MOTOTRBO

PROFESSIONAL DIGITAL TWO-WAY RADIO SYSTEM

™

REPEATER

SLR 1000 Repeater Basic

Service & Installation

Manual

DECEMBER 2018

©

2019 Motorola Solutions, Inc. All rights reserved

*MN003557A01*

MN003557A01-AF

MN003557A01-AF

Notice Foreword

Notice

Foreword

This manual covers all versions of the MOTOTRBO SLR 1000 Repeater, unless otherwise specified. It

includes all the information necessary to maintain peak product performance and maximum working

time, using levels 1 and 2 maintenance procedures. These levels of service go down to software

issues or replacement of an accessory, commonly performed by local service centers, Motorola

Solutions Authorized Dealers, self-maintained customers, and distributors.

CAUTION: These servicing instructions are for use by qualified personnel only. To reduce the

risk of electric shock, do not perform any servicing other than what is contained in the Operating

Instructions unless you are qualified to do so. Refer all servicing to qualified service personnel.

Related Links

Notations Used in This Manual on page 2

General Safety Precautions on page 2

Copyrights on page 3

Disclaimer on page 3

Trademarks on page

4

Notations Used in This Manual

Throughout the text in this publication, three types of notations are used to emphasize that safety

hazards exist, and due care must be taken and observed.

NOTICE: An operational procedure, practice, or condition which is essential to emphasize.

CAUTION: CAUTION indicates a potentially hazardous situation which, if not avoided, might

result in equipment damage.

WARNING: WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or injury.

Symbol indicates areas of the product that pose potential burn hazards.

Return to Process

Foreword

on page 2

General Safety Precautions

For more information, see General Safety and Installation

Standards and Guidelines.

Return to Process

Foreword on page 2

2

MN003557A01-AF

Notice

Foreword

Copyrights

The Motorola Solutions products described in this document may include copyrighted Motorola

Solutions computer programs. Laws in the United States and other countries preserve for Motorola

Solutions certain exclusive rights for copyrighted computer programs. Accordingly, any copyrighted

Motorola Solutions computer programs contained in the Motorola Solutions products described in this

document may not be copied or reproduced in any manner without the express written permission of

Motorola Solutions.

©

2019 Motorola Solutions, Inc. All Rights Reserved

No part of this document may be reproduced, transmitted, stored in a retrieval system, or translated

into any language or computer language, in any form or by any means, without the prior written

permission of Motorola Solutions, Inc.

Furthermore, the purchase of Motorola Solutions products shall not be deemed to grant either directly

or by implication, estoppel or otherwise, any license under the copyrights, patents or patent

applications of Motorola Solutions, except for the normal non-exclusive, royalty-free license to use that

arises by operation of law in the sale of a product.

Disclaimer

Please note that certain features, facilities, and capabilities described in this document may not be

applicable to or licensed for use on a specific system, or may be dependent upon the characteristics of

a specific subscriber unit or configuration of certain parameters. Please refer to your Motorola

Solutions contact for further information.

Trademarks

MOTOROLA, MOTO, MOTOROLA SOLUTIONS, and the Stylized M Logo are trademarks or

registered trademarks of Motorola Trademark Holdings, LLC and are used under license. All other

trademarks are the property of their respective owners.

European Union (EU) Waste of Electrical and Electronic Equipment (WEEE)

directive

The European Union's WEEE directive requires that products sold into EU countries must have

the crossed out trash bin label on the product (or the package in some cases).

As defined by the WEEE directive, this cross-out trash bin label means that customers and end-users

in EU countries should not dispose of electronic and electrical equipment or accessories in household

waste.

Customers or end-users in EU countries should contact their local equipment supplier representative or

service centre for information about the waste collection system in their country.

Return to Process

Foreword

on page 2

Disclaimer

The information in this document is carefully examined, and is believed to be entirely reliable.

However, no responsibility is assumed for inaccuracies. Furthermore, Motorola Solutions reserves the

right to make changes to any products herein to improve readability, function, or design. Motorola

Solutions does not assume any liability arising out of the applications or use of any product or circuit

described herein; nor does it cover any license under its patent rights nor the rights of others.

Controlled copies of this document are available through Motorola Solutions On-Line (MOL).

3

MN003557A01-AF

Foreword

Notice

Return to Process

Foreword

on page 2

Trademarks

MOTOROLA, MOTO, MOTOROLA SOLUTIONS and the Stylized M logo are trademarks or registered

trademarks of Motorola Trademark Holdings, LLC and are used under license. All other trademarks are

the property of their respective owners.

©

2018 Motorola Solutions, Inc.

All rights reserved.

Return to Process

Foreword on page 2

4

MN003557A01-AF

General Safety and Installation

Standards and Guidelines

Notice

General Safety and Installation Standards and Guidelines

ATTENTION!

WARNING: For safe installation, operation, service and repair of this equipment, follow the

safety precautions and instructions, as well as any additional safety information in Motorola

Solutions product service and installation manuals and the Motorola Solutions R56 Standards

and Guidelines for Communications Sites manual

9880384V83). To obtain copies of these materials, contact Motorola Solutions as directed at the

end of this section. After installation, these instructions should be retained and readily available

for any person operating or servicing this repeater or working near it.

Failure to follow these safety precautions and instructions could result in serious injury or property

damage.

The installation process requires preparation and knowledge of the site before installation begins.

Review installation procedures and precautions in the Motorola Solutions R56 manual before

performing any site or component installation. Personnel must use safe work practices and good

judgment, and always follow applicable safety procedures, such as requirements of the Occupational

Safety and Health Administration (OSHA), the National Electrical Code (NEC), and local codes.

The following are additional general safety precautions that must be observed:

• To continue compliance with any applicable regulations and maintain the safety of this equipment,

do not install substitute parts or perform any unauthorized modifications.

• All equipment must be serviced by Motorola Solutions trained personnel.

• If troubleshooting the equipment while the power is on, be aware of live circuits which could contain

hazardous voltage.

• Do not operate the radio transmitters unless all RF connectors are secure and all connectors are

properly terminated.

• All equipment must be properly grounded in accordance with the Motorola Solutions R56 and

specified installation instructions for safe operation.

• Openings between the fins on the chassis are provided for ventilation. Do not block or cover

openings between the fins that protect the devices from overheating.

(which can be obtained by ordering CDROM

•

•

• Never store combustible materials in or near equipment. The combination of combustible material,

• Equipment shall be installed in a site that meets the requirements of a

Some equipment components can become extremely hot during operation. Turn off all power

to the equipment and wait until sufficiently cool before touching.

Maintain emergency first aid kits at the site.

heat, and electrical energy increases the risk of a fire hazard.

“restricted access location,” per (UL60950-1 & EN60950-1), which is defined as follows: "Access

can only be gained by service persons or by users who have been instructed about the reasons for

the restrictions applied to the location and about any precautions that shall be taken; and access is

through the use of a tool or lock and key, or other means of security, and is controlled by the

authority responsible for the location."

5

Attention

MN003557A01-AF

Notice General Safety and Installation

Standards and Guidelines

• Ensure that the installation area can safely support the weight of the repeater.

• Burn hazard. The metal housing of the product may become extremely hot. Use caution

when working around the equipment.

•

RF energy burn hazard. Disconnect power to prevent injury before disconnecting and

connecting antennas.

•

Shock hazard. The outer shields of all Tx and Rx RF cables outer shields must be grounded per

Motorola Solutions R56 manual.

• All Tx and Rx RF cables shall be connected to a surge protection device according to Motorola

Solutions R56 manual. Do not connect Tx and Rx RF cables directly to an outside antenna.

•

Compliance with National and International standards and guidelines for human exposure to

Electromagnetic Energy (EME) at Transmitter Antenna sites generally requires that persons having

access to a site shall be aware of the potential for exposure to EME and can exercise control of

exposure by appropriate means, such as adhering to warning sign instructions. See this installation

manual and Appendix A of Motorola Solutions R56.

This product complies with the requirements set forth by the European R&TTE regulations and

applicable CENELEC standards concerning human exposure to Electromagnetic Energy (EME) at

Transmitter Antenna sites. MOTOTRBO Repeater EME Assessment

on page 132 in this manual

includes an EME exposure analysis of a typical system configuration for this product.

For a different system configuration than the typical configuration, compliance with applicable EME

exposure standards (current versions of the EN50384, EN50385, IEC/IEEE 62704-2, and United

States Federal Communication Commission, “Evaluating compliance with FCC guidelines for

human exposure to radio frequency electromagnetic fields,” OET Bulletin 65 (Ed. 97-01), August

1997. Supplement C (Edition 01-01) to US FCC OET Bulletin 65 (Edition 97-01), “Additional

Information for Evaluating Compliance of Mobile and Portable Devices with FCC Limits for Human

Exposure to Radio frequency Emissions,” June 2001 standards for occupational and general public

exposure, respectively) can be evaluated by either employing the indoor or outdoor methods

illustrated in the typical system configuration EME exposure analysis included in MOTOTRBO

Repeater EME Assessment on page 132 in this manual, or employing another suitable method

among those described in the current version of the EN50383 standard.

