Page 1

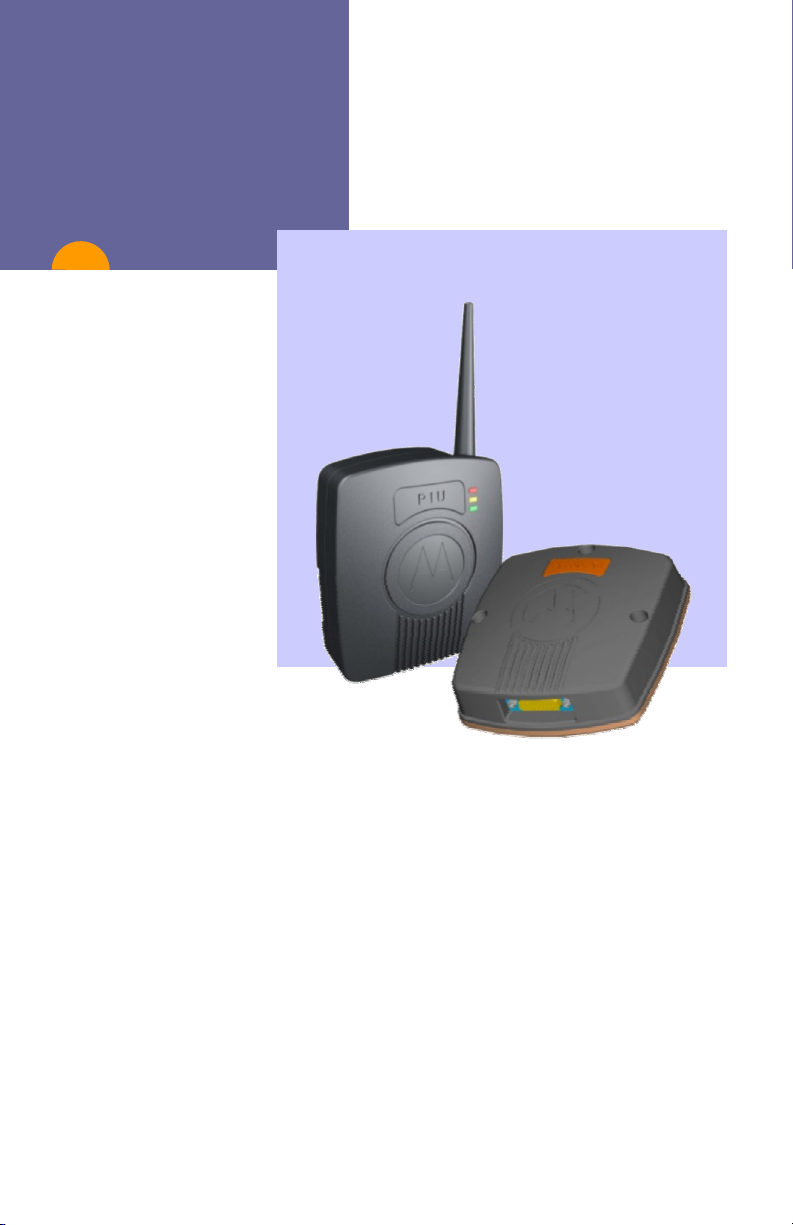

Owner’s Manual

Distributed I/O

SystemPiccolo Interface

Unit (PIU) and

Piccolo-XR Unit

6802974C40-O

MOTOROLA and the Stylized M Logo are registered in the U.S.

Patent and Trademark Office. All other product or service names

are the property of their respective owners.

6802974C40-O

6802974C40

Copyright © 2004 Motorola All Rights Reserved

Page 2

Motorola radio communications products are warranted to be free from defects

in material and workmanship for a period of ONE (1) YEAR, (except for crystals

and channel elements which are warranted for a period of ten (10) years), from

the date of shipment. Parts, including crystals and channel elements, will be

replaced free of charge for the full warranty period but the labor to replace

defective parts will only be provided for one Hundred-Twenty (120) days from

the date of shipment. Thereafter purchaser must pay for the labor involved in

repairing the product or replacing the parts at the prevailing rates together with

any transportation charges to or from the place where warranty service is

provided. This express warranty is extended by Motorola Communications and

Electronics Inc., 1301 E. Algonquin Road, Schaumburg, Illinois 60196, to the

original purchaser only, and only to those purchasing for purpose of leasing or

solely for commercial, industrial, or governmental use.

THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES

EXPRESS OR IMPLIED WHICH ARE SPECIFICALLY EXCLUDED,

INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL MOTOROLA BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES TO THE FULL EXTENT

SUCH MAY BE DISCLAIMED BY LAW.

In the event of a defect, malfunction or failure to conform to specifications

established by seller, or if appropriate, to specifications accepted by Seller in

writing, during the period shown, Motorola, at its option, will either repair or

replace the product or refund the purchase price thereof, and such action on

the part of Motorola shall be the full extent of Motorola’s liability hereunder.

This warranty is void if:

a. the product is used in other than its normal and customary manner;

b. the product has been subject to misuse, accident neglect or damage;

c. unauthorized alterations or repairs have been made, or unapproved parts

used in the equipment.

This warranty extends only to individual products, batteries are excluded, but

carry their own separate limited warranty. Because each radio system is

unique, Motorola disclaims liability for range, coverage, or operation of the

system as a whole under this warranty except by a separate written agreement

signed by an officer of Motorola.

Non-Motorola manufactured products are excluded from this warranty, but

subject to the warranty provided by their manufacturers, a copy of which will be

supplied to you on specific written request.

In order to obtain performance of this warranty, purchaser must contact its

Motorola salesperson or Motorola at the address first above shown, attention

Quality Assurance Department.

This warranty applies only within the United States.

COMMERCIAL WARRANTY (STANDARD)

Page 3

COMPUTER SOFTWARE COPYRIGHTS

The Motorola products described in this instruction manual may include

copyrighted Motorola computer programs stored in semi conductor memories

or other media. Laws in the United States and other countries preserve for

Motorola certain exclusive rights for copyrighted computer programs including

the exclusive right to copy or reproduce in any form the copyrighted computer

program. Accordingly, any copyrighted Motorola computer programs contained

in the Motorola products described in this instruction manual may not be copied

or reproduced in any manner without the express written permission of

Motorola. Furthermore, the purchase of Motorola products shall not be

deemed to grant either directly or by implication, estoppel, or otherwise, any

license under the copyrights, patents or patent applications of Motorola, except

for the normal non-exclusive, royalty free license to use that arises by operation

of law in the sale of a product.

Page 4

Page 5

Introduction

CONTENTS

INTRODUCTION ..............................................................................1

Scope of this Manual ....................................................................1

General Description......................................................................1

Safety Handling Instructions.......................................................5

INSTALLATION ...............................................................................7

General ..........................................................................................7

PIU Installation.............................................................................8

Mounting the PIU On A Wall Using Screws..............................9

Mounting the PIU Using a Bracket...........................................10

PIU DIN Rail Mounting.............................................................11

PIU Electrical Connections........................................................12

PIU Antenna Connection...........................................................18

Piccolo–XR Installation .............................................................19

Piccolo–XR Screw Mounting Options ......................................20

Piccolo–XR Electrical Connections...........................................22

THE DIOS PIU AND PICCOLO-XR UNITS ....................................27

PIU Overview..............................................................................27

PIU Communication Ports.........................................................28

PIU Connectors...........................................................................29

PIU LED Operation ...................................................................29

PIU Adapter Operation .............................................................30

PIU Portable Use ........................................................................30

Piccolo-XR Overview .................................................................36

Piccolo-XR Communication Ports ............................................36

Piccolo-XR Connector................................................................37

APPENDIX A: PIU AND PICCOLO-XR SPECIFICATIONS ........39

1

Page 6

Introduction

PIU Specifications.......................................................................39

Environmental ............................................................................39

Mechanical ..................................................................................39

PIU Board ...................................................................................40

Power ...........................................................................................41

PICCOLO XR Specifications ....................................................44

Environmental ............................................................................44

Mechanical ..................................................................................44

PICCOLO XR Board.................................................................44

Communication Ports ................................................................45

Power ...........................................................................................46

APPENDIX B: MODELS AND ACCESSORIES ............................49

General ........................................................................................49

APPENDIX C: ANTENNA ............................................................51

General ........................................................................................51

Flexible Antenna Specifications ................................................51

Pole Antenna ...............................................................................52

Pole Antenna installation ...........................................................53

APPENDIX D: PIU/PICCOLO–XR MOUNTING TEMPLATES ...57

2

Page 7

Introduction

INTRODUCTION

Scope of this Manual

This manual provides instructions for the installation and

operation of the Distributed I/O system Piccolo Interface

Unit (PIU) and Piccolo–XR units. The Distributed I/O

System includes PIUs and Piccolo–XRs. Each PIU can be

linked to up to 256 Piccolo–XRs. For more information on

the PIU and Piccolo–XR, see the online help of the DIOS

Service Toolkit.

