Page 1

Motorola Inc.1999

All rights reserved

ToolBox for MOSCAD

For Programming ToolBox Versi on 7. 51

RTUs

System Overview

68P02956C45-A

Page 2

COMMERCIAL WARRANTY (STANDARD)

Motorola radio communic ations products are warranted to be free from defects in mat eri al and workmanship for a

period of ONE (1) YEAR, (except for c rystals and channel element s which are warranted for a period of ten (10) years),

from the date of shipm ent . Parts, including crystals and channel elements, will be replaced free of charge for t he f ull

warranty period but the labor to replace defective parts will only be provided for one Hundred-Twenty (120) days from

the date of shipment. Thereafter purchaser must pay for the labor involved in repairing the product or replacing the

parts at the prevailing rates together with any transportation charges t o or f rom the place where warranty service is

provided. This express warranty is extended by Motorola Communications and Elect roni cs Inc., 1301 E. Al gonqui n

Road, Schaumburg, Illinois 60196, to the original purchaser only, and only to those purchasing for purpose of leasing or

solely for comm ercial, industrial, or governmental use.

THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED WHICH ARE

SPECIFICALLY EXCLUDED, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL MOTOROLA BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES TO THE FULL EXTENT SUCH MAY BE DISCLAIMED BY LAW.

In the event of a defect, malfunction or failure t o conform to specif i cations established by s el l er, or if appropriate, to

specifications accept ed by Seller in writing, during t he period shown, Motorola, at its option, will either repair or replace

the product or refund the purchase price thereof, and such action on the part of Motorola shall be the full extent of

Motorola’s liability hereunder.

This warranty is void if:

a. the product is used in other t han i ts normal and customary manner;

b. the product has been subject to misuse, acci dent neglect or damage;

c. unauthorized alt erat ions or repairs have been made, or unapproved parts used in the equipment.

This warranty extends only to individual products, batteries are excluded, but carry their own separate limited warranty.

Because each radio system is unique, Motorola disclaims liability for range, c overage, or operat ion of the system as a

whole under this warranty except by a separate written agreement s igned by an officer of Motorola.

Non-Motorola manufactured product s are excluded from this warranty, but s ubj ect to the warranty provided by their

manufacturers, a copy of which will be supplied to you on spec if ic written request.

In order to obtain performance of this warranty, purchaser must contact its Moto rol a salesperson or Motorola at the

address first above shown, att ention Quality Assurance Department.

This warranty applies only within the United S t ates.

COMPUTER SOFTWARE COPYRIGHTS

The Motorola products described in t hi s instruction manual may include copyrighted Motorola computer programs

stored in semi conductor memories or other media. Laws in the United Stat es and other countries preserve for Motorola

certain exclusive rights for copyrighted computer programs including the exclusive right to copy or reproduce in any

form the copyrighted computer program. Accordingly, any copyrighted Motorola computer programs contained in the

Motorola products described in t hi s instruction manual may not be copied or reproduced in any manner without the

express written permission of Motorol a. Furthermore, the purchase of Motorol a products shall not be deemed t o grant

either directly or by impli cation, estoppel, or otherwise, any l i cense under the copyrights, patents or patent applications

of Motorola, except for the normal non-exclusive, royalty free license t o use that arises by operation of law in the sale of

a product.

Page 3

Table of Contents

GENERAL ..............................................................................................................................................................III

Glossary...........................................................................................................................................................iii

Terms and Conventions....................................................................................................................................vi

MOSCAD RTU And ToolBox Software Version Policy ...................................................................................vii

Applicable Documentation...............................................................................................................................viii

Model Complements.........................................................................................................................................ix

Options.............................................................................................................................................................x

Accessories.......................................................................................................................................................xi

HE MOSCAD SYSTEM -OVERVIEW................................................................................................................... 1

T

The MOSCAD System ......................................................................................................................................1

Control Center ..............................................................................................................................................................1

Remote Terminal Unit (RTU)....................................................................................................................................... 2

Communication Processor/MODBUS (MCP-M).........................................................................................................2

Communication Processor/TCP/IP (MCP-T)................................................................................................................2

ToolBox for MOSCAD RTUs ...........................................................................................................................3

Features and Functions.................................................................................................................................................3

The RTU Programming Concept.................................................................................................................................. 3

Programming Sequence................................................................................................................................................ 4

RTU Definition.................................................................................................................. ........................................... 4

Communication Network..................................................................................................................................6

The RTUs and the Network..........................................................................................................................................7

Communication Links...................................................................................................................................................7

Communication Types.................................................................................................................................................. 7

Network Configurations ...............................................................................................................................................8

Starting a ToolBox Application........................................................................................................................ 15

Entering the Password .................................................................................................................................................. 15

Changing the Session Password.................................................................................................................................... 15

THE TOOLBOX FOR MOSCAD RTUS...................................................................................................................16

Hardware and Software Requirements ............................................................................................................16

Installing ToolBox............................................................................................................................................16

Connecting ToolBox to RTU ............................................................................................................................16

A Brief Tour .....................................................................................................................................................16

The RTU....................................................................................................................................................................... 16

Database Principles....................................................................................................................................................... 18

Programming Philosophy..............................................................................................................................................20

The Tools..........................................................................................................................................................22

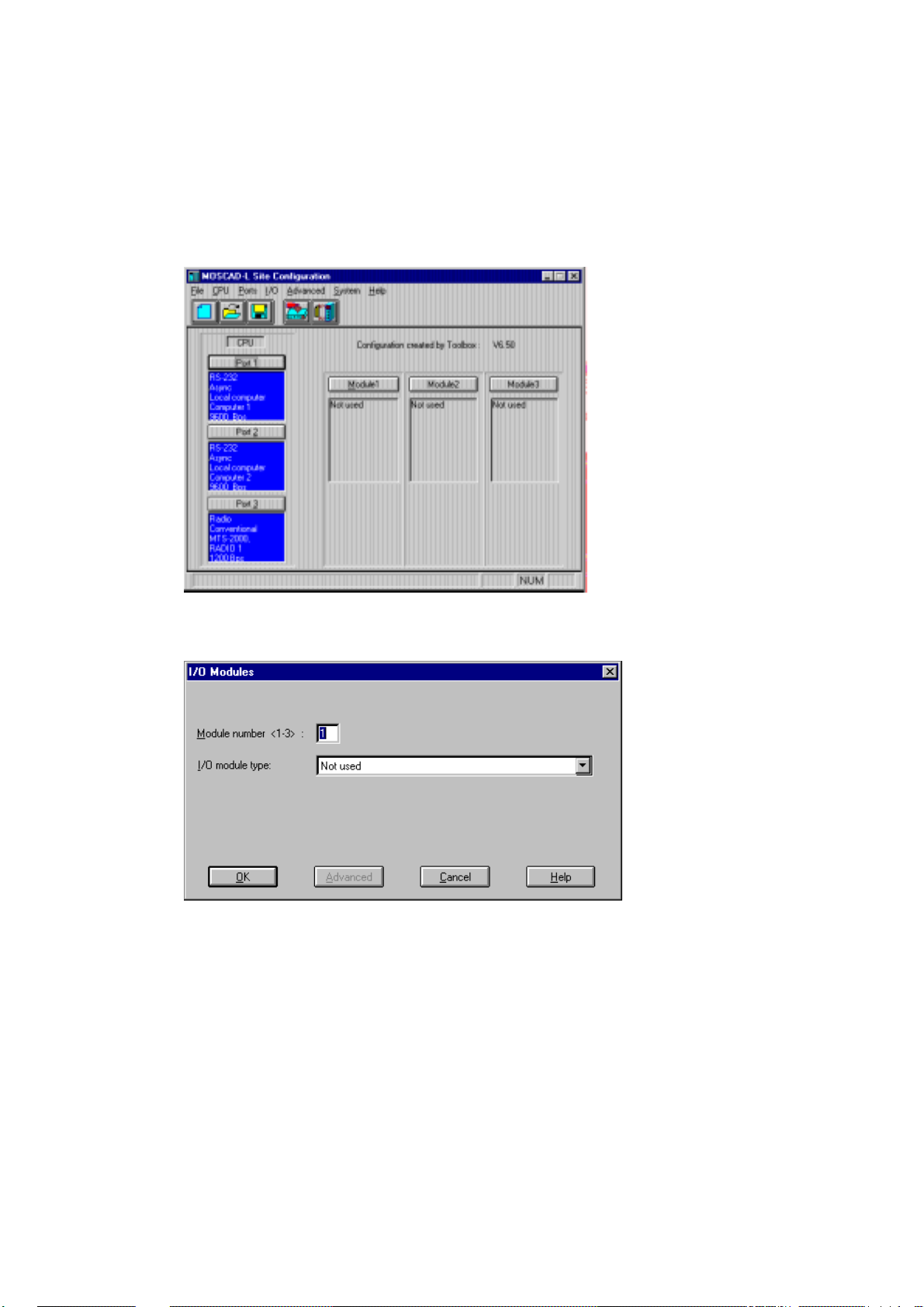

Site Configuration (MOSCAD-L).................................................................................................................................23

Network Configuration................................................................................................................................................. 25

Application Programmer .................................................................................................................................26

Database Builder........................................................................................................................................................... 28

Process Programming................................................................................................................................................... 28

I/O Link ........................................................................................................................................................................29

Compiler....................................................................................................................................................................... 30

Downloading and Monitoring....................................................................................................................................... 31

REMOTE TERMINALUNIT......................................................................................................................................32

The RTU Hardware..........................................................................................................................................32

i

Page 4

CPU Module................................................................................................................................................................. 32

I/O Modules.................................................................................................................................................................. 38

RTU Software...................................................................................................................................................38

MDLC C

OMMUNICATION PROTOCOL...................................................................................................................40

Physical Layer..................................................................................................................................................41

Link Layer ........................................................................................................................................................41

Network Layer..................................................................................................................................................42

Transportation Layer .......................................................................................................................................42

Session Layer ...................................................................................................................................................42

Presentation Layer...........................................................................................................................................43

Application Layer.............................................................................................................................................43

ii

Page 5

General

Glossary

This list of terms consists of abbreviations, acronyms and specialized words used in this

manual.

Acronyms and Abbreviations

ACK Acknowledge

AGA American Gas Association

ASL Arithmetical Shift to Left

ASR Arithmetical Shift to Right

BCD Convert to BCD Format

BIN Convert to Binary Format

CD Carrier Detect

COS Change of State

CPU Central Processing Unit

CPY Copy

CRC Cyclic Redundancy Check

CTD Count Down

CTS Clear to Send

CTU Count Up

DBB Data Base Builder

DCE Data Communication Equipment

DFM Direct Frequency Modulation

DOF Delay Off

DON Delay On

DPL Digital Private Line

DPSK Differential Phase Shift Keying

DSP Digital Signal Processing

DSR Data Set Ready

DTE Data Terminal Equipment

DTR Data Ready

EGU Engineering Units

FEP Front End Processor (MCP-M, MCP-T, or FIU)

FIU Field Interface Unit

FSK Frequency Shift Keying

GND Ground

GPS Global Positioning System

HDLC High -level Data Link Communication

HW Hardware

I/O Input/Output

IGC/M IBM Graphic Center for MOSCAD (old)

IMP Integrated Multiprotocol Processor

INTRAC Two-layer (32 bits) protocol

iii

Page 6

General

JMP Jump

JSP Jump To Subprocess

LED Light Emitting Diode

LSL Shift to Left

LSR Shift to Right

MCP-M Motorola Communication Processor – MODBUS

MCP-T Motorola Communication Processor – TCP/IP

MDLC MDLC Motorola Data Link Communication (Seven-layer OSI protocol)

MEIC Previous generation RTU type

MMI Man Machine Interface

MODBUS MODICON BUS Protocol

MOSCAD Motorola SCADA

MOSCAD-L Motorola SCADA-Light

MOVE Move Value

MOVH Move High

MTE Multi Task Environment

NACK Negative Acknowledge

N.C. Normally Closed

N.O. Normally Open

NEMA National Electrical Manufacturers Association (issues enclosure

standards)

OSI Open System Interconnection

OVF Overflow

PC Personal Computer

PID Proportional Integral Derivative

PL Private Line

PLC Programmable Logic Controller

PPH Pulse per Hour

PPS Pulse per Second

PSTN Public Switching Telephone Network

PTT PushtoTalk(buttononradio)

RAM Random Access Memory

RET Return

RF Radio Frequency

ROM Read Only Memory

ROR Rotate to Right

RNR Receive, Not Ready

RR Receive, Ready

RST Reset

RTS Request to Send

RTU Remote Terminal Unit (can be MOSCAD or MOSCAD-L)

RUNP Run Process

RX Receive

SCADA Supervisory Control and Data Acquisition

SW Software

TDPSK Trunked Differential Phase Shift Keying

iv

Page 7

TRT Retentive Timer

TX Transmit

UART Universal Asynchronous Receiver Transmitter

UCL User Call Function

UDF Underflow

XTAL Crystal

Definitions

Upload Load a block of data or code, from the RTU to the ToolBox

Download Load a block of data or code, from the ToolBox to the RTU.

General

v

Page 8

Terms and Conventions

The MOSCAD RTU is shipped in two versions, MOSCAD RTU and MOSCAD-L RTU.

Most of the features described in the MOSCAD documentation are common to MOSCAD

and MOSCAD-L. Throughout the documentation the terms “RTU” and “MOSCAD” refer

to the “generic” system. Differences are indicated by specific references to MOSCAD and

MOSCAD-L.

RTUs and MCP/Ms are “sites”. In the MOSCAD documentation, references to “site”

generally mean “RTU” and vice-versa. The MCP/M is a central adapter between SCADA

and the field.

The MOSCAD ToolBox package consists of several Windows 95/NT applications, such as

Site Configuration and Application Programmer. Throughout the MOSCAD

documentation the application names are printed in initial capitals.

Some features are valid from a certain version of Programming ToolBox. as specified

using the ≥ Va.b notation. See MOSCAD RTU And ToolBox Software Version Policy.

General

vi

Page 9

MOSCAD RTU And ToolBox Software Version Policy

The version numbers of the Programming ToolBox and MOSCAD RTU system software

are updated according to additional features and improvements.