Once the occupational and general public compliance boundaries are determined, means to ensure

that workers and people are outside the respective boundaries, for instance using appropriate

signage or restricted access, should be implemented; if this is not possible or practically achievable

for the specific system configuration, the configuration should be modified in order to make it

possible. The R56 Standards and Guidelines for Communications Sites manual (which can be

obtained by ordering CDROM 9880384V83) provides examples of signage that can be used to

identify the occupational or general public compliance boundaries.

Refer to product specific manuals for detailed safety and installation instructions. Manuals can be

obtained with product orders, downloaded from https://businessonline.motorolasolutions.com, or

purchased through the Motorola Solutions Aftermarket & Accessory Department.

This is a class A product. In a domestic environment, this product may cause radio interference in

which case the user may be required to take adequate measures.

6

MN003557A01-AF

Declaration of Conformity

Declaration of Conformity

This declaration is applicable to your radio only if your radio is labeled with the FCC logo shown below.

Declaration of Conformity

Per FCC CFR 47 Part 2 Section 2.1077(a)

Responsible Party

Name: Motorola Solutions, Inc.

Address: 1303 East Algonquin Road, Schaumburg, IL 60196-1078, U.S.A.

Phone Number: 1-800-927-2744

Hereby declares that the product:

Model Name: SLR 1000

conforms to the following regulations:

FCC Part 15, subpart B, section 15.107(a), 15.107(d), and section 15.109(a)

Class A Digital Device

This device complies with Part 15 of the FCC rules. This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following two conditions:

1 This device may not cause harmful interference, and

2 This device must accept any interference received, including interference that may cause unde-

sired operation.

NOTICE: This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC Rules and Industry Canada license-exempt RSS standard. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio or TV technician for help.

7

MN003557A01-AF

MOTOTRBO SLR 1000 Repeater

Notice

Supplemental Safety and Installation Requirements

Notice

MOTOTRBO SLR 1000 Repeater Supplemental Safety and Installation Requirements

CAUTION:

The MOTOTRBO SLR 1000 Repeater must be installed in a suitable, in-building location, or

suitable outdoor location. A restricted access location is required when installing this equipment

into the end system.

When installing the equipment, all requirements of relevant standards and local electrical codes

must be fulfilled.

The maximum operating ambient temperature of this equipment is 60 °C, at sea level.

Operating altitudes up to 5000 meters above sea level are supported, but maximum operating

temperature shall degrade by 1 °C /1000 m elevation. Operation above 5000 may be feasible

but operating specifications and parameters are not guaranteed, and reduced performance may

result.

8

MN003557A01-AF

Environmental Information

Notice

Environmental Information

Related Links

Material Content on page 9

Disposal of your Electronic and Electric Equipment on page

Disposal Guideline on page 10

Material Content

This is to declare that Motorola Solutions products comply with the EU Directive 2011/65/EU

(Restriction of Hazardous Substance or RoHS-2) and India RoHS, including applicable exemptions,

concerning the following substances:

• Lead (Pb) < 0.1% by weight (1000 ppm)

• Mercury (Hg) < 0.1% by weight (1000 ppm)

• Cadmium (Cd) < 0.01% by weight (100 ppm)

• Hexavalent Chromium (Cr6+) < 0.1% by weight (1000 ppm)

• Polybrominated Biphenyls (PBB) < 0.1% by weight (1000 ppm)

• Polybrominated Diphenyl Ethers (PBDE) < 0.1% by weight (1000 ppm)

9

NOTICE:

The Motorola Solutions MOTOTRBO SLR 1000 Repeater system and its subsystems have

•

been created in compliance with the environmental goals of the European Union's

Restriction of Hazardous Substances (RoHS 2) Directive 2011/65/EU and the Waste

Electrical and Electronic Equipment (WEEE) Directive 2012/19/EU as well as Motorola

Solutions corporate goals to minimize environmental impact of its products.

• This Motorola Solutions policy is reflected throughout the entire design, procurement,

assembly, and packaging process.

• In support of these efforts to provide environmentally-responsible products, comply with the

information in the following sections regarding product disposal for systems being replaced.

Return to Process

Environmental Information on page 9

Disposal of your Electronic and Electric Equipment

Do not dispose of electronic and electric equipment or electronic and electric accessories with your

household waste.

In some countries or regions, collection systems have been set up to handle waste of electrical and

electronic equipment.

In European Union countries, contact your local equipment supplier representative or service center for

information about the waste collection system in your country.

Return to Process

Environmental Information on page 9

9

MN003557A01-AF

Notice Environmental Information

Disposal Guideline

The European Union's WEEE directive symbol on a Motorola Solutions product indicates that the

product should not be disposed of with household waste.

Return to Process

Environmental Information on page

9

10

MN003557A01-AF

Document History

Document History

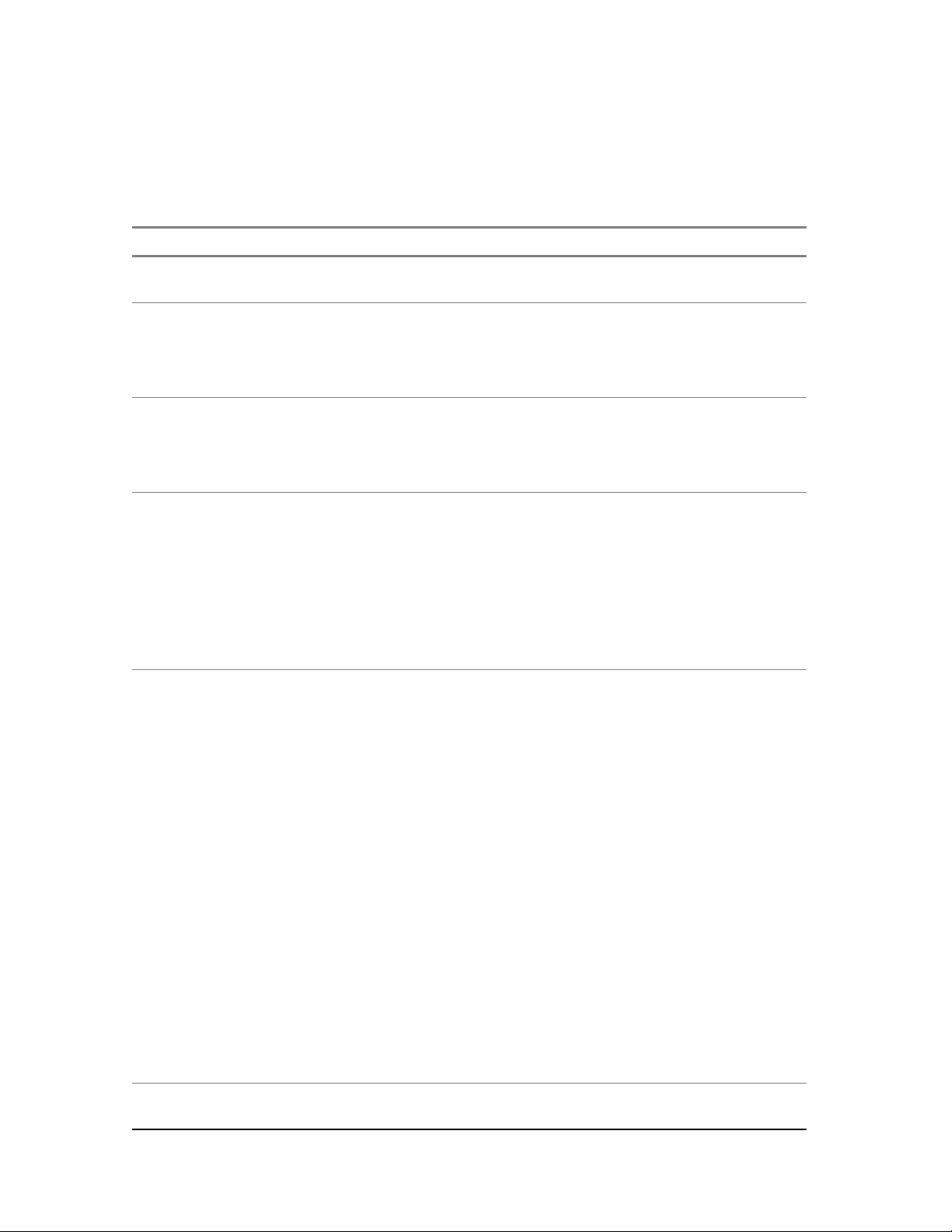

The following major changes have been implemented in this manual since the previous edition:

Edition Description Date

MN003557A01-AA Initial release of the MOTOTRBO SLR 1000 Re-

peater Basic Service & Installation manual

MN003557A01-AB Second release of the MOTOTRBO SLR 1000

Repeater Basic Service & Installation

• The Duplexer part numbers were updated in

Appendix A.

