Page 1

A3100 Troubleshooting

A3100 Troubleshooting

Guide

Guide

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 2

Agenda

A. Cannot Power On

B. SIM Card Not Found

C. Display Abnormal

D. No Keypad Backlight

E. No LCM Backlight

F. Flash Light No Function

G. Light Sensor No Function

H. Cannot Charge

I. Keypad No Function

J. Touch No Function

K. Jog Ball No Function

N. ActiveSync No Function

O. Earphone Malfunction

P. Microphone Malfunction

Q. Receiver No Key Tone

R. Speaker No Function

S. RTC failed

T. Can’t Take Picture

U. Phone Hang Up

V. Auto Power On

W. Auto Power Off

X. Cannot Call Out

L. Can’t Access MicroSD Card

M. Vibrator Out of Control

Service Engineeing & Optimization

Level 3 , Rev.1.0

Y. WIFI Can’t Turn On and Test

Z. BT Can’t Turn On and Test

Page 3

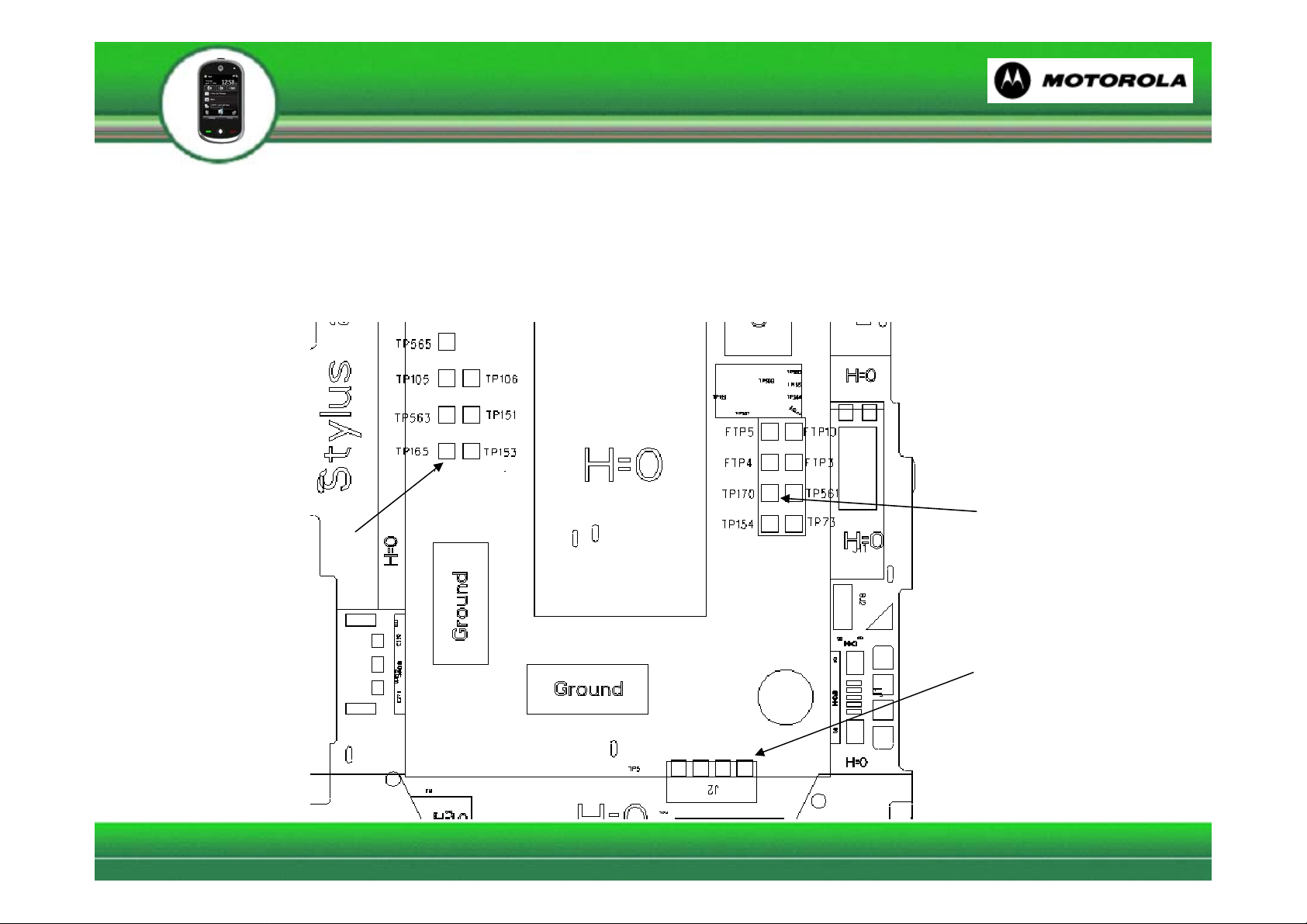

Can’t Power On (1)

1. Check the voltage of the Battery

Vbat (TP170) > 3.8V

2. Check the battery connector J2

Vbat (TP170)

N_KB_PWR_KE

Y

Service Engineeing & Optimization

Level 3 , Rev.1.0

Vbat (J2)

