查询MC33023供应商

The MC34023 series are high speed, fixed frequency , single–ended pulse

width modulator controllers optimized for high frequency operation. They are

specifically designed for Off–Line and DC–to–DC converter applications

offering the designer a cost–effective solution with minimal external

components. These integrated circuits feature an oscillator, a temperature

compensated reference, a wide bandwidth error amplifier, a high speed

current sensing comparator, and a high current totem pole output ideally

suited for driving a power MOSFET.

Also included are protective features consisting of input and reference

undervoltage lockouts each with hysteresis, cycle–by–cycle current limiting,

and a latch for single pulse metering.

The flexibility of this series allows it to be easily configured for either

current mode or voltage mode control.

• 50 ns Propagation Delay to Output

• High Current Totem Pole Output

• Wide Bandwidth Error Amplifier

• Fully–Latched Logic with Double Pulse Suppression

• Latching PWM for Cycle–By–Cycle Current Limiting

• Soft–Start Control with Latched Overcurrent Reset

• Input Undervoltage Lockout with Hysteresis

• Low Start–Up Current (500 µA Typ)

• Internally Trimmed Reference with Undervoltage Lockout

• 90% Maximum Duty Cycle (Externally Adjustable)

• Precision Trimmed Oscillator

• Voltage or Current Mode Operation to 1.0 MHz

• Functionally Similar to the UC3823

Order this document by MC34023/D

16

1

P SUFFIX

PLASTIC PACKAGE

CASE 648

16

1

DW SUFFIX

PLASTIC PACKAGE

CASE 751G

(SO–16L)

PIN CONNECTIONS

Simplified Application

16

V

ref

4

Clock

5

R

T

C

T

Ramp

Error Amp

Output

Noninverting

Input

Inverting

Input

Soft–Start

Oscillator

6

7

3

2

1

8

Error

Amp

Soft–Start

This device contains 176 active transistors.

MOTOROLA ANALOG IC DEVICE DATA

5.1V

Reference

UVLO

Latching

PWM

Ground

10

15

V

CC

13

V

C

14

Output

12

Power

Ground

11

Current

Limit Ref

9

Current

Limit/

Shutdown

Error Amp

Inverting Input

Error Amp

Noninverting Input

Error Amp Output

Clock

R

T

C

T

Ramp

Soft–Start

1

2

3

4

5

6

7

8

(Top View)

16

V

ref

15

V

CC

14

Output

13

V

C

12

Power Ground

Current Limit

11

Reference

Ground

10

Current Limit/

9

Shutdown

ORDERING INFORMATION

Operating

Device

MC33023P Plastic DIP

MC33023DW SO–16L

MC34023P TA = 0° to +70°C Plastic DIP

Motorola, Inc. 1996 Rev 2

Temperature Range

TA = –40° to +105°C

Package

1

MC34023 MC33023

DIP Pack

648)

MAXIMUM RATINGS

Rating Symbol Value Unit

Power Supply Voltage V

Output Driver Supply Voltage V

Output Current, Source or Sink (Note 1)

DC

Pulsed (0.5 µs)

Current Sense, Soft–Start, Ramp, and Error Amp Inputs V

Error Amp Output and Soft–Start Sink Current I

Clock and RT Output Current I

Power Dissipation and Thermal Characteristics

SO–16L Package (Case 751G)

Maximum Power Dissipation @ TA = +25°C

Thermal Resistance, Junction–to–Air

age (Case

Maximum Power Dissipation @ TA = +25°C

Thermal Resistance, Junction–to–Air

Operating Junction Temperature T

Operating Ambient Temperature (Note 2)

MC34023

MC33023

Storage Temperature Range T

R

R

CC

I

O

O

CO

P

θJA

P

θJA

T

stg

C

–0.3 to +7.0 V

in

D

D

J

A

0 to +70

–40 to +105

–55 to +150 °C

30 V

20 V

0.5

2.0

10 mA

5.0 mA

862

145

1.25

100

mW

°C/W

W

°C/W

+150 °C

°C

A

ELECTRICAL CHARACTERISTICS (V

= 15 V , RT = 3.65 kΩ, CT = 1.0 nF, for typical values TA = +25°C, for min/max values TA is

CC

the operating ambient temperature range that applies [Note 2], unless otherwise noted.)

Characteristic

Symbol Min Typ Max Unit

REFERENCE SECTION

Reference Output Voltage (IO = 1.0 mA, TJ = +25°C) V

Line Regulation (VCC = 10 V to 30 V) Reg

Load Regulation (IO = 1.0 mA to 10 mA) Reg

T emperature Stability T

Total Output V ariation over Line, Load, and Temperature V

Output Noise Voltage (f = 10 Hz to 10 kHz, TJ = +25°C) V

ref

line

load

S

ref

n

5.05 5.1 5.15 V

– 2.0 15 mV

– 2.0 15 mV

– 0.2 – mV/°C

4.95 – 5.25 V

– 50 – µV

Long Term Stability (TA = +125°C for 1000 Hours) S – 5.0 – mV

Output Short Circuit Current I

SC

– 30 –65 –100 mA

OSCILLATOR SECTION

Frequency

TJ = +25°C

Line (VCC = 10 V to 30 V) and Temperature (TA = T

low

to T

high

)

Frequency Change with Voltage (VCC = 10 V to 30 V) ∆f

Frequency Change with Temperature (TA = T

low

to T

) ∆f

high

Sawtooth Peak Voltage V

Sawtooth Valley Voltage V

f

osc

/∆V – 0.2 1.0 %

osc

/∆T – 2.0 – %

osc

OSC(P)

OSC(V)

380

370

400

400

420

430

2.6 2.8 3.0 V

0.7 1.0 1.25 V

Clock Output Voltage

High State

Low State

NOTES: 1. Maximum package power dissipation limits must be observed.

2.Low duty cycle pulse techniques are used during test to maintain junction temperature as close to ambient as possible.

T

=0°C for MC34023 T

low

T

= –40°C for MC33023 T

low

= +70°C for MC34023

high

= +105°C for MC33023

high

V

OH

V

OL

3.9

–

2.3

4.5

–

2.9

kHz

V

2

MOTOROLA ANALOG IC DEVICE DATA

MC34023 MC33023

ELECTRICAL CHARACTERISTICS (V

= 15 V , RT = 3.65 kΩ, CT = 1.0 nF, for typical values TA = +25°C, for min/max values TA is

CC

the operating ambient temperature range that applies [Note 2], unless otherwise noted.)