MN003557A01-AC Third release of the MOTOTRBO SLR 1000 Re-

peater Basic Service & Installation manual.

• Appendix E: MOTOTRBO Repeater EME Assessment updated.

MN003557A01-AD Fourth release of the MOTOTRBO SLR 1000

Repeater Basic Service & Installation manual.

• Table 18: Auxiliary/Accessory Connector Callout Legend - Updated Pin 2, Pin 5, Pin 6 and

Pin 8 information.

• Appendix E: MOTOTRBO Repeater EME Assessment - Updated Reference of EN 50385:

2002 to EN 50385: 2017.

MN003557A01-AE Fifth release of the SLR 1000 Repeater Basic

Service & Installationmanual.

• Figure 9: SLR1000 Repeater Model Numbering Scheme - Updated frequencies for band

J.

• Table 6: SLR1000 Frequency Ranges and

Power Levels - Added VHF frequencies and

VHF self-quieting frequencies.

• Table 13: SLR1000 Repeater Specifications

of the Transmitter Exciter Subsystem - Updated VHF values.

• Added Figure 24: SLR1000 VHF Repeater

Band Reject (Notch) Duplexer.

manual.

June 2017

August 2017

December 2017

April 2018

November 2018

• Updated Appendix A: A.1.1 Antennas and

A.1.4 Duplexers

• Appendix E: MOTOTRBO Repeater EME Assessment - Added E.3.3: Equivalent Plane

Wave Power Density Evaluation; Updated E5

- EME Exposure Evaluation

MN003557A01-AF Sixth release of the SLR 1000 Repeater Basic

Service & Installationmanual.

December 2018

11

MN003557A01-AF

Document History

Edition Description Date

• Declaration of Conformity added

• Changed Spurious Harmonics and Emissions

figures for Repeater Specifications;

Industry Canada requirements added to SLR

•

1000 Repeater General Specifications;

January 2018

12

MN003557A01-AF

Contents

Contents

Declaration of Conformity.......................................................................................... 7

Document History..................................................................................................... 11

List of Figures............................................................................................................18

List of Tables............................................................................................................. 20

List of Procedures.....................................................................................................22

Related Publications.................................................................................................23

Summary of Bands Available...................................................................................24

Chapter 1: SLR 1000 Repeater.................................................................................28

1.1 Repeater Description............................................................................................................. 28

1.2 Repeater Operating Features................................................................................................ 35

1.3 Repeater Frequency Ranges and Power Levels................................................................... 36

1.4 Repeater Specifications.........................................................................................................37

1.5 Repeater Theory of Operation............................................................................................... 40

1.6 Basic Repeater Level Troubleshooting – RDAC and LEDs...................................................41

1.7 Repeater Model Numbering Scheme.................................................................................... 43

1.8 Repeater Model Chart........................................................................................................... 44

Chapter 2: SLR 1000 Satellite Receiver.................................................................. 45

2.1 Satellite Receiver Description................................................................................................45

2.2 Satellite Receiver Operating Features...................................................................................45

2.3 Satellite Receiver Frequency Ranges................................................................................... 45

2.4 Satellite Receiver Specifications............................................................................................46

2.5 Satellite Receiver Configuration............................................................................................ 46

2.6 Basic Satellite Receiver Level Troubleshooting – RDAC and LEDs......................................46

2.7 Satellite Receiver Model Chart.............................................................................................. 47

Chapter 3: SLR 1000 Transceiver Board.................................................................48

3.1 Transceiver Board Description.............................................................................................. 48

3.1.1 Transceiver Board General Description...................................................................48

3.1.2 Input and Output Connections................................................................................. 48

3.1.2.1 External On/Off Function............................................................................50

3.2 Receiver Subsystem..............................................................................................................50

3.2.1 Receiver Subsystem Specifications.........................................................................51

3.3 Transmitter Subsystem..........................................................................................................52

3.3.1 Transmitter Subsystem Specifications.....................................................................52

3.4 Station Control Subsystem.................................................................................................... 53

3.4.1 Station Control Audio............................................................................................... 53

13

MN003557A01-AF

Contents

3.4.2 Station Control Interface.......................................................................................... 54

Chapter

4: SLR 1000 Front Panel............................................................................ 55

4.1 Front Panel Description......................................................................................................... 55

Chapter 5: SLR 1000 Bottom Panel......................................................................... 56

5.1 Bottom Panel Description...................................................................................................... 56

5.2 Bottom Panel Interfaces and Pin Location.............................................................................57

Chapter 6: SLR 1000 Test Equipment And Service Aids.......................................62

6.1 Recommended Test Equipment............................................................................................ 62

6.2 Service Aids...........................................................................................................................62

Chapter 7: SLR 1000 Performance Check or Testing............................................ 64

7.1 Performance Check or Testing General Description............................................................. 64

7.2 Transmitter Testing................................................................................................................64

7.2.1 Required Transmitter Test Equipment..................................................................... 65

7.2.2 Verifying Transmitter Circuitry..................................................................................65

7.3 Receiver Testing....................................................................................................................67

7.3.1 Required Receiver Test Equipment......................................................................... 67

7.3.2 Verifying Receiver Circuitry......................................................................................67

Chapter 8: SLR 1000 Programming and Tuning.....................................................70

8.1 Programming and Tuning Introduction.................................................................................. 70

8.2 Radio Management Setup..................................................................................................... 70

8.3 Repeater Tuning Setup..........................................................................................................71

8.4 Tuning the Reference Oscillator............................................................................................ 72

8.5 Tuning the Rx Audio Level Set.............................................................................................. 72

8.6 Tuning the Tx Audio Level Set...............................................................................................73

8.7 Modulation Limit Alignment....................................................................................................74

8.7.1 Tuning the Modulation Limit (with no Tx Data and no PL)....................................... 75

8.7.2 Verifying the Modulation Limit (with no Tx Data and no PL).................................... 76

8.8 Tuning a Duplexer Module.....................................................................................................76

Chapter 9: SLR 1000 Maintenance and Disassembly/Reassembly...................... 82

9.1 Routine Maintenance.............................................................................................................82

9.2 Preventive Maintenance........................................................................................................ 82

9.2.1 Inspection.................................................................................................................82

9.2.2 Cleaning...................................................................................................................83

9.3 Safe Handling of CMOS and LDMOS Devices......................................................................83

9.4 Installing a Duplexer.............................................................................................................. 84

9.5 Installing a High-Speed Solid-State Antenna Switch............................................................. 88

Chapter 10: SLR 1000 Installation........................................................................... 93

10.1 Pre-Installation Considerations............................................................................................93

14

MN003557A01-AF

Contents

10.1.1 Installation Overview..............................................................................................93

10.1.2 Site Environmental Conditions

...............................................................................94

10.1.3 Equipment Mounting Methods............................................................................... 95

10.1.4 Equipment Ventilation............................................................................................ 95

10.1.4.1 Ventilation for a Ceiling Mount................................................................. 95

10.1.4.2 Ventilation for a Wall Mount..................................................................... 95

10.1.5 AC and DC Input Power Requirements................................................................. 96

10.1.5.1 DC Input Power Requirements................................................................ 96

10.1.5.2 AC Input Power Requirements.................................................................96

10.1.5.3 Ground Connection.................................................................................. 97

10.1.5.4 RF Antenna Connections......................................................................... 97

10.1.5.5 System Cable Connections......................................................................97

10.1.6 Site Grounding and Lightning Protection............................................................... 97

10.1.6.1 Electrical Ground......................................................................................98

10.1.6.2 RF Ground............................................................................................... 98

10.1.6.3 Lightning Ground......................................................................................98

10.1.6.4 Equipment Grounding.............................................................................. 98

10.1.7 Recommended Tools and Equipment....................................................................99

10.1.8 Equipment Unpacking and Inspection................................................................... 99

10.2 SLR 1000 Repeater Package Contents.............................................................................100

10.3 Mounting the SLR 1000 Repeater to a Wall or Ceiling...................................................... 100

10.4 Mounting the SLR 1000 Repeater to a Pole...................................................................... 103

10.5 Electrical Connections....................................................................................................... 108

10.5.1 Connecting the DC Input Power.......................................................................... 110

10.5.2 Connecting the Indoor Adapter AC Input Power..................................................111

10.5.3 Assembling an Outdoor Power Supply................................................................ 111

10.5.4 Ground Connection..............................................................................................113

10.5.5 RF Antenna Connections.....................................................................................113

10.5.6 System Cable Connections..................................................................................114

10.5.7 Installing Cable Grommet Connectors or Plugs...................................................114

10.6 General Bonding and Grounding Requirements................................................................114

10.7 General Cabling Requirements......................................................................................... 115

