SEMICONDUCTOR TECHNICAL DATA

Advance Information

Order this document

by MC14LC5480/D

The MC14LC5480 is a general purpose per channel PCM Codec–Filter with

pin selectable Mu–Law or A–Law companding, and is offered in 20–pin DIP,

SOG, and SSOP packages. This device performs the voice digitization and

reconstruction as well as the band limiting and smoothing required for PCM

systems. This device is designed to operate in both synchronous and

asynchronous applications and contains an on–chip precision reference

voltage.

This device has an input operational amplifier whose output is the input to the

encoder section. The encoder section immediately low–pass filters the analog

signal with an active R–C filter to eliminate very high frequency noise from being

modulated down to the passband by the switched capacitor filter. From the

active R–C filter, the analog signal is converted to a dif ferential signal. From this

point, all analog signal processing is done differentially. This allows processing

of an analog signal that is twice the amplitude allowed by a single–ended

design, which reduces the significance of noise to both the inverted and

non–inverted signal paths. Another advantage of this differential design is that

noise injected via the power supplies is a common–mode signal that is

cancelled when the inverted and non–inverted signals are recombined. This

dramatically improves the power supply rejection ratio.

After the differential converter, a differential switched capacitor filter band–

passes the analog signal from 200 Hz to 3400 Hz before the signal is digitized

by the differential compressing A/D converter .

The decoder accepts PCM data and expands it using a differential D/A

converter. The output of the D/A is low–pass filtered at 3400 Hz and sinX/X

compensated by a differential switched capacitor filter. The signal is then filtered

by an active R–C filter to eliminate the out–of–band energy of the switched

capacitor filter.

The MC14LC5480 PCM Codec–Filter accepts a variety of clock formats,

including Short Frame Sync, Long Frame Sync, IDL, and GCI timing

environments. This device also maintains compatibility with Motorola’s family of

Telecommunication products, including the MC14LC5472 U–Interface Transceiver, MC145474/75 S/T–Interface Transceiver, MC145532 ADPCM Transcoder, MC145422/26 UDLT–1, MC145421/25 UDLT–2, and MC3419/MC33120

SLIC.

The MC14LC5480 PCM Codec–Filter utilizes CMOS due to its reliable

low–power performance and proven capability for complex analog/digital VLSI

functions.

• Pin for Pin Replacement for the MC145480

• Single 5 V Power Supply

• Typical Power Dissipation of 15 mW, Power–Down of 0.01 mW

• Fully–Differential Analog Circuit Design for Lowest Noise

• Transmit Band–Pass and Receive Low–Pass Filters On–Chip

• Active R–C Pre–Filtering and Post–Filtering

• Mu–Law and A–Law Companding by Pin Selection

• On–Chip Precision Reference Voltage (1.575 V)

• Push–Pull 300 Ω Power Drivers with External Gain Adjust

• MC145536EVK is the Evaluation Kit that Also Includes the MC145532

ADPCM Transcoder

P SUFFIX

PLASTIC DIP

20

1

20

1

20

1

CASE 738

DW SUFFIX

SOG PACKAGE

CASE 751D

SD SUFFIX

SSOP

CASE 940C

ORDERING INFORMATION

MC14LC5480P Plastic DIP

MC14LC5480DW SOG Package

MC14LC5480SD SSOP

PIN ASSIGNMENT

RO+

RO–

PI

PO–

PO+ 5

V

DD

FSR

DR

BCLKR

PDI

1

2

3

4

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

V

AG

TI+

TI–

TG

Mu/A

V

SS

FST

DT

BCLKT

MCLK

This document contains information on a new product. Specifications and information herein are subject to change without notice.

REV 0.1

5/96

Motorola, Inc. 1996

MC14LC5480MOTOROLA

1

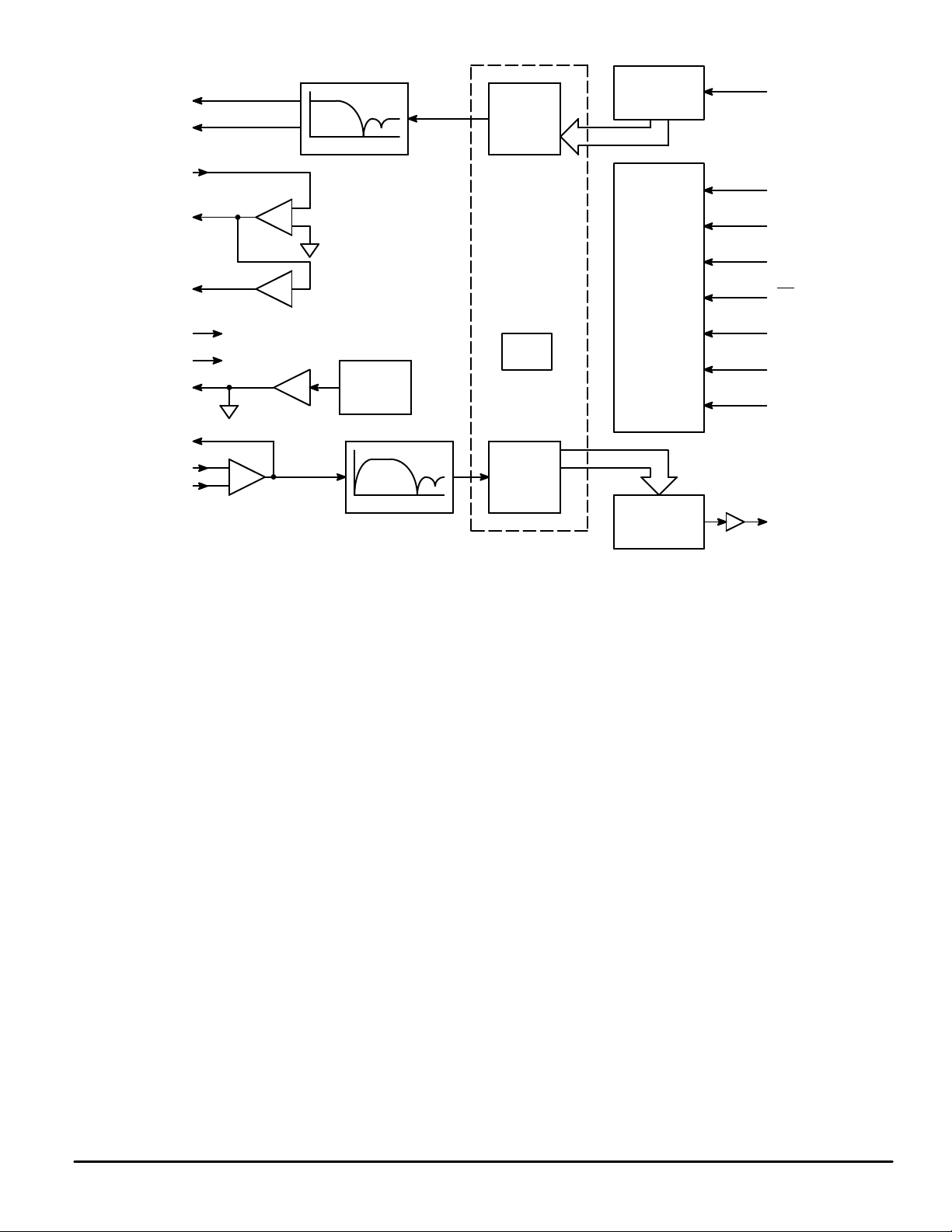

RO+

RO–

PO–

PO+

V

DD

V

SS

V

AG

TG

RECEIVE

SHIFT

DAC

FREQ

PI

–

– 1

+

1

2.4 V

REFERENCE

SHARED

DAC

1.575 V

REF

REGISTER

SEQUENCE

AND

CONTROL

DR

FSR

BCLKR

Mu/A

PDI

MCLK

BCLKT

FST

TI–

TI+

–

+

FREQ

Figure 1. MC14LC5480 PCM Codec–Filter Block Diagram

DEVICE DESCRIPTION

A PCM Codec–Filter is used for digitizing and reconstructing the human voice. These devices are used primarily for

the telephone network to facilitate voice switching and transmission. Once the voice is digitized, it may be switched by

digital switching methods or transmitted long distance (T1,

microwave, satellites, etc.) without degradation. The name

codec is an acronym from ‘‘COder’’ for the analog–to–digital

converter (ADC) used to digitize voice, and ‘‘DECoder’’ for

the digital–to–analog converter (DAC) used for reconstructing voice. A codec is a single device that does both the ADC

and DAC conversions.

To digitize intelligible voice requires a signal–to–distortion

ratio of about 30 dB over a dynamic range of about 40 dB.

This may be accomplished with a linear 13–bit ADC and

DAC, but will far exceed the required signal–to–distortion

ratio at larger amplitudes than 40 dB below the peak amplitude. This excess performance is at the expense of data per

sample. Two methods of data reduction are implemented by

compressing the 13–bit linear scheme to companded

pseudo–logarithmic 8–bit schemes. The two companding

schemes are: Mu–255 Law, primarily in North America and

Japan; and A–Law, primarily used in Europe. These companding schemes are accepted world wide. These companding schemes follow a segmented or ‘‘piecewise–linear’’ curve

formatted as sign bit, three chord bits, and four step bits. For

a given chord, all sixteen of the steps have the same voltage

weighting. As the voltage of the analog input increases, the

four step bits increment and carry to the three chord bits

ADC

TRANSMIT

SHIFT

REGISTER

DT

which increment. When the chord bits increment, the step

bits double their voltage weighting. This results in an effective resolution of six bits (sign + chord + four step bits) across

a 42 dB dynamic range (seven chords above 0, by 6 dB per

chord).

In a sampling environment, Nyquist theory says that to

properly sample a continuous signal, it must be sampled at a

frequency higher than twice the signal’s highest frequency

component. Voice contains spectral energy above 3 kHz, but

its absence is not detrimental to intelligibility. To reduce the

digital data rate, which is proportional to the sampling rate, a

sample rate of 8 kHz was adopted, consistent with a bandwidth of 3 kHz. This sampling requires a low–pass filter to

limit the high frequency energy above 3 kHz from distorting

the in–band signal. The telephone line is also subject to

50/60 Hz power line coupling, which must be attenuated

from the signal by a high–pass filter before the analog–to–

digital converter.

The digital–to–analog conversion process reconstructs a

staircase version of the desired in–band signal, which has

spectral images of the in–band signal modulated about the

sample frequency and its harmonics. These spectral images

are called aliasing components, which need to be attenuated

to obtain the desired signal. The low–pass filter used to attenuate these aliasing components is typically called a reconstruction or smoothing filter.

The MC14LC5480 PCM Codec–Filter has the codec, both

presampling and reconstruction filters, a precision voltage

reference on–chip, and requires no external components.

MC14LC5480 MOTOROLA

2

PIN DESCRIPTIONS

POWER SUPPLY

V

DD

Positive Power Supply (Pin 6)

This is the most positive power supply and is typically con-

nected to + 5 V. This pin should be decoupled to VSS with a

0.1 µF ceramic capacitor.

V

SS

Negative Power Supply (Pin 15)

This is the most negative power supply and is typically

connected to 0 V.

V

AG

Analog Ground Output (Pin 20)

This output pin provides a mid–supply analog ground reg-

ulated to 2.4 V. This pin should be decoupled to VSS with a

0.01 µF to 0.1 µF ceramic capacitor. All analog signal processing within this device is referenced to this pin. If the audio signals to be processed are referenced to VSS, then

special precautions must be utilized to avoid noise between

VSS and the VAG pin. Refer to the applications information in

this document for more information. The VAG pin becomes

high impedance when this device is in the powered down

mode.

CONTROL

Mu/A

Mu/A Law Select (Pin 16)

This pin controls the compression for the encoder and the

expansion for the decoder. Mu–Law companding is selected

when this pin is connected to VDD and A–Law companding is

selected when this pin is connected to VSS.

PDI

Power–Down Input (Pin 10)

This pin puts the device into a low power dissipation mode

when a logic 0 is applied. When this device is powered down,

all of the clocks are gated off and all bias currents are turned

off, which causes RO+, RO–, PO–, PO+, TG, VAG, and DT to

become high impedance. The device will operate normally

when a logic 1 is applied to this pin. The device goes through

a power–up sequence when this pin is taken to a logic 1

state, which prevents the DT PCM output from going low impedance for at least two FST cycles. The filters must settle

out before the DT PCM output or the RO+ or RO– receive

analog outputs will represent a valid analog signal.

ANALOG INTERFACE

TI+

Transmit Analog Input (Non–Inverting) (Pin 19)

This is the non–inverting input of the transmit input gain

setting operational amplifier . This pin accommodates a differential to single–ended circuit for the input gain setting op

amp. This allows input signals that are referenced to the V

pin to be level shifted to the VAG pin with minimum noise.

This pin may be connected to the VAG pin for an inverting

amplifier configuration if the input signal is already referenced to the VAG pin. The common mode range of the TI+

and TI– pins is from 1.2 V, to VDD minus 2 V. This is an FET

gate input. Connecting the TI+ pin to VDD will place this am-

SS

plifier’s output (TG) into a high–impedance state, thus allowing the TG pin to serve as a high–impedance input to the

transmit filter.

TI–

Transmit Analog Input (Inverting) (Pin 18)

This is the inverting input of the transmit gain setting operational amplifier. Gain setting resistors are usually connected from this pin to TG and from this pin to the analog

signal source. The common mode range of the TI+ and TI–

pins is from 1.2 V to VDD – 2 V. This is an FET gate input.

Connecting the TI+ pin to VDD will place this amplifier’s output (TG) into a high–impedance state, thus allowing the TG

pin to serve as a high–impedance input to the transmit filter.

TG

Transmit Gain (Pin 17)

This is the output of the transmit gain setting operational

amplifier and the input to the transmit band–pass filter. This

op amp is capable of driving a 2 kΩ load. Connecting the TI+

pin to VDD will place this amplifier’s output (TG) into a high–

impedance state, thus allowing the TG pin to serve as a

high–impedance input to the transmit filter. All signals at this

pin are referenced to the VAG pin. This pin is high impedance

when the device is in the powered down mode.

RO+

Receive Analog Output (Non–Inverting) (Pin 1)

This is the non–inverting output of the receive smoothing

filter from the digital–to–analog converter. This output is

capable of driving a 2 kΩ load to 1.575 V peak referenced to

the VAG pin. This pin is high impedance when the device is in

the powered down mode.

RO–

Receive Analog Output (Inverting) (Pin 2)

This is the inverting output of the receive smoothing filter

from the digital–to–analog converter. This output is capable

of driving a 2 kΩ load to 1.575 V peak referenced to the V

pin. This pin is high impedance when the device is in the

powered down mode.

PI

Power Amplifier Input (Pin 3)

This is the inverting input to the PO– amplifier. The non–

inverting input to the PO– amplifier is internally tied to the

VAG pin. The PI and PO – pins are used with external resistors in an inverting op amp gain circuit to set the gain of the

PO+ and PO– push–pull power amplifier outputs. Connecting PI to VDD will power down the power driver amplifiers and

the PO+ and PO– outputs will be high impedance.

PO–

Power Amplifier Output (Inverting) (Pin 4)

This is the inverting power amplifier output, which is used

to provide a feedback signal to the PI pin to set the gain of

the push–pull power amplifier outputs. This pin is capable of

driving a 300 Ω load to PO+. The PO+ and PO– outputs are

differential (push–pull) and capable of driving a 300 Ω load to

3.15 V peak, which is 6.3 V peak–to–peak. The bias voltage

and signal reference of this output is the VAG pin. The V

pin cannot source or sink as much current as this pin, and

AG

AG

MC14LC5480MOTOROLA

3

therefore low impedance loads must be between PO+ and

PO–. Connecting PI to VDD will power down the power driver

amplifiers and the PO+ and PO– outputs will be high impedance. This pin is also high impedance when the device is

powered down by the PDI

PO+

Power Amplifier Output (Non–Inverting) (Pin 5)

This is the non–inverting power amplifier output, which is

an inverted version of the signal at PO–. This pin is capable

of driving a 300 Ω load to PO–. Connecting PI to VDD will

power down the power driver amplifiers and the PO+ and

PO– outputs will be high impedance. This pin is also high impedance when the device is powered down by the PDI

See PI and PO– for more information.

DIGITAL INTERFACE

MCLK

Master Clock (Pin 11)

This is the master clock input pin. The clock signal applied

to this pin is used to generate the internal 256 kHz clock and

sequencing signals for the switched–capacitor filters, ADC,

and DAC. The internal prescaler logic compares the clock on

this pin to the clock at FST (8 kHz) and will automatically

accept 256, 512, 1536, 1544, 2048, 2560, or 4096 kHz. For

MCLK frequencies of 256 and 512 kHz, MCLK must be synchronous and approximately rising edge aligned to FST. For

optimum performance at frequencies of 1.536 MHz and

higher, MCLK should be synchronous and approximately rising edge aligned to the rising edge of FST. In many applications, MCLK may be tied to the BCLKT pin.