Characteristic

Symbol Min Typ Max Unit

ERROR AMPLIFIER SECTION

Input Offset Voltage V

Input Bias Current I

Input Offset Current I

Open–Loop Voltage Gain (VO = 1.0 V to 4.0 V) A

IO

IB

IO

VOL

– – 15 mV

– 0.6 3.0 µA

– 0.1 1.0 µA

60 95 – dB

Gain Bandwidth Product (TJ = +25°C) GBW 4.0 8.3 – MHz

Common Mode Rejection Ratio (VCM = 1.5 V to 5.5 V) CMRR 75 95 – dB

Power Supply Rejection Ratio (VCC = 10 V to 30 V) PSRR 85 110 – dB

Output Current, Source (VO = 4.0 V)

Output Current, Sink (VO = 1.0 V)

Output Voltage Swing, High State (IO = –0.5 mA)

Output Voltage Swing, Low State (IO = 1 mA)

I

Source

I

Sink

V

OH

V

OL

0.5

1.0

4.5

0

3.0

3.6

4.75

0.4

–

–

5.0

1.0

Slew Rate SR 6.0 12 – V/µs

PWM COMPARATOR SECTION

Ramp Input Bias Current I

Duty Cycle, Maximum

Duty Cycle, Minimum

DC

DC

Zero Duty Cycle Threshold Voltage Pin 3(4) (Pin 7(9) = 0 V) V

Propagation Delay (Ramp Input to Output, TJ =+25°C) t

PLH(in/out)

IB

(max)

(min)

th

– –0.5 –5.0 µA

80

–

90

–

0

–

1.1 1.25 1.4 V

– 60 100 ns

SOFT–START SECTION

Charge Current (V

Soft–Start

Discharge Current (V

= 0.5 V) I

Soft–Start

= 1.5 V) I

chg

dischg

3.0 9.0 20 µA

1.0 4.0 – mA

CURRENT SENSE SECTION

Input Bias Current (Pin 9(12) = 0 V to 4.0 V) I

Current Limit Comparator Input Offset Voltage (Pin 11(14) = 1.1 V) V

Current Limit Reference Input Common Mode Range (Pin 11(14)) V

Shutdown Comparator Threshold V

Propagation Delay (Current Limit/Shutdown to Output, TJ =+25°C) t

PLH(in/out)

IB

IO

CMR

th

– – 15 µA

– – 45 mV

1.0 – 1.25 V

1.25 1.40 1.55 V

– 50 80 ns

OUTPUT SECTION

Output Voltage

Low State (I

High State (I

Sink

(I

Sink

Source

(I

Source

= 20 mA)

= 200 mA)

= 20 mA)

= 200 mA)

Output Voltage with UVLO Activated (VCC = 6.0 V, I

= 0.5 mA) V

Sink

V

V

OL(UVLO)

Output Leakage Current (VC = 20 V) I

Output Voltage Rise T ime (CL = 1.0 nF, TJ = +25°C) t

Output Voltage Fall T ime (CL = 1.0 nF, TJ = +25°C) t

OL

OH

L

r

f

–

–

13

12

0.25

1.2

13.5

13

0.4

2.2

–

–

– 0.25 1.0 V

– 100 500 µA

– 30 60 ns

– 30 60 ns

UNDERVOLTAGE LOCKOUT SECTION

Start–Up Threshold (VCC Increasing) V

UVLO Hysteresis Voltage (VCC Decreasing After Turn–On) V

th(on)

H

8.8 9.2 9.6 V

0.4 0.8 1.2 V

TOTAL DEVICE

Power Supply Current

Start–Up (VCC = 8.0 V)

Operating

NOTES: 1. Maximum package power dissipation limits must be observed.

2.Low duty cycle pulse techniques are used during test to maintain junction temperature as close to ambient as possible.

T

=0°C for MC34023 T

low

T

= –40°C for MC33023 T

low

= +70°C for MC34023

high

= +105°C for MC33023

high

I

CC

–

–

0.5

20

1.2

30

mA

V

%

V

mA

MOTOROLA ANALOG IC DEVICE DATA

3

100 k

1 3 5 7

Ω

CT =

1. 100 nF

10 k

2. 47 nF

3. 22 nF

4. 10 nF

5. 4.7 nF

, TIMING RESISTOR ( )

