Motorola MC33035DW, MC33035P Datasheet

T

40° t

85°C

The MC33035 is a high performance second generation monolithic

brushless DC motor controller containing all of the active functions required

to implement a full featured open loop, three or four phase motor control

system. This device consists of a rotor position decoder for proper

commutation sequencing, temperature compensated reference capable of

supplying sensor power, frequency programmable sawtooth oscillator, three

open collector top drivers, and three high current totem pole bottom drivers

ideally suited for driving power MOSFETs.

Also included are protective features consisting of undervoltage lockout,

cycle–by–cycle current limiting with a selectable time delayed latched

shutdown mode, internal thermal shutdown, and a unique fault output that

can be interfaced into microprocessor controlled systems.

Typical motor control functions include open loop speed, forward or

reverse direction, run enable, and dynamic braking. The MC33035 is

designed to operate with electrical sensor phasings of 60°/300° or

120°/240°, and can also efficiently control brush DC motors.

• 10 to 30 V Operation

• Undervoltage Lockout

• 6.25 V Reference Capable of Supplying Sensor Power

• Fully Accessible Error Amplifier for Closed Loop Servo Applications

• High Current Drivers Can Control External 3–Phase MOSFET Bridge

• Cycle–By–Cycle Current Limiting

• Pinned–Out Current Sense Reference

• Internal Thermal Shutdown

• Selectable 60°/300° or 120°/240° Sensor Phasings

• Can Efficiently Control Brush DC Motors with External MOSFET

H–Bridge

ORDERING INFORMATION

Operating

Device

MC33035DW

MC33035P

Temperature Range

°

A

= –

o +

°

Package

SO–24L

Plastic DIP

Order this document by MC33035/D

BRUSHLESS DC

MOTOR CONTROLLER

SEMICONDUCTOR

TECHNICAL DATA

P SUFFIX

PLASTIC PACKAGE

CASE 724

DW SUFFIX

PLASTIC PACKAGE

CASE 751E

(SO–24L)

PIN CONNECTIONS

Top Drive

Output

Sensor

Inputs

Output Enable

Reference Output

Current Sense

Noninverting Input

Noninverting Input

Inverting Input

B

A

S

A

S

B

S

C

Oscillator

Error Amp

Error Amp

T

T

24

1

24

1

2

3

4

5

6

7

8

9

10

11

1

C

24

T

23

Brake

22

60°/120°SelectFwd/Rev

A

21

B

20

B

B

19

C

B

18

V

C

17

V

CC

Gnd

16

Current Sense

15

Inverting Input

14

Output

Fault

Error Amp Out/

1312

PWM Input

Bottom

Drive

Outputs

(Top View)

