Device

Operating

Temperature Range

Package

SEMICONDUCTOR

TECHNICAL DATA

HIGH ENERGY

IGNITION CIRCUIT

ORDERING INFORMATION

MC3334P

MC3334D

TA = – 40° to +125°C

Plastic DIP

SO–8

Order this document by MC3334/D

P SUFFIX

PLASTIC PACKAGE

CASE 626

8

1

D SUFFIX

PLASTIC PACKAGE

CASE 751

(SO–8)

MCC3334 Chip

MCCF3334 Flip–Chip

1

MOTOROLA ANALOG IC DEVICE DATA

This device is designed to use the signal from a reluctor type ignition

pickup to produce a well controlled output from a power Darlington output

transistor.

• Very Low Peripheral Component Count

• No Critical System Resistors

• Wide Supply Voltage Operating Range (4.0 V to 24 V)

• Overvoltage Shutdown (30 V)

• Dwell Automatically Adjusts to Produce Optimum Stored Energy

without Waste

• Externally Adjustable Peak Current

• Available in Chip and Flip–Chip Form

• Transient Protected Inputs and Outputs

MAXIMUM RATINGS

Rating Symbol Value Unit

Power Supply Voltage–Steady State

Transient 300 ms or less

V

bat

24

90

V

Output Sink Current–Steady State

Transient 300 ms or less

I

O(Sink)

300

1.0

mA

A

Junction Temperature T

J(max)