Page 4

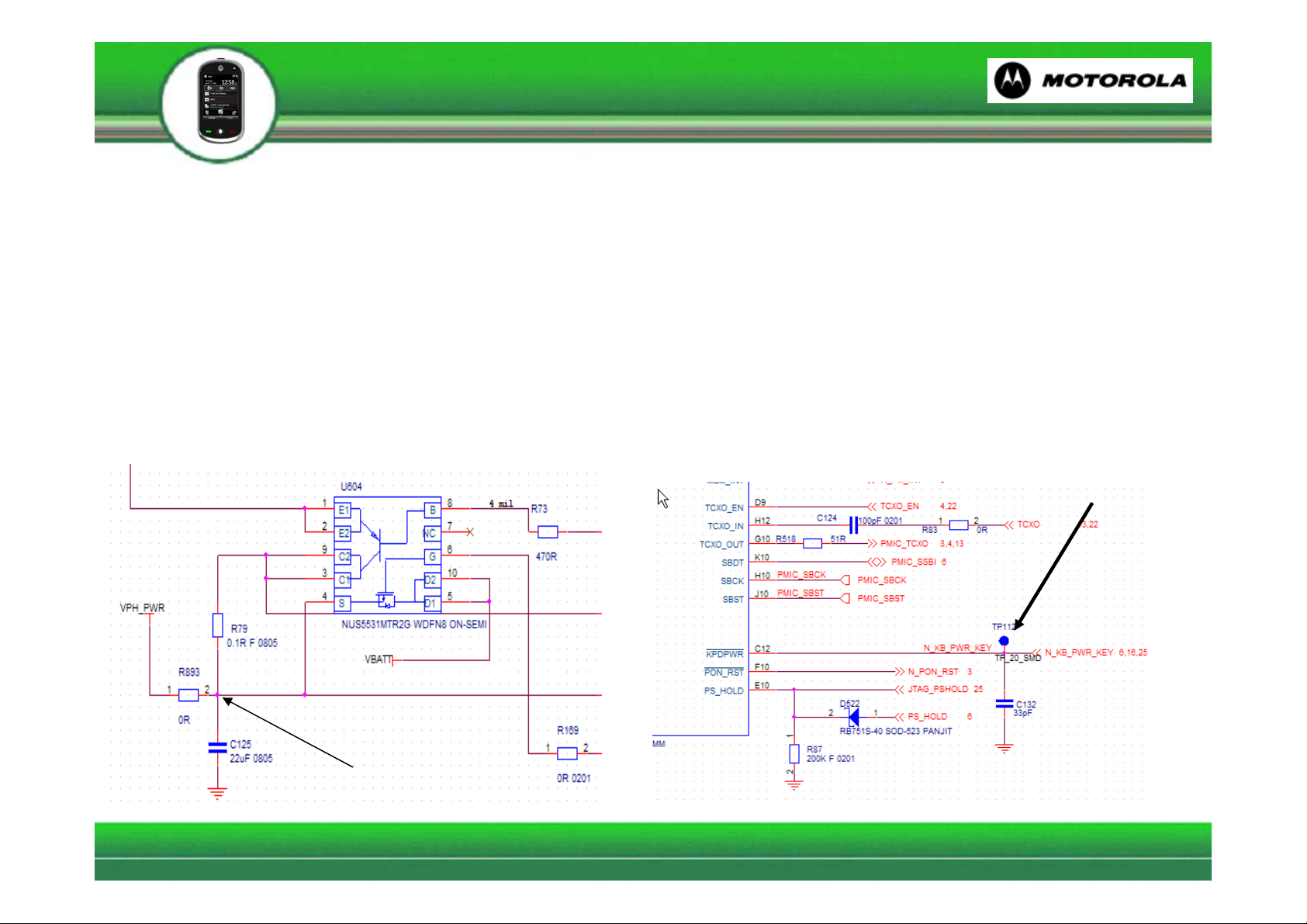

Can’t Power On (2)

3.Check the voltage of R79

R79 > 3.4V

4. Check the power-on key path

N_KB_PWR_KEY (TP165) > 2.6V

If N_KB_PWR_KEY is low, the unit will power on.