6. 2.2 nF

T

R

7. 1.0 nF

1.0 k

8. 470 pF

9. 220 pF

470

100 1000

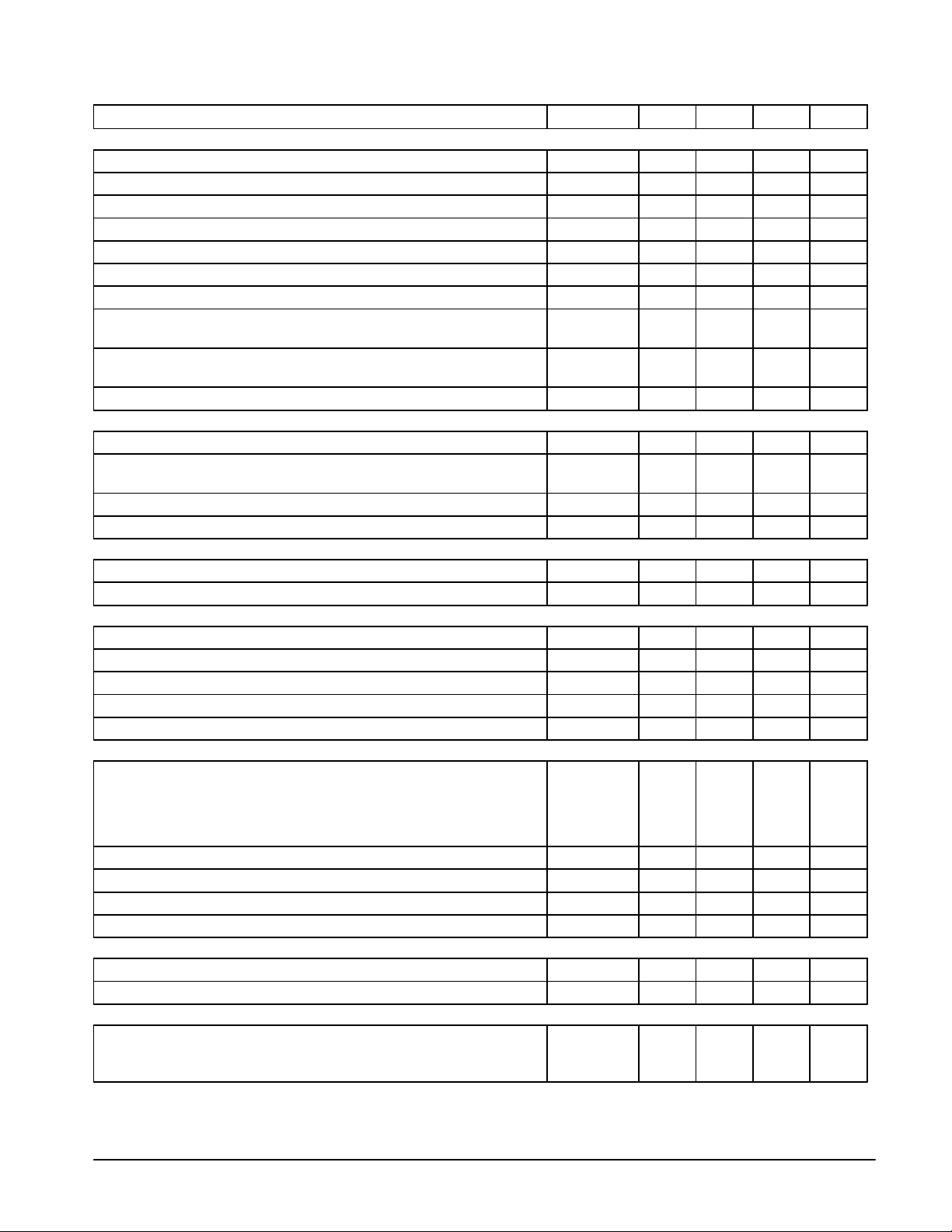

Figure 1. Timing Resistor versus

Oscillator Frequency

9

2 4 6 8

4

10

f

, OSCILLAT OR FREQUENCY (Hz)

osc

10

5

VCC = 15 V

TA = +25

10

MC34023 MC33023

Figure 2. Oscillator Frequency versus T emperature

1200

°

C

6

10

7

1000

800

600

400

, OSCILLAT OR FREQUENCY (kHz)f

200

osc

0

– 55 – 25 0 25 50 75

VCC = 15 V

1.0 MHz

400 kHz

50 kHz

TA, AMBIENT TEMPERATURE (°C)

RT = 1.2 k

CT = 1.0 nF

RT = 3.6 k

CT = 1.0 nF

RT = 36 k

CT = 1.0 nF

100 125

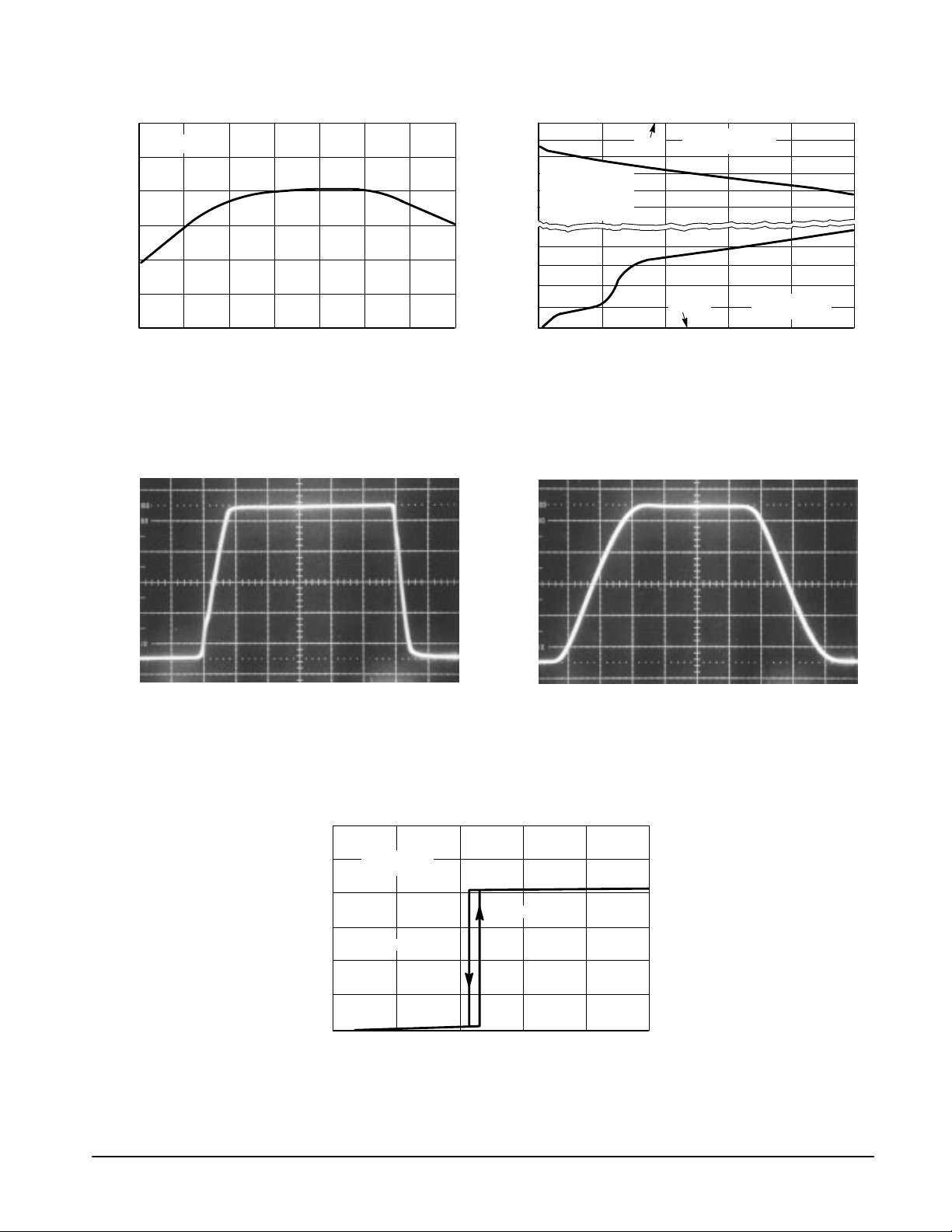

Figure 3. Error Amp Open Loop Gain and

Phase versus Frequency

120

100

80

60

40

20

, OPEN LOOP VOL TAGE GAIN (dB)

0

VOL

A

–20

10 100 1.0 k 10 k 100 k 1.0 M 10 M

Phase

Gain

f, FREQUENCY (Hz)

Figure 5. Error Amp Small Signal

Transient Response

2.55 V

0

45

90

θ

135

1.30

1.28

C)

°

1.26

1.24

, ZERO DUTY CYCLE (V)

