Page 1

E365 Trouble Shooting

Service Manual

Compal Communications, Inc.

1

Page 2

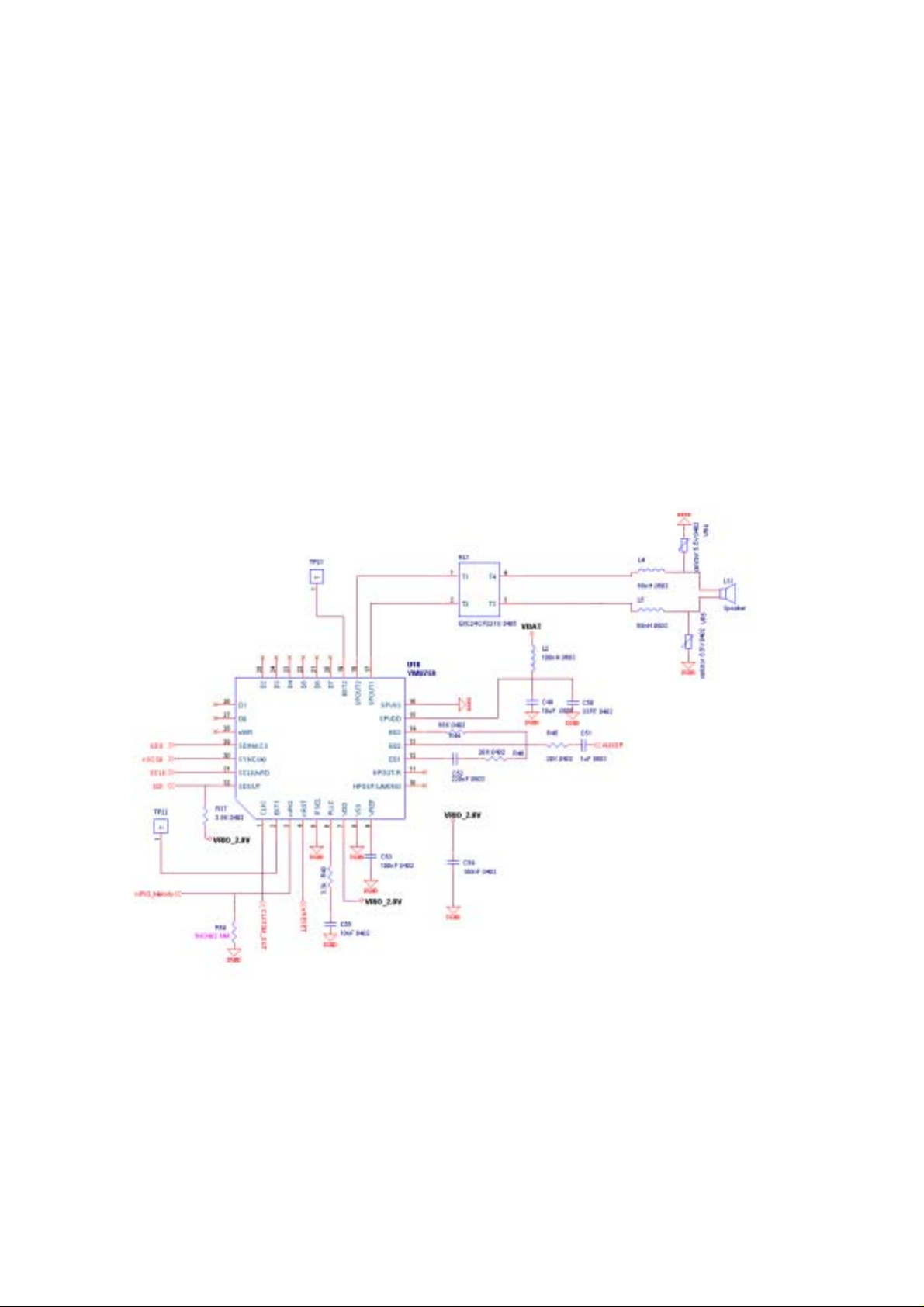

Baseband Descriptions

△

1. The mobile phone can’t boot after inserting the battery?

•STEP1. Check the energy of battery greater than 3.8v.(>3.8v)

a. to charge the battery. b. change the battery.

•STEP2. Check the battery connector

a. recombination. b.change the battery connector

•STEP3. Check the BTB connector between M/B and MMI

a. recombination

•STEP4. Check the MMI whether in normal

a. recombination

•STEP5. Check the software in correct

a. Re D/L

2. The mobile phone turn off automatically after turn on?

•STEP 1.Check battery if voltage enough greater than(>3.8v)

a. recombination b. Change battery

•STEP 2.Check ADC(3.4v) is correct

a. Re-adjustment ADC(3.4v)

•STEP 3.IF above-mentioned are all in normal condition then the problem could be

caused by M/B.