FST

Frame Sync, Transmit (Pin 14)

This pin accepts an 8 kHz clock that synchronizes the output of the serial PCM data at the DT pin. This input is compatible with various standards including IDL, Long Frame

Sync, Short Frame Sync, and GCI formats. If both FST and

FSR are held low for several 8 kHz frames, the device will

power down.

BCLKT

Bit Clock, Transmit (Pin 12)

This pin controls the transfer rate of transmit PCM data. In

the IDL and GCI modes it also controls the transfer rate of

the receive PCM data. This pin can accept any bit clock frequency from 64 to 4096 kHz for Long Frame Sync and Short

Frame Sync timing. This pin can accept clock frequencies

from 256 kHz to 4.096 MHz in IDL mode, and from 512 kHz

to 6.176 MHz for GCI timing mode.

DT

Data, Transmit (Pin 13)

This pin is controlled by FST and BCLKT and is high impedance except when outputting PCM data. When operating

in the IDL or GCI mode, data is output in either the B1 or B2

channel as selected by FSR. This pin is high impedance

when the device is in the powered down mode.

pin.

pin.

FSR

Frame Sync, Receive (Pin 7)

When used in the Long Frame Sync or Short Frame Sync

mode, this pin accepts an 8 kHz clock, which synchronizes

the input of the serial PCM data at the DR pin. FSR can be

asynchronous to FST in the Long Frame Sync or Short

Frame Sync modes. When an ISDN mode (IDL or GCI) has

been selected with BCLKR, this pin selects either B1 (logic 0)

or B2 (logic 1) as the active data channel.

BCLKR

Bit Clock, Receive (Pin 9)

When used in the Long Frame Sync or Short Frame Sync

mode, this pin accepts any bit clock frequency from 64 to

4096 kHz. When this pin is held at a logic 1, FST, BCLKT, DT,

and DR become IDL Interface compatible. When this pin is

held at a logic 0, FST , BCLKT, DT, and DR become GCI Interface compatible.

DR

Data, Receive (Pin 8)

This pin is the PCM data input, and when in a Long Frame

Sync or Short Frame Sync mode is controlled by FSR and

BCLKR. When in the IDL or GCI mode, this data transfer is

controlled by FST and BCLKT. FSR and BCLKR select the

B channel and ISDN mode, respectively .

FUNCTIONAL DESCRIPTION

ANALOG INTERFACE AND SIGNAL PATH

The transmit portion of this device includes a low–noise,

three–terminal op amp capable of driving a 2 kΩ load. This

op amp has inputs of TI+ (Pin 19) and TI– (Pin 18) and its

output is TG (Pin 17). This op amp is intended to be configured in an inverting gain circuit. The analog signal may be

applied directly to the TG pin if this transmit op amp is independently powered down by connecting the TI+ and TI–

inputs to the VDD power supply. The TG pin becomes high

impedance when the transmit op amp is powered down. The

TG pin is internally connected to a 3–pole anti–aliasing pre–

filter. This pre–filter incorporates a 2–pole Butterworth active

low–pass filter, followed by a single passive pole. This pre–

filter is followed by a single–ended to differential converter

that is clocked at 512 kHz. All subsequent analog processing

utilizes fully–differential circuitry. The next section is a fully–

differential, 5–pole switched–capacitor low–pass filter with a

3.4 kHz frequency cutoff. After this filter is a 3–pole

switched–capacitor high–pass filter having a cutoff frequency of about 200 Hz. This high–pass stage has a transmission zero at dc that eliminates any dc coming from the

analog input or from accumulated op amp offsets in the preceding filter stages. The last stage of the high–pass filter is

an autozeroed sample and hold amplifier.

One bandgap voltage reference generator and digital–to–

analog converter (DAC) are shared by the transmit and receive sections. The autozeroed, switched–capacitor

bandgap reference generates precise positive and negative

reference voltages that are virtually independent of temperature and power supply voltage. A binary–weighted capacitor

array (CDAC) forms the chords of the companding structure,

while a resistor string (RDAC) implements the linear steps

within each chord. The encode process uses the DAC, the

voltage reference, and a frame–by–frame autozeroed

comparator to implement a successive–approximation con-

MC14LC5480 MOTOROLA

4

version algorithm. All of the analog circuitry involved in the

data conversion (the voltage reference, RDAC, CDAC, and

comparator) are implemented with a differential architecture.

The receive section includes the DAC described above, a

sample and hold amplifier, a 5–pole, 3400 Hz switched capacitor low–pass filter with sinX/X correction, and a 2–pole

active smoothing filter to reduce the spectral components of

the switched capacitor filter. The output of the smoothing filter is buffered by an amplifier , which is output at the RO+ and

RO– pins. These outputs are capable of driving a 4 kΩ load

differentially or a 2 kΩ load to the VAG pin. The MC14LC5480

also has a pair of power amplifiers that are connected in a

push–pull configuration. The PI pin is the inverting input to

the PO– power amplifier. The non–inverting input is internally

tied to the VAG pin. This allows this amplifier to be used in an

inverting gain circuit with two external resistors. The PO+

amplifier has a gain of minus one, and is internally connected to the PO– output. This complete power amplifier circuit is a differential (push–pull) amplifier with adjustable gain

that is capable of driving a 300 Ω load to +12 dBm. The

power amplifier may be powered down independently of the

rest of the chip by connecting the PI pin to VDD.

POWER–DOWN

There are two methods of putting this device into a low

power consumption mode, which makes the device nonfunctional and consumes virtually no power. PDI

is the power–

down input pin which, when taken low, powers down the

device. Another way to power the device down is to hold both

the FST and FSR pins low. When the chip is powered down,

the VAG, TG, RO+, RO–, PO+, PO–, and DT outputs are high

impedance. To return the chip to the power–up state, PDI

must be high and the FST frame sync pulse must be present.

The DT output will remain in a high–impedance state for at

least two FST pulses after power–up.

MASTER CLOCK

Since this codec–filter design has a single DAC architecture, the MCLK pin is used as the master clock for all analog

signal processing including analog–to–digital conversion,

digital–to–analog conversion, and for transmit and receive filtering functions of this device. The clock frequency applied to

the MCLK pin may be 256 kHz, 512 kHz, 1.536 MHz,

1.544 MHz, 2.048 MHz, 2.56 MHz, or 4.096 MHz. This device has a prescaler that automatically determines the proper

divide ratio to use for the MCLK input, which achieves the required 256 kHz internal sequencing clock. The clocking requirements of the MCLK input are independent of the PCM

data transfer mode (i.e., Long Frame Sync, Short Frame

Sync, IDL mode, or GCI mode).

DIGITAL I/O

The MC14LC5480 is pin selectable for Mu–Law or A–Law.

Table 1 shows the 8–bit data word format for positive and

negative zero and full scale for both companding schemes

(see Tables 3 and 4 at the end of this document for a complete PCM word conversion table). Table 2 shows the series

of eight PCM words for both Mu–Law and A–Law that correspond to a digital milliwatt. The digital mW is the 1 kHz calibration signal reconstructed by the DAC that defines the

absolute gain or 0 dBm0 Transmission Level Point (TLP) of

the DAC. The 0 dBm0 level for Mu–Law is 3.17 dB below the

maximum level for an unclipped tone signal. The 0 dBm0

level for A–Law is 3.14 dB below the maximum level for an

unclipped tone signal. The timing for the PCM data transfer is

independent of the companding scheme selected. Refer to

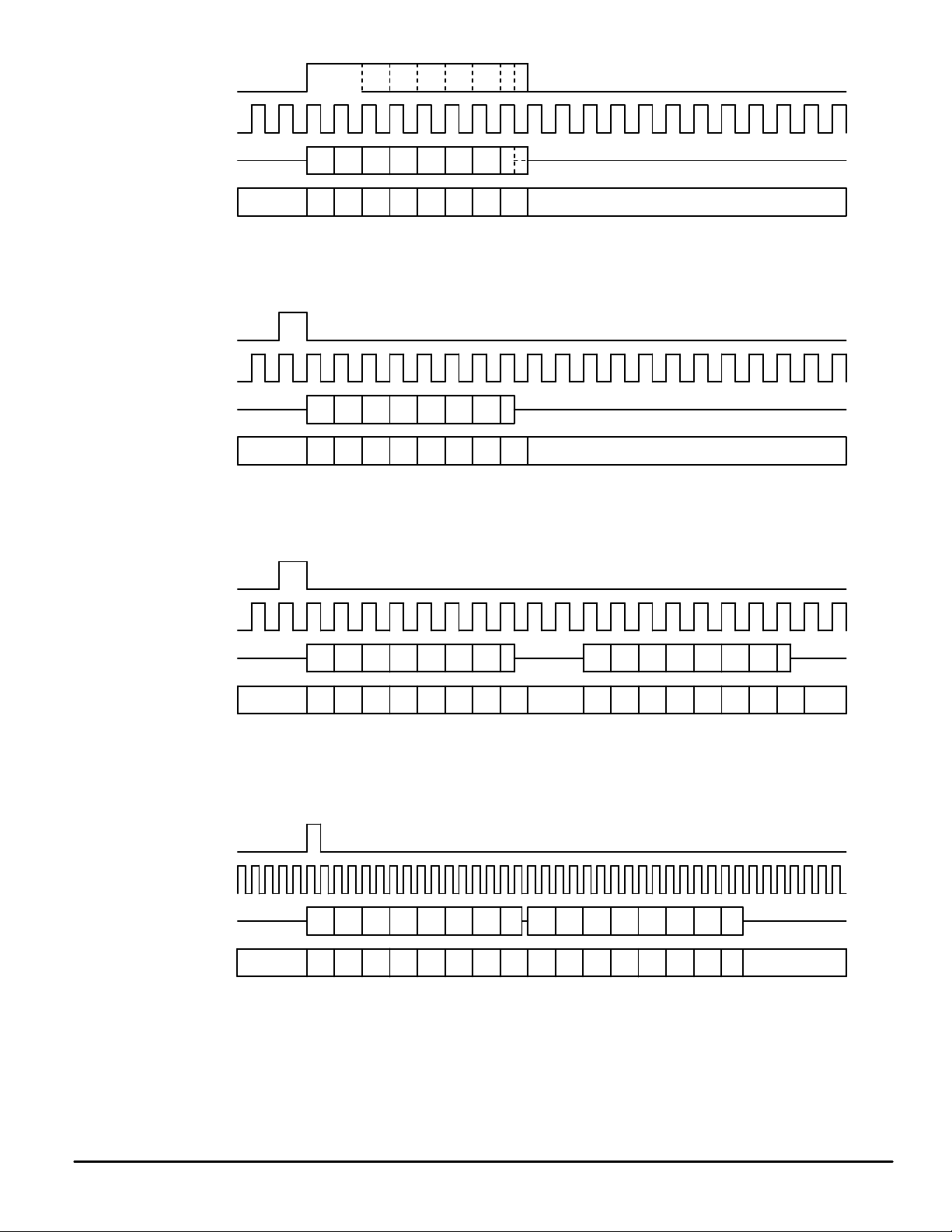

Figure 2 for a summary and comparison of the four PCM

data interface modes of this device.

