Page 1

™

PRO2150

Portable Radio

Detailed Service Manual

Page 2

Page 3

Table of Contents i

User Safety, Training, and General Information..........................................v

Chapter 1 Introduction ......................................................................... 1-1

1.1 Scope of Manual............................................................................................................................ 1-1

1.2 Warranty and Service Support....................................................................................................... 1-1

1.2.1 Warranty Period and Return Instructions.......................................................................... 1-1

1.2.2 After Warranty Period ....................................................................................................... 1-1

1.2.3 Piece Parts ....................................................................................................................... 1-2

1.2.4 Technical Support............................................................................................................. 1-2

1.2.5 Parts Identification ............................................................................................................ 1-2

1.3 Radio Model Information................................................................................................................ 1-3

1.4 Radio Features .............................................................................................................................. 1-4

Chapter 2 Maintenance ........................................................................ 2-1

2.1 Introduction .................................................................................................................................... 2-1

2.2 Preventive Maintenance ................................................................................................................ 2-1

2.2.1 Inspection ......................................................................................................................... 2-1

2.2.2 Cleaning Procedures ........................................................................................................2-1

2.3 Safe Handling of CMOS and LDMOS Devices.............................................................................. 2-2

2.4 Repair Procedures and Techniques — General............................................................................ 2-2

2.4.1 Parts Replacement and Substitution ................................................................................ 2-2

2.4.2 Rigid Circuit Boards .......................................................................................................... 2-2

2.4.3 Flexible Circuits ................................................................................................................ 2-3

2.4.4 Chip Components ............................................................................................................. 2-3

2.4.5 Shields .............................................................................................................................. 2-4

2.5 Disassembling and Reassembling the Radio — General.............................................................. 2-4

2.6 Radio Disassembly — Detailed ..................................................................................................... 2-5

2.6.1 Front Cover from Chassis Disassembly ........................................................................... 2-5

2.6.2 Control Board Disassembly .............................................................................................. 2-7

2.6.3 RF Board Disassembly ..................................................................................................... 2-7

2.7 Radio Reassembly — Detailed...................................................................................................... 2-8

2.7.1 RF Board Reassembly...................................................................................................... 2-8

2.7.2 Control Board Reassembly............................................................................................... 2-8

2.7.3 Chassis and Front Cover Reassembly ............................................................................. 2-8

2.8 Mechanical View and Parts List ................................................................................................... 2-12

2.8.1 Exploded View and Parts List ......................................................................................... 2-12

2.9 Service Aids................................................................................................................................. 2-14

2.10 Test Equipment............................................................................................................................ 2-15

2.11 Programming Cable (DSK001C706) ........................................................................................... 2-16

2.12 IF Test Box (DSK001C702) ......................................................................................................... 2-17

99R85452E01-O August 30, 2002

Page 4

ii Table of Contents

Chapter 3 Radio Tuning ....................................................................... 3-1

3.1 Introduction .................................................................................................................................... 3-1

3.2 Software Tuning Setup .................................................................................................................. 3-1

3.3 Affixing Antenna Ground Plate....................................................................................................... 3-2

3.4 Hardware Tuning Setup and Procedure ........................................................................................ 3-3

3.4.1 Audio Modulation Tuning .................................................................................................. 3-3

3.4.2 Sub-Audio Modulation Tuning........................................................................................... 3-4

3.4.3 Tuning Frequency .............................................................................................................3-4

Chapter 4 Radio Programming............................................................ 4-1

4.1 Introduction .................................................................................................................................... 4-1

4.2 Programming Your Radio .............................................................................................................. 4-1

4.2.1 Overview of the Programming Process ............................................................................ 4-1

4.2.2 Cloning Radio Parameters to User Radios ....................................................................... 4-1

4.2.3 Parameters Which are Cloned.......................................................................................... 4-1

4.2.4 Parameters Which are Not Cloned ................................................................................... 4-1

4.2.5 To Clone a Radio .............................................................................................................. 4-1

4.2.6 Error Conditions ................................................................................................................ 4-2

4.3 CPS Programming ......................................................................................................................... 4-2

4.4 Programming ................................................................................................................................. 4-3

4.4.1 PL Frequencies and Codes .............................................................................................. 4-3

4.4.2 DPL Codes........................................................................................................................ 4-4

4.4.3 Examples .......................................................................................................................... 4-4

Chapter 5 Error Code Displays............................................................ 5-1

5.1 Error Codes.................................................................................................................................... 5-1

Chapter 6 Accessories ......................................................................... 6-1

6.1 Antennas........................................................................................................................................ 6-1

6.2 Carrying Accessories ..................................................................................................................... 6-1

6.3 Carry Cases ................................................................................................................................... 6-1

6.4 Chargers ........................................................................................................................................ 6-1

6.5 Batteries......................................................................................................................................... 6-1

6.6 Audio Accessories ......................................................................................................................... 6-1

6.7 Manuals ......................................................................................................................................... 6-2

6.8 Software......................................................................................................................................... 6-2

August 30, 2002 99R85452E01-O

Page 5

Table of Contents iii

Chapter 7 VHF Band Information ........................................................ 7-1

7.1 Model Chart ................................................................................................................................... 7-1

7.2 Specifications................................................................................................................................. 7-2

7.3 Theory of Operation....................................................................................................................... 7-3

7.3.1 General Information .......................................................................................................... 7-3

7.3.2 Power Distribution............................................................................................................. 7-3

7.3.3 Power up Sequence ......................................................................................................... 7-3

7.3.4 CPU / Control Section....................................................................................................... 7-4

7.3.5 VCO / Synthesizer Section ............................................................................................... 7-4

7.3.6 Transmitter Section........................................................................................................... 7-5

7.3.7 Receiver Section............................................................................................................... 7-6

7.3.8 Battery Section ................................................................................................................. 7-7

7.4 Block Diagrams.............................................................................................................................. 7-8

7.4.1 Complete .......................................................................................................................... 7-8

7.4.2 Controller .......................................................................................................................... 7-9

7.4.3 VCO .................................................................................................................................. 7-9

7.4.4 Transmitter...................................................................................................................... 7-10

7.4.5 Receiver.......................................................................................................................... 7-10

7.5 Troubleshooting Charts ............................................................................................................... 7-11

Chapter 8 UHF Band Information ........................................................ 8-1

8.1 Model Charts ................................................................................................................................. 8-1

8.2 Specifications................................................................................................................................. 8-3

8.3 Theory of Operation....................................................................................................................... 8-4

8.3.1 General Information .......................................................................................................... 8-4

8.3.2 Power Distribution............................................................................................................. 8-4

8.3.3 Power up Sequence ......................................................................................................... 8-4

8.3.4 CPU / Control Section....................................................................................................... 8-5

8.3.5 VCO / Synthesizer Section ............................................................................................... 8-5

8.3.6 Transmitter Section........................................................................................................... 8-6

8.3.7 Receiver Section............................................................................................................... 8-7

8.3.8 Battery Section ................................................................................................................. 8-8

8.4 Block Diagrams.............................................................................................................................. 8-9

8.4.1 Complete .......................................................................................................................... 8-9

8.4.2 Controller ........................................................................................................................ 8-10

8.4.3 VCO ................................................................................................................................ 8-10

8.4.4 Transmitter...................................................................................................................... 8-11

8.4.5 Receiver.......................................................................................................................... 8-11

8.5 Troubleshooting Charts ............................................................................................................... 8-12

99R85452E01-O August 30, 2002

Page 6

iv Table of Contents

This Page Intentionally Left Blank

August 30, 2002 99R85452E01-O

Page 7

User Safety, Training, and General Information

Product Safety and RF Exposure Compliance

CAUTION: Before using this product, read the operating instructions for safe usage contained in

the Product Safety and RF Exposure booklet enclosed with your radio.

ATTENTION!

This radio is restricted to occupational use only to satisfy FCC RF energy exposure requirements. Before

using this product, read the RF energy awareness information and operating instructions in the Product

Safety and RF Exposure booklet enclosed with your radio (Motorola Publication part number 68P81095C98)

to ensure compliance with RF energy exposure limits.

For a list of Motorola-approved antennas, batteries, and other accessories, visit the following web site which

lists approved accessories: http://www.motorola.com/cgiss/index.shtml

.

Page 8

vi : Product Safety and RF Exposure Compliance

This Page Intentionally Left Blank

August 30, 2002 99R85452E01-O

Page 9

Chapter 1 Introduction

1.1 Scope of Manual

This manual is intended for use by service technicians familiar with similar types of equipment. It

contains service information required for the equipment described and is current as of the printing

date. Changes which occur after the printing date may be incorporated by a complete Manual

revision or alternatively as additions.

NOTE: Before operating or testing these units, please read the User Safety, Training and General

Information Section in the front of this manual.

1.2 Warranty and Service Support

Motorola offers long term support for its products. This support includes repair of the product during

the warranty period, and service/repair or spare parts support out of warranty.

Motorola de Colombia Service Center

Carrera 7 No. 71-52

Torre B, Piso 13

Oficina 1301

Bogota - Colombia

Phone: 571-376-6990

Motorola de Mexico Service Center

Bosques de Alisos #125

Col. Bosques de las Lomas

CP 05120 Mexico D.F.

Phone: 525-257-6700

1.2.1 Warranty Period and Return Instructions

Where the product is covered under warranty, a check of the product should be performed prior to

shipping the unit. This is to ensure that the product has been correctly programmed or has not been

subjected to damage outside the terms of the warranty.

Products should be shipped back in the original packaging, or correctly packaged to ensure no

damage occurs in transit.

1.2.2 After Warranty Period

After the Warranty period, Motorola continues to support its products in two ways.

1. Motorola’s authorized service centers offer a repair service to both end users and dealers at

competitive prices.

2. AAD supplies individual parts and modules that can be purchased by dealers who are

technically capable of performing fault analysis and repair.

Page 10

1-2

1.2.3 Piece Parts

Some replacement parts, spare parts, and/or product information can be ordered directly. If a

complete Motorola part number is assigned to the part, it is available from Motorola’s Accessories

and Aftermarket Division (AAD). If no part number is assigned, the part is not normally available from

Motorola. If the part number is appended with an asterisk, the part is serviceable by Motorola Depot

only. If a parts list is not included, this generally means that no user-serviceable parts are available

for that kit or assembly.

All orders for parts/information should include the complete Motorola identification number. All part

orders should be directed to your local AAD office. Please refer to your latest price pages.

To order parts in Latin America and the Caribbean:

7:00 a.m. to 7:00 p.m. (Central Standard Time)

Monday through Friday (Chicago, USA)

1-847-538-8023

Motorola Parts (Accessories and Aftermarket Division AAD):

Attention: Order Processing

1313 E. Algonquin Road

Schaumburg, IL 60196

Introduction

: Warranty and Service Support

1.2.4 Technical Support

https://businessonline.motorola.com

Select: "Contact Us"

1.2.5 Parts Identification

1-847-538-0021 (Voice)

1-847-538-8194 (Fax)

August 30, 2002 99R85452E01-O

Page 11

Introduction

: Radio Model Information 1-3

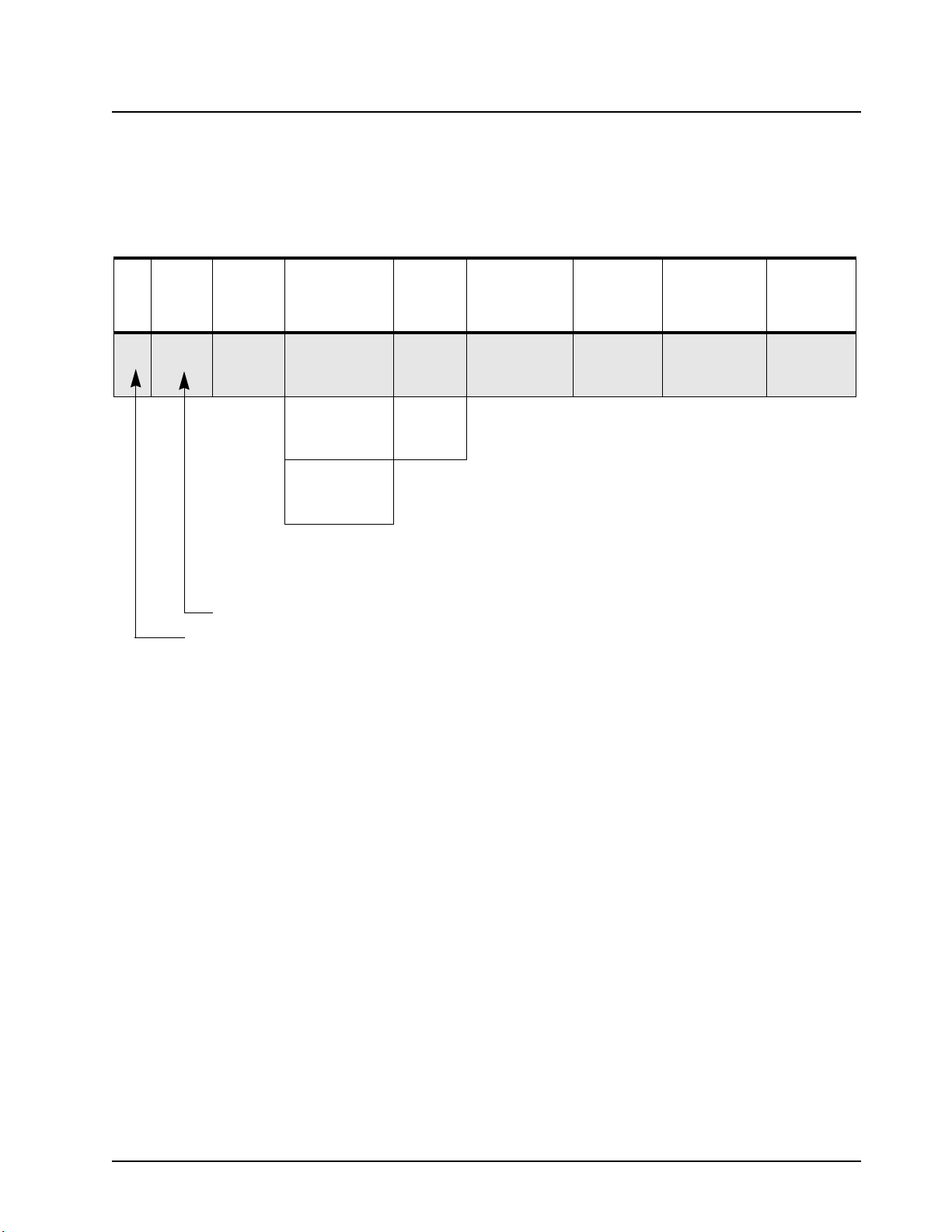

1.3 Radio Model Information

The model number and serial number are located on a label attached to the back of your radio. You

can determine the RF output power, frequency band, protocols, and physical packages. The

example below shows one portable radio model number and its specific characteristics.

