Page 1

™

Digital XTS 3500

Portable Radios

Basic Service Manual

™

1

Page 2

Foreword

This manual covers all models of the ASTRO™ Digital XTS 3500

specified. It includes all the information necessary to maintain peak product performance and maximum

working time, using the pass/fail service approach. This basic level of service is typical of some local

service centers, self-maintained customers, and some distributors.

Included in this manual are: radio specifications for the VHF and UHF frequency bands; a general

description of ASTRO Digital XTS 3500 models; recommended test equipment, service aids, and tools;

radio alignment procedures; fundamental disassembly/reassembly procedures; and general maintenance

recommendations.

For details on the operation of the radio, or board or component-level troubleshooting, refer to the

applicable manuals, available separately . T o help you with your selection, a list is provided under “Related

Publications” at the front of this manual.

®

Portable Radio, unless otherwise

Safety

Before operating an ASTRO XTS 3500 Radio, please read the “Safety Information” section in the front of

this manual.

Manual Revisions

Changes which occur after this manual is printed are described in “FMRs.” These FMRs provide complete

information on changes, including pertinent parts list data.

2

Page 3

Table of Contents

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .inside front cover

List Of Figures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

List of Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Portable Radio Model Numbering System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Specifications for VHF Radios. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Specifications for UHF Radios. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x

1 - Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Notations Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Radio Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FLASHport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 - Basic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Introduction to This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 - Recommended Test Equipment and Service Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service Aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Field Programming Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 - Performance Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Introduction to This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Display Radio Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Non-Display Radio Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 - Radio Alignment Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Introduction to This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Reference Oscillator Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Transmit Power Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Transmit Deviation Balance (Compensation) Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Transmit Deviation Limit Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Front End Filter Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

A

, Motorola, ASTRO, and Private-Line are registered trademarks of Motorola, Inc.

XTS 3500, FLASHport, and Digital Private-Line are trademarks of Motorola, Inc.

© 1999, 2000 by Motorola Inc.

Commercial, Government and Industrial Solutions Sector

8000 W. Sunrise Blvd., Ft. Lauderdale, FL 33322

Printed in U.S.A. 3/00

Basic Service Manual

68P81089C80-A

Page 4

6 - Basic Removal/Installation Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Introduction to This Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Antenna. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Belt Clip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Universal Connector Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Frequency Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Volume Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 -Basic Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

General Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Analog Mode of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

ASTRO Mode of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

RF Board Basic Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

VOCON Board Basic Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8 - Radio-Level Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Introduction to This Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Power-Up Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Operational Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Replacement Parts Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . inside back cover

List Of Figures

Figure 1. Radio Alignment Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 2. RSS Service Menu Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 3. Softpot Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 4. Reference Oscillator Alignment Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 5. Transmit Power Alignment Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 6. Transmit Deviation Balance (Compensation) Alignment Screen . . . . . . . . . . . . . . . . . 19

Figure 7. Transmit Deviation Limit Alignment Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 8. Front End Filter (VHF and UHF Only) Alignment Screen . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 9. Partial Exploded View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

List of Tables

Table 1. ASTRO XTS 3500 Basic Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Table 2. Recommended Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 3. Service Aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 4. Initial Equipment Control Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Table 5. Front-Panel Access Test-Mode Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 6. Test Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 7. Test Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 8. Receiver Performance Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 9. Transmitter Performance Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 10. Reference Oscillator Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 11. Transmit Power Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 12. Transmit Deviation Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 13. Partial Exploded View Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Table 14. Local Oscillator and First IF Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 15. Power-Up Error Code Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 16. Operational Error Code Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 17. Receiver Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 18. Transmitter Troubleshooting Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 19. Encryption Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Page 5

Related Publications

ASTRO Digital XTS 3500 Model I User Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68P81089C77

ASTRO Digital XTS 3500 Model II User Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68P81089C78

ASTRO Digital XTS 3500 Model III User Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68P81089C79

ASTRO Digital XTS 3500 Detailed Service Manual . . . . . . . . . . . . . . . . . . . . . . . . . . .68P81089C81