150 °C

Operating Temperature Range T

A

–40 to +125 °C

Storage Temperature Range Tstg –65 to +150 °C

Power Dissipation, Plastic Package, Case 626

Derate above 25°C

P

D

1.25

10

W

mW/°C

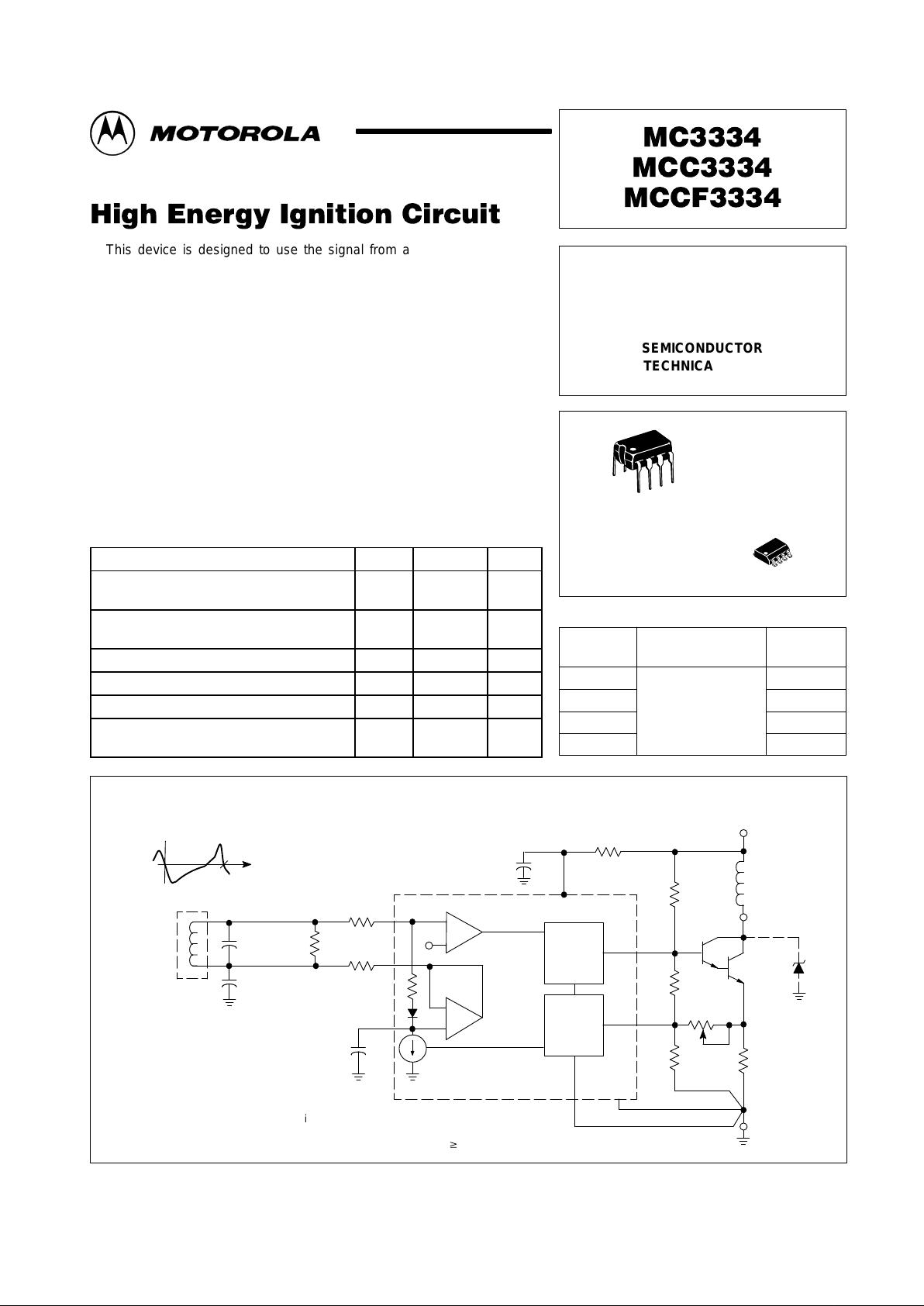

Figure 1. Block Diagram and Typical Application

**A 350 V zener clamp is required when using the standard MJ10012.

**This clamp is not required if a selected version with V

CEO(sus)

w 550 V is used.

*Optional parts for extended transient protection

+

+

–

–

Reluctor

Pickup

1.35H

V

t

s

t

C1*

470

C2*

0.01

R

A

20k

R

L

10k

R

B

20k

5

S1

S2

4

C

3

C

Dwell

0.1

C

Filter

0.1

Rbat

300

4.0 V

bat–

24 Vdc

Ignition

Coil

Primary

8.0mH

**MJ10012

R

Gain

5.0k

R

Drive

100

RS

0.075

R

D1

35–350

1

Power Ground

Sense

Ground

MC3334

VCC6

7

I

O

8

I

L

R

D2

100

Power

Output

& OVP

Current

Limit

Sense

Dwell

Reference

Buffer

Input

Comparator

with

Hysteresis

+

2

Motorola, Inc. 1996 Rev 0

MC3334 MCC3334 MCCF3334

2

MOTOROLA ANALOG IC DEVICE DATA

ELECTRICAL CHARACTERISTICS

(TA = –40° to +125°C, V

bat

= 13.2 Vdc, circuit of Figure 1, unless otherwise noted.)

Characteristics

Symbol Min Typ Max Unit

Internal Supply Voltage, Pin 6

V

bat

= 4.0 Vdc

V

bat

= 8.0 Vdc

V

bat

= 12.0

V

bat

= 14.0

V

CC

–

–

–

–

3.5

7.2

10.4

11.8

–

–

–

–

Vdc

Ignition Coil Current Peak, Cranking RPM 2.0 Hz to 27 Hz

V

bat

= 4.0 Vdc

V

bat

= 6.0

V

bat

= 8.0

V

bat

= 10.0

I

o(pk)

3.0

4.0

4.6

5.1

3.4

5.2

5.3

5.4

–

–

–

–

A pk

Ignition Coil Current Peak, Normal RPM

Frequency = 33 Hz

Frequency = 133 Hz

Frequency = 200 Hz

Frequency = 267 Hz

Frequency = 333 Hz

I

o(pk)

5.1

5.1

4.2

3.4

2.7

5.5

5.5

5.4

4.4

3.4

–

–

–

–

A pk

Ignition Coil On–Time, Normal RPM Range

Frequency = 33 Hz

Frequency = 133 Hz

Frequency = 200 Hz

Frequency = 267 Hz

Frequency = 333 Hz

t

on

–

–

–

–

–

7.5

5.0

4.0

3.0

2.3

14.0

5.9

4.6

3.6

2.8

ms

Shutdown Voltage V

bat

25 30 35 Vdc

Input Threshold (Static Test)

Turn–on

Turn–off

VS2–V

S1

–

–

360

90

–

–

mVdc

Input Threshold Hysteresis VS2–V

S1

75 – – mVdc

Input Threshold (Active Operation)

Turn–on

Turn–off

V

S2

–

–

1.8

1.5

–

–

Vdc

Total Circuit Lag from ts (Figure 1) until Ignition Coil Current Falls to 10% – 60 120 µs