General Description

The Distributed I/O System (DIOS) is a self-sustained

system designed to function within the IRRInet irrigation

control product line.

The DIOS consists of the following components:

• Piccolo Interface Unit (PIU)

• Piccolo–XR Units

The PIU functions as an interface between the host

application (irrigation SW and HW) and the Piccolo–XR

units. The PIU and Piccolo-XR are portable devices, which

are commonly used in fixed installations. The PIU uses

one of its communication ports to link to the host

application and radio communication to link to the

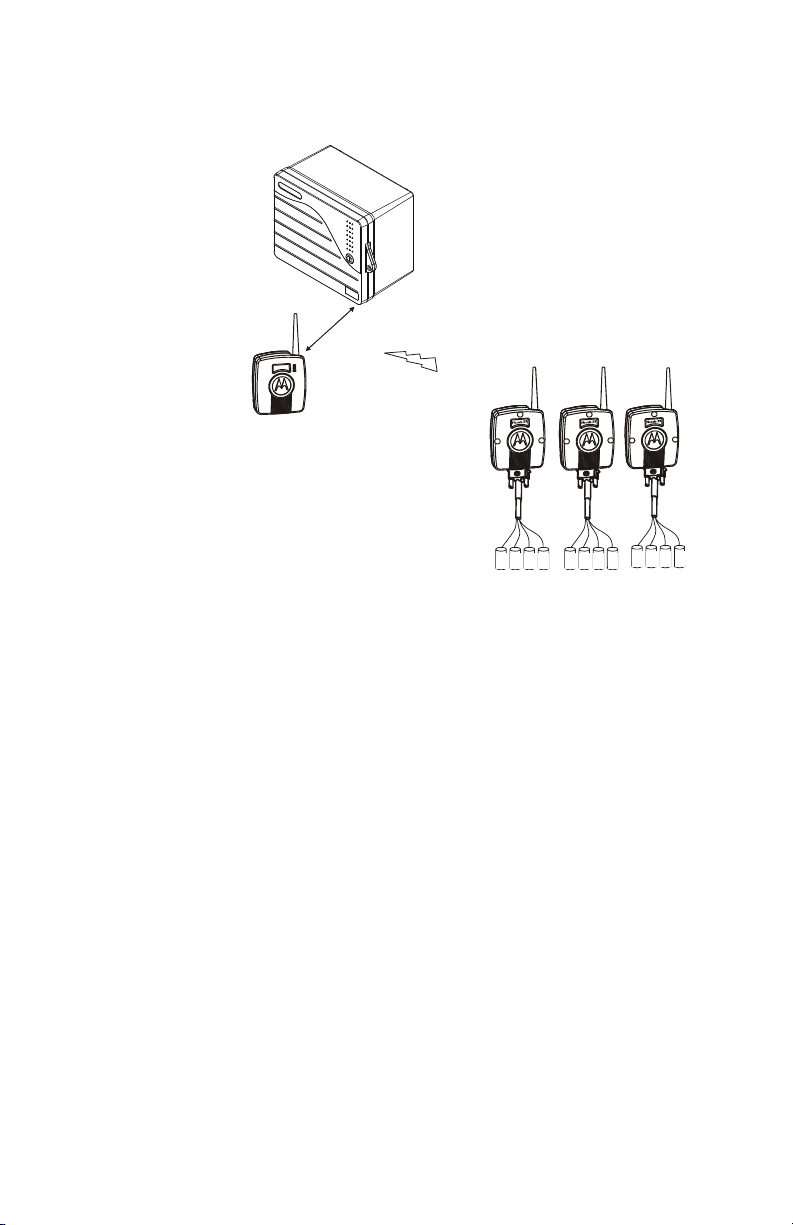

Piccolo–XR units. Figure 1 provides a general view of the

DIOS System.

1

Page 8

Introduction

IRRInet Field

Unit

Piccolo

Interface

Unit

PIU

Piccolo-XR Units

Figure 1

DIOS –General System View

RS485

or

RS232

I/O's

The battery-operated Piccolo–XR unit is available in

various models with different options of Inputs and

Outputs. The Piccolo–XR unit can operate DC latch

solenoids (outputs), read status and calculate flow of dry

contact meters (inputs).

The units are equipped with built-in radio for

communication with the PIU.

The DIOS automatically builds communication network,

using Store and Forward (S&F) technology, enabling the

DIOS to cover areas larger than normally possible when

using a single radio to communicate with the PIU.

Using the DIOS, the IRRInet system opens and closes

stations (manually or automatically by irrigation

programs), reads dry contact input status, calculates flow

rate and accumulates pulses from water meters.

2

Page 9

Introduction

PIU - Piccolo Interface Unit

The Piccolo Interface Unit (PIU; see Figure 2) is connected

to the IRRInet Field Unit (FU) via RS232

or RS485 serial ports.

Each PIU supports up to 256 Piccolo–XR units, with any

available I/O combination, limited by the capacity of the

IRRInet software only.

Utilizing the S&F technology and networking capabilities,

the PIU can be linked to Piccolo–XR units positioned in

distances of up to 1500-2000 meters (approx. 1 mile),

depending on topography, antenna type and antenna

installation.

The PIU is an interface between the Piccolo–XR and the

IRRInet FU, which provides communication and

networking operations only. (Monitor and control features

are not included in the PIU.) That is: The control and

monitor functions are provided either locally, by the

Piccolo–XR or by an upper hierarchy unit (i.e. IRRInet

FU).

The PIU is a portable device, which is most commonly

used in the fixed installations enclosed with an indoor

plastic housing.

The PIU must be installed by qualified and authorized

technicians, so as to meet applicable safety standards and

to ensure protection against weather hazards for the unit.

If the PIU will be connected to outdoor lines, an interface

unit, complying with Clause 6 of the UL 60950 standard

must be provided.

3

Page 10

Introduction

Figure 2

PIU – General View

Piccolo–XR

The Piccolo–XR is an intelligent, microprocessor based

unit that can be used to monitor and control local units in a

multi unit communication network. Piccolo–XR units

communicate data to a PIU while functioning as intelligent

nodes in Distributed I/O monitor and control systems. The

Piccolo–XR is often used in irrigation and water

distribution systems (i.e. irrigation valves, water meters,

fertilizing meters, various sensors, flushing filters, and

other non-irrigation devices).

The Piccolo–XR is ideal for use in applications where very

low power consumption is essential. The Piccolo–XR is

also available in an outdoor resistant housing (IP66),

designed to resist harsh environment, such as exposure to

sun, dust, and pouring rains.

4

Page 11

Introduction

Figure 3

Piccolo XR –General View

Safety Handling Instructions

For safety handling instructions, see the Product Safety and

RF Energy Exposure Booklet for PIU and Piccolo XR

Units, Motorola publication no. 6802974C70, which is

distributed with the devices.

5

Page 12

Introduction

6

Page 13

INSTALLATION

General

SAFETY SUMMARY

The PIU and Piccolo–XR must be installed by

qualified and authorized technicians, specifically

qualified to handle high voltage if the installation

involves high-voltage connections/installations.

If the PIU will be installed outdoors, an outdoor

plastic housing complying with UL60950 standard

clause 6 is required.

Note!

Note!

See Piccolo–XR Screw Mounting Options (pg 19)

for mounting details.

This equipment is tested with specified length

cables and in standard enclosure. If longer

cables or a different enclosure are used, the

installer is responsible to ensure that the

installation complies with the requirements of the

applicable standards.