MOTOROLA ANALOG IC DEVICE DATA

Motorola, Inc. 1996 Rev 2

1

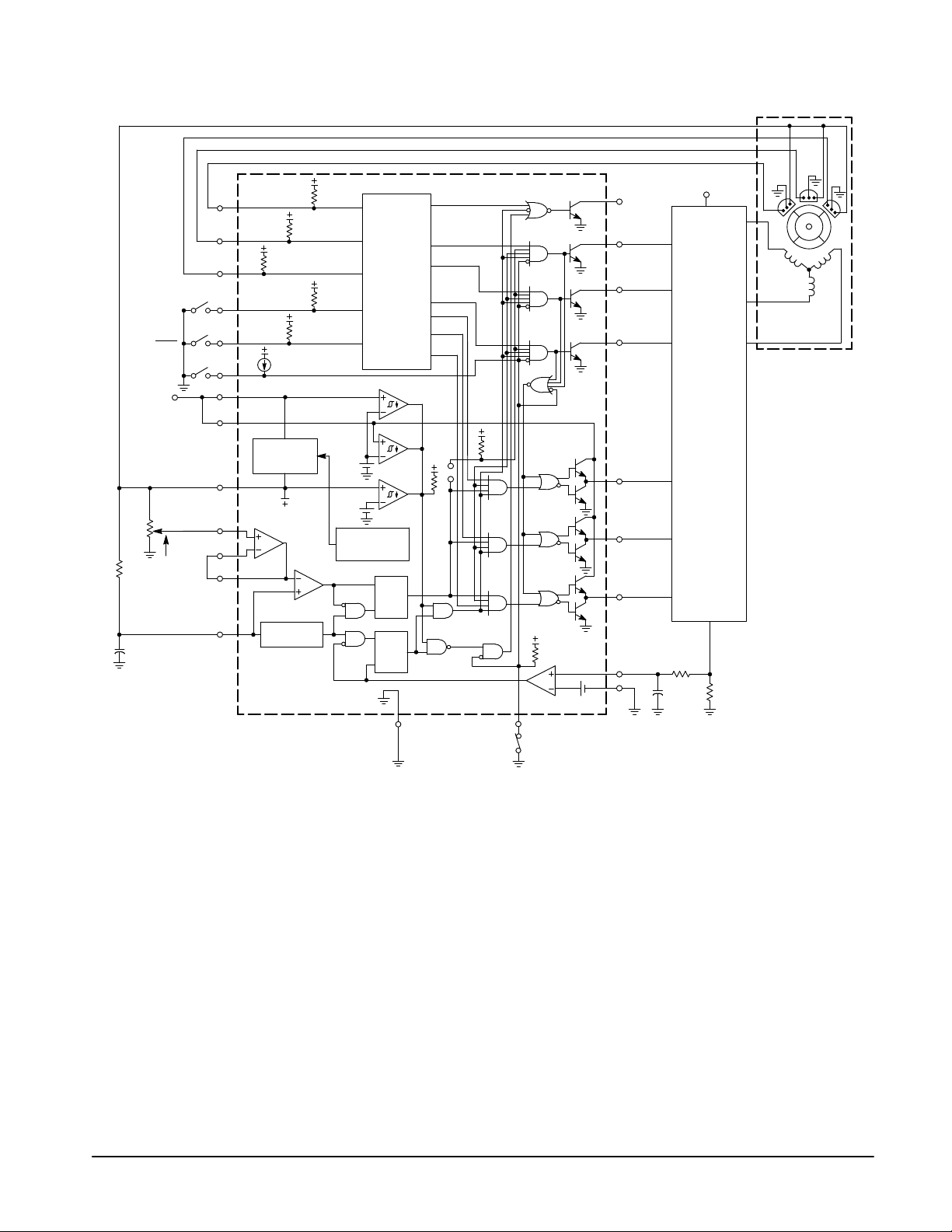

Fwd/Rev

60°/120

Enable

V

R

T

C

T

°

in

Speed

Set

Faster

17

18

11

12

13

10

4

5

6

3

2

7

8

Reference

Regulator

Error Amp

Oscillator

Undervoltage

Lockout

PWM

MC33035

Representative Schematic Diagram

Rotor

Position

Decoder

Thermal

Shutdown

R

Q

S

S

Q

R

14

24

21

20

19

2

1

9

Fault

V

M

Output

Buffers

N

SS

N

Motor

2316

Brake

This device contains 285 active transistors.

15

Current Sense

Reference

2

MOTOROLA ANALOG IC DEVICE DATA

MC33035

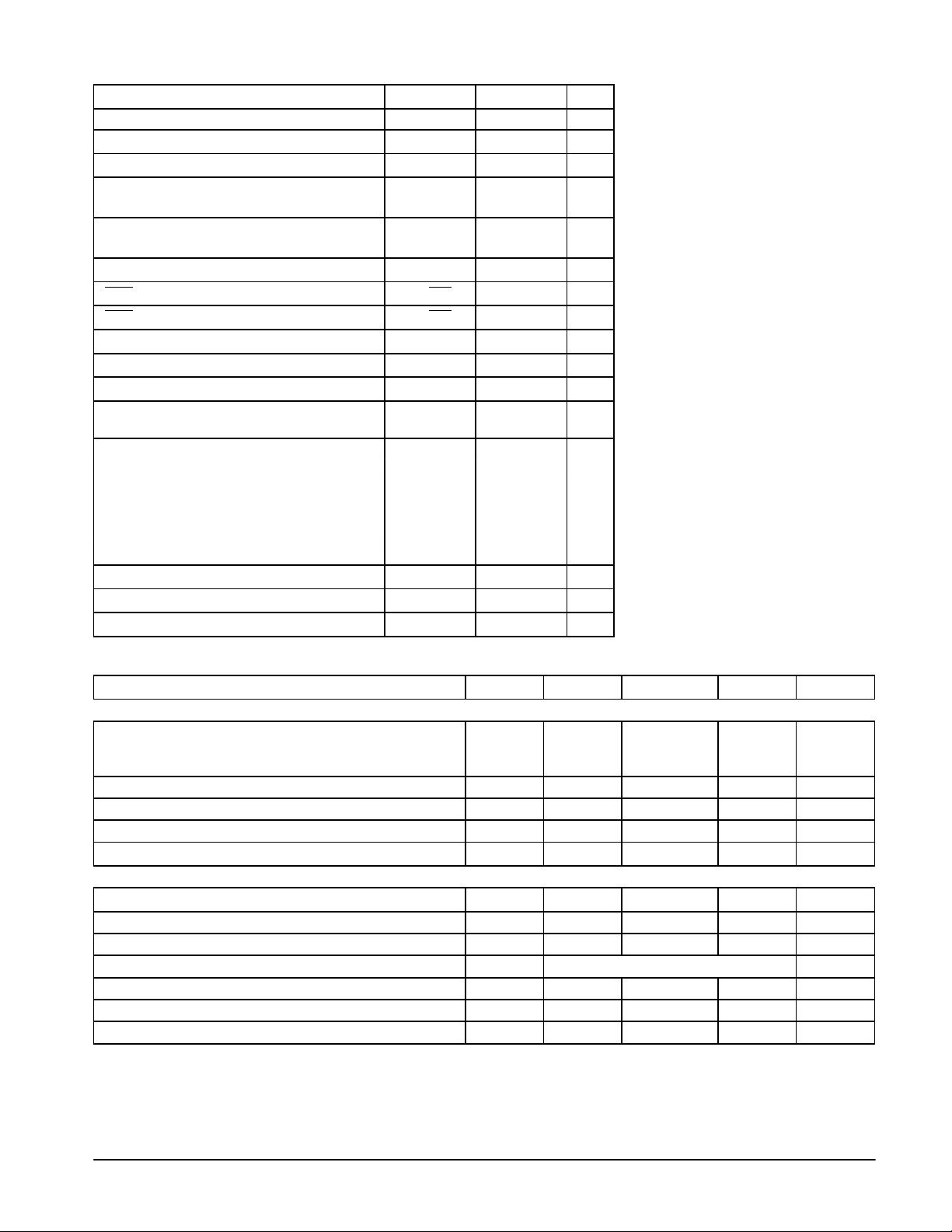

MAXIMUM RATINGS

Rating Symbol Value Unit

Power Supply Voltage V

Digital Inputs (Pins 3, 4, 5, 6, 22, 23) – V

Oscillator Input Current (Source or Sink) I

Error Amp Input Voltage Range

(Pins 11, 12, Note 1)

Error Amp Output Current

(Source or Sink, Note 2)

Current Sense Input Voltage Range (Pins 9, 15) V

Fault Output Voltage V

Fault Output Sink Current I

Top Drive Voltage (Pins 1, 2, 24) V

Top Drive Sink Current (Pins 1, 2, 24) I

Bottom Drive Supply Voltage (Pin 18) V

Bottom Drive Output Current I

(Source or Sink, Pins 19, 20, 21)

Power Dissipation and Thermal Characteristics

P Suffix, Dual In Line, Case 724

Maximum Power Dissipation @ TA = 85°C P

Thermal Resistance, Junction–to–Air R

DW Suffix, Surface Mount, Case 751E

Maximum Power Dissipation @ TA = 85°C P

Thermal Resistance, Junction–to–Air R

Operating Junction Temperature T

Operating Ambient Temperature Range T

Storage Temperature Range T

CC

OSC

V

IR

I

Out

Sense

CE(Fault)

Sink(Fault)

CE(top)

Sink(top)

C

DRV

D

θ

JA

D

θ

JA

J

A

stg

–0.3 to V

–0.3 to 5.0 V

–40 to +85 °C

–65 to +150 °C

40 V

ref

V

30 mA

V

ref

10 mA

20 V

20 mA

40 V

50 mA

30 V

100 mA

867 mW

75 °C/W

650 mW

100 °C/W

150 °C

ELECTRICAL CHARACTERISTICS (V

Characteristic

= VC = 20 V, RT = 4.7 k, CT = 10 nF, TA = 25°C, unless otherwise noted.)