10.8 Post Installation Checklist..................................................................................................115

10.8.1 Apply Power.........................................................................................................115

10.8.2 Verify Proper Operation....................................................................................... 115

10.8.2.1 Front Panel LEDs...................................................................................116

10.8.3 Repeater Codeplug Data Backup........................................................................ 116

Appendix A: Accessories.......................................................................................117

A.1 Introduction..........................................................................................................................117

15

MN003557A01-AF

Contents

A.1.1 Antennas............................................................................................................... 117

A.1.2 Power Supplies

A.1.3 Documentation...................................................................................................... 118

A.1.4 Duplexers.............................................................................................................. 118

A.1.5 Antenna Switches..................................................................................................119

A.1.6 Mounting................................................................................................................119

A.1.7 Surge Arrestors..................................................................................................... 119

A.1.8 Service Tools.........................................................................................................119

......................................................................................................118

Appendix B: Replacement Parts Ordering........................................................... 121

B.1 Basic Ordering Information..................................................................................................121

B.2 Motorola Solutions Online................................................................................................... 121

B.3 Mail Orders..........................................................................................................................122

B.4 Telephone Orders............................................................................................................... 122

B.5 Fax Orders.......................................................................................................................... 122

B.6 Parts Identification...............................................................................................................122

B.7 Product Customer Service.................................................................................................. 123

Appendix C: Motorola Solutions Service Centers............................................... 124

C.1 Servicing Information.......................................................................................................... 124

C.2 Motorola Solutions Service Center......................................................................................124

C.3 Motorola Solutions Federal Technical Center..................................................................... 124

C.4 Motorola Solutions Canadian Technical Logistics Center...................................................124

Appendix D: SLR 1000 Series Third-Party Controllers........................................126

D.1 Third-Party Controllers Overview........................................................................................ 126

D.2 Tone Remote Adapter.........................................................................................................127

D.2.1 Tone Remote Adapter Compatibility..................................................................... 128

D.2.2 Tone Remote Adapter Hardware Connections..................................................... 128

D.2.3 Radio Management Configuration (For a 2-Channel Remote Control)................. 129

D.2.4 Tone Remote Adapter Settings............................................................................. 130

D.2.4.1 Radio Rx..................................................................................................130

D.2.4.2 Radio Tx.................................................................................................. 131

D.2.4.3 Channel Steering.....................................................................................131

D.2.4.4 Monitoring................................................................................................131

D.2.4.5 PTT..........................................................................................................131

D.2.4.6 Wildcard 1 (optional)................................................................................131

Appendix E: MOTOTRBO Repeater EME Assessment........................................132

E.1 Executive Summary............................................................................................................ 132

E.2 Device Characteristics.........................................................................................................133

E.3 Exposure Prediction Model................................................................................................. 134

E.3.1 SAR Evaluation Formulas..................................................................................... 134

16

MN003557A01-AF

Contents

E.3.2 Implementation and Validation of SAR Formulas..................................................137

E.3.3 Equivalent Plane Wave Power Density Evaluation

............................................... 138

E.4 Exposure Limits...................................................................................................................139

E.5 EME Exposure Evaluation...................................................................................................139

E.6 Compliance Boundary Description...................................................................................... 141

E.7 Product Put In Service.........................................................................................................142

E.8 References.......................................................................................................................... 142

Glossary of Terms and Acronyms.........................................................................144

17

MN003557A01-AF

List of Figures

List of Figures

Figure 1: SLR 1000 Repeater Bottom View........................................................................................... 29

Figure 2: SLR 1000 Repeater Left View

Figure 3: SLR 1000 Repeater Right View.............................................................................................. 30

Figure 4: SLR 1000 Repeater Back View...............................................................................................31

Figure 5: SLR 1000 Repeater Padlock Opening.................................................................................... 32

Figure 6: SLR 1000 Repeater Front View.............................................................................................. 32

Figure 7: SLR 1000 Repeater Connections............................................................................................34

Figure 8: RDAC Diagnostic Screen........................................................................................................ 41

Figure 9: SLR 1000 Repeater Model Numbering Scheme..................................................................... 43

Figure 10: Operation Mode Configuration for Satellite Receiver Functionality.......................................46

Figure 11: SLR 1000 Repeater Transceiver Board Connector Locations.............................................. 49

Figure 12: SLR 1000 Repeater Audio Block Diagram............................................................................ 54

Figure 13: SLR 1000 Repeater Bottom Panel Connector Names and Locations...................................56

Figure 14: DC Power Inlet Connector.....................................................................................................57

Figure 15: USB Connector..................................................................................................................... 58

Figure 16: Ethernet Connector............................................................................................................... 59

Figure 17: Auxiliary/Accessory Connector..............................................................................................60

Figure 18: Test Equipment Setup for Verifying Transmitter Circuitry..................................................... 66

Figure 19: Test Equipment Setup for Verifying Receiver Circuitry......................................................... 69

Figure 20: Radio Management Setup.....................................................................................................71

Figure 21: SLR 1000 Repeater Tuning Equipment Setup...................................................................... 71

Figure 22: Auxiliary Connector............................................................................................................... 73

Figure 23: SLR 1000 UHF Repeater Band Reject (Notch) Duplexer..................................................... 77

Figure 24: SLR 1000 VHF Repeater Band Reject (Notch) Duplexer......................................................78

Figure 25: Example for HIGH Port Tuning of the UHF Duplexer............................................................79

Figure 26: Example for LOW Port Tuning of the UHF Duplexer.............................................................80

Figure 27: Rejection of Each Port for UHF Duplexer..............................................................................81

Figure 28: SLR 1000 Repeater Front View (without top cover)..............................................................85

Figure 29: SLR 1000 Repeater Front View (without top cover) with a Duplexer.................................... 87

Figure 30: SLR 1000 Repeater Front View (without top cover)..............................................................89

Figure 31: SLR 1000 Repeater Front View (without top cover) with an Antenna Switch....................... 91

Figure 32: Bracket Mounting Holes...................................................................................................... 101

Figure 33: Location of Repeater M6 Screw Mounts............................................................................. 102

Figure 34: Bracket Receiving Slots...................................................................................................... 102

Figure 35: U-Bolt and Pole Mount Bracket Assembly.......................................................................... 104

Figure 36: Band Clamps and Pole Mount Bracket............................................................................... 105

.................................................................................................29

18

MN003557A01-AF

List of Figures

Figure 37: Wall Mount Bracket Attached to Pole Mount Bracket..........................................................105

Figure 38: Power Supplies

................................................................................................................... 106

Figure 39: Location of Repeater M6 Screw Mounts............................................................................. 107

Figure 40: Bracket Receiving Slots...................................................................................................... 107

Figure 41: SLR 1000 Repeater Bottom Panel Connector Names and Locations.................................109

Figure 42: Attach AC Wires to Joiner A................................................................................................112

Figure 43: Attach DC Wires to Joiner B................................................................................................112

Figure 44: Assembled SLR 1000 Repeater Power Supply...................................................................113

Figure 45: Radio Management Settings to Configure SLR 1000 Repeater for Analog Mode.............. 126

Figure 46: Model L3276 Tone Remote Adapter................................................................................... 127

Figure 47: Signal Connections Between SLR 1000 Repeater and Motorola L3276 25-Pin

Connector for a 2-Channel Remote Control.................................................................................... 128

Figure 48: Radio Management Configuration for L3276 Tone Remote Adapter (for a 2-Channel

Remote Control).............................................................................................................................. 130

19

MN003557A01-AF

List of Tables

List of Tables

Table 1: SLR 1000 Repeater Bottom View Callout Legend................................................................... 29

Table 2: SLR 1000 Repeater Left View Callout Legend

Table 3: SLR 1000 Repeater Right View Callout Legend...................................................................... 30

Table 4: SLR 1000 Repeater Front View Callout Legend...................................................................... 33

Table 5: SLR 1000 Repeater Connections Callout Legend....................................................................35

Table 6: SLR 1000 Frequency Ranges and Power Levels.....................................................................36

Table 7: SLR 1000 Repeater General Specifications (All Bands).......................................................... 37

Table 8: SLR 1000 Repeater Specifications...........................................................................................38

Table 9: SLR 1000 Repeater Front Panel LED Indicators......................................................................42

Table 10: SLR 1000 Front Panel LED Definitions.................................................................................. 42

Table 11: SLR 1000 Repeater Front View (without Top Cover) Callout Legend....................................49

Table 12: SLR 1000 Repeater Specifications of the Receiver Subsystem.............................................51

Table 13: SLR 1000 Repeater Specifications of the Transmitter Exciter Subsystem.............................52

Table 14: SLR 1000 Repeater Bottom View Callout Legend................................................................. 56

Table 15: DC Power Inlet Connector Callout Legend.............................................................................57

