Datasheet MC33348D-6, MC33348D-4, MC33348D-5, MC33348D-3, MC33348D-1 Datasheet (Motorola)

...

The MC33348 is a monolithic lithium battery protection circuit that is

designed to enhance the useful operating life of a one cell rechargeable

battery pack. Cell protection features consist of internally trimmed charge

and discharge voltage limits, discharge current limit detection with a

delayed shutdown, and a virtually zero current sleepmode state when the

cell is discharged. An additional feature includes an on–chip charge pump

for reduced MOSFET losses while charging or discharging a low cell

voltage battery pack. This protection circuit requires a minimum number of

external components and is targeted for inclusion within the battery pack.

This MC33348 is available in standard SOIC 8 lead surface mount

package.

• Internally Trimmed Charge and Discharge Voltage Limits

• Discharge Current Limit Detection with Delayed Shutdown

• Virtually Zero Current Sleepmode State when Cells are Discharged

• Charge Pump for Reduced Losses with a Low Cell Voltage Battery Pack

• Dedicated for One Cell Applications

• Minimum Components for Inclusion within the Battery Pack

• Available in a Low Profile Surface Mount Package

Order this document by MC33348/D

LITHIUM BATTERY

PROTECTION CIRCUIT

FOR

ONE CELL

SMART BATTERY PACKS

SEMICONDUCTOR

TECHNICAL DATA

8

1

Ordering Information shown on following page.

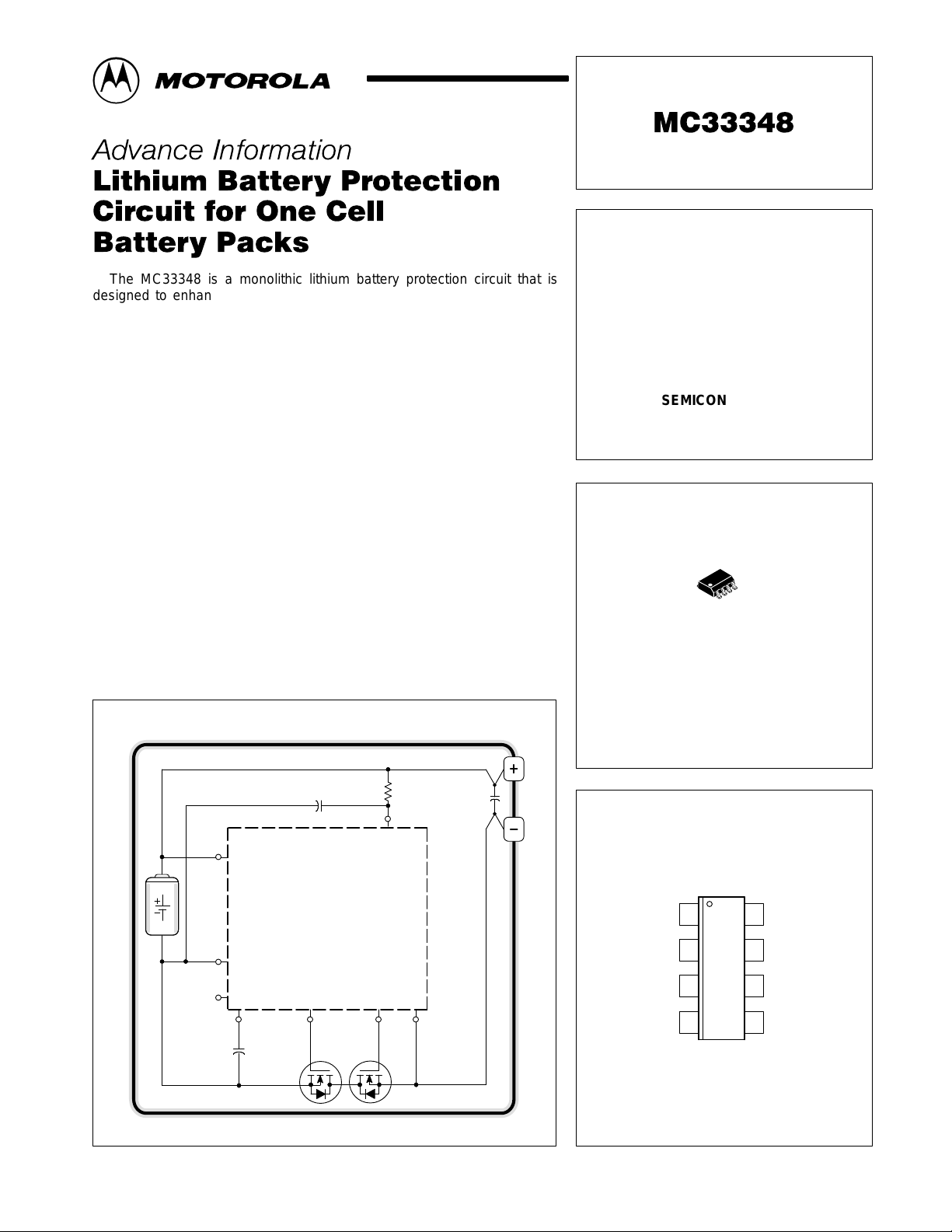

Typical One Cell Smart Battery Pack

Cell

Voltage

1

MC33348

Ground

3

T est

2

Charge Pump

8 Charge

Output

Discharge

Gate Drive

Output

4 6 5 Charge

Gate Drive

Output

7

V

CC

Gate Drive

Common/

Discharge

Current Limit

PLASTIC PACKAGE

PIN CONNECTIONS

Cell Voltage

Test

Ground

Discharge Gate

Drive Output

D SUFFIX

CASE 751

(SO–8)

18

2

3

4

(Top View)

Charge Pump

Output

V

7

CC

Charge Gate

6

Drive Output

Charge Gate Drive

5

Common/Discharge

Current Limit

This device contains 1170 active transistors.

This document contains information on a new product. Specifications and information herein

are subject to change without notice.