, EXCESS PHASE (

TH

1.22

V

1.20

– 55 – 25 0 25 50 75 100

3.0 V

Figure 4. PWM Comparator Zero Duty Cycle

Threshold V oltage versus Temperature

VCC = 15 V

Pin 7(9) = 0 V

°

TA, AMBIENT TEMPERATURE (

C)

Figure 6. Error Amp Large Signal

Transient Response

125

2.5 V

2.45 V

4

2.5 V

2.0 V

0.1 µs/DIV 0.1 µs/DIV

MOTOROLA ANALOG IC DEVICE DATA

MC34023 MC33023

Figure 7. Reference V oltage Change

0

– 5.0

VCC = 15 V

–10

–15

–20

–25

, REFERENCE VOLTAGE CHANGE (mV)

ref

V

–30

0

10 20 30 40 50

Figure 9. Reference Line Regulation Figure 10. Reference Load Regulation

versus Source Current

TA = – 55°C

TA = +125°C

I

, SOURCE CURRENT (mA)

Source

TA = +25°C

65.6

65.2

64.8

64.4

, REFERENCE SHORT CIRCUIT CURRENT (mA)

SC

I

Figure 8. Reference Short Circuit Current

versus T emperature

66

VCC = 15 V

64

–55

– 25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (

°

C)

– 100

, CURRENT LIMIT INPUT OFFSET VOLTAGE (mV)V

IO

100

60

20

–20

–60

2.0 mV/DIV

V

LINE REGULA TION 10 V to 24 V

ref

(2.0 ms/DIV)

Figure 11. Current Limit Comparator Input

Offset Voltage versus Temperature

VCC = 15 V

Pin 11(14) = 1.1 V

TA, AMBIENT TEMPERATURE (°C)

2.0 mV/DIV

V

LOAD REGULATION 1.0 mA to 10 mA

ref

Figure 12. Shutdown Comparator Threshold

V oltage versus Temperature

1.50

VCC = 15 V

1.46

1.42

1.38

, THRESHOLD VOLTAGE (V)V

1.34

th

1.30

100 0

– 55 – 25 25 50 75 100 125– 55 – 25 0 25 50 75 125

TA, AMBIENT TEMPERATURE (

(2.0 ms/DIV)

°

C)

MOTOROLA ANALOG IC DEVICE DATA

5

MC34023 MC33023

Figure 13. Soft–Start Charge Current

versus T emperature

A)

10

µ

, SOFT-ST ART CHARGE CURRENT (

I

chg

9.5

9.0

8.5

8.0

7.5

7.0

VCC = 15 V

– 55 – 25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

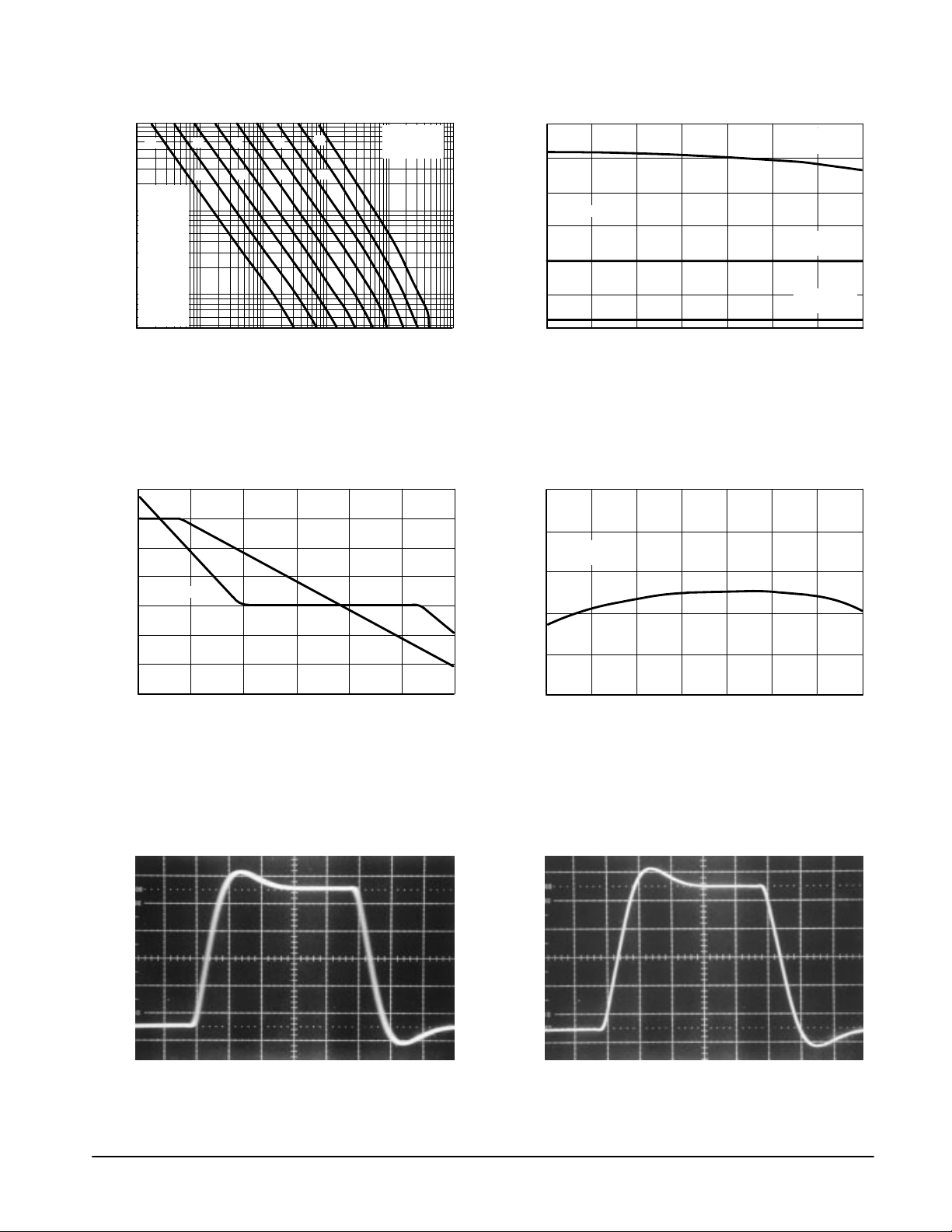

Figure 15. Drive Output Rise and Fall Time Figure 16. Drive Output Rise and Fall Time

Figure 14. Output Saturation Voltage

versus Load Current

0

– 1.0

VCC = 15 V

µ

s Pulsed Load

80

120 Hz Rate

– 2.0

, OUTPUT SA TURATION VOLTAGE (V)

sat

V

2.0

1.0

0

°

C

TA = 25

0 0.2 0.4 0.6 0.8 1.0

V

IO, OUTPUT LOAD CURRENT (A)