Table 16: USB Connector Callout Legend............................................................................................. 58

Table 17: Ethernet Connector Callout Legend....................................................................................... 59

Table 18: Auxiliary/Accessory Connector Callout Legend......................................................................60

Table 19: Recommended Test Equipment............................................................................................. 62

Table 20: Service Aids............................................................................................................................62

Table 21: SLR 1000 Repeater Front View (without top Cover) Callout Legend..................................... 85

Table 22: SLR 1000 Repeater Front View (without top Cover) with a Duplexer Callout Legend........... 87

Table 23: SLR 1000 Repeater Front View (without top Cover) Callout Legend..................................... 89

Table 24: SLR 1000 Repeater Front View (without top Cover) with an Antenna Switch Callout

Legend...............................................................................................................................................91

Table 25: SLR 1000 Repeater Package Contents............................................................................... 100

Table 26: SLR 1000 Repeater Connector Types and Primary Functions............................................ 109

Table 27: Indoor EME Compliance Distances Based on the UHF Evaluation Example (applicable

antennas: HKAE4003, HKAE4004, and HKAE4005)...................................................................... 132

Table 28: Outdoor EME Compliance Distances Based on the UHF Evaluation Example

(applicable antenna: DB408-B)....................................................................................................... 133

Table 29: Indoor EME Compliance Distances Based on the VHF Evaluation Example (applicable

antenna:HKAD4003, HKAD4004 and HKAD4005)......................................................................... 133

Table 30: Antenna Characteristics....................................................................................................... 133

Table 31: Reference and Validation Results........................................................................................ 138

Table 32: Compliance Distance in General Public Exposure (UHF).................................................... 140

Table 33: Compliance Distance in Occupational-Type Exposure (UHF)..............................................140

.........................................................................30

20

MN003557A01-AF

List of Tables

Table 34: Compliance Distance in General Public Exposure and Occupational-Type Exposure

(UHF)...............................................................................................................................................

140

Table 35: Compliance Distance in General Public Exposure (VHF).................................................... 141

Table 36: Compliance Distance in Occupational-Type Exposure (VHF)..............................................141

21

MN003557A01-AF

List of Procedures

List of Procedures

Verifying Transmitter Circuitry ............................................................................................................... 65

Verifying Receiver Circuitry

Tuning the Reference Oscillator ............................................................................................................ 72

Tuning the Rx Audio Level Set .............................................................................................................. 72

Tuning the Tx Audio Level Set .............................................................................................................. 73

Tuning the Modulation Limit (with no Tx Data and no PL) .....................................................................75

Verifying the Modulation Limit (with no Tx Data and no PL) ..................................................................76

Tuning a Duplexer Module .................................................................................................................... 76

Installing a Duplexer .............................................................................................................................. 84

Installing a High-Speed Solid-State Antenna Switch .............................................................................88

Mounting the SLR 1000 Repeater to a Wall or Ceiling ........................................................................100

Mounting the SLR 1000 Repeater to a Pole ........................................................................................103

Connecting the DC Input Power .......................................................................................................... 110

Connecting the Indoor Adapter AC Input Power ................................................................................. 111

Assembling an Outdoor Power Supply ................................................................................................111

Installing Cable Grommet Connectors or Plugs .................................................................................. 114

................................................................................................................... 67

22

Related Publications

Related Publications Part No.

MOTOTRBO SLR 1000 Quick Start Guide MN003581A01

MN003557A01-AF

Related Publications

23

MN003557A01-AF

Summary of Bands Available

Summary of Bands Available

The following table lists the SLR 1000 Repeater bands available in this manual.

For details, see Repeater Model Chart

Frequency Band Bandwidth Power Level

on page 44.

VHF

UHF

136-174 MHz

400–512 MHz

1–10 W

1-10 W

24

Notice

Commercial Warranty

Related Links

MN003557A01-AF

Commercial Warranty

Limited Commercial Warranty on page

25

Limited Commercial Warranty

This limited commercial warranty describes the conditions under, and period during, which the repeater

is repaired, replaced, and what is not covered.

I. What This Warranty Covers And For How Long

MOTOROLA SOLUTIONS INC. (“MOTOROLA”) warrants the MOTOROLA manufactured

Communication Products listed below (“Product”) against defects in material and workmanship under

normal use and service for a period of time from the date of purchase as scheduled below:

Repeater Two (2) Years

Product Accessories One (1) Year

Motorola, at its option, will at no charge either repair the Product (with new or reconditioned parts),

replace it (with a new or reconditioned Product), or refund the purchase price of the Product during the

warranty period provided it is returned in accordance with the terms of this warranty. Replaced parts or

boards are warranted for the balance of the original applicable warranty period. All replaced parts of

Product shall become the property of MOTOROLA.

This express limited warranty is extended by MOTOROLA to the original end user purchaser only and

is not assignable or transferable to any other party. This is the complete warranty for the Product

manufactured by MOTOROLA. MOTOROLA assumes no obligations or liability for additions or

modifications to this warranty unless made in writing and signed by an officer of MOTOROLA. Unless

made in a separate agreement between MOTOROLA and the original end user purchaser,

MOTOROLA does not warrant the installation, maintenance or service of the Product.

MOTOROLA cannot be responsible in any way for any ancillary equipment not furnished by

MOTOROLA which is attached to or used in connection with the Product, or for operation of the

Product with any ancillary equipment, and all such equipment is expressly excluded from this warranty.

Because each system which may use the Product is unique, MOTOROLA disclaims liability for range,

coverage, or operation of the system as a whole under this warranty.

II. General Provisions

This warranty sets forth the full extent of MOTOROLA's responsibilities regarding the Product. Repair,

replacement or refund of the purchase price, at MOTOROLA's option, is the exclusive remedy. THIS

WARRANTY IS GIVEN IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES,

INCLUDING WITHOUT LIMITATION, IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO THE DURATION OF THIS LIMITED

WARRANTY. IN NO EVENT SHALL MOTOROLA BE LIABLE FOR DAMAGES IN EXCESS OF THE

PURCHASE PRICE OF THE PRODUCT, FOR ANY LOSS OF USE, LOSS OF TIME,

INCONVENIENCE, COMMERCIAL LOSS, LOST PROFITS OR SAVINGS OR OTHER INCIDENTAL,

SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OR INABILITY TO USE

SUCH PRODUCT, TO THE FULL EXTENT SUCH MAY BE DISCLAIMED BY LAW.

III. State Law Rights

25

MN003557A01-AF

Notice Commercial Warranty

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LIMITATION ON HOW LONG AN IMPLIED WARRANTY LASTS,

SO THE ABOVE LIMITATION OR EXCLUSIONS MAY NOT APPLY.

This warranty gives specific legal rights, and there may be other rights which may vary from state to

state

IV. How To Get Warranty Service

You must provide proof of purchase (bearing the date of purchase and Product item serial number) in

order to receive warranty service and, also, deliver or send the Product item, transportation and

insurance prepaid, to an authorized warranty service location. Warranty service will be provided by

Motorola through one of its authorized warranty service locations. If you first contact the company

which sold you the Product, it can facilitate your obtaining warranty service. You can also .

V. What This Warranty Does Not Cover

Defects or damage resulting from use of the Product in other than its normal and customary manner.

Defects or damage from misuse, accident, water, or neglect.

Defects or damage from improper testing, operation, maintenance, installation, alteration, modification,

or adjustment.

Breakage or damage to antennas unless caused directly by defects in material workmanship.

A Product subjected to unauthorized Product modifications, disassemblies or repairs (including, without

limitation, the addition to the Product of non-Motorola supplied equipment) which adversely affect

performance of the Product or interfere with Motorola's normal warranty inspection and testing of the

Product to verify any warranty claim.

Product which has had the serial number removed or made illegible.

Freight costs to the repair depot.

A Product which, due to illegal or unauthorized alteration of the software/firmware in the Product, does

not function in accordance with MOTOROLA’s published specifications or the FCC type acceptance

labeling in effect for the Product at the time the Product was initially distributed from MOTOROLA.

Scratches or other cosmetic damage to Product surfaces that does not affect the operation of the

Product.

Normal and customary wear and tear.

VI. Patent And Software Provisions

MOTOROLA will defend, at its own expense, any suit brought against the end user purchaser to the

extent that it is based on a claim that the Product or parts infringe a United States patent, and

MOTOROLA will pay those costs and damages finally awarded against the end user purchaser in any

such suit which are attributable to any such claim, but such defense and payments are conditioned on

the following:

that MOTOROLA will be notified promptly in writing by such purchaser of any notice of such claim;

that MOTOROLA will have sole control of the defense of such suit and all negotiations for its

settlement or compromise; and

should the Product or parts become, or in MOTOROLA's opinion be likely to become, the subject of a

claim of infringement of a United States patent, that such purchaser will permit MOTOROLA, at its

option and expense, either to procure for such purchaser the right to continue using the Product or

parts or to replace or modify the same so that it becomes noninfringing or to grant such purchaser a

credit for the Product or parts as depreciated and accept its return. The depreciation will be an equal

amount per year over the lifetime of the Product or parts as established by MOTOROLA.

