“DRAFT”

Developer’s Guide

iO200 OEM Module

Module Description

Version: 01.00-D06

Date: Nov 28, 2004

© Motorola Israel Ltd., 2004

A subsidiary of Motorola Inc. All rights re served.

Documentation Copyrights

No duplication or distribution of this document or any portion thereof shall take place without the express

written permission of Motorola. No part of this manual may be reproduced, distributed, or transmitted in any

form or by any means, electronic or mechanical, for any purpose without the express written permission of

Motorola. To order additional copies contact your Motorola sales representative.

© 2004 Motorola

All Rights Reserved

Table of Contents

1.

Introduction......................................................................................................................................................................... 8

1.1. USING THIS GUIDE................................................................................................................................................ 8

1.2. PURPOSE ................................................................................................................................................................. 8

1.3. INTENDED AUDIENCE.......................................................................................................................................... 8

1.4. DISCLAIMER........................................................................................................................................................... 8

2. GENERAL NOTICES........................................................................................................................................................ 9

2.1. Safety Notice - ATTENTION ................................................................................................................................... 9

2.2. FCC Regulation - Letter of Notice ............................................................................................................................ 9

3. THE INTEGRATOR'S TASK.......................................................................................................................................... 10

3.1. GENERAL .............................................................................................................................................................. 10

3.2. INTRODUCTION................................................................................................................................................... 10

3.3. PLANNING THE PRODUCT AND CREATING THE DESIGN ......................................................................... 11

3.3.1. Developing a Usage Model................................................................................................................................. 11

3.3.2. Developing a Message Model............................................................................................................................. 11

3.3.3. Defining a Service Strategy................................................................................................................................ 12

3.3.4. Defining Remote Diagnostic Functionality ........................................................................................................ 12

3.3.5. Investigating and Obtaining Regulatory Approval ............................................................................................. 13

3.4. DEVELOPING AND VALIDATING THE HARDWARE.................................................................................... 13

3.5. Designing the Hardware Platform ........................................................................................................................... 13

3.6. Considering Power Supply Options......................................................................................................................... 13

3.7. Selecting the Antenna.............................................................................................................................................. 14

3.8. Setting Up a Development Test Environment......................................................................................................... 14

3.9. DEVELOPING SUPPORTING APPLICATION SOFTWARE............................................................................. 14

3.10. TESTING AND APPROVING THE PRODUCT................................................................................................... 14

3.11. Setting Up a Final Test Environment ...................................................................................................................... 14

3.12. Installing and Field-Testing the Product.................................................................................................................. 14

3.13. RESOURCE ASSISTANCE................................................................................................................................... 15

3.14. Integrating Engineering Support .............................................................................................................................15

3.15. ENVIRONMENTAL ISSUES ................................................................................................................................ 16

3.16. General Precautions................................................................................................................................................. 16

3.17. ESD Handling Precautions...................................................................................................................................... 16

4. MODEL DESCRIPTION ................................................................................................................................................. 17

4.1. GENERAL .............................................................................................................................................................. 17

4.2. INTRODUCTION................................................................................................................................................... 17

4.3. PRODUCT FEATURES ......................................................................................................................................... 17

4.4. INTERFACE CONNECTORS................................................................................................................................ 17

4.5. INTEGRATOR’S KIT ............................................................................................................................................ 18

4.6. MOUNTING ........................................................................................................................................................... 18

5. DESIGN CONSIDERATIONS ........................................................................................................................................ 19

5.1. GENERAL .............................................................................................................................................................. 19

5.2. POWER SUPPLY CONSIDERATIONS................................................................................................................ 19

5.3. Power Supply Losses............................................................................................................................................... 19

5.4. IO200 Current Consumption ................................................................................................................................... 19

5.5. IO200 Output Voltage ............................................................................................................................................. 20

5.6. Turning the Unit On ................................................................................................................................................20

5.7. Turning the Unit OFF By ON/OFF pin................................................................................................................... 21

5.8. AUDIO CIRCUIT CONSIDERATIONS................................................................................................................ 22

2

5.9.

Audio Interface........................................................................................................................................................ 22

5.10. Nominal Audio Signal............................................................................................................................................. 22

5.11. Audio Processing and Control................................................................................................................................. 23

5.12. COMMUNICATION .............................................................................................................................................. 23

5.13. SIM CARD CONSIDERATIONS .......................................................................................................................... 25

5.14. SIM Connection ...................................................................................................................................................... 25

5.15. ESD CONSIDERATIONS...................................................................................................................................... 26

5.16. ANTENNA CONSIDERATIONS .......................................................................................................................... 26

5.17. Antenna Systems ..................................................................................................................................................... 26

5.18. Antenna Safety ........................................................................................................................................................ 26

5.19. ESD Protection ........................................................................................................................................................ 26

5.20. Antenna Performance.............................................................................................................................................. 26

5.21. Portable Devices...................................................................................................................................................... 26

5.22. Fixed Devices.......................................................................................................................................................... 27

5.23. Antenna Test Methods............................................................................................................................................. 27

5.24. MECHANICS - MOUNTING IO200 .....................................................................................................................28

5.25. Fastening Units into the terminal............................................................................................................................. 28

5.26. GPS CONSIDERATIONS ...................................................................................................................................... 28

6. AT COMMANDS............................................................................................................................................................. 29

6.1. Data Services........................................................................................................................................................... 29

6.2. Supplementary AT commands ................................................................................................................................ 29

7. GPS AT COMMANDS .................................................................................................................................................... 30

7.1. GPS Request +WVGPS........................................................................................................................................... 30

7.2. GPS and Location Services ..................................................................................................................................... 30

8. SOFTWARE INTERFACE ..............................................................................................................................................31

8.1. Extended Error Codes.............................................................................................................................................. 31

9. CALL SCENARIO ........................................................................................................................................................... 32

9.1. General .................................................................................................................................................................... 32

9.2. List Current Voice Calls.......................................................................................................................................... 32

9.3. Get Subscriber Numbers.......................................................................................................................................... 33

9.4. Phone Activity Status .............................................................................................................................................. 34

9.5. Get User Identity ..................................................................................................................................................... 34

9.6. SIM access............................................................................................................................................................... 35

9.7. Signal Strength Access............................................................................................................................................ 35

9.8. Call Timers.............................................................................................................................................................. 36

9.9. Cell Tower Information........................................................................................................................................... 37

9.10. Equipment Information ........................................................................................................................................... 37

9.11. Trace Mode.............................................................................................................................................................. 38

9.12. GPS data.................................................................................................................................................................. 39

9.13. Operating Mode change .......................................................................................................................................... 40

9.15. Security Functionality ............................................................................................................................................. 43

9.16. Master Reset ............................................................................................................................................................ 45

9.17. Normal Group.......................................................................................................................................................... 46

9.18. Private Call.............................................................................................................................................................. 51

9.19. Call Alert ................................................................................................................................................................. 51

9.20. Telephone Interconnect ........................................................................................................................................... 51

9.21. Phone Only Mode.................................................................................................................................................... 51

9.22. Supplemental Services............................................................................................................................................. 51

9.23. Circuit Data Call...................................................................................................................................................... 51

9.24. Packet Data Service................................................................................................................................................. 51

9.25. Short Message Service ............................................................................................................................................ 51

9.26. Message Description ............................................................................................................................................... 51

9.27. TERMINAL -> io200.............................................................................................................................................. 51

9.28. io200 -> TERMINAL.............................................................................................................................................. 51

9.29. AT Command Cross-Reference............................................................................................................................... 51

9.30. Multiple Channel Access......................................................................................................................................... 51

9.31. Interconnect Call Extensions................................................................................................................................... 51

9.32. Private Call Extensions............................................................................................................................................ 51

10. GSM MUX INTEGRATION....................................................................................................................................... 51

3

10.1.