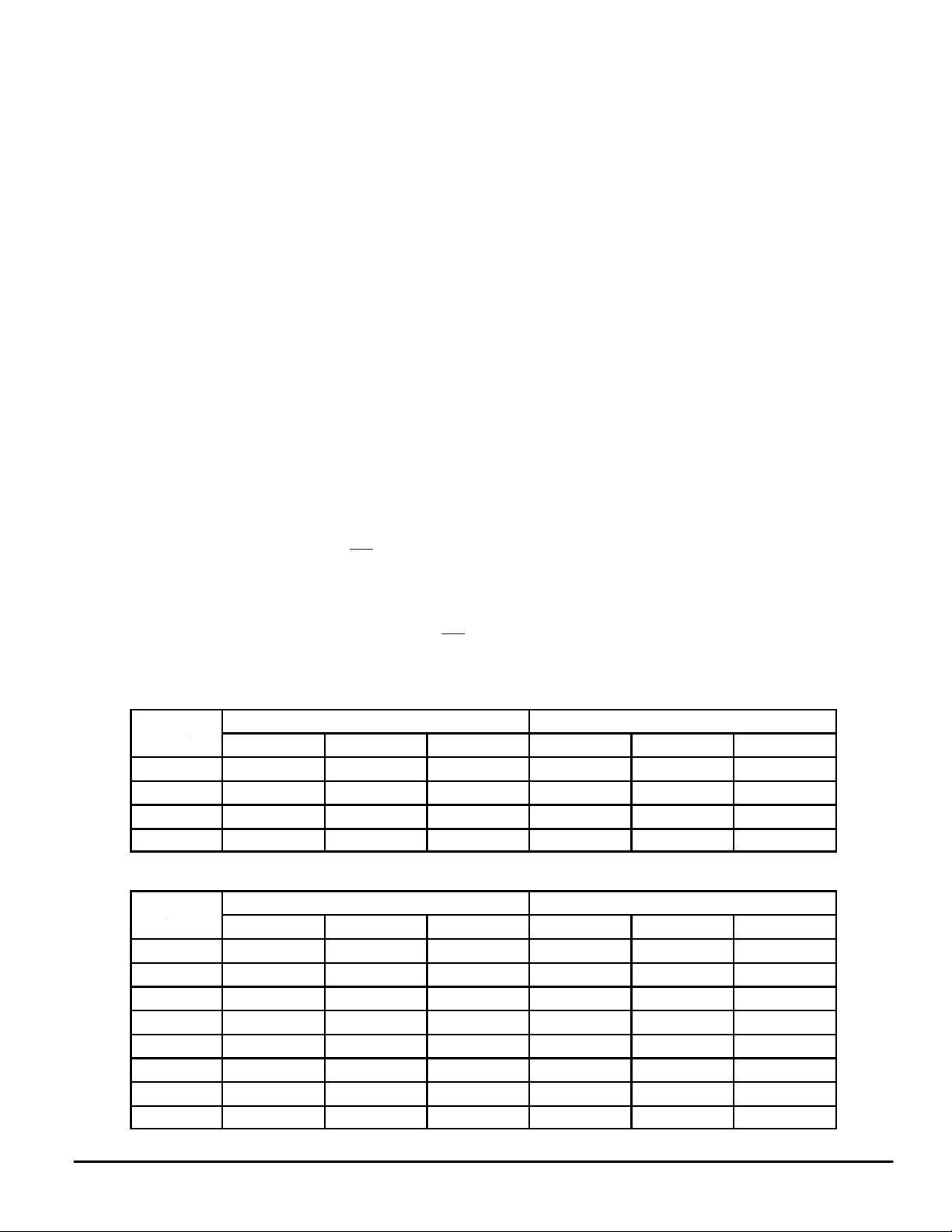

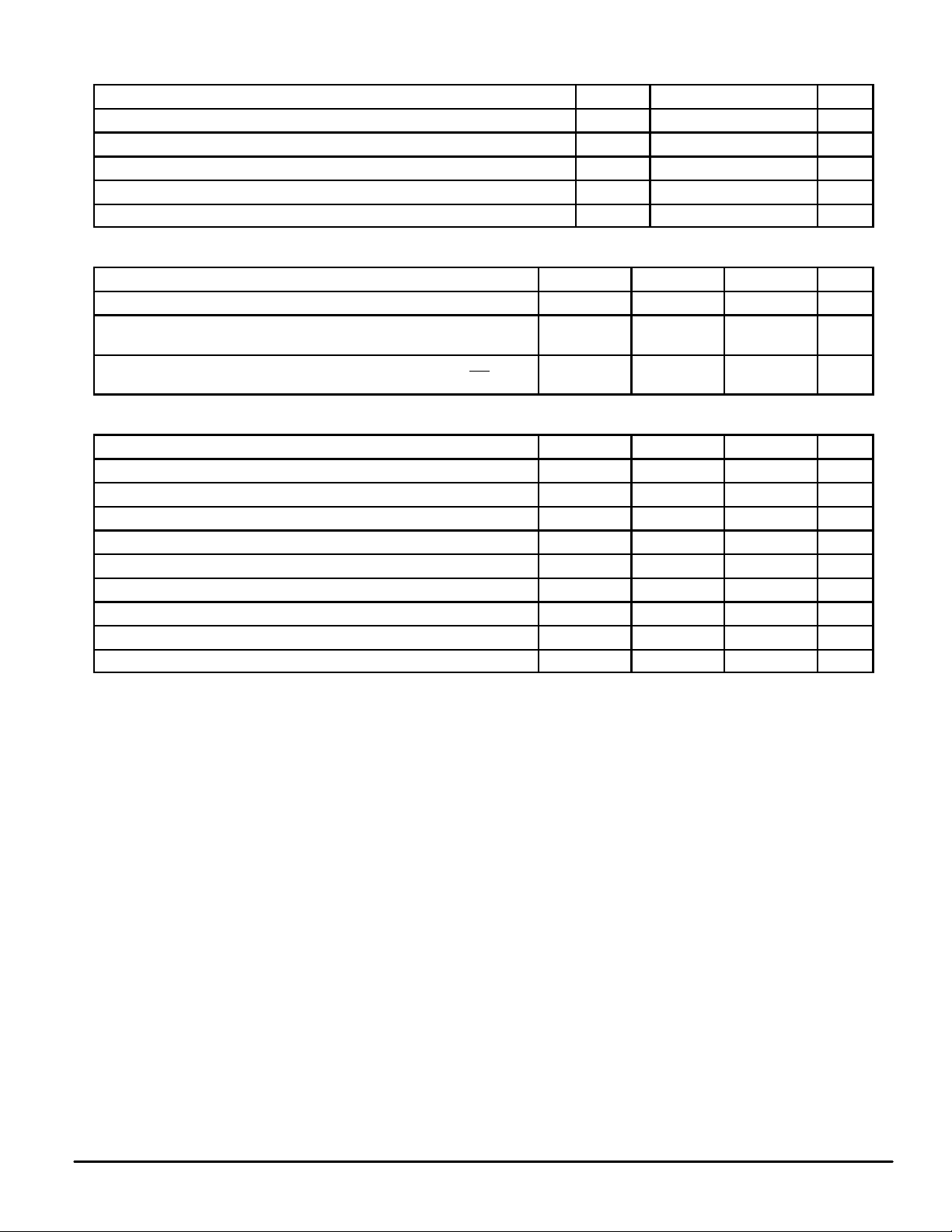

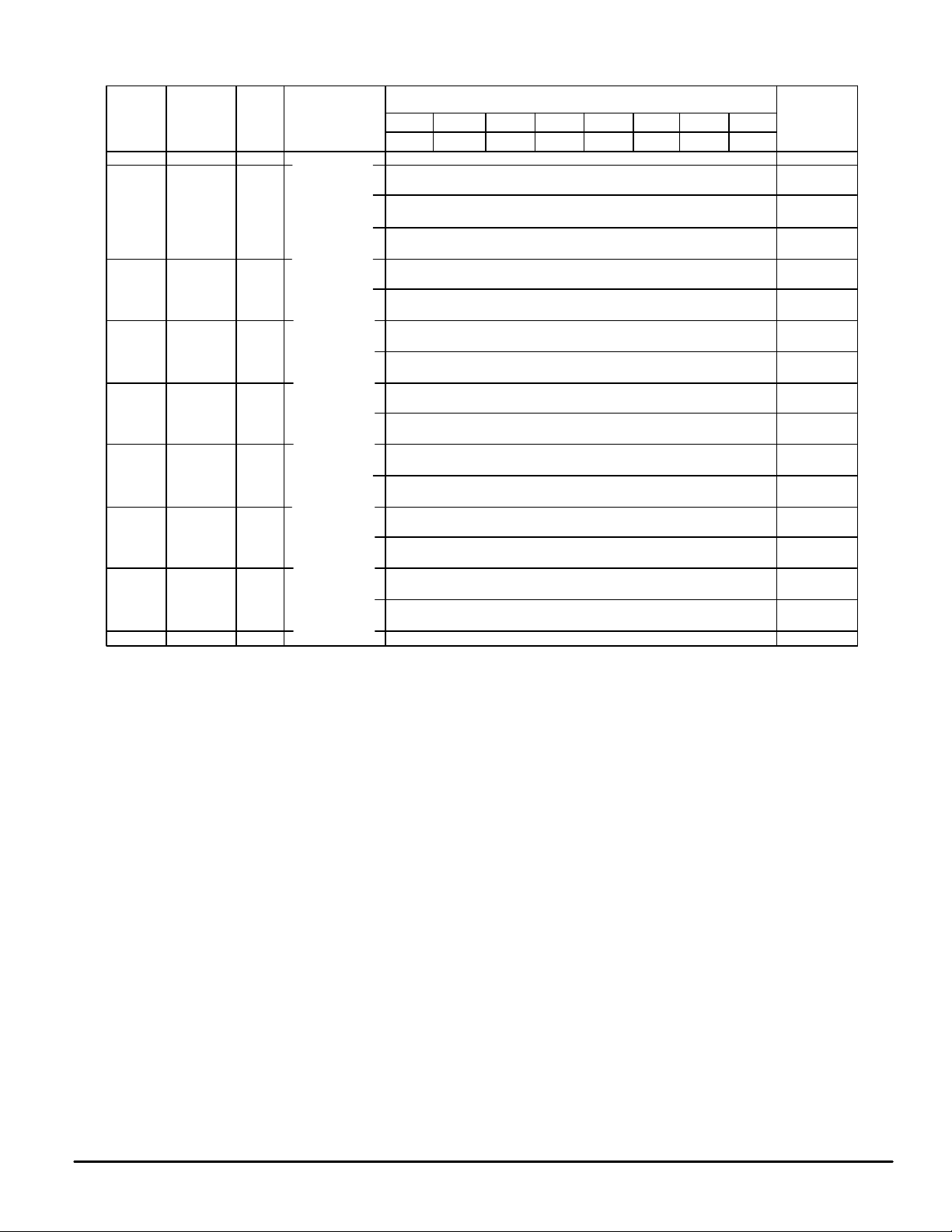

T able 1. PCM Codes for Zero and Full Scale

Mu–Law A–Law

Level

+ Full Scale 1 0 0 0 0 0 0 0 1 0 1 0 1 0 1 0

+ Zero 1 1 1 1 1 1 1 1 1 1 0 1 0 1 0 1

– Zero 0 1 1 1 1 1 1 1 0 1 0 1 0 1 0 1

– Full Scale 0 0 0 0 0 0 0 0 0 0 1 0 1 0 1 0

Sign Bit Chord Bits Step Bits Sign Bit Chord Bits Step Bits

Table 2. PCM Codes for Digital mW

Mu–Law A–Law

Phase

π/8 0 0 0 1 1 1 1 0 0 0 1 1 0 1 0 0

3π/8 0 0 0 0 1 0 1 1 0 0 1 0 0 0 0 1

5π/8 0 0 0 0 1 0 1 1 0 0 1 0 0 0 0 1

7π/8 0 0 0 1 1 1 1 0 0 0 1 1 0 1 0 0

9π/8 1 0 0 1 1 1 1 0 1 0 1 1 0 1 0 0

11π/8 1 0 0 0 1 0 1 1 1 0 1 0 0 0 0 1

13π/8 1 0 0 0 1 0 1 1 1 0 1 0 0 0 0 1

15π/8 1 0 0 1 1 1 1 0 1 0 1 1 0 1 0 0

Sign Bit Chord Bits Step Bits Sign Bit Chord Bits Step Bits

MC14LC5480MOTOROLA

5

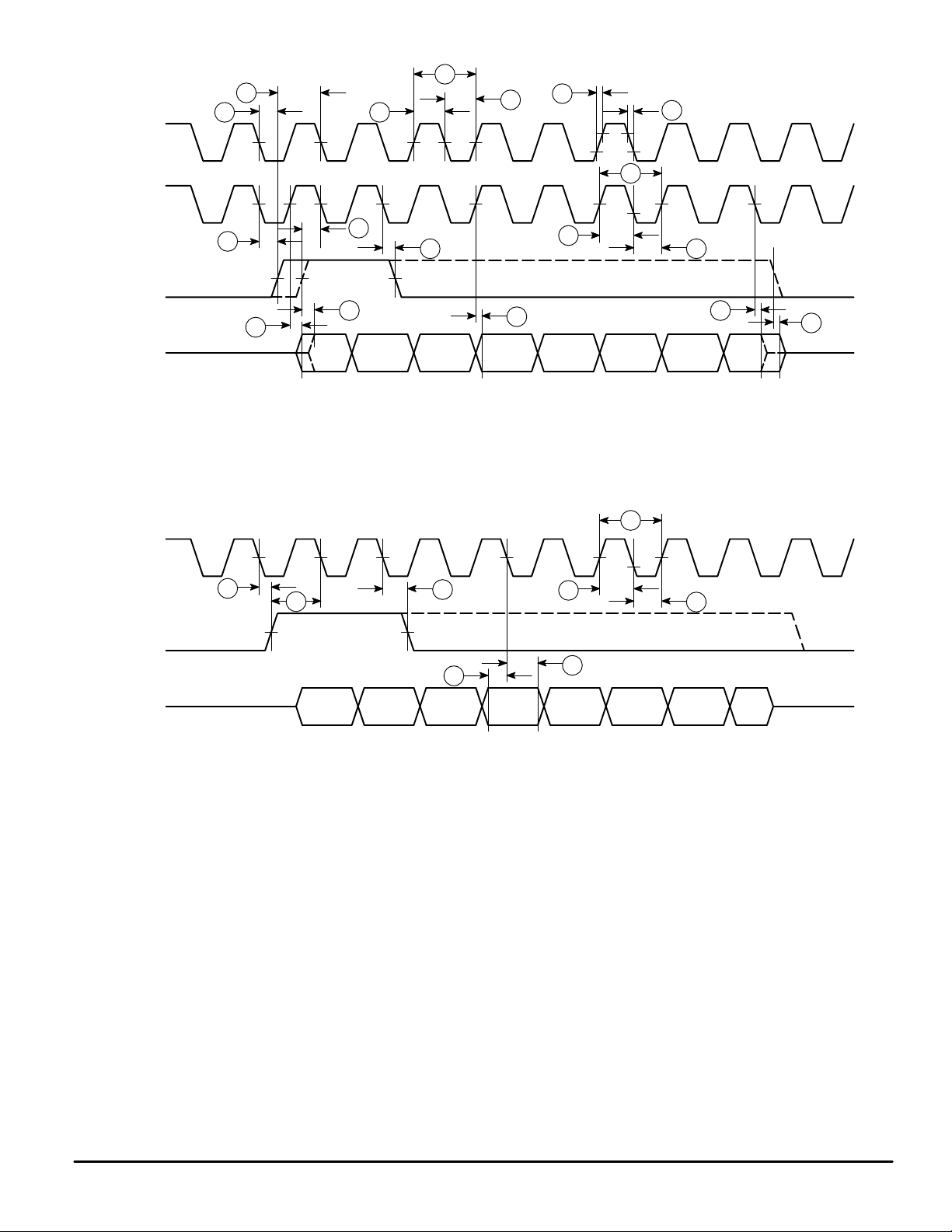

FST (FSR)

BCLKT (BCLKR)

DT

FST (FSR)

BCLKT (BCLKR)

DT

IDL SYNC (FST)

87654321

87654321DR DON’T CAREDON’T CARE

Figure 2a. Long Frame Sync (Transmit and Receive Have Individual Clocking)

87654321

8DR

7654321

DON’T CAREDON’T CARE

Figure 2b. Short Frame Sync (Transmit and Receive Have Individual Clocking)

IDL CLOCK (BCLKT)

IDL TX (DT)

IDL RX (DR)

Figure 2c. IDL Interface — BCLKR = 1 (Transmit and Receive Have Common Clocking)

FSC (FST)

DCL (BCLKT)

D

(DT)

out

Din (DR)

Figure 2d. GCI Interface — BCLKR = 0 (Transmit and Receive Have Common Clocking)

DON’T CARE

DON’T

CARE

Figure 2. Digital Timing Modes for the PCM Data Interface

87654321

DON’T

8

7654321 8

CARE

B2–CHANNEL (FSR = 1)B1–CHANNEL (FSR = 0)

87654321

87654321

B2–CHANNEL (FSR = 1)B1–CHANNEL (FSR = 0)

87654321

87654321

87654321

7654321

DON’T CARE

DON’T

CARE

MC14LC5480 MOTOROLA

6

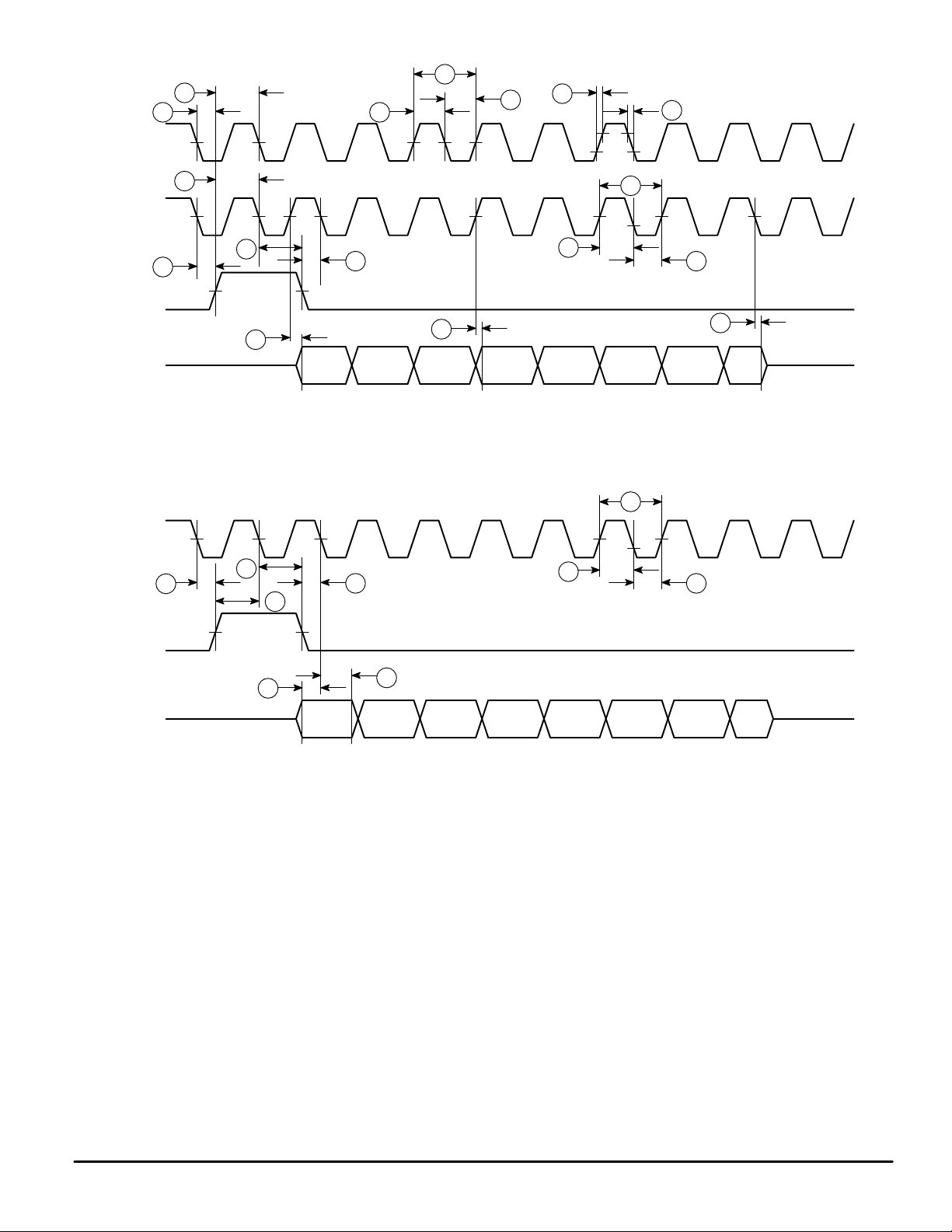

Long Frame Sync

Long Frame Sync is the industry name for one type of

clocking format that controls the transfer of the PCM data

words. (Refer to Figure 2a.) The ‘‘Frame Sync’’ or ‘‘Enable’’ is

used for two specific synchronizing functions. The first is to

synchronize the PCM data word transfer, and the second is

to control the internal analog–to–digital and digital–to–analog

conversions. The term ‘‘Sync’’ refers to the function of synchronizing the PCM data word onto or off of the multiplexed

serial PCM data bus, which is also known as a PCM highway. The term ‘‘Long’’ comes from the duration of the frame

sync measured in PCM data clock cycles. Long Frame Sync

timing occurs when the frame sync is used directly as the

PCM data output driver enable. This results in the PCM output going low impedance with the rising edge of the transmit

frame sync, and remaining low impedance for the duration of

the transmit frame sync.

The implementation of Long Frame Sync has maintained

compatibility and been optimized for external clocking simplicity . This optimization includes the PCM data output going

low impedance with the logical AND of the transmit frame

sync (FST) with the transmit data bit clock (BCLKT). The optimization also includes the PCM data output (DT) remaining

low impedance until the middle of the LSB (seven and a half

PCM data clock cycles) or until the FST pin is taken low,

whichever occurs last. This requires the frame sync to be

approximately rising edge aligned with the initiation of the

PCM data word transfer, but the frame sync does not have a

precise timing requirement for the end of the PCM data word

transfer. The device recognizes Long Frame Sync clocking

when the frame sync is held high for two consecutive falling

edges of the transmit data clock. The transmit logic decides

on each frame sync whether it should interpret the next

frame sync pulse as a Long or a Short Frame Sync. This decision is used for receive circuitry also. The device is designed to prevent PCM bus contention by not allowing the

PCM data output to go low impedance for at least two frame

sync cycles after power is applied or when coming out of the

powered down mode.

The receive side of the device is designed to accept the

same frame sync and data clock as the transmit side and to

be able to latch its own transmit PCM data word. Thus the

PCM digital switch needs to be able to generate only one

type of frame sync for use by both transmit and receive sections of the device.

The logical AND of the receive frame sync with the receive

data clock tells the device to start latching the 8–bit serial

word into the receive data input on the falling edges of the

receive data clock. The internal receive logic counts the receive data clock cycles and transfers the PCM data word to

the digital–to–analog converter sequencer on the ninth data

clock rising edge.