> 2.4 V

> 3.4 V

Service Engineeing & Optimization

Level 3 , Rev.1.0

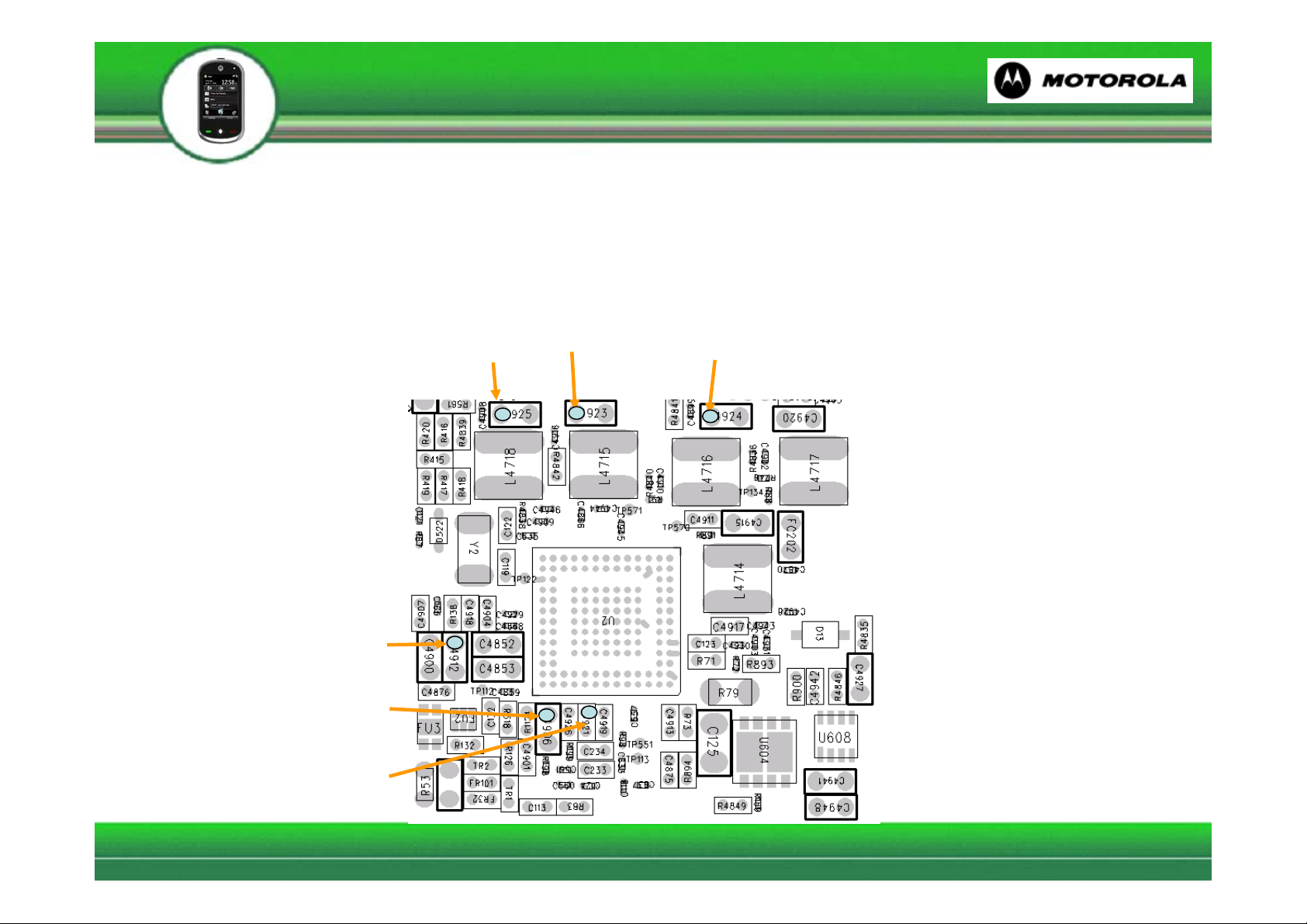

Page 5

Can’t Power On (3)

5. Check PM7540(U2) regulator voltage

A. VREG_MSMC1_1.2V on C4923

B. VREG_MSMC2_1.2V on C4924

C. VREG_MSME_1.8V on C4925

C

E

A

D.VREG_MSME2_2.8V on C4921

E. VREG_MSMP_2.6V on C4912

F. VREG_MSMA_2.6V on C4906

B

F

D

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 6

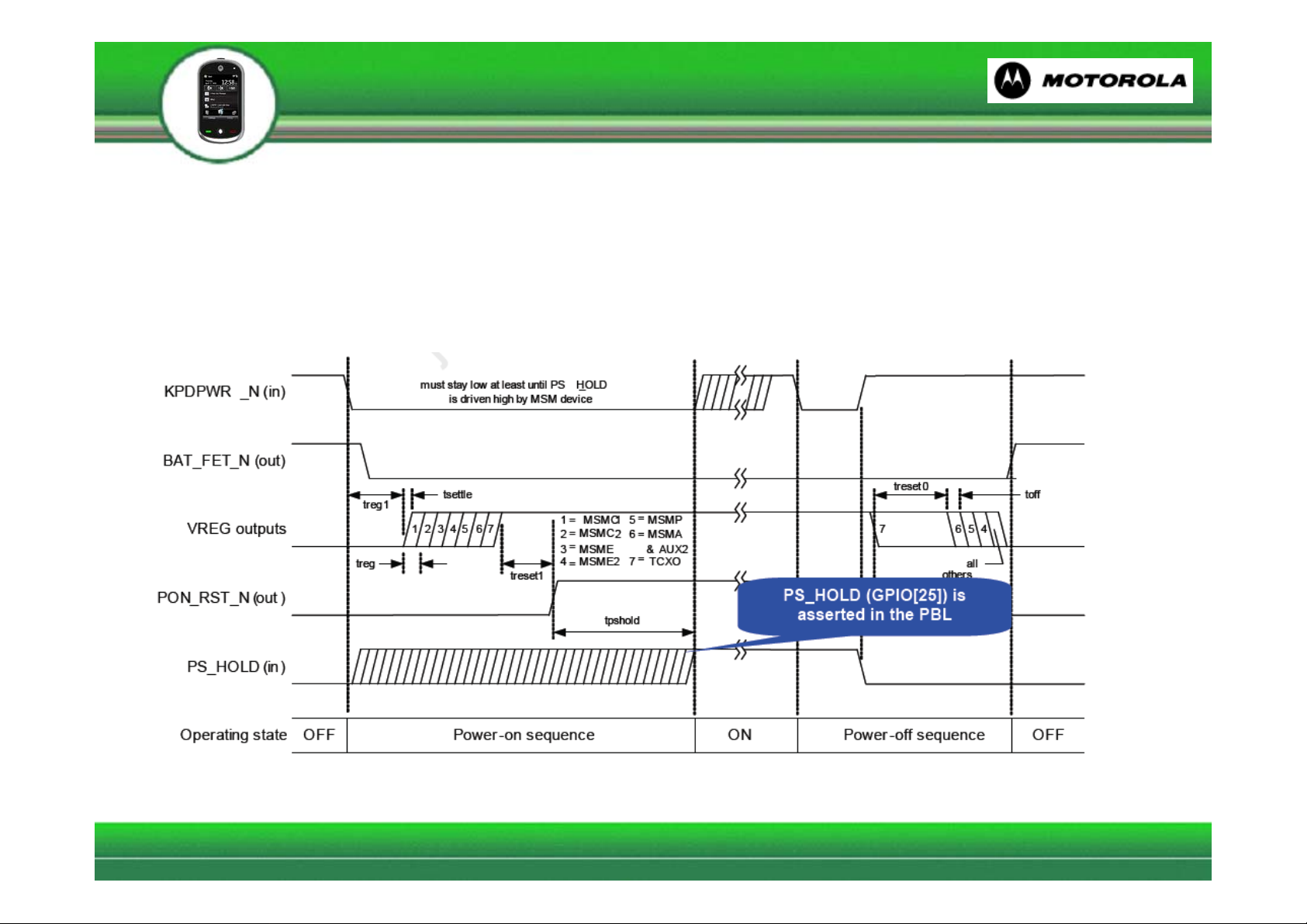

Can’t Power On (4)

6. Check Power On Sequence

After the voltage rails are brought up, PON_RST_N is asserted by

PM7540 IC, and then the MSM7200A IC asserts PS_HOLD signal.