Compatibility (at source level) between the Programming ToolBox and the MOSCAD

RTU is assured only if the version number of the Programming ToolBox Software is later

than the version number of the MOSCAD RTU system software.

A version number is composed of two numbers, as in the following example: V1.61. The

one-digit number to the left of the decimal point describes a major modification of the

software, while the two-digit number to the right of the decimal point describes a minor

modification.

In this manual, some headings of major subjects are marked by the following annotation:

≥

Va.b.

For example, ≥ V1.61 indicates that the marked subject is supported by an RTU whose

MOSCAD software version number is at least 1.61.

General

This numbering convention applies to MOSCAD-L as well, except for the versions below:

If no version number is specified, then that feature is supported by all versions of

MOSCAD and MOSCAD-L.

MOSCAD-L Version Supported by

ToolBox Version

1.0x 5.01

2.0x 6.00

2.40 6.50

vii

Page 10

Applicable Documentation

The MOSCAD system includes the following manuals:

• ToolBox for MOSCAD RTUs, MOSCAD Programming ToolBox - Overview,

Motorola publication no. 68P02956C45

• ToolBox for MOSCAD RTUs, MOSCAD Programming ToolBox - System Setup &

Diagnostic Tools,

Motorola publication no. 68P02956C50

• ToolBox for MOSCAD RTUs, MOSCAD Programming ToolBox - Application

Programmer,

Motorola publication no. 68P02956C55

• ToolBox for MOSCAD RTUs, MOSCAD Programming ToolBox - Third Party

Protocols Support, Modbus and Allen Bradley,

Motorola publication no. 68P02956C70

• ToolBox for MOSCAD RTUs, MOSCAD Programming ToolBox C Toolkit,

Motorola publication no. 68P02956C75

General

• ToolBox for MOSCAD RTUs, MOSCAD Programming ToolBox - AGA8 Gas Flow

Calculations,

Motorola publication no. 68P02957C10

• MOSCAD RTU Service manual,

Motorola publication no. 68P02991G90

• MOSCAD RTU Owner's manual,

Motorola publication no. 68P02994G10

• MCP/M User’s Manual,

Motorola publication no. 68P02945C05-0.

viii

Page 11

Model Complements

F2316 MOSCAD Programming ToolBox

FVN4126 Program Software Package on CD-ROM + Manuals

FLN6457 RS232 T e rminal Adapter Cable + Adapters

General

ix

Page 12

Options

V377 Third Party Protocols

V378 AC Analyzer Toolkit

V284 AGA8 Gas Flow Calculations

V212 Master Key Diskette

V385 X.25 option for ToolBox

V204 MDLC over IP option for ToolBox

General

FVN4119 Third Party Protocols

FVN 4335 AC Analyzer Toolkit

FVN 4334 AGA8 Gas Flow Calculations

FVN 4396 Master Key Diskette

FVN 4730 X.25 option for ToolBox

FVN 4782 MDLC over IP option for ToolBox

x

Page 13

Accessories

FVN1710 Upgrade ToolBox

FVN4126 Program Software Package on CD-ROM + Manuals

FVN4334 AGA8 Gas Flow Calculations + Manual

FVN4119 Third Party Protocols

FVN4335 AC Analyzer Toolkit

FVN4396 Master Key Diskette

FLN2391 “C” Toolkit Package + Manual

General

xi

Page 14

The MOSCAD System - Overview

MOSCAD Programming ToolBox is a package of computer programs that builds

sophisticated distributed SCADA (Supervisory Control and Data Acquisition) systems

for a wide range of applications.

The MOSCAD (Motorola SCADA) system consists of remote terminal units (RTU)

and one or more computerized control centers, connected to a communication network

via the Communication Processor/TCP/IP (MCP-T) or the Communication

Processor/MODBUS (MCP-M). The Programming ToolBox software package runs

on a Pentium 100 (or more powerful) computer.

The main function of the Programming ToolBox is to define and maintain the

MOSCAD system according to user needs and requirements.

The Programming ToolBox also enables the engineer to program/download the

application program to be executed in the RTU and to perform debugging in each

RTU, using a symbolic (graphic) debugging tool. The Programming ToolBox may be

operated either locally by direct connection to the selected unit’s computer port, or

remotely, by connection to a computer port of any other RTU in the system (MCP-M,

MCP-T, or RTU) via the system communication network.

By connecting the Programming ToolBox to a computer port of one of the RTUs,

MCP-Ms, or MCP-Ts in the system, you can program or service that specific RTU or

any other RTU in the system.

The MOSCAD System

The entire control system is comprised of the SCADA central computer as a master

station, communicating with RTUs over various communication links, such as

conventional radio, trunked radio, microwave, wireline, or dial system (telephone).

The communication system is used for transmitting alarms, status information,

telemetric readings, calculated data, diagnostics, and error logging information from

the RTUs to the central facility computer and vice versa. It is also used for

downloading, monitoring, and debugging the application program at the site.

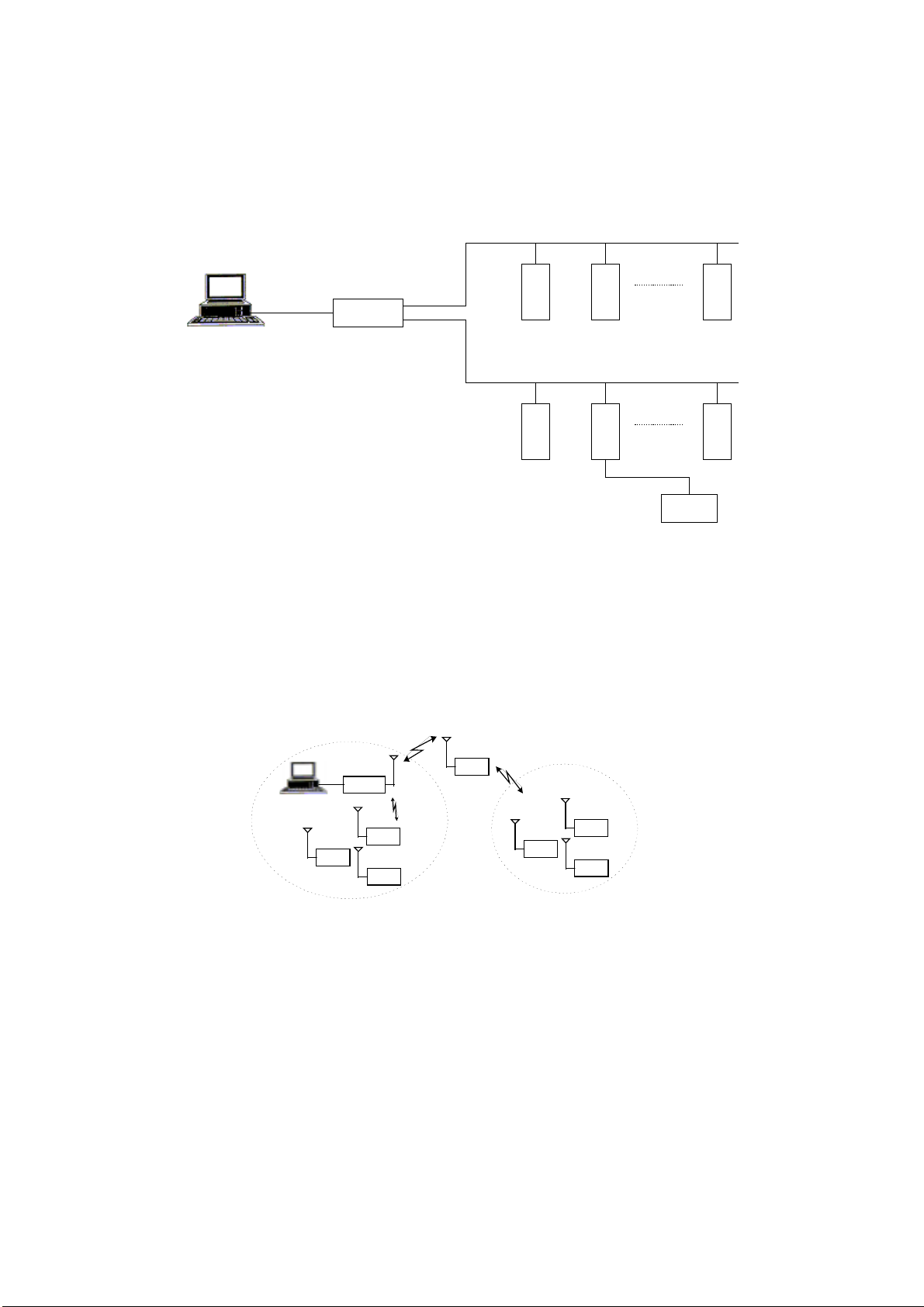

The system can be relatively simple, comprising several RTUs and a control center, or

a more complicated hierarchical system, where several sub-centrals communicate with

lower, parallel and higher hierarchies. The RTUs may also communicate with each

other and/or with any other hierarchy in the system.

Control Center

The control center computer, with the user i nterface, provides the user with full

graphic control of the RTUs’ operation, including database and parameter changes,

and on-line application monitoring for the system engineer. The central computer and

MCP-M communicate using the MODBUS protocol; MCP-T uses the TCP/IP

protocol.

1

Page 15

One of the functions of the control center is to exchange data with the RTUs. It may

interrogate the RTUs for any portion of their database. Multiple interrogation

(polling) cycles operate with different priorities and by different trigger mechanisms

(time or events).

Remote Terminal Unit (RTU)

The RTU is a smart modular unit designed to operate as a stand-alone controller or as

part of a system having any number of RTUs, control centers, and sub-centrals

connected through a communication network with any number of links and nodes.

The RTU is configured and loaded with the appropriate application using the

Programming ToolBox.

The RTU is a microprocessor-based unit, which consists of a CPU module and various

I/O and communication modules. The very wide range of I/O and communication

modules makes the MOSCAD system flexible to satisfy any application requirements.

MOSCAD-L, on the other hand, is a lighter version with a limited number of I/O

modules and fewer features.

The MCP-M and the RTUs communicate using the MDLC protocol, based on the

seven layers of the OSI (Open Systems Interconnection) model published by ISO, and

adapted for SCADA communications. The protocol provides network support and

multiple logical channels per physical port, enabling simultaneous central-to-RTU and

RTU-to-RTU sessions. It also enables each RTU to simultaneously run several

communication sessions, such as data exchange, on-line monitoring, diagnostics, etc.

The MOSCAD System - Overview

The RTU is discussed in more detail later in this manual. For technical information,

consult the Owner’s manual and the Service manual.

Note that throughout the ToolBox documentation, the terms RTU and unit are used

interchangeably.

Communication Processor/MODBUS (MCP-M)

The MCP-M is an intelligent, intermediary unit that ensures communications between

the control center and the RTUs. Its pre-loaded application and database allow it to

perform tasks independently, at times when the control center is not active. The MCPM application and database are dedicated to collecting data from the field and

performing scheduling tasks.

The MCP-M is installed in the control center and does not require any further

programming: the user only customizes the unit by setting parameters. It can be

configured using a ToolBox of its own, which differs from the ToolBox for RTUs

covered in this manual.

The communication processor does not have independent I/O capabilities. Any data

collection and assessment needs that may arise in the control center premises are met

by an additional RTU that is connected to the network like any remote terminal on the

field.

2

Page 16

Communication Processor/TCP/IP (MCP-T)

The MCP-T replaces the MCP-M where only a router that converts TCP/IP (over

Ethernet) to M DLC and vice versa, is needed. Unlike MCP-M, it does not have a

database or any control capabilities.

ToolBox for MOSCAD RTUs

This section is a brief review of Programming ToolBox, the software package used to

configure an RTU system and to build an application.

Features and Functions

The following are the main features of the Programming ToolBox:

• Configuring the RTU sites, configuring the network, building and maintaining the

application database and flow

• Preparing project documentation for the user

• Automatically creating a “central file” to be used later during RTU database

creation in the MCP-M.

The MOSCAD System - Overview

• Performing the following functions on any RTU either via local connection or via

the communication network:

Downloading and uploading the site configuration and related data

Downloading the application and the network configuration

Downloading and uploading the compressed source

Downloading C blocks which are run by the application

Downloading the phone book

Downloading the third-party protocol

Real-time symbolic (graphic) monitoring and debugging of the application (both

database and process)

Updating the time and the date in RTU sites

Testing all hardware modules, including software calibration of analog inputs and

outputs

Testing radio channels

Retrieving time-tagged events (of very high resolution) logged in the RTUs

Synchronizing the system clock according to MCP-M’s or FIU’s time

Retrieving errors logged in the RTUs (hardware or software malfunctions)