This device is compatible with four digital interface modes.

To ensure that this device does not reprogram itself for a different timing mode, the BCLKR pin must change logic state

no less than every 125 µs. The minimum PCM data bit clock

frequency of 64 kHz satisfies this requirement.

Short Frame Sync

Short Frame Sync is the industry name for the type of

clocking format that controls the transfer of the PCM data

words (refer to Figure 2b). The ‘‘Frame Sync’’ or ‘‘Enable’’ is

used for two specific synchronizing functions. The first is to

synchronize the PCM data word transfer, and the second is

to control the internal analog–to–digital and digital–to–analog

conversions. The term ‘‘Sync’’ refers to the function of synchronizing the PCM data word onto or off of the multiplexed

serial PCM data bus, which is also known as a PCM highway. The term ‘‘Short’’ comes from the duration of the frame

sync measured in PCM data clock cycles. Short Frame Sync

timing occurs when the frame sync is used as a ‘‘pre–synchronization’’ pulse that is used to tell the internal logic to

clock out the PCM data word under complete control of the

data clock. The Short Frame Sync is held high for one falling

data clock edge. The device outputs the PCM data word beginning with the following rising edge of the data clock. This

results in the PCM output going low impedance with the rising edge of the transmit data clock, and remaining low impedance until the middle of the LSB (seven and a half PCM

data clock cycles).

The device recognizes Short Frame Sync clocking when

the frame sync is held high for one and only one falling edge

of the transmit data clock. The transmit logic decides on each

frame sync whether it should interpret the next frame sync

pulse as a Long or a Short Frame Sync. This decision is used

for receive circuitry also. The device is designed to prevent

PCM bus contention by not allowing the PCM data output to

go low impedance for at least two frame sync cycles after

power is applied or when coming out of the powered down

mode.

The receive side of the device is designed to accept the

same frame sync and data clock as the transmit side and to

be able to latch its own transmit PCM data word. Thus the

PCM digital switch needs to be able to generate only one

type of frame sync for use by both transmit and receive sections of the device.

The falling edge of the receive data clock latching a high

logic level at the receive frame sync input tells the device to

start latching the 8–bit serial word into the receive data input

on the following eight falling edges of the receive data clock.

The internal receive logic counts the receive data clock

cycles and transfers the PCM data word to the digital–to–

analog converter sequencer on the rising data clock edge after the LSB has been latched into the device.

This device is compatible with four digital interface modes.

To ensure that this device does not reprogram itself for a different timing mode, the BCLKR pin must change logic state

no less than every 125 µs. The minimum PCM data bit clock

frequency of 64 kHz satisfies this requirement.

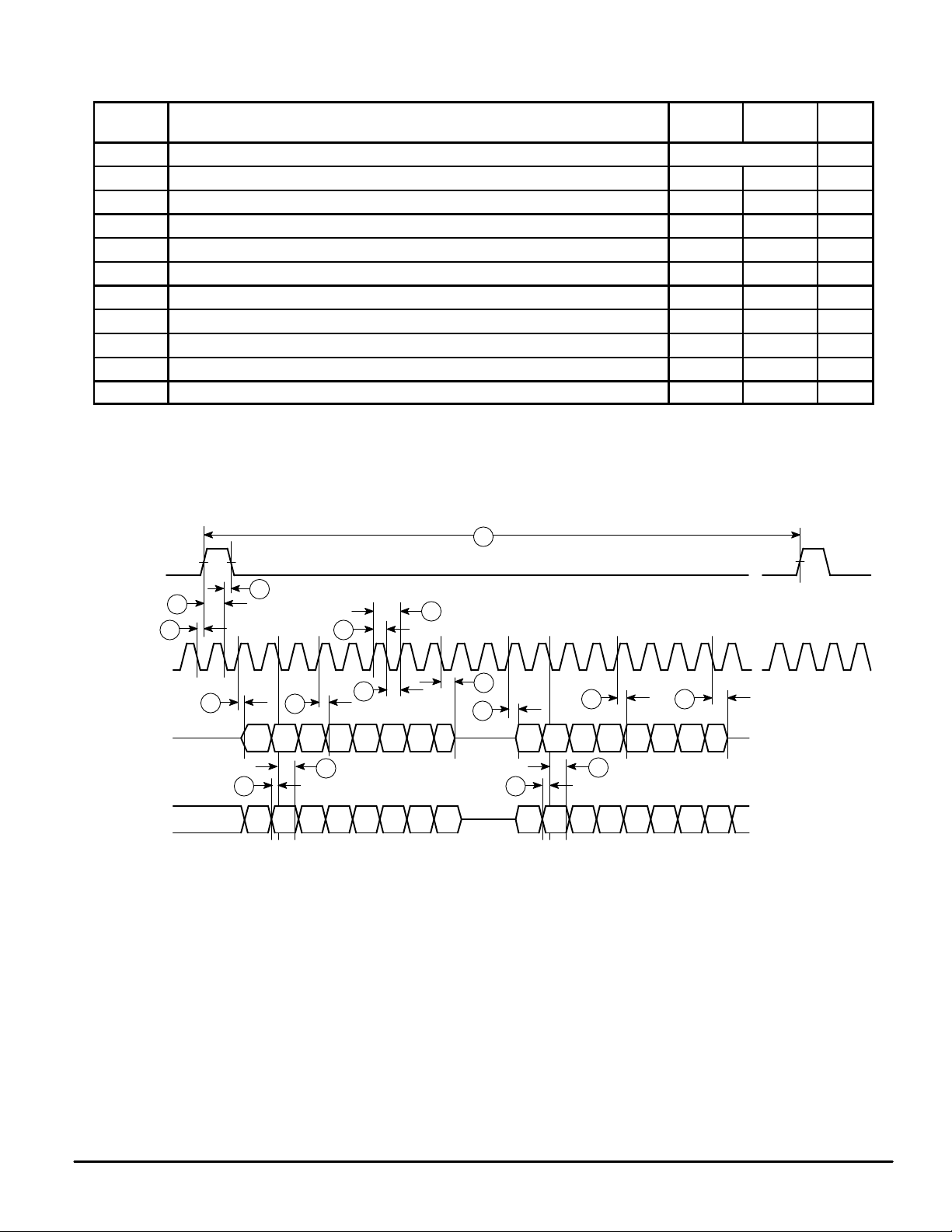

Interchip Digital Link (IDL)

The Interchip Digital Link (IDL) Interface is one of two

standard synchronous 2B+D ISDN timing interface modes

with which this device is compatible. In the IDL mode, the device can communicate in either of the two 64 kbps B channels (refer to Figure 2c for sample timing). The IDL mode is

selected when the BCLKR pin is held high for two or more

FST (IDL SYNC) rising edges. The digital pins that control

the transmit and receive PCM word transfers are reprogrammed to accommodate this mode. The pins affected are

FST , FSR, BCLKT, DT, and DR. The IDL Interface consists of

four pins: IDL SYNC (FST), IDL CLK (BCLKT), IDL TX (DT),

and IDL RX (DR). The IDL interface mode provides access to

both the transmit and receive PCM data words with common

control clocks of IDL Sync and IDL Clock. In this mode, the

MC14LC5480MOTOROLA

7

FSR pin controls whether the B1 channel or the B2 channel

is used for both transmit and receive PCM data word transfers. When the FSR pin is low, the transmit and receive PCM

words are transferred in the B1 channel, and for FSR high

the B2 channel is selected. The start of the B2 channel is ten

IDL CLK cycles after the start of the B1 channel.

The IDL SYNC (FST, Pin 14) is the input for the IDL frame

synchronization signal. The signal at this pin is nominally

high for one cycle of the IDL Clock signal and is rising edge

aligned with the IDL Clock signal. (Refer to Figure 4 and the

IDL Timing specifications for more details.) This event identifies the beginning of the IDL frame. The frequency of the IDL

Sync signal is 8 kHz. The rising edge of the IDL SYNC (FST)

should be aligned approximately with the rising edge of

MCLK. MCLK must be one of the clock frequencies specified

in the Digital Switching Characteristics table, and is typically

tied to IDL CLK (BCLKT).

The IDL CLK (BCLKT, Pin 12) is the input for the PCM

data clock. All IDL PCM transfers and data control sequencing are controlled by this clock following the IDL SYNC. This

pin accepts an IDL data clock frequency of 256 kHz to 4.096

MHz.

The IDL TX (DT , Pin 13) is the output for the transmit PCM

data word. Data bits are output for the B1 channel on sequential rising edges of the IDL CLK signal beginning after

the IDL SYNC pulse. If the B2 channel is selected, then the

PCM word transfer starts on the eleventh IDL CLK rising

edge after the IDL SYNC pulse. The IDL TX pin will remain

low impedance for the duration of the PCM word until the

LSB after the falling edge of IDL CLK. The IDL TX pin will remain in a high impedance state when not outputting PCM

data or when a valid IDL Sync signal is missing.

The IDL RX (DR, Pin 8) is the input for the receive PCM

data word. Data bits are input for the B1 channel on sequential falling edges of the IDL CLK signal beginning after the

IDL SYNC pulse. If the B2 channel is selected, then the PCM

word is latched in starting on the eleventh IDL CLK falling

edge after the IDL SYNC pulse.

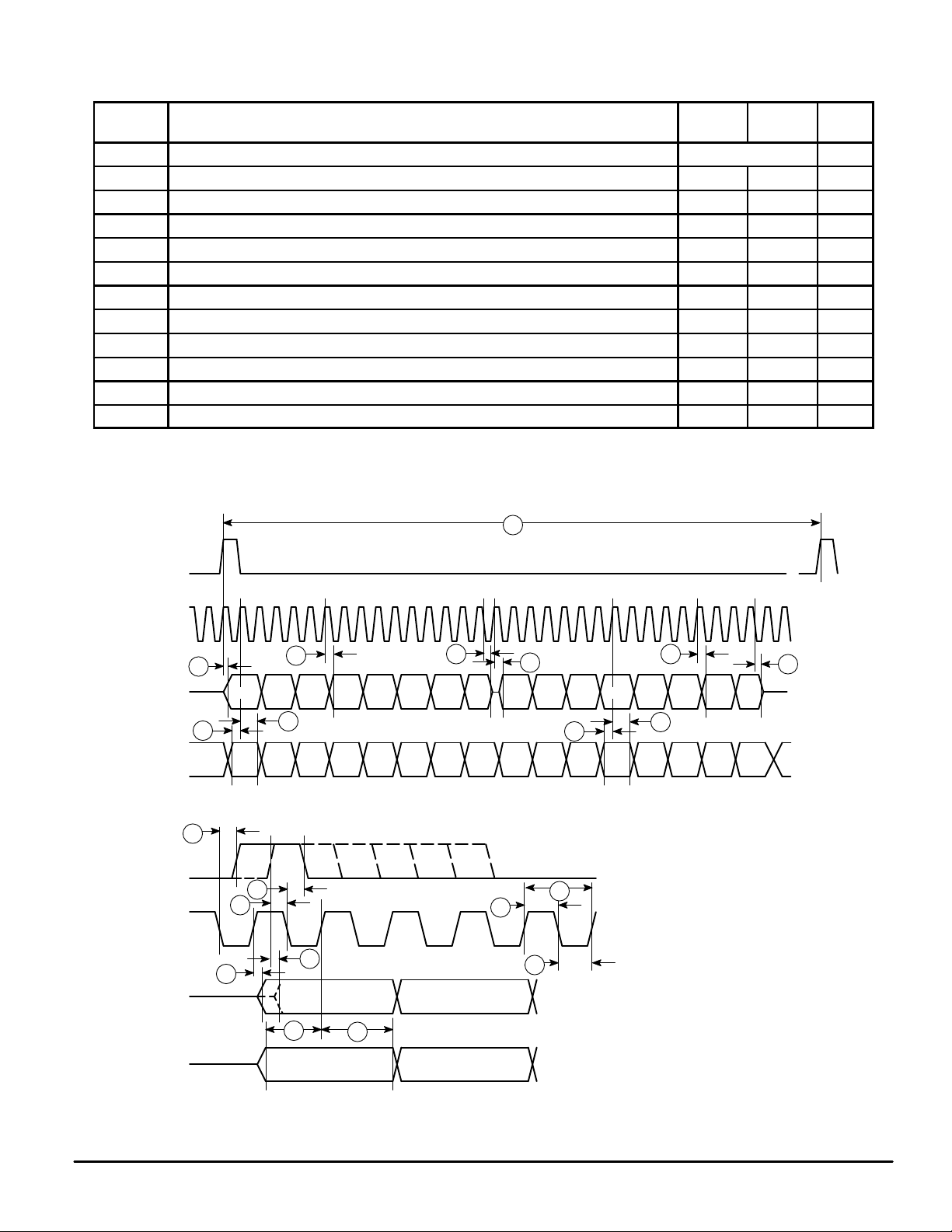

General Circuit Interface (GCI)

The General Circuit Interface (GCI) is the second of two

standard synchronous 2B+D ISDN timing interface modes

with which this device is compatible. In the GCI mode, the

device can communicate in either of the two 64 kbps B–

channels. (Refer to Figure 2d for sample timing.) The GCI

mode is selected when the BCLKR pin is held low for two or

more FST (FSC) rising edges. The digital pins that control

the transmit and receive PCM word transfers are reprogrammed to accommodate this mode. The pins affected are

FST, FSR, BCLKT, DT, and DR. The GCI Interface consists

of four pins: FSC (FST), DCL (BCLKT), D

(DR). The GCI interface mode provides access to both the

transmit and receive PCM data words with common control

clocks of FSC (frame synchronization clock) and DCL (data

clock). In this mode, the FSR pin controls whether the B1

channel or the B2 channel is used for both transmit and receive PCM data word transfers. When the FSR pin is low, the

transmit and receive PCM words are transferred in the B1

channel, and for FSR high the B2 channel is selected. The

start of the B2 channel is 16 DCL cycles after the start of the

B1 channel.

The FSC (FST, Pin 14) is the input for the GCI frame synchronization signal. The signal at this pin is nominally rising

(DT), and D

out

edge aligned with the DCL clock signal. (Refer to Figure 6

and the GCI Timing specifications for more details.) This

event identifies the beginning of the GCI frame. The frequency of the FSC synchronization signal is 8 kHz. The rising

edge of the FSC (FST) should be aligned approximately with

the rising edge of MCLK. MCLK must be one of the clock frequencies specified in the Digital Switching Characteristics

table, and is typically tied to DCL (BCLKT).

The DCL (BCLKT, Pin 12) is the input for the clock that

controls the PCM data transfers. The clock applied at the

DCL input is twice the actual PCM data rate. The GCI frame

begins with the logical AND of the FSC with the DCL. This

event initiates the PCM data word transfers for both transmit

and receive. This pin accepts a GCI data clock frequency of

512 kHz to 6.176 MHz for PCM data rates of 256 kHz to

3.088 MHz.

The GCI D

PCM data word. Data bits are output for the B1 channel on

alternate rising edges of the DCL clock signal, beginning with

the FSC pulse. If the B2 channel is selected, then the PCM

word transfer starts on the seventeenth DCL rising edge after

the FSC rising edge. The D

for 15–1/2 DCL clock cycles. The D

impedance after the second falling edge of the DCL clock

during the LSB of the PCM word. The D

a high–impedance state when not outputting PCM data or

when a valid FSC signal is missing.

The Din (DR, Pin 8) is the input for the receive PCM data

word. Data bits are latched in for the B1 channel on alternate

rising edges of the DCL clock signal, beginning with the second DCL clock after the rising edge of the FSC pulse. If the

B2 channel is selected then the PCM word is latched in starting on the eighteenth DCL rising edge after the FSC rising

edge.

(DT, Pin 13) is the output for the transmit

out

pin will remain low impedance

out

pin becomes high

out

pin will remain in

out

PRINTED CIRCUIT BOARD LAYOUT

CONSIDERATIONS

The MC14LC5480 is manufactured using high–speed

CMOS VLSI technology to implement the complex analog

signal processing functions of a PCM Codec–Filter. The fully–differential analog circuit design techniques used for this

device result in superior performance for the switched capacitor filters, the analog–to–digital converter (ADC) and the digital–to–analog converter (DAC). Special attention was given

to the design of this device to reduce the sensitivities of

noise, including power supply rejection and susceptibility to

radio frequency noise. This special attention to design includes a fifth order low–pass filter, followed by a third order

high–pass filter whose output is converted to a digital signal

in

with greater than 75 dB of dynamic range, all operating on a

single 5 V power supply. This results in a Mu–Law LSB size

for small audio signals of about 386 µV . The typical idle channel noise level of this device is less than one LSB. In addition

to the dynamic range of the codec–filter function of this device, the input gain–setting op amp has the capability of

greater than 35 dB of gain intended for an electret microphone interface.

This device was designed for ease of implementation, but

due to the large dynamic range and the noisy nature of the

environment for this device (digital switches, radio telephones, DSP front–end, etc.) special care must be taken to

assure optimum analog transmission performance.