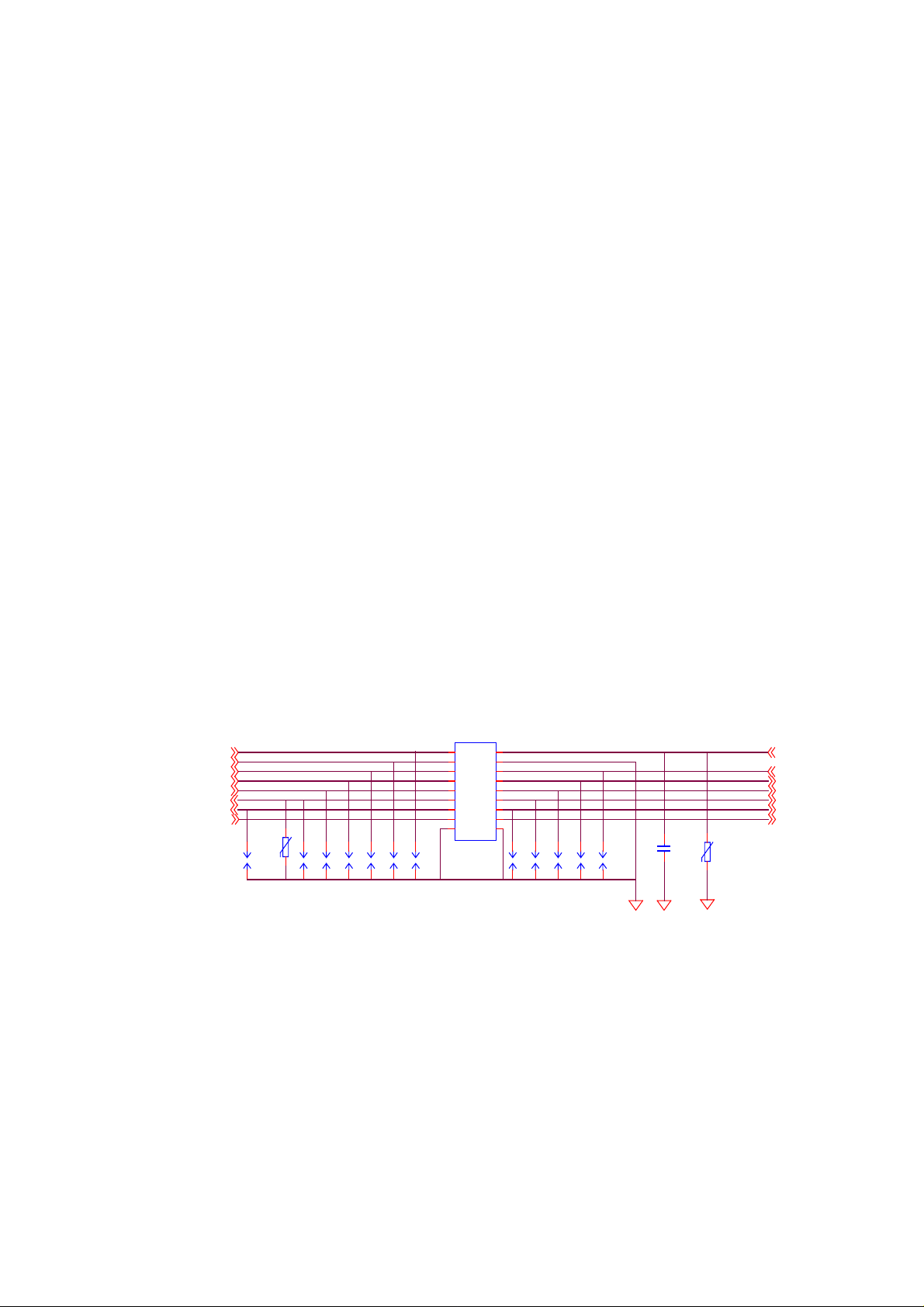

STEP3.1check J2.Row4 and GND maybe short.

STEP3.2.check J2 Pwon and GND maybe short.

BTB_CON

COL0

COL1

COL2

COL3

COL4

PWON

ROW0

VDDS-MIF_2.8V

varistor 5.5V 0402

GAP3

S

VR16

GAP4

S

GAP5

S

GAP7SGAP9

GAP6

S

GAP8

S

1

18

2

17

3

16

4

15

J2

5

14

6

13

7

12

11

8

10

9

GAP14

GAP12

GAP10

S

S

GAP11

S

GAP13

S

S

S

DGND

C46

22pF 0402

DGND

VR3

varistor 5.5V 0402

DGND

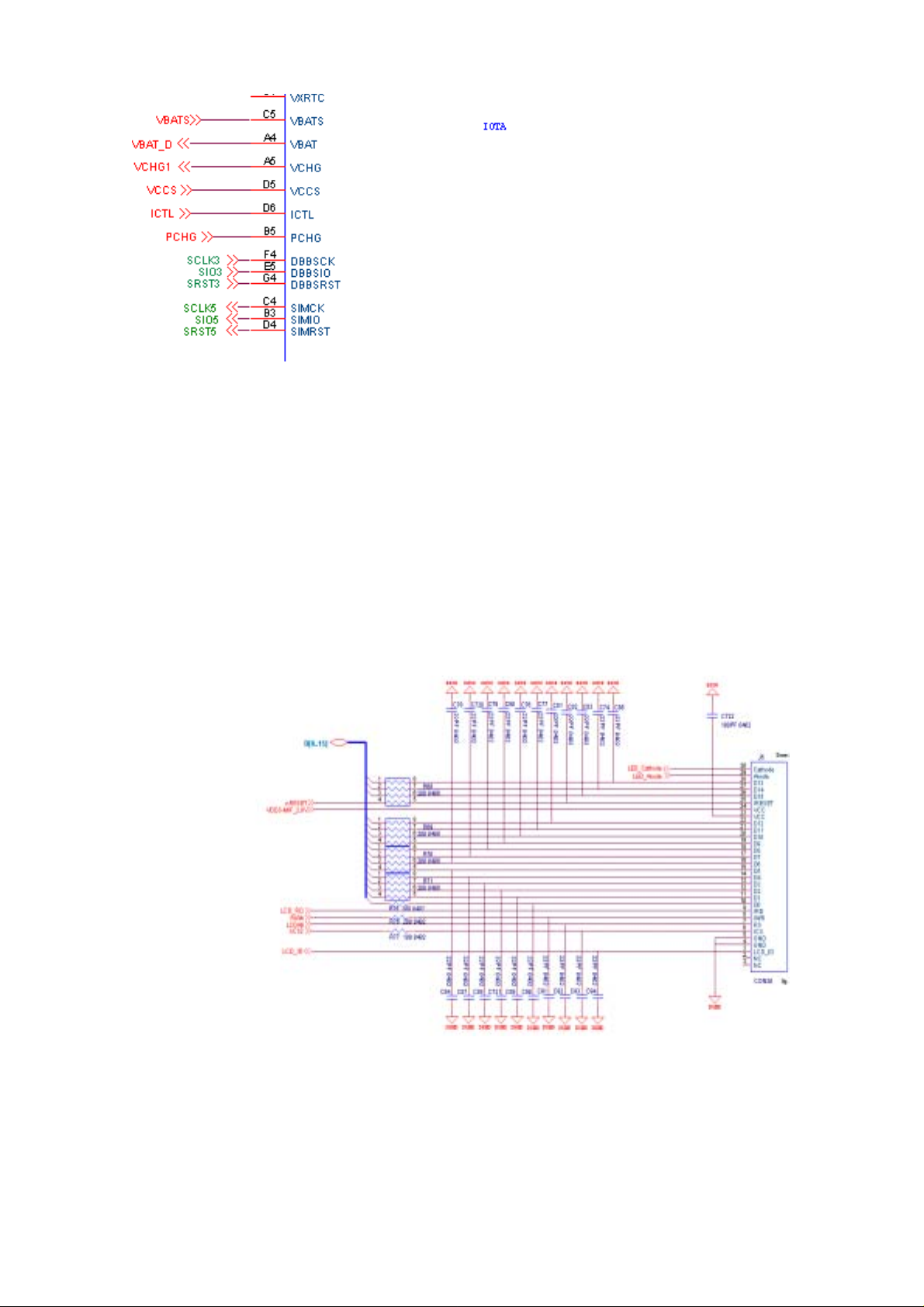

3. The screen display can’t search SIM card when insert SIM after turn on.

•STEP 1.Check the SIM card whether to louse.

a. Change SIM card.