– PS_HOLD should be high after power on (on D522)

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 7

Can’t Power On (5)

7. Try to check the external DDR and Nand Flash

1. External DDR check _ Check the External DDR by ram test tool

Pass=> The External DDR is workable

Fail => a) MSM7201A can find the memory

b) U3 is damaged

2. Flash check _ Dump the image from the damaged unit

Pass=> The External flash is workable

Fail => a) MSM7201A can find the flash

b) U3 is damaged

8. Redownload the SW

Try to redownload the SW if the main code image is damaged

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 8

SIM Card Not Found

1. Do the clean boot (Mater Clear)

2. Exam whether the contact between SIM and connector is ok

3. Check the Signal of SIM interface (VCC, RST ,and Clock)

USIM ,VCC =1.8V ; SIM= 1.8V / 2.85V

USIM SLOT

4. If the signal is abnormal ,please check U2.

VREG_UIM1

R249

10K 0201

UIM1_P_DATA12

21

R247

0R 0201

UIM1_P_RESET12

UIM1_P_CLK12

2 1

UIM1_DATA

C239

33pF 0201

2 1

2 1

33pF 0201

R245

0R 0201

R246

0R 0201

C296

VREG_UIM1

UIM1_RESET

UIM1_CLK

1

2

3

4

5

6

C297

33pF 0201

C288 1uF

J17

217-02000-04 6PIN 2.1H ACT

VCC

RST

CLK

GND

NC

I/O

Fix

Fix

Fix

Fix

Fix7Fix

C289 33pF

12

11

10

9

8

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 9

• White screen:

• Check LCM damage or not

• Check EMI filter (U4721) SMT

• Check panel voltage VDD 2.8V(C4921_1) & VDDIO 2.6V(C4918_1)

Display Abnormal

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 10

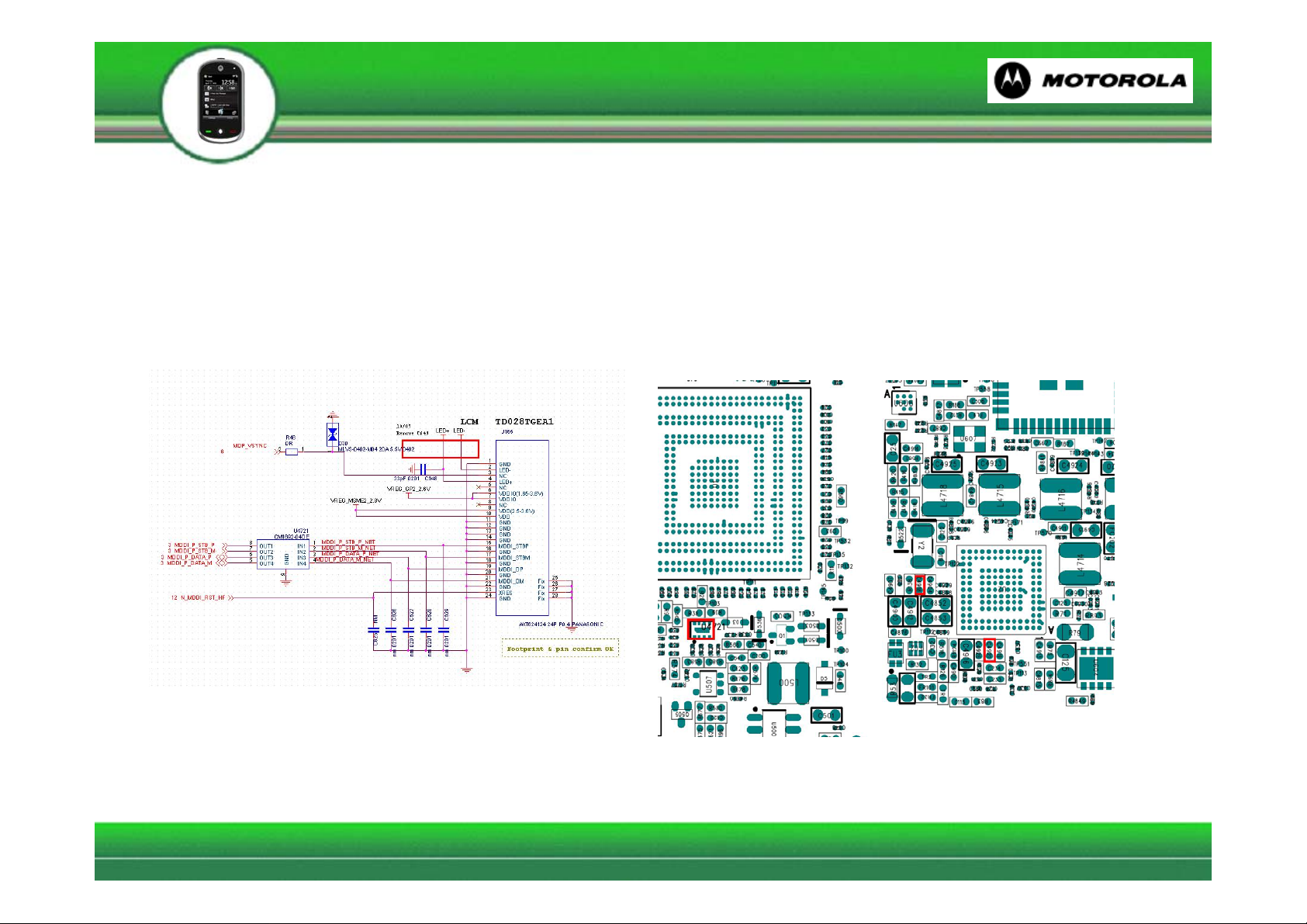

No Keypad Light

• Check keypad LED voltage VREG_5V(C259 pin2)

• Check LED damage or not

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 11

No LCM backlight

• No backlight:

1. LCM backlight damage

2. Measure R54 voltage: 15V

3. Backlight enable GPIO(Q1_2) pulled high 2.6V

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 12

Flash Light No Function

• Can’t turn on flash light:

1. Check flash LED (D523) SMT and damage or not

2. Check D523_pin1 voltage: 5V

3. R425_1 & R426_1 & R427_1 pulled to low when turn on flash

led.

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 13

Light Sensor No Function

– Check U39_2 voltage: 2.8V

– Check R685_1 signal pulled to low

– Measuring Vout voltage (U39_4) was change or not when light sensor

putting on different Lux environment.