Table 1-1. Radio Model Number (Example: LAH49KDH8AA9)

Type

of

Unit

LA H 49 K

Model

Series

H = Portable

Motorola Internal Use

Frequency

Band

(136-174

MHz)

(403-440

MHz)

(435-480

MHz)

Power

Level

D

5W

Q

R

C

4W

Physical

Packages

H

Full Keypad

with Display

Channel

Spacing

8

12.5/25KAAConventional

Protocol

Feature

Level

9

Full

Keypad

99R85452E01-O August 30, 2002

Page 12

1-4

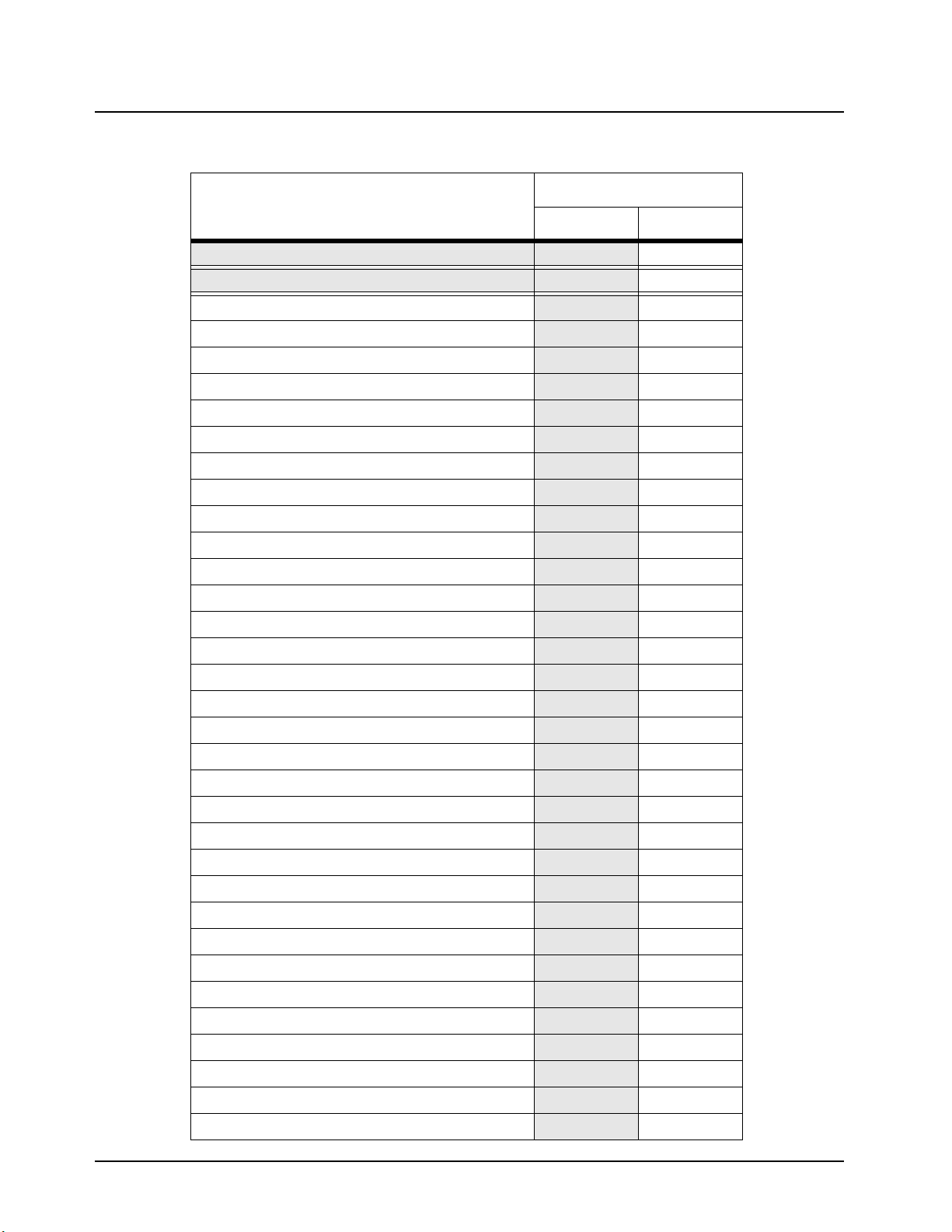

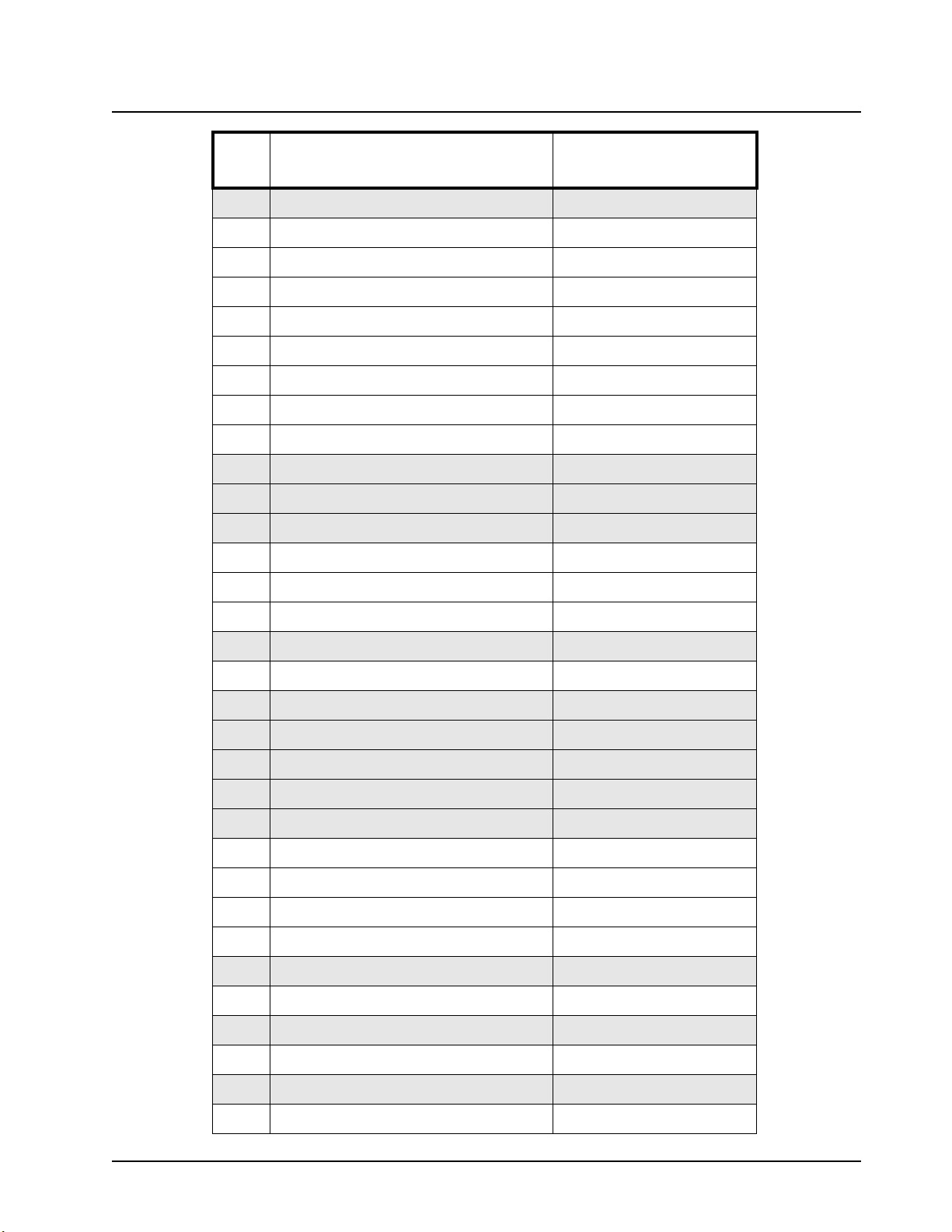

1.4 Radio Features

Feature

Introduction

PRO2150

CPS User

: Radio Features

Accessibility Yes

Normal Operation

Rx/Tx XX

Cloning

Factory Reset

VFO

Squelch Level

Scan List 1

Scan List 2

Scan List 3

Special PL 1,2,3

Norm/Inv DPL

TOT

Battery Saver

Battery Type

Alert Tone Volume

Prime Ch

Prime Ch Return Hang Time

XX

X

X

XX

XX

XX

XX

X

X

XX

XX

XX

XX

XX

X

Yes

PTT ID (OFF, PRE, POST, BOTH)