MC14LC5480 MOTOROLA

8

PC BOARD MOUNTING

It is recommended that the device be soldered to the PC

board for optimum noise performance. If the device is to be

used in a socket, it should be placed in a low parasitic pin

inductance (generally , low–profile) socket.

POWER SUPPLY, GROUND, AND NOISE

CONSIDERATIONS

This device is intended to be used in switching applications which often require plugging the PC board into a rack

with power applied. This is known as ‘‘hot–rack insertion.’’ In

these applications care should be taken to limit the voltage

on any pin from going positive of the VDD pins, or negative of

the VSS pins. One method is to extend the ground and power

contacts of the PCB connector. The device has input protection on all pins and may source or sink a limited amount of

current without damage. Current limiting may be accomplished by series resistors between the signal pins and the

connector contacts.

The most important considerations for PCB layout deal

with noise. This includes noise on the power supply, noise

generated by the digital circuitry on the device, and cross

coupling digital or radio frequency signals into the audio signals of this device. The best way to prevent noise is to:

1. Keep digital signals as far away from audio signals as

possible.

2. Keep radio frequency signals as far away from the audio

signals as possible.

3. Use short, low inductance traces for the audio circuitry

to reduce inductive, capacitive, and radio frequency

noise sensitivities.

4. Use short, low inductance traces for digital and RF

circuitry to reduce inductive, capacitive, and radio

frequency radiated noise.

5. Bypass capacitors should be connected from the V

and VAG pins to VSS with minimal trace length. Ceramic

monolithic capacitors of about 0.1 µF are acceptable to

decouple the device from its own noise. The V

capacitor helps supply the instantaneous currents of the

digital circuitry in addition to decoupling the noise which

may be generated by other sections of the device or

other circuitry on the power supply. The VAG decoupling

capacitor helps to reduce the impedance of the VAG pin

to VSS at frequencies above the bandwidth of the V

generator, which reduces the susceptibility to RF noise.

6. Use a short, wide, low inductance trace to connect the

VSS ground pin to the power supply ground. The VSS pin

is the digital ground and the most negative power supply

pin for the analog circuitry . All analog signal processing

is referenced to the VAG pin, but because digital and RF

circuitry will probably be powered by this same ground,

care must be taken to minimize high frequency noise in

the VSS trace. Depending on the application, a double–

sided PCB with a VSS ground plane connecting all of the

digital and analog VSS pins together would be a good

grounding method. A multilayer PC board with a ground

plane connecting all of the digital and analog VSS pins

together would be the optimal ground configuration.

These methods will result in the lowest resistance and

the lowest inductance in the ground circuit. This is

important to reduce voltage spikes in the ground circuit

DD

DD

AG

resulting from the high speed digital current spikes. The

magnitude of digitally induced voltage spikes may be

hundreds of times larger than the analog signal the

device is required to digitize.

7. Use a short, wide, low inductance trace to connect the

VDD power supply pin to the 5 V power supply.

Depending on the application, a double–sided PCB with

VDD bypass capacitors to the VSS ground plane, as

described above, may complete the low impedance

coupling for the power supply . For a multilayer PC board

with a power plane, connecting all of the VDD pins to the

power plane would be the optimal power distribution

method. The integrated circuit layout and packaging

considerations for the 5 V VDD power circuit are

essentially the same as for the VSS ground circuit.

8. T he VAG pin is the reference for all analog signal

processing. In some applications the audio signal to be

digitized may be referenced to the VSS ground. To

reduce the susceptibility to noise at the input of the ADC

section, the three–terminal op amp may be used in a

differential to single–ended circuit to provide level

conversion from the VSS ground to the VAG ground with

noise cancellation. The op amp may be used for more

than 35 dB of gain in microphone interface circuits, which

will require a compact layout with minimum trace lengths

as well as isolation from noise sources. It is recommended that the layout be as symmetrical as possible to

avoid any imbalances which would reduce the noise

cancelling benefits of this differential op amp circuit.

Refer to the application schematics for examples of this

circuitry.

If possible, reference audio signals to the VAG pin

instead of to the VSS pin. Handset receivers and telephone line interface circuits using transformers may be

audio signal referenced completely to the VAG pin. Refer to the application schematics for examples of this

circuitry. The VAG pin cannot be used for ESD or line

protection.

9. For applications using multiple MC14LC5480 PCM

Codec–Filters, the VAG pins cannot be tied together. The

VAG pins are capable of sourcing and sinking current and

will each be driving the node, which will result in large

contention currents, crosstalk susceptibilities, and increased noise.

10. The MC14LC5480 is fabricated with advanced high–

speed CMOS technology that is capable of responding

to noise pulses on the clock pins of 1 ns or less. It should

be noted that noise pulses of such short duration may not

be seen with oscilloscopes that have less bandwidth

than 600 MHz. The most often encountered sources of

clock noise spikes are inductive or capacitive coupling of

high–speed logic signals, and ground bounce. The best

solution for addressing clock spikes from coupling is to

separate the traces and use short low inductance PC

board traces. To address ground bounce problems, all

integrated circuits should have high frequency bypass

capacitors directly across their power supply pins, with

low inductance traces for ground and power supply. A

less than optimum solution may be to limit the bandwidth

of the trace by adding series resistance and/or capacitance at the input pin.

MC14LC5480MOTOROLA

9

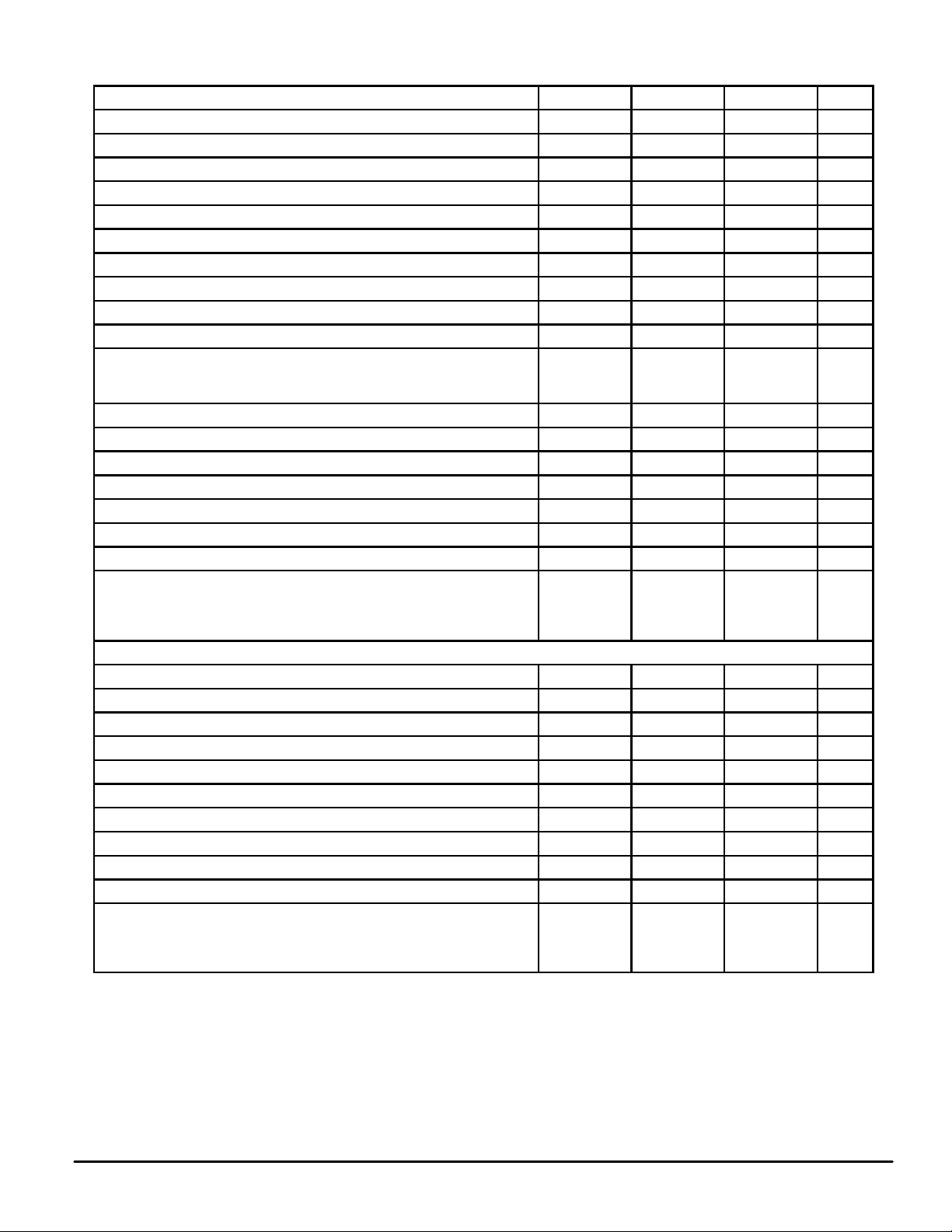

MAXIMUM RATINGS (Voltages Referenced to V

Rating Symbol Value Unit

DC Supply Voltage V

Voltage on Any Analog Input or Output Pin VSS – 0.3 to VDD + 0.3 V

Voltage on Any Digital Input or Output Pin VSS – 0.3 to VDD + 0.3 V

Operating Temperature Range T

Storage Temperature Range T

SS

Pin)

DD

stg

– 0.5 to 6 V

A

– 40 to + 85 °C

– 85 to +150 °C

POWER SUPPLY (T

DC Supply Voltage 4.75 5.0 5.25 V

Active Power Dissipation (VDD = 5 V) (No Load, PI ≥ VDD – 0.5 V)

Power–Down Dissipation (VIH for Logic Levels Must be ≥ 3.0 V) PDI = V

DIGITAL LEVELS (V

Input Low Voltage V

Input High Voltage V

Output Low Voltage (DT Pin, IOL= 2.5 mA) V

Output High Voltage (DT Pin, IOH = – 2.5 mA) V

Input Low Current (VSS ≤ Vin ≤ VDD) I

Input High Current (VSS ≤ Vin ≤ VDD) I

Output Current in High Impedance State (VSS ≤ DT ≤ VDD) I

Input Capacitance of Digital Pins (Except DT) C

Input Capacitance of DT Pin when High–Z C

NOTE: Bold type indicates a change from the MC145480 to the MC14LC5480.

= – 40 to + 85°C)

A

Characteristics

(No Load, PI ≤ VDD – 1.5 V)

FST and FSR = VSS, PDI

= + 5 V ± 5%, VSS = 0 V, TA = – 40 to + 85°C)

DD

Characteristics

= V

SS

DD

Min Typ Max Unit

—

—

—

—

Symbol Min Max Unit

IL

IH

OL

OH

IL

IH

OZ

in

out

15

15

0.01

0.05

— 0.6 V

2.4 — V

— 0.4 V

VDD – 0.5 — V

– 10 + 10 µA

– 10 + 10 µA

– 10 + 10 µA

— 10 pF

— 15 pF

24

25

0.5

1.0

mW

mW

MC14LC5480 MOTOROLA

10

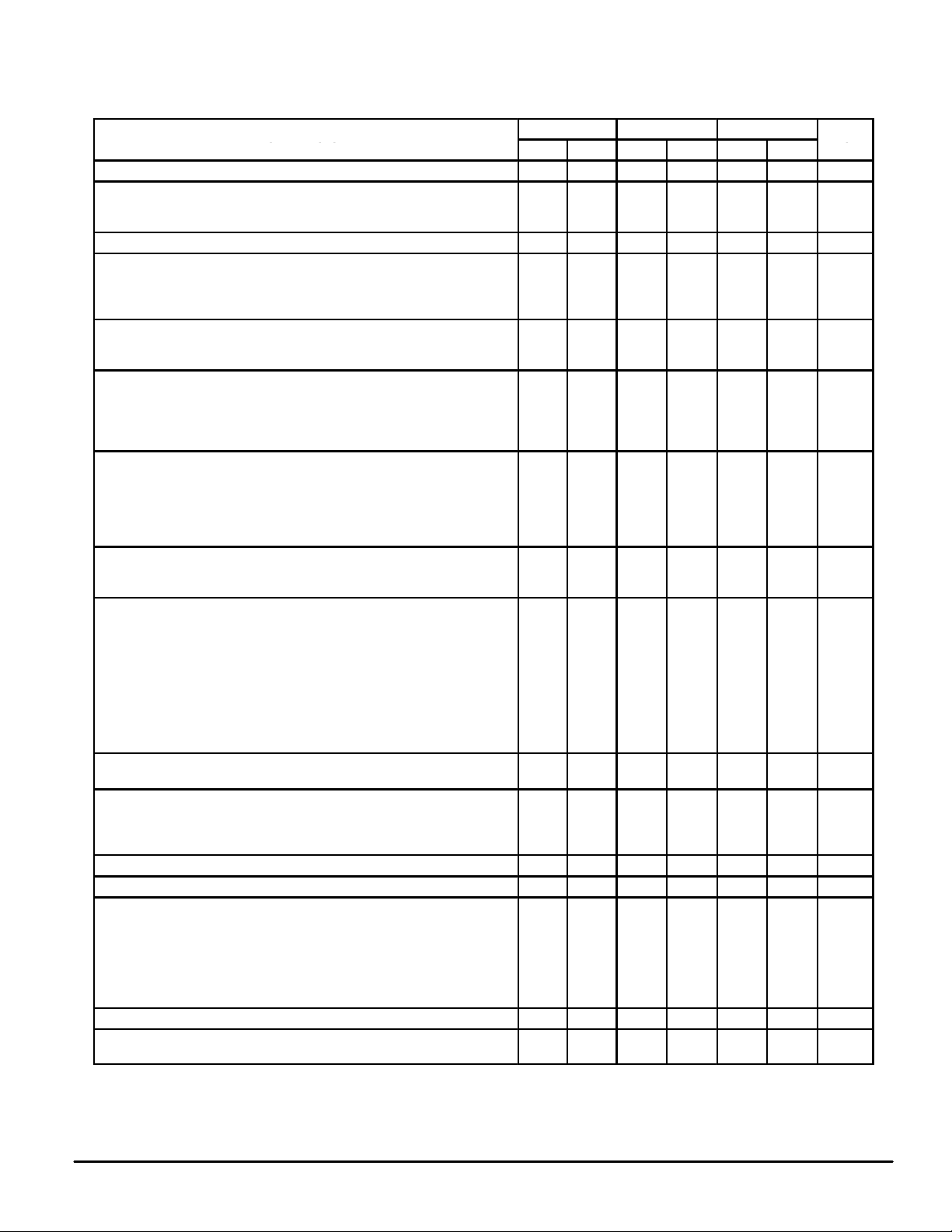

ANALOG ELECTRICAL CHARACTERISTICS (V

Characteristics

Input Current TI+, TI– — ± 0.1 ± 1.0 µA

Input Resistance to VAG (VAG – 0.5 V ≤ Vin ≤ VAG + 0.5 V)

Input Capacitance TI+, TI– — — 10 pF

Input Offset V oltage of TG Op Amp TI+, TI– — — ± 5 mV

Input Common Mode Voltage Range TI+, TI– 1.2 VDD – 2.0 V

Input Common Mode Rejection Ratio TI+, TI– — 60 — dB

Gain Bandwidth Product (10 kHz) of TG Op Amp (RL ≥ 10 kΩ) — 3000 — kHz

DC Open Loop Gain of TG Op Amp (RL ≥ 10 kΩ) — 95 — dB

Equivalent Input Noise (C–Message) Between TI+ and TI– at TG — –30 — dBrnC

Output Load Capacitance for TG Op Amp 0 — 100 pF

Output Voltage Range for TG

(RL = 10 kΩ to VAG)

(RL = 2 kΩ to VAG)

Output Current (0.5 V ≤ V

Output Load Resistance to V

Output Impedance (0 to 3.4 kHz) RO+ or RO– — 1 — Ω

Output Load Capacitance RO+ or RO– 0 — 500 pF

DC Output Offset Voltage of RO+ or RO– Referenced to V

VAG Output Voltage Referenced to VSS (No Load) 2.2 2.4 2.6 V

VAG Output Current with ± 25 mV Change in Output Voltage ± 2.0 ± 10 — mA

Power Supply Rejection Ratio Transmit

(0 to 100 kHz @100 mVrms Applied to VDD, Receive

C–Message Weighting, All Analog Signals

Referenced to VAG Pin)

Input Current (VAG – 0.5 V ≤ PI ≤ VAG + 0.5 V) PI — ± 0.05 ± 1.0 µA

Input Resistance (VAG – 0.5 V ≤ PI ≤ VAG + 0.5 V) PI 10 — — MΩ

Input Offset Voltage PI — — ± 20 mV

Output Offset Voltage of PO+ Relative to PO– (Inverted Unity Gain for PO–) — — ± 50 mV

Output Current (VSS + 0.7 V ≤ PO+ or PO– ≤ VDD – 0.7 V) ± 10 — — mA

PO+ or PO– Output Resistance (Inverted Unity Gain for PO–) — 1 — Ω

Gain Bandwidth Product (10 kHz, Open Loop for PO–) — 1000 — kHz

Load Capacitance (PO+ or PO– to VAG, or PO+ to PO–) 0 — 1000 pF

Gain of PO+ Relative to PO– (RL = 300 Ω, + 3 dBm0, 1 kHz) – 0.2 0 + 0.2 dB

Total Signal to Distortion at PO+ and PO– with a 300 Ω Differential Load 45 60 — dBC

Power Supply Rejection Ratio 0 to 4 kHz

(0 to 25 kHz @ 100 mVrms Applied to VDD. 4 to 25 kHz

PO– Connected to PI. Differential or Measured

Referenced to VAG Pin.)