Gemini Processor Architecture................................................................................................................................ 51

10.2. General Definitions ................................................................................................................................................. 51

10.3. Initialization............................................................................................................................................................. 51

10.4. IPC Commands/Protocols ....................................................................................................................................... 51

10.5. IPC Channel Configuration ..................................................................................................................................... 51

10.6. DL-CNTL (multiplexer control).............................................................................................................................. 51

10.7. DL-TEL (AT Telephony & Control)....................................................................................................................... 51

10.8. AT availability......................................................................................................................................................... 51

10.9. DL-SIM (SIM access control) ................................................................................................................................. 51

3.3.6. DL-AUD_CNTL ................................................................................................................................................ 51

3.3.7. DL-DATA1 (Internal Packet Data) ....................................................................................................................51

3.3.8. DL-DATA2 (External Packet Data and Circuit Data control)............................................................................ 51

10.10. DL-NMEA (GPS data) ....................................................................................................................................... 51

11. HARDWARE............................................................................................................................................................... 51

11.1. GENERAL .............................................................................................................................................................. 51

11.2. HOST INTERFACE................................................................................................................................................ 51

12. TESTING ..................................................................................................................................................................... 51

12.1. GENERAL .............................................................................................................................................................. 51

12.2. TESTING STAGES ................................................................................................................................................ 51

12.3. Hardware Integration............................................................................................................................................... 51

12.4. Enabler Functions.................................................................................................................................................... 51

12.5. Specific Tests .......................................................................................................................................................... 51

12.6. Desense and EMI..................................................................................................................................................... 51

12.7. Regulatory Compliance ........................................................................................................................................... 51

12.8. Application Software............................................................................................................................................... 51

12.9. Final Assembly........................................................................................................................................................ 51

12.10. End User Problem Resolution............................................................................................................................. 51

12.11. OEM Service Depot Repair ................................................................................................................................ 51

12.12. TROUBLESHOOTING ..................................................................................................................................... 51

13. SPECIFICATIONS...................................................................................................................................................... 51

13.1. GENERAL .............................................................................................................................................................. 51

13.2. MODEL SPECIFICATIONS .................................................................................................................................. 51

13.3. PIN DESCRIPTIONS .............................................................................................................................................51

13.4. Main Interface Connector........................................................................................................................................ 51

13.5. SIM Interface Connector ......................................................................................................................................... 51

13.6. MECHANICAL SPECIFICATION DIAGRAMS.................................................................................................. 51

14. GLOSSARY................................................................................................................................................................. 51

15. REFERENCES............................................................................................................................................................. 51

16. DESENSE .................................................................................................................................................................... 51

17. PC Applications ........................................................................................................................................................... 51

17.1. Upgrade Utility Application .................................................................................................................................... 51

17.2. Diagnostic application ............................................................................................................................................. 51

17.3. RF Tester Utility...................................................................................................................................................... 51

18. PPP Connection Setup.................................................................................................................................................. 51

18.1. Optional step (see note on page 6): Standard Modem setting instructions.............................................................. 51

18.2. Baud Rate ................................................................................................................................................................ 51