Ignition Coil Current Fall Time (90% to 10%) – 4.0 – µs

Saturation Voltage IC Output (Pin 7) (R

DRIVE

= 100 Ω)

V

bat

= 10 Vdc

V

bat

= 30 Vdc

V

bat

= 50 Vdc

V

CE(sat)

–

–

–

120

280

540

–

–

–

mVdc

Current Limit Reference, Pin 8 V

ref

120 160 190 mVdc

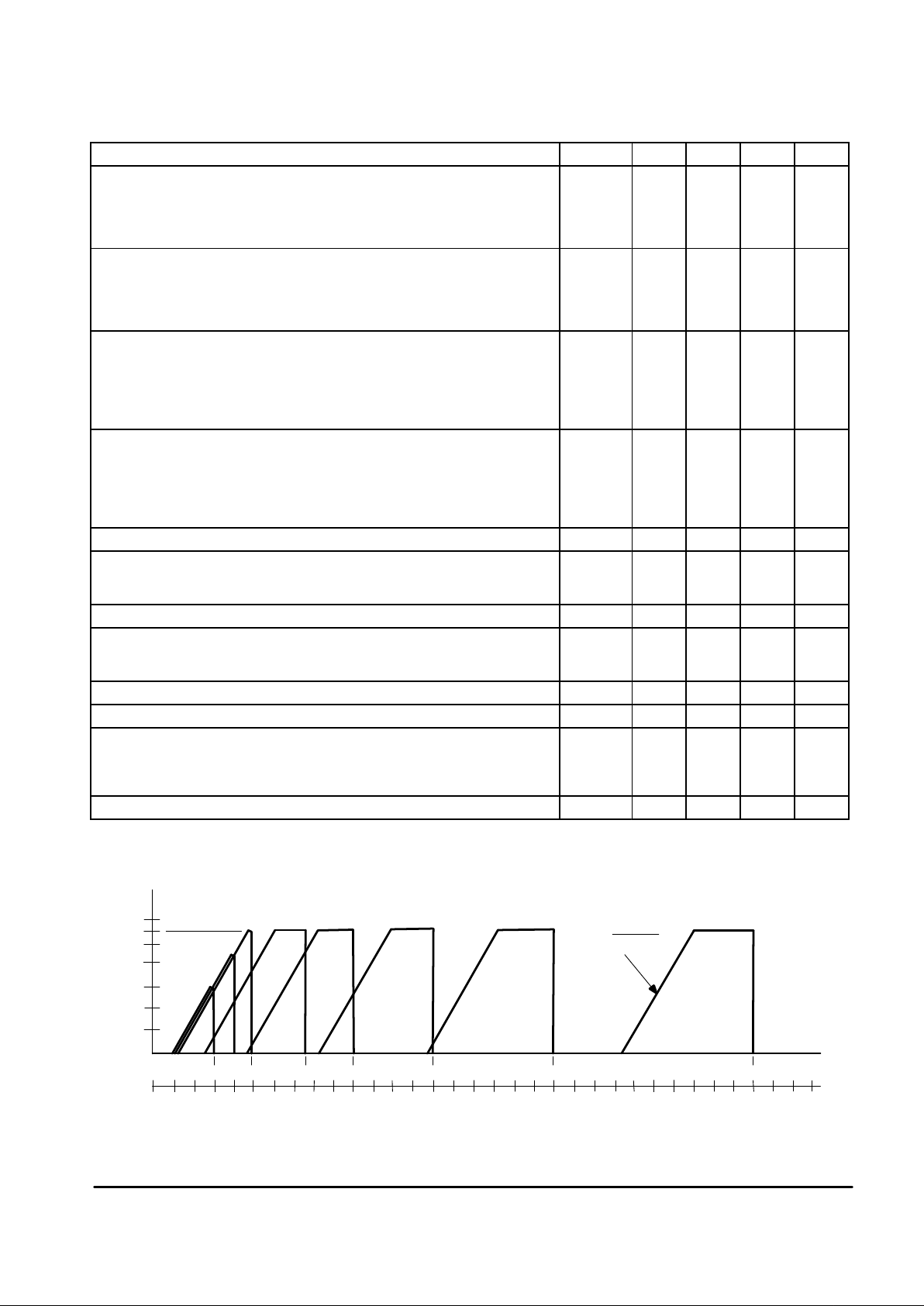

Figure 2. Ignition Coil Current versus Frequency/Period

333 200 133 100 70 50 33

1.0

2.0

3.0

4.0

5.0

6.0

5.5

0 5 10 15 20 25 30 ms

V

bat

= 13.2 Vdc

Slope =

V

bat

– 1.5 V

8.0 mH

I (A)

f, FREQUENCY (Hz)

O

MC3334 MCC3334 MCCF3334

3

MOTOROLA ANALOG IC DEVICE DATA

CIRCUIT DESCRIPTION

The MC3334 high energy ignition circuit was designed to

serve aftermarket Delco five–terminal ignition applications.

