Page 1

Vehicle Adapter

in Spanish

in Portuguese

in French

AAEN1006

AAEN1007

i1000

Professional Radio

Accessories

Page 2

English

Table of Contents i

Table of Contents

Important Safety Instructions.............................................................................................. v

Safe and Efficient Operation of Motorola Two-way Radios................................................ v

Chapter 1

1.0 Introduction......................................................................................................................1-1

2.0 Installation Planning ........................................................................................................1-1

3.0 Microphone Mounting...................................................................................................... 1-2

4.0 Antenna Installation.........................................................................................................1-2

5.0 Vehicle Adapter Installation.............................................................................................1-3

5.1 VA Installation............................................................................................................ 1-3

5.2 VA Cabling................................................................................................................. 1-4

5.3 Battery Connections .................................................................................................. 1-5

5.4 DC Power Cable Installation...................................................................................... 1-5

6.0 Optional Speaker Installation...........................................................................................1-7

7.0 Cables and Connectors...................................................................................................1-9

7.1 Flying Cable End Connections .................................................................................. 1-9

7.2 Microphone Connector ............................................................................................ 1-10

7.3 Computer / Service Connector ................................................................................ 1-10

8.0 Specifications ................................................................................................................1-11

Chapter 2

1.0 Introduction......................................................................................................................2-1

2.0 Installing the Configuration Tool......................................................................................2-1

2.1 Installing Using Windows 3.1..................................................................................... 2-1

2.2 Installing Using Windows 95/98/NT...........................................................................2-2

2.3 Program Set-up ......................................................................................................... 2-2

3.0 Vehicle Adapter Screen...................................................................................................2-3

3.1 File Menu...................................................................................................................2-3

3.2 Options Menu ............................................................................................................ 2-3

3.3 Help Menu and Info ................................................................................................... 2-4

4.0 Configuring the Vehicle Adapter......................................................................................2-4

5.0 Using the Settings Screen...............................................................................................2-4

5.1 Settings Screen Functions......................................................................................... 2-5

6.0 Using the Service Screen................................................................................................ 2-7

6.1 Service Screen Functions.......................................................................................... 2-7

6.2 Battery Information .................................................................................................... 2-7

6.3 Charger simulation / “CHARGE” LED Test................................................................ 2-8

6.4 “RADIO MODE” LED Test.........................................................................................2-9

6.5 PTT, On and Off Buttons...........................................................................................2-9

INSTALLATION

SOFTWARE CONFIGURATION TOOL

Page 3

ii Table of Contents

Chapter 3

1.0 Scope of This Chapter..................................................................................................... 3-1

2.0 Warranty, Service, and Technical Support......................................................................3-1

3.0 Preventive Maintenance..................................................................................................3-2

3.1 Inspection.................................................................................................................. 3-2

3.2 Cleaning Procedures................................................................................................. 3-2

3.3 Diagnostics................................................................................................................ 3-2

4.0 Theory of Operation ........................................................................................................3-3

4.1 Introduction................................................................................................................ 3-3

4.2 Circuit Functional Elements....................................................................................... 3-3

4.3 Power Supply Circuit................................................................................................. 3-3

4.4 Battery Charger Circuit.............................................................................................. 3-5

4.5 Microprocessor Circuit............................................................................................... 3-6

4.6 Speaker Amplifier...................................................................................................... 3-6

4.7 Accessory Interface................................................................................................... 3-7

4.8 RS232 Interface ........................................................................................................ 3-8

4.9 Computer Programming / Service Connector ......................................................... 3-10

4.10 Accessory Interface connection .............................................................................. 3-10

4.11 Antenna Connections.............................................................................................. 3-12

4.12 Spare Connectors ................................................................................................... 3-12

4.13 Spare Battery Spacers ............................................................................................ 3-12

5.0 Test Equipment............................................................................................................. 3-13

6.0 Programming Cable ENKN4002 ...................................................................................3-14

6.1 General Information................................................................................................. 3-14

7.0 Service Cable ENKN4003............................................................................................. 3-15

7.1 General Information................................................................................................. 3-15

8.0 RLN4460 Mobile / Portable Test Set.............................................................................3-16

8.1 Items having No Function with the VA .................................................................... 3-16

8.2 Items having a Different Function with the VA ........................................................ 3-16

8.3 Items having Similar Function with the VA.............................................................. 3-16

9.0 Programming................................................................................................................. 3-17

9.1 Configuration of Vehicle Adapter............................................................................. 3-17

9.2 Programming / Flashing the Portable Radio ........................................................... 3-17

10.0 Schematic Diagrams and Board Overlays ....................................................................3-18

10.1 Safe Handling of CMOS and LDMOS Devices ....................................................... 3-18

1.2 RF Adapter PCB ..................................................................................................... 3-19

1.3 Battery Contact PCB ............................................................................................... 3-20

1.4 Side Connector PCB ............................................................................................... 3-21

1.5 Sub Board PCB....................................................................................................... 3-22

1.6 Main Board PCB...................................................................................................... 3-26

1.7 RS232 Interface PCB.............................................................................................. 3-33

MAINTENANCE

Page 4

List of Figures

Figure 1-1 Microphone Bracket............................................................................................. 1-2

Figure 1-2 Vehicle Adapter Ball Bracket Mounting.............................................................. 1-3

Figure 1-3 Flying Cable Connections.................................................................................... 1-4

Figure 1-4 Vehicle Adapter Connection Diagram................................................................. 1-5

Figure 1-5 Battery Connections into Engine Compartment................................................... 1-6

Figure 1-6 Power Cable Assembly ........................................................................................ 1-7

Figure 1-7 Speaker Installation.............................................................................................. 1-8

Figure 2-1 Initial Opening Screen.......................................................................................... 2-2

Figure 2-2 Interface Selection Screen.................................................................................... 2-3

Figure 2-3 Vehicle Adapter Settings Screen.......................................................................... 2-5

Figure 2-4 Vehicle Adapter Service Screen........................................................................... 2-7

Figure 3-1 Vehicle Adapter Simplified Block Schematic Diagram ...................................... 3-4

Figure 3-2 Power Connector Pin-out Details......................................................................... 3-4

Figure 3-3 Battery Charger Terminals................................................................................... 3-6

Figure 3-4 Speaker Connector Pin-out Details ...................................................................... 3-7

Figure 3-5 Accessory Connector Pin-out Details .................................................................. 3-8

Figure 3-6 RS232 Interface.................................................................................................... 3-8

Figure 3-7 CRMS Circuits................................................................................................... 3-11

Figure 3-8 Option Connector Pin-out Details...................................................................... 3-12

Figure 3-9 Programming Cable ENKN4002 ....................................................................... 3-14

Figure 3-10 Service Cable ENKN4003 ................................................................................. 3-15

English

iii

List of Schematics and Circuit Board Details

RF Adapter - Schematic.......................................................................................................... 3-19

RF Adapter - PCB................................................................................................................... 3-19

Battery Contact - Schematic.................................................................................................... 3-20

Battery Contact - PCB............................................................................................................. 3-20

Side Connector - Schematic.................................................................................................... 3-21

Side Connector - PCB............................................................................................................. 3-21

Sub Board - Top Side.............................................................................................................. 3-22

1.5Sub Board - Bottom Side ................................................................................................... 3-23

Sub Board - Power Supply Schematic (1)............................................................................... 3-24

Sub Board - Charger Schematic (1) ........................................................................................ 3-25

Sub Board - Audio Amplifier Schematic................................................................................ 3-25

Main Board - Top Side............................................................................................................ 3-26

Main Board - Bottom Side...................................................................................................... 3-27

1.6Main Board - Power Supply Schematic (2) ....................................................................... 3-28

Main Board - Charger Schematic (2)...................................................................................... 3-29

Main Board - Microphone Preamplifier Schematic................................................................ 3-30

Main Board - Microprocessor Schematic................................................................................ 3-31

Main Board - RS232 Interface Schematic (1)....................................................................... 3-32

RS232 Interface PCB - Bottom Side.................................................................................... 3-33