Capturing the data packets on the communication links and analyzing the seven

layers of the MDLC protocol

System software diagnostics by object entity names

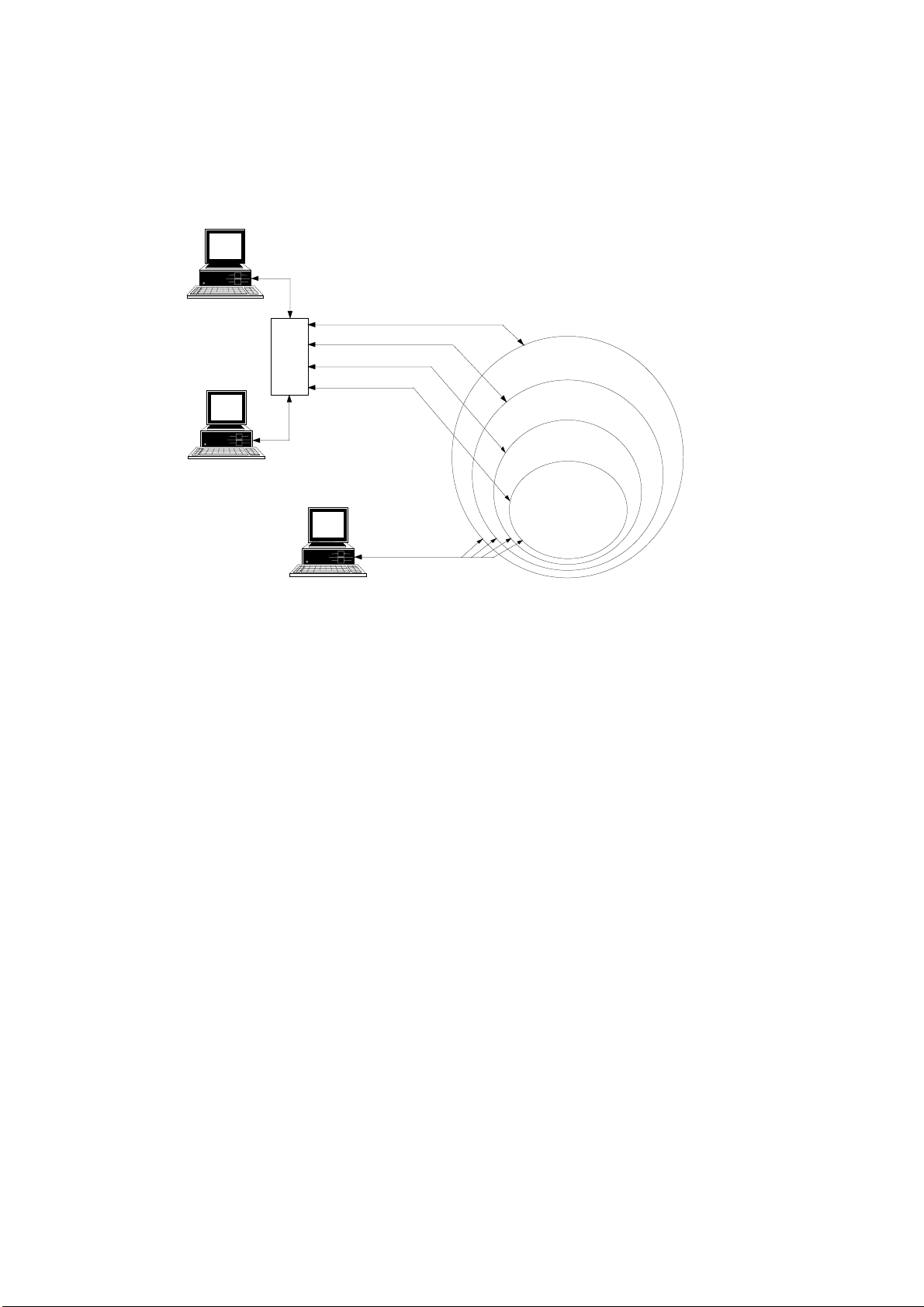

The RTU Programming Concept

The various circles illustrated below describe the RTU in layers. The first layer is the

RTU hardware that is the base for the system software and application (including

configuration) software. When the application software runs, the RTU database is

updated.

3

Page 17

The MOSCAD System - Overview

The following figure shows different ways of accessing and modifying each of the

RTU layers, using the Programming ToolBox:

• Locally by direct connection to the RTU

• Remotely via the communication network

p

Programming Sequence

The definition of the RTU application allows the system engineer to build a database

as a set of tables. The tables used for the RTU database definition are the basis for

process programming, I/O link definition, automatic central database definition, realtime monitoring of the RTU’s operation, etc.

Once the database is built, the RTU application is created using the symbolic Motorola

Advanced Ladder Diagram Language. These symbolic definitions are later used for

monitoring and debugging.

The necessary RTU application documentation is automatically produced, including

automatic insertion of notes into the produced documents.

After downloading the application to the RTU, the control program of the terminal

controls the RTU run-time operations. The Programming ToolBox terminal then

allows the system engineer to perform any required operation.

RTU Definition

The RTU definition is carried out in three stages, stored as corresponding sections in

the RTU:

• Site configuration - defining the I/O modules mounted on the RTU, the unit’s ports,

and the site address.

• Network configuration - for defining the communications network structure.

• Application program - building the application database and flow.

4

Page 18

The MOSCAD System - Overview

Site Configuration

The MOSCAD system operates with a very wide range of I/O modules and interface

communication boards which satisfy any application requirements. The site

configuration includes the definition of:

• The I/O modules mounted on the RTU and their location in the various racks

• The ports of the RTU and their parameters

• Site ID (logical address) and system address.

Since several RTUs in the system usually have the same configuration (except for the

logical address), you save the configuration to a file. Then, you can download the

same configuration to different RTUs, adding only their logical address and system

address.

Once the configuration is downloaded to the site, it i s ready to receive the user

application program. The site configuration must be defined and downloaded to the

RTU before downloading the application.

The file created by Site Configuration is later used by Application Programmer during

I/O Link definition function (I/O assignment). Full details can be found in the

Application Programmer manual.

Network Configuration

The Network Configuration application is designed to define the communication

nodes in the network. The program determines the network structure - there is no need

to define all RTUs, only the nodes in the network. The MDLC protocol uses these

definitions for t he automatic routing of the packets through the network.

Network configuration is needed only in MOSCAD systems that use more than one

communication link. A simple network, such as one MCP-M connected to one

communication link, does not require network configuration.

Like site configuration, the network configuration parameters can be saved to a file.

These parameters can be downloaded using Network Configuration or can be

automatically loaded into the RTUs with the application. During application loading,

the user is asked to provide the network configuration name, the site ID, and one link

ID of the destination RTU.

The same network configuration file is used for all the sites in the system and may also

be used in other systems (with the same structure).

Note: The network configuration must be loaded to all sites in the system (including

site nodes) to enable each site to route the packets through the network.

5

Page 19

The MOSCAD System - Overview

RTU Application

The RTU application is the control process to be executed by the remote terminal.

The application definition consists of the following:

• RTU database

• The process to be performed by the RTU (in the form of rungs, using the Motorola

Ladder Diagram Language and C functions)

• The connections between the database and the various inputs and outputs of the I/O

modules (I/O link). The I/O link portion of the RTU application is based on the

definition of the RTU I/O modules as determined in the site configuration.

The RTU database is divided into reserved variables or constants, retrieved from a

wide bank of system information (such as functional variables, reserved flags or

temporary buffers), and user variables or constants, arranged according t o various data

types (such as discrete inputs/outputs, value i nputs/outputs, timers, parameters,

integer/real values, etc.). User variables, in most cases, represent the actual

inputs/outputs from/to the outside world. They are designed to monitor and control

the user devices connected to the appropriate RT Us. They may also be used to

represent internal inputs/outputs for intermediate results and time elements, or to

perform various calculations.

The application database is built as a set of tables, where tables define a group of

devices. Each row defines a separate device, and each column contains devicespecific data. The table entries are assigned user-significant names, such as PUMP1.

During program execution, the process continuously updates the database according to

the following:

• RTU physical inputs/outputs incoming information

• Internal data stored in the RTU memory

• Data received via the communication channel and the communication ports.

Downloading

The downloading to the RTU is performed in the following order:

• Site configuration

• RTU application (and/or network configuration) according to the configuration

definition.

• Additional optional blocks, such as: Phone book, “C” blocks, special drivers

(MODBUS, AGA8, DNP3, etc.)

Communication Network

The MOSCAD system network consists of RTUs communicating with one or more

computerized control centers and/or with other RTUs. Each control center is

connected to the communication network via the MCP-M or MCP-T.

The system can be relatively simple, comprising several RTUs and one control center.

It can be modularly expanded to a more hierarchical system, where several sub-

6

Page 20

systems (comprising intelligent RTUs and/or sub-centrals controlling their peripheral

RTUs) communicate with a central computer.

The communication network is flexible, enabling each RTU to communicate with

hierarchies above it (RTU-to-central), parallel to it (RTU-to-RTU), under it (another

RTU), and also relaying messages through it (when the RTU serves as a

communication node).

While the communication protocol allows for a complex hierarchical system structure,

it does not make it complicated. This is because most of the communication

interactions are transparent to the user, except in those cases where the communication

is to be defined by the ladder application. In such cases, you should perform simple

programming operations to configure the required application.

The RTUs and the Network

Each RTU may be configured to serve as a far-end terminal or as a regional center.

The RTU may function as a regional center either by definition or only after loss of

communication with the central. It also can act as a communication node (an

interconnection point between two or more different links) while performing its other

tasks.

The MOSCAD System - Overview

The RTU network uses the MDLC protocol, which incorporates all seven layers of the

OSI model adapted for SCADA. It supports multiple logical channels per physical

port, enabling simultaneous central-to-RTU and RTU-to-RTU sessions. It also enables

each RTU to simultaneously run several kinds of communication applications, such as

reporting alarms by contention, on-line monitoring, performing diagnostics checks,

etc. The MDLC protocol is discussed later in this manual.

The Programming ToolBox may perform monitoring, modification, diagnostics, error

logging, etc., on any RTU in the system from any RS232 port in the system,

configured as either RS232 Local Computer port or RTU-to-RTU RS232 (RS-link1 –

RS-link19).

Communication Links

The system may support a network comprised of a nearly unlimited number of links.

The RTU supports a variety of communication media and baud rates, as detailed

below:

• Through the radio/wireline communication port:

Direct FM (DFM) modem on conventional radio, up to 4800 bps

FSK modem on conventional radio, up to 2400 bps

FSK modem on trunked radio, up to 2400 bps

Wireline, up to 19200 bps, using external modems

Wireline, up to 2400 bps, using built-in modems

Dial-up, up to 2400 bps, using built-in modems

External Dial-up modem

• Through the RS-232-C and RS-485 communication ports, up to 19200 bps.

The communication via the various ports may be simultaneous.

7

Page 21

The RTU operates on all radio frequencies: VHF 136-174 MHz, UHF 403-430 and

450-470 MHz, 900 MHz band, 800/900 MHz trunking and microwave.

The RTU contains a circuit for monitoring activity on the radio or line

communications channel. Channel access software prevents the RTU from

transmitting over a busy channel. Transmission is inhibited until the channel i s free.

There are also several priority levels for getting to the channel when it becomes

available.

Communication Types

TheRTUsinthesystemarelinkedtoaradioorwirelinenetworkasdefinedbythe

system engineer, according to user requirements. Each RTU executes its application

and, simultaneously, supports the communications link (or links) defined for it, and

serves as a network node, if so defined.

The MOSCAD system supports up to 29 wireline links (LINE 1 to LINE 29), up to

nine radio links (RADIO 1 to RADIO 9), and up t o 19 local RTU-to-RTU links (RSlink 1 to RS-link 19) that use RS232. Any of the radios may be either conventional or

trunked. Computers may be connected to the ports configured as RS232 Local

Computer or as local RTU-to-RTU link.

The MOSCAD System - Overview

For conventional radios, up to nine zones can be defined on every frequency (of the

nine supported frequencies). A radio link for conventional radios is divided into zones

when not all sites can communicate with each other and F1/F2 repeaters (using two

frequencies) are not to be used. In this case, some RTUs will serve as Store &

Forward repeaters and the link is divided into zones.

A zone is defined as a group of one or more sites that can directly communicate with

each other without a Store & Forward repeater. The name of a zone is composed of

the link name and the zone number. For example, for RADIO 3 zone number 1 is

named RADIO 3/1, zone number 2 - RADIO 3/2 and so on.

After defining the communications network, the user must define t he various links

used in the system as well as the RTUs that serve as nodes between the links. A

network node is an RTU that functions as an interconnection point between two or

more different links. A Store & Forward node, on the other hand, is a network node,

which relays messages using the same physical port.

Network Configurations

The MOSCAD system supports both simple and complex communication networks.

The following sections describe various configurations from different aspects.

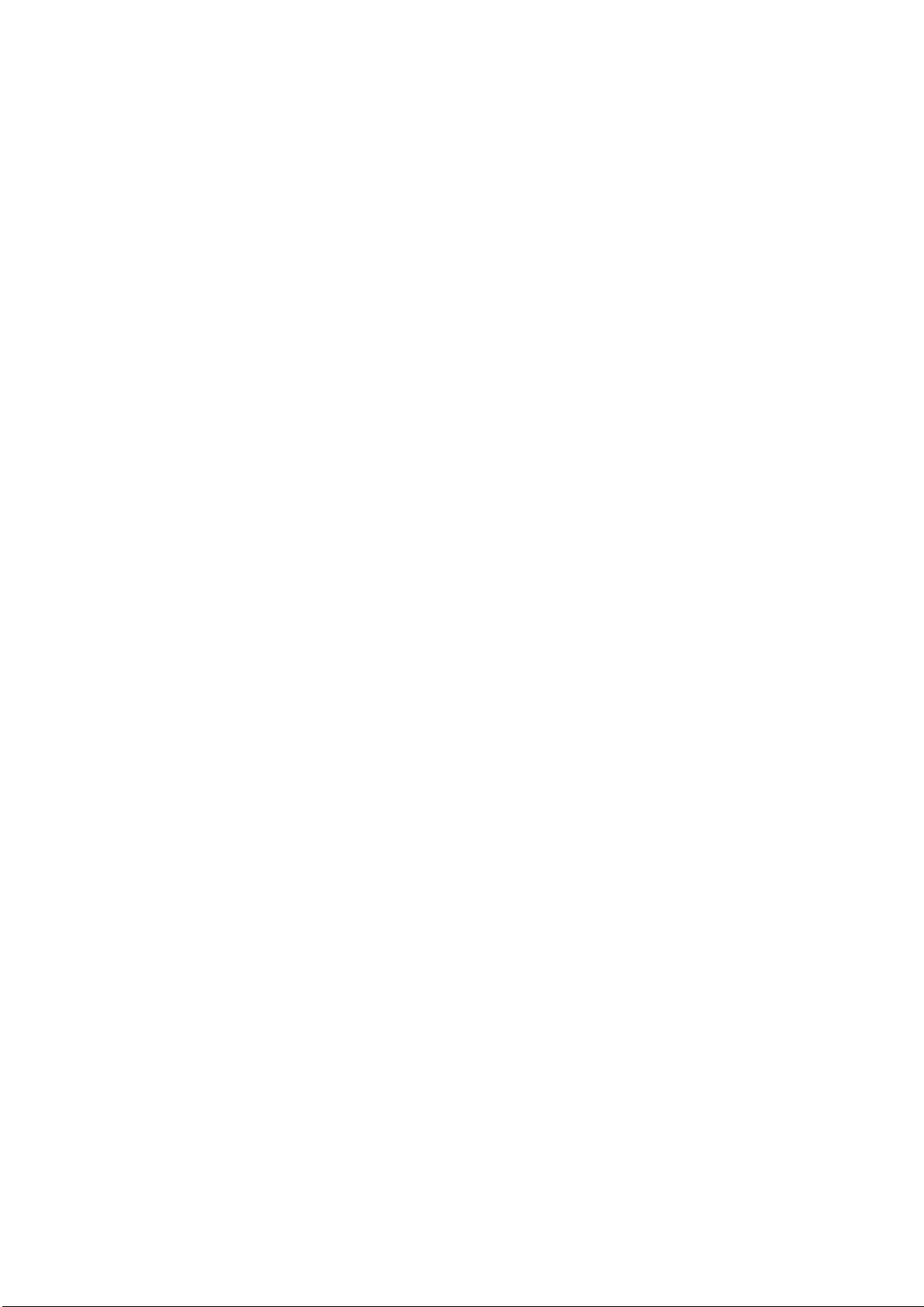

Simple System

A simple system, comprised of a central computer, MCP-M, and RTUs connected over

one communication link, is shown in the following figure:

8

Page 22

Central

Computer

The MOSCAD System - Overview

Radio link (

MCP/M

RS-232C

RTU 1

Programming

Toolbox

RADIO 1

RTU 2

Programming

Toolbox

)

RTU 3

The Programming ToolBox may be connected to any port of the RTU or MCP-M

configured as a computer port.