4

Figures

FIGURE 1. ON/OFF ...................................................................................................21

FIGURE 2. ELECTRICAL INTERFACE FOR AUDIO INPUT AND OUTPUT SIGNALS22

FIGURE 3. AUDIO MODE..........................................................................................23

FIGURE 4. SHOWS IO200 SIM CONNECTION........................................................25

FIGURE 5. MOUNTING IO200 MODEM (ISO VIEW) ................................................28

FIGURE 6. LIST CURRENT VOICE CALLS..............................................................32

FIGURE 7. GET SUBSCRIBER NUMBERS..............................................................33

FIGURE 8. PHONE ACTIVITY STATUS....................................................................34

FIGURE 9. GET USER IDENTITY.............................................................................34

FIGURE 10. SIM ACCESS...........................................................................................35

FIGURE 11. SIGNAL STRENGTH REQUEST.............................................................35

FIGURE 12. CALL TIMER QUERY..............................................................................36

FIGURE 13. RESET CALL TIMER...............................................................................36

FIGURE 14. CELL INFO REQUEST............................................................................37

FIGURE 15. EQUIPMENT INFORMATION .................................................................37

FIGURE 16. TRACE MODE QUERY...........................................................................38

FIGURE 17. TRACE MODE QUERY AND ENABLE ...................................................38

FIGURE 18. TRACE MODE QUERY AND DISABLE ..................................................39

FIGURE 19. GPS ENABLE AND DISABLE .................................................................39

FIGURE 20. INVOKING GSM27.010 MULTIPLEXER .................................................40

FIGURE 21. NON-RECONFIGURE MODE CHANGE.................................................40

FIGURE 22. RECONFIGURE MODE CHANGE WITH MUX.......................................40

FIGURE 23. RECONFIGURE MODE CHANGE WITH MUX.......................................41

FIGURE 24. LOCKING IO200 FACILITY CAPABILITIES QUERY ..............................43

FIGURE 25. LOCKING IO200 FACILITY .....................................................................43

FIGURE 26. UNLOCKING IO200 FACILITY................................................................44

FIGURE 27. CHANGE LOCK PASSWORD.................................................................44

FIGURE 28. GET LOCK STATUS................................................................................45

FIGURE 29. MASTER RESET.....................................................................................45

FIGURE 30. NORMAL GROUP CALL ORIGINATION.................................................47

FIGURE 31. NORMAL GROUP CALL JOIN ................................................................48

FIGURE 32. NORMAL GROUP CALL TRANSMIT/RECEIVE .....................................50

FIGURE 33. NORMAL GROUP CALL REJECTION...................................................50

FIGURE 34. NORMAL GROUP CALL TERMINATION (SYSTEM TERMINATED)....51

FIGURE 35. NORMAL GROUP CALL TERMINATION (USER TERMINATED)..........51

FIGURE 36. PRIVATE CALL ORIGINATION...............................................................51

FIGURE 37. PRIVATE CALL RECEPTION..................................................................51

FIGURE 38. PRIVATE CALL TRANSMIT/RECEIVE ...................................................51

FIGURE 39. PRIVATE CALL REJECTION..................................................................51

FIGURE 40. PRIVATE CALL TERMINATION..............................................................51

FIGURE 41. PRIVATE CALL TERMINATION (USER END)........................................51

FIGURE 42. CALL ALERT ORIGINATION...................................................................51

FIGURE 43. CALL ALERT RECEPTION ....................................................................51

FIGURE 44. CALL ALERT FAILURE...........................................................................51

FIGURE 45. QUERY INTERLEAVE SETTINGS..........................................................51

FIGURE 46. QUERY INTERLEAVE CAPABILITY.......................................................51

FIGURE 47. SETTING INTERLEAVE..........................................................................51

FIGURE 48. SUCCESSFUL CALL SETUP..................................................................51

FIGURE 49. FAILED CALL SETUP .............................................................................51

FIGURE 50. ABORTED CALL SETUP.........................................................................51

FIGURE 51. ANSWERED RECEIVED CALL...............................................................51

5

FIGURE 52. UNANSWERED MOBILE TERMINATED CALL......................................51

FIGURE 53. DENY RECEIVED CALL..........................................................................51

FIGURE 54. PHONE OVER DIAL – SINGLE DIGIT (SET DURATION)......................51

FIGURE 55. PHONE OVER DIAL – SINGLE DIGIT (PRESS-HOLD DURATION)......51

FIGURE 56. PHONE OVER DIAL – MULTI-DIGIT (TERMINAL CONTROL, SET DURATION) 51

FIGURE 57. PHONE OVER DIAL – MULTI-DIGIT (BURST, SET DURATION)..........51

FIGURE 58. CALL HOLD.............................................................................................51

FIGURE 59. CALL HOLD AND DIAL ...........................................................................51

FIGURE 60. CALL RETRIEVE.....................................................................................51

FIGURE 61. CALL ALTERNATE..................................................................................51

FIGURE 62. SUBSCRIBER TERMINATION................................................................51

FIGURE 63. REMOTE TERMINATION........................................................................51

FIGURE 64. MULTI-PARTY CONFERENCE CALLING ..............................................51

FIGURE 65. PHONE ONLY ENABLED REQUEST.....................................................51

FIGURE 66. PHONE ONLY DISABLE REQUEST.......................................................51

FIGURE 67. SUCCESS CALL FORWARD..................................................................51

FIGURE 68. CALL FORWARD ERASURE..................................................................51

FIGURE 69. CALL FORWARD INTERROGATION .....................................................51

FIGURE 70. ACCEPTING CALL WAITING..................................................................51

FIGURE 71. REJECT CALL WAITING.........................................................................51

FIGURE 72. ENABLE/DISABLE CALL-WAITING........................................................51

FIGURE 73. INTERROGATE CALL-WAITING ............................................................51

FIGURE 74. SUCCESSFUL CIRCUIT DATA CALL..................................................... 51

FIGURE 75. FAILED CALL SETUP .............................................................................51

FIGURE 76. ABORTED CIRCUIT DATA CALL ...........................................................51

FIGURE 77. CIRCUIT DATA CALL REQUEST REJECTION......................................51

FIGURE 78. ANSWERED RECEIVED CIRCUIT DATA CALL.....................................51

FIGURE 79. REJECTED CIRCUIT DATA CALL.........................................................51

FIGURE 80. UNANSWERED CIRCUIT DATA CALL...................................................51

FIGURE 81. DENY RECEIVED CIRCUIT DATA CALL ...............................................51

FIGURE 82. SUBSCRIBER TERMINATION OF CIRCUIT DATA CALL......................51

FIGURE 83. DTE TERMINATION OF CIRCUIT DATA CALL......................................51

FIGURE 84. REMOTE TERMINATION OF CIRCUIT DATA CALL..............................51

FIGURE 85. START PD CALL.....................................................................................51

FIGURE 86. PD TERMINATION..................................................................................51

FIGURE 87. PD REJECTION.......................................................................................51

FIGURE 88. SMS CONFIGURATION..........................................................................51

FIGURE 89. MOBILE TERMINATED SMS ..................................................................51

FIGURE 90. MOBILE ORIGINATED SMS...................................................................51

FIGURE 91. ACCESSING SMS MEMORY..................................................................51

FIGURE 92. VMAIL STATUS.......................................................................................51

FIGURE 93. ENABLE VMAIL NOTIFICATIONS..........................................................51

FIGURE 94. DISABLE VMAIL NOTIFICATIONS.........................................................51

FIGURE 95. DISABLE VMAIL NOTIFICATIONS.........................................................51

FIGURE 96. STARTED PHONE CALL ........................................................................51

FIGURE 97. SIM INTERFACE CONNECTOR.............................................................51

FIGURE 98. MECHANICAL SPECIFICATION.............................................................51

6

Tables

TABLE 1 INTEGRATOR’S TASKS .............................................................................10

TABLE 2 PARTS AND TOOLS REQUIREMENTS .....................................................15

TABLE 3 MODULE INPUT VOLTAGE SPECIFICATIONS.........................................19

TABLE 4 IO200 CURRENT CONSUMPTION.............................................................20

TABLE 5 MAIN CONNECTOR LINES ........................................................................24

TABLE 6 THE GPS LINES..........................................................................................28

TABLE 7 EXTENDED ERROR CODES......................................................................31

TABLE 8 AT COMMANDS: VOICE AND DISPATCH CALL CONTROL ....................51

TABLE 9 AT COMMANDS: MISCELLANEOUS .........................................................51

TABLE 10 AT COMMANDS: SIM ACCESS..............................................................51

TABLE 11 AT COMMANDS: SECURITY..................................................................51

TABLE 12 AT COMMANDS: MESSAGING ..............................................................51

TABLE 13 AT COMMANDS: NETWORK..................................................................51

TABLE 14 AT COMMANDS: SUPPLEMENTAL SERVICES....................................51

TABLE 15 AT COMMANDS: BASIC COMMANDS...................................................51

TABLE 16 AT RESPONSES.....................................................................................51

TABLE 17 DESCRIPTIONS OF INTERCONNECT PHONE CALL BETWEEN TWO IO200’S AND

TERMINAL...............................................................................................................51

TABLE 18 DESCRIPTION OF PRIVATE CALL BETWEEN TWO IO200’S AND TERMINAL. 51

TABLE 19 CHANNEL SPECIFICATION...................................................................51

TABLE 20 MULTIPLEXER CONTROL COMMANDS...............................................51

TABLE 21 AT AVAILABILITY MATRIX.....................................................................51

TABLE 22 AT COMMANDS: SIM ACCESS (TERMINAL TO IO200)........................51

TABLE 23 AUDIO AT COMMANDS..........................................................................51

TABLE 24 SIM INTERFACE CONNECTOR.............................................................51

7

1. Introduction

1.1. USING THIS GUIDE

This guide presents critical research and development issues affecting the design and development of products incorporating the

Motorola io200 800/900MHz iDEN Integrated Wireless Modem, used in North America, Asia, Africa and Europe.

The purpose of this document is to describe the technical details needed to integrate io200 Data Module into a host device. There are

several configurations of this product that provide flexibility in meeting full system integration requirements, as described in this

manual.

A product that incorporates the modem is referred to as the Original Equipment Manufacturer (OEM) host or simply

the host.

Note

1.2. PURPOSE

Data terminal equipment (DTE) OEM teams are often pulled together quickly from other work groups. For this reason, OEM team

members often need advice about how to best sustain a concerted design and development effort. The purpose of this guide is to

assist your team to successfully produce a wireless product that integrates the Motorola IO200 wireless modem.

This guide strives to bridge the gap between the various engineering and business disciplines that make up OEM teams. Our

approach is to provide a practical disclosure of useful information that can offer a common understanding of the problems you may

encounter and examples of probable solutions.

We at Motorola want to make this guide as helpful as possible. Keep us informed of your comments and suggestions for

improvements. You can reach us by email at: TBD

1.3. INTENDED AUDIENCE

The intended audience of this manual are data terminal equipment (DTE) OEM integration team members. Teams historically

consist of representatives from the disciplines of hardware, software and RF engineering. These readers will probably find the

entire document useful, if not enlightening. Other readers include marketing, business, and program managers. These readers

might find the first chapter, which discusses the integrator’s task, to be sufficiently informative for their needs. The remaining

chapters go into more detail.