MOTOROLA ANALOG IC DEVICE DATA

Motorola, Inc. 1997 Rev 1

1

MC33348

4.20

2.25

4.25

300

2.28

T

25° to +85°C

SO–8

4.35

2.30

ORDERING INFORMATION

Charge

Overvoltage

Device

MC33348D–1

MC33348D–2

MC33348D–3

MC33348D–4

MC33348D–5

MC33348D–6

NOTE: Additional threshold limit options can be made available. Consult factory for information.

Threshold (V)

MAXIMUM RATINGS

Ratings Symbol Value Unit

Input Voltage (Measured with Respect to Ground, Pin 3)

Cell Voltage (Pin 1) 7.5

Test (Pin 2) 7.5

Discharge Gate Drive Output (Pin 4) 18

Charge Gate Drive Common/Discharge Current Limit (Pin 5) ±11

Charge Gate Drive Output (Pin 6) ±11

VCC (Pin 7) 7.5

Charge Pump Output (Pin 8) 10

Thermal Resistance, Junction–to–Air

D Suffix, SO–8 Plastic Package, Case 751 178

Operating Junction Temperature (Note 1)

Storage Temperature

NOTES: 1. Tested ambient temperature range for the MC33348:

T

= –25°CT

low

2.ESD data available upon request.

Charge

Overvoltage

Hysteresis (mV)

= +85°C

high

Discharge

Undervoltage

Threshold (V)

V

IR

R

θJA

T

J

T

stg

Discharge

Current Limit

Threshold (mV)

–40 to +150

–55 to +150

400

200

400

200

400

200

Operating

Temperature Range

–

= –

A

V

°C/W

°C

°C

Package

°

°

–

2

MOTOROLA ANALOG IC DEVICE DATA

MC33348

ÁÁÁÁ

ÁÁÁ

ÁÁÁÁ

ÁÁÁ

ÁÁÁÁ

ÁÁÁ

ÁÁÁÁ

ÁÁÁ

ÁÁÁÁ

ÁÁÁ

ÁÁÁÁ

ÁÁÁ

Á

ÁÁÁÁ

Á

Á

ÁÁÁ

Á

ÁÁÁÁ

ÁÁÁ

ELECTRICAL CHARACTERISTICS (V

= 4.0 V, TA = 25°C, for min/max values TA is the operating junction temperature range

CC

that applies (Note 1), unless otherwise noted.)

Characteristic

Symbol Min Typ Max Unit

VOLTAGE SENSING

Cell Charging Cutoff (Pin 1 to Pin 3)

Overvoltage Threshold, V

Increasing, TA = 25°C V

Cell

th(OV)

–1 Suffix 4.158 4.20 4.242

–2 Suffix 4.158 4.20 4.242

–3 Suffix 4.208 4.25 4.293

–4 Suffix 4.208 4.25 4.293

–5 Suffix 4.306 4.35 4.394

–6 Suffix 4.306 4.35 4.394

Overvoltage Hysteresis V

Decreasing V

Cell

H

–1 Suffix – 300 –

–2 Suffix – 300 –

–3 Suffix – 300 –

–4 Suffix – 300 –

–5 Suffix – 300 –

–6 Suffix – 300 –

Cell Discharging Cutoff (Pin 1 to Pin 3, TA = 25°C)

Undervoltage Threshold, V

Decreasing V

Cell

th(UV)

–1 Suffix 2.205 2.25 2.295

–2 Suffix 2.205 2.25 2.295

–3 Suffix 2.234 2.28 2.326

–4 Suffix 2.234 2.28 2.326

–5 Suffix 2.254 2.30 2.346

–6 Suffix 2.254 2.30 2.346

Input Bias Current During Cell Voltage Sample (Pin 1)

Cell Voltage Sampling Rate

I

IB

t

(smpl)

–

–

28

1.0

–

–

CURRENT SENSING

Discharge Current Limit (Pin 3 to Pin 5, TA = 25°C)

Threshold Voltage V

th(dschg)

–1 Suffix 360 400 440

–2 Suffix 180 200 220

–3 Suffix 360 400 440

–4 Suffix 180 200 220

–5 Suffix 360 400 440

–6 Suffix 180 200 220

Delay I

dly(dschg)

1.0 2.3 4.0 ms

CHARGE PUMP

Output Voltage (Pin 8, RL ≥ 1010, TA = 25°C)

V

O

8.0

10.2

12

TOTAL DEVICE

Average Cell Current (TA = 25°C, Battery Pack Unloaded and without

БББББББББББББББББ

Current Limit Fault)

I

CC

ÁÁÁ

ÁÁÁÁÁÁÁÁÁ

Operating (VCC = 4.0 V) – 17 20 µA

Sleepmode (VCC = 2.0 V) – 2.0 – nA

Minimum Operating Cell Voltage for Logic and Gate Drivers

NOTE: 1.Tested ambient temperature range for the MC33348:

T

= –25°CT

low

high

= +85°C

V

CC

–

1.5

–

V

mV

V

µA

s

mV

V

ÁÁ

V

MOTOROLA ANALOG IC DEVICE DATA

3

MC33348

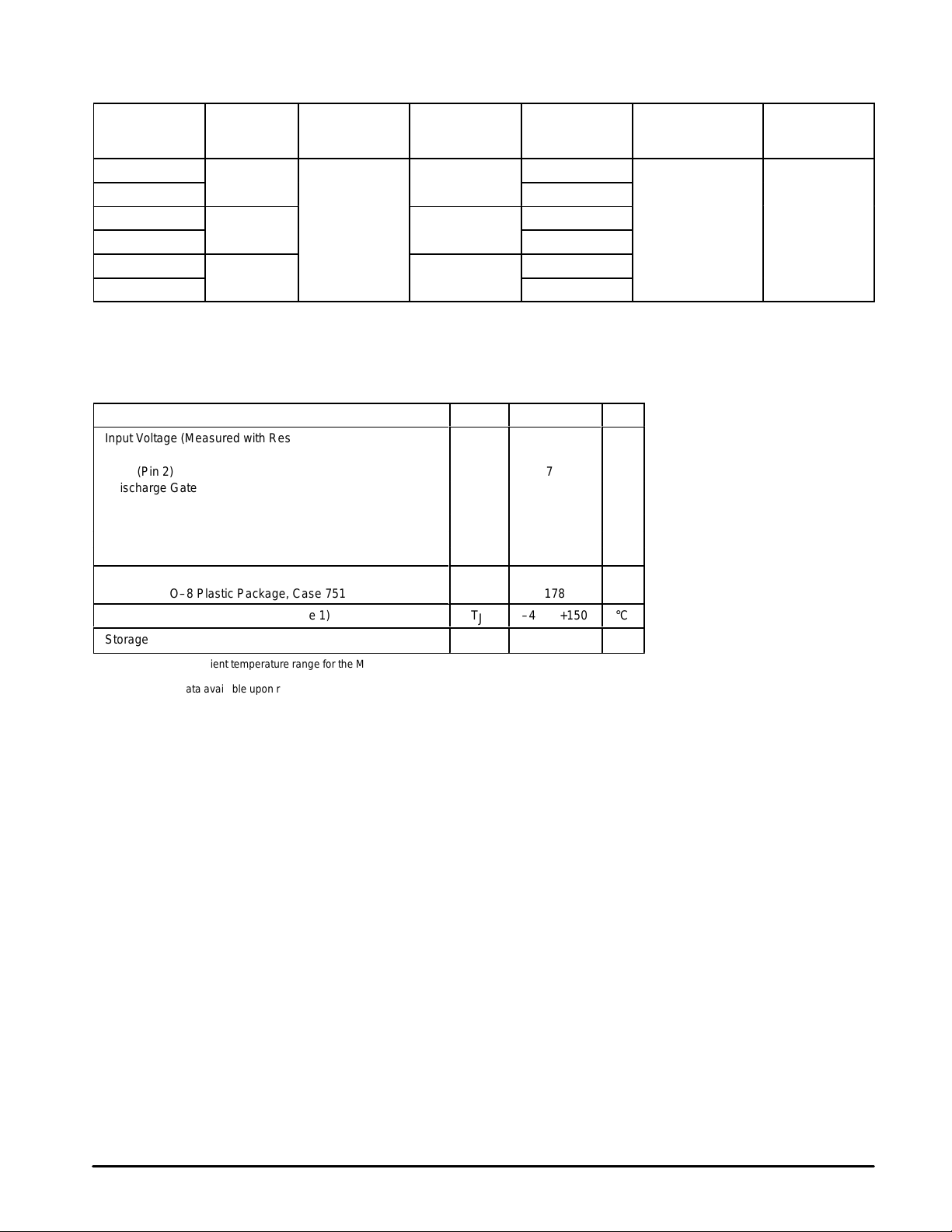

Figure 1. Charge and Discharge

Threshold V oltage Change versus Temperature

1.2

0.8

Maximum Threshold

0.4

0

Typical Threshold Change Typical Threshold Change

Charge Limits

–0.4

, THRESHOLD VOLTAGE CHANGE (%)

–0.8

–1.2

th(OV & UV)

V

∆

TA, AMBIENT TEMPERATURE (°C) TA, AMBIENT TEMPERATURE (°C)

Figure 3. Gate Drive Output Voltage

12

10

versus Load Current

CO = 10 nF

°

C

TA = 25

Figure 2. Discharge Current Limit

Threshold V oltage Change versus Temperature

16

VCC = 4.0 V

8.0

0

, CURRENT LIMIT THRESHOLD

–8.0

VOLTAGE CHANGE (%)

th(dschg)

–16

V

∆

1004020–20–40 0 60 80 1004020–20–40 0 60 80

Figure 4. Gate Drive Output Voltage

12

10

CO = 10 nF

Pin 2 = Gnd

RL ≥ 1010

TA = 25°C

versus Supply V oltage

Ω

8.0

6.0

, GATE DRIVE OUTPUT VOLTAGE (V)

O

V

4.0

12

11

10

9.0

, CHARGE PUMP OUTPUT VOL TAGE (V)

O

V

8.0

VCC = 4.15 V

VCC = 3.25 V

VCC = 2.35 V

IL, OUTPUT LOAD CURRENT (µA) VCC, SUPPLY VOLTAGE (V)

Figure 5. Charge Pump Output Voltage

versus T emperature

CO = 10 nF

≥

1010

RL

VCC = 4.15 V

In Regulation

VCC = 2.35 V

Out of Regulation

8.0

6.0

, GATE DRIVE OUTPUT VOLTAGE (V)

O

V

1.00.80.60.20 0.4

4.0

4.0

5.01.00 2.0 3.0

Figure 6. Supply Current

2

10

Battery Pack Sleepmode Range

1

Ω

1004020–20–40 0 60 80

10

µ

0

10

–1

10

–2

10

, SUPPLY CURRENT ( A)

CC

I

–3

10

–4

10

0 1.0 2.0 3.0 5.0

versus Supply V oltage

Battery Pack Operating Range

123

1 – Battery pack unloaded without

discharge current limit fault.

2 – Battery pack loaded without

discharge current limit fault.

3 – Battery pack loaded or unloaded

with discharge current limit fault.

VCC, SUPPLY VOLTAGE (V)TA, AMBIENT TEMPERATURE (°C)

TA = 25°C

4.0

4

MOTOROLA ANALOG IC DEVICE DATA

MC33348

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

PROTECTION CIRCUIT OPERATING MODE TABLE

Outputs

MOSFET Switches

Input Conditions

БББББББ

Cell Status

БББББББББББББББ

Circuit Operation

Battery Pack Status

Charge

Q1

DischargeQ2Charge

ÁÁ

CELL CHARGING/DISCHARGING

Storage or Nominal Operation:

No current or voltage faults

БББББББ

Both Charge MOSFET Q1 and Discharge MOSFET Q2 are on.