This device, driving a high voltage Darlington transistor, offers

an ignition system which optimizes spark energy at minimum

power dissipation. The IC is pinned–out to permit thick film or

printed circuit module design without any crossovers.

The basic function of an ignition circuit is to permit build–up

of current in the primary of a spark coil, and then to interrupt

the flow at the proper firing time. The resulting flyback action

in the ignition coil induces the required high secondary

voltage needed for the spark. In the simplest systems, fixed

dwell angle produces a fixed duty cycle, which can result in

too little stored energy at high RPM, and/or wasted power at

low RPM. The MC3334 uses a variable DC voltage

reference, stored on C

Dwell

, and buffered to the bottom end of

the reluctor pickup (S1) to vary the duty cycle at the spark

coil. At high RPM, the MC3334 holds the output “off” for

approximately 1.0 ms to permit full energy discharge from the

previous spark; then it switches the output Darlington

transistor into full saturation. The current ramps up at a slope

dictated by V

bat

and the coil L. At very high RPM the peak

current may be less than desired, but it is limited by the

coil itself.

As the RPM decreases, the ignition coil current builds up

and would be limited only by series resistance losses. The

MC3334 provides adjustable peak current regulation sensed

by RS and set by RD1, in this case at 5.5 A, as shown in

Figure 2. As the RPM decreases further, the coil current is

held at 5.5 A for a short period. This provides a reserve for

sudden acceleration, when discharge may suddenly occur

earlier than expected. The peak hold period is about 20% at

medium RPM, decreasing to about 10% at very low RPM.

(Note: 333 Hz = 5000 RPM for an eight cylinder four stroke

engine.) At lower V

bat

, the “on” period automatically stretches

to accommodate the slower current build–up. At very low V

bat

and low RPM, a common condition during cold starting, the

“on” period is nearly the full cycle to permit as much coil

current as possible.

The output stage of the IC is designed with an OVP circuit

which turns it on at V

bat

≈ 30 V (VCC ≈ 22 V), holding the

output Darlington off. This protects the IC and the Darlington

from damage due to load dump or other causes of

excessive V

bat

.

Component Values

Pickup – series resistance = 800 Ω ± 10% @ 25°C

inductance = 1.35 H @ 1.0 kHz @ 15 Vrms

Coil – leakage L = 0.6 mH

primary R = 0.43 Ω ± 5% @ 25°C

primary L = 7.5 mH to 8.5 mH @ 5.0 A

R

L

– load resistor for pickup = 10 kΩ ± 20%

RA, RB– input buffer resistors provide additional

transient protection to the already clamped

inputs = 20 k ± 20%

C1, C2 – for reduction of high frequency noise and

spark transients induced in pick–up and

leads; optional and non–critical

R

bat

– provides load dump protection (but small

enough to allow operation at V

bat

= 4.0 V)

= 300 Ω ± 20%

C

Filter

– transient filter on VCC, non–critical

C

Dwell

– stores reference, circuit designed for 0.1 µF

± 20%

R

Gain

–R

Gain/RD1

sets the DC gain of the current

regulator = 5.0 k ± 20%

R

D2

–RD2/RD1 set up voltage feedback from R

S

R

S

– sense resistor (PdAg in thick film techniques)

= 0.075 Ω ± 30%

R

Drive

– low enough to supply drive to the output

Darlington, high enough to keep V

CE(sat)

of

the IC below Darlington turn–on during load

dump = 100 Ω ± 20%, 5.0 W

R

D1

– starting with 35 Ω assures less than 5.5 A,

increasing as required to set 5.5 A

RD1 =

– (≈ 100 Ω)

I

O(pk) RS–Vref

V

ref

R

D2RGain

1.4

–

General Layout Notes

The major concern in the substrate design should be to

reduce ground resistance problems. The first area of concern

is the metallization resistance in the power ground to module

ground and the output to the R

drive

resistor. This resistance

directly adds to the V

CE(sat)

of the IC power device and if not

minimized could cause failure in load dump. The second

concern is to reference the sense ground as close to the

ground end of the sense resistor as possible in order to

further remove the sensitivity of ignition coil current to ground

I.R. drops.