1.4. DISCLAIMER

This guide provides advice and guidelines to OEM teams. Responsibility regarding how the information is used lies entirely with

the OEM. Statements indicating support provided by, or offered by, Motorola are subject to change at any time.

Motorola reserves the right to make any changes to this manual.

8

2. GENERAL NOTICES

2.1. Safety Notice - ATTENTION

This iDEN iO200 Module is restricted to Occupational use to satisfy FCC RF energy exposure requirements. This radio device is

not authorized for general population, consumer or similar use. The integrator shall be aware that after integrating this module

and connecting it to an antenna and DC power supply, the integrated device shall be treated as a Two-Way Radio.

Before using this product, read the awareness information and operating instructions for usage and RF safety in the following

section.

2.2. FCC Regulation - Letter of Notice

The iO200 module is intended for integration into a host device. Any integrator who will integrate the module into his product

and connect it to an RF antenna, DC power supply, and internal signaling, must treat this product as a Two-Way radio that can

transmit RF signals.

Important: To meet the FCC’s RF Exposure Guidelines, the antenna should be installed so there is at least 20 cm of

separation between the body of the user and nearby persons and the antenna.

After integration, this device uses electromagnetic energy in the radio frequency (RF) spectrum to provide communications

between two or more users over a distance. It uses radio frequency (RF) energy or radio waves to send and receive

information. The integrated radio generates measurable RF energy only while it is transmitting (during talking or sending

data), not when it is receiving (listening or receiving data) or in standby mode.

Experts in science, engineering, medicine, health, and industry work with organizations to develop standards for safe exposure

to RF energy. These standards provide recommended guidelines of RF exposure for both workers and the general public.

These recommended RF exposure levels include substantial margins of protection.

Important: To meet the FCC’s RF Exposure Guidelines, the antenna gain shall not exceed 7.3 dBi. Note that the

antenna supplied with the developer evaluation board has maximum gain of 1.4 dBi. The antenna should be

located so there is at least 20 cm of separation between the body of the user and nearby persons and the

antenna, during transmission.

In the United States, the Federal Communications Commission requires that RF transmitting devices obtain approval before

being offered on the market, unless the device is exempt. While the iO200 has been designed to meet applicable FCC

requirements, provided in the code of Federal Regulation 47CFR Part 2 subpart J and 47CFR Part 90 subpart S, the Final

Product's compliance with the FCC's requirements, including RF Exposure requirements, must reflect product usage,

positioning of the iO200 within the product, the type of antenna used, the location of the antenna, and other factors that may

vary with the design and nature of the Final Product. Therefore, the manufacturer of the Final Product is responsible for taking

all steps needed to insure compliance with FCC requirements, for making the necessary testing to verify compliance and for

obtaining FCC approval for the sale and the operation of the Final Product.

9

3. THE INTEGRATOR'S TASK

3.1. GENERAL

This chapter provides background information and indicates the objectives and tasks required to achieve a successful

implementation.

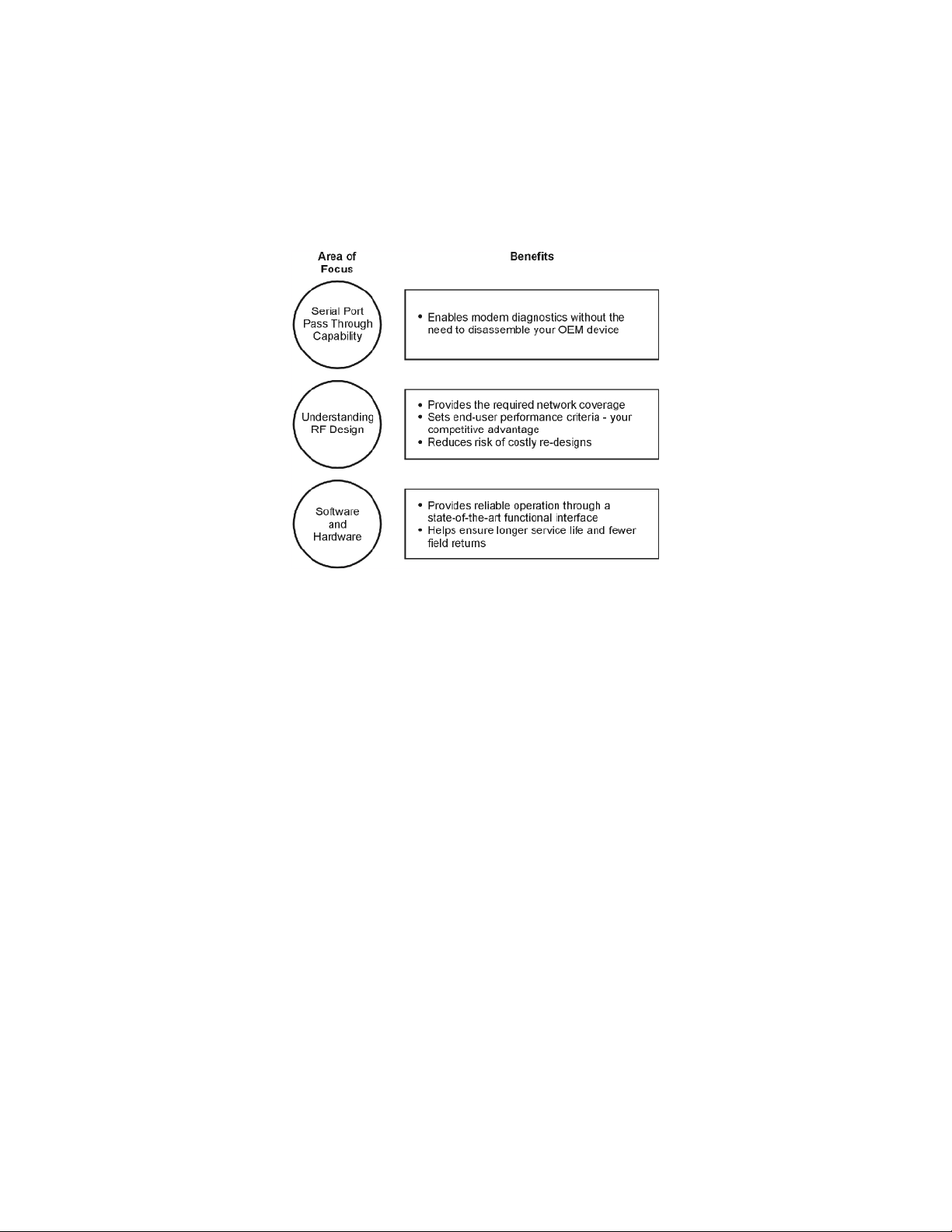

Table 1 Integrator’s Tasks

3.2. INTRODUCTION

As an OEM integrator, you must accurately choose where and how wireless technology will facilitate communication for your

customers. You will also have to evaluate which technical considerations will give your product an edge over the competition.

To successfully integrate Io200 wireless modems into your host platforms, you must perform the following tasks:

• Plan the product and create the design

• Develop and validate the hardware

• Develop supporting applications software

• Test and approve the product

As you review these tasks, allow sufficient time for required activities, such as the regulatory approval process, to identify critical

path activities ahead of time.