•STEP 2.Check the SIM connecter.

VBAT

LEDKEYN

ROW4

ROW3

ROW2

ROW1

LIGHTSENSER_EN

a. Change SIM connector.

•STEP 3.IF above-mentioned are all in normal condition then the problem could be

caused by M/B.

a. if change SIM connector isn’t ok,then change a new IOTA.

2

Page 3

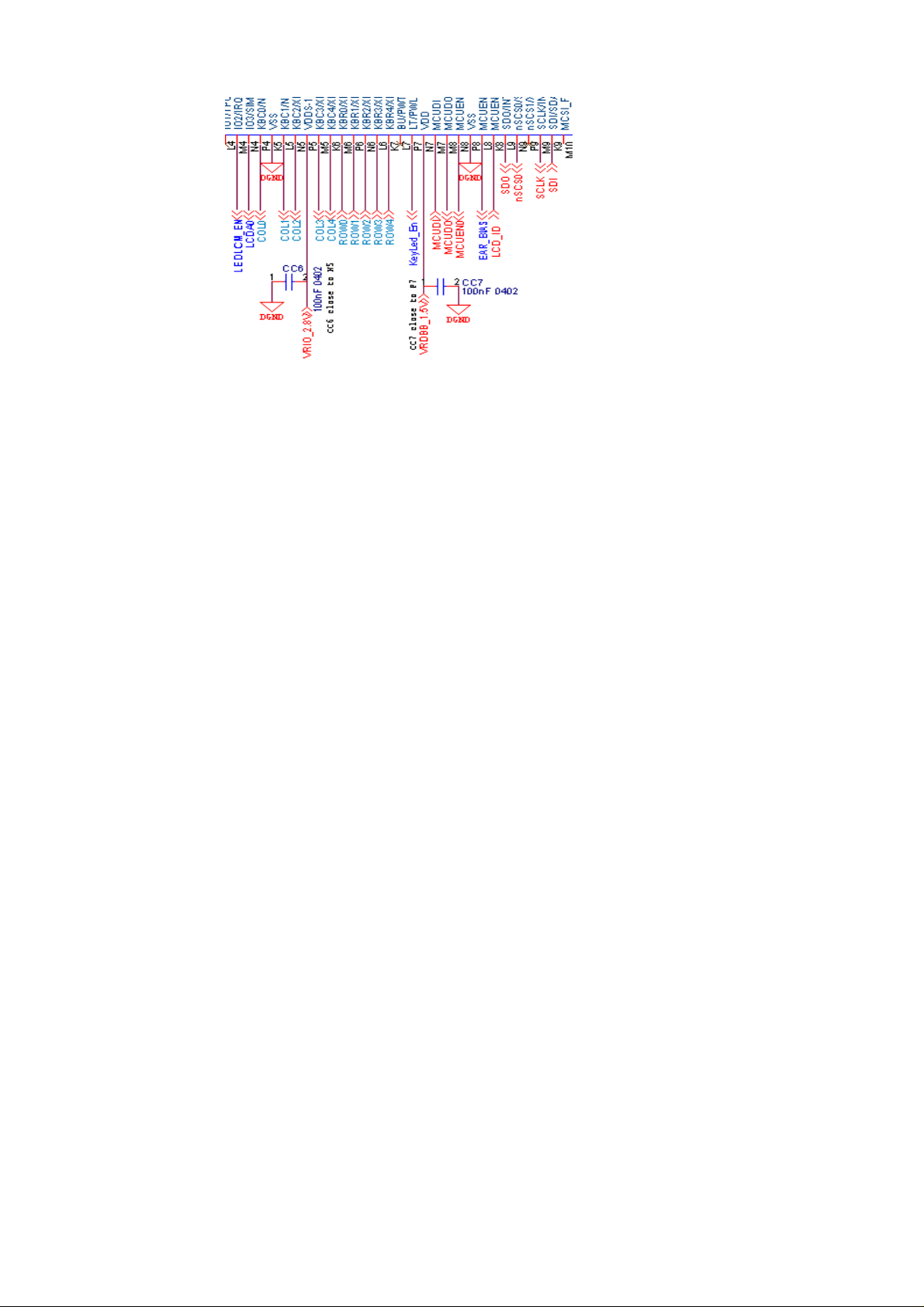

5. No display on LCD after turn on?

•STEP 1.Check the connector of LCD and FPC

a. recombination

•STEP 2.Check the LCD whether to louse

a. Change LCD

•STEP 3.IF above-mentioned are all in normal condition then the problem could be

caused by M/B.

STEP 3.1.checkVDDS-MIF_2.8V =2.8V (if VRMEM<2.7V, the LCD will not

work)

STEP 3.2. check J6 every PIN’s impedance, then you can find one of them

has problem

6. Has not LCM backlight :

•STEP 1. Check SET is correct

a. To set up LCD light bright mode.

•STEP 2. Check LCD and M/B whether to connect

a. Recombination.

•STEP 3. Check LCD failure

3

Page 4

a. Change LCD.