All versions were designed to provide the same pin–out

order viewed from the top (component side) of the board or

substrate. This was done to eliminate conductor

cross–overs. The standard MC3334 plastic device is

numbered in the industry convention, counter–clockwise

viewed from the top, or bonding pad side. The MCCF3334

“flip” or “bump” chip is made from reversed artwork, so it is

numbered clockwise viewed from its bump side. Since this

chip is mounted face down, the resulting assembly still has

the same counter–clockwise order viewed from above the

component surface. All chips have the same size and

bonding pad spacing. See Figure 4 for dimensions.

MC3334 MCC3334 MCCF3334

4

MOTOROLA ANALOG IC DEVICE DATA

Figure 3. Internal Schematic

Charge

Up

Charge

Down

Dwell

Reference

Buffer

X

V

CC

2.0

φ

2.0

φ

4

S1

3

C

5

S2

Input

Comparator

with

Hysteresis

5.2V

5.2V

5.2V

5.2V

6V

CC

14V

Simplified

Internal

Power

Supply

Output

Stage

with OVP

and

Current

Limiting

2

Sense

Ground

1

Power

Ground

8

I

L

7

Out

21V

X

V

CC

2.0

φ

2.0

φ

Figure 4. MCCF3334 Ignition Circuit Bump Side View

+

+

++

++++

S2

5

V

CC

6

Out

7

I

L

8

(8) Bumps 7 ± 1 Mil Dia.

raised minimum 0.5 Mils

above passivated chip surface

Sense

Ground

Power

Ground

20 Mils 20 Mils 20 Mils

50

Mils

66

±

2

Mils

76

±

2 Mils

1234

5.5

±

1

6

+1

S1

C

MC3334 MCC3334 MCCF3334

5

MOTOROLA ANALOG IC DEVICE DATA

P SUFFIX

PLASTIC PACKAGE

CASE 626–05

ISSUE K

D SUFFIX

PLASTIC PACKAGE

CASE 751–05

(SO–8)

ISSUE N

OUTLINE DIMENSIONS

14

58

F

NOTE 2

–A–

–B–

–T–

SEATING

PLANE

H

J

G

D

K

N

C

L

M

M

A

M

0.13 (0.005) B

M

T

NOTES:

1. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

2. PACKAGE CONTOUR OPTIONAL (ROUND OR

SQUARE CORNERS).

3. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

DIM MIN MAX MIN MAX

INCHESMILLIMETERS

A 9.40 10.16 0.370 0.400

B 6.10 6.60 0.240 0.260

C 3.94 4.45 0.155 0.175

D 0.38 0.51 0.015 0.020

F 1.02 1.78 0.040 0.070

G 2.54 BSC 0.100 BSC

H 0.76 1.27 0.030 0.050

J 0.20 0.30 0.008 0.012

K 2.92 3.43 0.115 0.135

L 7.62 BSC 0.300 BSC

M ––– 10 ––– 10

N 0.76 1.01 0.030 0.040

__

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

SEATING

PLANE

14

58

C

K

4X P

A0.25 (0.010)MTB

SS

0.25 (0.010)MB

M

8X D

R

M

J

X 45

_

_

F

–A–

–B–

–T–

DIM MIN MAX MIN MAX

INCHESMILLIMETERS

A 4.80 5.00 0.189 0.196

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.054 0.068

D 0.35 0.49 0.014 0.019

F 0.40 1.25 0.016 0.049

G 1.27 BSC 0.050 BSC

J 0.18 0.25 0.007 0.009

K 0.10 0.25 0.004 0.009

M 0 7 0 7

P 5.80 6.20 0.229 0.244

R 0.25 0.50 0.010 0.019

____

G

MC3334 MCC3334 MCCF3334

6

MOTOROLA ANALOG IC DEVICE DATA

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that Motorola

was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 or 602–303–5454 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 03–81–3521–8315

MFAX: RMF AX0@email.sps.mot.com – TOUCHT ONE 602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET.com 51 Ting Ko k Road, Tai Po, N.T., Hong Kong. 852–26629298

MC3334/D

*MC3334/D*

◊

Loading...

Loading...