PTT ID Sidetone

PTT Short Sidetone

Tx Pretime

Backlight Status

PTT ID

Button Programmability

Access/Deaccess Code

Telephone No

PL/DPL Type

Scan Interval Timer

Scan Hang Timer

Channel On/Off

Rx Freq

Tx Freq

Rx PL/DPL

X

X

X

X

XX

X

X

XX

XX

X

X

X

X

X

X

X

August 30, 2002 99R85452E01-O

Page 13

Introduction

: Radio Features 1-5

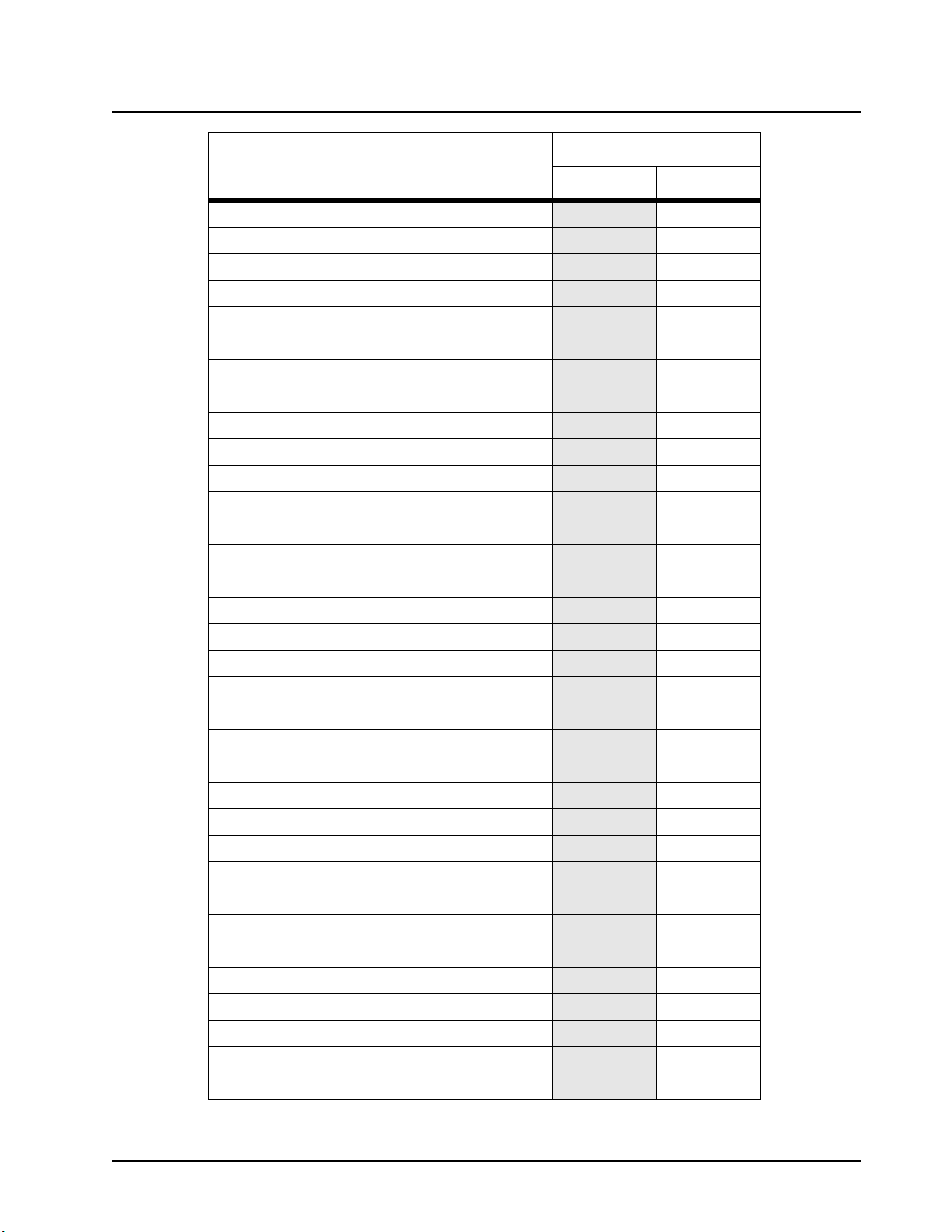

PRO2150

Feature

CPS User

Tx PL/DPL

TOC

Power Level

BCL

Ch Alias

Ch Spacing

PTT ID On/Off

PL Required for Selcall

Scan Type Select

Scan List Select

Copy Ch

Scan Lower Limit

Scan Upper Limit

Freq Step Size

Rx Freq

Tx Freq

Offset Freq

Repeater Offset

Rx PL/DPL

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Tx PL/DPL

TOC

Power Level

BCL

Ch Spacing

PTT ID On/Off

Radio Information

Radio Configuration

Conventional Personality

VFO Status

Scan List

Phone Information

Signalling

Programmable Button

Reverse Burst

X = Indicates available

Blank = Indicates unavailable

X

X

X

X

X

X

XX

XX

XX

X

XX

XX

XX

XX

X

99R85452E01-O August 30, 2002

Page 14

1-6

Introduction

: Radio Features

This Page Intentionally Left Blank

August 30, 2002 99R85452E01-O

Page 15

Chapter 2 Maintenance

2.1 Introduction

This chapter provides details about the following:

• Preventive Maintenance

• Safe Handling of CMOS and LDMOS Devices

• General Repair Procedures and Techniques

• Disassembling and Reassembling the Radio

2.2 Preventive Maintenance

The radio does not require a scheduled preventive maintenance program; however, periodic visual

inspection and cleaning is recommended.

2.2.1 Inspection

Check that the external surfaces of the radio are clean, and that all external controls and switches

are functional. It is not recommended to inspect the interior electronic circuitry.

2.2.2 Cleaning Procedures

The following procedures describe the recommended cleaning agents and the methods to be used

when cleaning the external and internal surfaces of the radio. External surfaces include the front

cover, housing assembly and battery case. These surfaces should be cleaned whenever a periodic

visual inspection reveals the presence of smudges, grease, and/or grime.

NOTE: Internal surfaces should be cleaned only when the radio is disassembled for service or repair.

The only recommended agent for cleaning external radio surfaces is a 0.5% solution of a mild

dishwashing detergent in water. The only factory recommended liquid for cleaning printed circuit

boards and their components is isopropyl alcohol (70% by volume).

CAUTION: The effects of certain chemicals and their vapors can have harmful results on certain

plastics. Avoid using aerosol sprays, tuner cleaners, and other chemicals.

2.2.2.1 Cleaning External Plastic Surfaces

Apply the 0.5% detergent-water solution sparingly with a stiff, non-metallic, short-bristled brush to

work all loose dirt away from the radio. Use a soft, absorbent, lintless cloth or tissue to remove the

solution and dry the radio. Make sure that no water remains entrapped near the connectors, cracks,

or crevices.

2.2.2.2 Cleaning Internal Circuit Boards and Components

Apply Isopropyl alcohol (70%) with a stiff, non-metallic, short-bristled brush to dislodge embedded or

caked materials located in hard-to-reach areas. The brush stroke should direct the dislodged

material out and away from the inside of the radio. Make sure that controls or tunable components

are not soaked with alcohol. Do not use high-pressure air to hasten the drying process since this

could cause the liquid to collect in unwanted places. After completing the cleaning process, use a

soft, absorbent, lintless cloth to dry the area. Do not brush or apply any isopropyl alcohol to the

frame, front cover, or back cover.

Page 16

2-2

Maintenance

NOTE: Always use a fresh supply of alcohol and a clean container to prevent contamination by

dissolved material (from previous usage).

: Safe Handling of CMOS and LDMOS Devices

2.3 Safe Handling of CMOS and LDMOS Devices

Complementary metal-oxide semiconductor (CMOS) devices are used in this family of radios, and

are susceptible to damage by electrostatic or high voltage charges. Damage can be latent, resulting

in failures occurring weeks or months later. Therefore, special precautions must be taken to prevent

device damage during disassembly, troubleshooting, and repair.

Handling precautions are mandatory for CMOS circuits and are especially important in low humidity

conditions. DO NOT attempt to disassemble the radio without first referring to the following

CAUTION statement.

CAUTION: This radio contains static-sensitive devices. Do not open the radio unless you are

properly grounded. Take the following precautions when working on this unit:

• Store and transport all CMOS devices in conductive material so that all exposed leads

are shorted together. Do not insert CMOS devices into conventional plastic “snow”

trays used for storage and transportation of other semiconductor devices.

• Ground the working surface of the service bench to protect the CMOS device. We

recommend using the Motorola Static Protection Assembly (part number

0180386A82), which includes a wrist strap, two ground cords, a table mat, and a floor

mat.

• Wear a conductive wrist strap in series with a 100k resistor to ground. (Replacement

wrist straps that connect to the bench top covering are Motorola part number RSX-

4015.)

• Do not wear nylon clothing while handling CMOS devices.

• Do not insert or remove CMOS devices with power applied. Check all power supplies

used for testing CMOS devices to be certain that there are no voltage transients

present.

• When straightening CMOS pins, provide ground straps for the apparatus used.

• When soldering, use a grounded soldering iron.

• If at all possible, handle CMOS devices by the package and not by the leads. Prior to

touching the unit, touch an electrical ground to remove any static charge that you may

have accumulated. The package and substrate may be electrically common. If so, the

reaction of a discharge to the case would cause the same damage as touching the

leads.

2.4 Repair Procedures and Techniques — General

2.4.1 Parts Replacement and Substitution

When damaged parts are replaced, identical parts should be used. If the identical replacement part

is not locally available, check the parts list for the proper Motorola part number and order the part

from the nearest Motorola Communications parts center listed in the Piece Parts section of this

manual.

2.4.2 Rigid Circuit Boards

This radio uses bonded, multi-layer, printed circuit boards. Since the inner layers are not accessible,

some special considerations are required when soldering and unsoldering components. The printedthrough holes may interconnect multiple layers of the printed circuit. Therefore, exercise care to

avoid pulling the plated circuit out of the hole.

August 30, 2002 99R85452E01-O

Page 17

Maintenance

: Repair Procedures and Techniques — General 2-3

When soldering near the 20-pin and 40-pin connectors:

• Avoid accidentally getting solder in the connector.

• Be careful not to form solder bridges between the connector pins.

• Examine your work closely for shorts due to solder bridges.

2.4.3 Flexible Circuits

The flexible circuits are made from a different material than the rigid boards, and require different

soldering techniques. Excessive prolonged heat on a flexible circuit can damage the material.

Therefore, avoid excessive heat and excessive bending.

For parts replacement, use the ST-1087 Temperature-Controlled Solder Station with a 600-700

degree F tip, and use small diameter solder such as ST-633. The smaller size solder will melt faster

and require less heat to be applied to the circuit.

To replace a component on a flexible circuit:

1. Grasp with seizers (hemostats) the edge of the flexible circuit near the part to be removed.

2. Pull gently.

3. Apply the tip of the soldering iron to the component connections while pulling with the seizers.

NOTE: Do not attempt to puddle-out components. Prolonged application of heat may damage the

flexible circuit.

2.4.4 Chip Components

Use either the RLN-4062 Hot-Air Repair Station or the Motorola 0180381B45 Repair Station for chip

component replacement. When using the 0180381B45 Repair Station, select the TJ-65 minithermojet hand piece. On either unit, adjust the temperature control to 700 degrees F. (370 degrees

C), and adjust the airflow to a minimum setting. Airflow can vary due to component density.

• To remove a chip component, select a hot-air hand piece and position the nozzle of the hand

piece approximately 1/8” above the component to be removed. Begin applying hot air. Once the

solder reflows, remove the component using a pair of tweezers. Using solder wick and a

soldering iron or a power desoldering station, remove the excess solder from the pads.

• To replace a chip component using a soldering iron, select the appropriate micro-tipped

soldering iron and apply fresh solder to one of the solder pads. Using a pair of tweezers,

position the new chip component in place while heating the fresh solder. Once solder wicks

onto the new component, remove the heat from the solder. Heat the remaining pad with the

soldering iron and apply solder until it wicks to the component. If necessary, touch up the first

side. All solder joints should be smooth and shiny.

• To replace a chip component using hot air, select the hot-air hand piece and reflow the solder

on the solder pads to smooth it. Apply a drop of solder paste flux to each pad. using a pair of

tweezers, position the new component in place. Position the hot-air hand piece approximately

1/8” above the component and begin applying heat. Once the solder wicks to the component,

remove the heat and inspect the repair. All joints should be smooth and shiny.

99R85452E01-O August 30, 2002

Page 18

2-4

2.4.5 Shields

Removing and replacing shields will be done with the R-1070 station with the temperature control set

to approximately 415°F (215°C); 445°F (230°C) max.

• To remove the shield, place the circuit board in the R-1070’s holder. Select the proper heat

focus head and attach it to the heater chimney. Add solder paste flux around the base of the

shield. Position the shield under the heat-focus head. Lower the vacuum tip and attach it to the

shield by turning on the vacuum pump. Lower the focus head until it is approximately 1/8”

(0.3cm) above the shield. Turn on the heater and wait until the shield lifts off the circuit board.

Once the shield is off, turn off the heat, grab the part with a pair of tweezers, and turn off the

vacuum pump. Remove the circuit board from the R-1070’s circuit board holder.

• To replace the shield, add solder to the shield if necessary, using a micro-tipped soldering iron.

Next, rub the soldering iron tip along the edge of the shield to smooth out any excess solder.

Use solder wick and a soldering iron to remove excess solder from the solder pads on the

circuit board. Place the circuit board back in the R1070’s circuit board holder. Place the shield

on the circuit board using a pair of tweezers. Position the heat-focus head over the shield and

lower it to approximately 1/8” above the shield. Turn on the heater and wait for the solder to

reflow.

Once complete, turn off the heat, raise the heat-focus head and wait approximately one minute

for the part to cool. Remove the circuit board and inspect the repair. No cleaning should be

necessary.

Maintenance

: Disassembling and Reassembling the Radio — General

2.5 Disassembling and Reassembling the Radio — General

Since these radios may be disassembled and reassembled with the use of only four (board to

casting) screws, it is important to pay particular attention to the snaps and tabs, and how parts align

with each other.

The following tools are required for disassembling the radio:

• Phillips screwdriver

• 4mm socket wrench

If a unit requires more complete testing or service than is customarily performed at the basic level,

send this unit to a Motorola Authorized Service Center.

August 30, 2002 99R85452E01-O

Page 19

Maintenance

: Radio Disassembly — Detailed 2-5

2.6 Radio Disassembly — Detailed

2.6.1 Front Cover from Chassis Disassembly

1. Turn off the radio.

2. Remove the battery:

a. Slide the battery clasp away from the radio (

See Figure 2-1.

).

Figure 2-1.

b. Slide battery down and away from radio.

3. Remove the antenna.

4. Pull the On/Off Volume knob off of its shaft.

5. Remove the two screws at the back of the rear chassis (

See Figure 2-2.

Insert screwdriver here

to remove chassis.

).

Figure 2-2.

6. Insert a small flat-head screwdriver at the bottom of the radio, between the chassis and

housing (location marked in

the housing or the O-ring underneath.