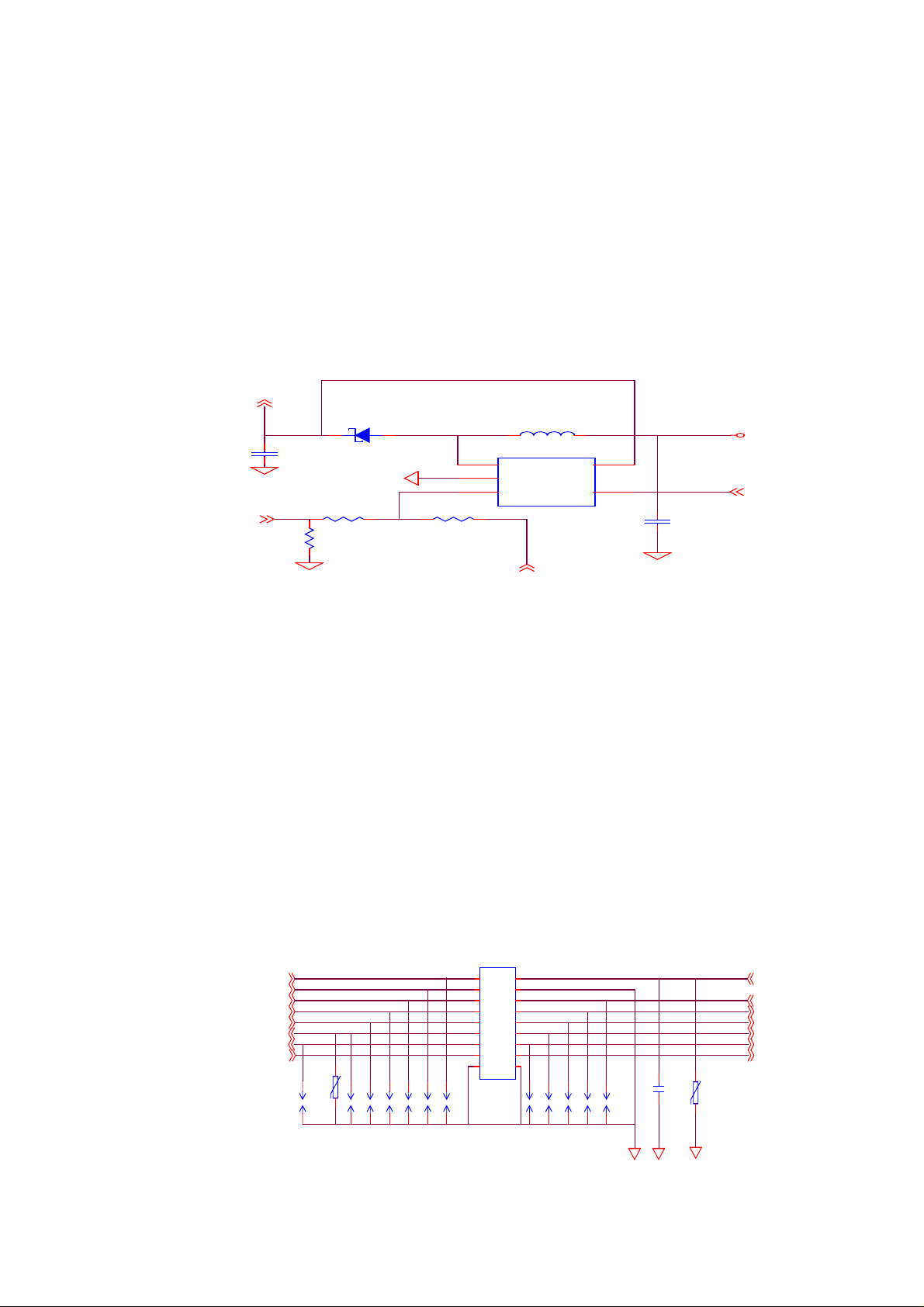

•STEP 4.IF above-mentioned are all in normal condition then the problem could be

caused by M/B

STEP 1.Check U11 is slant.

STEP 2. when you press the keypad ,measure U11.4=2.7V

STEP 3. if RR1 have about 0.4V,then change U11.

STEP 4.if U11.4 < 2.7V,then change a new G2.

STEP 5.if step1 to step4 is ok, then check U6.3 about 10V

STEP 6.if U11.1<8V ,then change a new U11 or FL1、D6.

.

LED_Anode

0.22uF 0603

LED_Cathode

D6

CC1

DGND

RR1

56 0402

RB551V-30

R36

0 0402

DGND

23

DGND

R40

0 0402 NM

1

2

3

VDDS-MIF_2.8V

U11

SW

GND

FB

22uH

MP1523

FL1

5

BIAS

4

EN

CC2

1uF 0603

DGND

7. Has not Keypad Backlight ?

•STEP 1 Check the BTB connector between M/B and MMI

a. Recombination

•STEP 2.Check MMI whether to have problem

a. Change MMI

•STEP 3.IF above-mentioned are all in normal condition then the problem could be

caused by M/B.

VBAT

LEDLCM_EN

STEP3.1.use meter to check J2 every PIN impedance, then you can find

one of them has

problem.