The battery pack is available for charging or discharging.

БББББББББББББББ

ÁÁOnÁÁOnÁÁ

CELL CHARGING FAULT/RESET

Charge Voltage Limit Fault:

БББББББ

V

≥ V

Pin 1

БББББББ

БББББББ

th(OV)

for 1.0 s

Charge Voltage Limit Reset:

V

< (V

Pin 1

БББББББ

for 1.0 s

БББББББ

th(OV)

– VH)

Charge MOSFET Q1 is latched off and the cell is disconnected

БББББББББББББББ

from the charging source. An internal current source pull–up is

applied to divider resistors R1 and R2 creating a hysteresis

БББББББББББББББ

voltage of VH. The battery pack is available for discharging.

БББББББББББББББ

Discharge current limit protection is disabled.

Charge MOSFET Q1 will turn on when the voltage across the cell

falls sufficiently to overcome hysteresis voltage VH. This can be

БББББББББББББББ

accomplished by applying a load to the battery pack. Discharge

БББББББББББББББ

current limit protection is enabled.

On to Off

ÁÁ

ÁÁ

ÁÁ

Off to On

ÁÁ

ÁÁ

On

ÁÁ

ÁÁ

ÁÁ

On

ÁÁ

ÁÁ

CELL DISCHARGING FAULT/RESET

Discharge Current Limit Fault:

V

≥ (V

Pin 5

БББББББ

for 3.0 ms and

V

БББББББ

БББББББ

БББББББ

БББББББ

< (V

Pin 1

for 1.0 ms

Discharge Current Limit Reset:

V

– V

Pin 5

Pin 3

th(OV)

Pin 3

+ V

– VH)

< V

th(dschg)

th(dschg)

Discharge Voltage Limit Fault:

V

≤ V

Pin 1

БББББББ

consecutive 1.0 s samples

th(UV)

for three

Discharge Voltage Limit Reset:

БББББББ

V

> (V

Pin 3

БББББББ

FAULTY CELL

ББББББББББББББББББББББББББББББББ

Discharge Voltage Limit Fault:

БББББББ

V

≤ 1.5 V

Pin 1

БББББББ

Pin 5

+ 0.6 V)

Discharge MOSFET Q2 is latched off and the cell is

)

disconnected from the load. Q2 will remain in the off state as long

БББББББББББББББ

as V

available for charging.

БББББББББББББББ

The Sense Enable circuit will reset and turn on discharge

БББББББББББББББ

MOSFET Q2 when V

≈ V

БББББББББББББББ

the load from the battery pack, or by connecting the battery pack

БББББББББББББББ

to the charger.

exceeds V

Pin 5

th(dschg)

by ≈ V

Pin 3

Pin 3

. This can be accomplished by either disconnecting

th(dschg)

no longer exceeds V

. The battery pack is

by

Pin 5

Discharge MOSFET Q2 is latched off, the cells are disconnected

from the load, and the protection circuit enters a low current

БББББББББББББББ

sleepmode state. The battery pack is available for charging.

The Sense Enable circuit will reset and turn on discharge

БББББББББББББББ

MOSFET Q2 when V

accomplished by connecting the battery pack to the charger.

БББББББББББББББ

This condition can happen if the cell is defective (<1.5 V). The

БББББББББББББББ

protection circuit logic will not function and the battery pack

cannot be charged.