≤ VDD – 0.5 V) TG, RO+, RO– ± 1.0 — — mA

out

AG

= + 5 V ± 5%, VSS = 0 V, TA = – 40 to + 85°C)

DD

Min Typ Max Unit

TI+, TI–

TG, RO+, and RO– 2 — — kΩ

AG

Power Drivers PI, PO+, PO–

10 —

0.5

1.0

— — ± 25 mV

50

50

40

—

—

—

80

75

55

40

— MΩ

VDD – 0.5

VDD – 1.0

—

—

—

—

V

dBC

dB

NOTE: Bold type indicates a change from the MC145480 to the MC14LC5480.

MC14LC5480MOTOROLA

11

ANALOG TRANSMISSION PERFORMANCE

(VDD = + 5 V ± 5%, VSS = 0 V, All Analog Signals Referenced to VAG, 0 dBm0 = 0.775 Vrms = + 0 dBm @ 600 Ω, FST = FSR = 8 kHz,

BCLKT = MCLK = 2.048 MHz Synchronous Operation, TA = – 40 to + 85°C, Unless Otherwise Noted)

End–to–End A/D D/A

Characteristics

Absolute Gain (0 dBm0 @ 1.02 kHz, TA = 25°C, VDD = 5.0 V) — — – 0.25 + 0.25 – 0.25 + 0.25 dB

Absolute Gain Variation with Temperature

Absolute Gain Variation with Power Supply (TA = 25°C) — — — ± 0.03 — ±

Gain vs Level Tone (Mu–Law, Relative to – 10 dBm0, 1.02 kHz)

(Referenced to 25°C)

0 to + 70°C

– 40 to + 85°C——

+ 3 to – 40 dBm0

– 40 to – 50 dBm0

– 50 to – 55 dBm0

Gain vs Level Pseudo Noise, CCITT G.712 – 10 to – 40 dBm0

(A–Law, Relative to – 10 dBm0) – 40 to – 50 dBm0

Total Distortion, 1.02 kHz Tone (Mu–Law, C–Message Weighting)

– 50 to – 55 dBm0

+ 3 dBm0

0 to – 30 dBm0

– 40 dBm0

– 45 dBm0

Total Distortion, Pseudo Noise, CCITT G.714 (A–Law) – 3 dBm0

– 6 to – 27 dBm0

– 34 dBm0

– 40 dBm0

– 50 dBm0

– 55 dBm0

Idle Channel Noise (For End–to–End and A/D, See Note 1)

Frequency Response (Relative to 1.02 kHz @ 0 dBm0) 15 Hz

(Mu–Law, C–Message Weighted)

(A–Law, Psophometric W eighted)

50 Hz

60 Hz

200 Hz

300 to 3000 Hz

3000 to 3200 Hz

3300 Hz

3400 Hz

4600 Hz to 100 kHz

In–Band Spurious (1.02 kHz @ 0 dBm0, Transmit and Receive)

Out–of–Band Spurious at RO+ (300 to 3400 Hz @ 0 dBm0 in)

8400 to 100,000 Hz

Idle Channel Noise Selective (8 kHz, Input = VAG, 30 Hz Bandwidth) — – 70 — — — – 70 dBm0

Absolute Delay (1600 Hz) — — — 315 — 205 µs

Group Delay Referenced to 1600 Hz 500 to 600 Hz

Crosstalk of 1020 Hz @ 0 dBm0 from A/D or D/A (Note 2) — — — –75 —

Intermodulation Distortion of Two Frequencies of Amplitudes

(– 4 to – 21 dBm0 from the Range 300 to 3400 Hz)

NOTES:

1. Extrapolated from a 1020 Hz @ – 50 dBm0 distortion measurement to correct for encoder enhancement.

2. Selectively measured while stimulated with 2667 Hz @ – 50 dBm0.

3. Bold type indicates a change from the MC145480 to the MC14LC5480.

4000 Hz

3400

300 to

4600 to 7600 Hz

7600 to 8400 Hz

600 to 800 Hz

800 to 1000 Hz

1000 to 1600 Hz

1600 to 2600 Hz

2600 to 2800 Hz

2800 to 3000 Hz

Min Max Min Max Min Max

—

—

——± 0.03

± 0.05——

± 0.03

± 0.05

0.03

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

Hz — – 48 — – 48 — – 48

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

– 30

– 40

– 30

—

—

—

—

—

—

—

– 0.30

– 0.8

– 1.2

– 0.25

– 0.60

– 1.00

34

36

30

25

30

36

34

29

19

14

—

—

—

—

—

– 1.0

– 0.20

– 0.20

– 0.35

– 0.8

—

—

—

—

—

—

—

—

—

—

—

—

+ 0.20

+ 0.40

+ 0.80

+ 0.25

+ 0.30

+ 0.45

—

—

—

—

—

—

—

—

—

—

17

– 69

– 40

– 30

– 26

– 0.4

+ 0.15

+ 0.20

+ 0.15

0

– 14

– 32

—

—

—

210

130

70

35

70

95

145

– 0.20

– 0.40

– 0.80

– 0.25

– 0.30

– 0.45

34

36

30

25

30

36

35

30

20

15

—

—

– 0.5

– 0.5

– 0.5

– 0.5

– 0.15

– 0.20

– 0.35

– 0.85

—

—

—

—

—

– 40

– 40

– 40

– 30

—

—

—

+ 0.20

+ 0.40

+ 0.80

+ 0.25

+ 0.30

+ 0.45

– 79

+ 0.15

+ 0.20

+ 0.15

– 14

– 30

– 40

– 30

110

175

–75

— – 41 — – 41 — – 41

—

—

—

—

—

—

—

—

—

—

11

30

—

—

—

—

85

Units

dB

dB

dB

dB

dBC

dB

dBrnc0

dBm0p

0

0

0

0

0

dB

dB

dB

µs

dB

dB

MC14LC5480 MOTOROLA

12

DIGITAL SWITCHING CHARACTERISTICS, LONG FRAME SYNC AND SHORT FRAME SYNC

(VDD = + 5 V ± 5%, VSS = 0 V, All Digital Signals Referenced to VSS, TA = – 40 to + 85°C, CL = 150 pF, Unless Otherwise Noted)

Ref.

No.

1 Master Clock Frequency for MCLK —

1 MCLK Duty Cycle for 256 kHz Operation 45 — 55 %

2 Minimum Pulse Width High for MCLK (Frequencies of 512 kHz or Greater) 50 — — ns

3 Minimum Pulse Width Low for MCLK (Frequencies of 512 kHz or Greater) 50 — — ns

4 Rise Time for All Digital Signals — — 50 ns

5 Fall Time for All Digital Signals — — 50 ns

6 Setup Time from MCLK Low to FST High 50 — — ns

7 Setup Time from FST High to MCLK Low 50 — — ns

8 Bit Clock Data Rate for BCLKT or BCLKR 64 — 4096 kHz

9 Minimum Pulse Width High for BCLKT or BCLKR 50 — — ns

10 Minimum Pulse Width Low for BCLKT or BCLKR 50 — — ns

11 Hold Time from BCLKT (BCLKR) Low to FST (FSR) High 20 — — ns

12 Setup Time for FST (FSR) High to BCLKT (BCLKR) Low 80 — — ns

13 Setup Time from DR Valid to BCLKR Low 0 — — ns

14 Hold Time from BCLKR Low to DR Invalid 50 — — ns

15 Hold Time from 2nd Period of BCLKT (BCLKR) Low to FST (FSR) Low 50 — — ns

16 Delay Time from FST or BCLKT, Whichever is Later, to DT for Valid MSB Data — — 60 ns

17 Delay Time from BCLKT High to DT for Valid Chord and Step Bit Data — — 60 ns

18 Delay Time from the Later of the 8th BCLKT Falling Edge, or the Falling Edge

of FST to DT Output High Impedance

19 Minimum Pulse Width Low for FST or FSR 50 — — ns

20 Hold Time from BCLKT (BCLKR) Low to FST (FSR) Low 50 — — ns

21 Setup Time from FST (FSR) Low to MSB Period of BCLKT (BCLKR) Low 50 — — ns

22 Delay Time from BCLKT High to DT Data Valid 10 — 60 ns

23 Delay Time from the 8th BCLKT Low to DT Output High Impedance 10 — 60 ns

Characteristics Min Typ Max Unit

LONG FRAME SPECIFIC TIMING

SHORT FRAME SPECIFIC TIMING

—

—

—

—

—

—

10 — 60 ns

256

512

1536

1544

2048

2560

4096

—

—

—

—

—

—

—

kHz

MC14LC5480MOTOROLA

13

MCLK

7

6 2

1

3

4

5

8

BCLKT

FST

DT

BCLKR

FSR

123456789

11

16

12

15

16

17

9

10

18

18

MSB CH1 CH2 CH3 ST1 ST2 ST3 LSB

8

123456789

11

12

15

9

10

DR

13

14

MSB CH1 CH2 CH3 ST1 ST2 ST3 LSB

Figure 3. Long Frame Sync Timing

MC14LC5480 MOTOROLA

14

7

6 2

MCLK

1

3

4

5

BCLKT

FST

DT

BCLKR

12

8

123456789

20

11

22

21

22

9

10

23

MSB CH1 CH2 CH3 ST1 ST2 ST3 LSB

8

123456789

11

20

12

21

9

10

FSR

DR

13

14

MSB CH1 CH2 CH3 ST1 ST2 ST3 LSB

Figure 4. Short Frame Sync Timing

MC14LC5480MOTOROLA

15

DIGITAL SWITCHING CHARACTERISTICS FOR IDL MODE

(VDD = 5.0 V ± 5%, TA = – 40 to + 85°C, CL = 150 pF, See Figure 5 and Note 1)

Ref.

No.

31 Time Between Successive IDL Syncs Note 2

32 Hold Time of IDL SYNC After Falling Edge of IDL CLK 20 — ns

33 Setup Time of IDL SYNC Before Falling Edge IDL CLK 60 — ns

34 IDL Clock Frequency 256 4096 kHz

35 IDL Clock Pulse Width High 50 — ns

36 IDL Clock Pulse Width Low 50 — ns

37 Data Valid on IDL RX Before Falling Edge of IDL CLK 20 — ns

38 Data Valid on IDL RX After Falling Edge of IDL CLK 75 — ns

39 Falling Edge of IDL CLK to High–Z on IDL TX 10 50 ns

40 Rising Edge of IDL CLK to Low–Z and Data Valid on IDL TX 10 60 ns

41 Rising Edge of IDL CLK to Data Valid on IDL TX — 50 ns

NOTES:

1. Measurements are made from the point at which the logic signal achieves the guaranteed minimum or maximum logic level.

2. In IDL mode, both transmit and receive 8–bit PCM words are accessed during the B1 channel, or both transmit and receive 8–bit PCM words

are accessed during the B2 channel as shown in Figure 5. IDL accesses must occur at a rate of 8 kHz (125 µs interval).

Characteristics Min Max Unit

IDLE SYNC

(FST)

IDL CLOCK

(BCLKT)

IDL TX

(DT)

IDL RX

(DR)

32

33

32

34

35

40

37 37

41

CH2

CH1MSB

36

38

LSBST3ST2ST1CH3CH2CH1MSB LSBST3ST2ST1CH3CH2CH1MSB

Figure 5. IDL Interface Timing

31

40

39

41 39

38

19181716151413121110987654321

LSBST3ST2ST1CH3CH2CH1MSBLSBST3ST2ST1CH3

21

MC14LC5480 MOTOROLA

16

DIGITAL SWITCHING CHARACTERISTICS FOR GCI MODE

(VDD = 5.0 V ± 5%, TA = – 40 to + 85°C, CL = 150 pF, See Figure 6 and Note 1)

Ref.

No.

42 Time Between Successive FSC Pulses Note 2

43 DCL Clock Frequency 512 6176 kHz

44 DCL Clock Pulse Width High 50 — ns

45 DCL Clock Pulse Width Low 50 — ns

46 Hold Time of FSC After Falling Edge of DCL 20 — ns

47 Setup Time of FSC to DCL Falling Edge 60 — ns

48 Rising Edge of DCL (After Rising Edge of FSC) to Low Impedance and Valid Data of D

49 Rising Edge of FSC (While DCL is High) to Low Impedance and Valid Data of D

50 Rising Edge of DCL to Valid Data on D

51 Second DCL Falling Edge During LSB to High Impedance of D

52 Setup Time of Din Before Rising Edge of DCL 20 — ns

53 Hold Time of Din After DCL Rising Edge — 60 ns

NOTES:

1. Measurements are made from the point at which the logic signal achieves the guaranteed minimum or maximum logic level.

2. In GCI mode, both transmit and receive 8–bit PCM words are accessed during the B1 channel, or both transmit and receive 8–bit PCM words

are accessed during the B2 channel as shown in Figure 6. GCI accesses must occur at a rate of 8 kHz (125 µs interval).

Characteristics Min Max Unit

out

out

out

out

— 60 ns

— 60 ns

— 60 ns

10 50 ns

FSC

(FST)

DCL

(BCLKT)

D

(DT)

out

Din (DR)

FSC

(FST)

DCL

(BCLKT)

D

(DT)

out

46

49

52

1 343332302928272625242322212019181715 1614138765432

48

MSB

47

46

53

50

49

42

1211109

51

LSBST3ST2ST1CH3CH2CH1

LSBST3ST2ST1CH3CH2CH1MSB LSBST3ST2ST1CH3CH2CH1MSB

4321

48

52

43

44

5

45

50

53

31

51

LSBST3ST2ST1CH3CH2CH1MSB

CH1MSB

Din (DR)