Computer Software Copyrights

The Motorola products described in this manual may include copyrighted Motorola computer programs

stored in semiconductor memories or other media. Laws in the United States and other countries preserve

for Motorola certain exclusive rights for copyrighted computer programs, including, but not limited to,

the exclusive right to copy or reproduce in any form the copyrighted computer program. Accordingly , any

copyrighted Motorola computer programs contained in the Motorola products described in this manual

may not be copied, reproduced, modified, reverse-engineered, or distributed in any manner without the

express written permission of Motorola. Furthermore, the purchase of Motorola products shall not be

deemed to grant either directly or by implication, estoppel, or otherwise, any license under the

copyrights, patents or patent applications of Motorola, except for the normal non-exclusive license to use

that arises by operation of law in the sale of a product.

Page 6

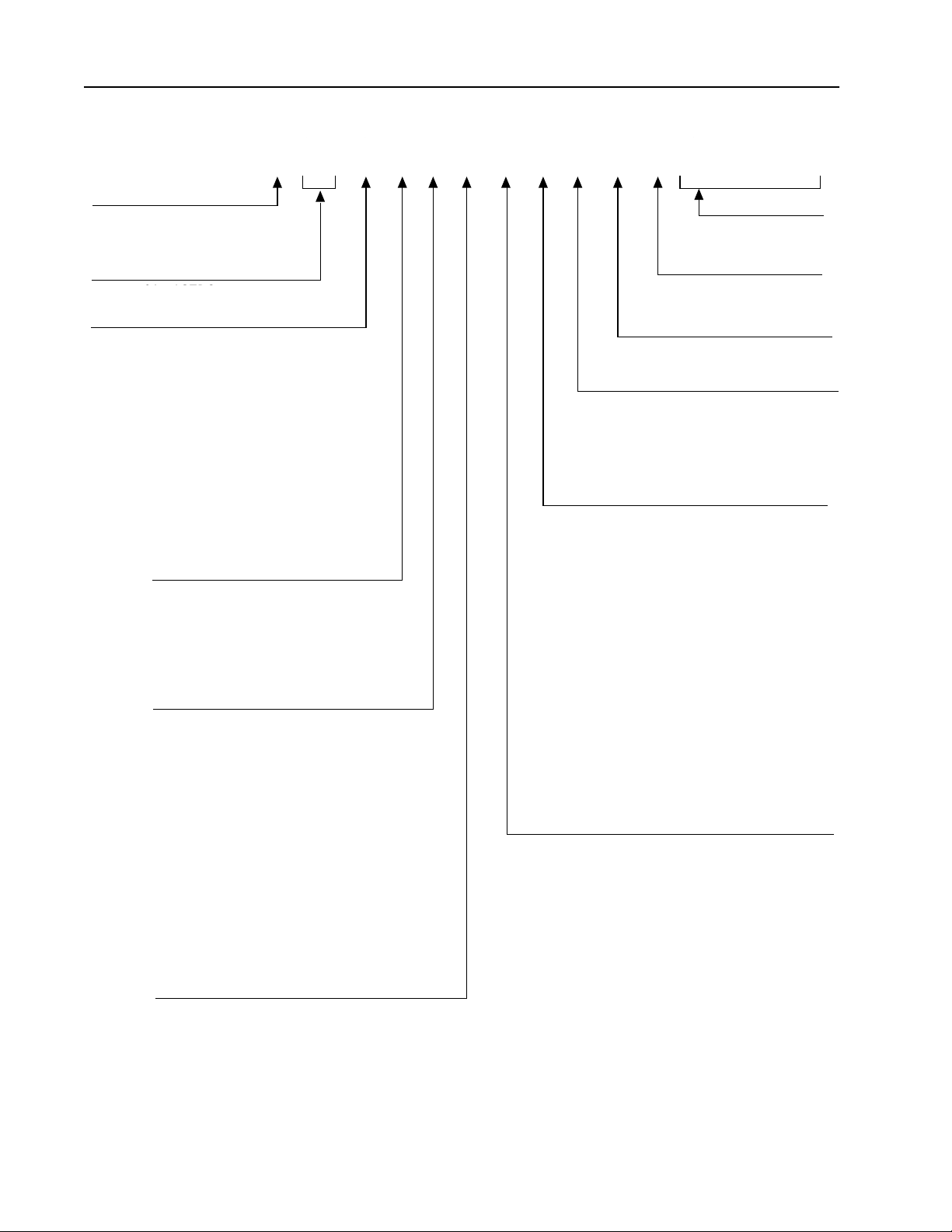

Portable Radio Model Numbering System

Typical Model Number:

