time of C1 during the

off

out

+

)(V

)

rip

1.2 V

+

0.472 A

2

Ǔ

2

Ǔ

I

ƫ

ppk

ǒ

Ǔ

0.2 T

33.5 E–6 m

ǒ

.00192 H

(

0.00192 H

(

6.0 V)0.3 V

fwd

(70 kHz)(0.1 V)

Ǔ

(

0.472 A

)

ƫ

100 nH

+

)

p

Ǔ

ƫ

ƪ

0.5ǒ127 V

)(1*ēmax)n

ƫ

)

in(min)

[0.5(127 V)]

50 V

2A

2.54W[

2

2

Ǔ

2

)

1ń2

+

139 turns

ǒ

Ǔ

1*0.5Ǔ139

Ǔ

ƫ

p

+

11.8mF

+

286mF

2.2

W

+

105 nH

+

7 turns

+

19 turns

The voltage of the optoisolator collector node sets the

peak current flowing through the power switch during each

cycle. This pin will be connected to the feedback pin of the

MC33364, which will directly set the peak current.

Starting on the secondary side of the power supply , assign

the sense current through the voltage–sensing resistor

divider to be approximately 0.25 mA. One can immediately

calculate the value of the lower and upper resistor:

V

(TL431)

R

R

current through the optoisolator and the TL431 is set by the

minimum operating current requirements of the TL431. This

currernt is minimum 1.0 mA. Assign the maximum current

through the branch to be 5 mA. That makes the bias resistor

value equal to:

R

100% with 25% tolerance. When the TL431 is full–on, 5 mA

will be drawn from the transistor within the MOC8102. The

transistor should be in saturated state at that time, so its

collector resistor must be

R

reference voltage to the feedback pin of the MC33364, the

external resistor can have a higher value

R

the optoisolator diode and the voltage sense divider on the

secondary side.

R

fpn+

+

lower

upper

The value of the resistor that would provide the bias

bias

The MOC8102 has a typical current transfer ratio (CTR) of

collector

Since a resistor of 5.0 k is internally connected from the

ext

This completes the design of the voltage feedback circuit.

In no load condition there is only a current flowing through

The load at that condition is given by:

noload

The output filter pole at no load is:

R11

+

R10

+

RS+

+

+

+R3+

+

(I

(2pR

ref

+

6.0 V*[2.5V)1.4V]

V

ref

(R

LED

noload

+

V

(R

I

int

V

1

I

div

V

*

V

out

out

*

LED

int

)*(R

out

)

ref

I

div

*

[V

(TL431))V

ref

I

5.0 mA

V

sat

+

)(R

collector

collector

I

)

div

+

(5.0 mA)0.25 mA)

C

)

out

+

(2p)(1143)(300mF)

2.5 V

+

0.25 mA

(TL431)

6.0 V*2.5V

+

0.25 mA

LED

LED

+

420W[

5.0 V*0.3 V

5.0 mA

)

(5.0 k)(940)

+

)

5.0 k*940

+

1157W[

6.0 V

1

+

+

10 k

]

940

1200

+

+

+

14 k

430

W

W

1143

0.46 Hz

W

W

8

MOTOROLA ANALOG IC DEVICE DATA

MC33364

In heavy load condition the I

heavy load resistance is given by:

V

out

6.0 V

R

fpn+

high input voltage will be:

A

fc+

bandwidth is calculated at the rated load because that yields

the bandwidth condition, which is:

+

heavy

The output filter pole at heavy load of this output is

(2pR

The gain exhibited by the open loop power supply at the

ǒ

V

in max

+

ǒ

(V

in max

The maximum recommended bandwidth is approximately:

fsmin

5

The gain needed by the error amplifier to achieve this

I

out

heavy

+

+

1

*

V

)(V

70 kHz

5

2.0 A

C

out

out

error

+

)

2

Ǔ

)(Np)

+

+

Ns

14 kHz

and I

LED

3.0

(2p)(3)(300mF)

+

Ǔ

div

W

1

(

382 V*6.0 V

(382 V)(1.2 V)(139)

+

15.53+23.82 dB

is negligible. The

+

177 Hz

2

)

(7)

f

Gc+20 log

The gain in absolute terms is:

Ac+

The output resistance of the voltage sense divider is given by

the parallel combination of resistors in the divider:

Rin+

R9+(Ac) (Rin)+29.75 k[30 k

C8

light load filter pole:

C7

(Gcń20)

10

Now the compensation circuit elements can be calculated.

R

upper

+

ƪ

2p(Ac)(Rin)(fc)

The compensation zero must be placed at or below the

+

ƪ

2p(R9) (fpn)

c

ǒ

f

ph

|| R

1

+

*A+

Ǔ

10

lower

20 log

(14.14ń20)