BTB_CON

COL0

COL1

COL2

COL3

COL4

PWON

ROW0

VDDS-MIF_2.8V

varistor 5.5V 0402

GAP3

S

VR16

GAP4

S

GAP5

S

GAP7SGAP9

GAP6

S

GAP8

S

1

18

2

17

3

16

4

15

J2

5

14

6

13

7

12

11

8

10

9

GAP10

S

S

GAP11

S

S

GAP13

S

S

DGND

22pF 0402

DGND

GAP14

GAP12

C46

varistor 5.5V 0402

DGND

VR3

Step3.2 LEDKEY_EN= 1.4 ~ 2.8V, BQ3.pin3 = 1V DC

4

VBAT

LEDKEYN

ROW4

ROW3

ROW2

ROW1

LIGHTSENSER_EN

Page 5

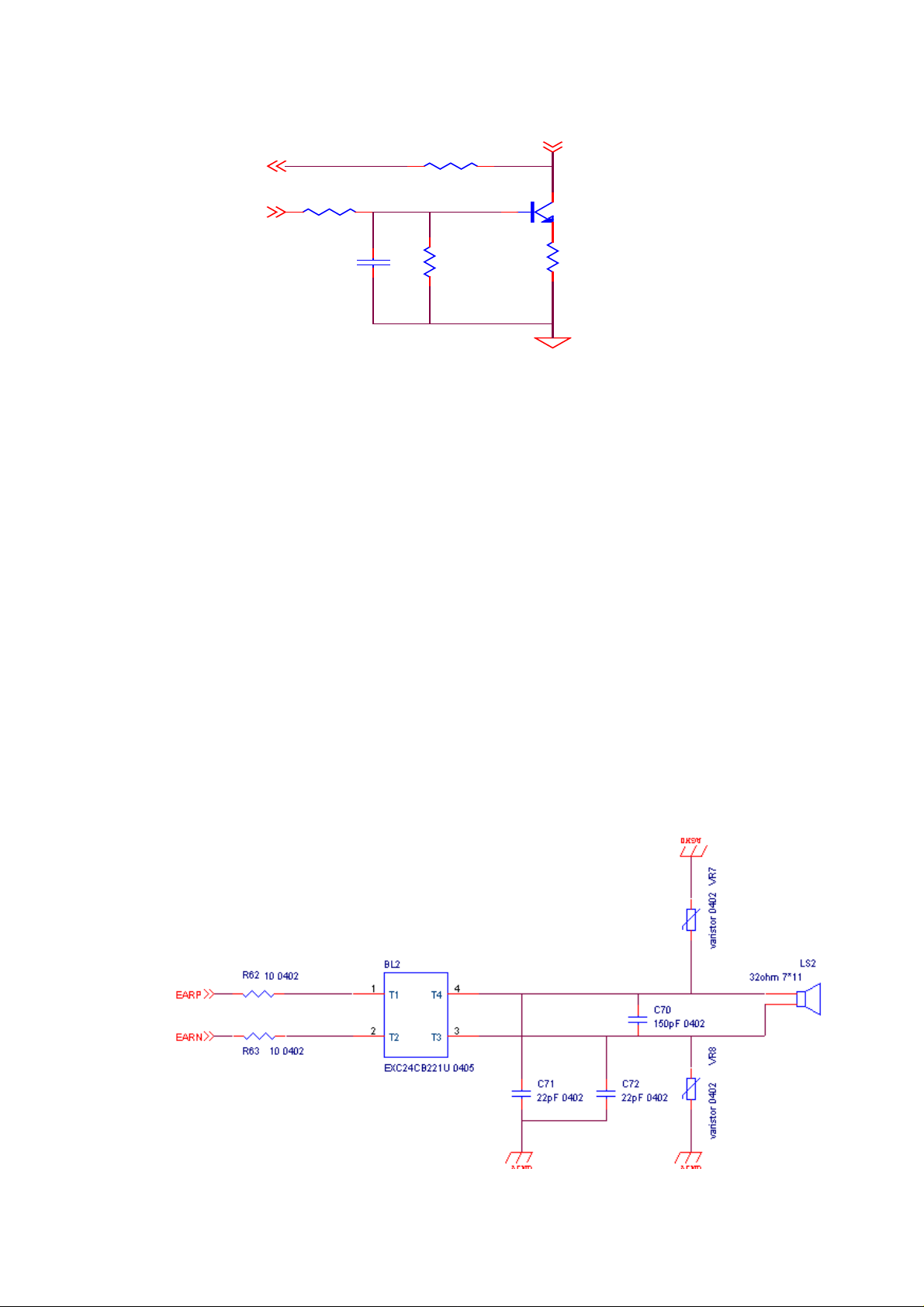

E

LEDB

R64 0 0402 NM

LEDK

KeyLed_En

R65 1.5K 0402

C73

33nF 0402

R67

1K 0402

8. Receiver has no key tone or sound.

•STEP 1.Check SET is correct

a. set up to key tone mode.

•STEP 2.Check Receiver pin is that slanting or sag

a. To adjust the Receiver pin.

•STEP 3.Check Receiver whether in normal

a. Change Receiver.

•STEP 4.Check M/B pad is that oxidation or dirty

a. Use a eraser to clean the pad.

2

DGND

2SC5585 EMT3

1 3

R66

4.7 0402

BQ3

•STEP 5.IF above-mentioned are all in normal condition then the problem could be

caused by M/B

STEP 5.1.check every part impedance (R62、R63、C70、C71,C72、VR7、

VR8).

STEP 5.2.if every part is ok, then change a new IOTA.

5

Page 6

9. No ring tone

•STEP 1.Check SET is correct

a. Set up to ring mode.

•STEP 2.Check speaker hold has screwed

a. lock up a screw.

•STEP 3.Check speaker failure?

a. Change Speaker.

•STEP 4.Check speaker Connector damage?

a. Changed Speaker Connector.

•STEP 5.IF above-mentioned are all in normal condition then the problem could be

caused by M/B.

STEP5.1.check MELODY “Pin17、Pin18” impedance.

STEP5.2.if step1 is ok, measure L2, C49, C50, R45, R46,

R44,C51,C52,R37,C53,C54,C55,R48 impedance. Then

you can find one of them has problem.