99R85452E01-O August 30, 2002

Figure 2-2

), and lift the chassis gently. Be careful not to damage

Page 20

2-6

Maintenance

: Radio Disassembly — Detailed

7. Lift the rear chassis away from the front cover (

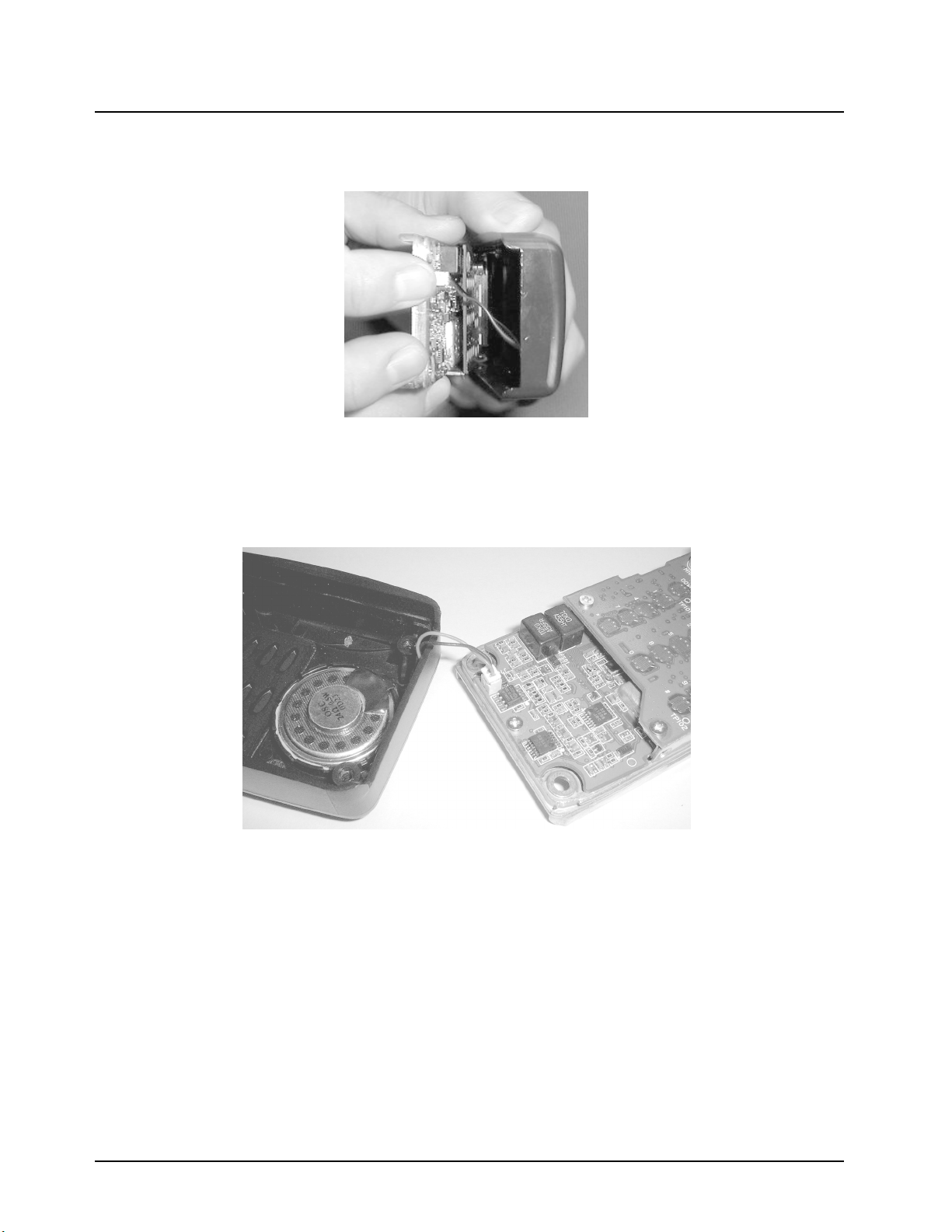

See Figure 2-3.

). Be careful not to damage the

speaker wire underneath.

Figure 2-3.

8. Slide the rear chassis downwards, and away from the front cover.

9. Remove the speaker connector, which connects between RF Board and the internal speaker

on the front cover (

See Figure 2-4.

).

Figure 2-4.

August 30, 2002 99R85452E01-O

Page 21

Maintenance

: Radio Disassembly — Detailed 2-7

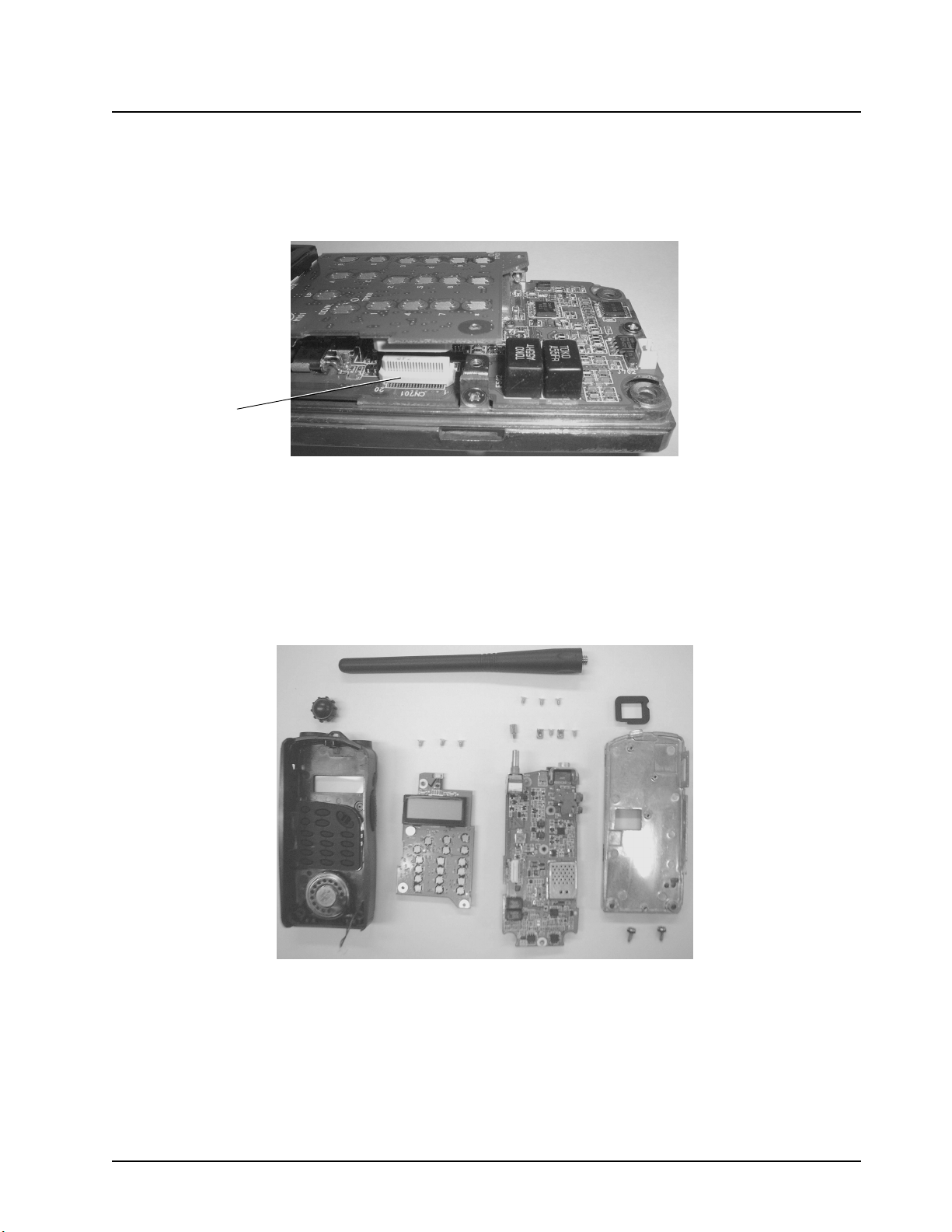

2.6.2 Control Board Disassembly

1. Remove the screws which hold the control board to the RF board.

2. Remove the control board which is connected to the RF board through a board-to-board

connector (

Board-to-board

connector

See Figure 2-5.

2.6.3 RF Board Disassembly

).

Figure 2-5.

1. Remove the screws and the stud which hold the RF board to the rear diecast with the Phillips

head screwdriver and socket wrench respectively.

2. Gently remove the RF board from rear diecast. The completely disassembled radio is shown

Figure 2-6

in

.

Figure 2-6.

NOTE: The Control and RF boards are mounted with cross recess screws meeting the Phillips Cross

Slot number 1 standard. Using a Phillips 0 will damage the screw recesses as will a poorly

fitting Phillips 1 screwdriver. One example of a correct fitting screwdriver is manufactured by

PB Baumann (http://www.pbtools.ch/index_e.html) and is available from many electronic tool

dealers. The PB Baumann item number is 121/1-70. Other high quality manufacturer's

pruducts meeting the Phillips 1 standard are also acceptable.

99R85452E01-O August 30, 2002

Page 22

2-8

2.7 Radio Reassembly — Detailed

2.7.1 RF Board Reassembly

1. Place the RF board on the rear diecast.

2. Tighten the screws and the stud.

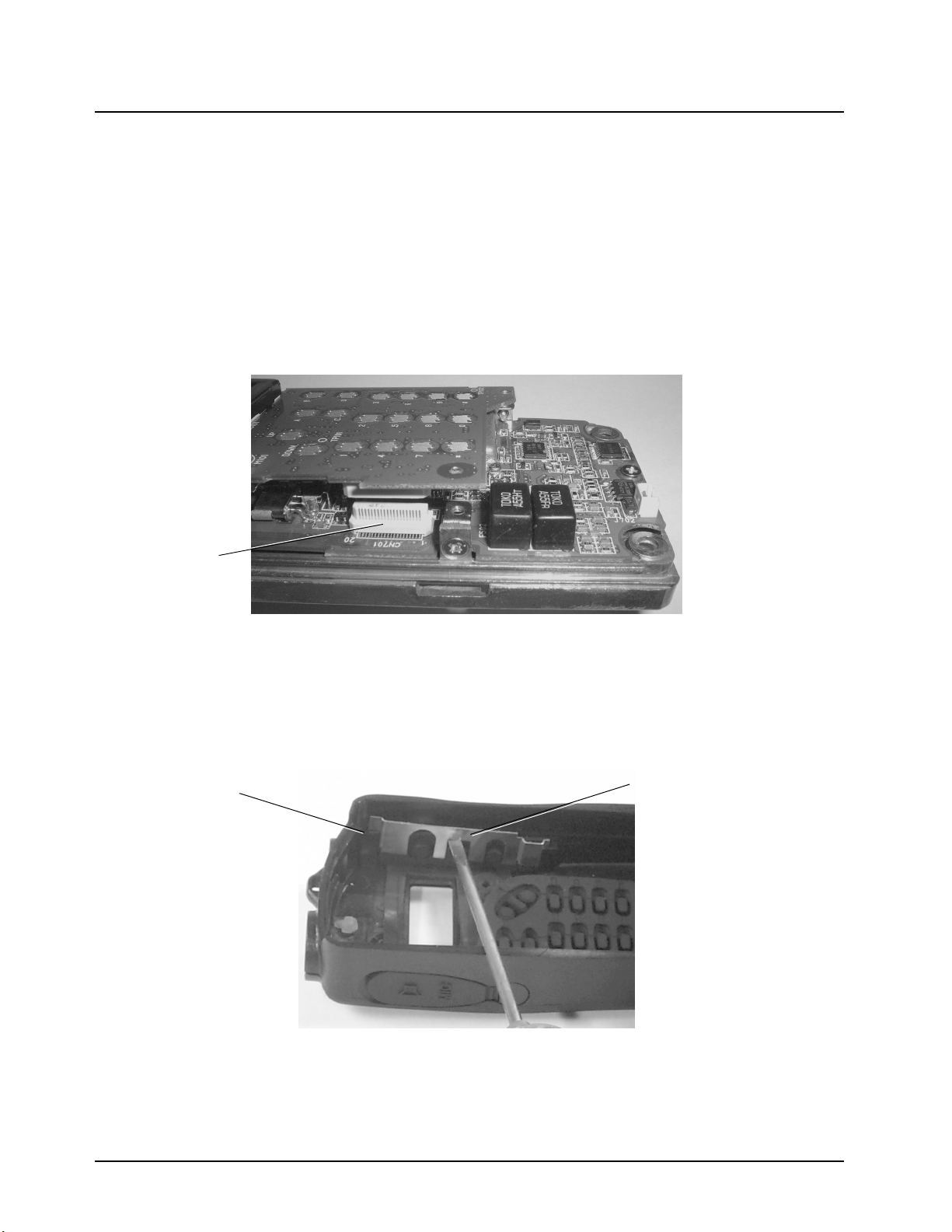

2.7.2 Control Board Reassembly

1. Place the control board on the RF board.

2. Connect the control board to the RF board by pressing it firmly downwards at the board-toboard connector (

Board-to-board

Connector

See Figure 2-7.

).

Maintenance

: Radio Reassembly — Detailed

Figure 2-7.

3. Tighten the screws using a screwdriver to hold the control board in place.

2.7.3 Chassis and Front Cover Reassembly

1. Remove the metal retainer with a small flat head screwdriver (

Housing tab

Figure 2-8.

See Figure 2-11.

Retainer

).

August 30, 2002 99R85452E01-O

Page 23

Maintenance

: Radio Reassembly — Detailed 2-9

2. Remove the rubber button insert behind the retainer (

Rubber button

Figure 2-9.

3. Push left hand side PTT hook until it releases (

See Figure 2-10.

PTT hooks

See Figure 2-9.

).

).

Figure 2-10.