CC

Symbol Min Typ Max Unit

REFERENCE SECTION

Reference Output Voltage (I

T

= 25°C

A

T

= –40° to +85°C

A

Line Regulation (VCC = 10 to 30 V, I

Load Regulation (I

= 1.0 to 20 mA) Reg

ref

Output Short Circuit Current (Note 3) I

Reference Under Voltage Lockout Threshold V

= 1.0 mA)

ref

= 1.0 mA) Reg

ref

V

ref

line

load

SC

th

5.9

5.82

6.24

–

6.5

6.57

– 1.5 30 mV

– 16 30 mV

40 75 – mA

4.0 4.5 5.0 V

ERROR AMPLIFIER

Input Offset Voltage (T

Input Offset Current (T

Input Bias Current (T

Input Common Mode Voltage Range V

Open Loop Voltage Gain (VO = 3.0 V, RL = 15 k) A

= –40° to +85°C) V

A

= –40° to +85°C) I

A

= –40° to +85°C) I

A

IO

IO

IB

ICR

VOL

– 0.4 10 mV

– 8.0 500 nA

– –46 –1000 nA

(0 V to V

) V

ref

70 80 – dB

Input Common Mode Rejection Ratio CMRR 55 86 – dB

Power Supply Rejection Ratio (VCC = VC = 10 to 30 V) PSRR 65 105 – dB

NOTES: 1. The input common mode voltage or input signal voltage should not be allowed to go negative by more than 0.3 V.

2.The compliance voltage must not exceed the range of –0.3 to V

3.Maximum package power dissipation limits must be observed.

.

ref

V

MOTOROLA ANALOG IC DEVICE DATA

3

MC33035

Output Enable

µA

gp (IH)

IH

Bottom Drive Output Voltage

V

g(

CC C source

)

OH

(

CC

)

(

CC

)

Power Supply Current

mA

Pin 17 (VCC VC 20 V)

I

CC

121416

(

CC

0,C30 )

0

(

CC C

)

C

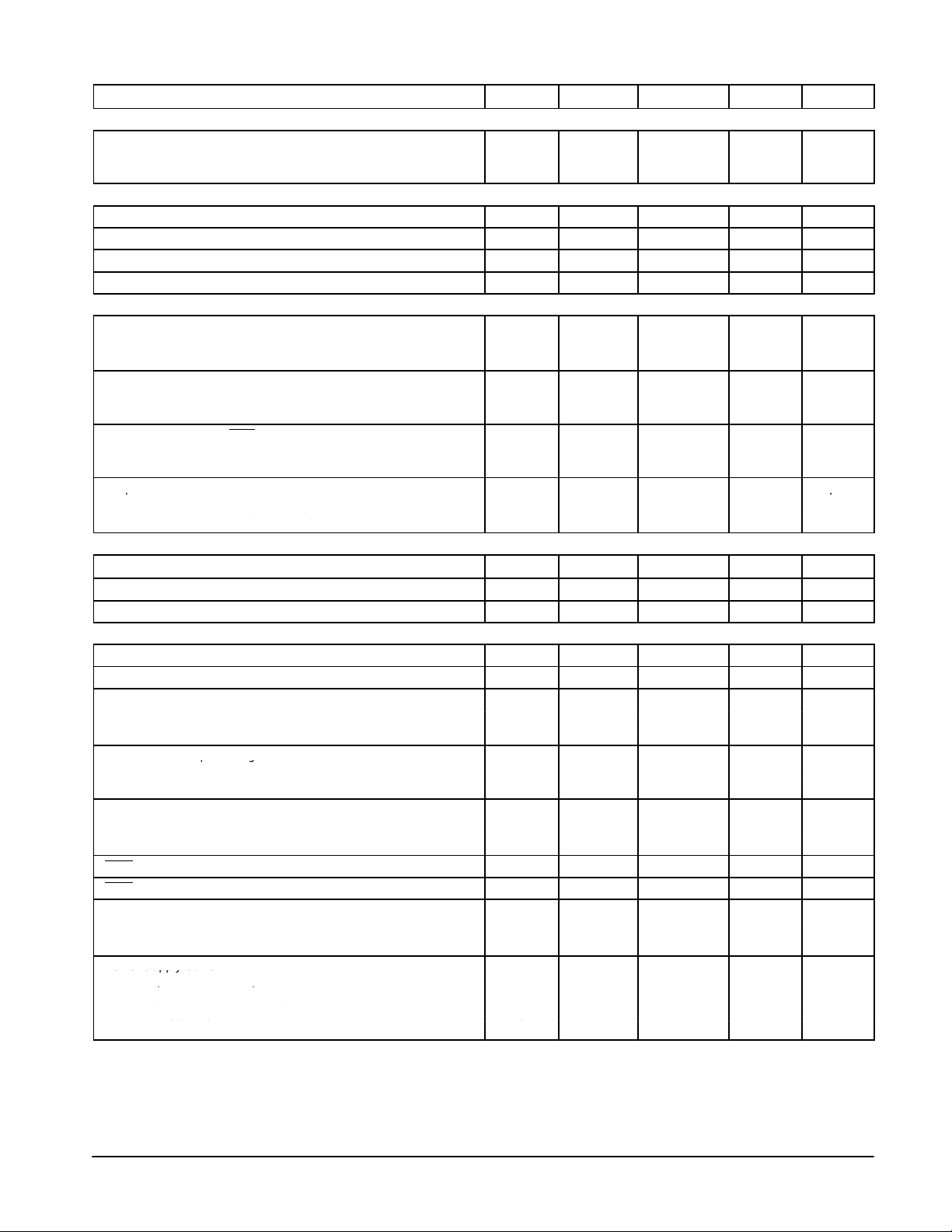

ELECTRICAL CHARACTERISTICS (continued) (V

Characteristic

= VC = 20 V, RT = 4.7 k, CT = 10 nF, TA = 25°C, unless otherwise noted.)