10

3.3. PLANNING THE PRODUCT AND CREATING THE DESIGN

To plan the product and create the design, perform the following steps:

• Develop a usage model

• Develop a message model

• Define a service strategy

• Define remote diagnostic functionality

• Investigate and obtain regulatory approval

3.3.1. Developing a Usage Model

The usage model answers the question, “How will the end product be used - will it be portable or mobile, how many hours a day

will it be used, how many days a week?” and so on.

Perhaps the most important factor for success is a clear understanding and decision regarding how the final product is to be used.

This guides the development process, since all design considerations drive toward meeting the needs of the end user. For example,

design issues related to a mobile device, such as alternator noise and vibration, are completely different from considerations

required for a fixed-point telemetry application powered by a solar panel. Defining what is and is not important to the end user

helps to make the critical engineering trade-off decisions that are inevitable in every product design.

As the integrator, it is your responsibility to develop the usage model. Motorola is available to provide assistance and answer

questions, but is not directly involved in this phase of the project.

3.3.2. Developing a Message Model

The message model defines the number of messages that are sent and received and their frequency. To create the message model,

determine the quantity and frequency of data sent in each of the uplink (terminal to network) and downlink (network to terminal)

directions.

Answer the question, “Is there a requirement for the terminal to be powered on and ready to receive eight hours a day, or does the

user turn the unit on only when making a query to the host system?” The answer has a direct bearing on the battery size and

capacity requirement for powering the device. The amount of data sent and received is relevant in calculating the cost of airtime

and deciding which type of network connection to use. In short, the message model is essential for making many engineering

design decisions, especially in calculating values such as sleep time versus wake time and in determining battery capacity

requirements.

You are responsible for developing the message model. The typical approach to creating the model is to define the peak and average

network throughput requirements based on input from the user. Motorola can provide current consumption figures for each of the

various modes of operation, for example, receive and transmit.

The network throughput of the host device depends on various factors, in addition to the raw throughput of the radio channel. For

example, in addition to the overhead involved in forward error correction and support for packet headers, the number of active

users on the network can directly affect network throughput.

11

3.3.3. Defining a Service Strategy

The service strategy determines whether the integrated modem is the cause of a user’s problem and sets a policy for keeping the end

user operational during repair. The service strategy must consider all potential service situations and evaluate them in light of the

usage model. You can create the service strategy jointly with Motorola. Contact your Motorola OEM sales representative for details.

To ensure that a final product can be efficiently serviced, it is recommended that you design for serviceability early in the R&D

process. At a minimum, you could develop a functional service strategy that contains a wellconsidered procedure for performing unit-level screening. The test may primarily determine whether a fault lies with the modem or

with the product. The test must also screen for network problems and human error.

Motorola supplies an evaluation board (a standalone test fixture) that provides a mounting platform and electrical interface to the

modem. (Refer to Developer’s Kit Manual for further information.) Testing is performed much more efficiently when the modem

is integrated within the OEM host, whether for a factory end-of-line test or while at the user’s site.

In order for your product to allow integrated testing of the modem, you may decide to provide a modem pass-through mode.

A thoroughly developed OEM serviceability plan typically includes a needs assessment for developing software utilities that can

assist in identifying communication problems between the product and the modem and between the modem and the RF network.

These utilities must be able to send commands to the modem, evaluate the modem responses, perform network connectivity

testing, and verify data communication with the network.

Such a software utility is essential for field service engineers and shop technicians to diagnose problems with the product and to

troubleshoot a problem to a failed assembly or mismanaged communication link.

3.3.4. Defining Remote Diagnostic Functionality

When customer problems are reported from the field, you must isolate the source of the problem remotely. You will need to

determine which part of the overall system is not functioning correctly. The following items need to be considered as a possible

source of the problem:

• Network

• Io200 wireless modem

• Host product

Often a problem is caused by a user’s lack of knowledge of how to use the product correctly. Regardless, remote troubleshooting is

essential in reducing the number of returned products and lowering service costs, particularly if the host must be disassembled in

order for the modem to be removed.

Motorola recommends that your product application (both at the terminal and host ends) incorporates sufficient problem diagnostic

software to determine the cause of the problem remotely. Often, the best approach is to incorporate progressively deeper loopback

tests to determine the point at which the communication link fails.

This remote diagnostic functionality should be an integral part of your standard software load.

12

3.3.5. Investigating and Obtaining Regulatory Approval

It is your responsibility to obtain regulatory approval of products that integrate an io200 Integrated Wireless Modem. The specific

details for achieving regulatory approval vary from country to country. Refer to “Regulatory Requirements”, page xvi ?, for

further information.

3.4. DEVELOPING AND VALIDATING THE HARDWARE

To develop and validate the hardware, perform the following steps:

• Design the hardware platform

• Consider power supply options

• Select the antenna

• Set up a development test environment

3.5. Designing the Hardware Platform

Integrating a wireless modem into a hardware design requires many steps. Here again, the usage and message models are

necessary to calculate issues such as battery size, heat dissipation, isolation from EMI, and physical mounting of the unit to ensure

proper grounding. Refer to Chapter 3, “Design Considerations”, page 13 ?, for further information.

Hardware design is your responsibility. The host device can introduce electromagnetic interference, which will interfere with the

performance of the modem. This EMI can be conducted into the modem via the serial and power lines, or radiated into the

antenna and antenna cable. It is your task to minimize the generation of EMI by your device so that the modem’s RF performance is

minimally affected. Contact your Motorola OEM representative for details.

3.6. Considering Power Supply Options

Power supply requirements vary according to the usage and message models. In addition to accounting for the current drain of the

modem in its various operating modes, you should also consider ripple and noise on the power lines and the ability to supply

sufficient instantaneous current to enable correct operation of the transmitter. You should also ensure that your power supply can

accommodate the highest power consumption for Io200 modem that you want to integrate.

Together, these requirements define the type and size of power supply (for example, linear versus switched) to use with the

wireless modem. Refer to Chapter 3, “Design Considerations”, page 13 ?, for further information.

It is recommended that the power applied to Io200 have a rise time of less than 1 ms to prevent potential latch up.

Note

13

3.7. Selecting the Antenna

Io200 is terminated by 50Ω; therefore, any antenna terminated by 50Ω will work with Io200. In order to protect the module from

ESD discharge, the selected antenna must be rubber-coated.. Refer to “Antenna Considerations”, page 5.16, for further

information.

You are responsible for selecting a suitable antenna and submitting the final product to the network operator for certification.

Note

A number of development test aids are available to assist in hardware and application development. Modem hardware and an

evaluation board can be purchased from Motorola. The evaluation board is a specially developed circuit board with test points

and jumper switches, which allows for maximum flexibility in accessing and controlling connections into and out of the modem.

Refer to “iO200 Developer’s Kit Manual” for further information. Motorola also provides various software utilities that can help

in performing development tests. Refer to chapter 0, “Testing” for further information.

The network operator may sometimes provide a live development network, supplementing the test environment supported by

Motorola. This development network, on which you can develop and test your application, is separate from the production network.

You must negotiate directly with the network operator for airtime and for building and maintaining a development test

environment at their facility.

3.8. Setting Up a Development Test Environment

3.9. DEVELOPING SUPPORTING APPLICATION SOFTWARE

To develop supporting application software, perform the following steps:

• Select a communications model

• Develop end-to-end application software

3.10. TESTING AND APPROVING THE PRODUCT

To test and approve the product, perform the following steps:

• Perform EMI and desense testing .