RS232 Interface PCB - Top Side ........................................................................................... 3-33

RS232 Interface - Schematic (2)........................................................................................... 3-34

Page 5

iv

List of Tables

Table A Motorola Authorized Batteries.....................................................................................v

Table 1-1 Power Connections.................................................................................................. 1-9

Table 1-2 Speaker Connections............................................................................................... 1-9

Table 1-3 Accessory Connections ........................................................................................... 1-9

Table 1-4 Option Connector .................................................................................................... 1-9

Table 1-6 Computer/Service Connector Pin-outs.................................................................. 1-10

Table 1-5 Microphone Connector Pin-out............................................................................. 1-10

Table 2-1 Programming Cable Mode Selection....................................................................... 2-4

Table 2-2 Battery chemistry and capacity ............................................................................... 2-8

Table 2-3 Simulated Charge Indicator Color........................................................................... 2-8

Table 2-4 Radio Mode LED Colors......................................................................................... 2-9

Table 3-1 Power connections................................................................................................... 3-4

Table 3-2 Battery Terminal Functions..................................................................................... 3-6

Table 3-3 Speaker Connections............................................................................................... 3-7

Table 3-4 Accessory Connections ........................................................................................... 3-8

Table 3-5 Data Port Operating Modes..................................................................................... 3-9

Table 3-6 Computer Service Connector Functions................................................................ 3-10

Table 3-7 Option Connector .................................................................................................. 3-12

Table 3-8 Antenna Connector................................................................................................ 3-12

Table 3-9 Recommended Test Equipment............................................................................. 3-13

Table 3-10Programming Cable Mode Selection..................................................................... 3-14

Page 6

Important Safety Instructions

This document contains important safety and operating instructions. Please read these

instructions carefully and save them for future reference.

Before using the vehicle adapter, read all the instructions and cautionary

markings on (1) the vehicle adapter, (2) the Radio, and (3) the battery fitted to the radio.

Safe and Efficient Operation of Motorola Two-way Radios

Please refer to the user guide for your radio for information and national and international standards and

guidelines on exposure to radio frequency electromagnetic energy.

MOTOROLA AUTHORIZED BATTERIES

The batteries listed in Table A are approved for use with the Motorola Professional Radios and the vehicle

adapter.

Table A Motorola Authorized Batteries

English

v

Kit (part)

Number

HNN9008 NiMH/High-Capacity

HNN9009 NiMH/Ultra-High-Capacity

HNN9010 NiMH/Ultra-High-Capacity, Factory Mutual

HNN9011 NiCd/High-Capacity, Factory Mutual

HNN9012 NiCd/High-Capacity

HNN9013 Lithium Ion

OPERA TIONAL W ARNINGS

1. To reduce risk of injury, use the vehicle adapter only with radios fitted with the authorized

rechargeable Motorola batteries listed in Table A. Other batteries may explode, causing per-

!

WARNING

or injury.

3. To reduce the risk of fire, electric shock, or injury, do not use the adapter if it has been broken or damaged in any way. Take it to a qualified Motorola service representative.

4. Do not place your vehicle adapter and/or portable radio in the area over an air bag or in the air bag

deployment area. Air bags inflate with great force. If a portable radio is placed in the air bag deployment

area and the air bag inflates, the radio may be propelled with great force and cause serious injury to occupants of the vehicle.

• Installation of vehicle communication equipment should be performed by a professional installer technician qualified in the requirements for such installations. An airbag’s size, shape, and deployment area

can vary by vehicle make, model, and front compartment configuration (for example, bench seats vs.

bucket seats).

• Contact the vehicle manufacturer’s corporate headquarters, if necessary, for specific air bag

information for the vehicle make, model and front compartment configuration involved in your

communication equipment installation.

Important Note : If a vehicle adapter is installed, verify operation of the adapter before leaving the

vicinity of the vehicle.

sonal injury and damage.

2. Use of accessories not recommended by Motorola may result in risk of fire, electric shock,

Battery Chemistry/Description

Page 7

vi

5. Do not install your radio in the vehicle adapter or remove your radio from the adapter in a potentially

explosive atmosphere. It is rare, but contact sparking may occur while installing or removing the radio.

Sparks in such areas could cause an explosion or fire, resulting in bodily injury or even death.

Note: Areas with potentially explosive atmospheres include fuelling areas, areas where the air contains

chemicals or particles such as grain dust or metal powders and any area where you would normally be

advised to turn off a vehicle engine. Areas with potentially explosive atmosphere are often, but not always,

posted.

6. Do not install your radio in the vehicle adapter or remove your radio from the adapter in a potentially

explosive atmosphere. It is rare, but contact sparking may occur while installing or removing the radio.

Sparks in such areas could cause an explosion or fire, resulting in bodily injury or even death.

Note: Areas with potentially explosive atmospheres include fuelling areas, areas where the air contains

chemicals or particles such as grain dust or metal powders and any area where you would normally be

advised to turn off a vehicle engine. Areas with potentially explosive atmosphere are often, but not always,

posted.

7. Do not transport or store flammable gas, flammable liquids or explosives in the compartment of your

vehicle that contains your vehicle adapter or accessories.

8. To avoid possible interference with blasting operations, turn your radio off before entering an area

where you may be close to electrical blasting caps , in a “blasting area” or in areas posted “Turn off two-way

radios”. Obey all signs and instructions.

OPERATIONAL CAUTIONS

CAUTION

1. Remove non-standard labels from the radio and battery that are not shipped with the standard product.

Non-standard labels may be peeled off by the action of installing the radio in the vehicle adapter and

may also interfere with proper vehicle adapter operation or may damage the vehicle adapter.

2. Remov e the accessory connector cov er (ref er to the User Guide for your radio) before fitting the radio in

the vehicle adapter. Failure to remove the accessory connector cover may result in permanent damage

to the vehicle adapter.

3. Most modern electronic equipment, typically equipment in ambulances and navigation equipment are

shielded from RF energy. RF energy from your radio may however interfere with some equipment.

Consult your physician, or the manufacturer of any personal medical devices (such as pacemakers,

hearing aids etc.) to determine if they are shielded from external RF energy.

4. Turn your radio OFF in any health care facilities when any regulations posted in these areas instruct you

to do so. Always request permission before using your radio or vehicle adapter near to medical

equipment.

OPERATIONAL SAFETY GUIDELINES

• This equipment is not suitable for outdoor use. Use only in dry locations. Ensure that rain or snow cannot

reach the vehicle adapter through an open vehicle window.

• Replacement fuses fitted in the vehicle adapter installation must comply with the type and rating specified in

the equipment instructions.

• Maximum ambient temperature around the vehicle adapter must not exceed 60°C (140°F).

• Prevent foreign objects or fluids from falling into the vehicle adapter.

Page 8

1.0 Introduction

This Chapter describes the complete installation procedure for the vehicle adapter. The Installation

procedure includes.

■

planning the installation.

■

■

■

mounting the vehicle adapter.

■

■

testing the installation.

Read these instructions carefully before installing the vehicle adapter.

English

1-1

Chapter 1

INSTALLATION

NOTE

The installation must be carried out by an adequately skilled technician .

2.0 Installation Planning

Before starting the installation, plan the location of the vehicle adapter (VA), microphone, and

external speaker (optional). Identify the routing path for the coaxial cable from the VA to the antenna

and verify that the length of coaxial cable is sufficient.

Consider the following guidelines when planning the installation:

■

DO make full use of available bracket mounting holes.

■

■

DO ensure that unit cables are not placed under stress, are not exposed to weather, and are

■

not subjected to damage due to engine heat.

■

DO follow proper supply connections (See Figures 1-5 and 1-6).

■

■

■

DO retain in-line cable fuses when trimming cables to fit. Locate in-line fuses as close as

practical to the supply voltage connection.

■

DO use heat-shrink tubing on all splices.

■

■

■

DON’T attach the units to any part of the vehicle that is not rigid or is subject to excessive

vibration.

■

■

DON’T install units in areas where rain or snow can easily get into them, such as next to a

vehicle window which may be left open.