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 14

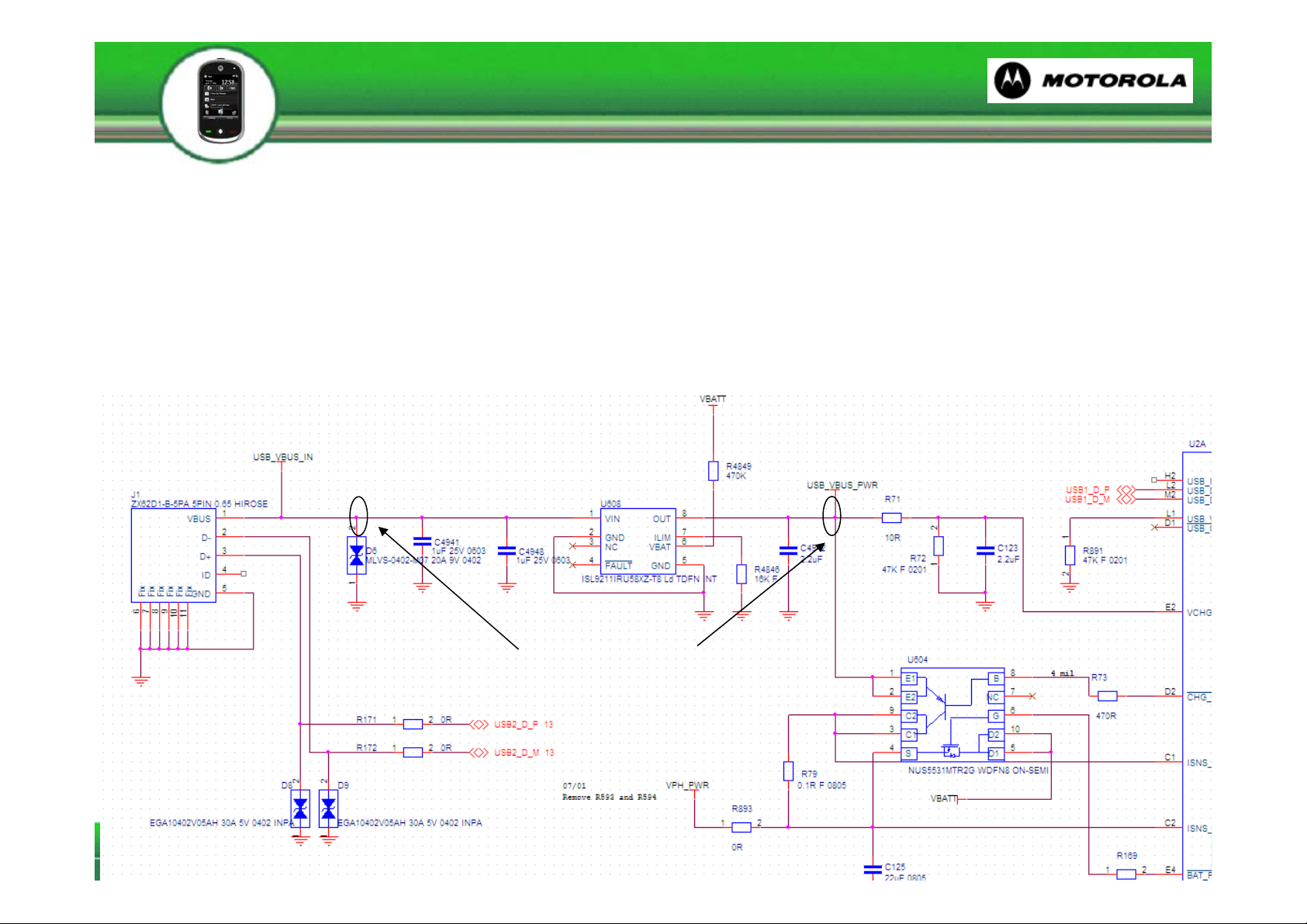

Cannot Charge (1)

1. Check the battery and the charger ; Only support BT-60 battery

2. Dial #06# to check the Charging status and the charging type

Power Source should be USB or Charger

Battery ID : Readable

If Power source is “No external power”, please check the charging path

Service Engineeing & Optimization

Level 3 , Rev.1.0

VBUS > 4.7V

Page 15

Cannot Charge (2)

• If Battery ID is not the readable , please check whether battery is

BT60 and contact to PIN3 OF J2

•

BATT_THERMAL_GAUGING

VREG_HKADC_2.85V

R93

J2

BATT+

DATA

THERM

BATT-

476150001 4P P2 MOLEX

4

3

2

1

n.m.

40mil

R147

100R

R92

VBATT

BATT_DATA_1

BATT_THERM 4

BATTERY CONNECTOR

BGND

Service Engineeing & Optimization

Level 3 , Rev.1.0

C197

39pF

n.m.