CC

Symbol Min Typ Max Unit

ERROR AMPLIFIER

Output Voltage Swing

High State (RL = 15 k to Gnd)

Low State (R

= 15 k to V

L

ref

)

V

OH

V

OL

4.6

–

0.5

5.3

–

1.0

OSCILLATOR SECTION

Oscillator Frequency f

Frequency Change with Voltage (VCC = 10 to 30 V) ∆f

Sawtooth Peak Voltage V

Sawtooth Valley Voltage V

OSC

/∆V – 0.01 5.0 %

OSC

OSC(P)

OSC(V)

22 25 28 kHz

– 4.1 4.5 V

1.2 1.5 – V

LOGIC INPUTS

Input Threshold Voltage (Pins 3, 4, 5, 6, 7, 22, 23)

High State

Low State

V

IH

V

IL

3.0

–

1.7

2.2

–

0.8

Sensor Inputs (Pins 4, 5, 6)

High State Input Current (VIH = 5.0 V)

Low State Input Current (V

= 0 V)

IL

I

IH

I

IL

–150

–600

–70

–337

–20

–150

Forward/Reverse, 60°/120° Select (Pins 3, 22, 23)

High State Input Current (V

Low State Input Current (V

= 5.0 V)

IH

= 0 V)

IL

I

IH

I

IL

–75

–300

–36

–175

–10

–75

Output Enable µA

High State Input Current (VIH = 5.0 V)

Low State Input Current (VIL = 0 V)

I

IH

I

IL

–60

–29

–10

–60 –29 –10

CURRENT–LIMIT COMPARATOR

Threshold Voltage V

Input Common Mode Voltage Range V

Input Bias Current I

th

ICR

IB

85 101 115 mV

– 3.0 – V

– –0.9 –5.0 µA

OUTPUTS AND POWER SECTIONS

Top Drive Output Sink Saturation (I

Top Drive Output Off–State Leakage (VCE = 30 V) I

= 25 mA) V

sink

CE(sat)

DRV(leak)

– 0.5 1.5 V

– 0.06 100 µA

Top Drive Output Switching Time (CL = 47 pF, RL = 1.0 k) ns

Rise Time t

Fall Time t

r

f

– 107 300

– 26 300

Bottom Drive Output Voltage V

High State (VCC = 20 V, VC = 30 V, I

Low State (VCC = 20 V, VC = 30 V, I

source

= 50 mA)

sink

= 50 mA)

V

OH

V

OL

(V

CC

–2.0) (V

–

–1.1)

CC

1.5 2.0

–

Bottom Drive Output Switching Time (CL = 1000 pF) ns

Rise Time t

Fall Time t

Fault Output Sink Saturation (I

= 16 mA) V

sink

Fault Output Off–State Leakage (VCE = 20 V) I

r

f

CE(sat)

FLT(leak)

– 38 200

– 30 200

– 225 500 mV

– 1.0 100 µA

Under Voltage Lockout V

Drive Output Enabled (VCC or V

Hysteresis V

Increasing) V

C

th(on)

H

8.2 8.9 10

0.1 0.2 0.3

Power Supply Current mA

Pin 17 (VCC = VC = 20 V) I

Pin 17 (VCC = 20 V, VC = 30 V)

Pin 18 (VCC = VC = 20 V) I

Pin 18 (VCC = 20 V, VC = 30 V)