■

DON’T dress cables over sharp edges that could cause wear or tearing of cable insulation.

■

■

■

DON’T install units in areas where they might interfere with the vehicle operator or the

operating controls.

■

■

DON’T install units where they will be difficult for the operator to reach.

Page 9

1-2 Microphone Mounting

Check the mounting penetrations required. On most v ehicles, it is necessary to penetrate the firewall

to reach the battery. Check the opposite side of the firewall for cable clearance before drilling holes

and protect the cable where it passes through the firewall by using grommets or other similar

protective measures. Survey the firewall for existing holes already occupied by vehicle wire

harnesses. Often there is an opportunity to route other cables using the same path.

Because of the wide variations in vehicle design, these instructions may be modified to suit each

particular installation.

3.0 Microphone Mounting

When possible, mount the microphone bracket on the dash near the operator side of the VA. The

location should be within easy reach of the operator, and it should be convenient to remove and

hang-up the microphone in its mounting bracket without interfering with any of the vehicle controls.

NOTE

The microphone bracket should be mounted on a substantial structure. Otherwise, repeated

insertion and removal of the microphone could loosen it.

Self-tapping Screws

No. 8 x 5/8"

ZWG0130127-A

Referring to Figure 1-1, use the microphone bracket as a template and drill two 3mm holes. Attach

the microphone bracket to the mounting surface with the two self-tapping screws provided. Be sure

to leave sufficient room above the bracket for insertion and removal of the microphone.

CAUTION: Do not attach the microphone bracket to the console housing .

1/8" Dia

Holes

Figure 1-1 Microphone Bracket

ZWG0130127-A

!

4.0 Antenna Installation

Install the antenna and antenna cable as outlined in the installation instructions supplied with the

antenna. Information on frequency matching and mounting details are provided with each antenna.

Page 10

1.

2.

3.

4.

Vehicle Adapter Installation 1-3

5.0 Vehicle Adapter Installation

The VA is mounted on a ball mounting bracket allowing approximately 15° angular movement. The

bracket should ideally be used to mount the VA v ertically on the vehicle dash (alternatively it ma y be

mounted off the vehicle floor).

Hex Socket-head Screw

Tooth Washer

Ball Joint

WasherPressure

English

Ball Joint Mounting

Bracket Foot

With the vehicle adapter on the mounting bracket evaluate the best mounting location. The VA

should be mounted to provide:

■

12 inches of clearance above the VA for inserting the radio.

■

■

Easy access to the controls on the radio for the operator.

■

■

■

A position to allow the microphone coil cable to be used during operation and when on-hook.

5.1 VA Installation

Install the VA by the following procedure or modify the procedure to suit the vehicle type.

Remove the hex socket head screw securing the ball bracket to the VA.

Using the ball bracket as a template, drill the 3 mounting holes and mount the bracket to the

dash using adequate screws.

Mount the VA on the ball bracket using the hex socket-head screw previously removed and

adjust the angle to the required position.

Tighten down the hex socket-head screw to secure the VA.

Figure 1-2 Vehicle Adapter Ball Bracket Mounting

Page 11

1-4 Vehicle Adapter Installation

5.2 VA Cabling

Refer to Figures 1-5 and 1-6, before routing or connecting any VA cabling.

CAUTION: This product is designed for a 12V or 24V DC, negative –ground system.

!

CAUTION: Remove the fuses from the battery supply and the in-line VA fuse holder

before connecting the flying cable.

Determine the best cable route from the VA flying cable to the vehicle battery through the engine

compartment firewall.

The best route should include the shortest path to the battery terminals, yet provide the cable with

protection from engine heat. Cut off any excess cable.

Be sure to use a grommet or similar protective measure wherever a cable must pass through a hole

in a metal panel, such as a firewall.

Route the power cables in a way that protects them from being pinched, chafed, or crushed. Cable

fuses (in addition to the 4A fuse fitted at the VA flying cable that protects the VA) must be retained

and located as close to the battery as practical to protect against cable or equipment shorts.

Antenna Connector

(BNC)

Figure 1-3 Flying Cable Connections

Option

(3 Terminals)

DC Power

(2 Terminals)

Ext Speaker

(2 Terminals)

Accessory

(4 Terminals)

ZWG0130116-A

Page 12

1.

2.

Vehicle Adapter Installation 1-5

Vehicle

Vehicle

Chassis

Vehicle

Battery

Adapter

10A Fuse

(Blade Type)

Grommet

V ehicle

Antenna

DC Power

VA Fuse

Antenna BNC

Palm

Microphone

English

Accessory

Car Radio Mute

CRMS

Aux. 12V and Ground

Ext. Speaker (Optional)

Figure 1-4 Vehicle Adapter Connection Diagram

Option

Ext. Speaker

5.3 Battery Connections

For extending the power connection from the VA flying cable terminals to the vehicle battery use

either the DC power cable GKN6270 or produce a similar cable with adequate fuse holder (including

10A fuse). Crimp the 6.25mm female automotive blade contacts (part of delivery) to the red and

black DC wires (after the DC connector is removed), push the contacts into the mating plastic

housing and connect them to the flying cable.

5.4 DC Power Cable Installation

The VA must be operated only in negative ground electrical systems. Re verse polarity will cause the

cable fuse to blow. Chec k the vehicle ground polarity before you begin installation to prevent w asted

time and effort.

Computer Cable

To PC

(Optional)

ZWG0130115-A

The 10-foot DC power cable is long enough for installation in most vehicles. Begin the power cable

installation as follows:

Determine a routing plan for the power cable with ref erence to where the V A is to be mounted.

Locate an existing hole with a grommet in the vehicle fire w all, or drill a 10 mm access hole at

the location for passing the power cable into the engine compartment. Install a grommet with

5 mm inner diameter in the access hole to avoid damage to the cable.

Page 13

3.

4.

5.

6.

7.

8.

9.

1-6 Vehicle Adapter Installation

TO RADIO

BLACK LEAD

FIREWALL

!

RED LEAD

ENGINE COMPARTMENT

GROMMET

ZWG0130124-0

Figure 1-5 Battery Connections into Engine Compartment

CAUTION: A high degree of care must be exercised to prevent damage to any existing

vehicle wires.

From inside the vehicle, feed the red and black leads (without lugs attached) through the

access hole and into the engine compartment (see Figure 1-5).

Locate the nearest available vehicle chassis ground mounting point and shorten the black

lead to remove excess cable length.

Install ring lugs (supplied) onto the stripped end of the power cable black lead, and onto the

stripped end of the red lead.

Locate the fuse holder as close to the battery as possible and away from any hot engine

component. Mount the fuse holder via the mounting hole and dress wires as necessary.

Connect the fuse holder red adaptor lead plug to the mating receptacle on the red lead of the

power cable (see Figure 1-6).

Connect the power cable black lead directly to the vehicle chassis ground.

Connect the power cable red lead from the fuse holder to the positive (+) battery terminal.

Make sure the adaptor cable is connected to the main power cable red lead.

Plug the fuse into the in-line fuse holder (See Figure 1-6).

NOTE

Failure to mount the red lead of the power cable kit directly to the battery may result in

severe alternator whine interference .

Page 14

Optional Speaker Installation 1-7

Fuse

Red Lead

Cover

Adapter

Red Lead

Firewall

In-line

Fuse Holder

Red Lead

Mounting

Hole

English

Black Lead

Figure 1-6 Power Cable Assembly

NOTE

If the black lead is connected to the battery negative (-) terminal an additional 10A fuse must

be fitted in the lead.

6.0 Optional Speaker Installation

Select a location for the speaker that will be neither dangerous to the operator nor damaging to the

speaker. The speaker is normally hung under the dash near the right side of the console; however,

the speaker may be mounted against a wall or other vertical surface, if desired.

A location close to the operator, such as on a door pillar, will minimize VA volume adjustments that

might otherwise be needed when ambient noise conditions worsen (such as when a siren is used).

This location is also favorable during low-volume security patrol, when message traffic should not

pre-announce the location of the VA operator.