The radio link, named RADIO 1 in the above figure, can be a conventional radio using

DFM (Direct Frequency Modulation) or FSK (Frequency Shift Keying) radio modems,

or a t runked radio using FSK radio modem.

The ports of the RTUs and MCP-M should be defined via Site Configuration. The

logical name (in this case, RADIO 1) of the communication link is also defined. As

networks involve at least two types of links, simple systems do not need to be

configured as networks.

Two-Link and Multiple Link Systems

A two-link system utilizing a communications network, comprised of two

communication links, is described in the following figure:

RADIO 1

Central

Computer

RS-232C

MCP/M

The MCP-M in the system illustrated above serves as a network node between link

RADIO 1 and link LINE 1. Configuring the MCP-M to have access to two different

links enables the MCP-M to serve as a node between these links.

The MDLC protocol permits RTU-to-RTU communications without the intervention

of the central computer. RTUs that are not on the same link communicate with each

other via the network node (in this case, the MCP-M).

RTU 1

RTU 4

RTU 2

LINE 1

RTU 5

RTU 3

RTU 6

9

Page 23

The MOSCAD System - Overview

A multi-link system is a network that uses several link types. The following figure

illustrates a system where a third link type, RADIO 3, connects an RTU to another

terminal that communicates over RADIO 2. RTUs connected to the RADIO 1 link can

reach RTU 7 via MCP-M and then RADIO 2.

RADIO 1

Central

Computer

RS-232C

MCP/M

RTU 1

RTU 4

RTU 2

RADIO 2

RTU 5

RTU 3

RTU 6

RADIO 3

RTU 7

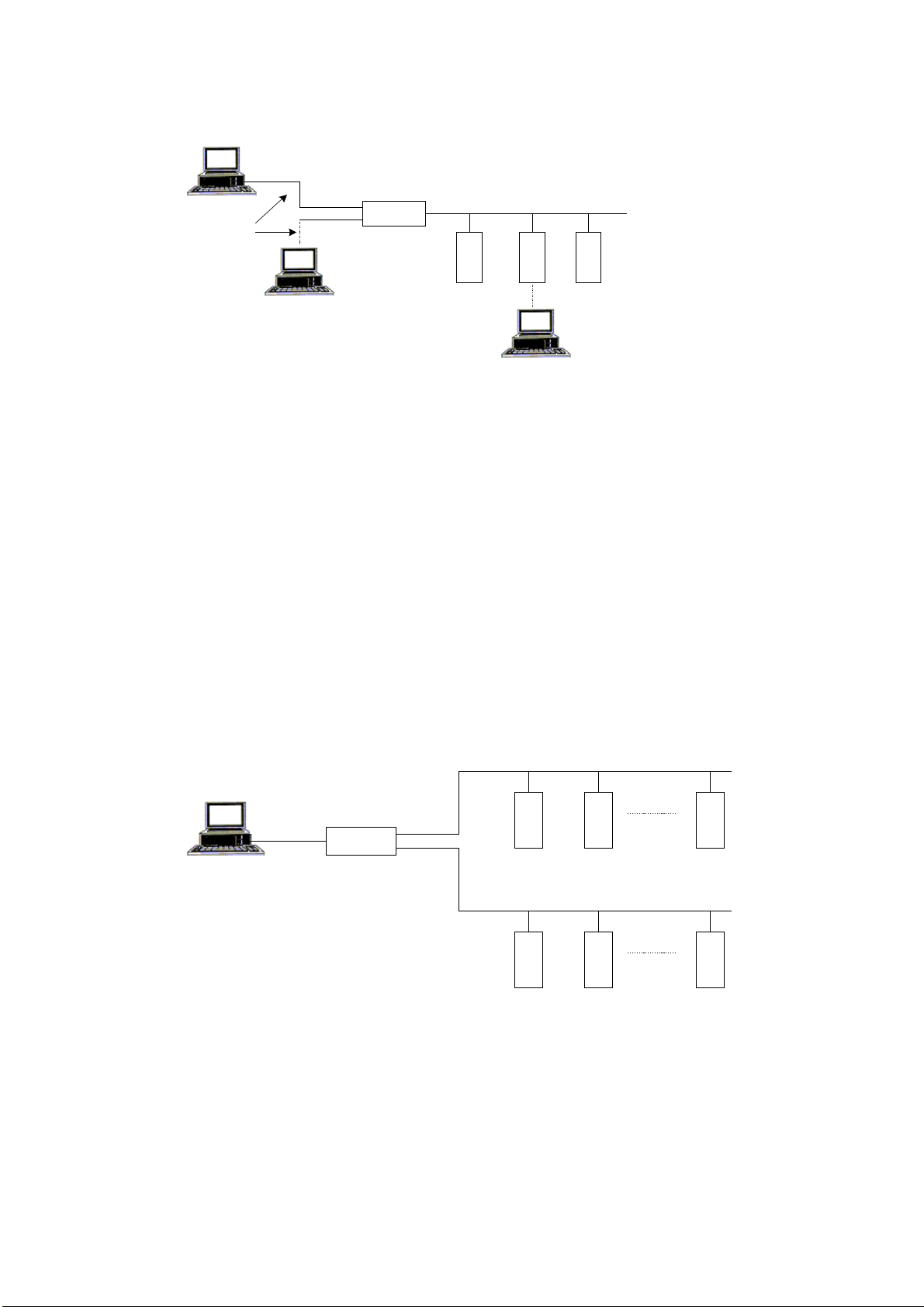

Two-Zone System

A t wo-zone system that uses conventional radio over a single frequency is described in

the following figure:

ZONE 1

MCP/M

RTU 1

RTU 2

RTU 3

RTU 9

Store & Forward

ZONE 2

RTU 5

RTU 4

RTU 6

RTU 9 (Site ID = 9) is configured as a Store & Forward repeater. It performs data

exchange between units that operate on the same frequency but are unable to

communicate directly for reasons of path and propagation. Any RTU in zone 1 may

communicate with any RTU in zone 2 via this repeater.

The figure below illustrates this system schematically. In this case, RTU 9 is a

network node between the RADIO 1/1 and RADIO 1/2 links. The network software

10

Page 24

The MOSCAD System - Overview

treats the Store & Forward node as it treats the node between line and radio: logically

the links appear as two different links, but physically they share the same port.

MCP/M

RADIO 1/1

RTU 1

RTU 9

RTU 2

RADIO 1/2

RTU 3

RTU 4

Using Site Configuration, the MCP-M and the RTUs in zone 1 are configured to have

access to the RADIO 1/1 link. The RTUs in zone 2 are configured to have access to

the RADIO 1/2 link, and RTU 9, the network node, is configured to have access to

both RADIO 1/1 and RADIO 1/2 links.

Using Network Configuration, RTU 9 is configured as the only node in the network.

This terminal is configured to have two links, RADIO 1/1 and RADIO 1/2.

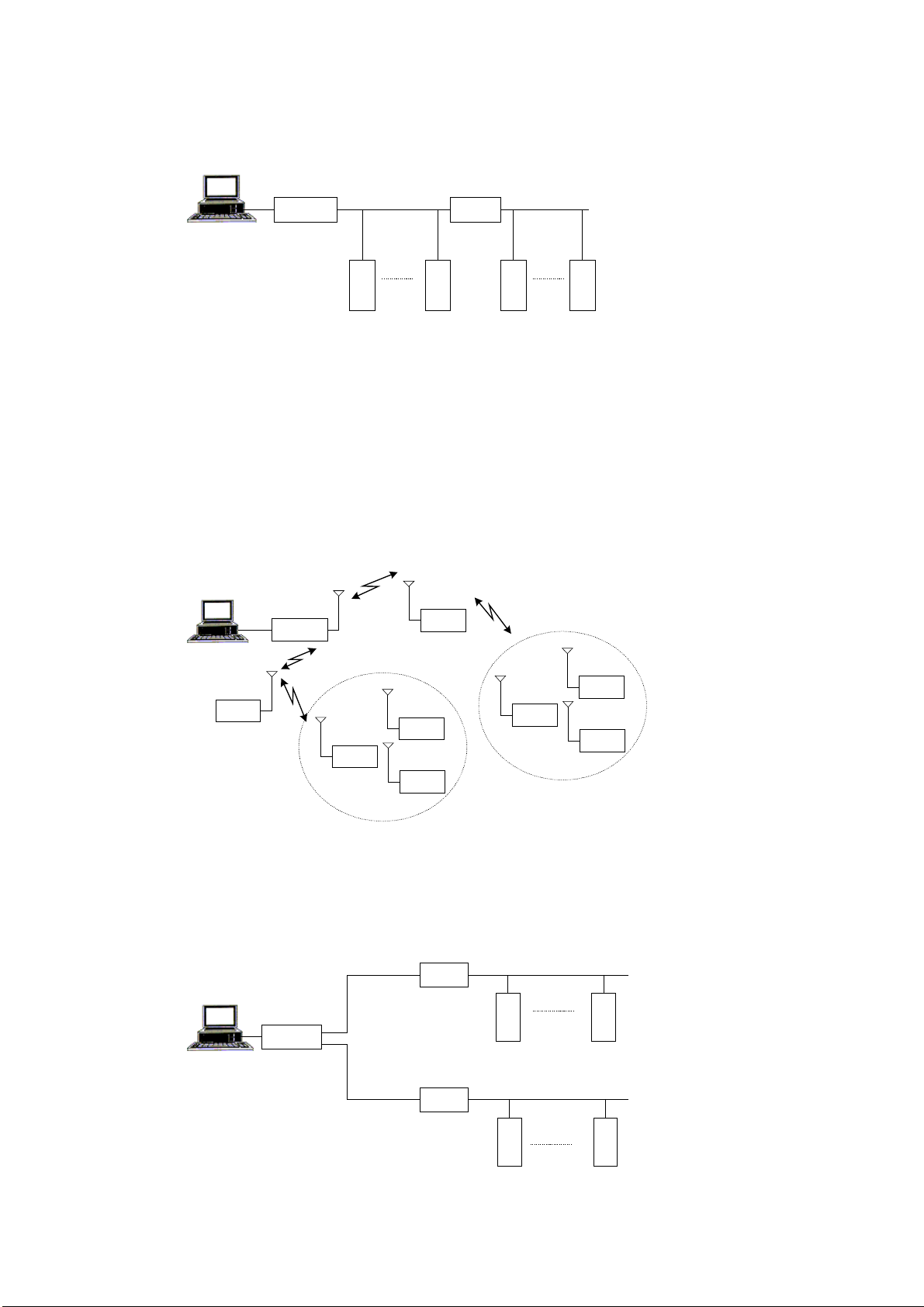

Multiple Zone System

The following figure illustrates a MOSCAD system spanning multiple zones.

MCP/M

RTU 15

ZONE 1

ZONE 2

RTU 5

RTU 40

RTU 1

RTU 2

RTU 3

RTU 4

RTU 6

The schematic representation of this system is shown below. The system assumes that

the two nodes, RTU 15 and RTU 40, cannot “hear” each other. They communicate via

the MCP-M, which is also a Store & Forward node. This system, therefore, consists

of four zones and three nodes (RTU 15, RTU 40, and MCP-M). Any communication

between RTUs in different zones passes through these three nodes.

MCP/M

RADIO 1/3

RADIO 1/4

RTU 15

RTU 40

RADIO 1/1

RTU 1

RADIO 1/2

RTU 2

11

RTU 1

RTU 2

Page 25

The MOSCAD System - Overview

In the above situation, three nodes with their accessible (logical) links should be

defined, using Network Configuration.

Using Site Configuration, the RTUs in zone 1 should be configured to have access to

the RADIO 1/1 link, and the RTUs in zone 2 to the RADIO 1/2 link.

RTU 15 should be configured to have access to both RADIO 1/1 and RADIO 1/3

links, while RTU 40 should be configured to have access to both RADIO 1/2 and

RADIO 1/4 links.

The MCP-M is configured to have access to both RADIO 1/3 and RADIO 1/4 links.

Assuming that the two nodes (RTU 15 and RTU 40) can “hear” each other, the result

is a system consisting of three zones and two nodes, as shown in the following figure:

RTU 15

MCP/M

RADIO 1/3

RTU 40

RADIO 1/1

RTU 4

RADIO 1/2

RTU 1

RTU 5

RTU 2

In this case, the two nodes do not communicate through the MCP-M. Therefore, the

MCP-M does not serve as a node in the system. Note that the communication between

RTUs in different zones passes only through two nodes.