7

Page 14

Installation

PIU Installation

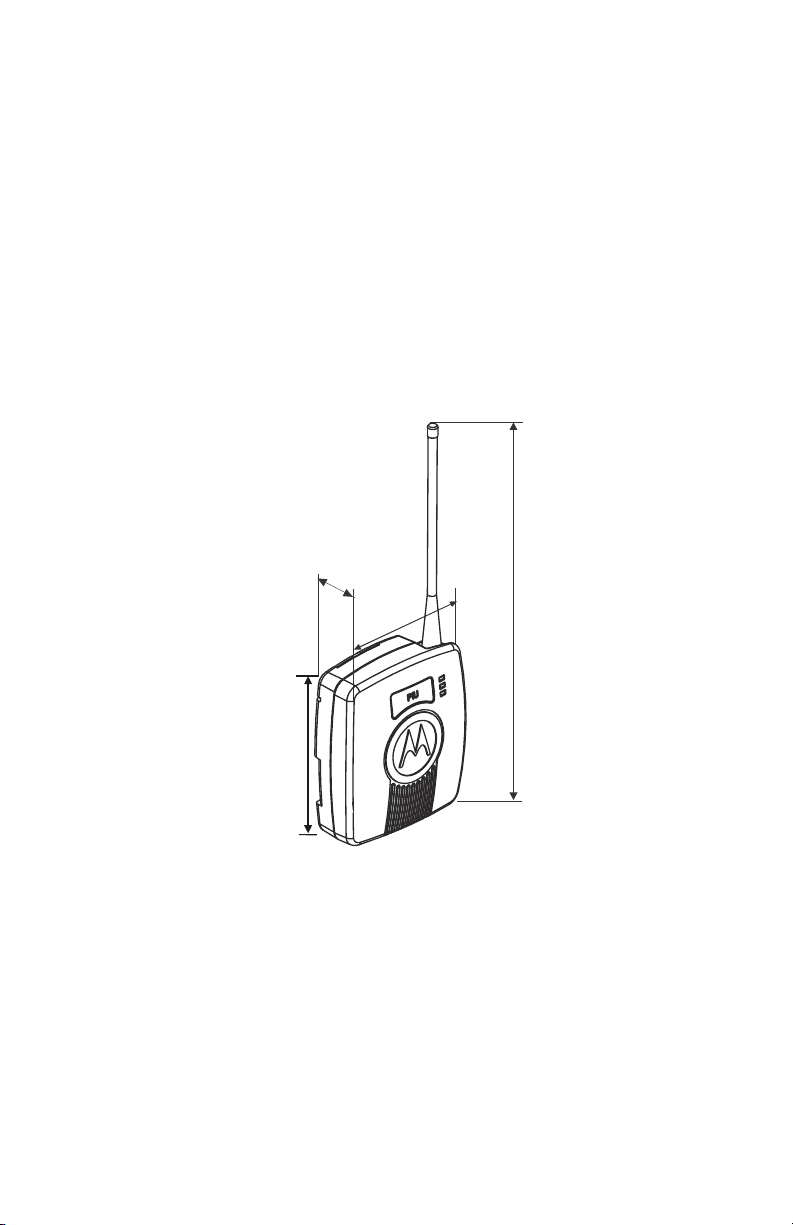

PIU Dimensions

The unit dimensions are (see Figure 4):

• Width – 4.25" (108 mm),

• Height – 4.96" (126 mm),

• Height including antenna – 11.46” (291.1 mm),

• Depth – 1.67" (42 .6mm),

• Weight – 0.558 Lb (253g) maximum.

1

.

6

7

4

"

2

.

6

m

m

"

5

2

.

4

m

m

8

0

1

"

11.46

mm

291.1

4.96”

126 mm

Figure 4

Dimensions of PIU Unit

The PIU is enclosed in a plastic housing, allowing 3 mounting

options:

• Wall mount (Screws)

• Bracket mount

• DIN rail mount

8

Page 15

Installation

Before installing the PIU, verify that there is sufficient space

around the unit according to the specific installation.

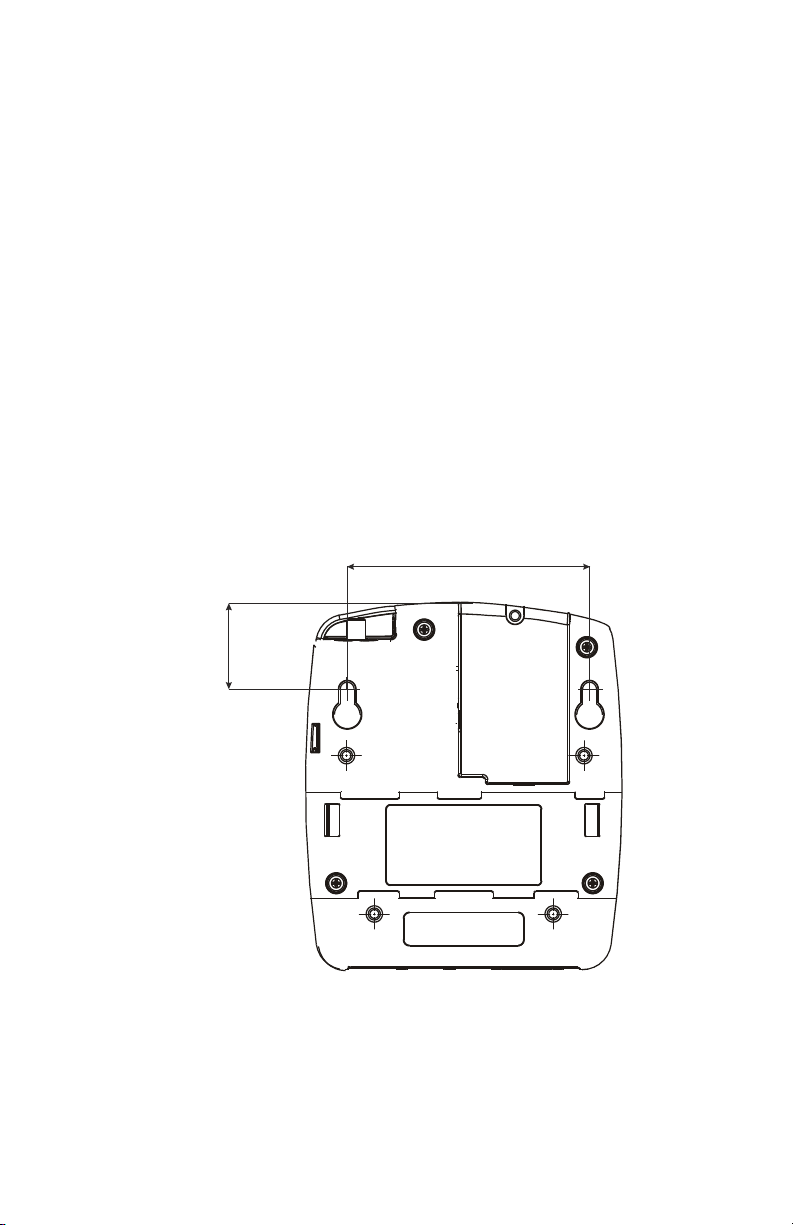

Mounting the PIU On A Wall Using Screws

Secure two screws (not supplied) of maximum 0.37” (9.5 mm)

head size to the wall, 3.256” (82.7 mm) apart. The wallmounting template in Appendix D can be used to determine the

space between both screws.

The screws must not protrude from the wall surface by more

than 0.23” (6 mm) or by less than 0.16” (4 mm).

Attach the unit to the wall, fitting the two shaped cavities on

the back cover of the unit over the screws and sliding it down.

(See Figure 5.)

3.26"

82.7 mm

1.19"