Position:

Position 1 - Type of Unit

D = Dash-Mounted Mobile Radio

H = Hand-Held Portable

M = Motorcycle Mobile Radio

T =Trunk-Mounted Mobile Radio

Positions 2 & 3 - Model Series

24 = XTS 3500

04 = ASTRO

Position 4 - Frequency Band

A

Less than 29.7MHz

=

B

29.7 to 35.99MHz

=

C

36 to 41.99MHz

=

D

42 to 50MHz

=

F

66 to 80MHz

=

G

74 to 90MHz

=

H

Product Specific

=

J

136 to 162MHz

=

K

146 to 178MHz

=

L

174 to 210MHz

=

M

190 to 235MHz

=

H24 S C F 9 P W 7 A N S P 0 1

T04S LF 9 P W7 A N S P 0 1

123 4 5 6 7 8 9 1011 1213141516

336 to 410MHz

P

=

403 to 437MHz

Q

=

438 to 482MHz

R

=

470 to 520MHz

S

=

Product Specific

T

=

806 to 870MHz

U

=

825 to 870MHz

V

=

896 to 941MHz

W

=

1.0 to 1.6GHz

Y

=

1.5 to 2.0GHz

Z

=

Values given represent range only; they are

not absolute.

Position 5 - Power Level

0 to 0.7 Watts

A

=

0.7 to 0.9 Watts

B

=

1.0 to 3.9 Watts

C

=

4.0 to 5.0 Watts

D

=

5.1 to 6.0 Watts

E

=

6.1 to 10 Watts

F

=

Position 6 - Physical Packages

RF Modem Operation

A

=

Receiver Only

B

=

Standard Control; No Display

C

=

Standard Control; With Display

D

=

Limited Keypad; No Display

E

=

Limited Keypad; With Display

F

=

Full Keypad; No Display

G

=

Full Keypad; With Display

H

=

Limited Controls; No Display

J

=

Limited Controls; Basic Display

K

=

Limited Controls; Limited Display

L

=

Rotary Controls; Standard Display

M

=

Enhanced Controls; Enhanced Display

N

=

Low Profile; No Display

P

=

Low Profile; Basic Display

Q

=

Low Profile; Basic Display, Full Keypad

R

=

Position 7 - Channel Spacing

1 = 5kHz

2 = 6.25kHz

3 = 10kHz

4 = 12.5kHz

5 = 15kHz

6 = 20/25kHz

7 = 30kHz

9 = Variable/Programmable

10.1 to 15 Watts

G

=

16 to 25 Watts

H

=

26 to 35 Watts

J

=

36 to 60 Watts

K

=

L

= 61 to 110 Watts

Positions 13 - 16

“SP” Model Suffix

Position 12 -

Unique Model Variations

C = Cenelec

N = Standard Package

Position 11 - Version

Version Letter (Alpha) - Major Change

Position 10 - Feature Level

1 = Basic

2 = Limited Package

3 = Limited Plus

4 = Intermediate

5 = Standard Package

Position 9 - Primary System Type

A

=

Conventional

B

=

Privacy Plus®

C

=

Clear SMARTNET™

D

=

Advanced Conventional Stat-Alert™

E

=

Enhanced Privacy Plus®

F

=

Nauganet 888 Series

G

=

Japan Specialized Mobile Radio (JSMR)

H

=

Multi-Channel Access (MCA)