CC

C

– 12 16

–

– 3.5

20

6.0

– 5.0 10

V

V

µA

µA

4

MOTOROLA ANALOG IC DEVICE DATA

MC33035

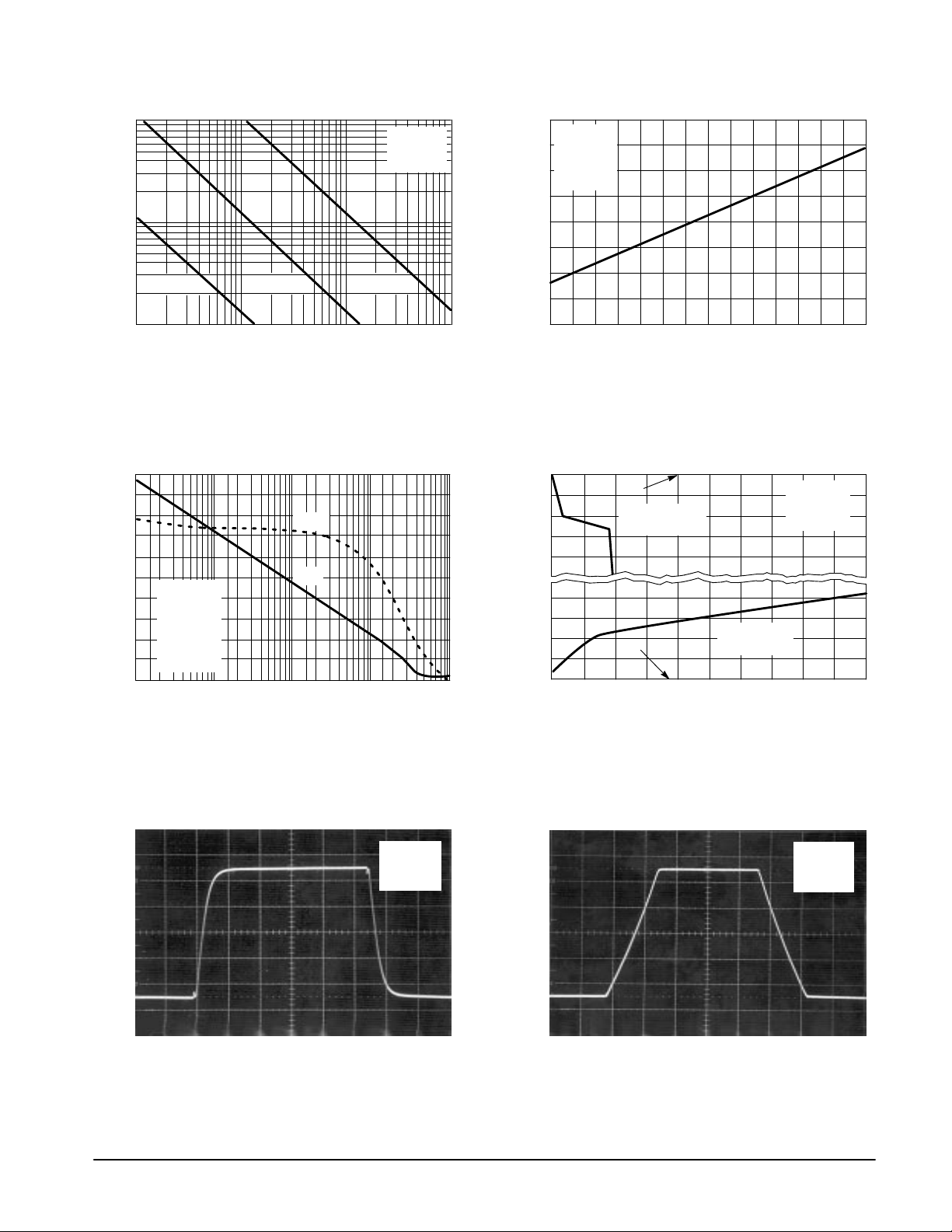

Figure 1. Oscillator Frequency versus

100

10

OSCILLA TOR FREQUENCY (kHz)

CT = 100 nF

,

OSC

f

0

1.0

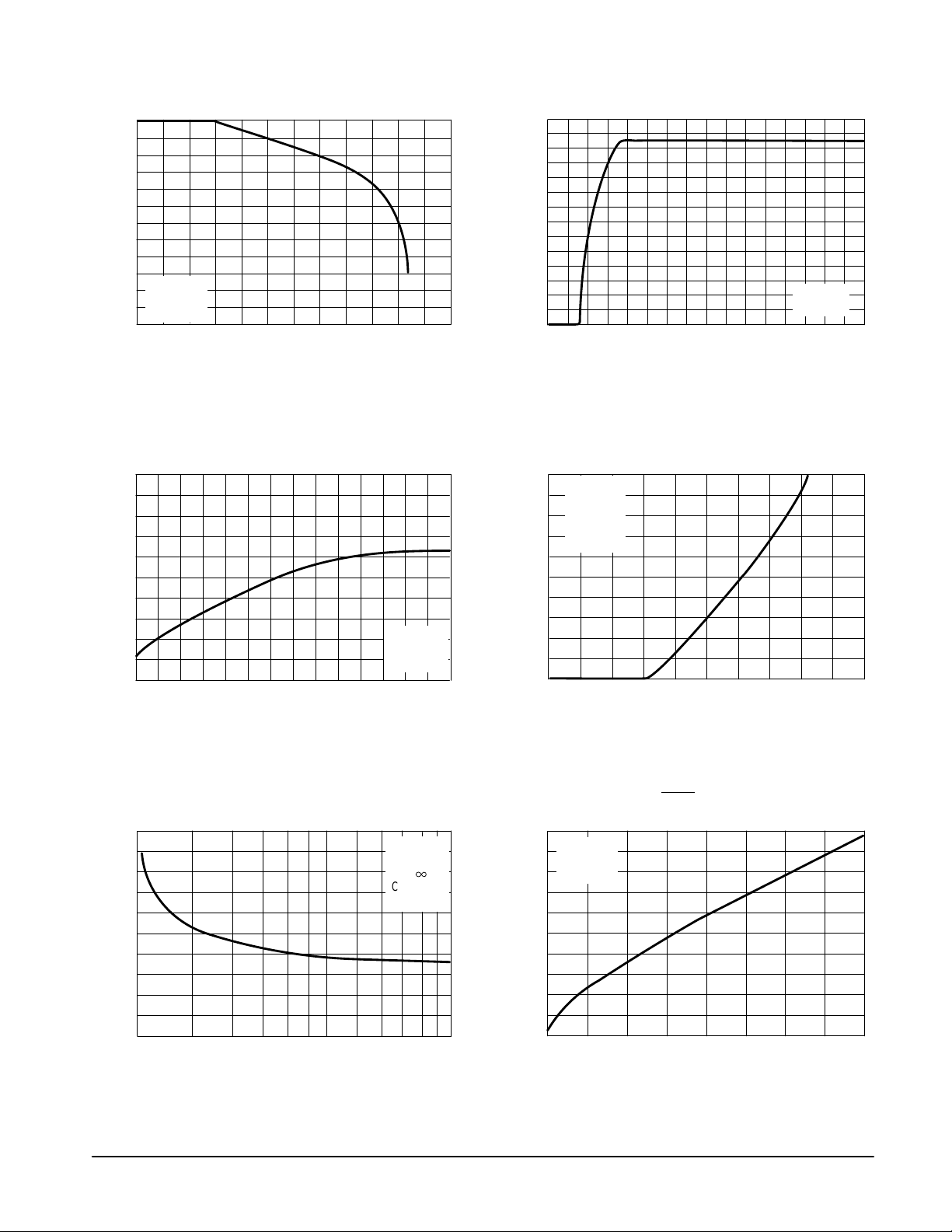

Figure 3. Error Amp Open Loop Gain and

56

48

40

32

24

16

0

1.0 k

VCC = 20 V

= 20 V

V

C

= 3.0 V

V

O

= 15 k

R

L

= 100 pF

C

L

= 25°C

T

A

8.0

–8.0

, OPEN LOOP VOL TAGE GAIN (dB)

–16

VOL

A

–24

Timing Resistor

CT = 10 nF

, TIMING RESISTOR (kΩ)

R

T

CT = 1.0 nF

Phase versus Frequency

Phase

Gain

f, FREQUENCY (Hz)