30.3mm

Figure 5

PIU Installation– Screw Mount dimensions

9

Page 16

Installation

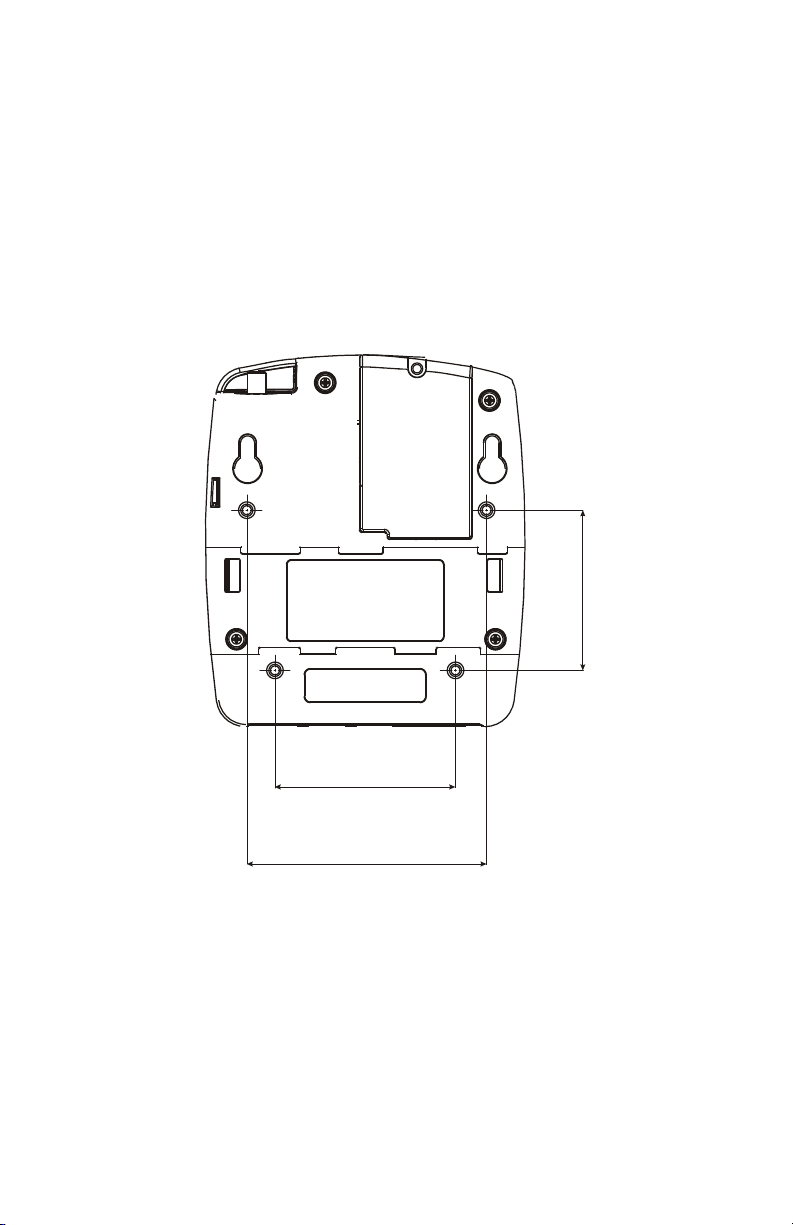

Mounting the PIU Using a Bracket

Using four M3x6 or M3x8 screws, attach a bracket (not

supplied) to the back of the PIU. The upper two bracket holes

must be 81 mm (3.19”) apart, and the lower two bracket holes

must be 61 mm (2.40”) apart and 54 mm (2.13”) below the

upper holes, as shown in Figure 6.

Attach the bracket to the mounting surface.

2.13"

54mm

2.40"

61 mm

3.19"

81mm

Figure 6

PIU Installation– Bracket Mount dimension

10

Page 17

Installation

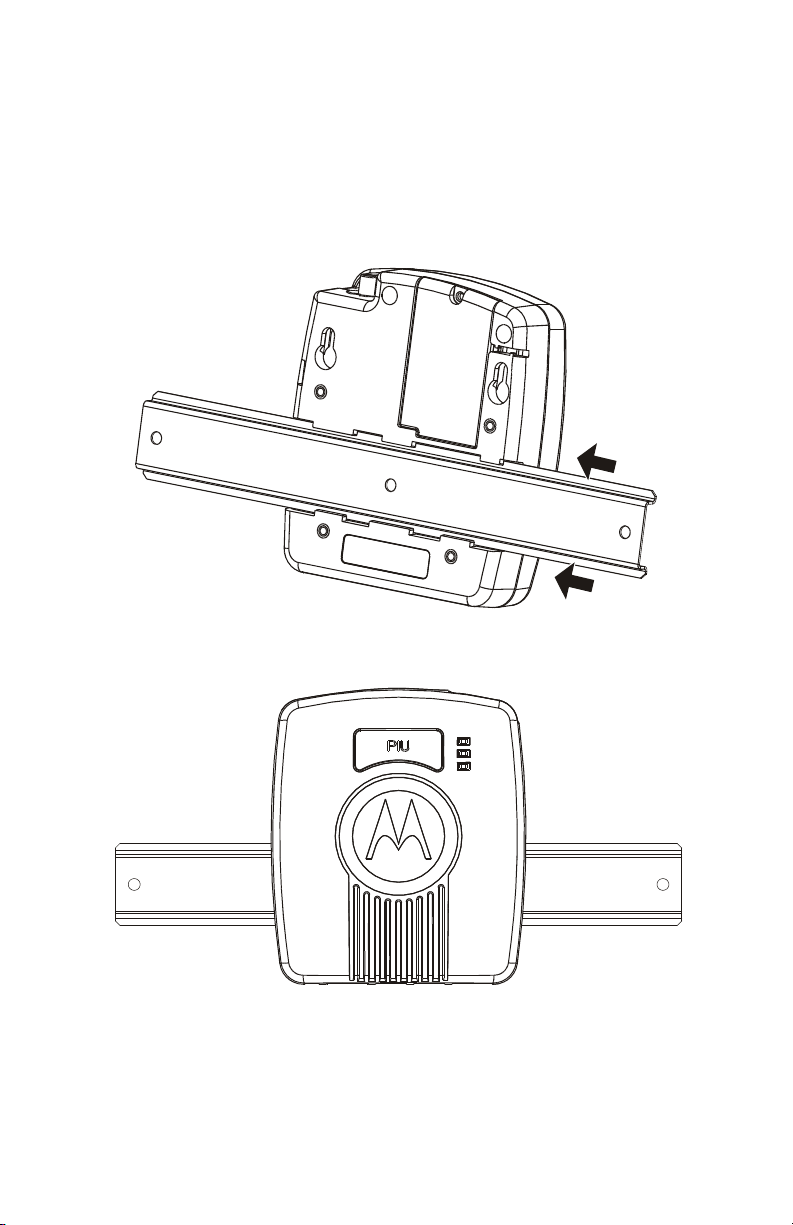

PIU DIN Rail Mounting

To mount the PIU on a DIN rail (not supplied), slide the PIU

onto the rail at the grooves on the back of the unit. See Figures

7 and 8.

Figure 7

DIN Rail Attachment – Back View

Figure 8

DIN Rail Attachment – Front View

11

Page 18

Installation

PIU Electrical Connections

NOTE!

Verify that all power connections are made in

accordance with the applicable local standards.

PIU Ground Connections

Use the FKN8254A cable to connect the grounding cable

directly to the TB connector of the PIU as shown in Figure 9.

The grounding connector is also used as an

NOTE!

ON/OFF switch, and the unit cannot be powered on

without connecting it.

Grounding Cable

(FKN8254A)

Figure 9

PIU Ground connection

12

Ground

Page 19

Installation

Power Connection

The PIU can be powered by various types of supply sources:

• Internal (9VDC) battery;

• External 6V or 12V DC battery;

• Motorola power supplies – controllers. For example:

IRRInet XL, IRRInet XM, IRRIcom, MOSCAD;

• 24VAC.

NOTE!

9VDC Internal Battery

The unit DC voltage range is 6 to 16 volts.

Incorrect replacement of the battery can result in

explosion! Replace only with the same or with an

equivalent type of battery recommended by the

manufacturer.

Dispose of used batteries according to the battery

manufacturer instructions.

Place a standard 9VDC alkaline battery (not supplied) into the

PIU battery chamber (see Figure10). Battery operation is

applicable when operating the unit in a non-radio mode, e.g.

when the PIU is used as an adapter.