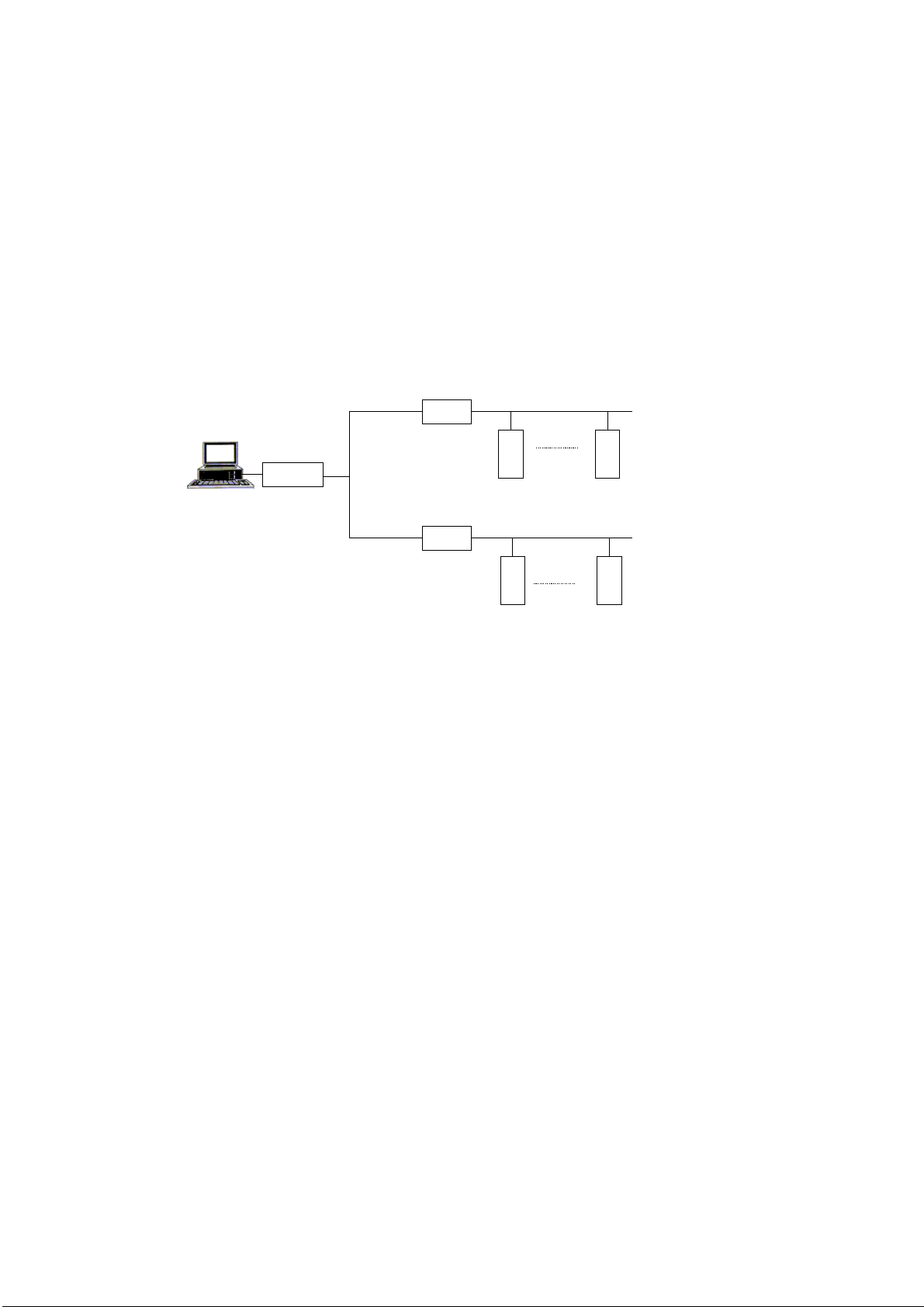

Dual Dial Port

(MOSCAD version ≥ V3.70, MOSCAD-L version ≥ V1.00)

The CPU supports two dial links at Port2 and Port3. Port2 may be connected to an

external AT modem and Port3 may be connected to either an external AT modem, or

to an internal modem configured at dial option.

Prior to using an external modem, emulate an external terminal using a PC and any

standard communication program, and set its parameters as follows:

• 9600 bps (for example)

• 8 bits

• no parity

• 1stopbit

Enter the modem telephone numbers into the MOSCAD Phone Book utility. If your

telephone works either in a pulse or in a tone mode, it is recommended to add the

letter P(pulse) or T (tone) in front of the telephone number.

If you are using an external modem, set its configuration according to the following

list.

12

Page 26

The MOSCAD System - Overview

Action Command

Disable off-line echoing ATE0

Enable audio messages ATV1

Disable quiet mode (The status codes are sent to

ATQ0

the terminal.)

Enable all codes ATX4

Enable carrier detect when a connection is

AT&C1

established.

You may enter the commands in one string, ATE0V1Q0X4&CI&W, where &W

implies saving the above parameters for the next power-up.

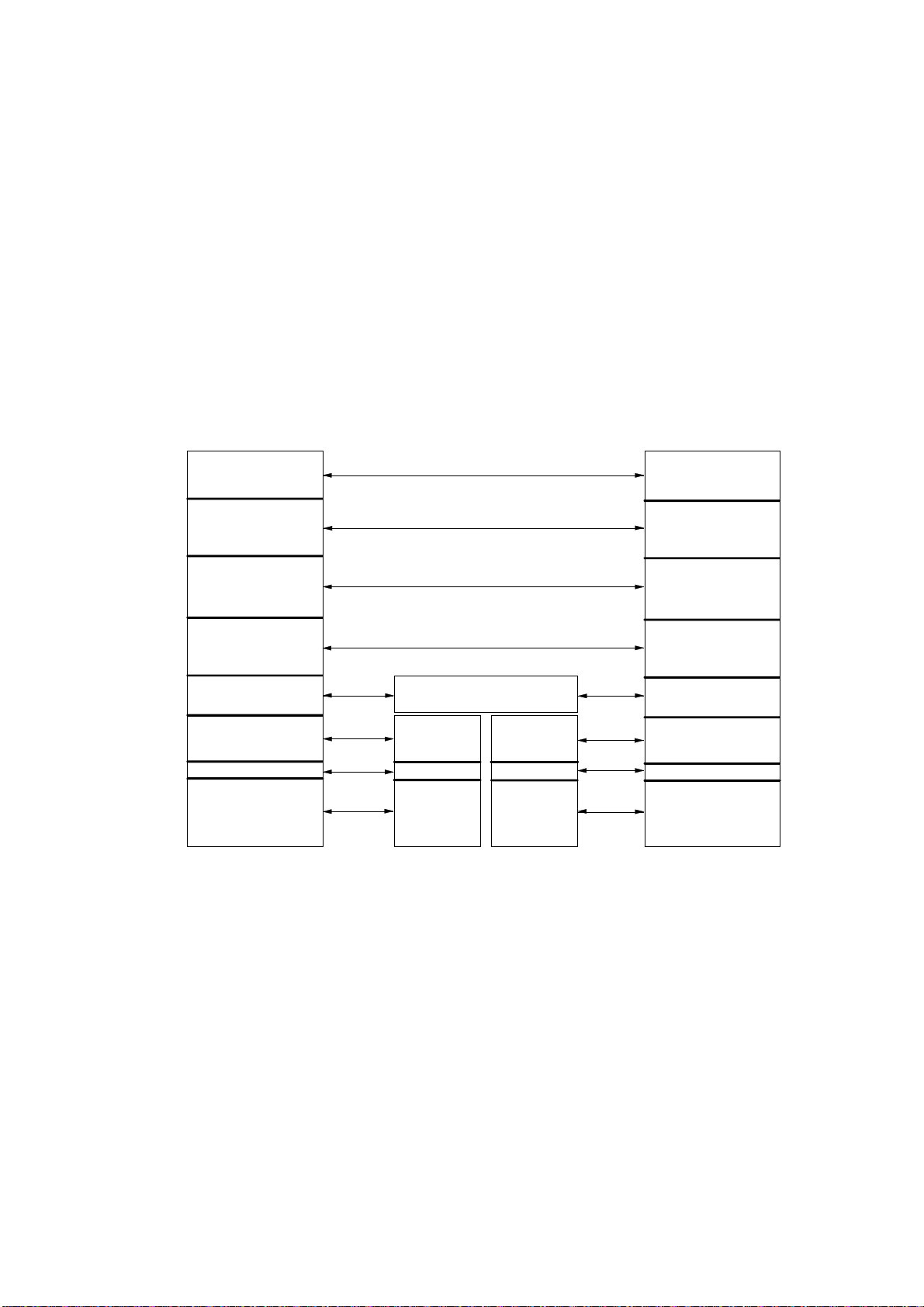

When several RTUs are connected to the PSTN (Public Switching Telephone

Network), as illustrated below, several configurations are viable as described in the

examples that follow.

RTU 2

INTERNAL MODEM

AT PORT3

RTU 1

EXTERNAL MODEM

AT PORT2

PSTN

EXTERNAL MODEM

AT PORT3

RTU 3

EXTERNAL

EXTERNAL

MODEM AT

PORT 2

RTU 4 RTU 5

INTERNAL

MODEM AT

PORT 3

EXTERNAL

MODEM AT

PORT 2

MODEM AT

PORT 3

Note that in the illustrated configurations, as in all the connections over the PSTN,

there is only one link ID. It is the responsibility of the software to decide which line to

dial. When two lines are available, the Port 2 line has priority.

1. To communicate between RTU 1 and RTU 2:

• Configure RTU 1 Port 2 as external modem.

• Update the RTU 2 telephone number.

• Any transmission from RTU 1 to RTU 2 will cause automatic dialing.

As the connection is established, information will be transferred from

one modem to the other. When no information is transferred for a

period longer than the “Hanging up an unused line by INITIATOR

after...” Advanced Physical Layer parameter, the line will be

disconnected.

13

Page 27

The MOSCAD System - Overview

2. To communicate between RTU 1 and RTU 4:

• Configure RTU 1 Port 2 as external modem.

• Update the two RTU 4 telephone numbers.

• Any transmission from RTU 1 to RTU 4 will cause automatic dialing

to the first number in the phone book. If the first number is busy, or

there is no answer, the second number is automatically dialed. As the

connection is established, information will be transferred from one

modem to the other. When no information i s transferred for a period

longer than the “Hanging up an unused line by INITIATOR after...”

Advanced Physical Layer parameter, the line will be disconnected.

3. To communicate between RTU 4, RTU 5, and RTU 3 simultaneously:

• Configure RTU 4 Port 2 as external modem and RTU 4 Port 3 as

internal modem dial-up, Auto Answer & Dial.

• Update the two RTU 5 telephone numbers and the RTU 3 telephone

number.

• Any transmission from RTU 4 to RTU 5 will cause automatic dialing

from the first available port (when both ports are available, Port 2 is

chosen) to t he first number on the list. If the first number is busy, or

there is no answer, the second number is automatically dialed. As the

connection is established, information will be transferred from one

modem to the other. When no information is transferred for a period

longer than the “Hanging up an unused line by INITIATOR after...”

Advanced Physical Layer parameter, the line will be disconnected.

• AnytransmissionfromRTU4toRTU3whileRTU4andRTU5are

connected, will cause automatic dialing from Port 3. If RTU 4 and

RTU 5 are disconnected, then Port 2 will be selected for dialing.

14

Page 28

Starting a ToolBox Application

ToolBox consists of different Windows applications. Each application is activated via

an icon included in the ToolBox program folder.

Entering the Password

When a ToolBox application is activated at the beginning of a work s ession, ToolBox

displays the Password window, where the password is entered and OK is clicked.

(See The Tools in the The ToolBox for MOSCAD RTUs section of this manual.)

This operation activates the communication driver and the password remains in force

throughout the session. If you want to access an RTU that requires a different

password, you must stop the communication driver first. See Changing the Session

Password below.

Changing the Session Password

To access an RTU that requires a different password, close all ToolBox tools and then

double-click the Stop Communication Driver application icon in the ToolBox program

folder. Then, activate the ToolBox application you want and enter the password.

The MOSCAD System - Overview

!

WARNING

If you try to stop the communication driver while a communication session is

in progress, a message warns you that a logical channel is currently open. If

you chose to continue (stop the driver), the results of the current

communication cannot be predicted. It is advisable to finish the current task

andthentostopthedriver.

15

Page 29

The ToolBox for MOSCAD RTUs

MOSCAD ToolBox is a set of software tools designed to implement MOSCAD

projects. The core of a MOSCAD project is one or more applications that reside in the

RTUs that make up a MOSCAD system. ToolBox allows users of different levels and

interests to deal with different aspects of the applications. For example, the

application developer would usually work with the ToolBox programming tools, while

other types of users would fine-tune the applications at the field, using the ToolBox

customization and setup tools.

Hardware and Software Requirements

MOSCAD ToolBox runs on a Pentium 100 (or more powerful) computer under

Windows 95 or Windows NT. It requires a minimum of 32Mb of RAM.

Installing ToolBox

The MOSCAD Programming ToolBox is installed like any other Windows

application. Insert the installation disk in your CD driver, activate setup.exe, and

follow installation messages and instructions. Written instructions can be found on

the leaflet attached to the CD.

Connecting ToolBox to RTU

The unit (RTU) may be connected to a local computer via cable FLN6457, which ends

with an adapter suitable for computer connection (25-pin female D-type connector).

Any RS232 port of the RTU defined as RS232 Local Computer may be used for

connection to the Programming ToolBox. This connection provides access to that

specific RTU, or to any other RTU in the network, to perform all the functions

described in this manual.

The RS232 ports default configuration of RTUs received from factory is RS232 Local

Computer (9600 baud).

A Brief Tour

This chapter provides a brief description of the MOSCAD/MOSCAD-L

communication system, and clarifies basic concepts.

The RTU

MOSCAD™ is the name of Motorola’s family of SCADA products. It is available in

a variety of enclosures, with a multiplicity of two-way radios, and with many different

types of input/output (I/O) modules. A MOSCAD RTU is a remote terminal unit in a

MOSCAD system.

16

Page 30

The ToolBox for MOSCAD RTUs

Think of an RTU as a computer. It has a CPU, real-time clock, RAM and ROM

memory, serial communication ports, etc. A remote terminal unit (RTU) which i s

installed at some field location is a computer. An RTU which may act as a district

controller is a computer. An RTU that functions as the communications bridge

between the radio (or other) communications system and the Master Control Center is

a computer. Certainly, that Master Control Center is a computer.

Just as a computer may be programmed to perform required tasks on a continuous

basis, MOSCAD is programmed in an advanced, powerful version of the ladder-logic

programming language (and/or ‘C’). The programmed rungs are compiled into the

very same format that would be used to program an EPROM; the compiled code is

downloaded into electrically-programmed ROM within the RTU. The application, as

programmed, may then be monitored and debugged.