Vehicle Chassis

Battery +ve

Ground

ZWG0130129-0

!

CAUTION: Grounding either of the speaker lines may permanently damage the speaker

amplifier in the vehicle adapter.

Page 15

1-8 Optional Speaker Installation

Install the speaker as follows:

1. Remove the speaker from the trunnion bracket by loosening the two wing screws.

Using the trunnion bracket as a template, mark the locations of the three mounting holes.

Center punch and drill a 4 mm hole at each location.

4. Mount the trunnion bracket with the screws supplied (Figure 1-7).

5. Insert the speaker into the trunnion bracket and tighten the two wing screws.

6. Insert the external speaker accessory plug into the accessory connector of radio.

Bracket

Trunnion

2.

3.

Dashboard

Firewall

Figure 1-7 Speaker Installation

or

ZWG0130130-0

Page 16

Cables and Connectors 1-9

7.0 Cables and Connectors

7.1 Flying Cable End Connections

The ends to the flying cable are suitable for connection to automotive blade connectors. The

connections are shown in the Tables below.

7.1.1 Power Connections (0.25 in. automotive blades, male)

Table 1-1 Power Connections

English

Terminal Description Wire color

DC Ground Batt. - black

Supply Batt. + red

7.1.2 Speaker Connections (0.25 in. automotive blades, female)

Table 1-2 Speaker Connections

Terminal Description Wire color

1 Speaker + output brown

2 Speaker - output blue

7.1.3 Accessory Connections (0.112 in. automotive blades, female)

Table 1-3 Accessory Connections

Terminal Description Wire color

1 Microphone hot black

2 Microphone ground transparent

3 Hook orange

Connector Front View

(2) Speaker (-)

(1) Speaker (+)

Connector Front View

PTT input (4)

HUB input (3)

Connector Front View

DC Ground

+ ve Supply

(1) Microphone

(2) AF Ground

4 External PTT violet

7.1.4 Option Connector (0.112 in. automotive blades, female)

Table 1-4 Option Connector

Terminal Description Wire color

1 12Vdc switched red

2 DC ground grey

3 CRMS output blue

(3) CRMS o/p

(2) DC Ground

(1) 12V o/p

Connector Front View

Page 17

1-10 Cables and Connectors

7.2 Microphone Connector

10-pole modular connector.

Table 1-5 Microphone Connector Pin-out

Pin Description

0 Not Connected

1 Battery +ve

2 Speaker -ve

3 Hook

4 Ground

5 Microphone Audio

6 PTT

7 Not Connected

8 Speaker +ve

9 Not Connected

7.3 Computer / Service Connector

9-pole “D” type socket with female jacks.

Table 1-6 Computer/Service Connector Pin-outs

Pin Description

1 External microphone input

2 RX data input

3 TX data input

4 Ground

5 12V DC switched output

6 RX Audio

7 Service select input

8 Boot control

9 MAP27 (not available)

Page 18

Specifications 1-11

8.0 Specifications

Part Numbers:

EN1006 Vehicle Adapter VHF (136-174 MHz)

EN1007 Vehicle Adapter UHF (403-470 MHz)

All units are supplied with RF Switch Adapter and palm microphone

Input voltage: 10.8Vdc to 31.2Vdc negative earth

(typical 12V or 24V car battery range)

In-line Fuse 7.8 x 1.95 in. in-line fuse holder

4A quick-blow fuse

Temperature -22°F to +140°F (operational)

range: -13°F to +131°F (to specification)

-40°F to +176°F (storage)

Dimensions: H 9.75 in.; W 3.9 in.; D 3.315 in. (without por table radio)

(approximate) (H includes anti-kink device but without the 60cm cable tail)

(D includes mounting facility).

English

Weight: 800g (without portable radio).

(approximate)

Speaker 5 Watts maximum at 4 Ohms

Page 19

1-12 Specifications

Page 20

1.0 Introduction

Vehicle Adapter Product Manual/Configuration Tool ENLN4114 may be used to:

■

■

Configure the vehicle adapter.

■

■

Check the status of the battery fitted to the radio in the vehicle adapter.

■

■

Check the operation of the vehicle adapter battery charger.

■

■

Test the operation of the two indicator LEDs on the vehicle adapter.

The configuration tool must first be installed on the PC and the PC then connected to the vehicle

adapter using the Programming Cable ENKN4002.

English

2-1

Chapter 2

SOFTWARE CONFIGURATION TOOL

2.0 Installing the Configuration Tool

2.1 Installing Using Windows 3.1

If you are using a PC with windows 3.1 installed, the minimum hardware specification required is:

■

■

486 CPU operating at 50MHz.

■

■

8Mb of RAM.

■

■

1Mb of available Hard Disk space.

■

■

Microsoft Windows 3.1 or above.

■

■

One free serial port.

2.1.1 Installation

Install the Vehicle Adapter Configuration Tool as follows:

1. Insert the software diskette into drive A.

2. Create a directory on your hard disk with an appropriate name.

3. Copy the files from the distribution disk into this new directory.

4. From within Windows Program Manager, choose ‘File,’ ‘New,’ then ‘Program Group.’

5. Enter a suitable name in the ‘Description:’ box and then click OK.

6. Open the new group by choosing ‘File,’ ‘New,’ then ‘Program Item.’

7. Click the ‘Browse’ button and when the ‘Browse’ window opens, navigate to the directory

created in Step 2.

8. Click on the

9. Double clicking on the Vehicle Adapter Icon will start the Configuration Tool.

‘waris.ex e’

file and then click OK.

Page 21

2-2 Installing the Configuration Tool

2.2 Installing Using Windows 95/98/NT

If you are using a PC with windows 95/98/NT4.0 installed, the minimum hardware specification

required is:

■

■

486 CPU operating at 50MHz.

■

■

8Mb of RAM.

■

■

1Mb of available Hard Disk space.

■

■

Microsoft Windows 95/98/NT4.0 or above.

■

■

One free serial port.

2.2.1 Installation

1. Insert the software diskette into drive A.

2. Create a directory on your hard disk with an appropriate name.

3. Copy the files from the distribution disk into this new directory.

4. Create a Shortcut to the ‘waris.exe’ file and copy it to the Desktop.

5. Double clicking on the Vehicle Adapter Icon on the Desktop will start the Configuration Tool.

2.3 Program Set-up

When the program is first run the opening Vehicle Adapter screen is displayed as shown in

Figure 2-1 below:

Figure 2-1 Initial Opening Screen

Set up the Configuration Tool to your requirements as follows:

1. Click on the button for the language you require the program to open with in future.

2. Click the ‘Save language’ button.

Page 22

Vehicle Adapter Screen 2-3

English

NOTE

The language selection box will not appear again on the opening screen. If you require to

choose a different language select ‘Language’ from the ‘Options’ menu.

3. Select ‘Interface’ from the ‘Options’ menu and from the ‘Interface’ screen (Figure 2-2) click on

the serial port (COM 1 to 4) you wish to use.

4. Click on the ‘Close’ button.

Figure 2-2 Interface Selection Screen

3.0 Vehicle Adapter Screen

The menu options on the Vehicle Adapter screen are shown below:

3.1 File Menu

New : Opens a new ‘Settings’ screen, the fields will contain the default VA settings.

Open: Opens the ‘File Open’ dialogue box allowing you to navigate and open a previously

saved settings file.

Read V A: Reads the settings parameters programmed into the vehicle adapter and displays them

in the ‘Settings’ screen.

Save: Re-saves the current settings to the currently open file.

Save as: Opens the ‘File Save’ dialogue box allowing you to name the file you are about to save

and navigate to the preferred save location.

Close: Closes the current window without exiting the application.

Exit: Exits the application.

3.2 Options Menu

Interface: Opens the ‘Interface’ screen (Figure 2-2) click on the serial port (COM 1 to 4) you wish

to use. Clicking the 'Close' button saves the setting.

Service: Opens the ‘Service’ screen (Figure 2-4) described later.

Language: Opens the language box (Figure 2-1). Select the language you require the program to

open with in future and then click the ‘Save language’ button.