13

Page 20

Installation

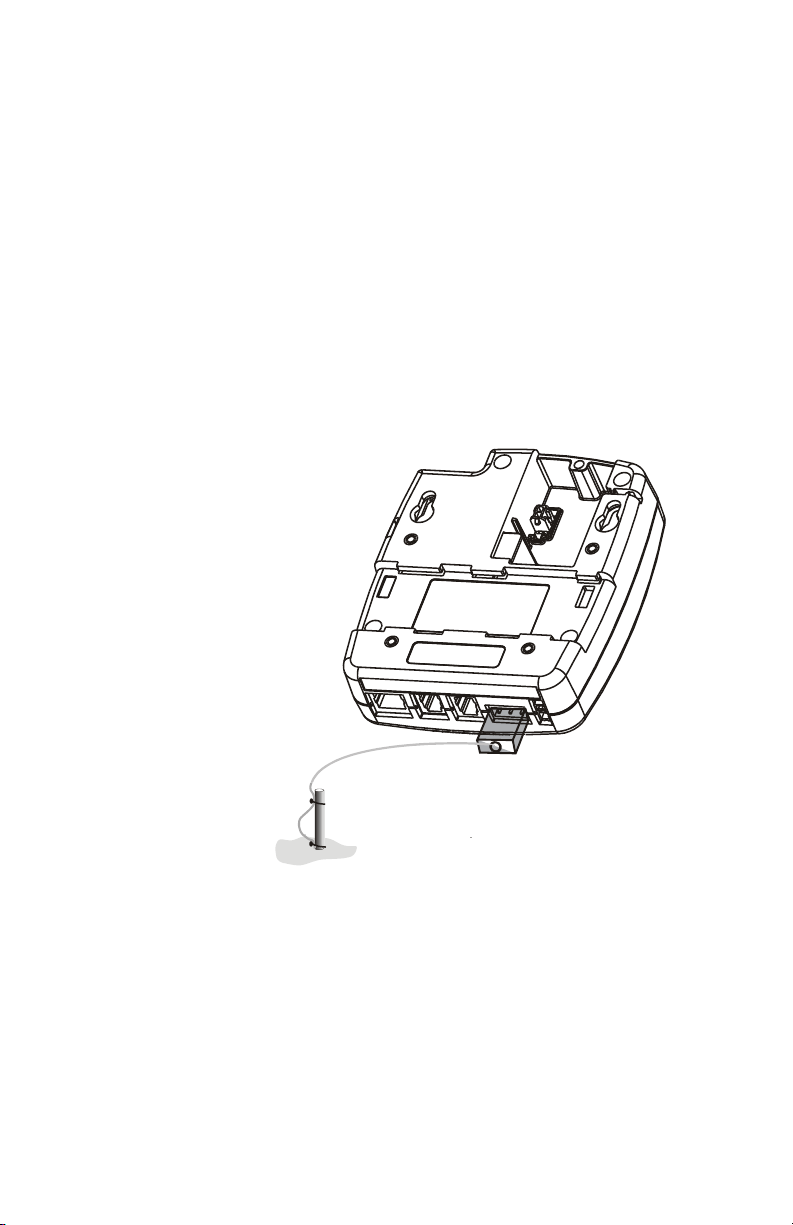

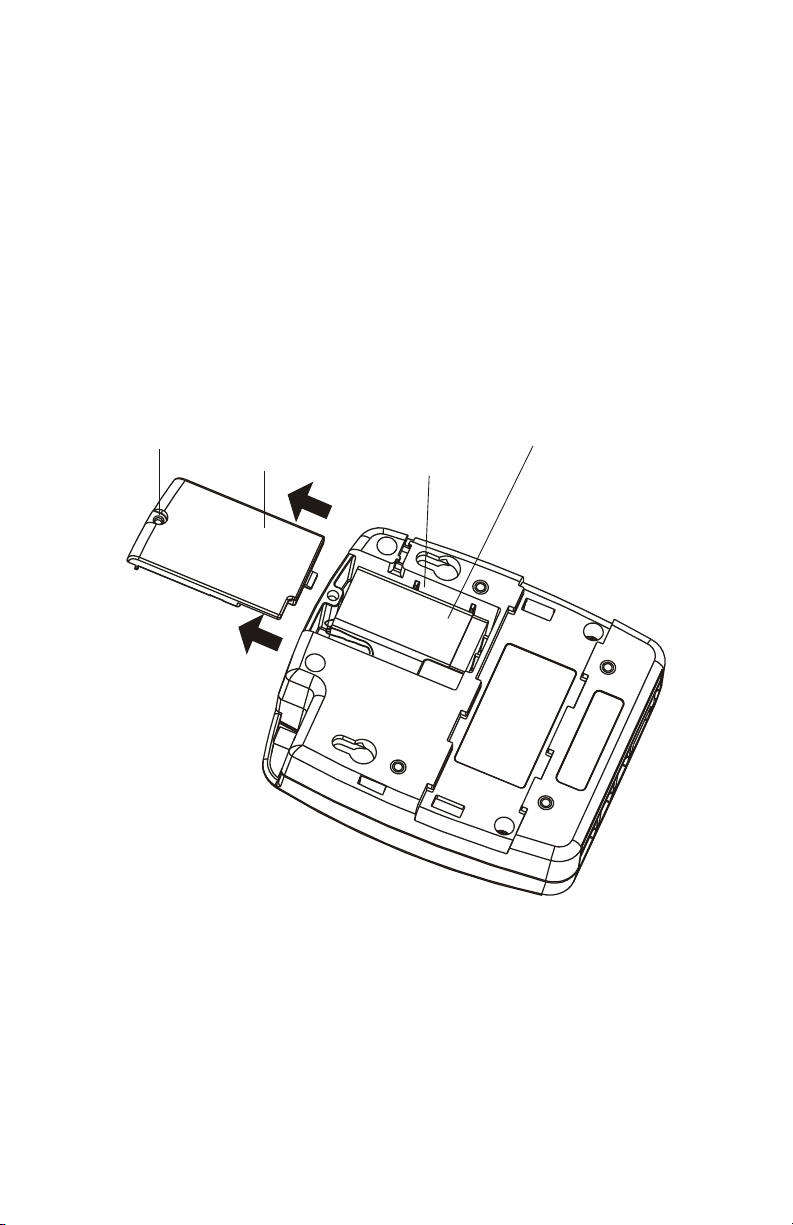

Installation of an Internal Battrey

Release the screw at the top of the battery chamber door, and

slide the door out, as shown in Figure 10.

Connect the 9V battery cable (FKN8204A) to the DC power

input connector on the back of the unit.

Connect the 9V DC battery to the cable.

Place the 9V DC alkaline battery in the chamber as shown in

Figure 10.

Close the battery chamber door and secure with the screw.

Screw Battery

Chamber Door

Figure 10

PIU Battery Chamber

Battery

Chamber

Battery

14

Page 21

Installation

External Battery Power Connections

The unit must be powered by a limited power

source in accordance with standard

UL/IEC 60950-1.

This connection is used for normal operation of the PIU, when

radio communication is required, or when RS485 or RS232

ports are used.

Release the screw at the top of the battery chamber door and

slide the door out, as shown in Figure 10.

Connect the DC Adapter board (FCN6538A) to the DC power

input connector on the back of the unit (Figure 11).

Connect the FKN8250A 7 ft cable to the DC Adapter board.

Connect the other cable end to an external 12VDC battery

through 1A fuse (not supplied).

Close the battery chamber door and secure with the screw.

Error! Not a valid link.

Figure 11

PIU Unit – Rear View with DC Adapter

15

Page 22

Installation

External Power Supply Connections

Use the applicable cable from the V152AH PIU installation kit

to connect the PIU to Motorola standard controller power

supply.

Release the screw at the top of the battery chamber door and

slide the door out, as shown in Figure 10.

Connect one end of the cable to the DC power input connector

on the back of the unit.

Connect the other end of the cable to the power supply output

of a Motorola controller.

Close the battery chamber door and secure with the screw.

16

Page 23

Installation

24VAC Power Connections

The PIU must be connected to a power source

equivalent to one or more of the following:

a. A listed Direct plug-in unit.

b. A Class II power source (defined by the

National Electrical Code (NEC) and the

Canadian Electrical Code (CEC).

c. A power source that complies with UL1950

C1.2.1 or UL60950 C1.2.5.

The unit must be powered by a limited power

source in accordance with standard

UL/IEC 60950-1.

Connect the FKN8264A cable to the 24 V AC PWR IN

connector as shown in Figure 12.

Connect the other end of the cable to the 24 V AC connection

of a 110 V AC/220 V AC transformer (not supplied) through a

1 A fuse (not supplied).

AC Cable

FKN8264A

1A Fuse

24 V AC

0

~

110/220 V AC

Figure 12

24VAC Power In Connection

17

Page 24

Installation

PIU Antenna Connection

Flexible Antenna: Attach the flexible monopole antenna to the

antenna connector at the top of the unit. See Appendix C for

detailed information.

Pole Antenna: Attach the FKN8258A antenna cable to the

antenna connector at the top of the unit. Connect the other end

of the antenna cable to the pole antenna. See Appendix C for

detailed information

18

Page 25

Piccolo–XR Installation

Piccolo–XR Dimensions

The unit dimensions are (see Figure 13):

• Width – 4.6" (117 mm)

• Height – 5.00" (127 mm)

• Hight including antenna – 11.46” (291.1 mm)

• Depth –1.63" (41.5mm)

• Weight – 3.3 lb (240 gr) maximum.

1

.

6

3

4

"

1

.

5

m

m

"

6

.

4

m

m

7

1

1

11.46"

Installation

291.1mm

5.00”

127 mm

Figure 13

Dimensions of the Piccolo–XR Unit

19

Page 26

Installation

The Piccolo–XR unit can be attached to any vertical or horizontal

surface using screws. Before mounting the Piccolo–XR, verify that

sufficient clearance is left around the unit. Allow 7.87" (20 cm)

clearance off the bottom of the Piccolo–XR case for the TB

connectors and 6.3" (16 cm) off the top of the unit for the flexible

antenna.

Piccolo–XR Screw Mounting Options

Mount the Piccolo–XR on a vertical surface as follows:

Secure the unit to any vertical surface using one 0.35"

(9 mm) maximum head screw. Use the mounting hole

marked A in Figure 14 to attach it to the mounting surface.

See figure 15 B.

Mount the Piccolo–XR on a horizontal surface as

follows:

Secure the unit to any horizontal surface using two 0.35"

(9 mm) maximum head screws. Use the mounting holes

marked B and C in Figure 14 to attach it to the mounting

surface. See Figure 15 A.