CC

Ground

Source Saturation

(Load to Ground)

Sink Saturation

(Load to VCC)

OUTPUT RISE & FALL TIME 1.0 nF LOAD

50 ns/DIV

Figure 17. Supply V oltage versus Supply Current

30

25

20

15

10

, SUPPLY CURRENT (mA)

CC

5.0

I

RT = 3.65 k

CT = 1.0 nF

VCC Decreasing

0

0 4.0 8.0 12 16 20

OUTPUT RISE & FALL TIME 10 nF LOAD

50 ns/DIV

Ω

VCC Increasing

VCC, SUPPLY VOLTAGE (V)

6

MOTOROLA ANALOG IC DEVICE DATA

MC34023 MC33023

Clock

R

T

C

T

Ramp

Error Amp Output

Noninverting Input

Inverting Input

Soft–Start

C

SS

Figure 18. Representative Block Diagram

V

CC

16

V

ref

4

5

Oscillator

6

1.25 V

7

3

2

1

8

Error

Amp

4.2 V

PWM

Comparator

+

µ

A

9.0

R

Q

S

Reference

Regulator

V

ref

UVLO

0.5 V

Soft–Start Latch

Ground10

VCC

UVLO

9.2 V

R

Q

S

PWM Latch

Current

Limit

Shutdown

15

V

CC

13

V

C

14

Output

12

Power Ground

11

Current Limit Reference

9

Current Limit/Shutdown

1.4 V

V

in

C

T

Clock

Soft–Start

Error Amp Output

Ramp

PWM

Comparator

Output

Figure 19. Current Limit Operating Waveforms

MOTOROLA ANALOG IC DEVICE DATA

7

MC34023 MC33023

OPERA TING DESCRIPTION

The MC33023 and MC34023 series are high speed, fixed

frequency, single–ended pulse width modulator controllers

optimized for high frequency operation. They are specifically

designed for Off–Line and DC–to–DC converter applications

offering the designer a cost effective solution with minimal

external components. A representative block diagram is

shown in Figure 18.

Oscillator

The oscillator frequency is programmed by the values

selected for the timing components RT and CT. The RT pin is

set to a temperature compensated 3.0 V. By selecting the

value of RT, the charge current is set through a current mirror

for the timing capacitor CT. This charge current runs

continuously through CT. The discharge current is ratioed to

be 10 times the charge current, which yields the maximum

duty cycle of 90%. CT is charged to 2.8 V and discharged to

1.0 V . During the discharge of CT, the oscillator generates an

internal blanking pulse that resets the PWM Latch and,

inhibits the outputs. The threshold voltage on the oscillator

comparator is trimmed to guarantee an oscillator accuracy of

5.0% at 25°C.

Additional dead time can be added by externally

increasing the charge current to CT as shown in Figure 23.

This changes the charge to discharge ratio of CT which is set

internally to I

ratio will be:

% Deadtime

A bidirectional clock pin is provided for synchronization or

for master/slave operation. As a master, the clock pin

provides a positive output pulse during the discharge of CT.

As a slave, the clock pin is an input that resets the PWM latch

and blanks the drive output, but does not discharge CT.

Therefore, the oscillator is not synchronized by driving the

clock pin alone. Figures 27, 28 and 29 provide suggested

synchronization.

Error Amplifier

A fully compensated Error Amplifier is provided. It features

a typical DC voltage gain of 95 dB and a gain bandwidth

product of 8.3 MHz with 75 degrees of phase margin

(Figure 3). Typical application circuits will have the

noninverting input tied to the reference. The inverting input

will typically be connected to a feedback voltage generated

from the output of the switching power supply. Both inputs

have a common mode voltage (VCM) input range of 1.5 V to

5.5 V . The Error Amplifier Output is provided for external loop

compensation.

Soft–Start Latch

Soft–Start is accomplished in conjunction with an external

capacitor. The Soft–Start capacitor is charged by an internal

9.0 µA current source. This capacitor clamps the output of

the error amplifier to less than its normal output voltage, thus

charge

/10 I

charge

I

+

. The new charge to discharge

)

I

10 (I

l

charge

charge

)

additiona

limiting the duty cycle. The time it takes for a capacitor to

reach full charge is given by:

t[(4.5 • 105)C

A Soft–Start latch is incorporated to prevent erratic

operation of this circuitry. Two conditions can cause the

Soft–Start circuit to latch so that the Soft–Start capacitor

stays discharged. The first condition is activation of an

undervoltage lockout of either VCC or V

condition is when current sense input exceeds 1.4 V. Since

this latch is “set dominant”, it cannot be reset until either of

these signals is removed and, the voltage at C

than 0.5 V.

PWM Comparator and Latch

A PWM circuit typically compares an error voltage with a

ramp signal. The outcome of this comparison determines the

state of the output. In voltage mode operation the ramp signal

is the voltage ramp of the timing capacitor. In current mode

operation the ramp signal is the voltage ramp induced in a

current sensing element. The ramp input of the PWM

comparator is pinned out so that the user can decide which

mode of operation best suits the application requirements.

The ramp input has a 1.25 V offset such that whenever the

voltage at this pin exceeds the error amplifier output voltage

minus 1.25 V , the PWM comparator will cause the PWM latch

to set, disabling the outputs. Once the PWM latch is set, only

a blanking pulse by the oscillator can reset it, thus initiating

the next cycle.

Current Limiting and Shutdown

A pin is provided to perform current limiting and shutdown

operations. Two comparators are connected to the input of

this pin. The reference voltage for the current limit

comparator is not set internally . A pin is provided so the user

can set the voltage. When the voltage at the current limit

input pin exceeds the externally set voltage, the PWM latch is

set, disabling the output. In this way cycle–by–cycle current

limiting is accomplished. If a current limit resistor is used in

series with the power devices, the value of the resistor is

found by:

I

R

Sense

If the voltage at this pin exceeds 1.4 V, the second

comparator is activated. This comparator sets a latch which,

in turn, causes the soft start capacitor to be discharged. In

this way a “hiccup” mode of recovery is possible in the case

of output short circuits. If a current limit resistor is used in

series with the output devices, the peak current at which the

controller will enter a “hiccup” mode is given by:

Limit Reference Voltage

+

I

shutdown

Soft-Start

I

pk (s witch)

1.4 V

+

R

Sense

. The second

ref

Soft–Start

is less

8

MOTOROLA ANALOG IC DEVICE DATA

MC34023 MC33023

Undervoltage Lockout

There are two undervoltage lockout circuits within the IC.