4. Push right hand side PTT hook until PTT button is completely released.

5. Reinstall the rubber insert and metal retainer.

6. Connect the RF board to the internal speaker on the front cover with the speaker connector

(

See Figure 2-11.

).

Figure 2-11.

99R85452E01-O August 30, 2002

Page 24

2-10

Maintenance

: Radio Reassembly — Detailed

7. Place the front cover over the tabs on the rear diecast.

8. Insert the On/Off Volume shaft into the front cover opening.

9. Lower the front cover until the bottom edges snap firmly into place on the rear diecast (

Figure 2-12.

).

Figure 2-12.

10. Tighten the two (2) screws at the bottom of rear diecast using a screwdriver (

2-13.

).

See Figure

See

Figure 2-13.

11. Reinsert the PTT button (

Press to insert

See Figure 2-15.

).

Large hook side

Figure 2-14.

August 30, 2002 99R85452E01-O

Page 25

Maintenance

: Radio Reassembly — Detailed 2-11

12. Attach the battery.

13. Attach the On/Off Volume knob and the antenna.

Figure 2-15.

99R85452E01-O August 30, 2002

Page 26

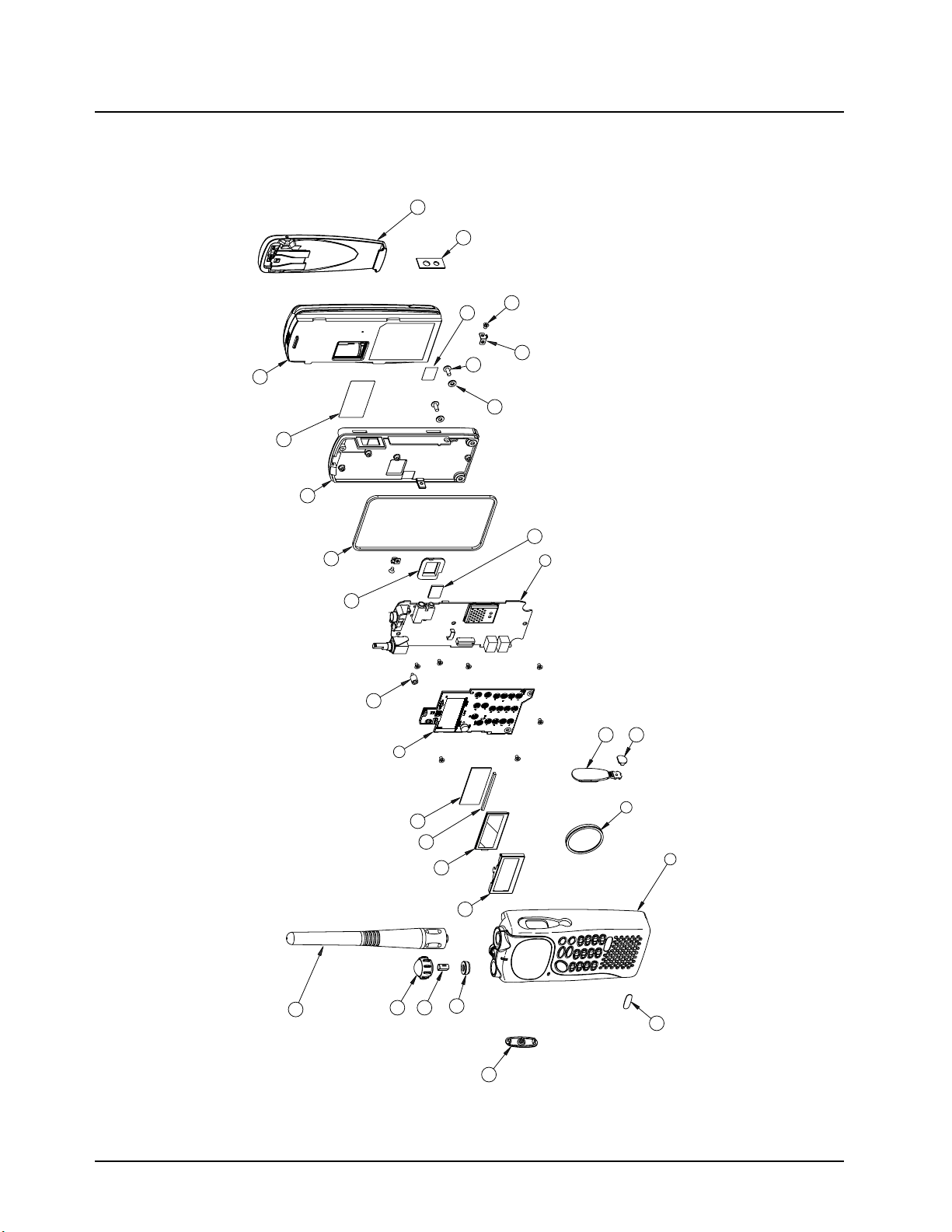

2-12

2.8 Mechanical View and Parts List

2.8.1 Exploded View and Parts List

14

Maintenance

2g

2f

8c

: Mechanical View and Parts List

10

2d

8b

15

12

11

2a

5

2e

2c

2b

6

4a

4b

9

7d

7c

7b

7a

17

3a

13

3b

16

1

8a

Figure 2-16.

August 30, 2002 99R85452E01-O

Page 27

Maintenance

: Mechanical View and Parts List 2-13

Item

1 DS1M001110 Front Cover Kit

2 DS1M001120 Chassis Hardware Kit

2a Rod (M2)

2b Heatsink Tape

2c DSM4193013 Gasket (Screw M2.6)

2d DSM1B26051 Screw M2.6

2e PCB Bracket

2f Screw M2 Cfims

2g External Tape

3 DS1M001130 Knob Assembly

3a Knob

3b Spring (D4.75)

4 DS1M001140 External Cover Kit

4a External Cover

Part

Number

Description

4b External Cover Cap

5 Model Dependent Controller Board Assembly

6 Model Dependent RF Board Assembly

7 DS1M001170 LCD Kit

7a LCD Bracket

7b LCD

7c Interconnector

7d Reflector

8 DSM4193042 PRO2150 Nameplate

8a Label Nameplate

8b Label Serial

8c Label Tuning

9 DS1M001190 Speaker Assembly

10 PMNN4046 Battery

11 DSM2192004 Contact Gasket

12 DSM2192005 Main Gasket

13 DSM2192006 Volum e Gasket

14 HLN9844_ Beltclip

99R85452E01-O August 30, 2002

Page 28

2-14

Maintenance

: Service Aids

Item

15 DSM5190001 Back Housing

16 DSM6189003 PTT Button

17 Frequency dependent. Please see

Part

Number

“6.1

Description

Antenna

Antennas” on page 6-1

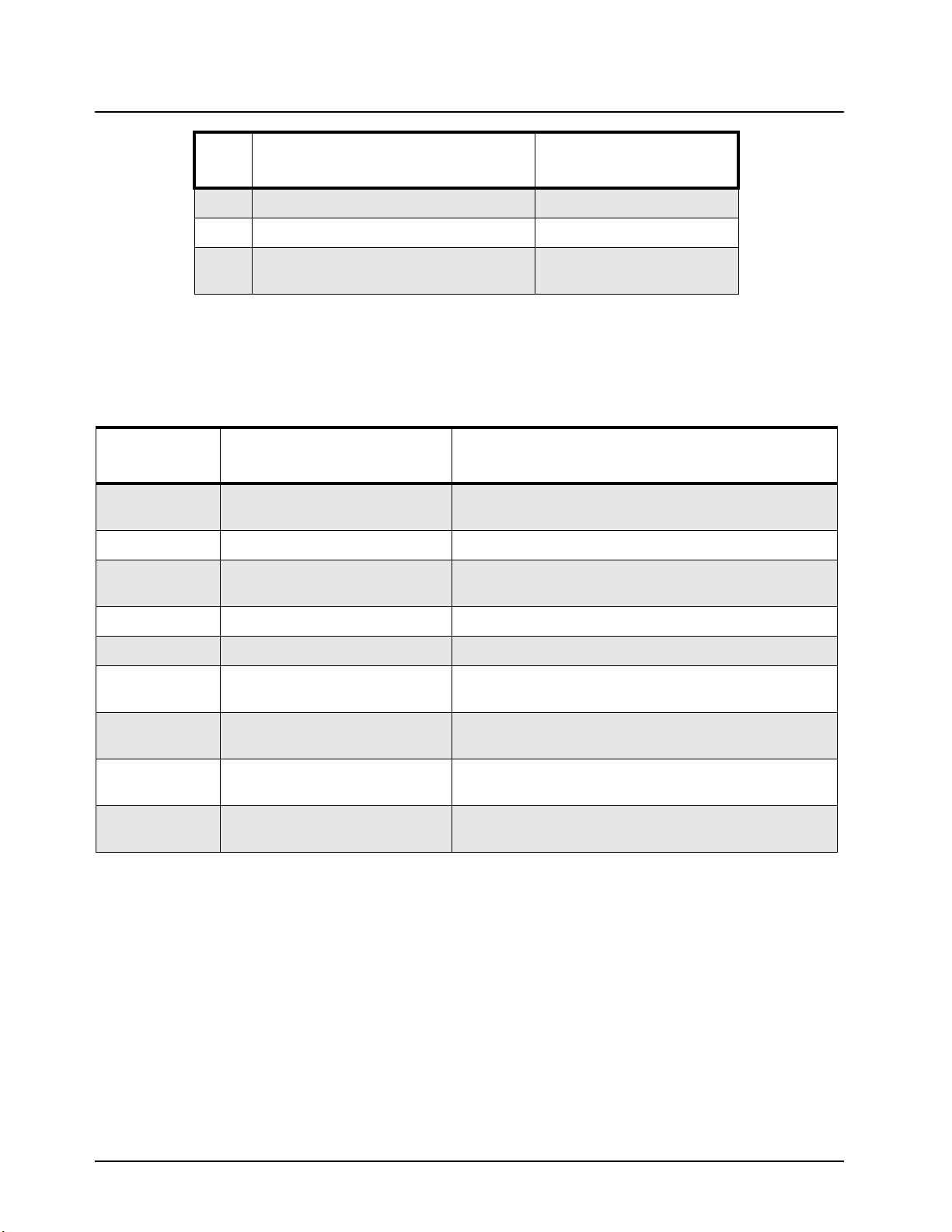

2.9 Service Aids

Table 2-1

these items are available from Motorola, most are standard shop equipment items, and any

equivalent item capable of the same performance may be substituted for the item listed.

Motorola Part

No.

H5197

HKVN4002_

DSK001C706 Programming Cable (2.5mm) Connects radio and IF Test Box to Computer.

AAPMKN4003_ Cloning Cable (2.5mm) To clone programmable information from one radio to

lists service aids recommended for working on the PRO2150 Portable Radio. While all

Table 2-1.

Description Application

Customer Programming and

Tuning Software (CD)

Program customer options, channel data, and tuner

hardware parameters, front end, power, etc.

another radio.

DSK001C704 Test Cable Connects radio to IF Test Box.

DSK001C714 Interconnect Service Cable Connects RF board and CPU board.

DSK001C702 IF Test Box Enables connection to the audio/accessory jack. Allows

switching for radio testing.

DSK001C705 Battery Eliminator Interconnects radio to power supply (red-and-black power

cable included).

DSK001C719 Antenna Ground Plate To improve the grounding while tuning and doing conducted

measurement.

HLN8262_ BNC Adaptor Adapts radio’s antenna port to BNC cabling of test

equipment.

August 30, 2002 99R85452E01-O

Page 29

Maintenance

: Test Equipment 2-15

2.10 Test Equipment

Table 2-2

lists test equipment required to service the PRO2150 Portable Radio and other two-way

radios.

Table 2-2.

Motorola Part

No.