Mount the Piccolo–XR on a wide plane as follows:

Secure the unit to any plane using three 0.35" (9 mm)

maximum head screws. Use all three mounting hole marked A,

B and C in Figure 14 to attach it to the mounting surface. See

figure 15 C.

20

Page 27

m

m

4

5

A

3

x

4

B C

98mm

49mm

Installation

.

7

5

Figure 14

Piccolo–XR Mounting Screw holes – Back View

A

B

Figure 15

Piccolo–XR Mounting Options

C

21

Page 28

Installation

W

Piccolo–XR Electrical Connections

NOTE!

Wire (1)-Red

1A Fuse

Wire (17)-Yellow

Verify that all power connections are made in

accordance with the applicable local standards.

ire (2)-Black

-

+

6 V DC Battery

User Cable-FKN8199A

I/O's

Ground

Figure 16

Piccolo–XR Ground and DC Power Connections

Piccolo–XR Ground Connections

Connect the yellow wire (17) of the FKN8199A user cable to

the PGND, as shown in Figure 16.

22

Page 29

Installation

Power Connections

The unit must be powered by a limited power

source in accordance with standard

UL/IEC 60950-1.

The Piccolo–XR is powered by an external 6 V DC battery

source.

Use the FKN8199A cable to connect the Piccolo–XR to an

external battery. Connect Wire #1 (red) to the positive (+) pole

of the battery through a 1 A fuse (not supplied) and wire #2

(black) to the battery negative (–) pole. See Figure 16.

I/O Connections

The Piccolo–XR RTU can control up to four DC Latch

Solenoids.

The solenoid operating voltage can vary in the range of +9 to

+20V DC (defined by the site configuration definition in the

DIOS Service Toolkit).

The Piccolo–XR also responds to back indication signals from

a maximum of eight different field input sensors.

The available I/O module options are as follows:

1 DI / 1 DO

2 DI / 2 DO

4 DI / 4 DO

7 DI / 1DO

8 DI / 0DO

23

Page 30

Installation

W

Solenoids

Output

Common

Wire (9) Gray

Figure 17

Piccolo–XR I/O Connections

For proper operation, the Piccolo–XR unit must be

NOTE!

connected either to a flexible antenna or to a pole

antenna. See Appendix C for antenna installation

details.

Input

Common

ire (6) Green

User Cable-FKN8199A

Sensors

24

Page 31

Installation

Table 1: Pin assignment of the Piccolo–XR user cable

(FKN8199A) Connector

PIN No COLOR DESCRIPTION

1 Red Battery 6V (+)

2 Black Battery 6V (–)

3 Brown Solenoid 2

4 Orange Input 3

5 White Input 4

6 Green Input Common

7 Blue Solenoid 3

8 Violet Solenoid 4

9 Gray Solenoid Common

10 Pink Solenoid 1

11 Light Green Input 7

12 Black/White Input 8

13 Brown/White Input 1

14 Red/White Input 2

15 Orange/White Input 5

16 Green/White Input 6

17 Yellow PGND (Chassis)

25

Page 32

Installation

Table 2: Pin assignment of the Piccolo–XR user cable

(FKN8199A) Connector

DESCRIPTION PIN No COLOR

Input 1 13 Brown/White

Input 2 14 Red/White

Input 3 4 Orange

Input 4 5 White

Input 5 15 Orange/White

Input 6 16 White/Green

Input 7 11 Light Green

Input 8 12 Black/White

Input Common 6 Green

Solenoid 1 10 Pink

Solenoid 2 3 Brown

Solenoid 3 7 Blue

Solenoid 4 8 Violet

Solenoid Common 9 Gray

Battery 6V (+) 1 Red

Battery 6V (–) 2 Black

PGND (Chassis) 17 Yellow

26

Page 33

THE DIOS PIU AND PICCOLO-XR

UNITS

PIU Overview

The PIU unit (see Figure 18) is comprised of the following:

• Internal radio interfaces and a radio modem

• A logic board

• Communication ports

LEDs

24V AC

Power IN

Figure 18

PIU Unit General View

PGND/

DC Switch

RS485 Adaptor

Port

RS232

27

Page 34

The DIOS PIU and Piccolo-XR Units

DC Power In

Figure 19

PIU Unit DC Power Connection– Rear View

PIU Communication Ports

The PIU has four ports:

Only one of the two RS ports (232 and 485) can be

NOTE!

28

operated at a time, i.e. they do not operate

together.

• RS485: Communication between multiple PIU units and

the FU.

• RS232: Communication between the PIU and the FU;

Configuration Port (unit programming and monitoring).

• Adapter port: Communication with and programming

the Piccolo-XR units.

• Internal Radio interface: internal DPSK modem.

Page 35

The DIOS PIU and Piccolo-XR Units

PIU Connectors

The PIU connectors (see Figure 18):

• RS232 (RJ45, 8 pin)

• RS485 (RJ10, 4 pin)

• Adapter port (RJ10, 4 pin)

• PGND And Power Switch (TB 3 pin)

• 24 V AC PWR IN (2 pin)

• 6, 9, 12 V DC Battery Input (2 pin)

PIU LED Operation

Three software programmable LED indicators are located on

the PIU enclosure (see Figure 18). These indicators can be used

for diagnostics purposes.

• Radio TX/RX (RED): ON – a valid frame is received by the

internal DPSK modem or the PIU transmits a frame.

• RS232/RS485 RX/TX (ORANGE): ON – a valid frame is

received or transmitted through the RS232/RS485 port

(UART1).

• Adapter port TX/RX (GREEN): ON – a valid frame is

received or transmitted through the adapter port (UART2),

or the Radio is being programmed.

29

Page 36

The DIOS PIU and Piccolo-XR Units

PIU Adapter Operation

The PIU can be used as an adapter to perform the following

functions:

• Communicating with the Piccolo–XR for configuration,

monitoring or hardware test.

• Downloading new software to a Piccolo–XR unit.

• Downloading new software to a PIU unit.

PIU Portable Use

Use the PIU adapter while holding it in your hand

(see Figure 20) or using a holster (see Figure 21).

Figure 20

PIU hand held use.

30

Page 37

The DIOS PIU and Piccolo-XR Units

Figure 21

Holster with a PIU.

Communicating With a Piccolo–XR Unit

1. Connect the PIU adapter RS232 port to the computer with

the FTN6597A cable (see Figure 22).

2. Connect the PIU adapter unit to an external 12VDC battery

or to an internal 9V battery. (See page 13 for power

options).

3. Connect the Piccolo–XR unit to an external 6VDC power

source. (See Power Connections on page 23.)

4. Use the P5 connector (communication) of the FKN8177A

cable to connect the Piccolo–XR unit to the Adapter port of

the PIU unit.

5. Use the Distributed I/O Service Toolkit to configure and

monitor the Piccolo–XR or to test its hardware.

For additional information, please refer to the online help of the

DIOS Service Toolkit.

31

Page 38

The DIOS PIU and Piccolo-XR Units

R

C

ccolo

Piccolo-X

-

+

PIU Adapter Toolkit P

-

+

RS232

P5

Programming

Cable

Connectors

GND

P4

Figure 22

PIU Adapter – Piccolo–XR Communication Mode

Connections

The grounding connector is also used as an ON/OFF

NOTE!

switch, and the unit cannot be powered on without

connecting it. (See Figure 9.)

RS485

RS232

To PC

Adapter To

XR

Pi

32

Page 39

The DIOS PIU and Piccolo-XR Units

5

C

Downloading new software to a Piccolo–XR unit.

1. Connect the PIU adapter RS232 port to the computer using

the FTN6597A cable (see Figure 23).

2. Connect the PIU adapter unit to an external 12VDC battery

or to an internal 9V battery. (

options

).

See page 13 for power

3. Connect the Piccolo–XR unit to an external 6 V DC power

source. (

See Power Connections on page 23.)

4. Use the P4 connector (programming) of the FKN8177A

cable to connect the Piccolo–XR unit to the Adapter port of

the PIU unit.

5. Use the Distributed I/O Service Toolkit Downloader.

For additional information, please refer to the online help of the

DIOS Service Toolkit.

Piccolo-XR

-

+

P4

PIU Adapter Toolkit P

-

+

Programming

Cable

RS232

Connectors

P

Figure 23

PIU Adapter – Piccolo–XR Downloading Mode

Connections

The grounding connector is also used as an ON/OFF

NOTE!

switch, and the unit cannot be powered on without

connecting it. (See Figure 9.)

GND

RS485

RS232

To PC

Adapter To

Piccolo XR

33

Page 40

The DIOS PIU and Piccolo-XR Units

C

Communicating with a PIU unit

1. Connect the PIU unit RS232 port to the computer with the

FTN6597A cable (see Figure 24).