MOTOROLA will have no liability with respect to any claim of patent infringement which is based upon

the combination of the Product or parts furnished hereunder with software, apparatus or devices not

furnished by MOTOROLA, nor will MOTOROLA have any liability for the use of ancillary equipment or

26

MN003557A01-AF

Notice Commercial Warranty

software not furnished by MOTOROLA which is attached to or used in connection with the Product.

The foregoing states the entire liability of MOTOROLA with respect to infringement of patents by the

Product or any parts thereof.

Laws in the United States and other countries preserve for MOTOROLA certain exclusive rights for

copyrighted MOTOROLA software such as the exclusive rights to reproduce in copies and distribute

copies of such Motorola software. MOTOROLA software may be used in only the Product in which the

software was originally embodied and such software in such Product may not be replaced, copied,

distributed, modified in any way, or used to produce any derivative thereof. No other use including,

without limitation, alteration, modification, reproduction, distribution, or reverse engineering of such

MOTOROLA software or exercise of rights in such MOTOROLA software is permitted. No license is

granted by implication, estoppel or otherwise under MOTOROLA patent rights or copyrights.

VII. Governing Law

This Warranty is governed by the laws of the State of Illinois, USA.

Return to Process

Commercial Warranty on page 25

27

MN003557A01-AF

Chapter 1: SLR 1000 Repeater

Chapter 1

SLR 1000 Repeater

The Motorola Solutions SLR 1000 Repeater provides a modular, flexible analog and digital station

designed for today's communication systems and for the future.

Related Links

Repeater Description

Repeater Operating Features on page 35

Repeater Frequency Ranges and Power Levels on page 36

Repeater Specifications on page 37

Repeater Theory of Operation on page 40

Basic Repeater Level Troubleshooting – RDAC and LEDs on page 41

Repeater Model Numbering Scheme on page 43

Repeater Model Chart on page 44

1.1

on page 28

Repeater Description

The station is available for use in these configurations:

• Analog Conventional

• Digital (MOTOTRBO)

• MOTOTRBO DMR Tier 2 Conventional – Single Site

• MOTOTRBO DMR Tier 2 Conventional – IP Site Connect

• MOTOTRBO Capacity Plus Trunking

• MOTOTRBO Connect Plus Trunking

• MOTOTRBO Capacity Max Trunking

• MOTOTRBO Digital Voting

NOTICE: Certain software features enabled through Radio Management can be configured with

the Online Help or with a regional representative. See the regional Ordering Guide to determine

the features available within the respective regions.

The repeater can either be configured as a stand-alone repeater or as a repeater connected to a

network, as in the case of operating in IP Site Connect mode. As a repeater, it listens on one uplink

frequency, and then re-transmits on a downlink frequency, thus providing the RF interface to the field

subscribers. When configured for analog station operation, the repeater is designed to operate with

most existing analog systems, which enables a smooth migration to the MOTOTRBO system.

When configured for digital operation, the repeater offers additional services. The digital repeater

operates in TDMA mode, which essentially divides one channel into two virtual channels using time

slots; therefore the user capacity is doubled. The repeater utilizes embedded signaling to inform the

field radios of the busy/idle status of each channel (time slot), the type of traffic, and even the source

and destination information.

See the following figures and tables for connections, ports, LEDs, and their descriptions.