*R1049 Digital Multimeter Two meters recommended for

*S1100 Audio Oscillator 67 to 200Hz tones Used with service monitor to

*S1053,

*SKN6009,

*SKN6001

R1053 Dual-trace

*S1350, *ST1215

(VHF)

*ST1223 (UHF)

*T1013

S1339 RF Millivolt Meter 100 µV to 3 VRF, 10 kHz

Description Characteristics Application

AC/DC voltage and current

measurements

inject PL tones

AC Voltmeter, Power

Cable for meter, Test

leads for meter

Oscilloscope

Wattmeter,

Plug-in Elements

(VHF & UHF), RF

Dummy Load

1 mV to 300 V,

10 Mega Ohm input

impedance

20 MHz bandwidth,

5 mV/cm - 20 V/cm

50-Ohm, ±5% accuracy

10 W, max. 0-1000 MHz,

300 W

to 1.2 GHz

Audio voltage measurements

Waveform measurements

Transmitter power output

measurements

RF level measurements

*R1013 SINAD Meter Receiver sensitivity

measurements

S1347 or

S1348 (prog)

*Frequency/deviation meter and signal generator for wide-range troubleshooting and alignment

DC Power Supply 0-20 Vdc, 0-5 Amps Bench supply for 7.5Vdc

99R85452E01-O August 30, 2002

Page 30

2-16

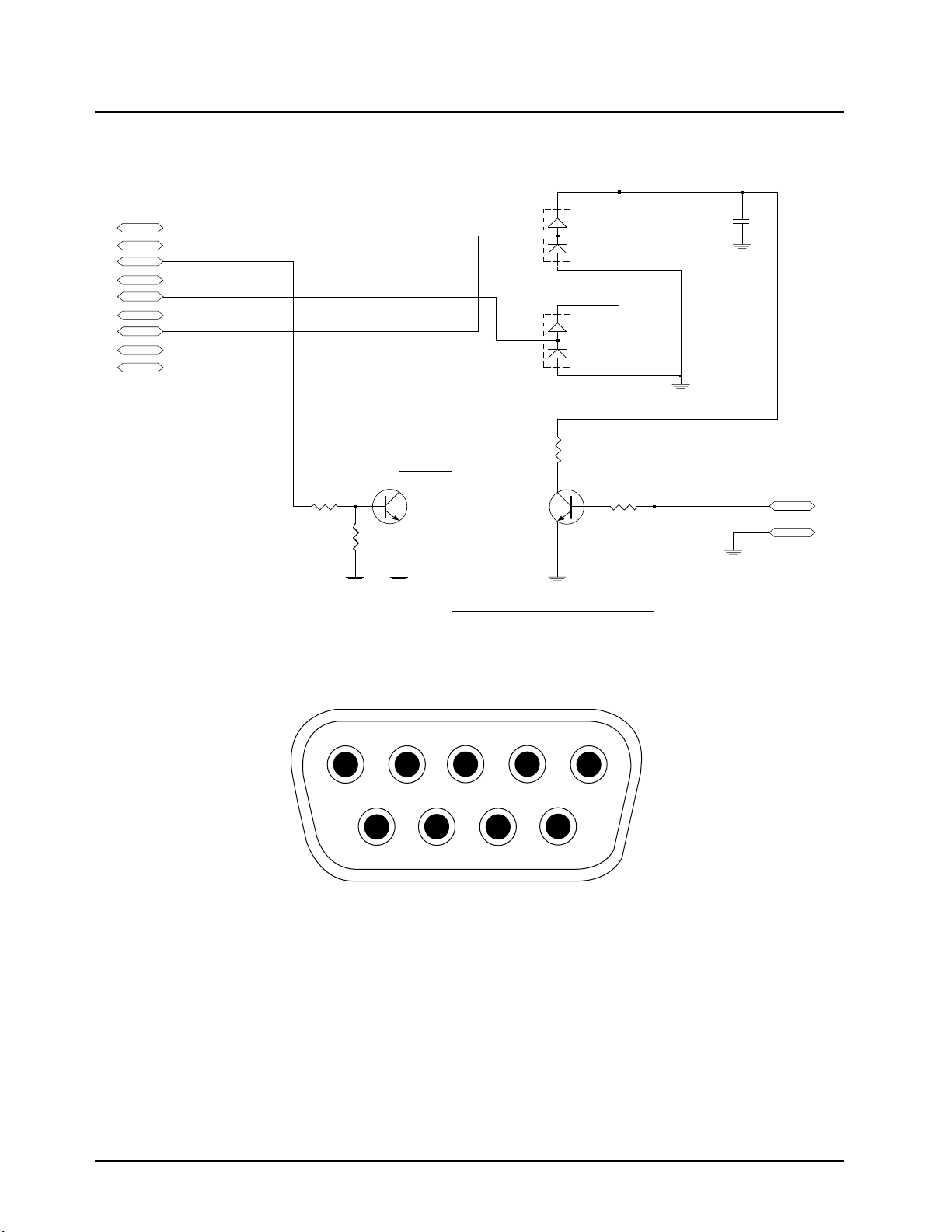

2.11 Programming Cable (DSK001C706)

To: PC

RS232C 9PD-SUB

1: DCD

2: RXD

3: TXD

4: DTR

5: GND

6: DSR

7: RTS

8: CTS

9: RI

Maintenance

D101

1SS362

D102

1SS362

R103

10k

: Programming Cable (DSK001C706)

C101

0.1

R101

10k

R102

10k

Q101

UMW1N

Q102

UMW1N

Figure 2-17.

543 2 1

987 6

Figure 2-18.

R104

10k

PROG

GND

August 30, 2002 99R85452E01-O

Page 31

Maintenance

: IF Test Box (DSK001C702) 2-17

2.12 IF Test Box (DSK001C702)

D-Sub 9P

Non

9

Non

8

SP +

7

SP101

INT_SPEAKER

P101

SPK OUT

J101

Mic/Prog Input

P102

Mic Input

S101

Out on/off

S103

INT_PTT

R101

24 ohm

S102

Spk/Load

T101

Balan

C101

1/25V

SP -

6

GND

5

Non

4

Mic

3

PRG

2

Non

1

R102

10k

Figure 2-19.

99R85452E01-O August 30, 2002

Page 32

2-18

Maintenance

: IF Test Box (DSK001C702)

This Page Intentionally Left Blank

August 30, 2002 99R85452E01-O

Page 33

Chapter 3 Radio Tuning

3.1 Introduction

This chapter provides an overview of the software and hardware tuning material available for the

PRO2150 Portable Radio.

The PRO2150 Portable Radio’s Customer Programming and Tuner Software are designed for use in

a Windows 95/98/NT environment. This software covers all the functions of the traditional Radio

Service Software (RSS) package.

An Installation instruction manual is contained within each kit.

Description Kit Number

Customer Programming and Tuning Software (CD)

3.2 Software Tuning Setup

A Windows 95/98/NT PC (personal computer) and Tuner are required to tune parameters such as

power, sensitivity, squelch and RSSI. To perform the tuning procedures, the radio must be connected

to the PC and IF Test Set as shown in the figure below.

Refer to online help files for specific tuning procedures. See

Ground Contact Finger

(Refer to Figure below

on how to attach to radio)

Antenna Port

Acc

Jack

Test Cable

(DSK001C704)

Radio

N Type

TEST EQUIPMENT

BNC

Input Output

BNC

IF TEST SET

DSK001C702

9 Pin

Connector

BNC

Mic

BNC

Spk

H5197

HKVN4002_

Figure 3-2

(DSK001C706)

, how to attach the radio.

Comm

PortProgramming Cable

Figure 3-1.

Page 34

3-2

3.3 Affixing Antenna Ground Plate

(Strictly for Radio’s Testing and Tuning Purpose Only)

1. Insert the antenna ground plate (DSK001C719) through the antenna adaptor (HLN8262).

Ground Plate

Figure 3-2.

2. Screw the antenna adaptor into the radio’s antenna jack as shown in

NOTE: Make sure the antenna ground plate is placed properly before the battery eliminator is

inserted to the radio. This is to ensure that the radio has a better grounding.

Radio Tuning

Antenna Adaptor

: Affixing Antenna Ground Plate

Figure 3-3

.

Ground Plate

Antenna Adaptor

Figure 3-3.

August 30, 2002 99R85452E01-O

Page 35

Radio Tuning

: Hardware Tuning Setup and Procedure 3-3

3.4 Hardware Tuning Setup and Procedure

There is a silver seal on the bottom left of the radio chassis. Remove the seal to expose the two

potentiometers for audio and sub-audio (CTCSS) modulation adjustment. RV601, which is slightly

higher, is the trimmer potentiometer for audio modulation tuning. The lower trimmer potentiometer

(RV602) is meant for sub-audio modulation tuning.

RV601

RV602

Figure 3-4.

3.4.1 Audio Modulation Tuning

1. Set the radio to transmit at the appropriate tuning frequency (

3-1

) with low power. Set Channel Spacing to "CS-25.0" for 25kHz (see “Radio Programming”

section).

2. On the test equipment, set it to receive at the appropriate tuning frequency (

Frequency” on page 3-4

Audio bandwidth: 0.25Hz to 15,000Hz.

De-emphasis: OFF

3. Inject a 60mV 1kHz tone to the radio through the external mic connector.

4. Key up the radio.

5. Using a ceramic tuning tool, adjust RV601 to tune the audio modulation deviation to settle

between 4.3kHz to 4.5kHz.

See “Tuning Frequency” in Ta bl e

See “Tuning

) and with the following configurations:

99R85452E01-O August 30, 2002

Page 36

3-4

3.4.2 Sub-Audio Modulation Tuning

1. Set the radio to transmit at the appropriate tuning frequency (See “Tuning Frequency” on

table 3-1) with low power and TX PL frequency of 100.0Hz. Set Channel Spacing to "CS-

25.0" for 25kHz (see “Radio Programming” section).

2. On the test equipment, set it to receive at the appropriate tuning frequency (see “PRO2150

Portable Radio Programming” section) and with the following configurations:

Audio bandwidth: 0.25Hz to 3,000Hz.

De-emphasis: OFF

3. Do NOT inject any tone to the radio.

4. Key up the radio.

5. Using a ceramic tuning tool, adjust RV602 to tune the sub-audio modulation deviation to

settle between 0.65kHz to 0.75kHz.

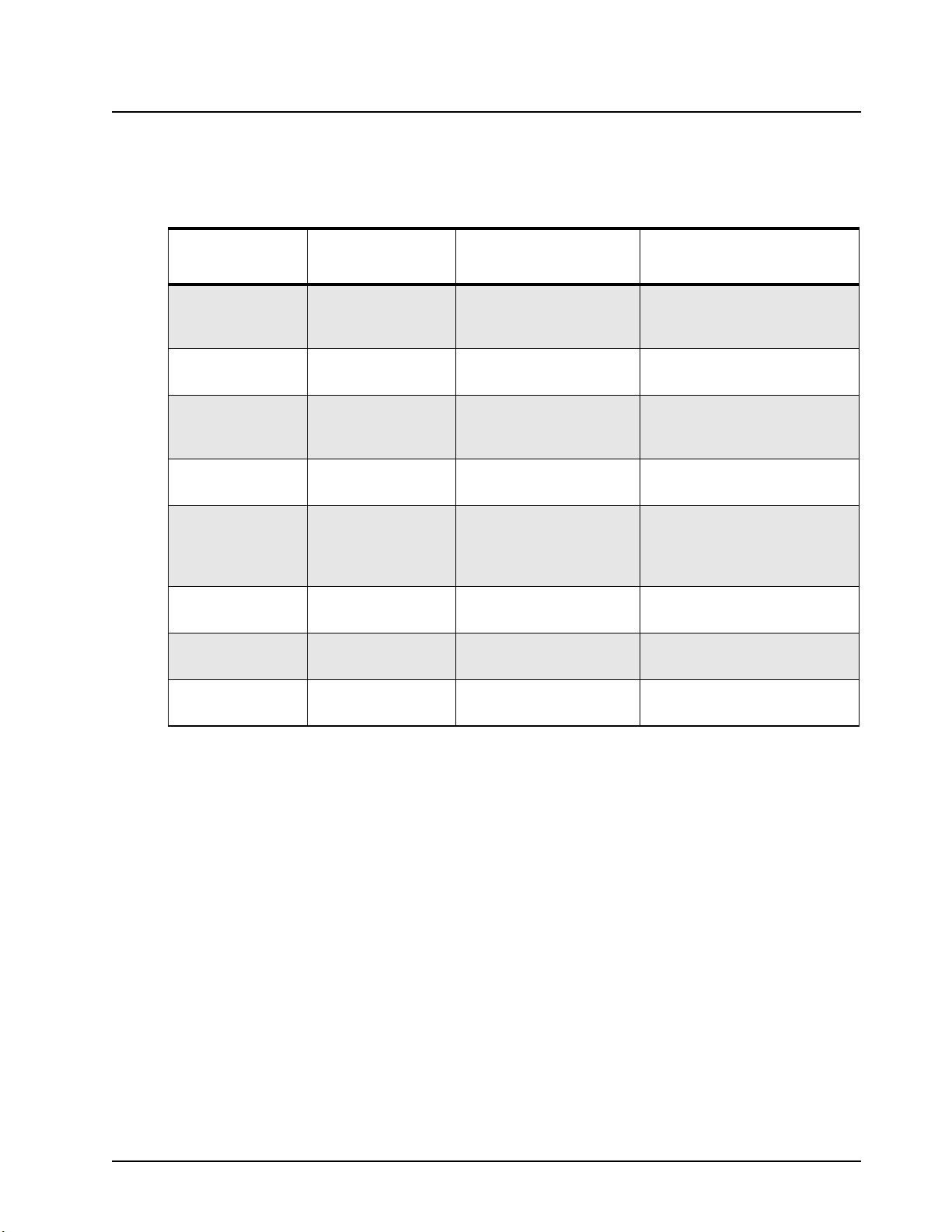

3.4.3 Tuning Frequency

Band Frequency (MHz)

VHF 136-174 MHz 155.025

Table 3-1.

Radio Tuning

: Hardware Tuning Setup and Procedure

UHF 403-440 MHz 421.5

UHF 435-480 MHz 457.5

August 30, 2002 99R85452E01-O

Page 37

Chapter 4 Radio Programming

4.1 Introduction

The PRO2150 Portable Radio can be programmed by using the Customer Programming Software

(CPS).