C198

39pF

Page 16

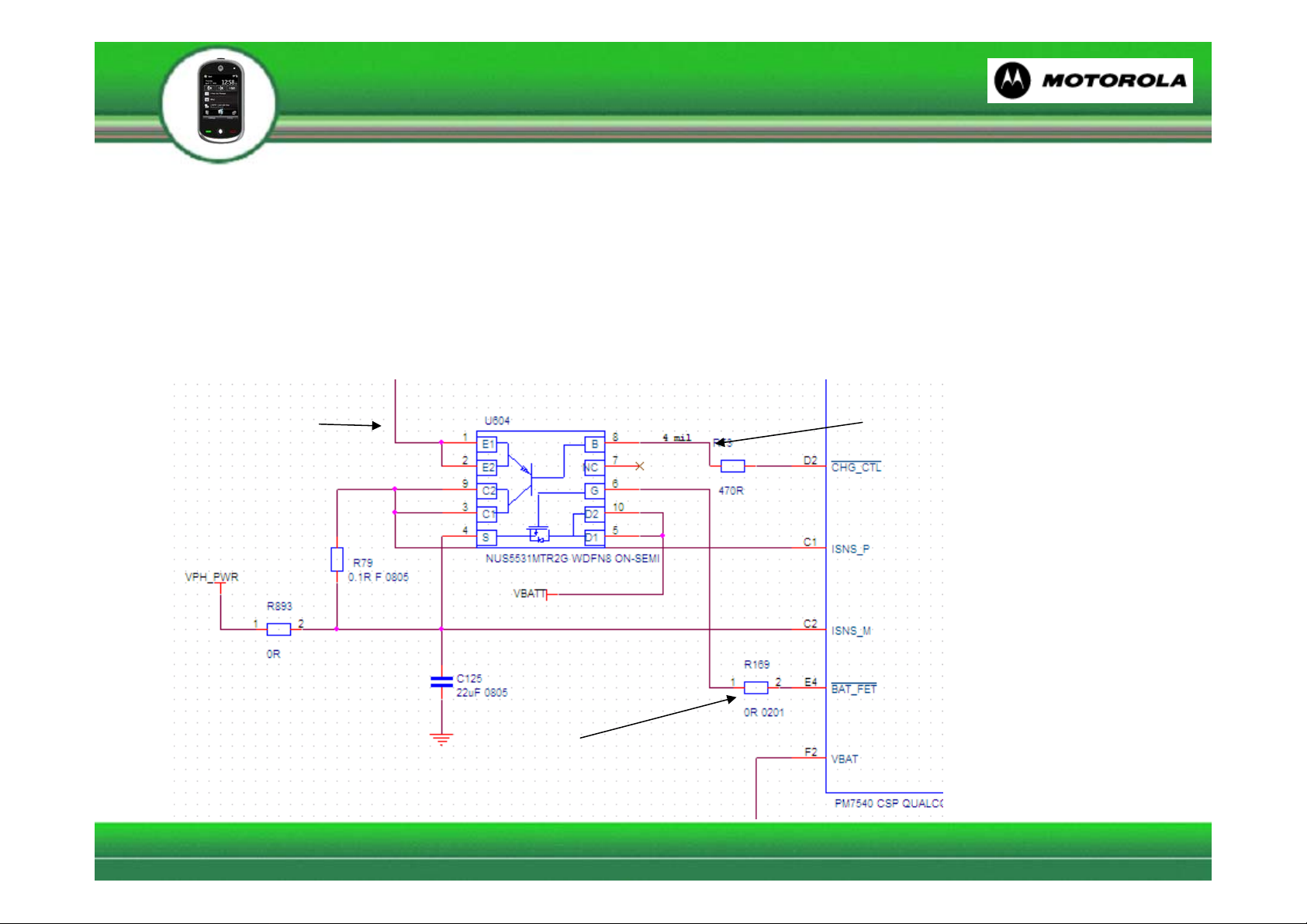

Cannot Charge (3)

3. Dial #77704# to check the gas gauge Status

AC Line : On (Has detect the charger)

Flag : Charging (The charger driver is active)

The current is minus, please check U604 circuit.