• Set up a final test environment

• Install and field-test the product

3.11. Setting Up a Final Test Environment

To ensure correct assembly of the final product (that the antenna is properly connected, the serial port is operational, and so on),

perform an end-to-end test that proves that the final product can receive and transmit at the required signal levels. In locations

where the final assembly test is performed within network coverage area, this test is relatively simple. However, in locations

where network coverage is not available, or for products being shipped to other countries, it is necessary to test by secondary

means.

The final assembly test must verify that all connections to the modem are made correctly. Testing on a network is not required.

Io200

can support an antenna with 0 Ω (in DC).

For 800/900MHz and GPS, the antenna should

Ω.

be 50

3.12. Installing and Field-Testing the

Product

When the product is shipped to a site, it is installed or mounted in a location that may restrict RF communications. It must be

verified whether the behavior of a dysfunctional product is caused by poor coverage or is due to the fact that the network service

14

provider is down. To guarantee that the modem is located in an area with good coverage, and that an end-to-end loopback message is

possible, your product needs a software application to perform the test.

The most effective approach to field-testing is to include an installation test procedure as part of your standard software load.

Motorola can recommend specific network information that you can obtain from the modem describing how to implement an endto-end loopback test. Refer to Chapter 7, “Testing”, page 83 ?, for further information.

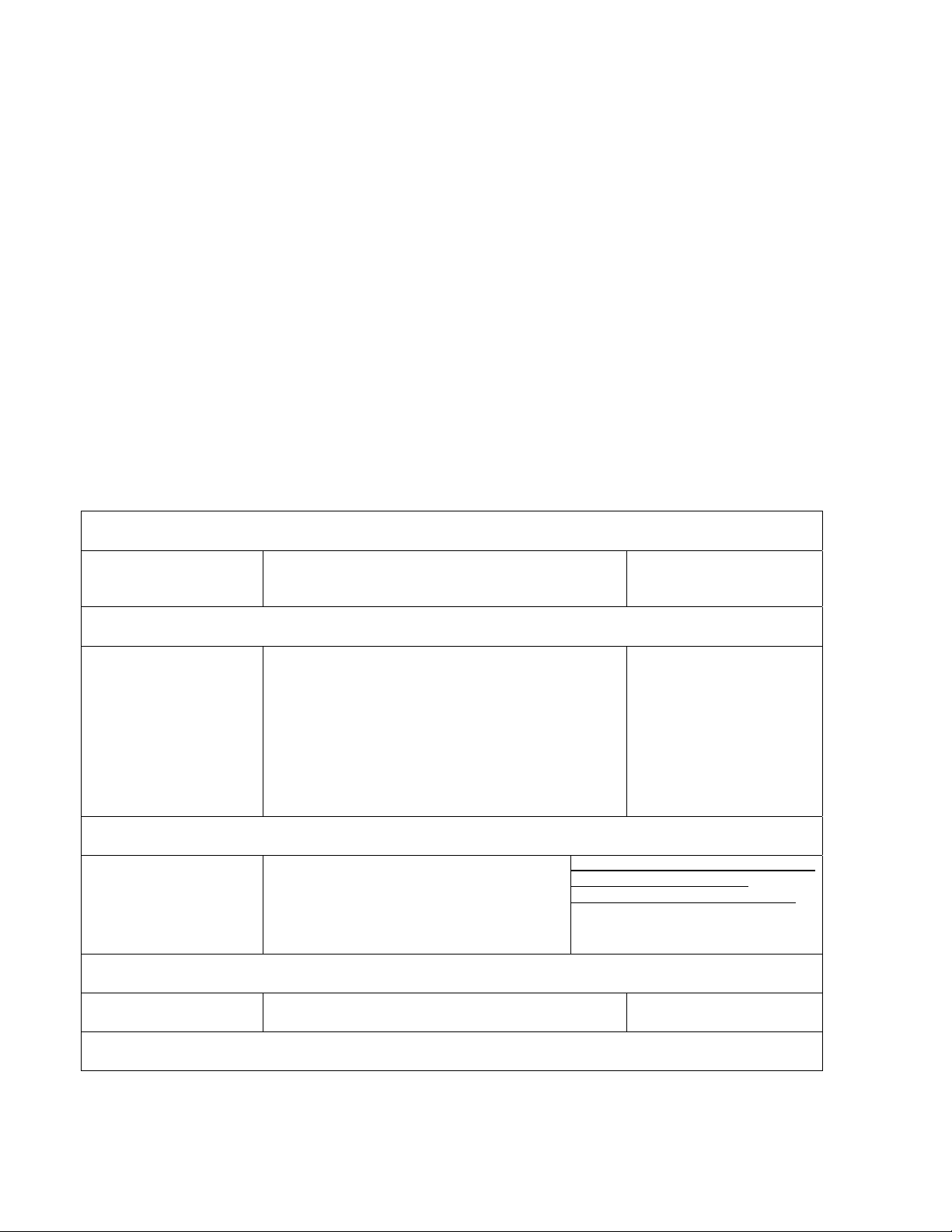

3.13. RESOURCE ASSISTANCE

Developing and testing a wireless integrated product requires a well-equipped development lab and access to resources and

outside information. Table 1, “Parts and Tools Requirements”, below, identifies the required development and service tools.

Information is also provided regarding where to obtain the tools and how to obtain further assistance.

3.14. Integrating Engineering Support

Questions on this manual and the integration process are handled by Motorola’s integration engineering teams located in North

America. Send an email to TBD, with your name, phone number, company name, description of the project and your question.

An engineer will be assigned to your project and will contact you by phone or by email to assist you in resolving any issues.

Table 2 Parts and Tools Requirements

IO200 Evaluation Board P/N FCN6529

iDEN Test Set

Unique Development and Se rv ice Aids

This board provides interface connectors and circuitry

that allow the modem to be powered and interfaced to

a host device (PC) via a serial port and cable.

Includes instructions, interface ribbon cable, jumpers,

mounting hardware, antenna and antenna cable.

Communication Test Set R-2660

Wireless Verification Equipment

Related Documentation

Modem Test Equipment

http://www.motorola.com.cn/cgiss/soluti

ons/test_ep/r2660/2660.html

http://www.gdds.com/cte/2660d.html

Live Network When available, a live network can be used Network Operator

Traditional Shop Equipment

15

Power Supply

Oscilloscope

Digital Volt Meter

Dual Power Supply with 3-6V/2A and 12V/2A output

supplies

900Mhz, digital storage

Fluke 77 multimeter or equivalent

Commercial Items

Commercial Item

Commercial Item

3.15. ENVIRONMENTAL ISSUES

Io200 Integrated Wireless Modems are designed for a combination of easy serviceability and general robustness. These integrated

modems are designed to be housed in an OEM host product. The modem is tested to conform to the environmental levels (for

example, industrial use specifications) that meet the intended applications of most integrators. If you need additional robustness

and safety in your products, you must engineer the environmental characteristics of your host product to achieve a special safety

rating.

3.16. General Precautions

Follow these precautions when working with wireless modems:

• Minimize the handling of static-sensitive modules and components.

• Wear a grounded anti-static wrist strap while handling static-sensitive components.

• Do not bend or stress the modem in any way.

• Reinsert connectors straightly and evenly to avoid causing short and open circuits.