The first senses VCC and the second V

VCC must exceed 9.2 V and V

the outputs can be enabled and the Soft–Start latch released.

If VCC falls below 8.4 V or V

are disabled and the Soft–Start latch is activated. When the

UVLO is active, the part is in a low current standby mode

allowing the IC to have an off–line bootstrap start–up circuit.

Typical start–up current is 500 µA.

Output

The MC34023 has a high current totem pole output

specifically designed for direct drive of power MOSFETs. It is

capable of up to ± 2.0 A peak drive current with a typical rise

and fall time of 30 ns driving a 1.0 nF load.

Separate pins for VC and Power Ground are provided.

With proper implementation, a significant reduction of

switching transient noise imposed on the control circuitry is

possible. The separate VC supply input also allows the

designer added flexibility in tailoring the drive voltage

independent of VCC.

Reference

A 5.1 V bandgap reference is pinned out and is trimmed to

an initial accuracy of ±1.0% at 25°C. This reference has short

circuit protection and can source in excess of 10 mA for

powering additional control system circuitry.

Design Considerations

Do not attempt to construct the converter on

wire–wrap or plug–in prototype boards. With high

frequency, high power, switching power supplies it is

imperative to have separate current loops for the signal paths

and for the power paths. The printed circuit layout should

contain a ground plane with low current signal and high

current switch and output grounds returning on separate

paths back to the input filter capacitor. Shown in Figure 35 is

a printed circuit layout of the application circuit. Note how the

power and ground traces are run. All bypass capacitors and

snubbers should be connected as close as possible to the

specific part in question. The PC board lead lengths must be

less than 0.5 inches for effective bypassing for snubbing.

Instabilities

In current mode control, an instability can be encountered

at any given duty cycle. The instability is caused by the

must exceed 4.2 V before

ref

falls below 3.6 V, the outputs

ref

. During power–up,

ref

current feedback loop. It has been shown that the instability is

caused by a double pole at half the switching frequency . If an

external ramp (Se) is added to the on–time ramp (Sn) of the

current–sense waveform, stability can be achieved.

One must be careful not to add too much ramp

compensation. If too much is added the system will start to

perform like a voltage mode regulator. All benefits of current

mode control will be lost. Figure 25 is an example of one way

in which external ramp compensation can be implemented.

Figure 20. Ramp Compensation

Ramp Compensation

Ramp Input

Ramp

Compensation S

A simple equation can be used to calculate the amount of

external ramp slope necessary to add that will achieve

stability in the current loop. For the following equations, the

calculated values for the application circuit in Figure 34 are

also shown.

where: = DC output voltage

For the application circuit:

NP, N

e

Current

Signal S

n

V

N

O

S

ǒ

Ǔ

N

P

Se+

= 0.1 15 V/ms

V

O

S

A

R

S

Se+

i

L

L

= number of power transformer primary

= or secondary turns

= gain of the current sense network

= (see Figures 23 and 24)

= output inductor

= current sense resistance

(RS)A

5

1.8 µ

1.25 V

i

2

ǒ

Ǔ

8

(

0.3)(0.55

)

MOTOROLA ANALOG IC DEVICE DATA

9

MC34023 MC33023

PIN FUNCTION DESCRIPTION

Pin

DIP/SOIC

1 Error Amp

2 Error Amp

3 Error Amp

4 Clock This is a bidirectional pin used for synchronization.

5 R

6 C

7 Ramp Input For voltage mode operation this pin is connected to CT. For current mode operation this pin is

8 Soft–Start A capacitor at this pin sets the Soft–Start time.

9 Current Limit/

10 Ground This pin is the ground for the control circuitry.

11 Current Limit

12 Power Ground This is a separate power ground return that is connected back to the power source. It is used to reduce

13 V

14 Output This is a high current totem pole output.

15 V

16 V

Function Description

Inverting

Input

Noninverting

Input

Output

T

T

Shutdown

Reference

Input

C

CC

ref

This pin is usually used for feedback from the output of the power supply.

This pin is used to provide a reference in which an error signal can be produced on the output of the

error amp. Usually this is connected to V

This pin is provided for compensating the error amp for poles and zeros encountered in the power

supply system, mostly the output LC filter.

The value of RT sets the charge current through timing Capacitor, CT.

In conjunction with RT, the timing Capacitor sets the switching frequency.

connected through a filter to the current sensing element.

This pin has two functions. First, it provides cycle–by–cycle current limiting. Second, if the current is

excessive, this pin will reinitiate a Soft–Start cycle.

This pin voltage sets the threshold for cycle–by–cycle current limiting.

the effects of switching transient noise on the control circuitry .

This is a separate power source connection for the outputs that is connected back to the power source

input. With a separate power source connection, it can reduce the effects of switching transient noise

on the control circuitry.

This pin is the positive supply of the control IC.

This is a 5.1 V reference. It is usually connected to the noninverting input of the error amplifier.

, however an external reference can also be used.

ref

Figure 21. V oltage Mode Operation

4

5

Oscillator

C

T

Output Voltage

Feedback Input

In voltage mode operation, the control range on the output of the Error

Amplifier from 0% to 90% duty cycle is from 2.25 V to 4.05 V.

6

7

3

1

V

ref

1.25 V

2

10

Figure 22. Current Mode Operation

4

5

Oscillator

C

From Current

Sense Element

Output Voltage

Feedback Input

In current mode control, an RC filter should be placed at the ramp input

to filter the leading edge spike caused by turn–on of a power MOSFET .

6

T

1.25 V

7

3

1

2

V

ref

MOTOROLA ANALOG IC DEVICE DATA

MC34023 MC33023

Figure 23. Resistive Current Sensing

9

The addition of an RC filter will eliminate instability caused by the

leading edge spike on the current waveform. This sense signal can also

be used at the ramp input pin for current mode control. For ramp

compensation it is necessary to know the gain of the current feedback

loop. If a transformer is used, the gain can be calculated by:

R

+

i

Sense

turns ratio

A

I

Sense

Figure 25A. Slope Compensation (Noise Sensitive)

C

T

Figure 24. Primary Side Current Sensing

9

The addition of an RC filter will eliminate instability caused by the

leading edge spike on the current waveform. This sense signal can also

be used at the ramp input pin for current mode control. For ramp

compensation it is necessary to know the gain of the current feedback

loop. The gain can be calculated by:

+

i

R

turns ratio

A

4

5

6

C

1

Oscillator

R

w

w

I

Sense

R

Current Sense

Information

This method of slope compensation is easy to implement, however, it

is noise sensitive. Capacitor C1 provides AC coupling. The oscillator

signal is added to the current signal by a voltage divider consisting of

resistors R1 and R2.