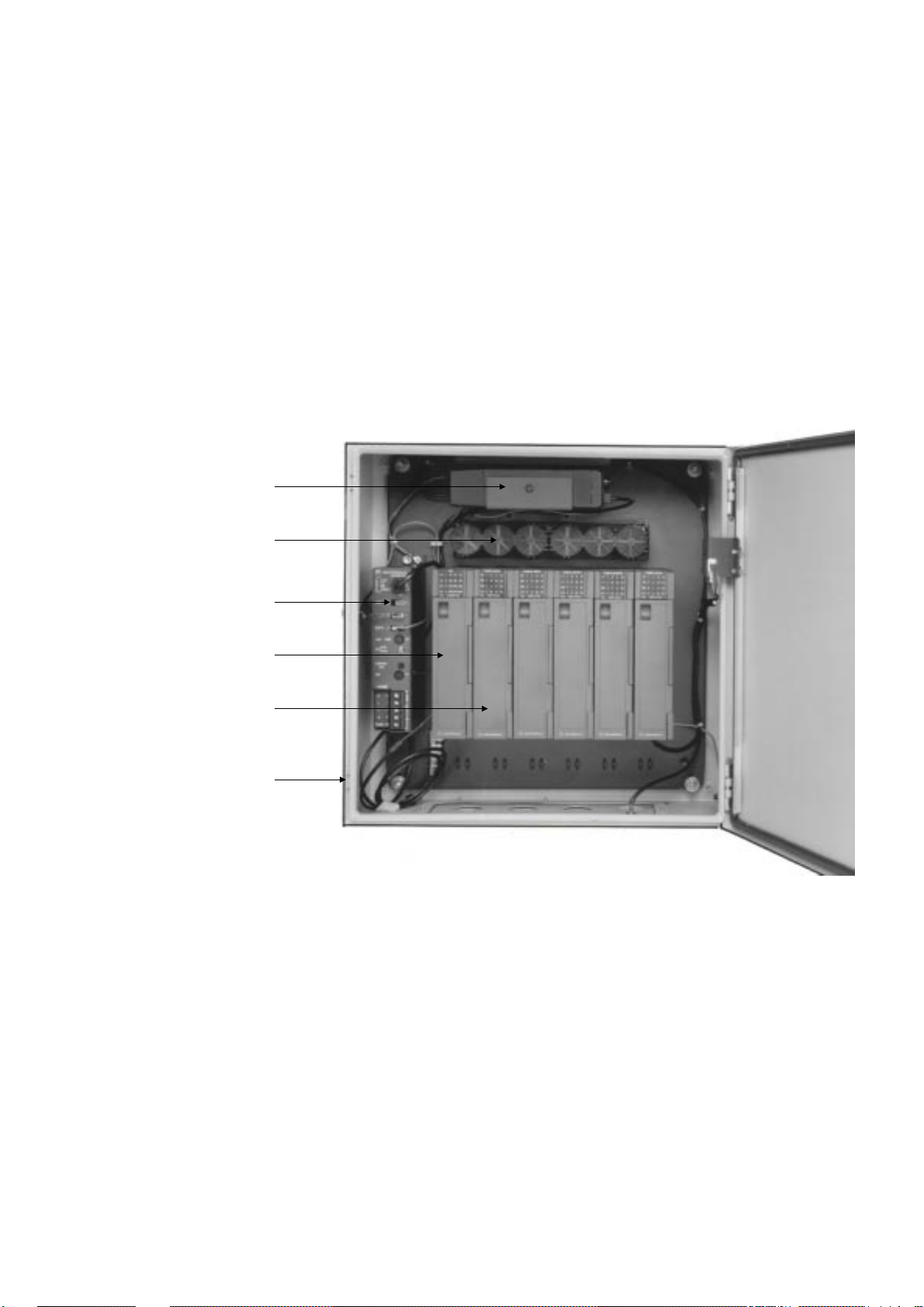

The following picture shows the main parts of the MOSCAD.

Radio or

Modem

Backup

Battery

AC Power

Supply

CPU

Module

Expansion

I/O Modules

NEMA

Enclosure

17

Page 31

The following picture illustrates MOSCAD-L.

The ToolBox for MOSCAD RTUs

The MOSCAD application developer need not have a degree or background in

computer science. Any programming experience in ladder-logic, Basic, Pascal or C is

helpful, but not required.

Database Principles

All worthwhile computer programming languages require the programmer to define

the variables before they are used. The definition includes the variable name and

variable logic type. The programming language reserves the appropriate memory for

the variable type, and can check for type mismatches as the logic statements are

written (create an immediate error if the logic statement uses an illegal named variable

type). RTU applications must have all variables defined by name and type before they

may be used.

How t hose named variables are organized is unconventional from a computer

programming perspective. However, it makes perfect sense when RTU-to-RTU or

RTU-to-central communications is considered.

The language organizes the programming variables into collections called tables.

Tables look very much like computer spreadsheets: they include many rows and may

include many columns. Each row and column intersection (cell) is a variable. Some

tables have many rows but only one column. All the variables in a single-column table

are of the same type, i.e. all bits, all values, all digital inputs, etc. Each variable in the

table is uniquely named: PUMP1, PUMP2, etc. Such a table may contain up to 250

uniquely named variables. A single-column table is illustrated below:

18

Page 32

The ToolBox for MOSCAD RTUs

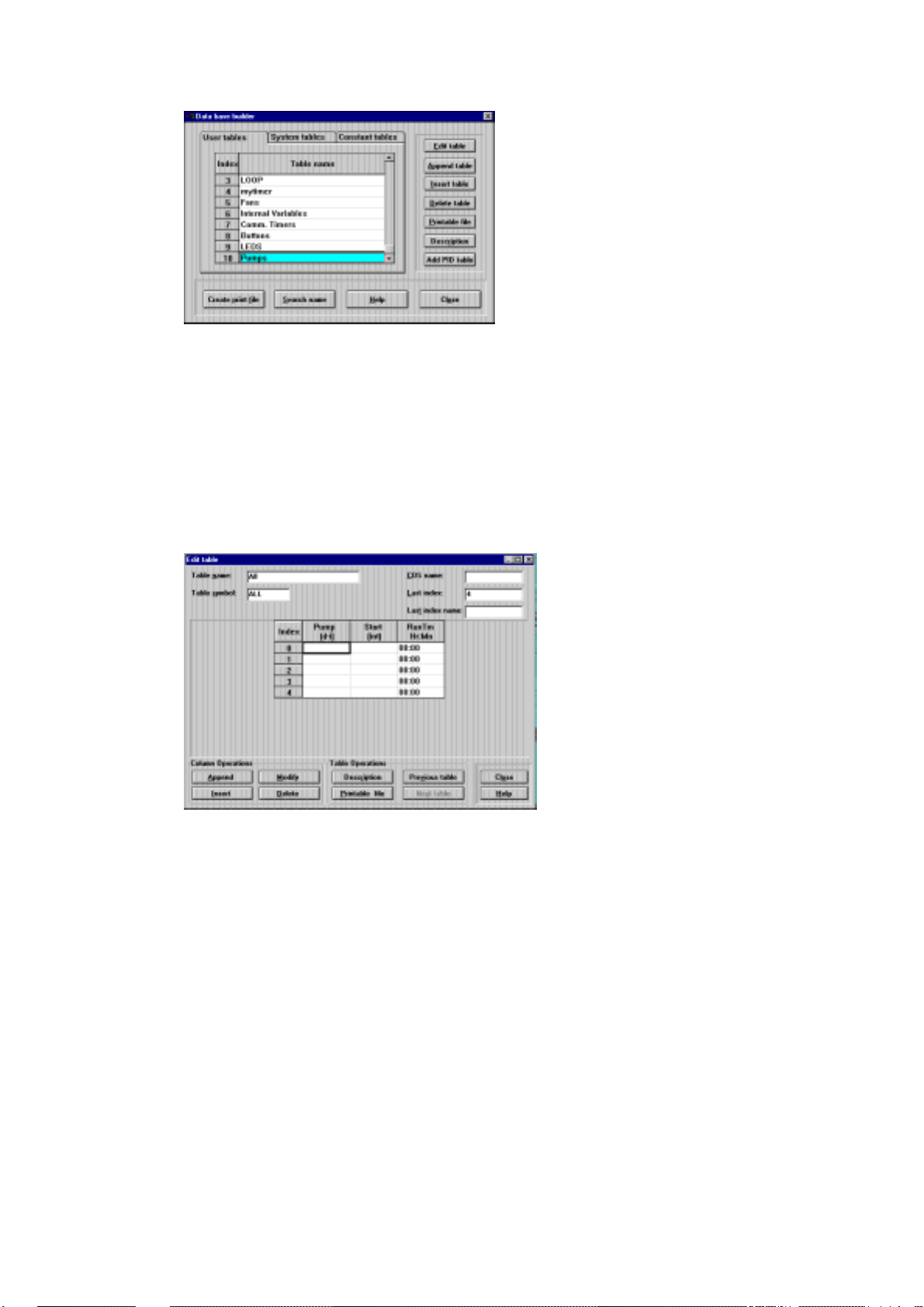

Other tables have many rows and many columns. All variable types within any column

are the same, but the several different columns may be of different variable types. For

example, a three column table may contain one column labeled PUMP and be a

digital-input type; the next column may be labeled START and be an internal value

type; the third column may be labeled RUNTIM and be a timer type. The variable

names are a combination of the column name and the row number, i.e. PUMP,2 and

START,4. This multiple-column table structure is particularly attractive when dealing

with dissimilar but related data, particularly as it may apply to some physical device

such as the pumps at a pump site. A multiple-column table may contain up to 250 rows

and up to 8 columns. Such a table is illustrated below:

The programmer may create up to 127 tables of his/her own design. The design and

organization of the tables should be carefully planned. The operation of the

application can be monitored by observing the variables; a good table design collects

related variables so that many different, but related, things can be observed

simultaneously.

A good table design anticipates which variables must be reported to a central site, and

organizes those variables (whenever possible) into just a few tables. Understand this

part of the proj ect, and the technical details of the applications—they are both very

important. Note that the protocol driver in the central has the same table structures as

do the RTUs communicating with the central. Data transfer becomes the simple task

of moving row/column data between identical tables.

You, the programmer, define the variable names. You are not required to use a bitand-register notation that reflects the electrical design of the RTU. You may define

and name your variables as you wish, with no restrictions other than name length.

Even if you program in another language, the RTU system will accept your variable

names.

19

Page 33

The database supports many variable (data) types. For full details, refer to the

Database Concept chapter in the Application Programmer manual.

Programming Philosophy

In order to create an application program which meets your needs, first identify the

tasks required of the program, including the information needed to complete each task

(e.g. digital inputs, variables from another site, permission flags from the central, etc.).

Next, sketch, in flowchart form, the logical steps required to convert the stated inputs

into the required output(s). Make sure that all combinations of inputs are properly

addressed and lead to the correct output(s). This step is key, as it is much easier to

correct mistakes in a flowchart on paper than to debug and correct lines of

programming code.

All of t he logic operators that are used in Basic or Pascal or C programming languages

are available to the RTU ladder-logic programmer. Only the syntax is different.

Remember, the logic statements will eventually be compiled; you can’t tell how it was

programmed by looking at the compiled code.

The operators are discussed at length in the Ladder Diagram Language chapter of the

Application Programmer manual.

The ToolBox for MOSCAD RTUs

Ladder logic originated from the language of relays. The contacts of the relays, singly

or in combinations, appear to the left of the logic statements and constitute the tests.

The coil of the relays appears to the right of the logic statement and constitutes the

actions. Tests on the left, actions on the right. Line after line. The structure looks

like the rungs of a ladder, hence the name of the programming language and the name

(rung) of each logic statement.

The RTU implementation of ladder logic programming allows up to six lines per rung,

and up to eight symbols on a single line. Therefore each RTU rung may indeed be a

complete logic statement (IF this THEN that ORIF other-this THEN other-that ELSE

...).

Some of the basic tests and actions are listed below.

Tests (inputs)

—| |— The fundamental relay contact is Normally Open; it closes when the coil is

active. There is also a Normally Closed relay contact that opens when the

coil is active. The variable name being tested must be a bit-type(not a

—| / |— value-type) and appears above the symbol. T hese are illustrated on the left.

It’s quite amazing how many decisions can be made with only these two

operators. Put them in series and you have a logical AND – see below. Put

them in parallel and you have a logical OR. You can apply Boolean logic to

reduce the number of required open/close contacts, as is mandatory with

hardware logic solutions. But every RTU “coil” has an unlimited number

of like-named contacts, so there is no cost incentive to minimize the number

of relay contacts. You can therefore avoid such reductions and keep the

logic readable.

—| |— —| |— —| / |—……. x •

• y •••• z

• •

20

Page 34

The ToolBox for MOSCAD RTUs

—| < |— Ladder logic originally treated only binary data – relay contact open or

closed. Ladder logic was later modified to handle value (non-binary) data.

—| = |— The variable names being tested must be value-types (not bit-types) and

appear above and below the symbol. These symbols are shown at left.

—| ≠

≠ |—

≠ ≠

—| > |—

Testing value data has many applications. Consider some process that must

operate if a value exceeds some setpoint.

—| ↑

↑ |—

↑ ↑

—| ↓

↓ |—

↓ ↓

A third type of test operator is the Differentiator. It checks for a difference

between the current and previous state of the named variable(s) that precede

it in the rung; the operator is true only when this difference occurs. The

operator can be used to check for the r ising or falling “edge” of the named

variable(s), so that the associated action only occurs once. The index

variable, if used in any of the preceding named variables, also appears

above the differentiator symbol.

Actions (Outputs)

—( ) Relay On & Relay Off: The original ladder logic action was to energize the

coil of a relay – this remains the fundamental action. As long as the

—( / ) associated test is true, then t he coil (action) will be energized (true). A

extension of this concept is the NOT – as long as the test is true, the action

will not be true. The named variable associated with the coil appears above

these symbols as illustrated on the left.

—( L ) Latch & Unlatch: Situations exist wherein the test may be momentarily true,

but the associated action should remain true until specifically made not true.