Page 23

2-4 Configuring the Vehicle Adapter

3.3 Help Menu and Info

The ‘Help’ option displays a single page of help describing the use of the functions within the

‘Settings’ screen. The ‘Info’ option displays the Version Number and a copyright statement for the

Vehicle Adapter configuration tool.

4.0 Configuring the Vehicle Adapter

The vehicle adapter is configured via the Programming Cable ENKN4002 (Ref er to the Maintenance

chapter of this manual for details of this cable). The cable incorporates a switch which allows the

mode of testing or programming to be selected. The modes are shown in Table 2-1 below:

To configure the vehicle adapter proceed as follows:

1. Connect the vehicle adapter to the computer with the Programming Cable ENKN4002.

2. Select the ‘Vehicle Adapter Configuration and Service’ position (Position 1) on the MODE

:

switch.

Table 2-1 Programming Cable Mode Selection

Switch

Position

1 Vehicle Adapter Configuration

2 Radio Flash

3 Radio Service

4 MAP 27 (not available)

3. On the Vehicle Adapter screen, select the ‘File’ menu.

4. From the ‘File’ menu select ‘Read VA,’ ‘New’ or ‘Open’ to open the ‘Settings’ screen

(Figure 2-3).

5.0 Using the Settings Screen

The ‘Settings’ screen permits the configuration of the vehicle adapter to be carried out to customer

requirements.

The ‘Car Radio Mute Signal’ and an external speaker (optional) can be enabled and the function of

the microphone hook switches can be configured as required. The Car Radio Mute Signal delay and

the microphone gain can be set.

The ‘Settings’ screen functions are described below and shown in Figure 2-3:

Mode

Page 24

Using the Settings Screen 2-5

5.1 Settings Screen Functions

Use the functions of the ‘Settings’ as follows:

Write V A: Writes the settings displayed on the ‘Settings’ screen into the vehicle adapter.

Default: Returns all the parameters in the ‘Settings’ screen to the factory defaults shown in

Figure 2-3.

Close: Closes the ‘Settings’ screen without exiting the application.

English

Figure 2-3 Vehicle Adapter Settings Screen

NOTE

Figure 2-3 shows the default values for the ‘Settings’ screen.

Function Select Box

Car Radio Mute Signal enable (CRMS)

The vehicle adapter contains a function that will mute a broadcast receiver or entertainment system

fitted into the vehicle. When enabled the mute function operates when:

1. The portable radio squelch is open.

2. The radio PTT is activated by the vehicle adapter.

3. A microphone connected to the vehicle adapter is OFF HOOK (optional).

Checking the ‘Car Radio Mute Signal enable’ box enables the CRMS function with one of the

following:

Off Hook Enable

Checking the ‘Off Hook Enable’ box adds the OFF HOOK function to the CRMS function.

NOTE

When selected one of the hook switches must also be selected to allow the function

to work.

Page 25

2-6 Using the Settings Screen

Hook for VA microphone

Checking the ‘Hook for VA microphone’ box adds the hook switch of the microphone plugged

into the base of the vehicle adapter, into the CRMS function.

Hook for Accessory microphone

Checking the ‘Hook for Accessory microphone’ box adds the hook switch of the microphone

connected to the accessory connector, located at the end of the VA flying cable, into the

CRMS function.

External speaker enable

The vehicle adapter can be fitted with an optional external speaker. To enable the external speaker

check the ‘External speaker enable’ box.

Car Radio Mute Signal delay [sec]

When the CRMS function is active it is desirable to continue muting for a short time after the

enabling signals have gone . This is achie v ed b y introducing a delay after the mute signal is removed.

The delay should be long enough to permit a user to respond to a received message or to start a

new call. Also in areas of poor signal strength, where the squelch may be repeatedly opening and

closing, the delay holds the mute on.

The delay may be set to between 1 and 10 seconds in steps of 1 second.

Check the button corresponding to the delay required.

Microphone gain

The microphone gain can be adjusted over a wide range to allow for different types of microphone,

acoustic environments and user requirements. The gain may be set in 6dB steps from -18db to

+24dB.

Check the button corresponding to the gain required.

Page 26

Using the Service Screen 2-7

6.0 Using the Service Screen

The ‘Service’ screen permits the battery status to be checked and the vehicle adapter charging

circuits to be dynamically tested. The operation of the vehicle adapter LEDs may also be checked.

The Service screen is shown in Figure 2-4 below with typical values displayed.

To display the ‘Service’ screen, select the ‘Options’ menu from the Vehicle Adapter Screen

(Figure 2-2) then select the ‘Service’ function from the ‘Options’ menu to open the ‘Service’ screen

(Figure 2-4).

English

Figure 2-4 Vehicle Adapter Service Screen

6.1 Service Screen Functions

Use the functions of the Service screen as follows:

6.2 Battery Information

When the Radio with battery attached is inserted into the vehicle adapter, information held in the

battery memory is displayed on the Service Screen to check on the battery status.

The information displayed is that held in the v ehicle adapter memory at the time the ‘Service’ screen

is enabled. If the battery in the vehicle adapter is changed the ‘Service’ screen must be closed and

re-enabled to display the updated information.

Type

Displays the battery chemistry, either Ni for Nickel Cadmium and Nickel Metal Hydride or Li for

Lithium Ion.

Page 27

2-8 Using the Service Screen

Capacity

Displays battery capacity as shown in Figure 2-3 below:

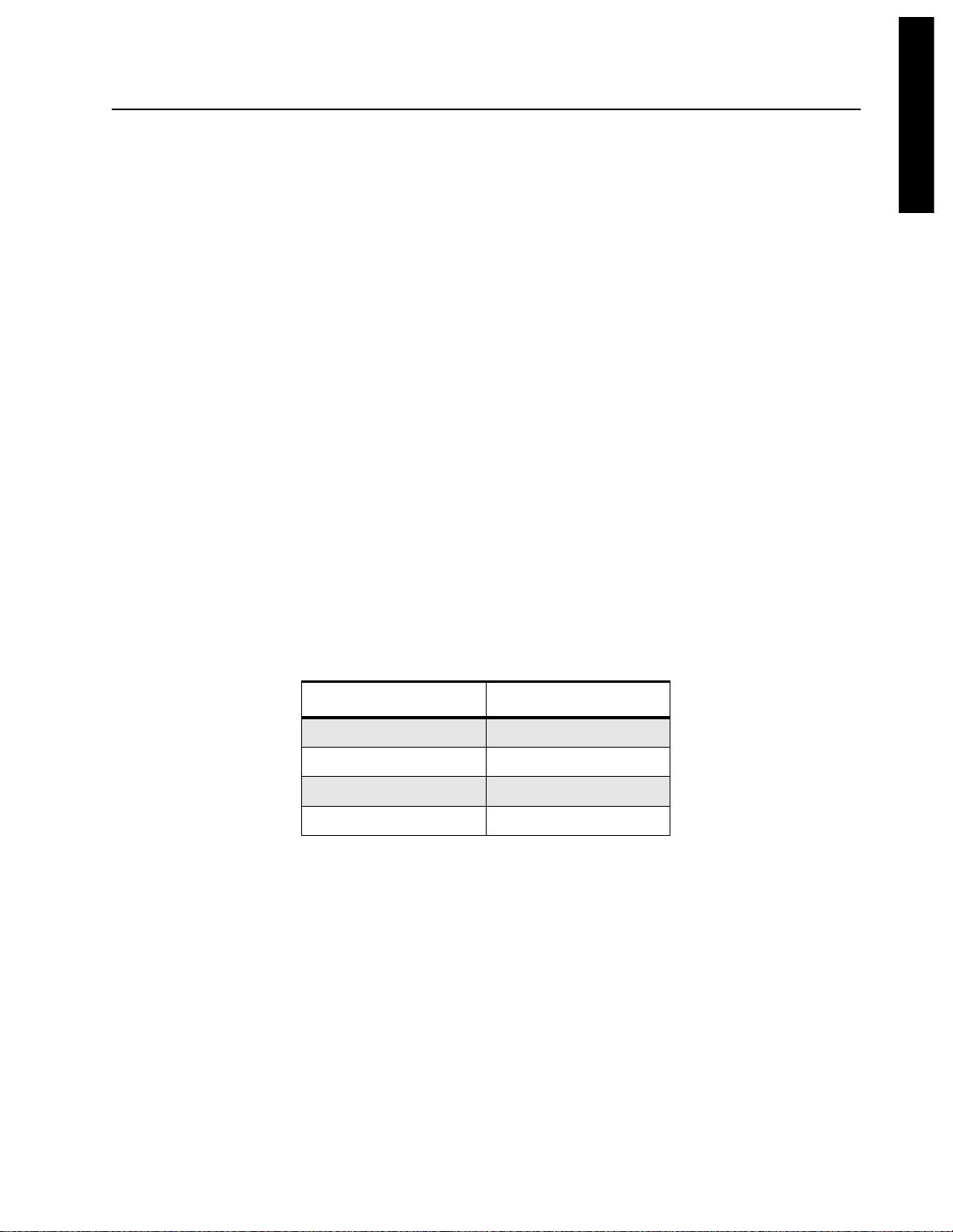

Table 2-2 Battery chemistry and capacity

Kit (part) Number Battery Chemistry / Description Display

HNN9008 Nickel Metal Hydride - High Capacity high

HNN9009 Nickel Metal Hydride - Ultra High Capacity ultra-high

HNN9010 Nickel Metal Hydride - Ultra High Capacity FM ultra-high

HNN9011 Nickel Cadmium - High Capacity FM high

HNN9012 Nickel Cadmium - High Capacity high

HNN9013 Lithium Ion standard

Firmware version

Displays the firmware version of the VA.

Charger currents

Displays the charge currents for the battery type fitted to the radio in the vehicle adapter. The values

are the actual current values stored in the battery memory and it is these values that are used to test

the performance of the vehicle adapter charging circuit.

6.3 Charger simulation / “CHARGE” LED Test

The currents displayed here should match the currents displayed in the 'Info' screen described

above.

The small rectangle in the top right hand corner of the ‘Charger simulation / “CHARGE” LED Test’

box should be the same color as the “CHARGE” status LED on the vehicle adapter for the charge

mode selected.

Fast, Top Off, Maint and Off Buttons

Clicking one of these buttons will terminate normal charging and set the battery charge current to

the appropriate value for the battery type fitted into the vehicle adapter and the simulated charge

selected. Both the “CHARGE” status LED on the VA and the colored rectangle on the screen should

indicate the color stated in the table below.

Table 2-3 Simulated Charge Indicator Color

Simulated Charge Button Charge Color

Fast Red

TopOff Yellow

Maintenance (Trickle) Green

Off None

Page 28

Using the Service Screen 2-9

Charge current, Battery voltage and Battery temperature Boxes

These three boxes display the actual measured parameters from the vehicle adapter.

The measured ‘Charge current’ should correspond closely to that stated in the ‘Info’ box for the

current charge state thus demonstrating the correct capability of the charger circuit.

The ‘Battery voltage’ indicated should be between 6 and 10 volts. Values below 6 volts indicate a

completely discharged or faulty battery. Completely discharging a battery will adversely affect its

cycle life, and so should be avoided. Values of battery voltage above 10.5 volts indicate a faulty

battery.

To update the information in these boxes click on the ‘Read status’ button.

Read status

Clicking on this button updates the information in the ‘Charge current,’ ‘Battery voltage’ and ‘Battery

temperature’ boxes.

6.4 “RADIO MODE” LED Test

The small rectangle in the top right hand corner of the “RADIO MODE” LED Test box should be the

same color as the “RADIO MODE” status LED on the vehicle adapter for the radio mode selected.

English

6.5 PTT, On and Off Buttons

Clicking one of these buttons will set both the “RADIO MODE” LED on the vehicle adapter and the

colored rectangle on the screen to the ‘Mode Color’ stated in Table 2-4 below.

Table 2-4 Radio Mode LED Colors

Radio Mode Button Mode Color

PTT Red

MAP 27 (Not available)

On Green

Off None

Page 29

2-10 Using the Service Screen

Page 30

1.0 Scope of This Chapter

This chapter is intended for use by service technicians familiar with similar types of equipment. It

contains service information required for the equipment described and is current as of the printing

date. Changes which occur after the printing date may be incorporated by a complete Manual

revision or alternatively as additions.

English

3-1

Chapter 3

MAINTENANCE

NOTE

Before operating or testing the vehicle adapter, please read the Safety Information Section

in the front of this manual.

The chapter provides details about the following:

■

■

Preventive maintenance (inspection and cleaning).

■

■

Service and Diagnostic Information.

■

■

Test Equipment and Service tools.

■

■

Programming and Configuration Information.

■

■

Safe handling of CMOS and LDMOS devices.

2.0 Warranty, Service, and Technical Support

Other than cleaning all metal contacts and pins and dusting the unit with a clean, dry cloth, any

maintenance, troubleshooting, service, or repair of the vehicle adapter should be perf ormed only by

an authorized Motorola service provider. During the warranty period, contact the Accessories and

Aftermarket Division (AAD) at 1-800-422-4210 for warranty return authorizations. After the warranty

period, contact the Motorola Radio Support Center at 1-800-227-6772 for limited repair information.

For technical assistance with this product, please contact Product Services at 1-800-927-2744

prompt 3 followed by prompt 1.

Page 31

3-2 Preventive Maintenance

3.0 Preventive Maintenance

The vehicle adapter does not require a scheduled preventive maintenance program; however,

periodic visual inspection and cleaning is recommended.

3.1 Inspection

■

■

Check that the external surfaces of the vehicle adapter are clean.

■

■

Check that all metal contacts are clean and that the connectors are undamaged with no bent

or missing pins.

■

■

Check that the locking button mechanism oper ates correctly with one press to lock the radio in

place and a second press to release the radio.

■

■

It is recommended that the interior electronic circuitry is NOT inspected on a routine basis.

3.2 Cleaning Procedures

The following procedures describe the recommended cleaning agents and the methods to be used

when cleaning the external surfaces of the vehicle adapter. These surfaces should be cleaned

whenever a periodic visual inspection reveals the presence of smudges, grease, and/or grime.

NOTE

CAUTION: The effects of certain chemicals and their vapors can have harmful results on

certain plastics. Avoid using aerosol sprays, tuner cleaners, and other chemicals.

!

NOTE

Internal surfaces should be cleaned only when the vehicle adapter is disassembled for

service or repair.

The only recommended agent for cleaning the external vehicle adapter surfaces is a 0.5% solution

of a mild dishwashing detergent in water.

Cleaning External Plastic Surfaces

Apply the 0.5% detergent-water solution sparingly with a stiff, non-metallic, short-bristled brush to

work all loose dirt away from the vehicle adaptor. Use a soft, absorbent, lintless cloth or tissue to

remove the solution and dry the vehicle adaptor. Make sure that no water remains entrapped near

the connectors, cracks, or crevices.

Cleaning of connectors and contacts

Clean all connector pin and battery charge contact surfaces of the vehicle adapter, the ring contact

surfaces of the antenna adapter and the side connector contact surfaces of the portable radio.

Always use a fresh supply of alcohol and a clean container to prevent contamination by

dissolved material (from previous usage).

3.3 Diagnostics

Some basic functional tests can be performed by the use of the “Service” screen in the configur ation

tool. These tests will help with diagnostics of the battery and the charging circuits. Refer to

Chapter 2 for details of the Software Configuration Tool.

Page 32

Theory of Operation 3-3

4.0 Theory of Operation

4.1 Introduction

The following paragraphs provide a description of the various functional blocks for the vehicle

adapter. These functional bloc ks may have the corresponding components or block sections located

on one or more boards.

The vehicle adapter consists of the following five boards:

■

■

the processor main board,

■

■

the PSU / charger/ speaker amplifier board,

■

■

the side connector board,

■

■

the battery contact board and,

■

■

the sub-D (RS232 Interface) board.