+

10 k || 14 k+5833

+

ƫ

1

+

11.63mF[10mF

ƫ

14 kHz

ǒ

+

382 pF[390 pF

51

177

Ǔ

+

*

23.82 dB

14.14 dB

W

MOTOROLA ANALOG IC DEVICE DATA

9

MC33364

Figure 9. 12 W Power Supply

92 to

270 Vac

Zero Current

Frequency

R13

100

R2

22 k

Clamp

EMI

Filter

C2

0.01

D9

1N4148

1N4006

1N4006

4.0 K

10 V

1N4006

D2

D1

U1

MC33364

Zero

Current

Detect

0.3/

0.25 V

2.0 V

R

S

D4

En

R

Q

Q

5.0 V

D3

1N4006

Timer

3.0

10 pF

C1

10

Line

C3

20

+

R1 56

V

CC

P V

CC

Gate Drive

470 R4

P Gnd

Current

Sense

Voltage FB

V

ref

R5 47 k

R6

47 K

D7

1N4148

R12 100

C9 .01

44 K

14 K

V

5.0 V

Reference

+

+

15/7.6

Leading

Edge

Blanking

5.0 k

CC

A Gnd

En

UVLO

RQ

R

Q

S

µ

A

2.0 V

1.5 V

UVLO

1N4934

D5

C4

.001

T1

D6

MURS160T3

Q1

MTD1N60

R7

2.2

R3

1.2 K

C10

0.1

D8

MBRS340T3

C5

300

U3

MOC8102

5

TL431

U2

R9

30 k

6.0 V

2 Amp

R8

430

R10

14 k

1

24

C7

10

3

C8

330 pF

1

2

R11

10 k

10

Line Regulation IO = 930 mA

Line Regulation Vin = 115 Vrms

Output Ripple

Efficiency

Vin = 90 to 270 Vac

IO = 110 to 1100 mA

Vin = 115 Vac, IO = 1100 mA

Vin = 115 Vac, IO = 1100 mA

∆

= 78 mV or ±6.5%

∆

= 103 mV or ±8.6%

600 mVpp

72.9%

MOTOROLA ANALOG IC DEVICE DATA

MC33364

Figure 10. Universal Input Battery Charger

J2

12

Output 12 V @ 0.8 Amp max

Input Voltage Range 90 – 270 Vac, 50/60 Hz

R8

4.7 k

D7

1N4148

5.1 V

D8

B2X84C5V1LT1

C6

µ

F

1.0

R7

100

T1

R13

22 k

54

6

7

8

C5

µ

F

100

D6

MURS320T3

79

543 2

R4

47 k

R12

82 k

S

CSB

U2

MC33341

V

CC

DO

D5

MURS

C4 1.0 nF

R5

47 k

160T3

R11

10 k

GndV

3

CMP

2

CTA

CSA

Q1

MTD1N60E

C7

33 nF

1

R9

100

R4

47 k

R10

0.25

12

54

U3

MOC8102

D3

1N4148

R1

220

20

18 V

D2

B2X84C18LT1

D1 B250R

F1

T 0.2 A

12

J1

Line

MOTOROLA ANALOG IC DEVICE DATA

C1

C2

R3

µ

F

10

350 V

22 k

6

Gate

1 ZCD

MC33364D1

7V

CC

8 Line

µ

f

T1 = 139 Turns #28 Awg, primary winding 2 – 3

2

CS

ref

3FB

C3

4V

µ

F

0.1

U1

Gnd

5

7 Turns, Bifilar 2 x #26 Awg, output winding 9 – 7

19 Turns #28 Awg, auxiliary winding 4 – 5 on Philips

EF20–3C85 core gap for a primary inductor of 1.92 mH.

11

–T–

MC33364

OUTLINE DIMENSIONS

D1, D2 SUFFIX

PLASTIC PACKAGE

CASE 751–05

A

E

B

C

A1

16 9

18

G

SEATING

PLANE

D

58

1

H

4

e

B

SS

–A–

–B–

K

D

16 PL

0.25 (0.010) A

M

S

B

T

0.25MB

A

SEATING

PLANE

A0.25MCB

C

S

M

h

0.10

PLASTIC PACKAGE

CASE 751B–05

8 PLP

0.25 (0.010) B

M

(SO–8)

ISSUE S

X 45

_

D SUFFIX

(SO–16)

ISSUE J

M

R

NOTES:

C

q

L

S

X 45

_

F

J

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. DIMENSIONS ARE IN MILLIMETERS.

3. DIMENSION D AND E DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 TOTAL IN EXCESS

OF THE B DIMENSION AT MAXIMUM MATERIAL

CONDITION.

MILLIMETERS

DIM MIN MAX

A 1.35 1.75

A1 0.10 0.25

B 0.35 0.49

C 0.18 0.25

D 4.80 5.00

E

3.80 4.00

1.27 BSCe

H 5.80 6.20

h

0.25 0.50

L 0.40 1.25

0 7

q

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

DIM MIN MAX MIN MAX

A 9.80 10.00 0.386 0.393

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.054 0.068

D 0.35 0.49 0.014 0.019

F 0.40 1.25 0.016 0.049

G 1.27 BSC 0.050 BSC

J 0.19 0.25 0.008 0.009

K 0.10 0.25 0.004 0.009

M 0 7 0 7

P 5.80 6.20 0.229 0.244

R 0.25 0.50 0.010 0.019

__

INCHESMILLIMETERS

____

12

MOTOROLA ANALOG IC DEVICE DATA

MC33364

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “T ypicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

MOTOROLA ANALOG IC DEVICE DATA

13

MC33364

How to reach us:

USA/EUROPE /Locations Not Listed: Motorola Literature Distribution; JAP AN: Nippon Motorola Ltd.: SPD, Strategic Planning Office, 4–32–1,

P.O. Box 5405, Denver, Colorado 80217. 1–303–675–2140 or 1–800–441–2447 Nishi–Gotanda, Shinagawa–ku, Tokyo 141, Japan. 81–3–5487–8488

Customer Focus Center: 1–800–521–6274

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 1–602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

Moto rola Fa x Back Syst em – US & Canada ONLY 1–800–774–1848 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

HOME PAGE: http://motorola.com/sps/

14

– http://sps.motorola.com/mfax/

◊

MOTOROLA ANALOG IC DEVICE DATA

Mfax is a trademark of Motorola, Inc.

MC33364/D

Loading...

Loading...