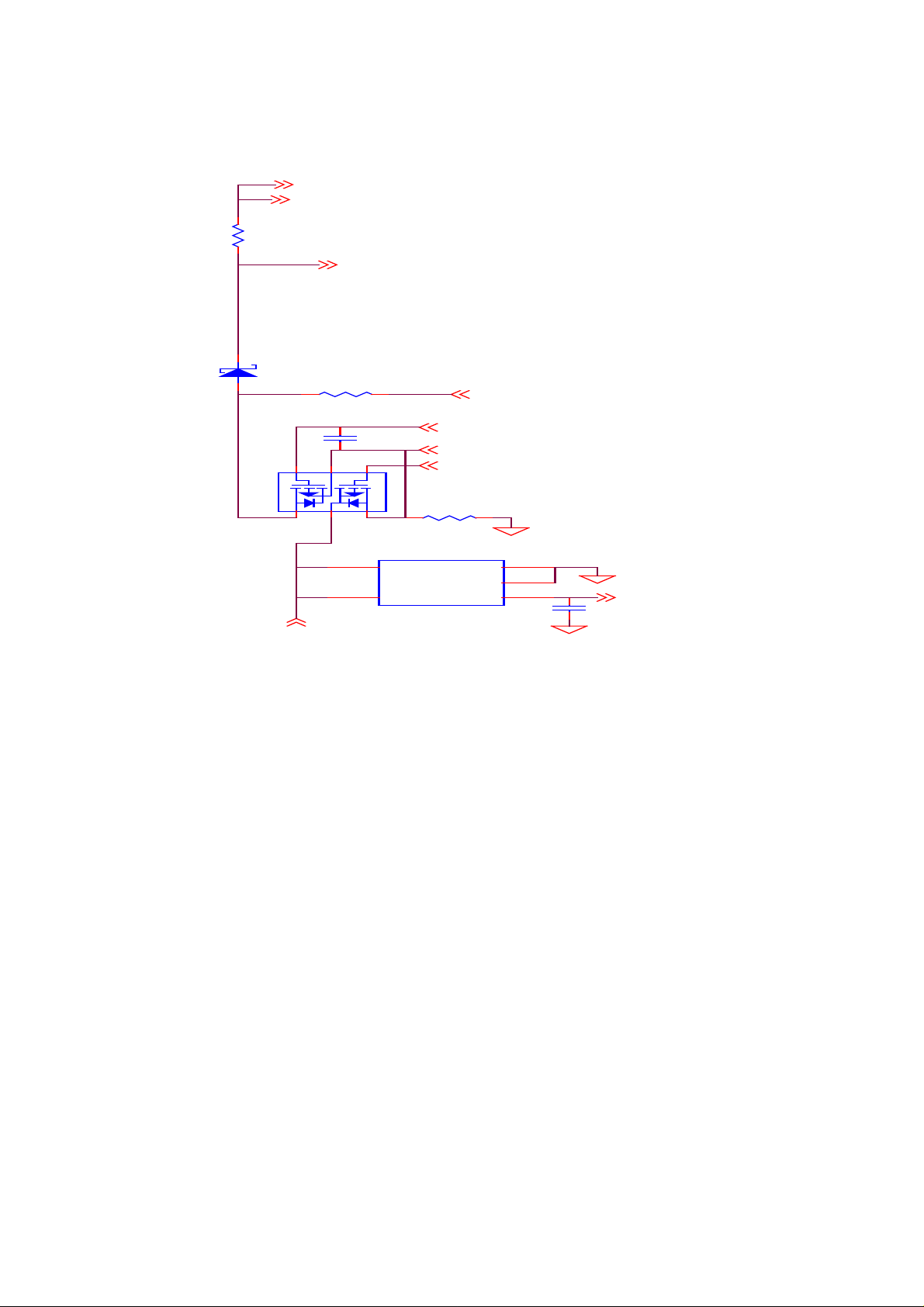

10. Can not charging:

•STEP 1.Check if you use the right adaptor

a. Change right adaptor.

•STEP 2.Check I/O Connector failure?

a. Change I/O Connector.

•STEP 3.Check I/O Connector Pin1&Pin2 solder creak?

a. I/O Connector Pin1&Pin2 re-soldering.

6

Page 7

•STEP 4.IF above-mentioned are all in normal condition then the problem could be

caused by M/B. STEP 4.1.if U2.4 <5.8v,then change a new U2.

STEP 4.2.if step1 is ok, then change a new IOTA.

VBAT

VBATS

R1

0.15 0805 1%

VCCS

D2

RB160M-30

2 3

68 0805 1% NM

3

4

VCHG

R5

C10

22nF 0402

2

1

FDC6506P

5

6

U3

4

IN

5

VCC

NCP345

U2

ICTL

VCHG1

nCHG

CNTRL

GND

R15

OUT

PCHG

100K 0402

DGND

3

2

1

DGND

DGND

1uF 0603

nCHG

C21

11. Key has not function

•STEP 1. Check the BTB connector between M/B and MMI is well?

a. Recombination.

•STEP 2. Check MMI whether to have problem

a. Change MMI.

•STEP 3.Check MMI Pad whether to oxidize and dirty

a. Use a eraser to clean the pad.

•STEP 4. .IF above-mentioned are all in normal condition then the problem could

be caused by M/B.

STEP 4.1.check BTB connector is short.

STEP 4.2.if not short, then change a new G2

7

Page 8

12. Has not vibration or vibrator can not stop.

•STEP 1.Check SET is correct

a. Set up to vibrate mode.

•STEP 2.Check Vibrator Pin is that slanting and sag

a. To adjust the Vibrator Pin.

•STEP 3. Check Vibrator failure?

a. Change Vibrator.

•STEP 4. Check M/B pad is that oxidation or dirty

a. Use a eraser to clean the pad.

•STEP 5.IF above-mentioned are all in normal condition then the problem could be

caused by M/B.

STEP 5.1.check F1 ,BQ1 ,R42, R43, D4 maybe slant.

STEP 5.2.check the voltage of BQ1.3 > 3.4V.

STEP 5.3.measure R42, R43 impedance is ok.

STEP 5.4.if step1 to step3 is ok, then change new BQ1

STEP 5.5.if above mention all in normal, then change a new IOTA.

8

Page 9

VBAT

F1

1

SGM20F1E104-2A 2012

I/O1

4

G

DGND DGND

3

G

I/O2

2

No. G3240010

DAC

1 2

R42

33 0402

DGND

R43

10K 0402

1SS400 SC79

2

1 3

D4

2 1

DGND

BQ1

2SC5592 SC59

0.95mm

M1

MOTOR 4.0*8.8-1.5V-KHN4NZ1D

3930408801W

13. Micphone can not work:

•STEP 1.Check MIC failure?

a. Change MIC.

•STEP 2.Check M/B pad is that oxidation or dirty

a. Use a eraser to clean the pad.

•STEP 3.IF above-mentioned are all in normal condition then the problem could

be caused by M/B.

STEP 3.1.check EF2 is slant.

STEP 3.2.check C65、C66、C67、R59、R61、C68、C69、R58、R60 impedance.

STEP 3.3.if above mention all in normal, then change a new IOTA.

MICIP

MICIN

MICBIAS

AGND

C65 100nF 0402

C66

R58

330 0402

C68

10uF 0805

R60

330 0402

100nF 0402

R59

1K 0402

C69

100nF 0402

R61

1K 0402

EMIF01-10005W5 SOT323-5L

EF2

5

O1

4

O2

GND

1

I1

2

3

I2

AGND

C67

100pF 0402

1

MIC+

2

MIC-

OBG-13SA 42-C2

14. No sound on earphone?

•STEP 1.Check use Earphone is failure?

a. Change right Earphone.

•STEP 2. Check Earphone Jack is failure?

a. Change Earphone Jack.

•STEP 3.IF above-mentioned are all in normal condition then the problem could be

MIC1

9

Page 10

caused by M/B.

STEP 3.1.if the earphone has no sound, check the soldering of SPACE R51.

STEP 3.2.if step1 is ok, then check EF1、L3、C57 soldering.

STEP 3.3.if above mention all in normal, then change a new SPACE IOTA

15. Has big Leakage current :

If leakage current > 100mA , battery on for a long time , we can touch the surface

of component , If the component heat more than other , It may be fail .