52

53

CH1MSB

Figure 6. GCI Interface Timing

MC14LC5480MOTOROLA

17

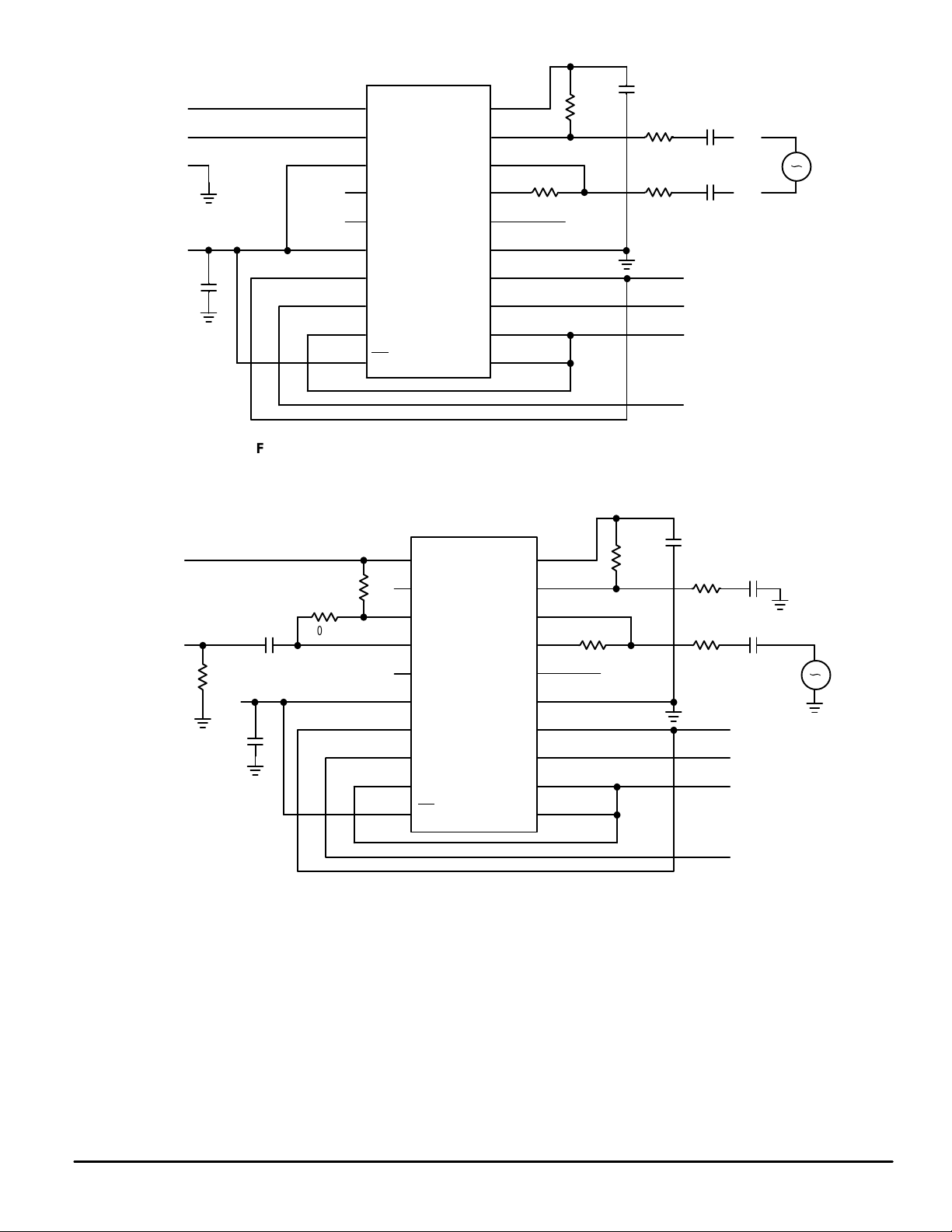

AUDIO OUT

+ 5 V

0.1 µF

0.1

µ

10 k

10 k

F

Ω

Ω

1.0 µF

1.0 µF

8 kHz

PCM OUT

2.048 MHz

PCM IN

ANALOG IN

Y

+

–

1

2

3

4

5

6

7

8

9

RO+

RO–

PI

PO–

PO+

V

DD

FSR

DR

BCLKR

PDI

V

AG

TI+

TI–

TG

Mu/A

V

SS

FST

DT

BCLKT

MCLK

20

19

18

17

16

15

14

13

12

11 10

10 k

Ω

10 k

Ω

+ 5 V

Figure 7. MC14LC5480 Test Circuit with Differential Input and Output

AUDIO OUT

RL ≥ 2 k

Ω

AUDIO OUT

RL ≥ 150

Ω

10 k

1

RO+

2

3

4

5

6

7

8

9

RO–

PI

PO–

PO+

V

DD

FSR

DR

BCLKR

PDI

Ω

10 k

68

µ

F

10 k

+

Ω

+ 5 V

0.1 µF

Ω

V

AG

TI+

TI–

TG

Mu/A

V

SS

FST

DT

BCLKT

MCLK

20

19

18

17

16

15

14

13

12

11 10

10 k

Ω

+ 5 V

Figure 8. MC14LC5480 Test Circuit with Input and Output Referenced to V

10 k

µ

F

0.1

Ω

10 k

10 k

1.0 µF

Ω

Ω

ANALOG IN

1.0 µF

Y

8 kHz

PCM OUT

2.048 MHz

PCM IN

SS

MC14LC5480 MOTOROLA

18

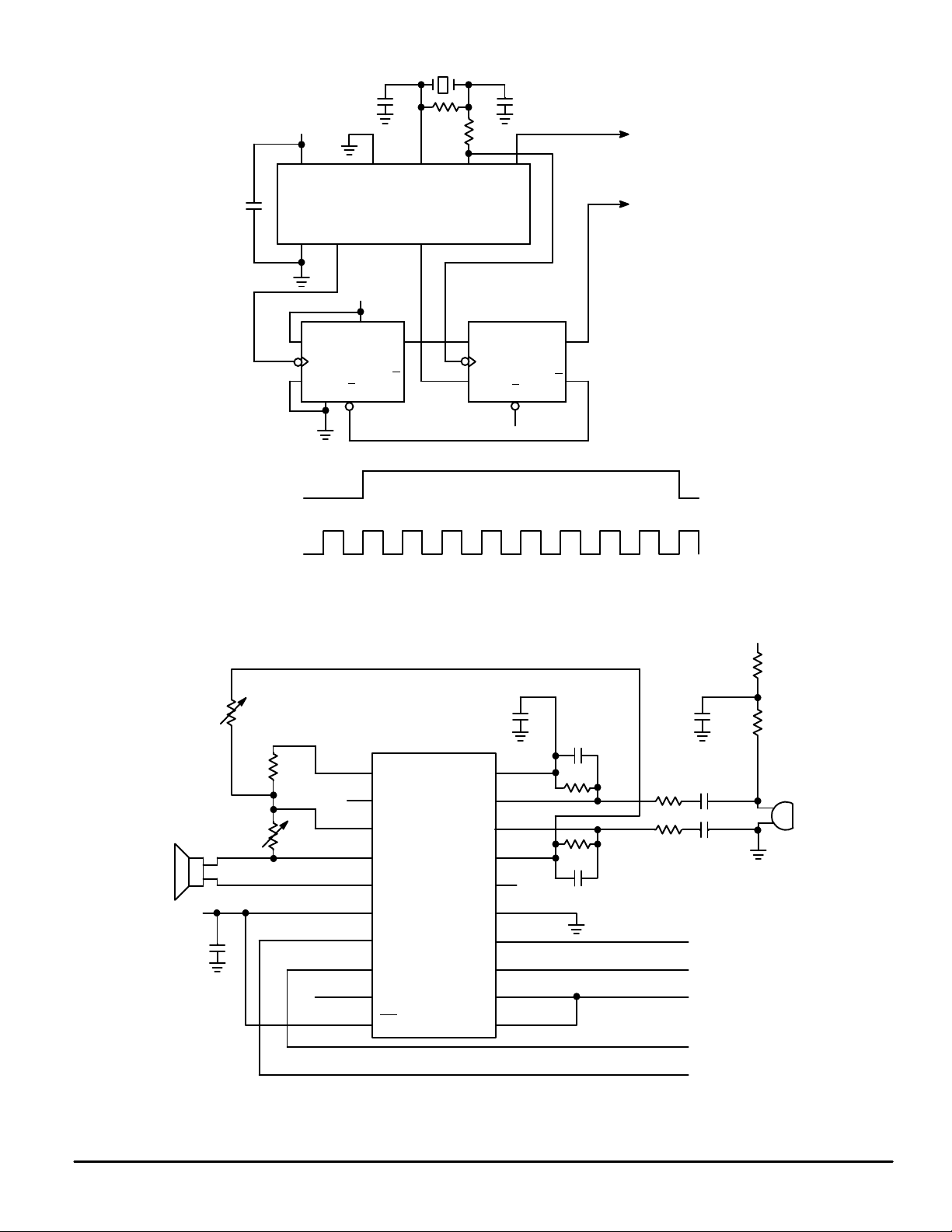

+ 5 V

2.048 MHz

Ω

10 M

300

18 pF18 pF

Ω

2.048 MHz

(BCLKT, BCLKR, MCLK)

0.1

µ

F

8 kHz

2.048 MHz

V

CC

GND

V

J

1/2 MC74HC73

K

GND

256 8 97654321

R OSC

OSC IN

MC74HC4060

+ 5 V

CC

Q

Q

R

OSC

OUT 2

OUT 1

Q4Q8

R

Q

Q

+ 5 V

J

1/2 MC74HC73

K

Figure 9. Long Frame Sync Clock Circuit for 2.048 MHz

8 kHz

(FST, FSR)

REC

+ 5 V

0.1

+5 V

1 k

Ω

SIDETONE

68

µ

0.1 µF

420 pF

1

RO+

2

RO–

3

PI

4

PO–

5

PO+

6

V

DD

7

µ

F

+ 5 V

8

9

10

FSR

DR

BCLKR

PDI

V

AG

TI+

TI–

TG

Mu/A

V

SS

FST

DT

BCLKT

MCLK

20

19

18

17

16

15

14

13

12

11

+ 5 V

75 k

Ω

75 k

Ω

420 pF

F

0.1

µ

1 k

1 k

F

Ω

Ω

0.1 µF

IDL SYNC – 8 kHz

IDL TX

IDL CLOCK – 2.048 MHz

IDL RX

B1 – 0 V

B2 – + 5 V

1 k

Ω

MIC

Figure 10. MC14LC5480 Analog Interface to Handset with IDL Clocking

MC14LC5480MOTOROLA

19

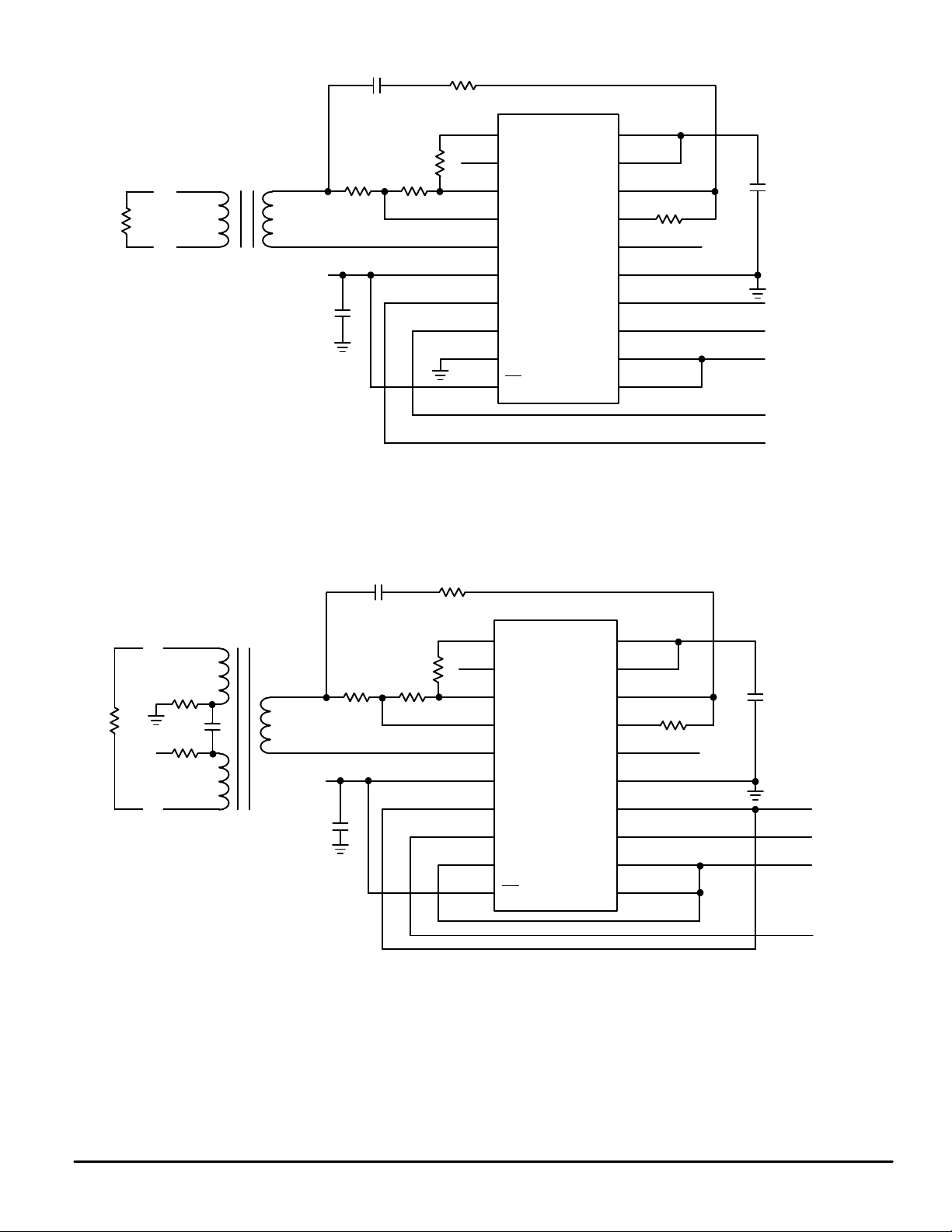

1.0 µF

10 k

Ω

R0 = 600

1

RO+

2

10

3

4

5

6

7

8

9

RO–

PI

PO–

PO+

V

DD

FSR

DR

BCLKR

PDI

10 k

Ω

TIP

N = 1N = 1

RING

+ 5 V

0.1 µF

R0

10 k

Ω

Ω

V

AG

TI+

TI–

TG

Mu/A

V

SS

FST

DT

BCLKT

MCLK

20

19

18

17

16

15

14

13

12

11

10 k

Ω

Figure 11. MC14LC5480 Transformer Interface to 600 Ω Telephone Line with GCI Clocking