5V

Should be < 2V in charging

Service Engineeing & Optimization

Should be < 4.3V in charging

Level 3 , Rev.1.0

Page 17

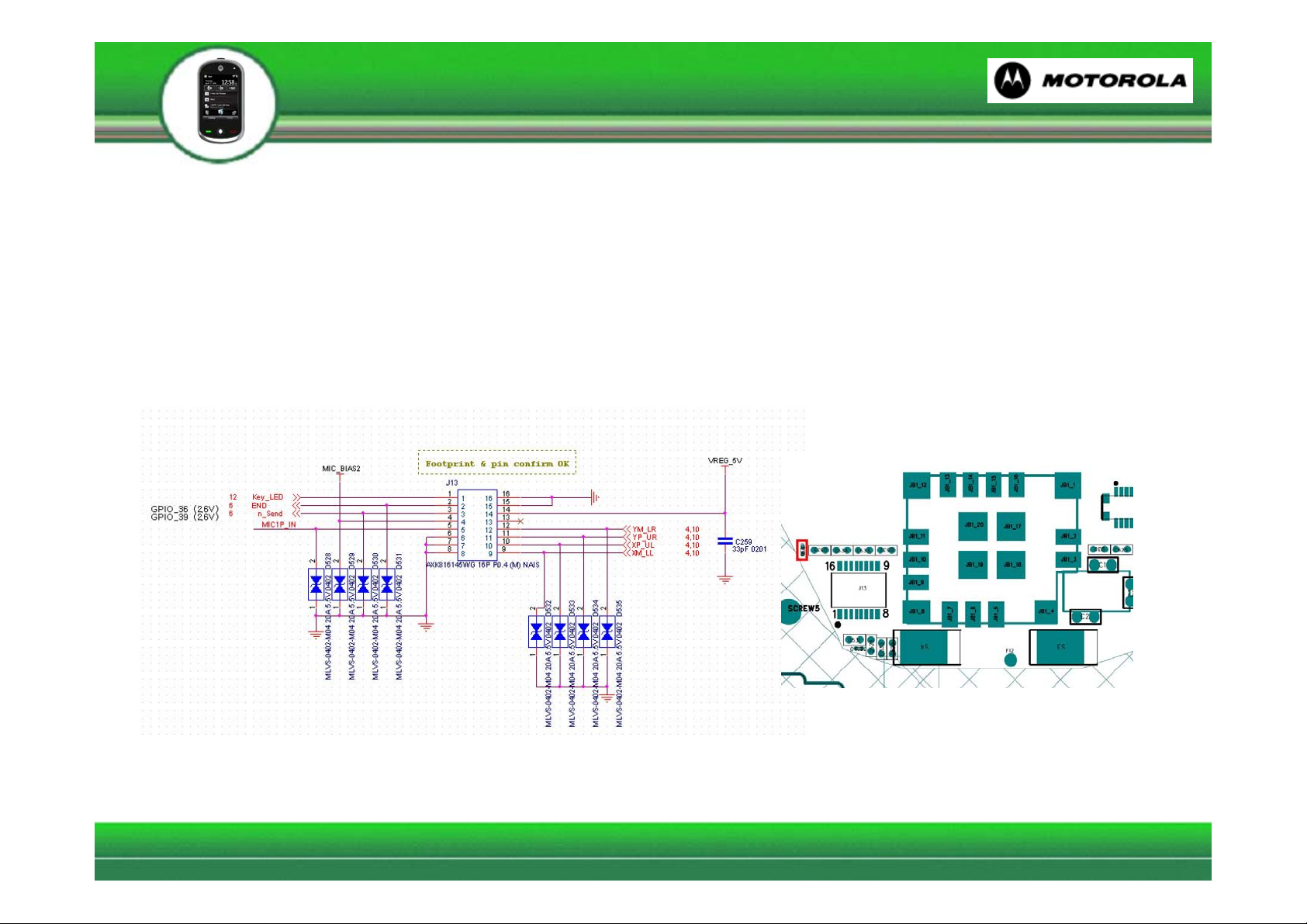

Keypad No Function

1. Check S/B connector J13

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 18

Touch No Function

– Check TP damage or not

– Check assembly between main PCB and sub PCB

– Check J13 SMT

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 19

Jog Ball No Function

• 1. Check the magnet is at the correct position

• 2. Check the voltage (JB1-10 =2.85V)

• 3. Check the related circuit

Jog Left

Jog Up

Jog Right

U17

3

NC1

2

GND

1

NC

AN48840B

U18

3

NC1

2

GND

1

NC

AN48840B

U19

3

NC1

2

GND

1

NC

AN48840B

OUT

VCC

OUT

VCC

OUT

VCC

5

4

5

4

5

4

JOG_2.85V

C322 33pF 0201

Jog_RIGHT 6

GPIO_40 (2.6V)

D25

RCLAMP0521P

1 2

Jog_DOWN 6

GPIO_38 (2.6V)

D26

RCLAMP0521P

1 2

Jog_LEFT 6

GPIO_49 (2.6V)

D27

RCLAMP0521P

1 2

2.85V

Jog Down

Service Engineeing & Optimization

Level 3 , Rev.1.0

Magnet

Location

U20

3

NC1

2

GND

1

NC

AN48840B

OUT

VCC

5

4

C321

33pF 0201

Jog_UP 6

GPIO_90 (2.6V)

D28

RCLAMP0521P

1 2

Page 20

Can’t access the Micro SD Card

• If the T-Flash card can not be detected, check if the pin12 of J16 is

low. If not, check if J16 is OK.

• If pin12 of J16 is low when inserted, check if pin5 of J16 is 3V. If not,

check U2.

• Check if all the clock and data pins are normal. If not, check U1.

T-Flash Slot J16

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 21

Vibrator Out Of Control

• Remove the lower case and have the vibrator exposed, then retest.

• If retest OK after removing the case, reassemble and check if it is

interfered by the case.

• If retest still fail, check if pin1 of J11 is 5V. If not, check if U2 is

working normally.

• Check if there is PWM signal on pin2 of J11. If not, check if U2 is

working normally.

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 22

ActiveSync No Response

• 1. Do the clean boot (Master Clear)

• 2. Check the USB transceiver circuit while the unit has connected to

PC

Reset in High

Level

3.3V

Vbus > 4.3V

1.8V

19.2MHz

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 23

Earphone Malfunction (1)

• Check if the voltage at Pin 1 of R148 is logic low, if not, check the

audio jack J170 is OK and well-contacted with the main board.

• Using the oscilloscope to see if the waveform is visible at U10 or

U11, if visible at pin 4 but not pin 3, replace U10 or U11 with new

chips.

• If not visible at both pin 4 and pin 3, replace U1 with a new chip.

J170 Audio Jack

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 24

Earphone Malfunction (2)

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 25

Microphone Malfunction

• Check if the voltage at C113 is 2V, if not, replace U2 with a new chip.

• Check if the voltage at Pin 4 of J3 on sub board is 2V, if not, check if

the sub board is well-contacted with the main board, and if male and

female BTB connectors are robust and clean.

• Using the oscilloscope to see if the waveform is visible at R3 on sub

board, if not, replace the microphone.

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 26

Receiver Malfunction

• Check if J6 is blocked by anything.

• Using the oscilloscope to see if the waveform is visible at J6, if not,

replace U1 with a new chip.

• If the waveform is visible at J6, replace the receiver.

Receiver Pads J6

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 27

Speaker Malfunction (1)

• Using the oscilloscope to see if the waveform is visible at C233, if

not, replace U1 with a new chip.

• Using the oscilloscope to see if the waveform is visible at L15 & L14,

and the two waveforms should be out of phase with each other, if

not, replace U2 with a new chip.

• Using the oscilloscope to see if the waveform is visible at S1 & S2, If

yes, check if the sprints of S1 & S2 are distorted.

• If the sprints are in good shape, replace the speaker.

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 28

Speaker Malfunction (2)

Speaker Amp.

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 29

RTC failed

• 1, Do a power cycle with the unit

• 2. Check the Vcoin Voltage (BJ2)

• 3. Check the 32KHz oscillator

1V~ 3V

Service Engineeing & Optimization

Level 3 , Rev.1.0

32.768KHz

Page 30

Can’t Take Picture

• Can’t turn on:

• Check Camera damage or not

• Check camera module assembly

• I2C interface working normally (you could verify this by LCD

backlight level adjustment or turn on VGA camera)

• Check camera power when turn on ( R178_1.8V, R751_2.8V,

R752_2.6V )

• Check camera reset pin (R755) signal should pull high after turn on

camera

– AF no function:

• Check S7 SMT

• Check S7_pin3 signal from 2.6V to GND when you press the

capture key to the half.

• Check camera module AF pad short with shielding case or not.

– Capture key no function:

• Check S7 SMT

• Check S7_pin1 signal from 2.6V to GND when you press the

Service Engineeing & Optimization

Level 3 , Rev.1.0

capture key.

Page 31

3M Camera schematic and placement

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 32

Phone Hang Up

• 1. Dump the image

• 2. Copy the log in my device

• 3. Perform the clean boot

(press the end key and Jog ball before the power key in off mode)

4. If the unit can not into windows mobile, please redownload SW

image to the damaged unit.

5. If the issue isn’t solved ,please use Ram test tool to check U3.

If any error message , the U3 may be damaged.