4.2 Circuit Functional Elements

English

The key functional elements of the vehicle adapter are:

1. Power supply circuit - consisting of input filtering and reverse / overvoltage protection, a

DC/DC converter for the battery charge circuit, a DC/DC converter providing auxiliary

switched 12Vdc (maximum 250mA) for optional accessories, a 5V regulator and the power

down circuitry.

2. Battery charger circuit - consisting of a regulated current source and the analog to digital

converter.

3. Microprocessor circuit - with all the necessary peripheral circuitry.

4. External speaker amplifier - providing the required amplification of the portable radio audio

into 5 watts at 4 Ohms.

5. Microphone circuits - providing adequate amplification or attenuation for the selected

microphone.

6. RS232 interface - allowing the connection of a PC to the vehicle adapter for various

operating modes.

4.3 Power Supply Circuit

The power supply has input filtering and provides protection against reverse polarity and over

voltage supply input. In case of reverse polarity or over v oltage the input fuse will b lo w and separ ate

the vehicle adapter from the power source.

The DC/DC converter for the battery charge circuit operates in “step down” mode and provides a

regulated supply for the linear current source stage. For input voltages below 13Vdc the con v erter is

bridged to allow full charging current for the fast charge mode.

An additional DC/DC converter provides a regulated 12Vdc (max. 250mA) supply for optional

accessories without their own power source.

Page 33

3-4 Theory of Operation

LED

Battery

Charger

Circuit

RADIO

LED

CHARGE

Side ConnectorBattery Contacts

Microprocessor

Circuit

RS232

Interface

Computer

Connector

Option Select

Interface

Microphone

Circuits

Microphone

Connector

VEHICLE ADAPTER

Power Supply

Circuit

Speaker

Amplifier

Circuit

FLYING CABLE

Options

Accessory

Power

Speaker

Figure 3-1 Vehicle Adapter Simplified Block Schematic Diagram

The 5V regulator is driven from the regulated 12Vdc and supplies the integrated circuits like the

microprocessor, analog switches and most of the operational amplifiers.

The power down circuit detects a voltage drop below 5Vdc and causes the microprocessor to reset

and perform a controlled start-up.

4.3.1 Power Connections

The power connections are shown in Table 3-1 below, the connector pin-outs are shown in

Figure 3-2.

Terminal Description Function

DC Ground Battery -ve Ground

Supply Battery +ve 4A fused supply from vehicle battery

Vehicle Connector Front View

Table 3-1 Power connections

DC Ground

+ ve Supply

Figure 3-2 Power Connector Pin-out Details

Page 34

Theory of Operation 3-5

4.4 Battery Charger Circuit

The battery charger circuit uses the stabilized voltage from the output of the “step down” DC/DC

converter to deliver a constant charge current to the battery of the radio. This constant charge

current is generated by a linear transistor stage within a control loop f ormed by series current sense

resistors, current amplifier and comparator also fed with a reference signal.

This reference signal provides the necessary input from the charging program in the microprocessor

setting the current required via a digital to analogue converter.

4.4.1 Charging routine

When the portable radio, with a battery attached, is inserted into the vehicle adapter the

microprocessor reads the EPROM in the battery and commences automatically with the appropriate

charging routine required for that type of battery.

While the microprocessor circuits are reading the EPROM the “BATTERY” LED flashes green.

If a relatively discharged battery (within the environmental limits for fast charge) has been inserted

into the vehicle adapter , the charger circuit r amps up the charge current from approximately 0.1A to

1.2A within the first 3 minutes.

English

This fast charge continues for Ni-type batteries until one of the various criteria for fast charge

termination causes the charge status to change.

Under normal conditions, the Top Off charge phase follows the Fast charge phase when the battery

has reached approximately 90% of it’s rated capacity. The Top Off charge delivers a much lower

current (approximately 200mA) for 2 hours.

Finally, after having fully charged the battery , the charger will begin the Maintenance charge phase,

providing only the current (below 100mA) required to maintain the battery in a fully charged

condition.

Compared to the Ni-type batteries the Li-type battery sees a different charging routine after ramp up

from approximately 0.1A to 0.9A. The current is stepped down continuously to maintain the battery

voltage below the maximum limit, until the charging stabilizes at the Maintenance current.

In daily use, where the battery temperature or voltage may be outside permitted limits, the battery

charger will automatically make decisions on the way to proceed to maintain the best battery charge

conditions without damage to the battery. In practice therefore the Fast charge, Top Off charge,

Maintenance charge sequence may not proceed in that order if damage to the battery is a risk.

The charger circuits operate as a fully separate function from the portable radio functionality and are

not controlled by the radio controls.

Page 35

3-6 Theory of Operation

4.4.2 Battery Charging Contacts

The battery charger connections are shown in Table 3-2 and Figure 3-3 below:

Table 3-2 Battery Terminal Functions

Pin # Assignment Description

1 +ve positive terminal for charging voltage

(internally protected via diode)

2 TC temperature sense resistor (thermistor)

3 EPROM EPROM access (this port defines the

type and status of the selected battery)

4 -ve negative terminal for charging voltage

and functional ground

Figure 3-3 Battery Charger Terminals

4.5 Microprocessor Circuit

The microprocessor controls the battery charging routines and all communication from and to the

portable radio and the attached battery. It also supports the inputs and outputs for the associated

accessories and switches according to the vehicle adapter firmware configuration program.

4.6 Speaker Amplifier

The speaker audio amplifier consists of an LM4752 integrated circuit connected for operation in

bridge-mode. This IC is directly supplied from the DC power source without routing through the

DC/DC converter. This supply is switched by FETs controlled by the switched B+ from the portable

radio, thus reducing the high quiescent current of the IC during idle mode of the vehicle adapter.

Battery Rear View

4 3 2 1

The two phase outputs of the portable radio speaker audio, SPKR+ and SPKR-, are atten uated and

routed to the two input ports of this audio amplifier IC. The amplifier provides a maximum of 5 watts

audio into a 4 ohm speaker. The audio level is adjusted via the portable radio volume control.

During transmit mode the inputs to the audio amplifier are muted via audio gates.

NOTE

Grounding either of the speaker lines may permanently damage the speaker amplifier in the

vehicle adapter.

Page 36

Theory of Operation 3-7

4.6.1 Speaker Connections

The speaker connections are shown in Table 3-3 and Figure 3-4 below:

Table 3-3 Speaker Connections

Terminal Description Function

1 Speaker + Output 5watt 4ohm speaker

2 Speaker - Output 5watt 4ohm speaker

(2) Speaker (-)

(1) Speaker (+)

Vehicle Connector Front View

Figure 3-4 Speaker Connector Pin-out Details

English

4.7 Accessory Interface

4.7.1 Microphone Circuit

The microphone amplifier/buffer stage adds the two different microphone inputs. One is routed from

the palm microphone via the TELCO connector on the bottom of the vehicle adapter, the other is

routed from the accessory connector at the end of the flying cable. The buffer stage matches the

normal mobile microphone level of 80mV to the portable microphone level of 8mV.

4.7.2 Microphone Level

The microphone sensitivity can be adjusted in steps of 6dB within the range -18dB to +24dB. The

adjustment may be performed with the aid of the configuration software running on an external PC

connected via programming cable ENKN4002 to the vehicle adapter 9 pin type “D” connector.

Page 37

3-8 Theory of Operation

4.7.3 Accessory Connections

The Accessory connections are shown in Table 3-4 and Figure 3-5 below:

Table 3-4 Accessory Connections

Terminal Description Function

1 External microphone input 80mV Mic audio i/p

2 AF Ground Ground

3 Hang up Box input Ground to de-activate

4 External PTT input Ground to activate

4.8 RS232 Interface

The RS232 interface consists of a MAX232 integrated circuit followed by switching gates providing

the selection of the data port operating modes for Service, MAP27 (not available) and Boot. It also

provides the buffer for the TXdata and the driver for the RXdata from the portable radio. An

additional reed relay switch bridges the two ports TXdata and RXdata from the portable radio, to

simulate a standard RIB single line connection as shown in Figure 3-6 below.