2. Connect the PIU unit to an external 12VDC battery or to an

internal 9V battery. (See page 13 for power options.)

3. Use the Distributed I/O Service Toolkit for configuration,

monitoring or hardware test.

For additional information, please refer to the online help of the

DIOS Service Toolkit.

PIU Toolkit P

-

+

RS232

Connectors

GND

Figure 24

PIU Adapter – PC Communication Connections

NOTE!

The grounding connector is also used as an ON/OFF

switch, and the unit cannot be powered on without

connecting it. (See Figure 9.)

34

RS485

RS232

To PC

Adapter

Page 41

The DIOS PIU and Piccolo-XR Units

A

Adap

C

Downloading new software to a PIU.

1. Connect the PIU adapter RS232 port to the computer with

the FTN6597A cable (see Figure 25).

2. Connect the PIU adapter to an external 12VDC battery or to

an internal 9V battery. (

See page 13 for power options).

3. Connect the PIU unit to an external 12VDC battery or to an

internal 9V battery.

(See page 13 for power options)

4. Use the FKN8203A cable to connect the Adapter port of the

PIU unit to the RS232 connector of the PIU unit to be

programmed.

5. Use the Distributed I/O Service Toolkit Downloader.

For additional information, please refer to the online help of the

DIOS Service Toolkit.

PIU unit

PIU Adapter Toolkit P

-

+

+

Programming

Cable

Connectors

-

GND

RS232

Connectors

RS485

GND

RS232 To Adap te r o f

Programming PIU

ter

Figure 25

PIU Adapter Programming Mode Connections

The grounding connector is also used as an ON/OFF

NOTE!

switch, and the unit cannot be powered on without

connecting it. (See Figure 9.)

RS485

RS232

To PC

dapter To RS232 of

Programmed PIU

35

Page 42

The DIOS PIU and Piccolo-XR Units

Piccolo-XR Overview

The Piccolo -XR Remote Terminal Unit (RTU) is

comprised of:

– Logic board, which includes:

• I/Os

• Radio interface

• Power supplies

• Communication ports

– Radio

26 pin

Connector

Figure 26

Piccolo-XR Unit

Piccolo-XR Communication Ports

The Piccolo-XR has three ports:

• Programming port: for downloading SW.

• UART Port: Configuration Port (for programming and

monitoring the unit)

• Internal Radio interface: internal DPSK modem.

36

Page 43

The DIOS PIU and Piccolo-XR Units

Piccolo-XR Connector

The Piccolo -XR has one D-type 26 pin connector (see

Figure 26). See Table 1 and Table 2 on pages 25–26 for more

information

Input/Output options

A variety of I/O options is available for use with the

Piccolo-XR, increasing the system flexibility.

The available Piccolo-XR I/O options are:

• 1 DI / 1 DO (Option V608AC)

• 2 DI / 2 DO (Option V379AH)

• 4 DI / 4 DO (Option V118AG)

• 7 DI / 1DO (Option V115AL)

• 8 DI / 0DO (Option V508AD)

37

Page 44

The DIOS PIU and Piccolo-XR Units

38

Page 45

APPENDIX A: PIU AND PICCOLOXR SPECIFICATIONS

PIU Specifications

Environmental

Operating Temperature

Storage Temperature

Relative Operating

Humidity

Operating Altitude -400 m to +4000 m

-30 °C to +60 °C (-22 °F to +140 °F)

-40 °C to +85 °C (-40 °F to + 185 °F)

0 to 95% without condensation

@ +50 °C (122 °F)

(-1300 ft to 13,000 ft) above sea level

Mechanical

Dimensions

Weight

User Connection

126x108x42.6 mm ± 1 mm

(4.96”x4.25”x1.67”)

253 gr ± 25 gr (8.9 oz ± 0.9 oz)

RS232 (RJ45)

Adapter port (RJ10)

RS485 (RJ10)

PGND and DC switch (TB 3 PIN)

24 VAC (Molex header

6V, 9V, 12V DC

BAT IN (Straight 2 PIN)

2 PIN)

39

Page 46

APPENDIX A: PIU AND PICCOLO-XR SPECIFICATIONS

PIU Board

Communication Ports

RS232 Serial RS-232

RS485 Multi Drop 2 Wire

Adapter Serial interface between PIU as

Boot-Strap Software programming port

Internal Radio

RF Frequency UHF 450–470 MHz

Channel spacing 12.5 KHz

Internal Modem DPSK 1200

adapter and PICCOLO–XR

(UART levels)

(Service Toolkit programmable)

TX RF Low power mode:

8 – 12 mW @+25 °C (+77 °F)

5 – 16.3 mW @–30 °C - +60 °C

(-22 °F to 140 °F)

TX RF High power

80 – 120 mW @+25

°C (+77 °F)

mode:

Frequency Error:

TX deviation:

50 – 120 mW @–30

± 0.0001% max.

2KHz ± 15%

°C - +60 °C

RX BER BER<1% (See Note 5 on p. 43)

LEDs Red, Orange, Green

(SW Programmabale)

40

Page 47

APPENDIX A: PIU AND PICCOLO-XR SPECIFICATIONS

Power

Input Voltage

External Source

(DC Power In)

External Source

(24V ~ IN)

6.00 to 16.00 VDC

24VAC±20%

Power Modes

Adapter Mode (Using the internal 9 V battery)

Normal Operation 1 – 5 mA (See Note 4 on p. 43)

Sleep Mode

LPM0 250 – 400 µA (See Note 1 on p. 43)

LPM3 140 – 290 µA (See Note 1 on p. 43)

Power Fail Mode

LPM3 270 – 850 µA (See Note 3 on p. 43)

41

Page 48

APPENDIX A: PIU AND PICCOLO-XR SPECIFICATIONS

PIU Mode (Using a 12 V or 6 V external power source)

Radio Transmission

(TX power-10 mW) 25 – 40 mA (PWR IN =14 V)

65 – 90 mA (PWR IN = 6 V)

(TX power-100 mW) 30 – 65 mA (PWR IN =14 V)

85 – 135 mA (PWR IN = 6 V)

Standby current

Radio Receives

13 – 18 mA (PWR IN =14 V)

30 – 38 mA (PWR IN = 6 V)

Sleep Mode

LPM0

200 – 320 µA (See Note 2 on p. 43)

LPM3 130 – 250 µA (See Note 2 on p. 43)

Power Monitors

Power OK Voltage (Service Toolkit Adjustable Default

= 12 V DC) ± 200 mV

LOW Power Voltage

(Service Toolkit Adjustable Default

= 11.2 V DC) ± 200 mV

Very Low Battery

(Service Toolkit Adjustable Default

= 10.8 V DC) ± 200 mV

Reverse Input Voltage

Connection

Protected

42

Page 49

APPENDIX A: PIU AND PICCOLO-XR SPECIFICATIONS

Note 1: Power In = 9 V DC (Adapter), RS232 = shutdown,

RS485 = disable, Radio (On Board Circuits) = off, internal

Radio is off. RS232 cable connected.

Note 2: Power Supply = 14 V DC (PIU), RS232 = shutdown,

RS485 = disable, Radio (On Board Circuits) = off, internal

Radio is off. RS232 cable connected.

Note 3: Power In = 5.4 V DC (Power fail), RS232 =

shutdown, RS485 = disable, Radio (On Board Circuits) = off,

internal Radio is off. RS232 cable connected.

Note 4: Power In = 9 V DC (Adapter), RS232 = auto

shutdown, RS485 = disable, Radio (On Board Circuits) = off,

internal Radio is off. RS232 cable connected.

Note 5: Apply 1.2 KHz FM signal with 2 KHz Deviation,

Sensitivity @–110 dBm to the radio, and read BER. At

extreme temperatures apply –104 dBm.

43

Page 50

APPENDIX A: PIU AND PICCOLO-XR SPECIFICATIONS

PICCOLO XR Specifications

Environmental

Operating Temperature

Storage Temperature

Relative Operating

Humidity

Operating Altitude -400 m to +4000 m (-1300 ft to

Housing IP66

-30 °C to +60 °C

(-22 °F to +140 °F)

-40 °C to +85 °C

(-40 °F to + 185 °F)

0 to 95% without condensation

@ +50 °C (122 °F)

13,000 ft) above sea level

Mechanical

Dimensions

Weight

User Connection 17 pin User Cable

Wire Gage 22 AWG

127x117x41.5 mm ± 1 mm

(5.00”x4.60”x1.63”)

240 gr ± 24 gr (8.5 oz ± 0.85 oz)

(26 pin D-type connector)

PICCOLO XR Board

INPUTS:

Number of Inputs Modularity: 1, 2, 4, 7, 8

Dry contact Input Ratings

Minimum pulse width 100 msec

Maximum pulse rate 7200 pulses per hour

44

Open: > 45 kΩ (OFF)

Closed: < 6 kΩ (ON)

Page 51

APPENDIX A: PIU AND PICCOLO-XR SPECIFICATIONS

OUTPUTS:

Number of Outputs Modularity: 1, 2, 4

Output Drive Voltage 9 - 20 Volts (± 10%) (Service

Toolkit Adjustable)2200 µF capacitor

Output Short Circuit

Protection

>5 A

Communication Ports

UART 1 port Serial port uart levels (Async.)