1

7

R

2

3

1.25 V

Figure 25B. Slope Compensation (Noise Immune)

R

Output

C

M

f

Ramp

Input

R

M

1.25 V

7

3

C

f

Current Sense

Transformer

R

w

Ramp

Figure 25.

Input

R

Output

R

M

C

When only one output is used, this method of slope compensation can be used and it is relatively noise immune. Resistor RM and capacitor CM provide the added

slope necessary. By choosing RM and CM with a larger time constant than the switching frequency, you can assume that its charge is linear . First choose CM, then

RM can be adjusted to achieve the required slope. The diode provides a reset pulse at the ramp input at the end of every cycle. The charge current IM can be calculated

by IM = CMSe. Then RM can be calculated by RM = VCC/I

f

C

f

M

1.25 V

7

Current Sense

3

M.

Resistor

MOTOROLA ANALOG IC DEVICE DATA

11

MC34023 MC33023

Figure 26. Dead Time Addition

V

ref

R

DT

4

5

R

6

T

Additional dead time can be added by the addition of a dead time

resistor from V

information.

C

T

to CT. See text on Oscillator section for more

ref

Oscillator

Figure 28. Current Mode Master/Slave Operation Over Short Distances

Figure 27. External Clock Synchronization

5.0 V

0 V

R

T

The sync pulse fed into the clock pin must be at least 3.9 V . RT and C

need to be set 10% slower than the sync frequency. This circuit is also

used in Voltage Mode operation for master/slave operation. The clock

signal would be coming from the master which is set at the desired

operating frequency, while the slave is set 10% slower.

4

5

6

C

T

Oscillator

T

Reference

Master

Oscillator

Master

Oscillator

4

5

6

R

C

T

T

4

V

5

ref

6

Slave

Oscillator

Figure 29. Synchronization Over Long Distances

1.0 k

4.7 k

20

MMBT3906

MMBD0914

MMBT3904

C

1.15 R

T

NC

T

16

4

5

6

2200

C

T

R

430

T

4

5

6

Slave

Oscillator

12

MOTOROLA ANALOG IC DEVICE DATA

MC34023 MC33023

Figure 30. Buffered Maximum Clamp Level

1

2

V

ref

R

1

R

2

In voltage mode operation, the maximum duty cycle can be clamped. By the

addition of a PNP transistor to buffer the clamp voltage, the Soft–Start current

is not affected by R1.

The new equation for Soft–Start is t

In current mode operation, this circuit will limit the maximum voltage allowed

at the ramp input to end a cycle.

8

C

SS

V

[

clamp

9.0 µA

+

)

0.6

(CSS)

Figure 32. MOSFET Parasitic Oscillations

Figure 31. Bipolar Transistor Drive

I

B

+

V

0

–

Base Charge

Removal

C

15

V

in

14

12

T o Current

Sense Input

The totem pole output can furnish negative base current for enhanced

transistor turn–off, with the addition of the capacitor in series with the base.

Figure 33. Isolated MOSFET Drive

R

S

V

C

V

in

15

14

12

To Current

R

S

Sense Input

A series gate resistor may be needed to dampen high frequency parasitic

oscillation caused by the MOSFET’s input capacitance and any series wiring

inductance in the gate–source circuit. The series resistor will also decrease the

MOSFET switching speed. A Schottky diode can reduce the driver’s power

dissipation due to excessive ringing, by preventing the output pin from being

driven below ground. The Schottky diode also prevents substrate injection when

the output pin is driven below ground.

V

C

15

14

12

The totem pole output can easily drive pulse transformers. A Schottky diode

is recommended when driving inductive loads at high frequencies. The diode

can reduce the driver’s power dissipation due to excessive ringing, by preventing

the output pin from being driven below ground.

MOTOROLA ANALOG IC DEVICE DATA

13

MC34023 MC33023

V = 5.0 V

µ

10 F

1.8

1500 pF 22

1

T

1N5819

in

V = 40 V to 56 V

47 k

4.7

15

O

1

1

L

1500 pF

22

Figure 34.

±

±

10 mVp–p

54 mV = 1.0%

14 mV = 0.275%

69.8%

MBR2535 CTL

MUR410

3.9 k

1.0 k

1600 pF

100

47

10

50

IRF640

10

4.7

2

Ω

0.3

1N5819

100

100

220 pF

47

in O

in O

V = 40 V to 56 V, I = 7.5A

V = 48 V, I = 4.0 A to 7.5 A

in O

in O

V = 48 V, I = 7.5 A

V = 48 V, I = 7.5 A

Test Condition Result

13

14

12

11

9

Line Regulation

Load Regulation

Output Ripple

Efficiency

Figure 34. Application Circuit

Reference

16

ref

V

CC

V

UVLO

Regulator

4.2 V

5

4

1.2 k

1.0

9.2 V

ref

V

UVLO

Oscillator

6

1000 pF

R

PWM

0.01

Current

Q

S

PWM Latch

Comparator

1.25 V

7

3

22 k

2.0 k

Limit

+

1

2

ref

V

µ

0.015 F

Shutdown

0.5 V

µ

9.0 A

Error

Amp

8

47 k

1.4 V

Soft–Start Latch

R

S

Q

0.1

Soft–Start

10

µ

Primary: 8 turns #48 A WG (1300 strands litz wire)

Secondary: 2 turns 0.003’’ (2 layers) copper foil

Bootstrap: 1 turn added to secondary #36 A WG

Core: Philips 3F3, part #4312 020 4124

Bobbin: Philips part #4322 021 3525

Coilcraft P3269–A

2 turns #48 A WG (1300 strands litz wire)

Core: Philips 3F3, part #EP10–3F3

Bobbin: Philips part #EP10PCB1–8

L = 1.8 H

–

1

T

–

1

L

Coilcraft P3270–A

µ

Ω

Output Rectifiers: AA VID Heatsink #533402B02552 with clip

Power FET : AAVID Heatsink #533902B02552 with clip

All power devices are insulated with Berquist Sil–Pad 150

5(1.5 ) resistors in parallel

10(1.0 F) ceramic capacitors in parallel

–

–

1

2

Insulators –

Heatsinks –

14

MOTOROLA ANALOG IC DEVICE DATA

100 pF

1000 pF

0.01

100 pF

0.01

MC34023

+10

MC34023 MC33023

Figure 35. PC Board With Components

1N5819

1N5819

2535CTI

MBR

1N5819

0.01

1500 pF

4.0

″

100

2200 pF

6.5

″

(Top View)