28

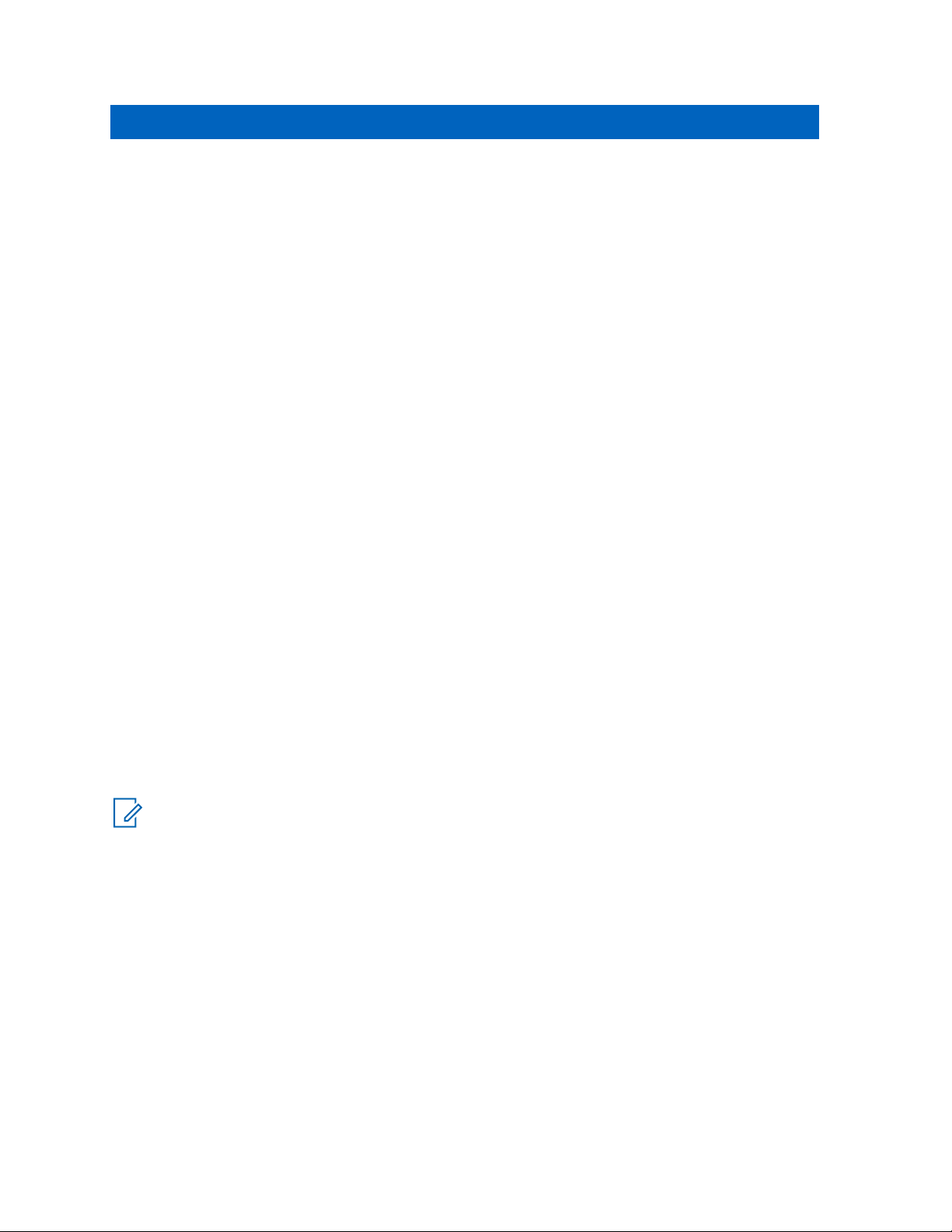

Figure 1: SLR 1000 Repeater Bottom View

1 2 3 4 5

1 2

MN003557A01-AF

Chapter 1: SLR 1000 Repeater

Table 1: SLR 1000 Repeater Bottom View Callout Legend

Label Description

1 USB Port Programming Interface

2 Ethernet Port

3 Aux/Accessory Port

4 DC Power Inlet

5 Bonding Ground Connection

Figure 2: SLR 1000 Repeater Left View

29

1 2

MN003557A01-AF

Chapter 1: SLR 1000 Repeater

Table 2: SLR 1000 Repeater Left View Callout Legend

Label Description

1 Receiver RF (Rx) Input Cable Port

2 Option Dependent 1/GNSS

Option Dependent 2/WLAN

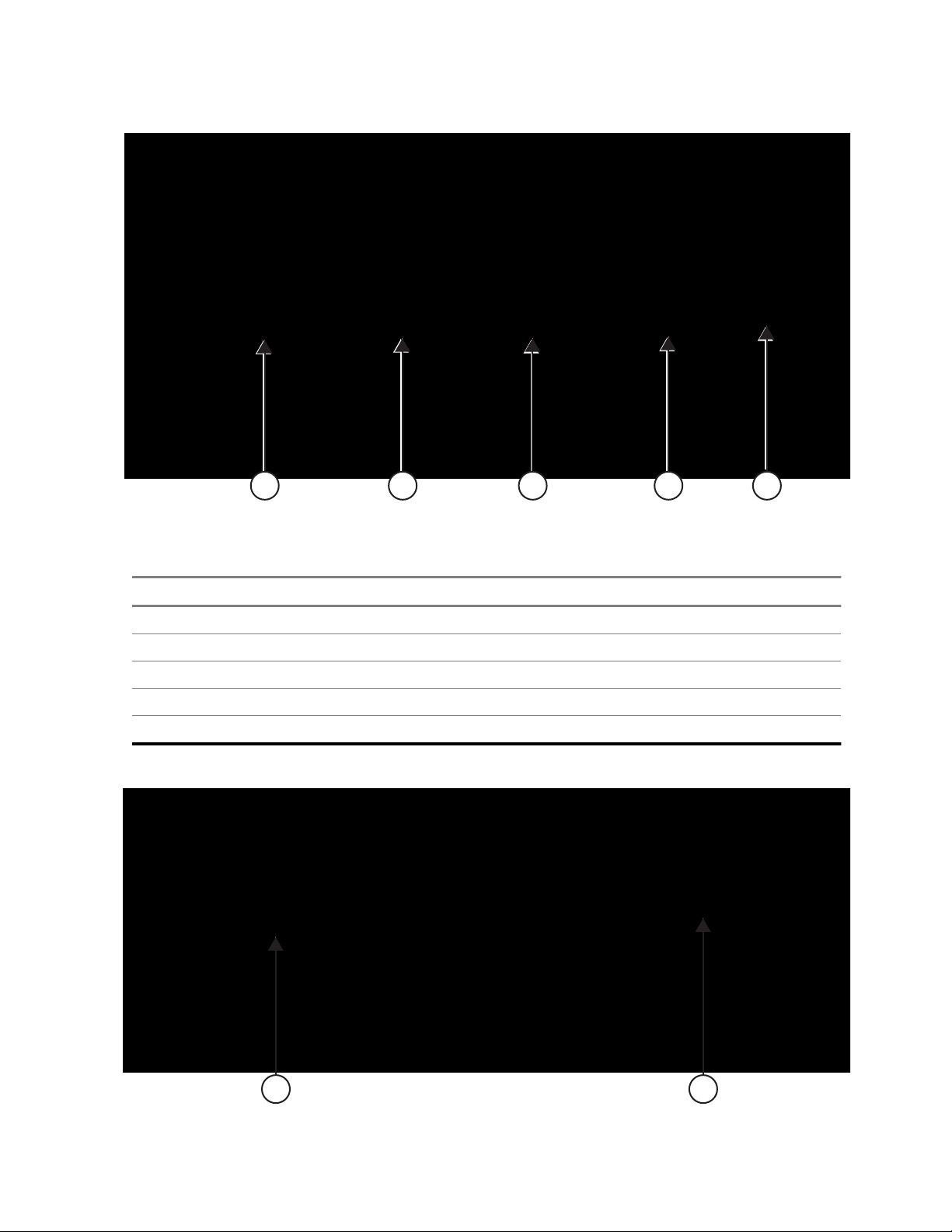

Figure 3: SLR 1000 Repeater Right View

Table 3: SLR 1000 Repeater Right View Callout Legend

Label Description

1 Transmitter RF (Tx) Output Cable Port

2 Pressure Equalization Vent

30

Figure 4: SLR 1000 Repeater Back View

MN003557A01-AF

Chapter 1: SLR 1000 Repeater

31

1 2 3

MN003557A01-AF

Chapter 1: SLR 1000 Repeater

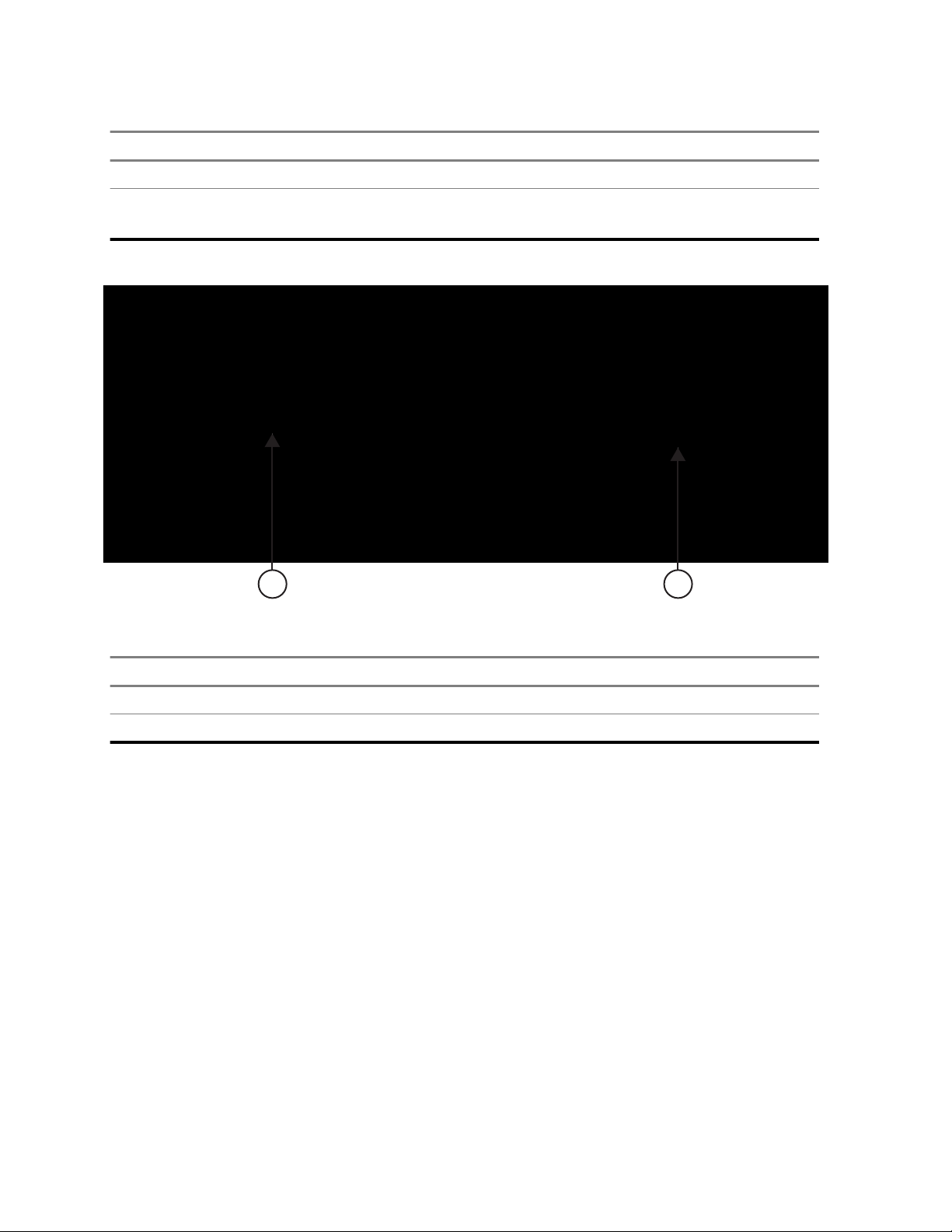

Figure 5: SLR 1000 Repeater Padlock Opening

Figure 6: SLR 1000 Repeater Front View

32

Table 4: SLR 1000 Repeater Front View Callout Legend

Label Description

1 Status

2 Ethernet Link/Network Connectivity

3 Reference (for future use)

MN003557A01-AF

Chapter 1: SLR 1000 Repeater

33

6

1

2

14

3

4

5

7910

8

11

13

12

15

MN003557A01-AF

Chapter 1: SLR 1000 Repeater

Figure 7: SLR 1000 Repeater Connections

34

Chapter 1: SLR 1000 Repeater

Table 5: SLR 1000 Repeater Connections Callout Legend

Label Description

1 Transmitter RF (Tx) Output Board Connection

2 Pressure Equalizer Vent

3 Receiver RF (Rx) Input Board Connection

4 Transmitter RF (Tx) Output Cable Port

5 Jumper Connection to enable external on/off function

6 Bonding Ground Connection

7 DC Power Inlet

8 Header Connection for optional antenna switch

9 Aux/Accessory Port

10 Ethernet Port

11 USB Port Programming Interface

12 Option Dependent 1 and 2

MN003557A01-AF

13 Expansion Board Connection (for future use)

14 Receiver RF (Rx) Input Cable Port

15 Front Panel Flex Connector

Return to Process

SLR 1000 Repeater on page

1.2

28

Repeater Operating Features

The SLR 1000 Repeater model provides the following features and interfaces.