3.17. ESD Handling Precautions

All electronic devices contain components that are sensitive to ESD (electrostatic discharge). For example, people typically

experience up to 35 kV ESD, while walking on a carpet in low humidity environments. In the same manner, many electronic

components can be damaged by less than 1000 V of ESD. For this reason, you must observe the following handling precautions

when servicing this equipment:

• Always wear a conductive wrist strap.

• Eliminate static generators (plastics, styrofoam, and so on) in the work area.

• Remove nylon or polyester jackets, roll up long sleeves, and remove or tie back loose hanging neckties, jewelry, and long

hair.

• Store and transport all static sensitive components in ESD-protective containers.

• Disconnect all power from the unit before ESD-sensitive components are removed or inserted, unless instructed otherwise.

• Use a static safe-guarded workstation, which can be set up by using an anti-static kit (Motorola part number 0180386A82).

This kit includes a wrist strap, two ground cords, a static control table mat, and a static control floor mat. The Motorola part

number for a replacement wrist strap that connects to the tablemat is 4280385A59.

When anti-static facilities are unavailable, use the following technique to minimize the chance of damaging the equipment:

• Rest the static-sensitive component on a conductive surface when you are not holding it.

• When setting down or picking up the static-sensitive component, make skin contact with a conductive work surface first and

maintain this contact while handling the component.

• If possible, maintain relative humidity of 70-75% in development labs and service shops.

16

4. MODEL DESCRIPTION

4.1. GENERAL

This chapter provides an overview of Io200 integrated wireless modem.

For model number, and specifications, refer to “Specifications”, on page 0.

4.2. INTRODUCTION

Io200 is an iDEN modem providing circuit/packet data connectivity, interconnect and dispatch calls. The modem operates in iDEN

800 & 900 MHz networks using the iDEN Packet-switched and Circuit-switched Data protocols. The modem is of a standard

interface consisting of a main board to board connector, an RF antenna connector and a SIM flex connector. The modem has the

smallest footprint possible for ease of embedding into multiple 3rd party manufacturers' products including those with space

limitations such as Remote Terminal Units, special purpose terminals, PDA’s, hand-held terminals, etc. The SIM card is remoted

from the physical layout of the board to enable a smaller module footprint as well as provide flexibility to the integrator to locate the

SIM card for ease of product-maintenance.

This product operates on iDEN 800 and 900 MHz bands as specified below.

IDEN/WiDEN 800:

Tx: 806-825 MHz Rx: 851-870 MHz

IDEN/WiDEN 900:

Tx: 896-902 MHz Rx: 935-941 MHz

WiDEN capability is dependent on the availability of the network and associated radio firmware. The modem has WiDEN-enabled

hardware that requires an upgraded software to support WiDEN functionality. The availability date of WiDEN within this module

will be determined by the WiDEN network implementation schedule.

The iDEN IO200 modem supports the following modulation types:

− Quad-16QAM

− Quad-QPSK (packet data mode only)

− Quad-64QAM (packet data mode only)

4.3. PRODUCT FEATURES

− Packet switched data

− Circuit switched data (AT commands compliant)

− AGPS via second UART and through UDP on the primary UART

− Fax

− Split 3:1 Interconnect (Voice Cellular)

− Dispatch (Push To Talk™/Direct Connect™)

− SMS

− Full 600 entry Falcon Contacts

− Minimal Mechanical Form factor

− Host wake-up capabilities.

− Remote SIM

− Thermal Protection Mechanisms through Power Reduction.

− OTA Firmware Update and Provisioning (to be performed by the host, which will then flash the module).

− Firmware Update Utility on Host.

− RF & EMI shielded

− Regulatory / Network Approved for Host Independent Modular Applications.

4.4. INTERFACE CONNECTORS

The modem has 3 Interface connectors:

Main Interface Connector (40-pin board-to-board)

17

SIM Interface Connector (6-pin ZIF)

RF Antenna Connector (coaxial)

4.5. INTEGRATOR’S KIT

The Integrator's Kit includes the RF modem and Developers' Kit with installation SW via a CD or on-line. The kit has sufficient

documentation for integrators to be able to successfully embed the device into their products.

4.6. MOUNTING

The RF module includes 4 mounting holes.

18

5. DESIGN CONSIDERATIONS

5.1. GENERAL

When integrating a wireless modem, internal connections and placements are critical for a successful implementation.

Specific attention must be paid to the following support mechanisms:

• Power supply considerations

• Audio circuit considerations

• Data port considerations

• SIM card considerations

• ESD considerations

• Antenna considerations

• Mechanical mounting

• Desense control

• GPS considerations

Note

Antennas must be separated by a minimum of 10 inches (25.4 cm).

5.2. POWER SUPPLY CONSIDERATIONS

5.3. Power Supply Losses

IO200 is specified to operate between 3.2V and 4.2V on the Main Connector. To enable operation with the lower battery

values, it is important to reduce the losses in the power supply lines. IO200 has to support iDEN training pulses of approximately

0.4 mS. The peak current is up to 3A.

Table 3 Module Input Voltage Specifications

Conditions Min.

Input

Voltage

Input

Voltage

Ripple

In order to minimize ripple, noise and voltage loss it is recommended to use short and thick battery lines and to connect a lowESR, 1000 uF capacitor (or maximum possible) on the DC input.

In addition it is recommended to have a current limit in the power supply (3.5-5 A), in order to avoid damage if a short-circuit

occurs.

Standby/

Rx mode

At peak TX

current

3.0A

In STBY

mode

3.2 4.0 4.2 V

3.1 4.0 4.2 V

Nom. Max. Unit

50

mV

(peak)

5.4. IO200 Current Consumption

In order to design the power supply correctly, you need to take into account the current consumption of IO200 in its different

modes.

19

Table 4 IO200 Current Consumption

Mode Current Consumption

5.5. IO200 Output Voltage

IO200 can supply DC voltage to accessories.

Option_V+ line (Main Connector, pin #14) can drive 100mA @ 2.775VDC. Using this source for external RS232 transceiver

ensures proper communication at correct voltage levels.

5.6. Turning the Unit On

IO200 is powered from a single power supply in the range of 3.2 to 4.2 VDC.

The unit will not power up automatically by connecting the power. To turn the unit ON, apply 4V to ON/OFF pin (Main connector,

pin 5).

To verify that the unit is On or Off, check the OPTION_V+ line (pin #14). If it is high, the unit is on; if it is low, the unit is off.

20

p

5.7. Turning the Unit OFF By ON/OFF pin

There are two ways to turn off the unit: apply logic low, 0V, to ON/OFF pin or by “turn off” AT command. When IO200 is

powered off by disconnecting the power to the unit, IO200 doesn’t deregister. SIM card might be damaged, and units containing

IO200 that need to pass SIM card type approval tests will fail due to the SIM’s incorrect power off sequence.

There is a risk that if power is removed to soon after applying OFF, the Flash or SIM may be corrupted since the radio would still

be in process of writing to these memories. Therefore, 11 seconds delay from Off event (AT command or de-assertion of 4V

from ON/OFF pin) to B+ removal is required.

IO200

Modem

Pin #6

Pin #10

Pin #11

Pin #26

Pin #25

Host Wake-U

Op_Sel_1

Op_Sel_2

DSR

DTR

RX, TX, RTS, CTS, RI, DCD

Host

Figure 1. On/Off

21

5.8. AUDIO CIRCUIT CONSIDERATIONS

IO200 supports both voice calls and data calls.

IO200 module supports 3 modes of operation for voice communication:

- Speakerphone

- Headset

- Raw

For both received audio (speaker) and transmit audio (microphone), the module will utilize standard iDEN audio signal

conditioning and processing.