2535CTI

MBR

1500 pF

MOTOROLA ANALOG IC DEVICE DATA

15

MC34023 MC33023

Figure 36. PC Board Without Components

(Top View)

4.0

″

16

6.5

″

(Bottom View)

MOTOROLA ANALOG IC DEVICE DATA

MC34023 MC33023

OUTLINE DIMENSIONS

P SUFFIX

PLASTIC PACKAGE

CASE 648–08

–A–

916

B

18

F

C

S

–T–

H

G

D

16 PL

K

M M

TA0.25 (0.010)

–A–

916

–B–

P 8 PL

18

0.25 (0.010)

G 14 PL

C

–T–

SEATING

K

16 PL

D

0.25 (0.010) T A B

M

PLANE

S S

SEATING

PLANE

J

DW SUFFIX

PLASTIC PACKAGE

CASE 751G–02

(SO–16L)

M M

B

J

F

M

R

L

X 45°

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD FLASH.

5. ROUNDED CORNERS OPTIONAL.

INCHES MILLIMETERS

MIN MINMAX MAX

DIM

A

0.740

B

0.250

C

0.145

D

0.015

F

0.040

G

0.100 BSC

H

M

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE

DAMBAR PROTRUSION. ALLOWABLE

DAMBAR PROTRUSION SHALL BE 0.13

(0.005) TOTAL IN EXCESS OF D DIMENSION

AT MAXIMUM MATERIAL CONDITION.

DIM

A

B

C

D

F

G

J

K

M

P

R

0.050 BSC

J

0.008

K

0.110

L

0.295

M

0

S

0.020

INCHES

MIN MAX

0.411

0.400

0.299

0.292

0.104

0.093

0.019

0.014

0.035

0.020

0.050 BSC

0.012

0.010

0.009

0.004

0

°

0.395

0.415

0.010

0.029

°

0.770

0.270

0.175

0.021

0.070

0.015

0.130

0.305

10

°

0.040

MILLIMETERS

MIN MAX

10.15

7.40

2.35

0.35

0.50

1.27 BSC

0.25

0.10

7

0

°

10.05

0.25

°

18.80

6.35

3.69

0.39

1.02

2.54 BSC

1.27 BSC

0.21

2.80

7.50

0

°

0.51

10.45

7.60

2.65

0.49

0.90

0.32

0.25

10.55

0.75

19.55

6.85

4.44

0.53

1.77

0.38

3.30

7.74

10

°

1.01

7

°

MOTOROLA ANALOG IC DEVICE DATA

17

MC34023 MC33023

OUTLINE DIMENSIONS

FN SUFFIX

PLASTIC PACKAGE

CASE 775–02

(PLCC)

–L–

20

C

0.010 (0.250) T L

–N–

Y BRK

B

0.007 (0.180) T L

D

U

0.007 (0.180) T L

–M

SNSM

SNSM

–M

–M–

W

1

D

V

Z

G1

X

0.010 (0.250) T L

–M

SNSS

VIEW D–D

A

0.007 (0.180) T L

–M

SNSM

Z

G1

R

0.007 (0.180) T L

E

0.004 (0.100)

G

J

–T–

SEATING

PLANE

VIEW S

SNSS

–M

–M

SNSM

0.007 (0.180) T L

H

–M

SNSM

K1

K

F

0.007 (0.180) T L

–M

SNSM

VIEW S

NOTES:

1. DATUMS –L–, –M–, AND –N– DETERMINED WHERE

TOP OF LEAD SHOULDER EXITS PLASTIC BODY

AT MOLD PARTING LINE.

2. DIM G1, TRUE POSITION TO BE MEASURED AT

DATUM –T–, SEATING PLANE.

3. DIM R AND U DO NOT INCLUDE MOLD FLASH.

ALLOWABLE MOLD FLASH IS 0.010 (0.250) PER

SIDE.

4. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

5. CONTROLLING DIMENSION: INCH.

6. THE PACKAGE TOP MAY BE SMALLER THAN THE

PACKAGE BOTTOM BY UP TO 0.012 (0.300).

DIMENSIONS R AND U ARE DETERMINED AT THE

OUTERMOST EXTREMES OF THE PLASTIC BODY

EXCLUSIVE OF MOLD FLASH, TIE BAR BURRS,

GATE BURRS AND INTERLEAD FLASH, BUT

INCLUDING ANY MISMATCH BETWEEN THE TOP

AND BOTTOM OF THE PLASTIC BODY.

7. DIMENSION H DOES NOT INCLUDE DAMBAR

PROTRUSION OR INTRUSION. THE DAMBAR

PROTRUSION(S) SHALL NOT CAUSE THE H

DIMENSION TO BE GREATER THAN 0.037 (0.940).

THE DAMBAR INTRUSION(S) SHALL NOT CAUSE

THE H DIMENSION TO BE SMALLER THAN 0.025

(0.635).

INCHES MILLIMETERS

MIN MINMAX MAX

DIM

A

0.385

0.385

0.165

0.090

0.013

0.026

0.020

0.025

0.350

0.350

0.042

0.042

0.042

2

0.310

0.040

0.395

0.395

0.180

0.110

0.019

0.032

–

–

0.356

0.356

0.048

0.048

0.056

–

0.020

°

10

0.330

–

G1

K1

B

C

E

F

G

H

J

K

R

U

V

W

X

Y

Z

9.78

10.03

9.78

10.03

4.20

4.57

2.29

2.79

0.33

0.48

1.27 BSC0.050 BSC

0.66

0.81

0.51

–

0.64

–

8.89

9.04

8.89

9.04

1.07

1.21

1.07

1.21

1.07

1.42

–

0.50

°

2

7.88

1.02

10

8.38

°

–

°

18

MOTOROLA ANALOG IC DEVICE DATA

MC34023 MC33023

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.: SPD, Strategic Planning Office, 4–32–1,

P.O. Box 5405, Denver, Colorado 80217. 303–675–2140 or 1–800–441–2447 Nishi–Gotanda, Shinagawa–ku, Tokyo 141, Japan. 81–3–5487–8488

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 602–244–6609 ASIA /PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://motorola.com/sps

MOTOROLA ANALOG IC DEVICE DATA

– US & Canada ONLY 1–800–774–1848 51 Ting Kok Road, T ai Po, N.T., Hong Kong. 852–26629298

◊

Mfax is a trademark of Motorola, Inc.

19

MC34023/D

Loading...

Loading...