VCC = 20 V

= 20 V

V

C

= 25°C

T

A

4.0

2.0

0

–2.0

OSCILLA T OR FREQUENCY CHANGE (%)

,

OSC

–4.0

f

100010010

40

∆

–55

0

60

80

– 0.8

100

120

–1.6

140

160

1.6

180

EXCESS PHASE (DEGREES)

,

200

φ

220

240

10 M1.0 M100 k10 k

, OUTPUT SA TURATION VOLTAGE (V)

V

sat

0.8

0

Figure 2. Oscillator Frequency Change

versus T emperature

VCC = 20 V

= 20 V

V

C

= 4.7 k

R

T

= 10 nF

C

T

TA, AMBIENT TEMPERATURE (°C)

Figure 4. Error Amp Output Saturation

V oltage versus Load Current

V

ref

Source Saturation

(Load to Ground)

Sink Saturation

Gnd

(Load to V

1.0 2.0

IO, OUTPUT LOAD CURRENT (mA)

)

ref

1007550250–25

VCC = 20 V

= 20 V

V

C

= 25°C

T

A

125

5.04.03.00

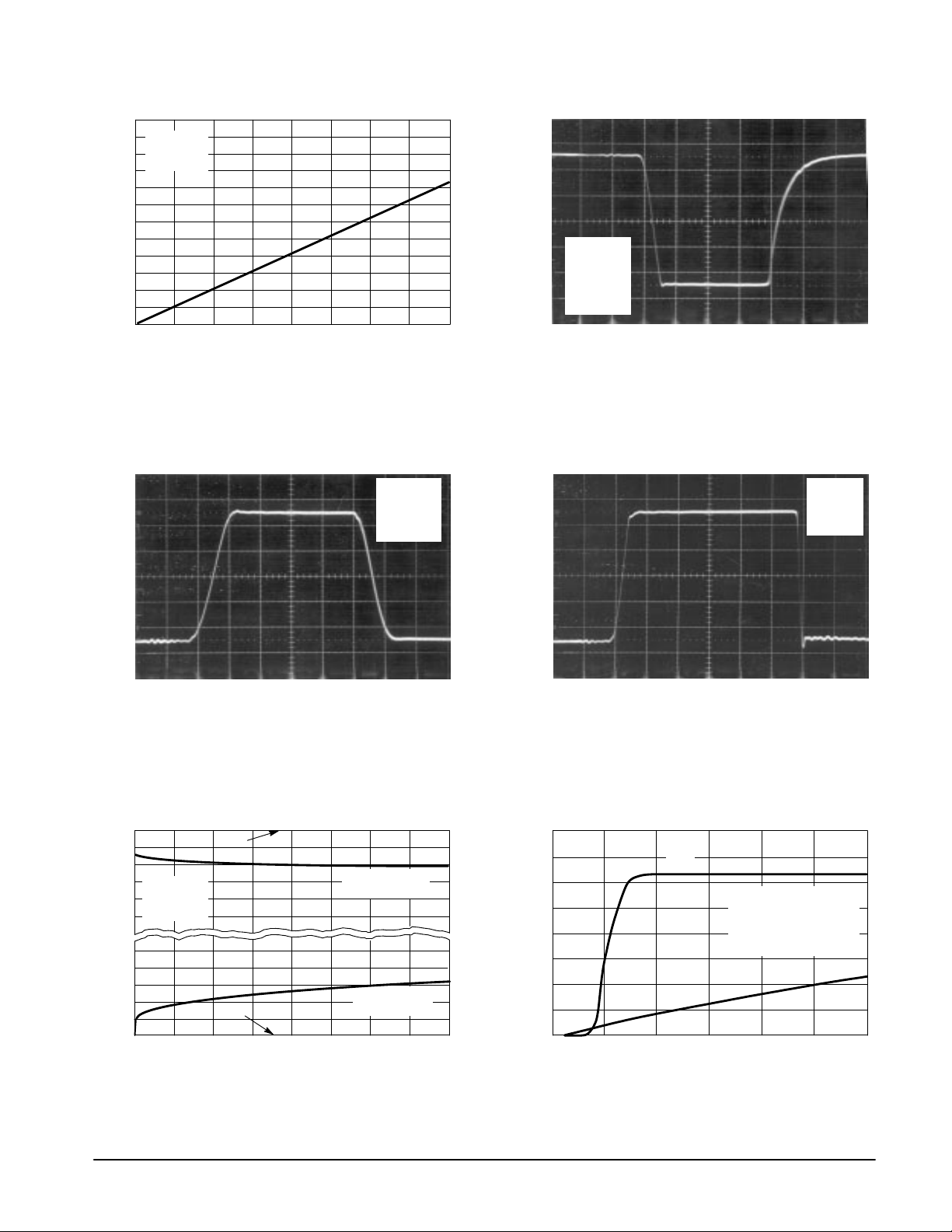

Figure 5. Error Amp Small–Signal

Transient Response

3.05

3.0

, OUTPUT VOL TAGE (V)

O

V

2.95

µ

s/DIV

1.0

MOTOROLA ANALOG IC DEVICE DATA

AV = +1.0

No Load

= 25°C

T

A

, OUTPUT VOL TAGE (V)