Standard Features

• MOTOTRBO Conventional Operation (2-Slot TDMA, 4FSK Modulation)

• Analog Conventional Operation (FM)

• Continuous Duty Cycle Operation over -30 °C to +60 °C

• Meets or exceeds the following standards:

- TIA603E

- ETSI 086

- ETSI 113

- ETSI TS 102 361-1 Part 1: DMR Air Interface Protocol

- ETSI TS 102 361-2 Part 2: DMR Voice and Generic Services and Facilities

- ETSI TS 102 361-3 Part 3: DMR Packet Data Protocol

- ETSI TS 102 361-4 Part 4: DMR Trunking Protocol

• Synthesized Frequency Generation

• Female N-type Antenna Connector (Tx)

• Female N-type Antenna Connector (Rx)

35

MN003557A01-AF

Chapter 1: SLR 1000 Repeater

• Ethernet Port (Network)

USB Port (Service)

•

• Four configurable GPIO ports (Digital)

• One configurable GPI port (Analog)

• One configurable GPO port (Analog)

• 1.5 PPM Frequency Stability (temperature AND 1-year aging) (VHF and UHF)

• Station Diagnostic Tests – fixed set of tests run upon start-up

• Physical Dimensions: 11" H x 9" W x 4" D (27.94 x 22.86 x 10.16 cm) without brackets or other

peripheral equipment

• Weight: 10 pounds (4.56 kg) excluding other peripheral equipment

Motorola Solutions Network Interface

• IP Site Connect

• Repeater Diagnostics and Control (RDAC)

• Capacity Plus

• Connect Plus

• Capacity Max

Third Party Controller Interface

• Tone Remote Adapter

Additional Features

These features are shipped in a preset condition, but may be altered through the use of Radio

Management.

• 64 Tx/Rx Frequencies – factory programmed with 1 Tx, 1 Rx

• 12.5 kHz or 25 kHz Operation – factory programmed to 12.5 kHz

• One Tx and one Rx (PL or DPL) Squelch Code per channel – factory programmed to CSQ

• Base Station Identification (BSI) – factory programmed as “BLANK” (“BLANK” disables BSI)

• Push-To-Talk (PTT) Priority – factory programmed to repeat path

Return to Process

SLR 1000 Repeater on page 28

1.3

Repeater Frequency Ranges and Power Levels

The SLR 1000 Repeater is available in various UHF frequency ranges and power levels as specified in

the following table.

Table 6: SLR 1000 Frequency Ranges and Power Levels

Frequency

Band

VHF 136–174 MHz 1-10 W

36

Bandwidth Power Level

MN003557A01-AF

Chapter 1: SLR 1000 Repeater

Frequency

Band

UHF 400–512 MHz 1–10 W

Bandwidth Power Level

Self-Quieting Frequencies

When using an indoor antenna, there is a potential for degraded receiver performance with the

following frequencies:

VHF UHF

147.03125 MHz 400 MHz

150 MHz 403.2 MHz

153.6 MHz 422.4 MHz

425 MHz

441.6 MHz

450 MHz

460.8 MHz

475 MHz

480 MHz

499.2MHz

500 MHz

518.4 MHz

525 MHz

Return to Process

SLR 1000 Repeater on page

1.4

28

Repeater Specifications

The SLR 1000 Repeater meets the following Radio Frequency (RF) operating specifications.

Table 7: SLR 1000 Repeater General Specifications (All Bands)

Parameter Specifications

Number of Channels 64

Frequency Generation Synthesized

Input Voltage DC 10.8–15.6 VDC

Station Weight 10 lbs (4.56 kg)

Temperature Range -30 °C to +60 °C (-22 °F to +140 °F)

Ingress IP65, NEMA 4

Antenna Connectors Tx: N-type Rx: N-type

Modes of Operation Half-Duplex/ Duplex

37

MN003557A01-AF

Chapter

1: SLR 1000 Repeater

Parameter Specifications

Height 11” (27.94 cm)

Width 9” (22.86 cm)

Depth 4” (10.16 cm)

Table 8: SLR 1000 Repeater Specifications

All specifications are in accordance to their respective TIA603E, ETSI 300 – 086, and ETSI 300 – 113

standards unless otherwise noted.

Parameter Specifications

VHF UHF

Input Power (All Modulations)

Standby (13.6 VDC) 0.73 A

10 W Transmit at Rated

3 A

Power (13.6 VDC)

Frequency Reference

Internal Frequency Sta-

±0.5 PPM (temperature)

bility (PPM)

Frequency Bands

Electronic Bandwidth 136-174 MHz 400-512 MHz

Receiver

Selectivity 25 kHz / 12.5

83/68 dB 80 dB/68dB

kHz (TIA603)

Selectivity 25 kHz / 12.5

70 dB/63 dB

kHz (ETSI)

Sensitivity (12 dB SI-

0.3 uV

NAD)

Sensitivity (5% BER) 0.3 uV

Intermodulation Rejec-

80 dB

tion (TIA603E)

Intermodulation Rejec-

70 dB

tion (ETSI)

Spurious Rejection

85 dB

(TIA603E)

Spurious Rejection (ET-

75 dB

SI)

Conducted Spurious

-57 dBm

Emissions

Audio Distortion <3%

Audio Response Per TIA/ ETSI

1

Typical performance under the following conditions (when applicable): Nominal VSWR conditions (VSWR <1.5:1)

38

Parameter Specifications

VHF UHF

MN003557A01-AF

Chapter 1: SLR 1000 Repeater

FM Hum and Noise 25

kHz / 12.5 kHz

Rated Output Power

(Continuous Duty)

Intermodulation Attenuation

Adjacent Channel Power 25 kHz / 12.5 kHz

Modulation Fidelity

(4FSK)

Wideband Noise (1

MHz) @ Rated Pout

Rated System Deviation

Spurious Harmonics

and Emissions

-50 dB/ -45 dB

Transmitter

1 – 10 W

40 dB

75 dB / 60 dB

FSK Error 5%

FSK Magnitude 1%

-152 dBc/ Hz

±2.5 kHz @ 12.5 kHz

±5.0 kHz @ 25 kHz

-40 dBm < 1 GHz,

-30 dBm > 1 GHz

Audio Distortion < 3%

Audio Response Per TIA/ ETSI

FM Hum and Noise 25

-50 dB/ -45 dB

kHz / 12.5 kHz

FCC Identifier ABZ99FT3096 ABZ99FT4100

Industry Canada

IC Certification/Registra-

109AB-99FT3096 109AB-99FT4100

tion Number

IC Model Number SLR 1000-VHF SLR 1000-UHF

Tx/Rx Frequency Range Tx: 138-174 MHz

Rx: 138-174 MHz

Tx: 406.1-430 MHz and

450-470 MHz

Rx:406.1-430 MHz and

450-470 MHz

FCC Emission Designators

11K0F3E

16K0F3E

7K60FXD

7K60F7D

7K60FXE

39

MN003557A01-AF

Chapter 1: SLR 1000 Repeater

Parameter Specifications

VHF UHF

7K60F7E

7K60F7W

7K60FXW

Return to Process

SLR 1000 Repeater on page

1.5

28

Repeater Theory of Operation

The SLR 1000 Repeater provides the radio frequency (RF) link between the network infrastructure and

the subscriber radios.

The repeater acquires inbound signals through its external receive (Rx) antenna and then amplifies,

filters, and demodulates the signals into data or voice packets. From that point, the data is either

forwarded to the repeater’s transmitter to subscriber radios, and/or the data is delivered through a

wired interface for distribution to networked repeaters, consoles, or other networked infrastructure.

The repeater consists of a single transceiver board. The transceiver board is comprised of three

subsystems:

Receiver Subsystem

The Receiver subsystem is a dual heterodyne Receiver which receives the RF signal from the

subscriber’s transmitter. It then converts the resulting final Intermediate Frequency (IF) from an

analog signal to that of a digital word in IQ signal format. Finally, the Receiver delivers the IQ

signal, through the Synchronous Serial Interface (SSI) bus, to the Station Control subsystem for

demodulation. Also, the Receiver subsystem provides its own metering and diagnostics through

software, and self-contained calibration (no field tuning is needed for the Receiver subsystem).

Transmitter Subsystem

The Transmitter subsystem converts a two-port base band data signal, sent over the SSI bus from

the Station Control subsystem, to an analog signal representation. The Exciter subsystem

modulates the analog signal with a low-power RF transmitter carrier. The power modulated RF

carrier is then amplified and delivered to the antenna. The Exciter subsystem constitutes the

transmitter of the repeater. Also, the Exciter subsystem provides its own metering and diagnostics

through software, and a self-contained calibration (no field tuning is needed for the Exciter

subsystem).

The Transmitter subsystem delivers the amplified signal to the transmitter antenna port at a power

level within the rated power band of the repeater, for transmission to the subscriber radios. In

addition, it provides the following hardware functions for the repeater.

• Harmonic attenuation

• Inter-modulation attenuation (IMA) suppression

• RF power control (primary means)

• Meters for diagnostics

• Power rollback for temperature

• Self-Contained calibration (no field alignment is needed for the power amplifier).

40

MN003557A01-AF