If leakage current <100mA , replace component.

16. Can not record Time

•STEP 1.Check RTC battery whether powerful or failure

a. Change RTC battery.

•STEP 2.IF above-mentioned are all in normal condition then the problem could

be caused by M/B.

STEP 2.1.if TP24 <> 32.768K,then change a new U2.

STEP 2.2.if change a new U2 isn’t ok ,then change a new G2.

17. Can not Download

•STEP 1.Check Download Tool SET

10

Page 11

a. Reset.

•STEP 2.Check use right Data cable or failure

a. Change Data cable.

•STEP 3.Check I/O Connector failure

a. Change I/O Connector.

•STEP 4.Check I/O Connector Pin3-Pin16 solder creak

a. I/O Connector Pin3-Pin16 re-soldering.

•STEP 5.IF above-mentioned are all in normal condition then the problem could

be caused by M/B.

STEP5.1.if TP4<>13M,then change a new 13M.

STEP5.2. if TP24=32.768k,then change a new flash.

STEP5.3.if TP24<>32.768k,then change G2.

STEP5.4.if TP24<>32.768k,then pull out G2.measure IOTA’s 5 modules

voltage whether in normal.

STEP5.5.if IOTA is ok, then change a new G2. Space final, you can download

software.

TP4(13M) TP24(32K)

18 DSC no function

STEP 1..Check the connector of DSC and FPC

11

Page 12

a. recombination

STEP 2.Check the DSC whether to louse

a. Change DSC

STEP 3 . check the DSC’s LDO whether have output voltage.

STEP3.1 If the COMS_EN <2.5V, then change the G2

STEP3.2 If the LDO (U13) has no voltage output, then change U13

D25V

L6

100nH 0402

RR26

L8

100nH 0402

C97

2.2uF/6V

L7

100nH 0402

VBAT

COMS_EN

C99

RR9

100K 0402 nm

DGND

C700

100nF 0402

10nF 0402

DGND

2.5V FOR OV7645FB

U13

1

Vin

VOUT2.5

2

EN1

VOUT3.0

3

EN2

4

BYP

NC5GND

MIC2211-2.5/3.3BML

NC

NC

RR26

1SS400 SC-79(W99685)

DD25V

10

9

8

7

6

D33V

C98

1uF/6V

DGND

0 0603

DGND

AVDDP

S25V

AVSSP

STEP 4. CLK13M_DSC have no 13MHz

a. Change the inverter U18.

D33V

RR14

10

C723

5

100pF

0402

DGND

CLK13M_DSC

10%

50V

NPO

4

U18

NC

VCC

IN

OUT

GND

TC7SHU04FU

SC70-5

RR15

1M

1

2

3

DGND

C724

CLK13M_OUT

100pF

X7R

0402

10%

50V

STEP5. check the U12.E10 have no 13MHz

a. change the U12

12

Page 13

#02#.

STEP6 move the CMOS sensor , then power on the handset and press

If it can’t get the firmware version such as 1.08 . the U12’s data

bus or control bus could have some trouble

a. change the U12

19. light sensor no function

step 1. check the VDDS-MIF-2.8V whether have 2.8V.

a. Check the BTB connector between M/B and MMI

step 2. check the LIGHTSENSER_EN whether have variably voltage

a. please change Q1 or R1.

VDDS-MIF_2.8V

R1

10k

Q1

Photo-Transistor

DGND

C6

?nF 0402 NM

DGND

LIGHTSENSER_EN

Step 3 check the LIGHTSENSER_EN have variably voltage

13

Page 14

a. please change the IOTA.

14

Page 15

△ Radio Frequency Descriptions

E365 RF Block Diagram :

The Aero transceiver consists of the Si4200 GSM transceiver, Si4201 universal

baseband interface, and Si4133T dual RF synthesizer. The highly integrated

solution eliminates the IF SAW filter, low noise amplifiers (LNAs) for three bands,

transmit and RF voltage controlled oscillator (VCO) modules, and more than 60

other discrete components found in conventional designs.

The receive section uses a digital low-IF architecture which avoids the difficulties

associated with directconversion while delivering lower solution cost and reduced

complexity. The universal baseband interface is compatible with any supplier’s

baseband subsystem.

The transmit section is a complete up conversion path from the baseband

subsystem to the power amplifier, and uses an offset phase locked loop (PLL) with

a fully integrated transmit VCO. The frequency synthesizer uses Silicon

Laboratories’ proven technology, which includes integrated RF and IF VCOs,

varactors and loopfilters.

15

Page 16

Receiver Block Diagram :

The Aero transceiver uses a low-IF receiver architecture that allows for the on-chip

integration of the channel selection filters. The Si4200 integrates three

differential-input LNAs. The LNA inputs are matched to the 200 Ohm balanced

output SAW filters through external LC matching networks.

A quadrature image-rejeject mixer downconverts the RF signal to a 100kHz

intermediate frequency (IF) with the RFLO from the Si4133T frequency

synthesizer. The mixer output is amplified with an analog programmable gain

amplifier (PGA). The quadrature IF signal is digitized with high resolution A/D

converters (ADCs).

The Si4201 downconverts the ADC output to baseband with a digital 100kHz

quadrature LO signal. Digital decimation and IIR filters perform channel selection

to remove blocking and reference interference signals. After channel selection, the

digital output is scaled with a digital PGA. DACs drive a differential analog signal

onto the RXIP, RXIN, RXQP and RXQN pins.

16

Page 17

Transmitter Block Diagram :

The transmit (TX) section consists of an I/Q baseband upconverter, an offset

phase-locked loop (OPLL) and two 50 Ohm output buffers that can drive external

poweramplifiers (PA).

A quadrature mixer upconverts the differential in-phase (TXIP, TXIN) and

quadrature (TXQP, TXQN) signals with the IFLO to generate a SSB IF signal

which is filtered and used as the reference input to the OPLL. The Si4133

generates the IFLO frequency between 766MHz and 896 MHz. The IFLO is

divided by two to generate the quadrature LO signals for the quadrature

modulator, resulting in an IF between 383 and 448MHz.

The OPLL consists of a feedback mixer, a phase detector, a loop filter, and a fully

integrated TXVCO. The TXVCO is centered between the DCS1800 and PCS1900

bands, and its output is divided by two for the GSM 850 and E-GSM 900 bands.