V

4.5

3.0

O

1.5

Figure 6. Error Amp Large–Signal

Transient Response

AV = +1.0

No Load

T

A

5.0 µs/DIV

= 25°C

5

MC33035

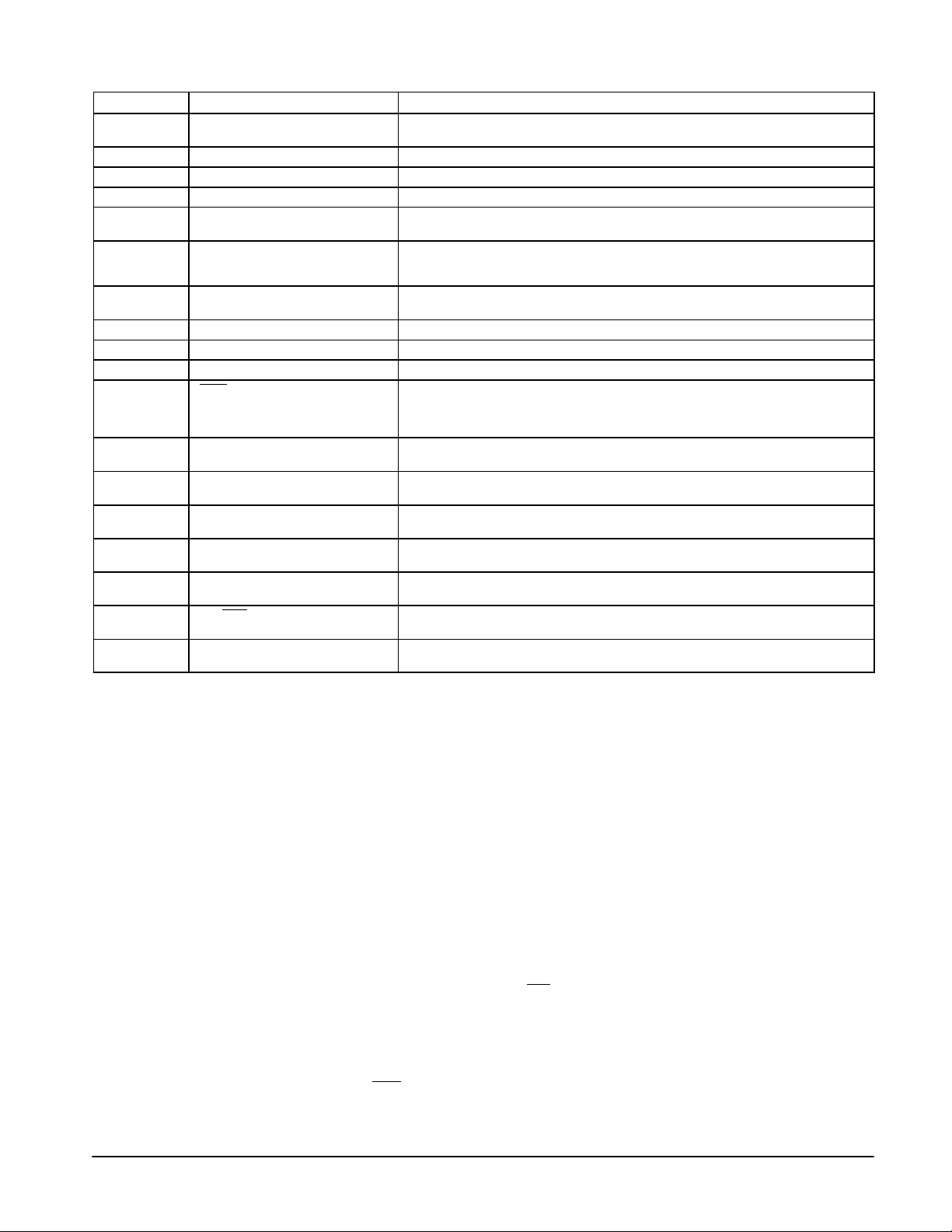

Figure 7. Reference Output V oltage Change

versus Output Source Current

0

–4.0

–8.0

– 12

– 16

VCC = 20 V

–20

, REFERENCE OUTPUT VOLTAGE CHANGE (mV)

–24

ref

V

∆

= 20 V

V

C

= 25°C

T

A

0

, REFERENCE OUTPUT SOURCE CURRENT (mA)

I

ref

Figure 9. Reference Output Voltage

versus T emperature

40

20

0

–20

–40

, NORMALIZED REFERENCE VOLTAGE CHANGE (mV)

ref

V

∆

–25

–55 0

T

A

, AMBIENT TEMPERATURE (°C)

= 20 V

V

CC

= 20 V

V

C

No Load

Figure 8. Reference Output Voltage

versus Supply V oltage

7.0

6.0

5.0

4.0

3.0

2.0

1.0

, REFERENCE OUTPUT VOLTAGE (V)

ref

V

0

605040302010

0

V

, SUPPLY VOLT AGE (V)

CC

No Load

= 25°C

T

A

40302010

Figure 10. Output Duty Cycle versus

PWM Input Voltage

100

VCC = 20 V

= 20 V

V

C

= 4.7 k

R

80

60

40

20

OUTPUT DUTY CYCLE (%)

125100755025

T

= 10 nF

C

T

= 25°C

T

A

0

0

5.04.03.02.01.0

PWM INPUT VOLTAGE (V)

Figure 11. Bottom Drive Response T ime versus

Current Sense Input Voltage

250

200

150

100

50

, BOTTOM DRIVE RESPONSE TIME (ns)

HL

t

0

1.0 2.0 3.0 4.0 5.0 7.0 8.0 10

CURRENT SENSE INPUT VOLTAGE (NORMALIZED TO V

VCC = 20 V

V

R

CL = 1.0 nF

T

6.0 9.0

6

= 20 V

C

=

1

L

= 25°C

A

Figure 12. Fault

Output Saturation

versus Sink Current

0.25

VCC = 20 V

= 20 V

V

C

0.2

= 25°C

T

A

0.15

0.1

0.05

, OUTPUT SA TURATION VOLTAGE (V)V

sat

0

016128.04.0

)

th

, SINK CURRENT (mA)

I

Sink

MOTOROLA ANALOG IC DEVICE DATA

1.2

0.8

Figure 13. Top Drive Output Saturation

V oltage versus Sink Current

VCC = 20 V

= 20 V

V

C

= 25°C

T

A

MC33035

Figure 14. Top Drive Output Waveform

100

, OUTPUT SA TURATION VOLTAGE (V)

sat

V

OUTPUT VOLTAGE (%)

0

VCC = 20 V

= 20 V

V

C

= 1.0 k

R

L

= 15 pF

C

L

= 25°C

T

A

100 ns/DIV

0.4

0

0

10 30 40

I

Sink

20

, SINK CURRENT (mA)

Figure 15. Bottom Drive Output Waveform Figure 16. Bottom Drive Output Waveform

VCC = 20 V

= 20 V

V

100

C

= 1.0 nF

C

L

= 25°C

T

A

0

100

OUTPUT VOLTAGE (%) OUTPUT VOLTAGE (%)