5.9. Audio Interface

The following figure shows the expected electrical interface for audio input and output signals:

IO200 Module

Amp

Amp

100Ω

100Ω

18KΩ

18KΩ

0.1uF

0.1uF

0.1uF

0.1uF

Audio

Out

Audio

In

0.1uF

1.0uF

1.0uF

10KΩ0.1uF

10KΩ

100Ω

100Ω

Host Terminal

Amp

Amp

Figure 2. Electrical interface for audio input and output signals

Note that it is the integrator’s responsibility to properly interface a High Audio speaker or a Headset earpiece to the module’s

differential Audio Out terminals.

Notes:

• 15pf and 39pF capacitor should be place on audio out/ in lines to avoid chopper noise.

• Audio In/Out are differential lines, they need to be routed close to each other and need to be parallel.

5.10. Nominal Audio Signal

22

Audio In

The nominal differential Audio In signal shall have a level of:

TBD mVrms in Speakerphone mode

TBD mVrms in Headset mode

TBD mVrms in Raw mode

Audio Out

The nominal differential Audio Out (volume 4) signal shall have a level of:

TBD mVrms in Speakerphone mode

TBD mVrms in Headset mode

TBD mVrms in Raw mode

5.11. Audio Processing and Control

The available audio AT commands will support the following functions:

- Speaker Volume control (0-5 Steps, TBD Resolution)

- Mic gain adjustment (0 to 31dB at 1 dB step size)

- Mode selection: Speakerphone, Headset, Raw

It is the responsibility of the integrator to detect the presence of a Headset and send the appropriate AT command to the

module to switch its audio mode to ‘Headset’.

On removal of a headset the host device should send an AT command to switch the module to ‘Speakerphone’ mode.

The following table lists the applicable signal conditioning processes applied in each audio mode, Speakerphone, Headset and

Raw and in each connection mode, Interconnect or Direct connect.

Phone (Interconnect) Dispatch (Direct Connect)

Speakerphone Headset Raw

Audio

Echo

cancellation/Suppression

Noise Suppression Y Y Y Y Y Y

Sidetone N Y N N N N

Y Y N N N N

Speaker Headset Raw

Audio

Figure 3. Audio Mode

Note that the characteristics of these processes will be the same as on other iDEN portables.

5.12. COMMUNICATION

IO200 Modem can communicate via RS232 CMOS levels (0-2.7V) or USB by configuring the following main connector

lines.

MODE OPTION1

Pin10

Default (Normal) 1 1 0

USB 1 1 >4.0V

OPTION2

Pin 11

RTS1 / USB_PWR

Pin 24

23

RS-232 (8 wire) 0 1 X

Table 5 main connector lines

Notes:

Default state is internally set by the modem via pull up resistors.

To configure the modem for USB operation, the host terminal should only apply >4V to RTS1/USB_PWR pin.

To configure the modem for RS-232 operation, the host terminal should only pull OPTION1 pin to ground level.

24

5.13. SIM CARD CONSIDERATIONS

IO200 includes a SIM card driver, however it does not contain a SIM socket. SIM signals are routed to the 6-pin ZIF interface

connector.

The connector includes all the functionality required for SIM card operation. The SIM card socket must be located on the

customer’s board and connected to IO200 interface connector as shown in Figure below.

5.14. SIM Connection

User Application

SIM VCC

SIM RESET

SIM Clock

IO200 6-Pin

ZIF Interface

Connector

2

1

6

4

5/3

Resistor

Network

&

Zener

Diodes

VSIM

SIM

Driver

6V

Zener

0.1uF

SIM I_O

SIM VPP (NC)

GROUND

Figure 4. Shows IO200 SIM connection

The following applies to IO200 SIM connections:

• IO200 passes all SIM ETSI tests when an external socket is connected to IO200 with lines shorter than 6.5 cm.

• Longer connections require SIM testing, under integrator’s responsibility.

• IO200 works with 3V SIM cards.

• IO200 provides ESD protection on SIM VCC line (6V Zener diode with low capacitance and 0.1uF cap.

• RC network was added on all lines to protect against EMI interference.

A SIM card should be replaced with the unit powered off.

If the SIM card is replaced with the unit powered on then the user must cycle power (turn off and then turn

on) after the replacement.

Note

25

r

a

5.15. ESD CONSIDERATIONS

Generally, ESD protection, up to 8KV, can be provided by using ceramic capacitors of 0.1uF or higher.

The capacitors protect against ESD on all static lines, power and so on. The protection is performed inside IO200.IO200 also

contains ESD Zener diode protection on almost all external lines; however, it is recommended to add protection on user PCB.

For lines with high data rates, it is recommended to use Transguard with low capacitance. There are Transguards of 3pF or less.

In order to protect against ESD, the IO200 is required to operate only with rubber antennas.

5.16. ANTENNA CONSIDER ATIONS

The antenna must be mounted like any other cellular or land mobile radio antenna. The best position for the antenna is usually the

center of the vehicle roof, which provides a fairly symmetric ground plane on metal cars. For vehicles of non-metallic material,

such as fiberglass, mount the antenna where it will not be obstructed by items, such as mirrors.

5.17. Antenna Systems

Use this information to assist you in selecting the appropriate antenna to incorporate into your product package. For specific

detailed information, Motorola recommends that you use the expertise of an antenna design engineer to solve individual application

concerns.

5.18. Antenna Safety

The following statement from the American National Standards Institute (ANSI) specifies the safety criteria that integrators must

use when designing the antenna for a product integrating Io200 modem.

For Mobile operation with external antenna the modem must be installed in a manne

that provides a minimum separation distance of 20 cm or more between the antenn

“The design of the

integrated product must be such that the location used and other particulars of the antenna comply with the then current American

National Standards Institute (ANSI) Guidelines concerning Radio Frequency Energy Exposure and with any other nationally

recognized radio frequency standards that may be applicable thereto.”

and all persons to satisfy FCC RF exposure requirements for mobile transmitting

5.18.1.1. User Operation

For Mobile installation with external antenna do not operate your modem when a person is within 8 inches (20 centimeters) of

the antenna. A person or object within 8 inches (20 centimeters) of the antenna could impair call quality and may cause the modem

to operate at a higher power level than necessary and expose that person to RF energy in excess of that established by the FCC RF

Exposure Guidelines.

5.19. ESD Protection

In order to protect the module against ESD damage, the IO200 is required to operate only with rubber-coated antennas.

5.20. Antenna Performance

The network operator usually sets the antenna network requirements.

5.21. Portable Devices

In an environment where portable devices are in use, many variables exist that can affect the transmission path. In this case, it is

preferable to use a vertically-polarized, omni-directional antenna.

26

Antennas for portable devices include the following designs:

• Internal antenna (invisible or pull-up)

• External antenna, removable and directly connected to the device

• External, remote antenna

5.21.1.1. Internal Antenna (Invisible or Pull-up)

This is the most difficult antenna design scenario. Despite greater physical constraints, an internal antenna must still provide a

gain sufficient to meet network specifications. Metal-cased products cannot have internal antennas since the metal acts as a shield

around the antenna and prevents RF signals from reaching the antenna. (A metal case acts like a Faraday cage.) The antenna should be

positioned so that it is vertically oriented when the device is carried normally. This will ensure that the optimal antenna performance

is available the majority of the time.