UART 2 port Serial port UART levels (Async.)

Bootstrap Port Software programming port

Internal Radio

RF Frequency UHF 450–470 MHz

Channel spacing 12.5 KHz

Internal Modem DPSK 1200

TX RF Low power mode:

TX RF High power

mode:

(Service Toolkit programmable)

8 – 12 mW @+25 °C (+77 °F)

5 – 16.3 mW @–30 °C - +60 °C

(-22 °F to 140 °F)

80 – 120 mW @+25

50 – 120 mW @–30

°C (+77 °F)

°C - +60 °C

Frequency Error

TX deviation

± 0.0001% max.

2KHz ± 15%

RX BER BER<1% (See Note 10 on p. 47)

45

Page 52

APPENDIX A: PIU AND PICCOLO-XR SPECIFICATIONS

Power

Input Voltage

External Battery Source

Power Consumption (6 V battery operation)

Normal Operating Mode:

Radio Transmission

Radio Off 1.2 – 1.5 mA (See Notes 6, 7 p. 47)

(TX power-10mW) 65 – 90 mA (See Notes 8, 9 p. 47)

(TX power-100mW)

Radio Receives

Sleep Mode

LPM0

LPM3 40 – 65 µA (See Note 7 p. 47)

Power Fail Mode

LPM3

Power Monitors

Power In Report

Power OK Voltage (Service Toolkit Adjustable Default =

4 to 7.8 V DC

100 – 150 mA (See Notes 8, 9 p. 47)

30 – 40 mA (See Notes 8, 9 p. 47)

190 – 250 µA (See Note 7 p. 47)

40 – 70 µA (See Note 6 p. 47)

± 200 mV

6 V DC) ± 200 mV

(See Note 11 p. 47)

Low Power Voltage (Service Toolkit Adjustable Default =

5 V DC) ± 200 mV

Very Low Battery (Service Toolkit Adjustable Default =

4.8 V DC) ± 200 mV

Reverse Input Voltage

Connection

Protected

46

Page 53

APPENDIX A: PIU AND PICCOLO-XR SPECIFICATIONS

Note 6: Power In = 4 V DC, Radio (On Board Circuits) = Off,

internal Radio is off.

Note 7: Power In = 7.8 V DC, Radio (On Board Circuits) =

Off, internal Radio is off.

Note 8: Power In = 5 V DC, Radio (On Board Circuits) =

On, internal Radio is On.

Note 9: Power In = 7.8 V DC, Radio (On Board Circuits) =

On, internal Radio is On.

Note 10: Apply 1.2 KHz FM signal with 2 KHz Deviation,

Sensitivity @-110 dBm to the radio, and read BER. At

extreme temperatures apply -104 dBm.

Note 11: For radio functionality external Power In minimum

voltage=5 V

47

Page 54

APPENDIX A: PIU AND PICCOLO-XR SPECIFICATIONS

48

Page 55

APPENDIX B: MODELS AND

ACCESSORIES

General

The following tables describe the available models, options

and accessories.

DIOS Models Model

Piccolo Interface Unit (PIU) F4604

Piccolo–XR DC F4614

PIU Options Option

INT: 12 VDC Operation (INDOOR) V260AG

ADD: RS-485 Option (INDOOR) V440AD

ADD: 12 VDC Operation (OUTDOOR) V274BQ

ADD: RS-485 Option (OUTDOOR) V186AC

ADD: RS-232 Cable 3 m V666AA

ADD: RS-232 Cable 80 cm V75EF

ADD: PIU Installation Kit V152AH

ADD: Antenna for PIU V208AF

ADD: PIU Adapter V345AL

ADD: PIU DIOS Application V377AD

INT: 12.5 KHz UHF Radio, 450–470

MHz

V347CC

49

Page 56

Appendix B: Models and Accessories

Piccolo-XR Options Option

ADD: 1 DI / 1DO Option V608AC

ADD: 2 DI / 2DO Option V379AH

ADD: 4 DI / 4DO Option V118AG

ADD: 7 DI / 1 DO Option V115AL

ADD: 8 DI / 0 DO V508AD

ADD: Antenna for Piccolo–XR V208AE

INT: 12.5 KHz UHF Radio,

V347CC

450–470 MHz

Accessories: Kit number

TEC Programming & Monitoring Cable

FKN 8171A

(26 pin)

Pole Antenna Kit (SMA TO SMA) FAE5534A

Pole Antenna Kit (SMA TO N-TYPE) FLN3373A

50

Page 57

APPENDIX C: ANTENNA

A

General

The PIU and Piccolo–XR units can be connected either to a

flexible or to a pole antenna.

The antenna connector (see Figure 27), located at the top of

the unit, is used for both antenna types.

PIU

Antenna SMA Connector

Figure 27

PIU and Piccolo–XR Antenna Connectors

Piccolo - XR

ntenna

SMA Connector

Flexible Antenna Specifications

Frequency Range: UHF

Polarization: Vertical

Nominal Impedance: 50 ohms

VSWR: 1.5:1 max at resonance

Power Rating 50 watts

Temperature Range: -40ºC to +85ºC

51

Page 58

Appendix C: Antenna

Pole Antenna

The pole antenna installation must comply with the

following requirements in order to ensure optimal

performance and guarantee human exposure to radio

frequency electromagnetic energy is within the guidelines

set forth by the applicable local regulations.

The antenna must be mounted outdoors, preferably on a

tower, if possible.

Building mounted antennas must be located on the building

roof.

All fixed site antenna installations, including the

installation of this pole antenna, require that, under the

responsibility of the licensee, the installation site be

managed in accordance with the applicable regulatory

requirements. This may require taking additional

compliance actions such as signage and site access

restrictions in order to ensure that human exposure limits

are not exceeded.

Figure 28

PIU/Piccolo–XR Pole Antenna

52

Page 59

Pole Antenna installation

W

W

SMA to SMA option

Antenna

Support

Appendix C: Antenna

Antenna

Rubber

ashers

Nut

Adjustable

Straps

SMA Connector

SMA to N-Type

Antenna Cable

N-Type

Washer

Rubber

Sleeve

SMA Connector

Figure 29

SMA To SMA type PIU/Piccolo–XR Pole Antenna

1. Connect a flexible antenna to the antenna support plate

using rubber washers, lock washer and a nut

(see Figure 29).

2. Connect one end of the SMA cable to the antenna

connection.

3. Connect the other end to the PIU/Piccolo–XR.

Lock

asher

53

Page 60

Appendix C: Antenna

A

A

r

SMA TO N-TYPE

ntenna

ntenna

Support

Rubber

Washers

Adjustable

Straps

Nut

N-Type

Connector

N-Type

Washer

SMA Connecto

SMA to N-Type

Antenna Cable

Figure 30

SMA to N Type Pole Antenna

1. Connect a flexible antenna to the antenna support plate using

rubber washers, lock washer and a nut (see Figure 30).

2. Connect the SMA end of the cable to the antenna

connection.

3. Connect the N Type end to the PIU/Piccolo–XR.

Nut

Lock

Washer

54

Page 61

Appendix C: Antenna

m

m

Pole Antenna Dimension

Figure 31 shows recommended dimensions for a

supporting plate for the pole antenna.

174mm

91.5mm

83

200mm

270mm

Figure 31

PIU/Piccolo–XR Pole Antenna Supporting Plate

Dimensions

200mm

55

Page 62

Appendix C: Antenna

56

Page 63

APPENDIX D: PIU/PICCOLO–XR

MOUNTING TEMPLATES

Use the following template for PIU wall mounting.

3.16"

82.7mm

Figure 32

PIU Wall Mounting Template (Full Size)

Figure 33

PIU Back

57

Page 64

Appendix D: PIU/Piccolo – XR Mounting Templates

The following is a template that can be used for mounting

the Piccolo–XR unit.

3.86"

2.126"

98mm

58

54mm

Figure 34

Piccolo–XR Mounting Template (Full Size)

1.93"

49mm

Loading...

Loading...