—( U ) Combinational logic can be used to create this action, or – more simply –

the Latch and Unlatch actions may be used. If the test(s) in the rung used to

latch the coil is true then the named variable will be latched; a similar action

will happen in the rung used to unlatch the coil. Rungs are tested and

executed sequentially, as they appear in the task, so if both rungs are

simultaneously true then the action i n the last rung to be executed will

determine the state of the named variable. The symbols are shown on the

left.

—( SCAN ) Scan: This action reads input data from physical I/O modules into the CPU

module, and updates the appropriate variables i n the several data tables. The

action also writes data from the CPU data tables to the I/O modules. And

the action updates mapped bit and value variables within the data tables.

—( MOVE ) Move Low & Move High: When the associated test is true, these actions

move (copy) value data from one variable to another without changing the

—( MOVH) source variable. Move Low (MOVE) is more commonly used; it moves all

16 bits of one value variable to another value variable. Move Low may also

be used to move 8 consecutive bits in a single-column table into the low

byte of a value variable (bit packing); Move High (MOVH) would be used

to move 8 other consecutive bits in a single-column table into the high byte

of the value variable. MOVE or MOVH can also be used to move the low or

high byte respectively of a value variable to 8 consecutive bits of a singlecolumn table (bit unpacking).

21

Page 35

The Tools

ToolBox is a collection of software programs t hat eases the task of coding the

flowchart steps and making t he RTU run the application correctly. A printer is

required if the user wants hard copies of the application; the application is also stored

on the hard disk.

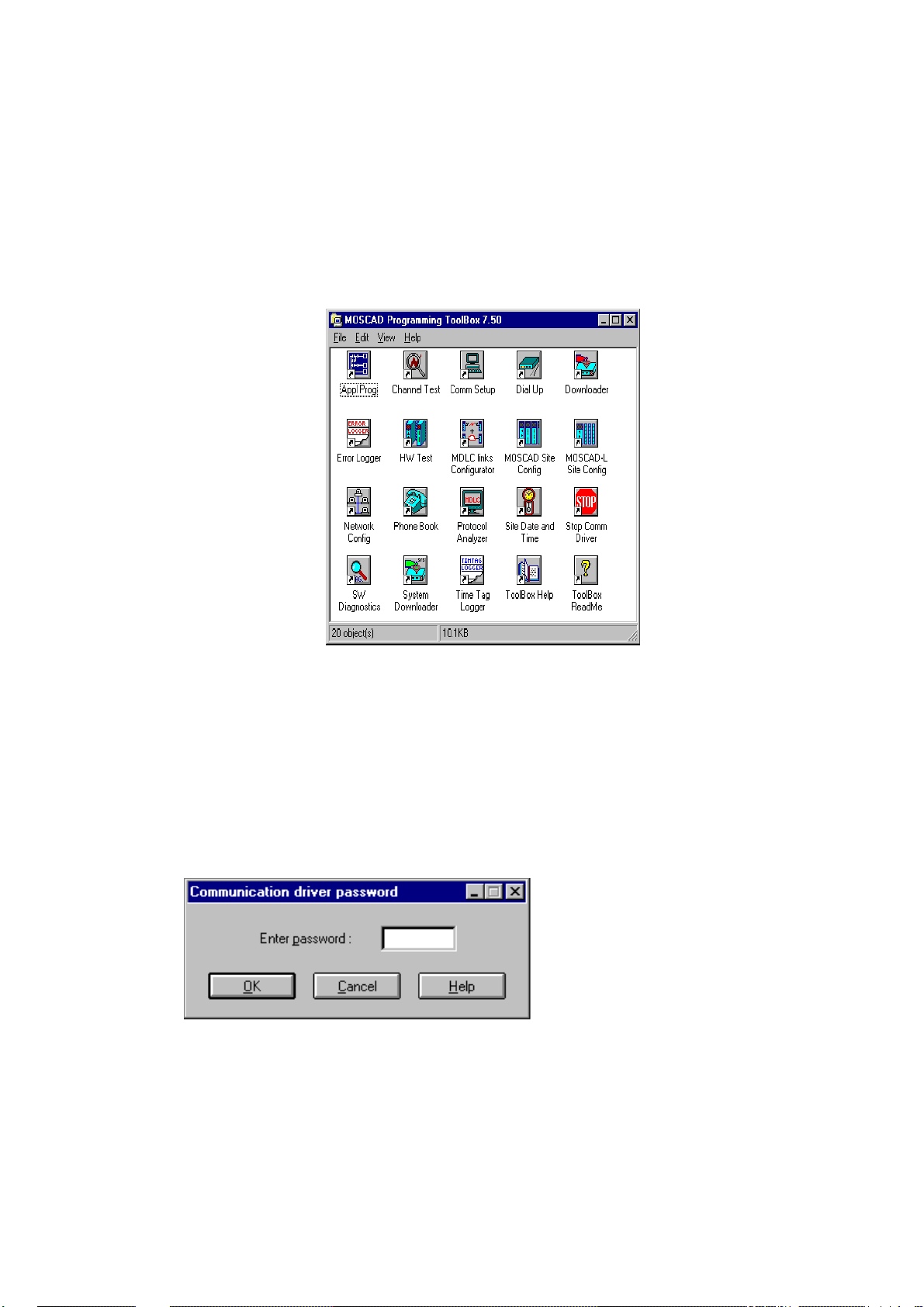

After installing ToolBox, the icons of the various tools included in your package

appear in the MOSCAD Programming ToolBox folder, as shown below.

The ToolBox for MOSCAD RTUs

Many of the basic tools are described in detail in the System Setup and Diagnostics

(SSD) manual. These include, Site Configuration, Network Configuration, various

Utilities, and Diagnostic tools.

To start a tool:

1. Connect to the RTU (though you can set configuration values and develop

applications without an RTU connection).

2. Double-click the icon of the t ool you want. If a password is required, the

following dialog box appears.

3. Type the password and click OK.

4. The main window of the selected t ool appears. If a password was required, but

was incorrectly entered, no communication is established between the RTU and

the ToolBox. If the Cancel button is pressed, the tool starts up, but some of the

communications-related functions will be hidden (gray)

22

Page 36

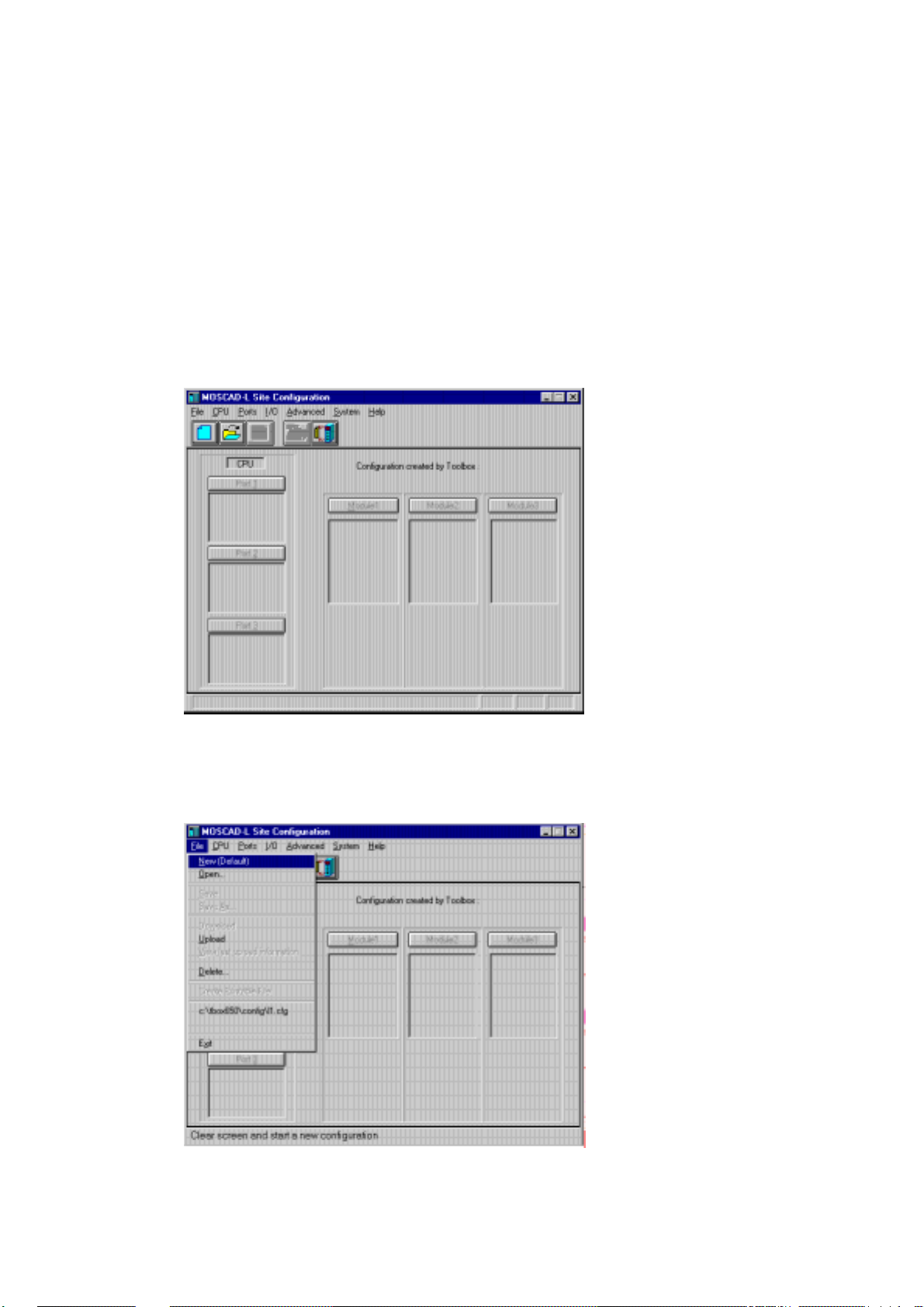

Site Configuration (MOSCAD-L)

Let’s start with Site Configuration (this brief tour illustrates the site configuration for

MOSCAD-L; the processes described here are very similar to those that apply to the

full MOSCAD system). This program is used t o define which I/O modules are present

in the unit and where they will be placed in the module rack. It is also used to

determine the functionality of the RS-232 and radio (modem) ports on the CPU

module to be defined. The address of the specific RTU is then defined, and the

combination downloaded into the RTU’s CPU module. This process gives some

personality to the RTU; this process must be accomplished via a local cable between

the ToolBox computer and the RTU.

After activating the MOSCAD-L Site Configuration application, the following

window appears:

The ToolBox for MOSCAD RTUs

The File menu includes commands for starting a new configuration, retrieving an

existing set (file) of configuration values, saving a configuration, printing the contents

of a configuration file, and the like. Click the File menu (or press ALT+F) to open it.

It looks as shown below.

23

Page 37

The ToolBox for MOSCAD RTUs

To start configuring a site, select the New command from the File menu or click on the

New icon. This automatically opens a new file, with default configuration settings, as

shown below. The sections marked Module1 Module2, Module3 each represent an

expansion I/O module in the unit. (See the picture of the unit in The RTU section

above.) The CPU module does not appear on the Site Configuration screen, as it is

always placed in Rack 0, Module 0. The other I/O modules may be specified by

clicking the desired Module (e.g. Module1) button.

After clicking Module1, the I/O Modules dialog box appears, which enables you to

select a t ype for the module:

After selecting the module type from the list, click OK.

Repeat the process (click the Module2 button, then open the type list, etc.) for all the

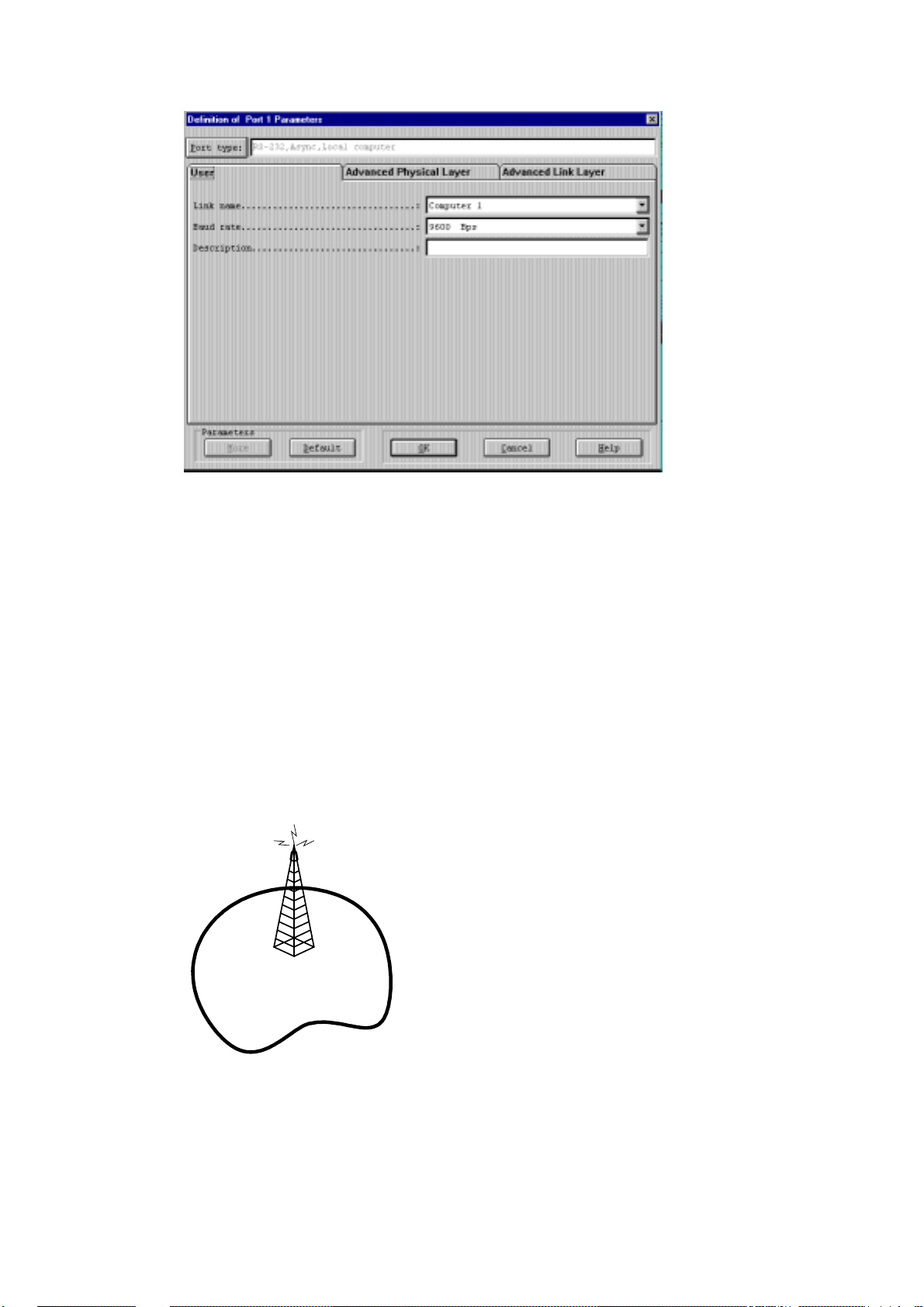

required I/O modules. Made a mistake? Just click Type again, and select another

value from the type list. The current definitions of the three ports of the CPU module

appear on the main window. One port, usually Port 1, is by default defined as Link

Name = Computer 1, and Port Type = RS232- Local Computer. Use this port for the

local connection of the ToolBox. To see the default port definition, click the Port 1

button. The f ollowing is displayed:

24

Page 38

The ToolBox for MOSCAD RTUs

The other two ports are configured in a similar way, though the values vary. Port 2

defaults to the same configuration as Port 1, but can be changed as necessary. Port 3

usually defines the communications medium required (e.g. radio, modem ). Once the

ports are configured, the values are saved in a site configuration file and downloaded

to the unit. The Site Configuration section of the System Setup and Diagnostics

manual describes the types and parameters for each port, as well as the procedure for

defining, saving and downloading the site configuration to the RTU.