The Si4133T generates the RFLO frequency between 1272 and 1483 MHz.

Low-pass filters before the OPLL phase detector reduce the harmonic content of

the quadrature modulator and feedback mixer outputs.

17

Page 18

Frequency Plan of Aero

For Tx and Rx intermediate frequency plan

Tx intermediate frequency

Band IF frequency (MHz) Channel LO frequency (MHz)

E-GSM

399*2 975~1023 (890+0.2*(ARFCN-1024))+IF/2

399*2 0~24 (890+0.2*ARFCN)+IF/2

395*2 25~49 (890+0.2*ARFCN)+ IF/2

399*2 50~124 (890+0.2* ARFCN)+ IF/2

DCS 383*2 512~885 (1710.2+0.2*( ARFCN -512))-IF/2

E-GSM : fLO=fRF + fIF/2

DCS/PCS : fLO=fRF - fIF/2

Rx intermediate frequency 100kHz

Band Channel LO frequency (MHz)

975~1023 ((935+0.2*(ARFCN-1024))-0.1)*2 E-GSM

0~124 ((935+0.2*ARFCN)-0.1)*2

DCS 512~885 (1805.2+0.2*(ARFCN-512))-0.1

E-GSM: f

/2 =fRF – 0.1 DCS / PCS: fLO =fRF – 0.1

LO

Tx (Low, Mid, High channel)

Band IF frequency(MHz) LO frequency (MHz) Channel

399*2 1279.2 975

E-GSM

399*2 1301.4 62

399*2 1313.8 124

DCS

383*2 1327.2 512

383*2 1364.6 699

383*2 1401.8 885

Rx (Low, Mid, High channel)

Band LO frequency (MHz) Channel

E-GSM

1850.2 975

1894.6 62

1919.4 124

DCS

1805.1 512

1842.5 699

1879.7 885

18

Page 19

RX : GSM900

1. Set HP8960 or HP8922 : Operating mode : Test mode , Test function :

BCH+TCH

2. Ch 62 : 947.4MHz , cell power : -60dBm

3. Press RX_900(62)

Signal 2

Signal 1

4. RX 900 signal 1 : Use probe to touch U101 pin 8 (freq = 947.4MHz)

5. RX 900 signal 2 : Use probe to touch U101 pin 10 (freq = 947.4MHz)

Signal 3

6. RX 900 signal 3 : Use probe to touch F101 pin 4/6 (freq = 947.4MHz)

19

Page 20

Signal 4

7. RX 900 signal 4 : Use oscilloscope probe to touch RXQP, RXQN, RXIP,

RXIN from U203 pin 2~5 and you can find that ( For Example : The RXIP

signal )

20

Page 21

RX : DCS1800

1. Set HP8960 or HP8922 : Operating mode : Test mode , Test function :

BCH+TCH

2. Ch 699 : 1842.6MHz , cell power : -60dBm

3. Press RX_1800(699)

Signal 2

4. RX 1800 signal 1 : Use probe to touch U101 pin 8 (freq = 1842.6MHz)

5. RX 1800 signal 2 : Use probe to touch U101 pin 1 (freq = 1842.6MHz)

Signal 1

Signal 3

6. RX 1800 signal 3 : Use probe to touch F102 pin 4/6 (freq = 1842.6MHz)

21

Page 22

TX : GSM900

1. Set HP8960 or HP8922 : Operating mode : Test mode , Test function :

BCH+TCH

2. Ch 62 : 902.4MHz , cell power : -60dBm , MS_TX_level : 5

3. Press TX_900(62)

Signal 2

Signal 1

4. TX 900 signal 1 : Use probe to touch U301 pin 23/24 (freq = 1301.4MHz)

5. TX 900 signal 2 : Use probe to touch U301 pin 26/27 (freq = 798MHz)

( If signal 1 and 2 are OK, synthesizer and tranceiver are OK

If there are not then we have to check the inductor (L302 or L301) value

and solder)

22

Page 23

Signal 3

6. TX 900 signal 3 : Use oscilloscope probe to touch R205/6/7/8 pin 4/3 and you

can find that ( For Example : The TXIP signal )

23

Page 24

Signal 4Signal 5

7. TX 900 signal 4 : Use probe to touch R402 pin 2 (frequency 902.4MHz)

8. TX 900 signal 5 : Use probe to touch R402 pin 1 (frequency 902.4MHz)

(If signal 4 and 5 are OK, TXVCO is OK.)

Signal 6

9. TX 900 signal 6 : Use oscilloscope probe to touch R401 and we can find that

24

Page 25

Signal 7

10. TX 900 signal 7 : If 8960 or 8922 could show output power, PA is OK. If

8960 or 8922 show Freq_error, Peak_phase_error, RMS_phase_error are

inside the standard, Tx is OK.

TX : DCS1800

1. Set HP8960 or HP8922 : Operating mode : Test mode , Test function :

BCH+TCH

2. Ch 699 : 1747.6MHz , cell power : -60dBm , MS_TX_level : 0

3. Press TX_1800(699)

Signal 2

Signal 1

4. TX 1800 signal 1 : Use probe to touch U301 pin 23/24 (freq = 1364.6MHz)

5. TX 1800 signal 2 : Use probe to touch U301 pin 26/27 (freq = 766MHz)

( If signal 1 and 2 are OK, synthesizer and tranceiver are OK

25

Page 26

If there are not then we have to check the inductor (L302 or L301) value and

solder)

Signal 3

6. TX 1800 signal 3 : Use oscilloscope probe to touch R205/6/7/8 pin 4 (3) and

the result is similar to the GSM TXIQ.

Signal 4

Signal 5

26

Page 27

7. TX 1800 signal 4 : Use probe to touch R403 pin 2 (frequency 1747.6MHz)

8. TX 1800 signal 5 : Use probe to touch R403 pin 1 (frequency 1747.6MHz)

(If signal 4 and 5 are OK, TXVCO is OK.)

Signal 6

9. TX 1800 signal 6 : Use oscilloscope probe to touch R401 and the diagram is

similar to GSM APC.

10. TX 1800 signal 7 : If 8960 or 8922 could show output power, PA is OK. If

8960 or 8922 show Freq_error, Peak_phase_error, RMS_phase_error are

inside the standard, Tx is OK.

27

Signal 7

Loading...

Loading...