1.0

µ

F

10 k

Ω

+ 5 V

0.1 µF

FSC – 8 kHz

D

out

DCL – 4.096 MHz

D

in

B1 – 0 V

B2 – + 5 V

R0 = 600

– 48 V

Ω

TIP

N = 0.5

N = 0.5

RING

N = 0.5

+ 5 V

0.1 µF

1/4 R0

10 k

10 k

1

RO+

Ω

Ω

2

3

4

5

6

7

8

9

10

RO–

PI

PO–

PO+

V

DD

FSR

DR

BCLKR

PDI

V

AG

TI+

TI–

TG

Mu/A

V

SS

FST

DT

BCLKT

MCLK

20

19

18

17

16

15

14

13

12

11

20 k

Ω

0.1 µF

+ 5 V

8 kHz

PCM OUT

2.048 MHz

PCM IN

Figure 12. MC14LC5480 Step–Up Transformer Interface to 600 Ω Telephone Line

MC14LC5480 MOTOROLA

20

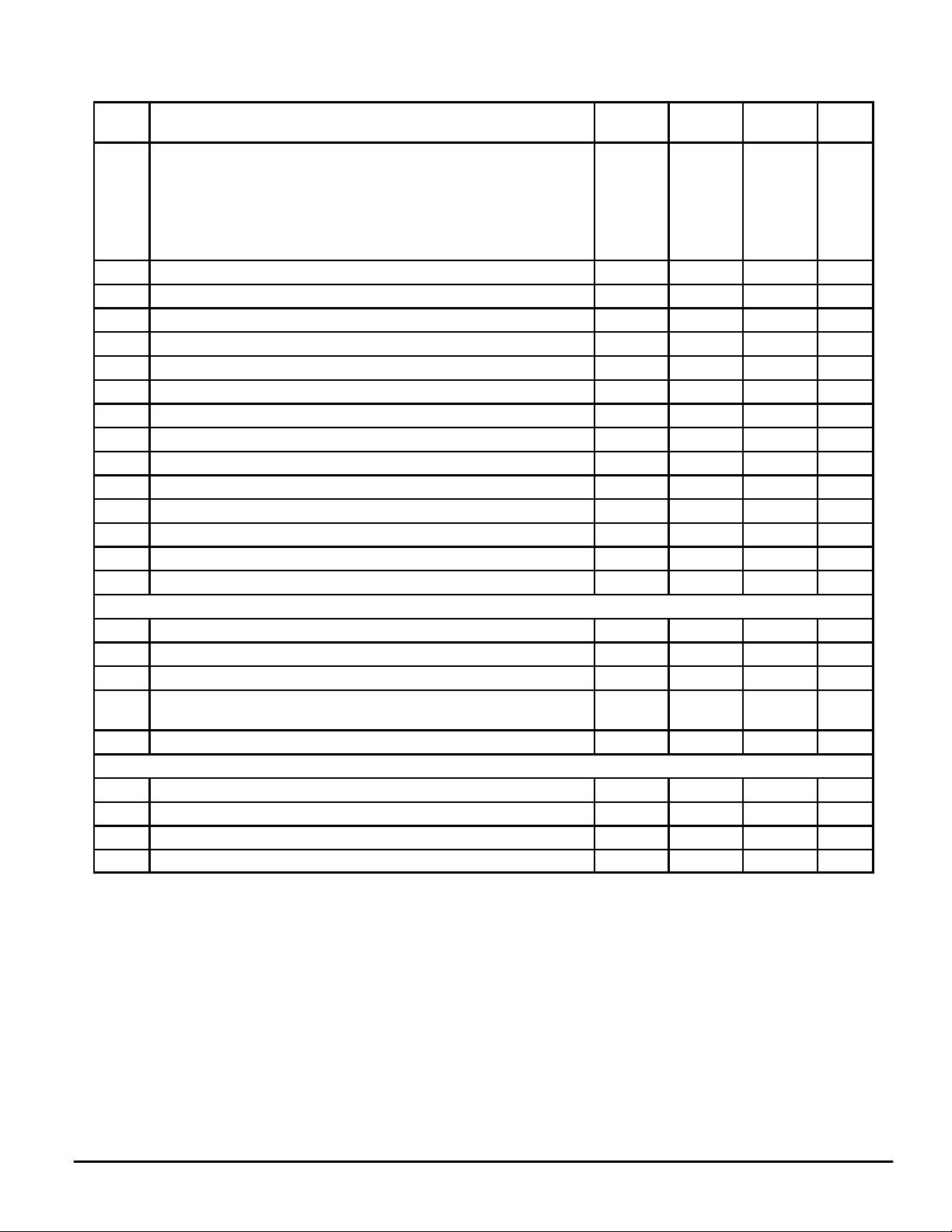

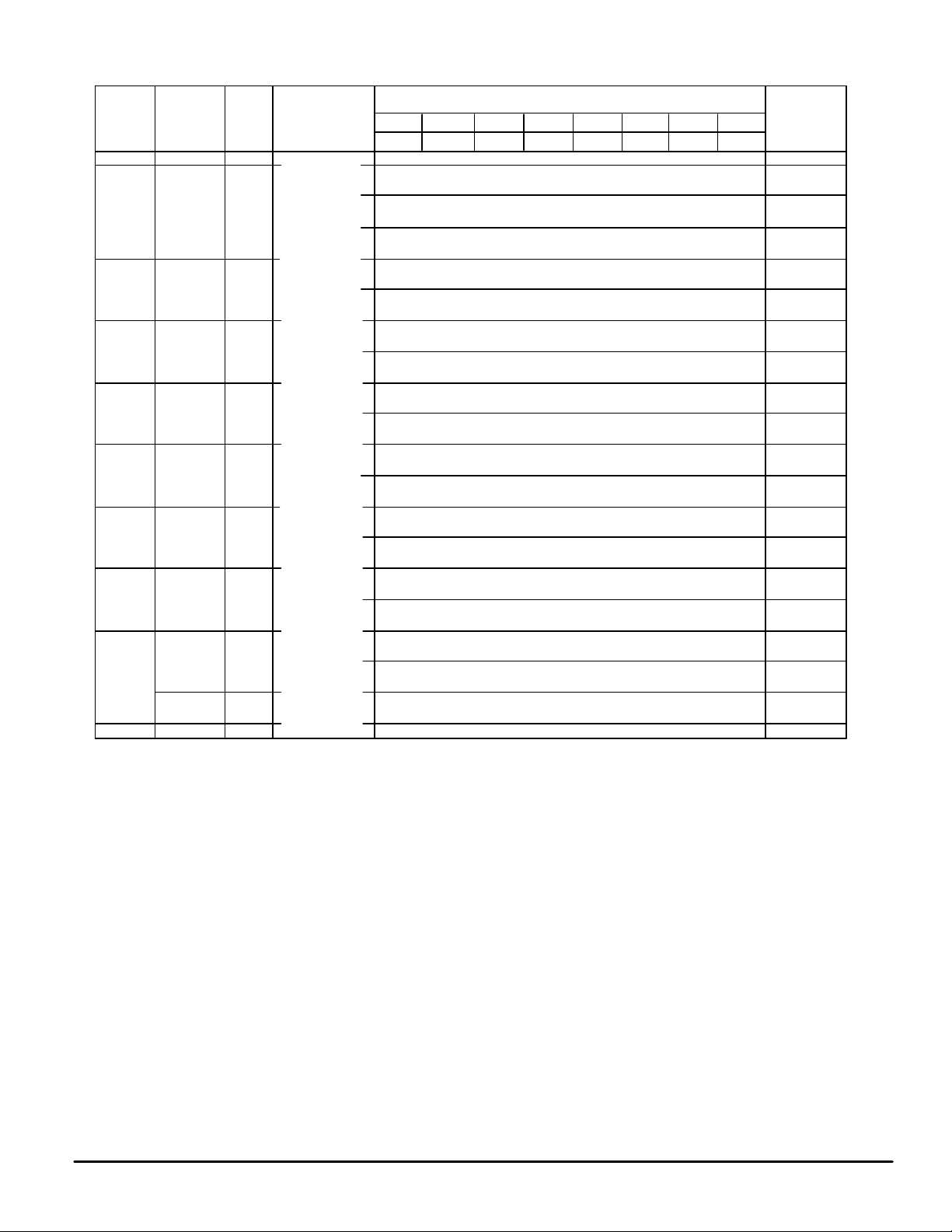

T able 3. Mu–Law Encode–Decode Characteristics

Normalized

Encode Normalized

Chord Number Step Decision Decode

Number of Steps Size Levels Sign Chord Chord Chord Step Step Step Step Levels

8159

8 16 256

7 16 128 2143

6 16 64 1055

51632511

4 16 16 239

3 16 8 103

2164 35

1152 3

11 11111111 0

NOTES:

1. Characteristics are symmetrical about analog zero with sign bit = 0 for negative analog values.

2. Digital code includes inversion of all magnitude bits.

7903

…

4319

4063

…

2015

…

991

…

479

…

223

…

95

…

31

…

1

0

12345678

1 0 0 0 0 0 0 0 8031

1 0 0 0 1 1 1 1 4191

1 0 0 1 1 1 1 1 2079

1 0 1 0 1 1 1 1 1023

1 0 1 1 1 1 1 1 495

1 1 0 0 1 1 1 1 231

11011111 99

11101111 33

11111110 2

Digital Code

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

MC14LC5480MOTOROLA

21

T able 4. A–Law Encode–Decode Characteristics

Normalized

Encode Normalized

Chord Number Step Decision Decode

Number of Steps Size Levels Sign Chord Chord Chord Step Step Step Step Levels

4096

7 16 128

6 16 64 1088

5 16 32 544

4 16 16 272

3 16 8 136

2164 68

1322 2

NOTES:

1. Characteristics are symmetrical about analog zero with sign bit = 0 for negative analog values.

2. Digital code includes inversion of all even numbered bits.

3968

…

2176

2048

…

1024

…

512

…

256

…

128

…

64

…

0

12345678

1 0 1 0 1 0 1 0 4032

1 0 1 0 0 1 0 1 2112

1 0 1 1 0 1 0 1 1056

1 0 0 0 0 1 0 1 528

1 0 0 1 0 1 0 1 264

1 1 1 0 0 1 0 1 132

11110101 66

11010101 1

Digital Code

…

…

…

…

…

…

…

…

…

…

…

…

…

…

MC14LC5480 MOTOROLA

22

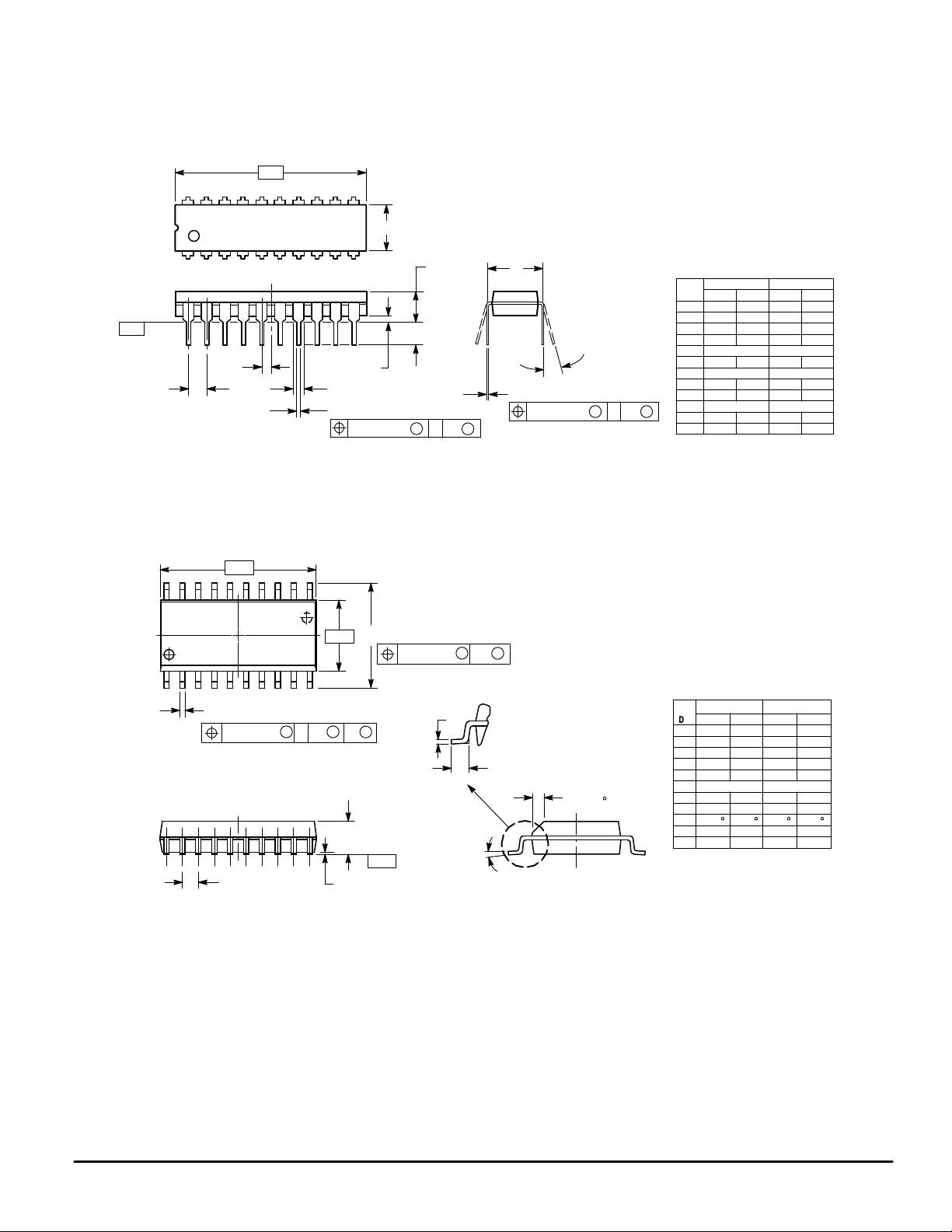

P ACKAGE DIMENSIONS

P SUFFIX

PLASTIC DIP

CASE 738–03

-T-

SEATING

PLANE

-A-

1120

B

110

C

K

E

N

GF

D

20 PL

0.25 (0.010) T A

M M

SOG PACKAGE

CASE 751D–04

–A–

20

11

–B–

P10X

0.010 (0.25)

1

10

D20X

0.010 (0.25) B

M

S

A

T

S

C

SEATING

–T–

18X

G

K

PLANE

DW SUFFIX

M

M

B

J

F

M

L

M

J 20 PL

0.25 (0.010) T B

R

X 45

M M

_

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD

FLASH.

INCHES MILLIMETERS

MIN MINMAX MAX

DIM

A

B

C

D

E

F

G

J

K

L

M

N

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.150

(0.006) PER SIDE.

5. DIMENSION D DOES NOT INCLUDE

DAMBAR PROTRUSION. ALLOWABLE

DAMBAR PROTRUSION SHALL BE 0.13

(0.005) TOTAL IN EXCESS OF D DIMENSION

AT MAXIMUM MATERIAL CONDITION.

DIM MIN MAX MIN MAX

A 12.65 12.95 0.499 0.510

B 7.40 7.60 0.292 0.299

C 2.35 2.65 0.093 0.104

D 0.35 0.49 0.014 0.019

F 0.50 0.90 0.020 0.035

G 1.27 BSC 0.050 BSC

J 0.25 0.32 0.010 0.012

K 0.10 0.25 0.004 0.009

M 0 7 0 7

P 10.05 10.55 0.395 0.415

R 0.25 0.75 0.010 0.029

1.070

1.010

0.260

0.240

0.180

0.150

0.022

0.015

0.050 BSC

0.070

0.050

0.100 BSC

0.015

0.008

0.140

0.110

0.300 BSC

15°

°

0

0.040

0.020

__

25.66

27.17

6.10

6.60

3.81

4.57

0.39

0.55

1.27 BSC

1.27

1.77

2.54 BSC

0.21

0.38

2.80

3.55

7.62 BSC

°

0

15

1.01

0.51

INCHESMILLIMETERS

__

°

MC14LC5480MOTOROLA

23

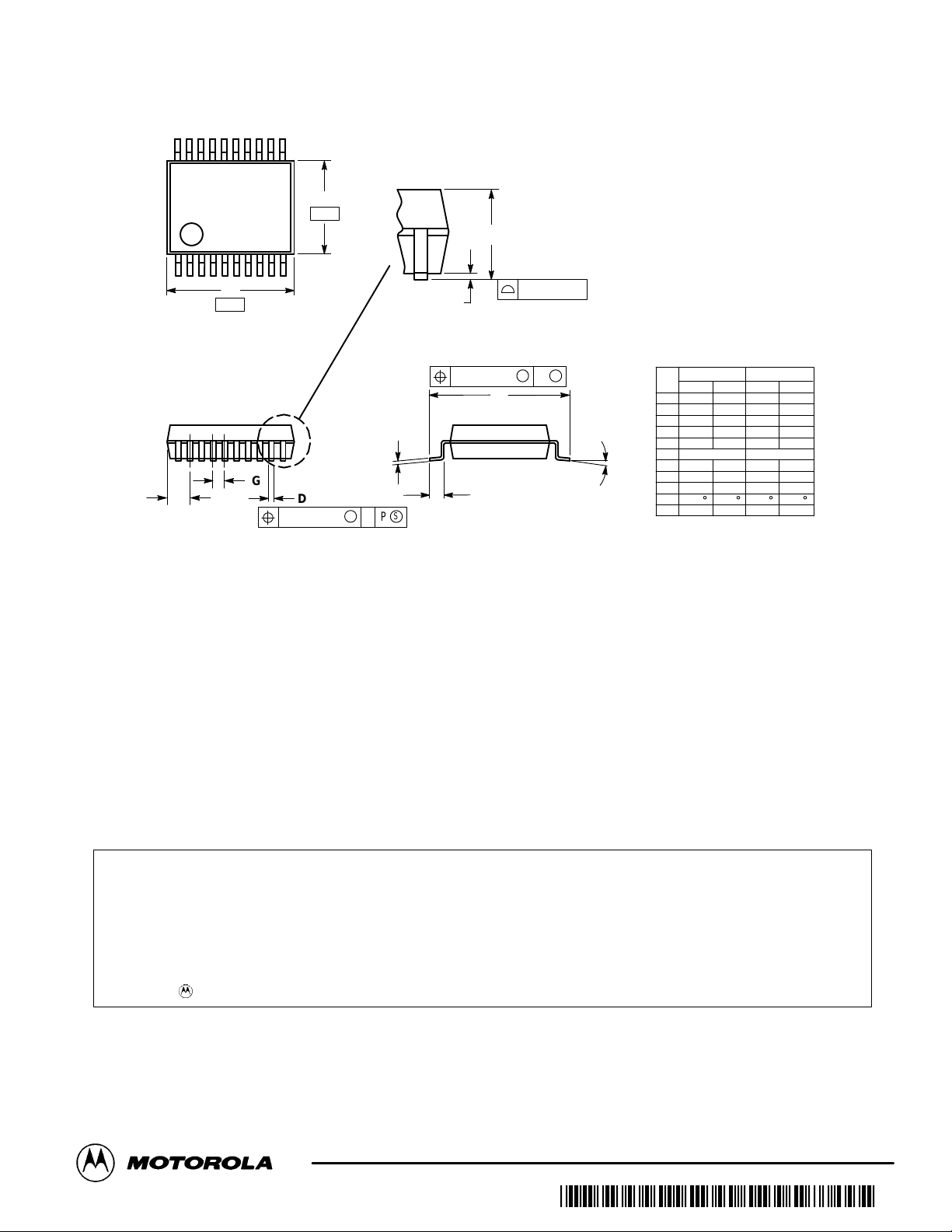

SD SUFFIX

SSOP

CASE 940C–02

20 11

A

–P–

G

H

B

–R–

101

D

0.120 (0.005) T

M

J

S

P

C

N

0.25 (0.010)

L

F

NOTE 4

0.076 (0.003)

M

M

R

NOTES:

1. CONTROLLING DIMENSION: MILLIMETER.

2. DIMENSIONS AND TOLERANCES PER ANSI

Y14.5M, 1982.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD FLASH OR PROTRUSIONS AND ARE

MEASURED AT THE PARTING LINE. MOLD

FLASH OR PROTRUSIONS SHALL NOT

EXCEED 0.15MM PER SIDE.

4. DIMENSION IS THE LENGTH OF TERMINAL

FOR SOLDERING TO A SUBSTRATE.

5. TERMINAL POSITIONS ARE SHOWN FOR

REFERENCE ONLY.

6. THE LEAD WIDTH DIMENSION DOES NOT

INCLUDE DAMBAR PROTRUSION.

ALLOWABLE DAMBAR PROTRUSION SHALL

BE 0.08MM TOTAL IN EXCESS OF THE LEAD

WIDTH DIMENSION.

DIM MIN MAX MIN MAX

A 7.10 7.30 0.280 0.287

B 5.20 5.38 0.205 0.212

C 1.75 1.99 0.069 0.078

M

D 0.25 0.38 0.010 0.015

F 0.65 1.00 0.026 0.039

G 0.65 BSC 0.026 BSC

H 0.59 0.75 0.023 0.030

J 0.10 0.20 0.004 0.008

L 7.65 7.90 0.301 0.311

M 0 8 0 8

N 0.05 0.21 0.002 0.008

INCHESMILLIMETERS

____

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit,

and specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters can and do vary in different

applications. All operating parameters, including “T ypicals” must be validated for each customer application by customer’s technical experts. Motorola does

not convey any license under its patent rights nor the rights of others. Motorola products are not designed, intended, or authorized for use as components in

systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of

the Motorola product could create a situation where personal injury or death may occur. Should Buyer purchase or use Motorola products for any such

unintended or unauthorized application, Buyer shall indemnify and hold Motorola and its officers, employees, subsidiaries, affiliates, and distributors harmless

against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that Motorola was negligent regarding the design or manufacture of the part.

Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, Toshikatsu Otsuki,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 6F Seibu–Butsuryu–Center , 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 03–3521–8315

MFAX: RMF AX0@email.sps.mot.com – T OUCHTONE (602) 244–6609 HONG KONG: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET .com 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

MC14LC5480 MOTOROLA

24

◊

*MC14LC5480/D*

MC14LC5480/D

Loading...

Loading...