0

VCC = 20 V

= 20 V

V

C

= 15 pF

C

L

= 25°C

T

A

, OUTPUT SA TURATION VOLTAGE (V)

V

50 ns/DIV

Figure 17. Bottom Drive Output Saturation

V oltage versus Load Current

–1.0

–2.0

2.0

1.0

sat

0

0

0

VCC = 20 V

= 20 V

V

C

= 25°C

T

A

V

C

Gnd

40

I

, OUTPUT LOAD CURRENT (mA)

O

Source Saturation

(Load to Ground)

Sink Saturation

(Load to V

)

C

50 ns/DIV

Figure 18. Power and Bottom Drive Supply

Current versus Supply Voltage

16

14

12

10

8.0

6.0

4.0

, POWER SUPPLY CURRENT (mA)

2.0

CC

, I

C

I

806020

0

0 5.0 10 15 20 25 30

I

CC

I

C

V

, SUPPLY VOLT AGE (V)

CC

RT = 4.7 k

= 10 nF

C

T

Pins 3–6, 9, 15, 23 = Gnd

Pins 7, 22 = Open

= 25°C

T

A

MOTOROLA ANALOG IC DEVICE DATA

7

MC33035

PIN FUNCTION DESCRIPTION

Pin Symbol Description

1, 2, 24 BT, AT, C

3 Fwd/Rev The Forward/Reverse Input is used to change the direction of motor rotation.

4, 5, 6 SA, SB, S

7 Output Enable A logic high at this input causes the motor to run, while a low causes it to coast.

8 Reference Output This output provides charging current for the oscillator timing capacitor CT and a

9 Current Sense Noninverting Input A 100 mV signal, with respect to Pin 15, at this input terminates output switch

10 Oscillator The Oscillator frequency is programmed by the values selected for the timing

11 Error Amp Noninverting Input This input is normally connected to the speed set potentiometer .

12 Error Amp Inverting Input This input is normally connected to the Error Amp Output in open loop applications.

13 Error Amp Out/PWM Input This pin is available for compensation in closed loop applications.

14 Fault Output This open collector output is active low during one or more of the following

15 Current Sense Inverting Input Reference pin for internal 100 mV threshold. This pin is normally connected to the

16 Gnd This pin supplies a ground for the control circuit and should be referenced back to

17 V

18 V

19, 20, 21 CB, BB, A

22 60°/120° Select The electrical state of this pin configures the control circuit operation for either 60°

23 Brake A logic low state at this input allows the motor to run, while a high state does not

T

C

CC

C

B

These three open collector Top Drive outputs are designed to drive the external

upper power switch transistors.

These three Sensor Inputs control the commutation sequence.

reference for the error amplifier. It may also serve to furnish sensor power.

conduction during a given oscillator cycle. This pin normally connects to the top

side of the current sense resistor.

components, R

conditions: Invalid Sensor Input code, Enable Input at logic 0, Current Sense Input

greater than 100 mV (Pin 9 with respect to Pin 15), Undervoltage Lockout

activation, and Thermal Shutdown.

bottom side of the current sense resistor.

the power source ground.

This pin is the positive supply of the control IC. The controller is functional over a

minimum V

The high state (VOH) of the Bottom Drive Outputs is set by the voltage applied to

this pin. The controller is operational over a minimum V

These three totem pole Bottom Drive Outputs are designed for direct drive of the

external bottom power switch transistors.

(high state) or 120° (low state) sensor electrical phasing inputs.

allow motor operation and if operating causes rapid deceleration.

and CT.

T

range of 10 to 30 V.

CC

range of 10 to 30 V.

C

INTRODUCTION

The MC33035 is one of a series of high performance

monolithic DC brushless motor controllers produced by

Motorola. It contains all of the functions required to

implement a full–featured, open loop, three or four phase

motor control system. In addition, the controller can be made

to operate DC brush motors. Constructed with Bipolar Analog

technology, it offers a high degree of performance and

ruggedness in hostile industrial environments. The MC33035

contains a rotor position decoder for proper commutation

sequencing, a temperature compensated reference capable

of supplying a sensor power, a frequency programmable

sawtooth oscillator, a fully accessible error amplifier, a pulse

width modulator comparator, three open collector top drive

outputs, and three high current totem pole bottom driver

outputs ideally suited for driving power MOSFETs.

Included in the MC33035 are protective features

consisting of undervoltage lockout, cycle–by–cycle current

limiting with a selectable time delayed latched shutdown

mode, internal thermal shutdown, and a unique fault output

that can easily be interfaced to a microprocessor controller.

Typical motor control functions include open loop speed

control, forward or reverse rotation, run enable, and dynamic

braking. In addition, the MC33035 has a 60°/120

which configures the rotor position decoder for either 60° or

120° sensor electrical phasing inputs.

° select pin

FUNCTIONAL DESCRIPTION

A representative internal block diagram is shown in

Figure 19 with various applications shown in Figures 36, 38,

39, 43, 45, and 46. A discussion of the features and function

of each of the internal blocks given below is referenced to

Figures 19 and 36.

Rotor Position Decoder

An internal rotor position decoder monitors the three

sensor inputs (Pins 4, 5, 6) to provide the proper sequencing

of the top and bottom drive outputs. The sensor inputs are

designed to interface directly with open collector type Hall

Effect switches or opto slotted couplers. Internal pull–up

resistors are included to minimize the required number of

external components. The inputs are TTL compatible, with

their thresholds typically at 2.2 V. The MC33035 series is

designed to control three phase motors and operate with four

of the most common conventions of sensor phasing. A

60°/120

the MC33035 to configure itself to control motors having

either 60°, 120°, 240° or 300° electrical sensor phasing. With

three sensor inputs there are eight possible input code

combinations, six of which are valid rotor positions. The

remaining two codes are invalid and are usually caused by an

open or shorted sensor line. With six valid input codes, the

° Select (Pin 22) is conveniently provided and affords

8

MOTOROLA ANALOG IC DEVICE DATA

Loading...

Loading...