БББББББББББББББ

Pin 3

exceeds V

by 0.6 V. This can be

Pin 5

On

ÁÁ

ÁÁ

On

ÁÁ

ÁÁ

ÁÁ

On

ÁÁ

On

ÁÁ

ÁÁ

Disabled

ÁÁ

ÁÁ

On to Off

ÁÁ

ÁÁ

Off to On

ÁÁ

ÁÁ

ÁÁ

On to Off

ÁÁ

Off to On

ÁÁ

ÁÁ

Disabled

ÁÁ

ÁÁ

Function

Pump

Active

Active

ÁÁ

ÁÁ

ÁÁ

Active

ÁÁ

ÁÁ

Active

ÁÁ

ÁÁ

Active

ÁÁ

ÁÁ

ÁÁ

Disabled

ÁÁ

Active

ÁÁ

ÁÁ

Disabled

ÁÁ

ÁÁ

MOTOROLA ANALOG IC DEVICE DATA

5

MC33348

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

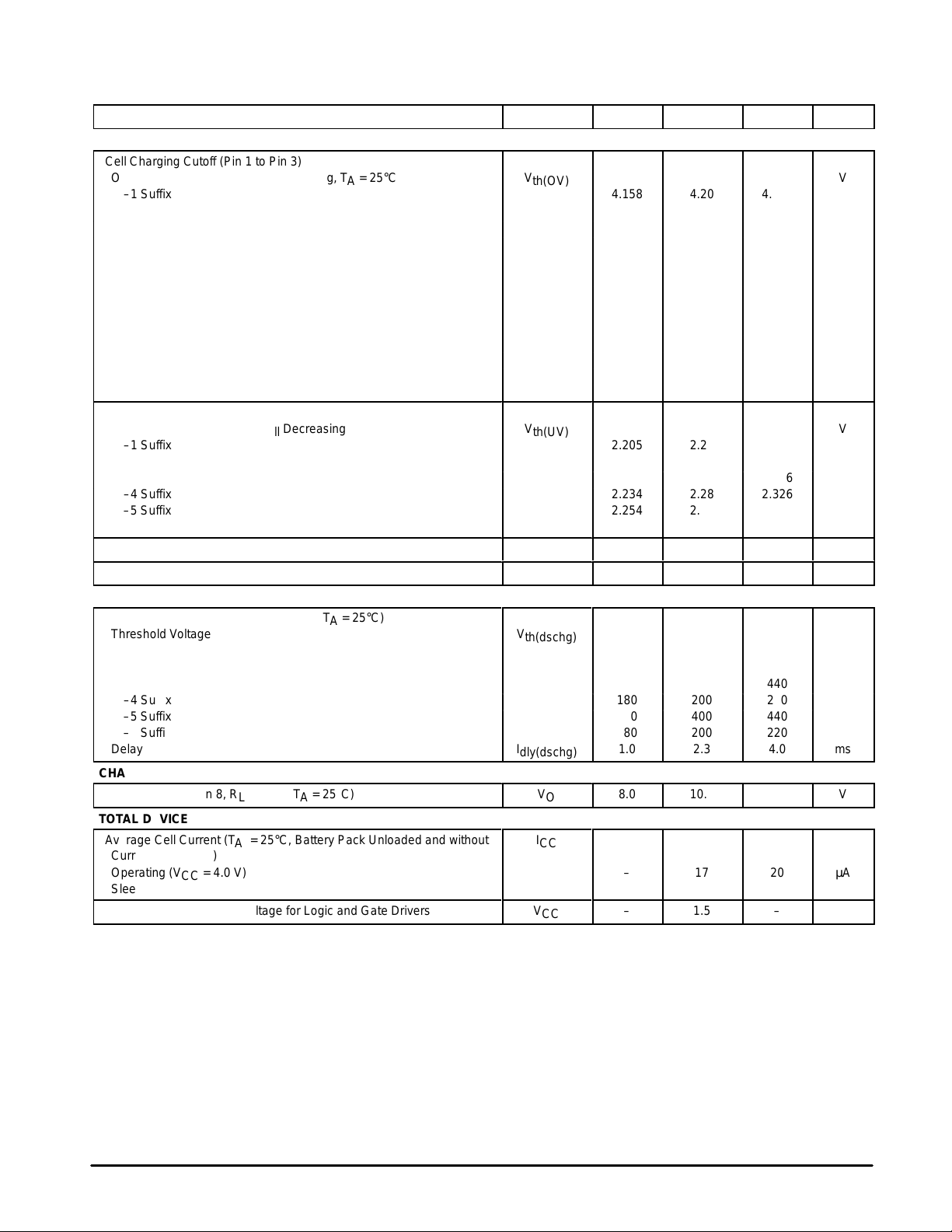

Figure 7. One Cell Smart Battery Pack

Cell

Cell

Voltage

1

Ground

3

Test

2

Charge Pump

MC33348

Cell Voltage

Sample

Switch

2.0 k

Ck

Oscillator

Ck

En

Charge Pump

8 Charge

C

O

Discharge

Gate Drive

Output

Discharge

Switch Q2

Output

0.01

10

Over/Under

Cell Voltage

Detector

&

Reference

Discharge

Over/Under

Data Latch

Overcurrent

Detector

&

Control Logic

Sense

Enable

Charge/Discharge

Gate Drivers

4 6 5 Charge

Gate Drive

Output

Charge

Switch

Q1

Gate Drive

Common/

Discharge

Current Limit

5.1 k

R1

R2

R3

7VCC

C

0.1

I

1.0 M

Components CI is mandatory. Refer to the Battery Pack Application text.

PIN FUNCTION DESCRIPTION

Pin Symbol Description

1

Cell Voltage

Á

Á

Á

Á

БББББ

БББББ

2

Test

БББББ

3

Ground

4

Discharge Gate Drive

Output

БББББ

5

Charge Gate Drive

Common/Discharge

Á

Á

Á

БББББ

Current Limit

БББББ

6

Charge Gate Drive

БББББ

Output

7

V

CC

8

Charge Pump Output

This input is connected to the positive terminal of the cell for voltage monitoring. Internally, the Cell

ББББББББББББББББББББББББ

Voltage Sample Switch applies this voltage to a resistor divider where it is compared by the Cell Voltage

Detector to an internal reference.

ББББББББББББББББББББББББ

This pin is normally not connected and is used in testing the protection IC. An active low at this input

resets the internal logic and turns on both MOSFET switches. Upon release, the logic becomes active and

ББББББББББББББББББББББББ

the cell voltage is sampled within 1.0 ms.

This is the protection IC ground and all voltage ratings are with respect to this pin.

This output connects to the gate of discharge switch Q2 allowing it to enable or disable battery pack

discharging.

ББББББББББББББББББББББББ

This is a multifunction pin that is used to monitor cell discharge current and to provide a gate turn–off

path for charge switch Q1. A discharge current limit fault is set when the battery pack load causes the

ББББББББББББББББББББББББ

combined voltage drop of charge switch Q1 and discharge switch Q2 to exceed the discharge current limit

threshold voltage, V

ББББББББББББББББББББББББ

This output connects to the gate of charge switch Q1 allowing it to enable or disable battery pack

ББББББББББББББББББББББББ

charging.

th(dschg)

, with respect to Pin 3.

This pin is the positive supply voltage for the protection IC.

This is the charge pump output. A reservoir capacitor is connected from this pin to ground.

6

MOTOROLA ANALOG IC DEVICE DATA

MC33348

ББББББ

ББББББ

INTRODUCTION

The insatiable demand for smaller lightweight portable

electronic equipment has dramatically increased the

requirements of battery performance. Batteries are expected

to have higher energy densities, superior cycle life, be safe in

operation and environmentally friendly. To address these

high expectations, battery manufacturers have invested

heavily in developing rechargeable lithium–based cells.

Today’s most attractive chemistries include lithium–polymer,

lithium–ion, and lithium–metal. Each of these chemistries

require electronic protection in order to constrain cell

operation to within the manufacturers limits.

Rechargeable lithium–based cells require precise charge

and discharge termination limits for both voltage and current

in order to maximize cell capacity, cycle life, and to protect

the end user from a catastrophic event. The termination limits

are not as well defined as with older non–lithium chemistries.

These limits are dependent upon a manufacturer’s particular

lithium chemistry, construction technique, and intended

application. Battery pack assemblers may also choose to

enhance cell capacity at the expense of cycle life. In order to

address these requirements, six versions of the MC33348

protection circuit were developed. These devices feature

charge overvoltage protection, discharge current limit

protection with delayed shutdown, low operating current, a

virtually zero current sleepmode state, and requires few

external components to implement a complete one cell smart

battery pack.