4.2 Programming Your Radio

4.2.1 Overview of the Programming Process

To prepare properly programmed radios for your customers, you should:

1. Program one radio with all the necessary parameters, as required by your customers.

2. Clone these parameters over to all your customer’s radios.

4.2.2 Cloning Radio Parameters to User Radios

Cloning duplicates the contents of Radio 1 (master radio) into Radio 2 (slave radio). However, tuning

and alignment information are not affected by cloning.

4.2.3 Parameters Which are Cloned

• Radio Wide parameters

• Channel settings

• VFO settings

4.2.4 Parameters Which are Not Cloned

• All hardware tuning and alignment parameters

• Unit Serial Number

4.2.5 To Clone a Radio

Cloning duplicates the contents of your radio (master radio) into your customer’s radio (slave radio).

Tuning and alignment information are not affected by cloning.

1. Turn off both the master and slave radios (if any of them are turned on).

2. Connect both radios with the cloning cable through the Programming Port (lower port of the

Accessory Connector).

3. Turn on the slave radio.

4. Press and hold the A button, and turn on the master radio.

5. The master radio displays CLONE if cloning can proceed, otherwise an error message is

shown.

6. The slave radio displays PROG while it is being programmed.

7. When cloning is completed, the master radio displays END, and the slave radio resets

automatically.

8. Disconnect radios from the cloning cable. They are now ready for operation.

Page 38

4-2

4.2.6 Error Conditions

An error may occur when cloning a radio. When this happens, an error message is displayed. The

following is a list of causes and the possible solutions for each error message.

Radio Programming

: CPS Programming

Error

Message

TIME OUT Data communications time-out. Please ensure that the slave radio is

switched on, and the cloning cable is properly connected.

BCC ERR Data communications checksum error.

TYPE ERR Mismatch in model numbers. Please ensure that the master and slave radios

are of the same model number.

CMD ERR Data communications command error.

4.3 CPS Programming

The CPS is designed for use in the Windows 95/98/NT environment.

An Installation instruction manual is contained within each CPS kit.

Description Kit Number

PRO2150 Customer Programming and Tuning Software (CD)

Refer to online help files for the CPS Programming procedures.

Description

H5197

HKVN4002_

Radio

Programming Cable (2.5mm)

DSK001C706

Comm

Port

Figure 4-1.

August 30, 2002 99R85452E01-O

Page 39

Radio Programming

: Programming 4-3

4.4 Programming

4.4.1 PL Frequencies and Codes

PL Freq (Hz)

67 001 XZ 136.5 022 4Z

69.3

71.9

74.4

77

79.7

82.5

85.4

88.5

91.5

94.8

97.4

100

103.5

Motorola

Code

002 WZ 141.3 023 4A

003 XA 146.2 024 4B

004 WA 151.4 025 5Z

005 XB 156.7 026 5A

006 WB 162.2 027 5B

007 YZ 167.9 028 6Z

008 YA 173.8 029 6A

009 YB 179.9 030 6B

010 ZZ 186.2 031 7Z

011 ZA 192.8 032 7A

012 ZB 203.5 033 M1

013 1Z 206.5 034 8Z

014 1A 210.7 035 M2

Equiv.

PL Code

PL Freq (Hz)

Motorola

Code

Equiv.

PL Code

107.2

110. 9

114. 8

118. 8

123

127.3

131.8

015 1B 218.1 036 M3

016 2Z 225.7 037 M4

017 2A 229.1 038 9Z

018 2B 233.6 039 M5

019 3Z 241.8 040 M6

020 3A 250.3 041 M7

021 3B 254.1 042 0Z

PL1 PL1

PL2 PL2

PL3 PL3

NOTE: PL1, PL2, PL3 are the User Defined PL Frequencies.

99R85452E01-O August 30, 2002

Page 40

4-4

4.4.2 DPL Codes

Radio Programming

: Programming

DPL

Code

23 043 152 065 343 087 606 109

25

26

31

32

43

47

51

54

65

71

72

73

74

Motorola

Code

044 155 066 346 088 612 110

045 156 067 351 089 624 111

046 162 068 364 090 627 112

047 165 069 365 091 631 113

048 172 070 371 092 632 114

049 174 071 411 093 645* 115

050 205 072 412 094 654 116

051 223 073 413 095 662 117

052 226 074 423 096 664 118

053 243 075 431 097 703 119

054 244 076 432 098 712 120

055 245 077 445 099 723 121

056 251 078 464 100 731 122

DPL

Code

Motorola

Code

DPL

Code

Motorola

Code

DPL

Code

Motorola

Code

114

115

116

125

131

132 062 311 084 532 106

134 063 315 085 546 107

143 064 331 086 565 108

057 261 079 465 101 732 123

058 263 080 466 102 734 124

059 265 081 503 103 743 125

060 271 082 506 104 754 126

061 306 083 516 105

NOTE: The codes marked with an asterisk are not part of the 83 standard EIA/TIA-603 codes.

4.4.3 Examples

4.4.3.1 Setting Up a Scan List

Scenario: To setup Scan List 2 with the following channels - CH 008, CH 036, CH 092, CH 083, CH

068.

Steps:

1. Enter Programming Mode, by pressing MON and turning on the radio.

2. Press PTT or MON until SCANLST2 is displayed.

3. Press +. The first scan list member holder, 2-01-, will be displayed. Use the keypad to enter

008.

August 30, 2002 99R85452E01-O

Page 41

Radio Programming

: Programming 4-5

4. Press + again. Enter 036, when 2-02- appears, and subsequently in this manner, enter the

other channels.

NOTE: If a mistake is made, use + or - to move to the appropriate scan list member holder and press

# to erase the channel number.

5. Press PTT or MON, when all the channel numbers have been entered.

6. Turn off your radio, if you have completed the programming, or proceed to the next

parameter.

4.4.3.2 Programming a Phone Number/Access Code/De-Access Code

Scenario: To program the phone number, 9-72886338 (where “-” represents a Pause digit), at

memory location 8.

Steps:

1. Enter Programming Mode, by pressing MON and turning on the radio.

2. Press PTT or MON until TELNO-8 is displayed.

3. Press +. The cursor will be placed on the first character.

4. Use the keypad to enter 9.

5. Enter a Pause digit, by entering * followed by #. These two characters will be converted into a

Pause, represented by ‘-’.

NOTE: Each Pause digit entered shortens the overall length of the code/number by a digit.

6. Use the keypad to enter the rest of the phone number.

NOTE: If a mistake is made, use + or - to move to the appropriate location and then re-enter the

correct character. To erase the complete phone number/code, enter # 16 times.

7. Press PTT or MON, when the complete phone number has been entered.

8. Turn off your radio, if you have completed the programming, or proceed to the next

parameter.

99R85452E01-O August 30, 2002

Page 42

4-6

Radio Programming

: Programming

This Page Intentionally Left Blank

August 30, 2002 99R85452E01-O

Page 43

Chapter 5 Error Code Displays

5.1 Error Codes

The radio performs cursory tests during start-up and during operations to determine if its basic

electronics and software are in working order . Problems detected during these tests are presented

as error codes on the radio display. The presence of an error code means that a problem exists and

that the user should contact a service technician. Use the following table to aid in understanding

particular error code displays.

Table 5-1.

Failure Display Description

MEM ERR Defective ROM.

EEP ERR Defective external EEPROM. Codeplug data is corrupted.

PLL ERR The radio cannot receive or transmit on the programmed frequencies.

Page 44

5-2

Error Code Displays

: Error Codes

This Page Intentionally Left Blank

August 30, 2002 99R85452E01-O

Page 45

Chapter 6 Accessories

6.1 Antennas

8504762J01_ 14cm Antenna, 136-155MHz

8504762J02_ 14cm Antenna, 155-174MHz

PMAD4012_ 9cm Antenna, 136-155MHz

PMAD4013_ 9cm Antenna, 155-174MHz

PMAE4010_ 10cm Antenna, 403-440MHz

PMAE4011_ 10cm Antenna, 435-480MHz

NAE6483_ Whip Antenna, 403-520MHz

6.2 Carrying Accessories

4285820Z01 Shoulder Strap

HLN9844_ Belt Clip (1.5")

HLN9985_ Waterproof Bag

RLN4815_ Universal RadioPak Carry Case

JMZN4020_ Handstrap for Radio

6.3 Carry Cases

PMLN4467_ Carrying Case, Soft Leather Black

PMLN4468_ Carrying Holster Case, Neoprene Grey

PMLN4469_ Carrying Holster Case, Neoprene Blue

6.4 Chargers

PMTN4047_ Wall Charger (16Hr), 230V, EU

PMTN4052_ Wall Charger (16Hr), 230V, UK

PMTN4053_ Wall Charger (16Hr), 110V, US

HTN9071_ Wall Charger (24Hr), 230V, ARG

PMTN4049_ Rapid Charger (3Hr), 230V, EU

PMTN4050_ Rapid Charger (3Hr), 240V, UK

PMTN4048_ Rapid Charger (3Hr), 110V, US

6.5 Batteries

PMNN4046_ Battery Std NiMH

6.6 Audio Accessories

PMLN4442_ MAG ONE Earbud w/In-line PTT/MIC/Vox Switch

Page 46

6-2

Accessories

PMLN4443_ MAG ONE Ear Receiver w/In-line PTT/MIC/Vox Switch

PMLN4444_ MAG ONE Earset Boom Mic w/In-line PTT/Vox Switch

PMLN4445_ MAG ONE Ultra-lightweight Headset w/in-line PTT/Vox

PMMN4008_ MAG ONE Remote Speaker Mic

HMN9030_ Remote Speaker Microphone

PMLN4294_ Ear Set Microphone w/PTT

PMLN4425_ Earset Boom Mic w/Remote Ring PTT

BDN6646_ Ear Mic w/PTT

BDN6647_ Lightweight Single Speaker w/Swivel

BDN6648_ Hvy-duty Hdset w/Noise Canceling Mic

BDN6720_ Flex Rec. Earpiece w/o Volume Control

HMN9022_ Medweight Dual Muff Headset (behind)

HMN9752_ Earpiece w/Volume Control

HMN9787_ Lightweight Headset w/Swivel Boom Mic

HMN9013_ Lightweight Headset w/Swivel Boom Mic

HMN9021_ Medweight Dual Muff Headset (overhead)

HMN9036_ Earbud w/clip Mic and PTT

: Manuals

HMN9727_ Earpiece w/o Volume Control

6.7 Manuals

HKLN4197_ PRO2150 Portable Radio User Guide (English, Spanish, and

HKLN4204_ PRO2150 Portable Radio Detailed Service Manual (English)

6.8 Software

H5197 2 Year CPS Subscription

HKVN4002_ PRO2150 Customer Programming and Tuning Software (CD)

Portuguese)

August 30, 2002 99R85452E01-O

Page 47

Chapter 7 VHF Band Information

7.1 Model Chart

PRO2150 Portable Radio, VHF, 136-174 MHz

Model Description

LAH49KDH8AA9_N PRO2150, 136-174MHz, 1-5W, 12.5/25K-99ch

Item Description

X PMUD1738_ _ L PRO2150, 136-174MHz, 1-5W, 12.5/25K

X DS1M001110 Front Cover Kit

X DS1M001120 Chassis Hardware Kit

X DS1M001130 Knob Assembly

X DS1M001140 Ext. Cover Kit

X DS1M001150 Controller Board Assembly VHF PRO2150

X DS1M001160 RF Board Assembly

X DS1M001170 LCD Kit

X DS1M001190 Speaker Assembly

X DSM1B26051 Screw M2.6

X DSM2192004 Contact Gasket

X DSM2192005 Main Gasket

X DSM2192006 Volume Gasket

X DSM4193013 Gasket (Screw 26)

X DSM5190001 Housing, Back

X DSM6189003 PTT Button

X PMNN4046_ Battery Std NiMH

X

PMAD4012_

X

PMAD4013_

X

PMAD4014_

X

PMAD4015_

X PMTN4053_ Std Wall Charger 110V US

X DSM4193042 PRO2150 Nameplate

X HLN9844_ Belt Clip

X HKLN4197_ PRO2150 Portable Radio User Guide CD (English, Spanish,

x = Indicates one of each is required.

VHF 9cm Antenna, 136-155MHz

VHF 9cm Antenna, 155-174MHz

VHF 15cm Antenna, 136-155MHz

VHF 15 cm Antenna, 155-174MHz

and Portuguese)

Page 48

7-2 Specifications

7.2 Specifications

General

VHF

Frequency: 136-174 MHz

Channel Capacity: 99

Power Supply: 7.5 Volts ±20%

Dimensions with Stan-

dard High

Capacity NiMH

Battery:

Weight: with Standard

High Capacity NiMH

Battery:

Average Battery Life @

(5-5-90 Duty Cycle)

Sealing: Passes rain testing per IPX4

Shock and

Vibration:

Dust: Meets MIL STD 810C, D and

Humidity: Weather resistant housing

115.5mm x 56mm x 35mm

350 g

(Low Power)

>11 hrs

(EN60529=1991)

Meets MIL STD 810C, D and

E

E

passes EIA RS-316B

(High Power)

>8 hrs

Receiver

VHF 12.5

kHz

Sensitivity

12dB SINAD:

Adjacent Channel

Selectivity EIA

Intermodulation 60 dB 65 dB

Spur Rejection: 60 dB 65 dB

Image Rejection: 60 dB 65 dB

Hum and Noise 40 dB

Audio Distortion < 5%

Conducted

Emmision

Audio Output

@ <5% Distortion

All specifications are subject to change without notice.