Network Configuration

The second major step is configuring the network. Most data radio communication

systems have a single base transmitter located somewhere near the center of the

physical coverage area, as illustrated below. The transmitter emits radio energy; the

distance the emission travels define t he coverage limits of the system. Normally, all

data equipment will lie within this coverage area, in which case, no network

configuration need be defined.

RTU

RTU

RTU

However, if one or more sites with data equipment lie outside this coverage area;

reliable communications with these sites cannot be assured. The RTU provides a

solution to this problem which requires no additional hardware. A map of the network

is created and existing units are used to relay information around the network to its

destination.

RTU

RTU

25

Page 39

The ToolBox for MOSCAD RTUs

Any RTU can receive data, validate that data, and store it in a buffer for

retransmission a few seconds later. An RTU with more than one communications

medium (link), known as a “network node”, stores the data and relays it to another

RTU. Note that network node RTUs are also capable of operating as regular RTUs;

thus no special, dedicated hardware is required. The data Store & Forward capability

is a communications protocol task; and requires nothing to be programmed in the

application.

A logical name is assigned to each communications medium in the network (e.g.

Radio1, Radio2, Line1, Line2). Most sites will have a single communications medium

– these are not network nodes. A few sites may have both a radio and a wireline

modem, or two radios – these are definitely network nodes. Some sites may have a

single radio that communicates both with the main portion of the system and also with

one or more out-of-range RTU sites. These are also network nodes; the link names

would be Radio1/Zone1 and Radio1/Zone2 (abbreviated Radio1/1 and Radio1/2

respectively) or their equivalent.

Use the Network Configuration program to define these network nodes and their

respective links, as described in the Network Configuration section of the System

Setup and Diagnostics manual.

Application Programmer

Once the site and network have been defined, building the application can be built,

using the Application Programmer. The application (also called a project) consists of

a database and a ladder program.

1 Activate Application Programmer from the MOSCAD Programming ToolBox

folder, as you opened the Site Configuration and Network Configuration. (If you

chose not to connect to the unit at this time, hit CANCEL when prompted for the

Communication driver password. The main window appears as shown below. Note

that most of the icons will be dimmed and unselectable.

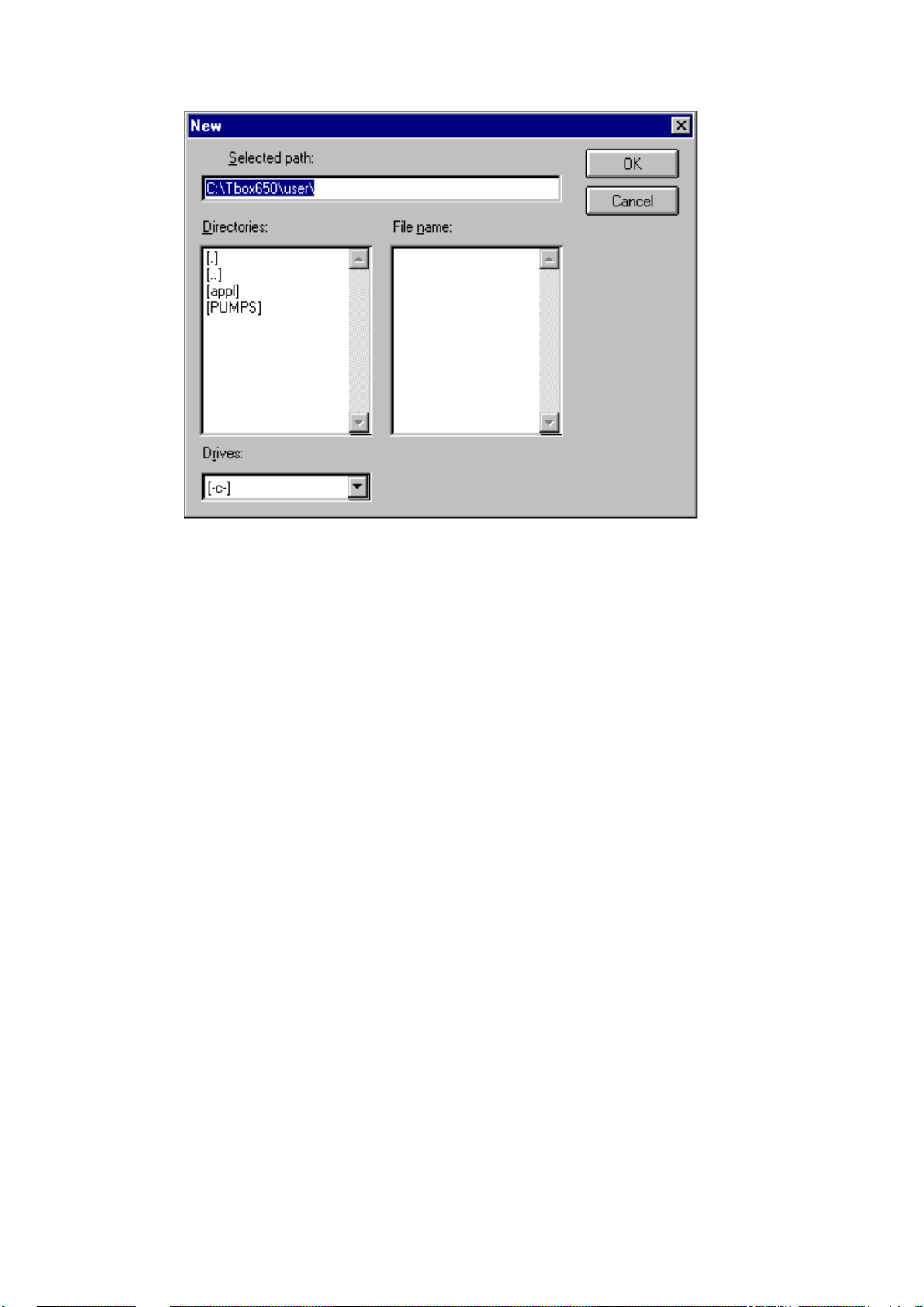

2. From the Project menu, select the New command, or click on the New icon. The

New dialog box is displayed. The ToolBox lists all existing applications (projects)

under Directories; hence the list may vary from computer to computer.

26

Page 40

The ToolBox for MOSCAD RTUs

3. For each project, Application Programmer opens a new subdirectory under

tbox750\user. The path appears in the Selected Path box, and the insertion point is

positioned where you are expected to type the name of t he project. Type a project

name of up to 8 characters and click the Create button. This creates the subdirectories and the application files. Anything you save related to the application will

be stored in that directory. Another user (e.g. user1) area can be created by changing

the value in Selected Path.

4. Open the Edit menu. The commands Database Builder, Process Programming and

I/O Link represent the main application building steps.

Database Builder

Database Builder is used to create the application variables. Variables are “declared”

in table-like windows.

Select Database Builder from the Edit menu. The following dialog box is displayed.

The Database Builder window tabs show three types of tables, User Tables (created by

the user specifically for the project), System Tables (available to the project), and

Constants Table (available to the project). User Tables is selected by default. Here

you may create (Append) and Edit tables of variables which represent the inputs and

outputs of your system, as mentioned in Database Principles above. For full details,

see the Application Programmer manual.

27

Page 41

Process Programming

The defined variables may now be used in the coding of the various rungs of the

application, which determine what actions are performed, under what conditions. You

may wish to refer at this time to the lists of available tests and actions in Programming

Philosophy above. Tests, actions, and variables – you're ready to go. Both the Data

Base Builder and the Process Programming use an Append/Add capability to define a

new table or process, and an Edit capability to insert variables or logic statements into

that table/process. Open the Edit menu and select Process Programming. The

following dialog box is displayed.

The ToolBox for MOSCAD RTUs

I/O Link

The MAIN process exists by default because it automatically runs at powerup or upon

an application restart. The MAIN process provides the framework in which the

application runs. Process and Rung Operations enable you to add and edit new rungs

and processes. The logic of the rungs is programmed according to the logic of the

flowchart created, which was based on the tasks required of the RTU. For full details

on Process Programming, see the Application Programmer manual.

The Site Configuration program is used to define the physical aspects of the RTU

hardware. The Application Programmer program is used to define a virtual process

28

Page 42

The ToolBox for MOSCAD RTUs

that has no link to any physical reality. Yet such a link is required. This is done using

I/O Link.

1. In the Application Programmer main window, open the File menu and select Import

Site Configuration.

2. Select the site configuration file related to your application (field.cfg).

3. Open the Edit menu and select I/O Link. The following dialog box is displayed.

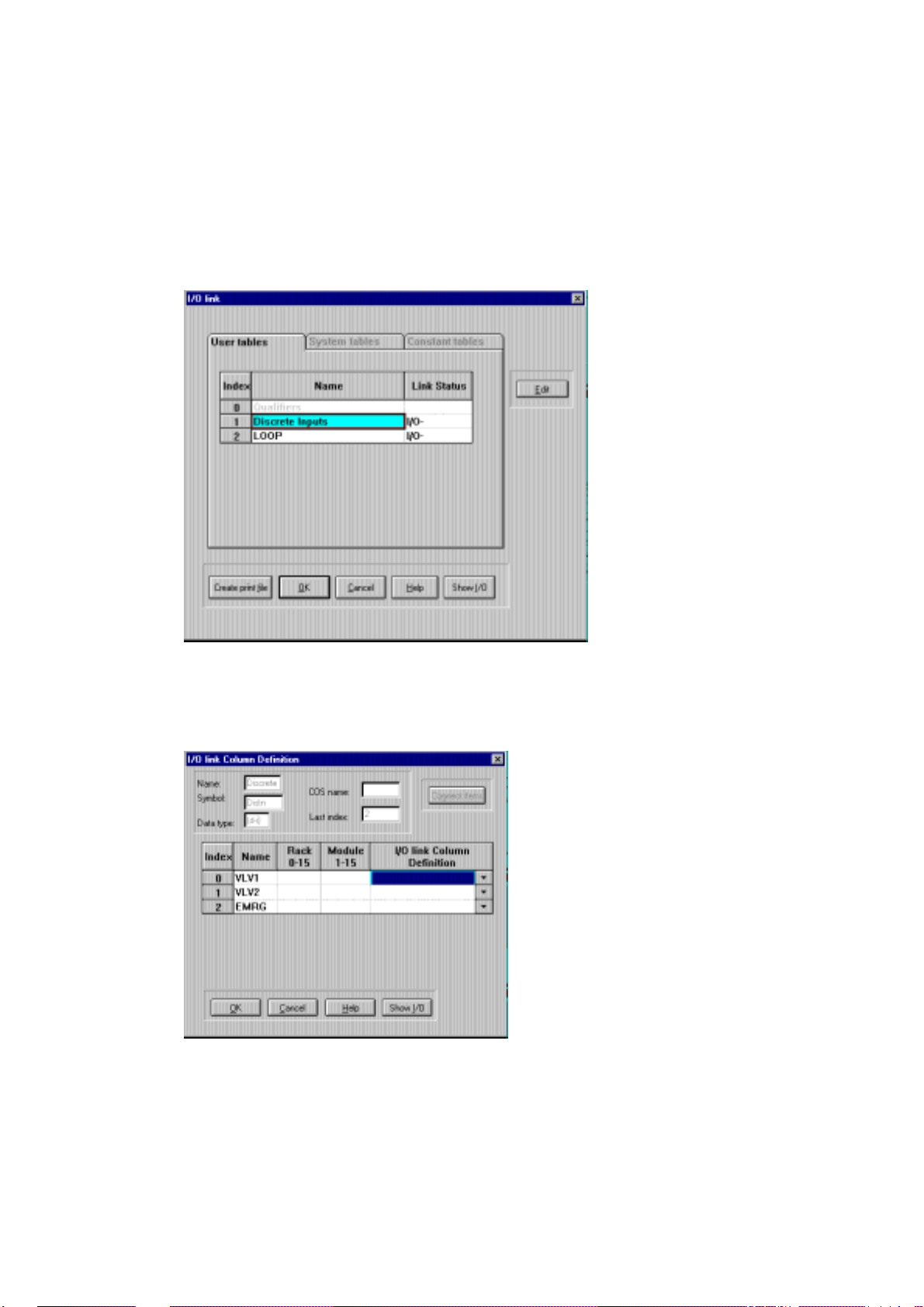

4. The I/O Link dialog displays the application tables. The Status column shows those

tables that include an I/O module which requires linking. The minus sign indicates

incomplete link data. Highlight the first table that needs link information and click the