Operating Description

The MC33348 is specifically designed to be placed in the

battery pack where it is continuously powered from a single

lithium cell. In order to maintain cell operation within specified

limits, the protection circuit senses both cell voltage and

discharge current, and correspondingly controls the state of

two N–channel MOSFET switches. These switches, Q1 and

Q2, are placed in series with the negative terminal of the Cell

and the negative terminal of the battery pack. This

configuration allows the protection circuit to interrupt the

appropriate charge or discharge path FET in the event that

either a voltage threshold or the discharge current limit for the

cell has been exceeded.

Figure 8. One Cell Smart Battery Pack

A functional description of the protection circuit blocks

follows. Refer to the detailed block diagram shown in

Figure 7.

Voltage Sensing

Voltage sensing is accomplished by the use of the Cell

Voltage Sample Switch in conjunction with the Over/Under

Voltage Detector and Reference block. The Sample Switch

applies the cell voltage to the top resistor of an internal

divider string. The voltage at each of the tap points is

sequentially polled and compared to an internal reference. If

a limit has been exceeded, the result is stored in the

Over/Under Data Latch and Control Logic block. The Cell

Voltage Sample Switch is gated on for a 1.0 ms period at a

one second repetition rate. This low duty cycle sampling

technique reduces the average load current that the divider

presents across the cell, thus extending the useful battery

pack capacity. The cell voltage limits are tested in the

following sequence:

Figure 9. Cell Sensing Sequence

Polling

Sequence

БББББ1ÁÁÁÁ

БББББ2ÁÁÁÁ

Time

(ms)

0.5

0.5

Tested

Limit

Overvoltage

БББББ

Undervoltage

БББББ

By incorporating this polling technique with a single

comparator and voltage divider, a significant reduction of

circuitry and trim elements is achieved. This results in a

smaller die size, lower cost, and reduced operating current.

Figure 10. Cell V oltage Limit Sampling

From

Cell Voltage

Sample Switch

Over/Under

Cell Voltage

Detector

&

Reference

To

Cell Negative

Terminal

Cell Voltage

Discharge Voltage

Threshold

Charge Voltage

Threshold

Cell Voltage

Return

R1

R2

R3

+

Cell

Voltage

–

MOTOROLA ANALOG IC DEVICE DATA

Cell

1

3

84 65

Discharge

MOSFET Q2

MC33348

7

Charge

MOSFET Q1

The cell charge and discharge voltage limits are controlled

by the values selected for the internal resistor divider string

and the comparator input threshold. As the battery pack

reaches full charge, the Cell Voltage Detector will sense an

overvoltage fault condition when the cell exceeds the

designed overvoltage limit. The fault information is stored in

a data latch and charge MOSFET Q1 is turned off,

disconnecting the battery pack from the charging source. An

internal current source pull–up is then applied to lower tap of

the divider, creating a hysteresis voltage. As a result of an

overvoltage fault, the battery pack is available for

discharging only .

The overvoltage fault is reset by applying a load to the

battery pack. As the voltage across the cell falls below the

hysteresis level, charge MOSFET Q1 will turn on and the

current source pull–up will turn off. The battery pack will now

be available for charging or discharging.

7

MC33348

Á

Á

Á

Á

As the load eventually depletes the battery pack charge,

the Cell Voltage Detector will sense an undervoltage fault

condition when the cell falls below the designed undervoltage

limit. After three consecutive faults are detected, discharge

MOSFET Q2 is turned off, disconnecting the battery pack

from the load. The protection circuit will now enter a low

current sleepmode state. Refer to Figure 6. As a result of the

undervoltage fault, the battery pack is available for charging

only . The typical cutof f thresholds and hysteresis voltage are

shown in Figure 1 1.

Figure 11. Cutoff and Hysteresis Limits

Device

ÁÁ

Suffix

–1, –2

–3, –4

–5, –6

Charging

Cutoff

ÁÁÁ

(V)

4.20

4.25

4.35

Hysteresis

ÁÁÁÁ

(mV)

300

300

300

The undervoltage logic is designed to automatically reset

if less than three consecutive faults appear. This helps to

prevent a premature disconnection of the load during high

current pulses when the battery pack charge is close to

being depleted.

The undervoltage fault is reset by applying charge current

to the battery pack. When the voltage on Pin 3 exceeds Pin 5

by 0.6 V, discharge MOSFET Q2 will turn on. The battery

pack will now be available for charging or discharging.

Figure 12. Additional Discharge Current Limit Delay

Disharging

Cutoff

ÁÁÁ

(V)

2.25

2.28

2.30

Current Sensing

Discharge current limit protection is internally provided by

the MC33348. As the battery pack discharges, Pins 5 and 3

sense the voltage drop across MOSFETs Q1 and Q2. A

discharge current limit fault is detected if the voltage at Pin 5

is greater than Pin 3 by 400 mV for –1, –3 and –5 suffix

devices, or 200 mV for –2, –4 and –6 suffix devices. The fault

information is stored in a data latch and discharge MOSFET

Q2 is turned off, disconnecting the battery pack from the load.

As a result of the discharge current fault, the battery pack is

available for charging only. The discharge current limit is

given by:

I

Lim(dschg)

+

V

R

th(dschg)

Lim(dschg)

+

R

V

th(dschg)

DS(on)Q1

)

R

DS(on)Q2

The discharge current fault is reset by either disconnecting

the load from the battery pack, or by connecting the battery

pack to the charger. When the voltage on Pin 5 no longer

exceeds Pin 3 by approximately V

th(dschg)

, the Sense Enable

circuit will turn on discharge MOSFET Q2.

Figure 13. Power Supply Decoupling

C

10

1

Cell

R

5.1 k

7

MC33348

3

84 65

C

dly

R

dly

The discharge current limit shutdown delay time is typically

3.0 ms. This time can be extended with the addition of

components R

dly

and C

. With an R

dly

of 5.1 k and C

dly

dly

of 10

µF, the current limit shutdown time is extended to 40 ms.