0.25 µV 0.25 µV

60 dB 65 dB

-57 dBm

500 mW 500 mW

VHF 25

kHz

Transmitter

RF Output

NiMH @ 7.5V:

Channel Spacing 12.5/25 kHz

Freq. Stability

(-30°C to +60°C)

Spurs/Harmonics: -26 dBm

Audio Response:

(from 6 dB/oct. PreEmphasis, 300 to

3000Hz)

Audio Distortion:

@ 1000 Hz, 60%

Rated Max. Dev.

FM Noise: 40 dB

Low

1W

0.00025%

+1, -3 dB

<5%

VHF

High

5W

August 30, 2002 99R85452E01-O

Page 49

VHF Band Information

: Theory of Operation 7-3

7.3 Theory of Operation

7.3.1 General Information

Your radio has two printed circuit boards: the Controller board, and the Radio Frequency (RF) board.

The Controller board contains the CPU/Control section. The RF board contains the VCO/Synthesizer

section, Transmitter section, Receiver section, Transmitter Audio circuitry, Receiver Audio circuitry,

and Battery section.

7.3.2 Power Distribution

Battery

RF PA

Q411

Driver AMP

Q412

+ SW B

Power

Switch

SW201

Audio Power

AMP

Q702

SAVE SW

Q210

5V REG

Q204

VCO Buffer

Q308

RX SW

Q211

TX/RX SW

Q208,209

TX REG

Q201,202

Diode

Q126

PLL IC

Q323

RF AMP

Q404

MIC AMP

Q602

Reset

Q105

Ripple Filter

Q330

Local AMP

Q416

Sub Audio

LPF Q610

CPU

EEPROM

Q101

Q114

TX/RX SW

Q309,310

IF AMP

Q408

TX Driver

Q413,414

Divide

by 2

Q122

TX VCO

RX VCO

IF AMP

Q506

RF Power

Control

Converter

Q325

Q324

Q419

DA

Q121

LPF

Q502

TX +5V

Figure 7-1.

The above figure illustrates the DC distribution throughout the radio board. A battery supplies power

directly to the electronic on/off control. Radio power supply is triggered by the Power Switch (On/

Off/Volume control) and +SW B is distributed as show in the figure. Regulator output 5V is supplied

to the CPU. +SW B continues to support the Audio Power AMP, 5V Regulator, TX Regulator until the

radio is turned off.

HPF

Q505

DTMF

Decode

Q120

RX +5V

The radio can be turned off on two ways:

1. Power Switch turned-off

2. Low Battery

When a low battery level is detected by the CPU, it stores the radio personality data to EEPROM

before turning off the radio.

7.3.3 Power up Sequence

1. Power supply is turned on by the On/Off/Volume Control (Power Switch).

2. Power from battery is supplied to the regulator through the switch.

3. Output (5V) from the regulator is directed to the CPU (Q101).

4. Q105 resets the CPU (Q101).

5. The CPU loads radio personality data from EEPROM after the reset.

6. This personality data is used to initialize the radio.

99R85452E01-O August 30, 2002

Page 50

7-4

7. The radio restores last power up state (i.e. state before the radio was turned-off).

8. Power is supplied to PLL circuitry.

9. Power is supplied to Rx and Rx VCO circuitry.

10. CPU sends data to PLL circuitry. If LOCK status is confirmed, radio continues the power-up

sequence. Otherwise, PLL ERR is displayed.

11. If the Rx audio level is less than the pre-programmed squelch level, and other unmuting

conditions are met, the radio will open squelch.

7.3.4 CPU / Control Section

When the radio is turned ON, the CPU (Q101) reads the radio status from the EEPROM Q114. It

also monitors the keypad, the PTT line and other inputs such as the squelch detect, etc.

continuously. When there is a channel change, the CPU sends the correct frequency information to

the synthesizer via pins 1, 2 and 89. The CPU is clocked by the 8.388608MHz oscillator, which is

composed of X101, C101, C106, and R158.

7.3.5 VCO / Synthesizer Section

This section consists of the Temperature-Compensated Crystal Oscillator (TCXO), Voltage

Controlled Oscillator (VCO), Synthesizer and the Loop Filter. These circuits are found on the RF

board.

VHF Band Information

: Theory of Operation

7.3.5.1 Temperature-Compensated Crystal Oscillator (TCXO)

The reference oscillator is a temperature compensated crystal-controlled, Pierce type circuit. It

utilizes a logic gate within Q323 as a gain element. C335 is used to adjust the oscillator on frequency

(14.4MHz) at room temperature (22°C). Temperature variations cause resistance changes in

thermistor R330 and R567, which is on the base of Q320, thus varying the voltage applied to

varactor Q322. This changes the impedance across crystal X301 in a manner complementary to the

temperature drift characteristic of the crystal. In this way, the reference oscillator is held within the

specified ±2.5 PPM from -30 to +60°C.

7.3.5.2 Voltage-Controlled Oscillators

Only one of the VCOs runs at a time, which is controlled by Q310 and Q101. The receive VCO

consists of C344-C351, L302, L305, L306, L312-L314, Q311, and Q324. This VCO oscillates at 45.1

MHz above the programmed receive frequency. The VCO’s oscillating frequency is tuned by the

varactor Q311. The tuning voltage is supplied from the output of the Loop Filter. The output of the

VCO is AC coupled (C352) to the buffer Q308. The output of the VCO buffer Q308 is AC coupled

(C308) to the synthesizer and the output buffer Q416 respectively.

When the PTT is pressed, Q101 pin36 goes low (approx. 0V) disabling the receive VCO by the Q310

and biases on Q309 to enable the transmitter VCO. The transmitter VCO consists of C353, C355,

C357, C358, L315, L317, L318, Q325, Q326, and Q329. This VCO oscillates on the programmed

transmit frequency. The VCO’s oscillating frequency is tuned by the varactor Q326. The tuning

voltage is supplied from the output of the Loop Filter. The transmit voltage controlled oscillator is

directly frequency-modulated and operates on the carrier frequency. The synthesizer is tuned in

5.00kHz or 6.25kHz steps.

7.3.5.3 Synthesizer

The frequency synthesizer is a large-scale monolithic synthesizer integrated circuit Q323. The

synthesizer IC contains a dual modulus prescaler, programmable divide-by-N counter, prescale

control (swallow) counter, reference oscillator, reference divider, phase detector, charge pump and

lock detector. Also, included in Q323 are shift registers and control circuits for frequency controls and

general device control.

August 30, 2002 99R85452E01-O

Page 51

VHF Band Information

RF output from the active VCO is AC coupled to the synthesizer Q323 prescaler input at Pin 8. The

divide counter chain in Q323, consisting of the dual-modulus prescaler, swallow counter and

programmable counter, divides the VCO signal down to a frequency very close to 5.00kHz or

6.25kHz which is applied to the phase detector. The phase comparator compares the phase with the

5.00kHz or 6.25kHz reference signal from the reference divider and drives the external charge pump

(Q314, Q315 and Q316). The synthesizer unlock detector circuit prevents the operation of the

transmitter and receiver, when the phase lock loop (PLL) is unlocked. The following discussion

assumes the unit has been placed in the transmit mode. Q323 lock detector Pin 7 goes high when

the PLL is locked. This high level is applied to Pin 25 of the CPU Q101. A software timing routing

brings the RX/TX line low (Pin 36 of Q101). With the RX/TX line goes low, Q209 is cut off and Q208

is biased on passing +5VTX-B to Q202; it biases on Q201 to pass switched TX-B to the transmitter

amplifier string which enables transmission.

When the PLL is unlocked, the lock detector at Q323 Pin 7 will begin pulsing low. A RC circuit

converts this low pulse to a low level for the CPU. The CPU then changes the RX/TX line to a high,

thus signaling the other transistor switches to drive Q201 into cutoff, which disables transmission.

Therefore, the transmitter remains disabled while the loop remains out of lock, and “PLL ERR” is

displayed.

7.3.5.4 Loop Filter

The Loop Filter, a passive lead-lag filter consisting of R314-R317, R356, C323, C369, and C371,

integrates the charge pump output to produce the DC turning voltage for the VCO. One parasitic

pole, consisting of RF chokes L306/L318, prevent modulation of the VCOs by the 5.00kHz or

6.25kHz reference energy remaining at the output of the loop filter. Direct FM is obtained for

modulating frequencies outside the PLL bandwidth by applying the CTCSS/DCS signals and the preemphasized, limited microphone audio to the VCO modulation circuit. The modulation circuit

consists of R347 and Q329.

: Theory of Operation 7-5

7.3.6 Transmitter Section

7.3.6.1 RF Power Amplifier

After the PTT is pressed, the +5VTX-B line switches to approximately 5V. Q309 is turned on,

enabling transmit VCO. The VCO buffer, pre-driver, driver and power amplifier are biased on by

Q201. Q201 is biased on by the +5VTX-B line switching to 5V. RF output from the transmit

VCO(Q325) is applied to the VCO output buffer Q308. Output from Q308 feeds the buffer Q414. The

output signal from Q414 feeds the pre-driver amplifier Q413, and feeds the driver amplifier Q412,

whose output from the driver stage feeds the final RF power amplifier Q411 to produce the rated

output power of 5 watts. The final output is feed to a low-pass filter (C446-C448, C451, C452, L418,

and L419) and then to the transmit/receive switch Q410. RF power is then fed to the antenna via the

output low-pass filter consisting of C440-C445, L415, and L416.

7.3.6.2 Antenna Switching

Switching of the antenna between the transmitter and the receiver is accomplished by the antenna

transmit/receive switch consisting of diodes Q409 and Q410. In the transmit mode, switched TX B+

is applied through R419 and RF choke L417, hard forward biasing the two diodes on Q410, thus

permitting the flow of RF power from the output of the low-pass filter. L414 and C445 isolate the

receiver circuit from the transmitter power input.

99R85452E01-O August 30, 2002

Page 52

7-6

7.3.6.3 Power Control

Output power is controlled by the CPU (Q101), the D/A converter (Q121), the dual Op-Amp (Q419),

which is used as a differential amplifier and comparator. Current is sensed by the voltage drop

across R445. When the radio is in high power mode, this voltage is compared to the

D/A converter voltage at 5-watt. When the radio is in low power mode, this voltage is compared to

the D/A converter voltage at 1-watt. The power output is then reduced or increased by varying the

applied voltage to the gate of the power amplifier Q411 and Q412.

7.3.6.4 Transmitter Audio Circuits

The transmitter audio circuits consist of the audio processing circuits, the CTCSS circuits and the

DCS circuits.

7.3.6.4.1 Audio Processing

Transmit speech audio is provided by either the internal electric microphone M101 or the external

microphone. The audio is pre-emphasized by 6dB per octave by C615 and R655, and then its signal

is amplified. The microphone audio is directed to amplifier Q602B, Q602A and low-pass filter Q602C

and Q602D. Q602A has limiting function. The modulation adjustment is done by Pot RV601, and

directed to a four-pole active low-pass filter. The resulting signal is then limited, and is directed to a

low pass filter (18dB per octave roll-off above 3KHz). The audio is then directed through the 25KHz/

12.5KHz channel spacing SW Q601 to varactor diode Q329 in transmit VCO. By varying the voltage

on the varactor diode Q329 at an audio rate, VCO output is frequency-modulated.

VHF Band Information

: Theory of Operation

7.3.6.4.2 CTCSS Tone Encoder / Digital Code Squelch (DCS) Encoder

CTCSS signals and DCS signals are synthesized by CPU Q101 and appear as pulse waveform on I/

O line Pin 7. This I/O line is connected to a digital-to-analog converter network (consisting of C136,

C173, R150, R177 and R182), which produces a pseudo-sine wave at its output. The waveform is

smoothed by low pass filters Q610B to produce an acceptable sine wave output. The CTCSS tone

signal is adjusted to the proper level by RV602.

7.3.7 Receiver Section

7.3.7.1 Receiver Front End

In the receive mode, the RF signal enters thorough the antenna, then through the low-pass filter

C439-C445, and L414-L416. The diodes Q409 and Q410 are biased off, so that the output of the

low-pass filter is coupled (C437, C438, L413 and R418) to the first band-pass filter C401-C406,

C408-C410, L401, L402, PCB_L1, Q401, R401, and to the Front End RF overload protection diode

pair Q403. The signal from the band-pass filter is directed to the input of the RF amplifier Q404. The

output of the RF amplifier is sent to three stages of band-pass filters, consisting of C415-C429,

C486, L404-L406, Q405 and R410. The output from the band-pass filter is directed to the mixer’s

Q407/L407.

7.3.7.2 Local Oscillator (LO)

The Receive VCO (C344-C351, L302, L305, L306, L312-L314, Q311, and Q324) provides the LO

signal. The VCO is running at 45.1 MHz above the desired receive frequency and is applied to output

Buffer Q308/Q416. The output of the buffer is sent through the low-pass filter C430, C431, L409, and