PTT input (4)

HUB input (3)

Vehicle Connector Front View

(1) Microphone

(2) AF Ground

Figure 3-5 Accessory Connector Pin-out Details

Figure 3-6 RS232 Interface

RS 232 int er fa c eData l i nes to r adio

Page 38

Theory of Operation 3-9

4.8.1 Option Select Interface

The Option Select inputs to the portable radio are automatically controlled by the VA microprocessor

according to the radio operating mode required.

4.8.2 Data Port Operating Modes

The computer interface is switched between the available operating modes according to Table 3-5

below. The Option Select inputs to the radio are automatically set to those appropriate for the

selected operating mode.

Table 3-5 Data Port Operating Modes

English

Functionality

Normal operation - Data lines isolated - Option

select set to either Normal Operation, External

Speaker or External PTT as appropriate

*MAP27 mode - Data lines to radio Option select set to *MAP27 Enable

VA Service mode - Data lines to µP Option select set to Normal Operation

Radio Service mode - Data lines from RS232

interface to radio, but TX and RX lines

connected together, as in diagram below Option select set to Normal Operation

Radio Flash mode - Data lines from RS232

interface to radio, but TX and RX lines

connected together, as in Figure 3-6.

Option select set to Normal Operation

*NOTE: MAP27 is not available.

Service

Select

Pin 7

1 1 1

1 0 1

0 1 1

0 0 1

X X 0

*MAP27

Select

Pin 9

Boot

Control

Pin 8

Page 39

3-10 Theory of Operation

4.9 Computer Programming / Service Connector

The Computer programming / Service connector provides connections between the vehicle adapter

and a PC via the Programming cable ENKN4002. The connector functions are shown in Table 3-6.

Table 3-6 Computer Service Connector Functions

Pin Description Function

1 External Mic input 80mV Mic audio i/p

2 Rx data input RS232 Rx data

3 Tx data input RS232 Tx data

4 Ground Screens and DC ground

5 12V switched output 250mA max

6 RX audio AF Screened

7 Service select input Ground to activate

8 Boot Control Ground to activate

9 *MAP27 select input Ground to activate

*NOTE: MAP27 is not available.

See Table 3-5 for the functionality of pins 7, 8, and 9.

4.10 Accessory Interface connection

The accessory interface connector provides two functions; the Car Radio Mute Signal (CRMS) and

an auxiliary 12V supply.

4.10.1 Car Radio Mute Signal (CRMS)

The CRMS function provides a suitable signal to operate an external relay that can mute an

entertainment system mounted in the vehicle.

The CRMS output switches to ground when the vehicle entertainment system is required to be

muted. It has a maximum sink current of 1 Amp and is reverse polarity protected to

60 Vdc.

Consult the manual for the entertainment system to see if a direct mute function is available that

works from a ground signal.

Page 40

Theory of Operation 3-11

If the entertainment system has this functionality it may be possible to connect the CRMS output of

the VA directly to the mute input of the entertainment system.

If no such facility is available or it does not function from a ground signal an external relay interface

must be used.

+ve

Vehicle

Supply

Relay to suite

Vehicle supply

To Speaker A +ve

From Speaker o/p A +ve

To Speaker B +ve

From Speaker o/p B +ve

Speaker A -ve

Speaker B -ve

English

The CRMS function is activated when the receiver squelch is opened, the microphone PTT is

pressed or the microphone is taken off hook. It is possible to remove either the palm microphone

hook or the hook switch for the external microphone from this function. The selection can be

performed with the aid of the configuration software running on an external PC connected via the

programming cable ENKN4002 to the vehicle adapter 9pin type “D” connector.

A variable deactivating delay of between 1 and 10 seconds will prevent unintended reactivation of

the vehicle entertainment system.

4.10.2 Auxiliary 12v supply

The Auxiliary regulated 12V DC supply (maximum 250 mA) provides a supply to power accessories

without their own power source.

VA CRMS

Output

2 Resistors to suite

output circuit of vehicle

Systementertainment

Figure 3-7 CRMS Circuits

Page 41

3-12 Theory of Operation

Table 3-7 Option Connector

Terminal Description Function

1 12V switched output 250mA max

2 DC ground Ground

3 CRMS output 1A to ground max when

active

(3) CRMS o/p

(2) DC Ground

(1) 12V o/p

Connector Front View

Figure 3-8 Option Connector Pin-out Details

4.11 Antenna Connections

The antenna connection to the vehicle adapter is via a BNC connector , crimp plug with a strain relief

sleeve. The connections are shown in Table 3-8 below.

Pin Description Cable Type

1 Tx / Rx Antenna RF Core (RF screened cable)

2 Screen Screen (RF screened

4.12 Spare Connectors

A kit of replacement vehicle adapter connector parts is available from Motorola for the Power

connector, the VA options connector, the VA Accessory connector and the Speaker connectors. The

kit number is ENLN4117.

4.13 Spare Battery Spacers

A kit of replacement battery spacer parts is available from Motorola. The kit number is WALN4078.

Table 3-8 Antenna Connector

cable)

Page 42

Test Equipment 3-13

5.0 Test Equipment

Table 3-9 lists test equipment recommended to test the service the vehicle adapter with the portable

radio.

Table 3-9 Recommended T est Equipment

English

Motorola Part

No.

R2600CNT Comms System

R2680ANT Comms System

*R1072 Digital Multimeter AC/DC voltage and current

*R-1377A A C Voltmeter 100 µV to 300 V,

WADN4133A Delay

R1440A

0180305F14

0180305F30

0180305F39

RLN4610A

T1013

Description Characteristics Application

Analyzer (non

MPT)

Analyzer

(MPT1327) to be

ordered with

RLN1022A (H/W)

RLN1023A (S/W)

Oscilloscope

Wattmeter,

Plug-in Elements

Plug-in Elements

Plug-in Elements

Carry case

RF Dummy Load

This monitor will

substitute for items with

an asterisk *

This monitor will

substitute for items with

an asterisk *

5Hz-1MHz, 10 Megohm

input impedance

2 Channel 40 MHz

bandwidth,

5 mV/cm - 20 V/cm

Thruline 50-Ohm, ±5%

accuracy

10W, 25 - 60 MHz

10W, 100 - 250 MHz

10W, 200 - 500 MHz

Wattmeter and

6 elements

Frequency/deviation meter and

signal generator for wide-range

troubleshooting and alignment

Frequency/deviation meter and

signal generator for wide-range

troubleshooting and alignment

measurements

Audio voltage

measurements

Waveform measurements

Transmitter power output

measurements

S1339 RF Millivolt Meter 100mV to 3 VRF,

10 kHz to 1.2 GHz

RLN4460 Mobile/Portable

Test Set

ENKN4002 Programming

Cable

ENKN4003 Service Cable Interface cable for audio and DC

ENLN4114 Vehicle Adapter

Product Manual/

Configuration Tool

RF level measurements

Audio and DC testing

Interface cable for VA configuration

and portable radio programming and

flashing

testing in conjunction with RLN4460

Setting parameters in the vehicle

adapter

Page 43

3-14 Programming Cable ENKN4002

6.0 Programming Cable ENKN4002

6.1 General Information

The ENKN4002 Programming Cable connects the vehicle adapter to a personal computer for radio

programming, radio flashing, MAP27 (Not Available) testing or vehicle adapter configuration.

J1 To Personal

Computer

1

2

3

4

5

6

7

8

9

S1a

1

2

3

4

1

2

S1b

4

P1 To

Vehicle Adapter

3

1

RX Data

2

TX Data

3

Ground

4

5

6

Service Select

7

Boot Control

8

MAP27 Select (Not Available)

9

ZWG0130135-B

Figure 3-9 Programming Cable ENKN4002

The switch within the cable assembly is used to configure the cable to the appropriate functionality

as shown in Table 3-10 below:

:

Table 3-10 Programming Cable Mode Selection

Switch

Position

Mode

1 Vehicle Adapter Configuration

2 Radio Flash

3 Radio Service