The additional discharge current limit delay circuitry must

not be used if the anticipated open–circuit charger voltage

will exceed 6.0 V. When the charger causes the battery pack

input to exceed 6.0 V , additional current will flow out of Pin 5,

creating a voltage drop across resistor R

. This voltage drop

dly

causes the source of MOSFET Q1 to fall below it’s gate,

allowing it to unexpectedly turn back on.

MC33348

3

In order to guarantee proper discharge current limit

operation when the battery pack output is shorted, power

must be made available to the MC33348. This can be

accomplished by decoupling the VCC input with the R/C

component values shown above. The capacitor value must

be increased to 100 µF if the discharge current limit

shutdown delay time is extended to 40 ms as shown in

Figure 12. A small signal schottky diode can be used in place

of R for enhanced short circuit operation. The diode cathode

is connected to Pin 7 and C, and the anode is connected to

the positive terminal of the cell. The schottky diode solution

may be a better choice in applications that have a charger

with a relatively high open circuit voltage. These components

can be deleted if operation of the discharge current limit is not

required when the battery pack output is shorted.

8

MOTOROLA ANALOG IC DEVICE DATA

MC33348

As previously stated in the voltage sensing operating

description, charge MOSFET Q1 is held off during an

overvoltage fault condition. When this condition is present,

the discharge current limit protection function is internally

disabled. This is required, since the voltage across Q1, in the

off state, would exceed the current sense threshold. This

would cause Q2 to turn off as well, preventing both charging

and discharging of the cell. Discharge current limit protection

is enabled whenever an overvoltage fault is not present.

The discharge current protection circuit contains a built in

response delay of 3.0 ms. This helps to prevent fault

activation when the battery pack is subjected to pulsed

currents during discharging. An additional current sense

delay can be added as shown in Figure 12. If the battery pack

is subjected to extremely high discharge current pulses or is

shorted, the VCC pin must be decoupled from the cell. This is

required so that the protection circuit will have sufficient

operating voltage during the load transient, to ensure turn off

of discharge MOSFET Q2. Figure 13 shows the placement of

decoupling components.

Charge Pump and MOSFET Switches

The MC33348 contains an on chip Charge Pump to

ensure that the MOSFET switches are fully enhanced for

reduced power losses. An external reservoir capacitor

normally connects from the Charge Pump output to ground,

Pins 8 and 3. The capacitor value is not critical and is usually

within the range of 10 nF to 100 nF. The Charge Pump output

is regulated at 10.2 V allowing the use of the more

economical logic level MOSFETs. The main requirement in

selecting a particular type of MOSFET switch is to consider

the desired on–resistance at the lowest anticipated operating

voltage of the battery pack. A table of small outline surface

mount devices is given in Figure 14. When using extremely

low threshold MOSFETs, it may be desirable to disable the

Charge Pump so that the maximum gate to source voltage is

not exceeded. This can be accomplished by connecting Pin 6

to Pin 5, and will result in an additional cell drain current of

approximately 8.0 µA.

T esting

A test pin is provided in order to speed up device and

battery pack testing. By grounding Pin 2, the internal logic is

held in a reset state and both MOSFET switches are turned

on. Upon release, the logic becomes active and the cell

voltage is polled within 1.0 ms.

Battery Pack Application

The one cell smart battery pack application shown in

Figure 7 contains a capacitor labeled CI that connects

directly across the battery pack terminals. This component

prevents excessive currents from flowing into the MC33348

when the battery pack terminals are shorted or arced, and is

mandatory. Capacitor CI is a 100 nF ±20% ceramic leaded

or surface mount type. It must be placed directly across the

battery pack plus and minus terminals with extremely short

lead lengths (≤1/16″).

In applications where inordinately low leakage MOSFETs

are used, the protection circuit may take a considerable

amount of time to reset from an overcurrent fault after the

load is removed. This situation can be remedied by providing

a small leakage path for charging CI, thus allowing Pin 5 to

rapidly fall below the discharge current limit threshold. A

1.0 megohm resistor placed across the MOSFET switches

accomplishes this task with a minimum increase in cell

discharge current when the battery pack is connected to a

load.

ББББББББББББББББББББББББББББББББ

Device

ÁÁÁÁ

Type

ÁÁÁÁ

MMFT3055VL

ÁÁÁÁ

MMDF3N03HD

ÁÁÁÁ

MMDF4N01HD

ÁÁÁÁ

MMSF5N02HD

ÁÁÁÁ

MMDF6N02HD

БББББББББББББББББББББББББББ

2.5 V

ÁÁÁ

ÁÁÁ–ÁÁÁ–ÁÁÁ–ÁÁÁ

ÁÁÁ–ÁÁÁ

0.047 Ω

ÁÁÁ

ÁÁÁ–ÁÁÁ

0.043 Ω

Figure 14. Small Outline Surface Mount MOSFET Switches

On–Resistance (Ω) versus Gate to Source Voltage (V)