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 33

Auto Power On

1. Please check the follow Power on event

a) Press the power key ->Pull N_KB_PWR_KEY to low (TP112)

On Page 4

b) Plug the USB charger /USB cable -> Detect VBUS

Page 14, Page 15 , Page 16

2. Check the SW2(power key) and the rubber with upper case

3. Try to Dump the image

4. Copy the Log in my device with Today mode to SW team for further

analysis

5. Redownload the new image to the damaged unit

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 34

Auto Power off

1. 1. Check the leakage current (< 0.4mA)

2. if the power off is triggered by the power key, the vibrator will active

for a while and then the unit is off.

=> Please check the SW2 power key.

3. If the unit is off without any vibration, please measure the power on

current (< 450mA)

=> Copy the Log in my device with Today mode to SW team for

further analysis

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 35

Can’t call out (1)

GSM

• Check the metal contact of antenna

• Try to make call

• Setup BS/MS parameter

• Set HP8960, operating mode: test mode, test function: BCH+TCH, cell power:-60dBm

• Set MS GSM900/850 ch62/189 PL=5; DCS/PCS ch699/ch661 PL=0

• Check transmitter path

– Check the I/Q path

• Use oscilloscope probe to touch red point and check waveform

Antenna pad

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 36

Can’t call out (2)

• Check transmitter path

– Check PA control signal

• Use oscilloscope probe to touch red point and check waveform

GSM

PA_EN

Service Engineeing & Optimization

Level 3 , Rev.1.0

PA_RAMP

Page 37

Can’t call out (3)

• Check transmitter path

– Check ASM control signal

• Use oscilloscope probe to touch red point and check control table

GSM

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 38

Can’t call out (4)

• Check transmitter path

– Check RF path power

GSM

• Use spectrum probe to touch red point and check output power in

spectrum analyzer

High band RF signal

Low band RF signal

~29dBm

Service Engineeing & Optimization

Level 3 , Rev.1.0

~30dBm

~33dBm

~10dBm

Page 39

• Check receiver path

– Check ASM control signal

• Use oscilloscope probe to touch red point and check control table

Can’t call out (5)

GSM

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 40

• Check receiver path

– Check RF signal power

Can’t call out (6)

GSM

• Use spectrum probe to touch red point and check output power in

spectrum analyzer

~ -65dBm

~ -65dBm

High band RF signal

Low band RF signal

~ -61dBm

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 41

Can’t call out (1)

WCDMA

• Check the metal contact of antenna

• Try to make call

• Setup BS/MS parameter

• Set MT8820, operating mode: test mode, cell power:-60dBm

• Set MS WCDMA BC1 ch9750, BC2 ch9400 and BC5 ch4183

• Check transmitter path

– Check the I/Q path

• Use oscilloscope probe to touch red point and check waveform

Antenna pad

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 42

Can’t call out (2)

• Check transmitter path

– Check PA control signal

• Use oscilloscope probe to touch red point and check control table

WCDMA

BC1

Service Engineeing & Optimization

Level 3 , Rev.1.0

BC1

BC5

BC2

BC2/5

Page 43

Can’t call out (3)

• Check transmitter path

– Check ASM control signal

• Use oscilloscope probe to touch red point and check control table

WCDMA

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 44

Can’t call out (4)

• Check transmitter path

– Check RF path power

WCDMA

~24dBm

~24dBm~24dBm

• Use spectrum probe to touch red point and check output power in

spectrum analyzer

~26dBm

~26dBm

~26dBm

BC1 RF signal

BC2 RF signal

BC5 RF signal

~1dBm

~1dBm

~23dBm

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 45

• Check receiver path

– Check ASM control signal

• Use oscilloscope probe to touch red point and check control table

Can’t call out (5)

WCDMA

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 46

• Check receiver path

– Check RF signal power

Can’t call out (6)

WCDMA

~ -65dBm

~ -65dBm~ -65dBm

• Use spectrum probe to touch red point and check output power in

spectrum analyzer

~ -68dBm~ -68dBm

~ -68dBm

BC1 RF signal

BC2 RF signal

BC5 RF signal

~ -61dBm

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 47

Bluetooth cannot turn on and test (1)

• Check the voltages: VBATT, VREG_MSMP_2.6V, and V1P8_WLAN

V1P8_WLAN

Test point: C302

Voltage: 1.8V

VREG_MSMP_2.6V

Test point: C1707

Voltage: 2.6V

VBATT

Test point: C1706

Voltage: 3.4~4.2V

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 48

Bluetooth cannot turn on and test (2)

• Check BT_REQ_OUT pin voltage.

• When BT_REQ_OUT pulls high, OSC will have 19.2MHz clock.

Test point: R1701 or R194

Voltage: 2.6V

When BT turns on or is working,

BT_REQ_OUT pin needs to

pull high.

Test point: R191 or C315

Clock voltage: 0.5~0.9Vpp

Clock frequency: 19.2MHz

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 49

Wi-Fi cannot turn on and test (1)

• Check the voltages: VBATT, VREG_MSMP_2.6V, V1P2_WLAN, and

V1P8_WLAN

V1P8_WLAN

Test point: C302

Voltage: 1.8V

V1P2_WLAN

Test point: C1704

Voltage: 1.2V

VREG_MSMP_2.6V

Test point: C1707

Voltage: 2.6V

VBATT

Test point: C1706

Voltage: 3.4~4.2V

Service Engineeing & Optimization

Level 3 , Rev.1.0

Page 50

Wi-Fi cannot turn on and test (2)

• Check the reference clock 26MHz.

Service Engineeing & Optimization

Level 3 , Rev.1.0

Test point: C318 or C317

Clock voltage: 0.5~0.9Vpp

Clock frequency: 26MHz

Page 51

Wi-Fi cannot turn on and test (3)

• Check the pin states of the module.

WOW

Test point: U16 pin 5

Clock voltage: 2.6V

SYS_RST_L

Test point: TP140

Clock voltage: 2.6V

CHIP_PWD_L

Test point: TP558

Clock voltage: 2.6V

Service Engineeing & Optimization

Level 3 , Rev.1.0

Loading...

Loading...