3.0 V

ÁÁÁ

0.525 Ω

0.042 Ω

ÁÁÁ

0.065 Ω

0.035 Ω

4.0 V

ÁÁÁ

0.080 Ω

ÁÁÁ

0.037 Ω

ÁÁÁ

0.023 Ω

ÁÁÁ

0.029 Ω

5.0 V

ÁÁÁ

0.120 Ω

0.065 Ω

ÁÁÁ

0.035 Ω

ÁÁÁ

0.021 Ω

ÁÁÁ

0.028 Ω

6.0 V

ÁÁÁ

0.115 Ω

ÁÁÁ

0.063 Ω

ÁÁÁ

0.034 Ω

ÁÁÁ

0.020 Ω

ÁÁÁ

0.026 Ω

7.5 V

ÁÁÁ

0.108 Ω

ÁÁÁ

0.062 Ω

ÁÁÁ

0.033 Ω

ÁÁÁ

0.018 Ω

ÁÁÁ

0.025 Ω

9.0 V

ÁÁÁ

0.100 Ω

ÁÁÁ

0.060 Ω

ÁÁÁ

0.033 Ω

ÁÁÁ

0.018 Ω

ÁÁÁ

0.023 Ω

MOTOROLA ANALOG IC DEVICE DATA

9

MC33348

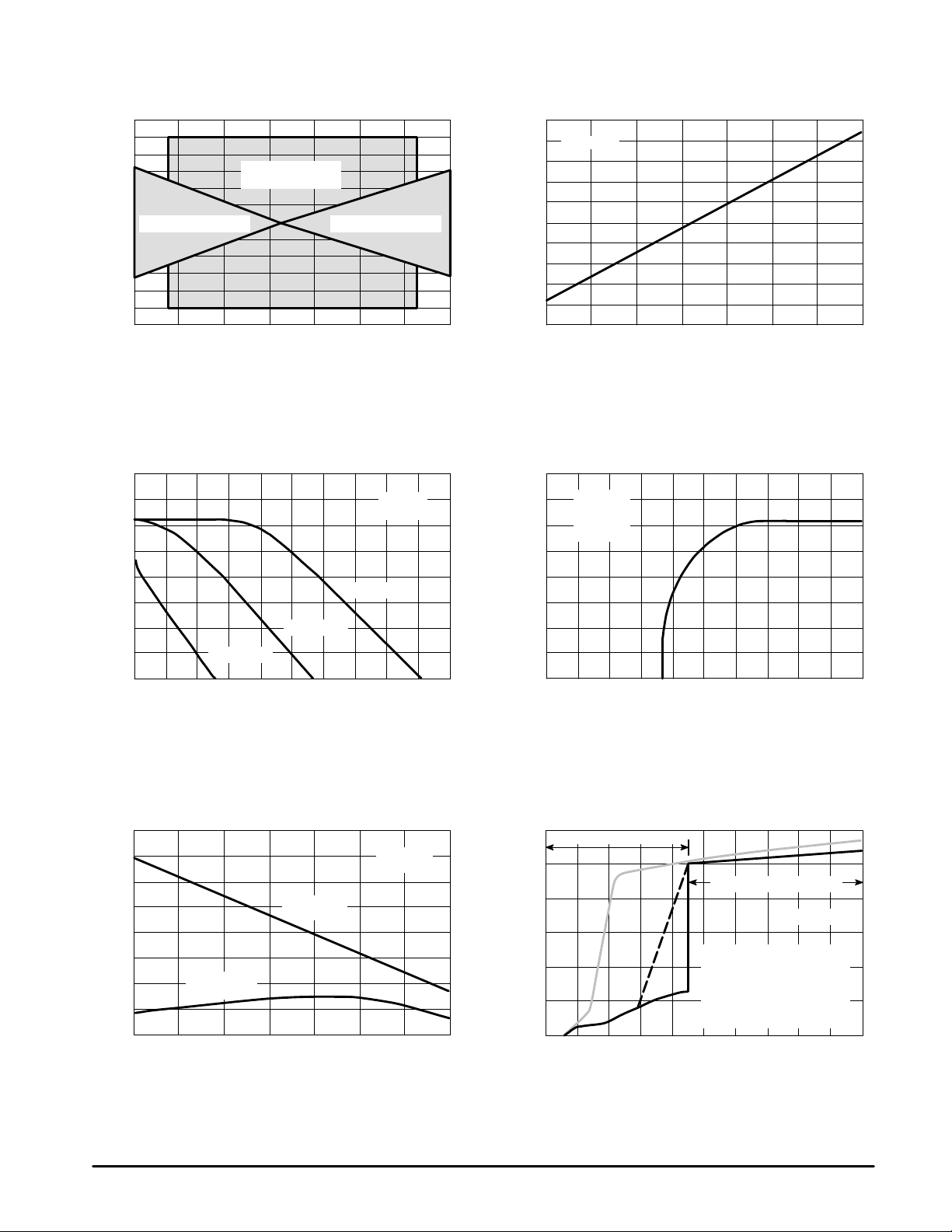

OUTLINE DIMENSIONS

D SUFFIX

PLASTIC PACKAGE

CASE 751–05

(SO–8)

ISSUE S

C

A

E

B

A1

D

58

0.25MB

1

H

4

e

M

h

X 45

_

q

C

A

SEATING

PLANE

0.10

L

B

SS

A0.25MCB

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. DIMENSIONS ARE IN MILLIMETERS.

3. DIMENSION D AND E DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 TOTAL IN EXCESS

OF THE B DIMENSION AT MAXIMUM MATERIAL

CONDITION.

MILLIMETERS

DIM MIN MAX

A 1.35 1.75

A1 0.10 0.25

B 0.35 0.49

C 0.18 0.25

D 4.80 5.00

E

3.80 4.00

1.27 BSCe

H 5.80 6.20

h

0.25 0.50

L 0.40 1.25

0 7

q

__

10

MOTOROLA ANALOG IC DEVICE DATA

MC33348

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

MOTOROLA ANALOG IC DEVICE DATA

11

MC33348

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.: SPD, Strategic Planning Office, 4–32–1,

P.O. Box 5405, Denver, Colorado 80217. 1–303–675–2140 or 1–800–441–2447 Nishi–Gotanda, Shinagawa–ku, Tokyo 141, Japan. 81–3–5487–8488

Customer Focus Center: 1–800–521–6274

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 1–602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

Moto rola Fax Back Syst em – US & Canada ONLY 1–800–774–1848 51 Ting Kok Road, Tai Po, N.T ., Hong Kong. 852–26629298

HOME PAGE: http://motorola.com/sps/

12

– http://sps.motorola.com/mfax/

◊

MOTOROLA ANALOG IC DEVICE DATA

Mfax is a trademark of Motorola, Inc.

MC33348/D

Loading...

Loading...