J

=

CoveragePLUS™

K

=

MPT1327* - Public

L

=

MPT1327* - Private

M

=

Radiocom

N

=

Tone Signalling

P

=

Binary Signalling

Q

=

Phonenet®

W

=

Programmable

X

=

Secure Conventional

Y

=

Secure SMARTNET™

6 = Standard Plus

7 = Expanded Package

8 = Expanded Plus

9 = Full Feature/

Programmable

* MPT = Ministry of Posts and Telecommunications

Position 8 - Primary Operation

A

=

Conventinal/Simplex

B

=

Conventional/Duplex

C

=

Trunked Twin Type

D

=

Dual Mode Trunked

E

=

Dual Mode Trunked/Duplex

F

=

Trunked Type I

G

=

Trunked Type II

H

=

FDMA* Digital Dual Mode

J

=

TDMA** Digital Dual Mode

K

=

Single Sideband

L

=

Global Positioning Satellite Capable

M

=

Amplitude Companded Sideband (ACSB)

P

=

Programmable

* FDMA = Frequency Division Multiple Access

** TDMA = Time Division Multiple Access

Page 7

or

or

or

or

or

or

SPECIFICATIONS FOR VHF RADIOS

All specifications are per Telecommunications Industries Association TIA-603 unless otherwise noted

GENERAL

FCC Designation: AZ489FT3799

Temperature Range:

Operating:

Storage:

Power Supply: Nickel-Cadmium Battery (NiCd)

Nickel-Metal-Hydride Battery (NiMH)

Lithium-Ion Battery (Li-Ion)

Battery Voltage:

Nominal:

Range:

Transmit Current Drain (Typical): 2100mA

Receive Current Drain (Rated Audio): 240mA

Standby Current Drain:

Recommended Battery:

Ultra-HIgh-Capacity NiCd:

Extended-Capacity NiMH:

Li-Ion:

Ultra–High-Capacity NiCd FM: NTN8295_*

Ultra–High-Capacity NiMH FM: NTN8299_*

Optional FM (Factory Mutual) Battery:

* FM Intrinsically Safe: Class I, II, III, Division 1,

Groups C, D,E, F, and G. FM Non-incendive:

Class 1, Division 2, Groups A, B, C, and D.

–30°C to +60°C

–40°C to +85°C

7.5 Volts

6 to 9 Volts

80mA

NTN8294_

NTN8293_

NTN8610_

RECEIVER TRANSMITTER

Frequency Range:

Bandwidth:

Quieting Sensitivity (20dBQ):

Usable Sensitivity

(12dB SINAD):

Intermodulation:

Selectivity (typical)

(25/30kHz Channel):

(12.5kHz Channel):

Spurious Rejection:

Frequency Stability

(–30+60°C; 25°C reference):

Rated Audio:

FM Hum and Noise (typical):

Distortion (At Rated Audio):

136-174MHz

38MHz

0.35µV (typical)

0.20µV (typical)

–78dB (typical)

–80dB

–67dB

–78dB

±.0002%

500mW

25kHz –50dB

12.5kHz –44dB

1.5% Typical

RF Power:

136-174MHz:

Frequency Range:

Frequency Stability (typical)

(–30 to +60°C; 25°C ref.):

Emission (Conducted and Radiated): –75dBc

FM Hum and Noise (typical)

(Companion Receiver):

Distortion:

Modulation Limiting: 25kHz chnls ±5.0kHz

12.5kHz chnls ±2.5kHz

Adjacent Channel Power Ratio:

Emissions Designators:

20K0F1E, 16K0F3E, 11K0F3E,

8K10F1D, and 8K10F1E

1 to 6 Watts

136-174MHz

±.0002%

25kHz –50dB

12.5kHz –44dB

2% Typical

25kHz –73dBc

12.5kHz –63dBc

Dimensions (H x W x D)

Note: 2.44" = width at PTT; 2.34" = width at

bottom; 1.83" = depth at speaker; 0.97" =

depth at keypad

Less Battery:

6.58" x 2.44" x 1.83"/6.58" x 2.34" x 0.97"

(167.13mm x 61.90mm x 46.42mm/

167.13mm x 59.49mm x 24.56mm)

With Battery:

6.58" x 2.44" x 1.83"/6.58" x 2.34" x 1.65"

(167.13mm x 61.90mm x 46.42mm/

167.13mm x 59.49mm x 41.97mm)

Weight: (w/Helical Antenna)

Less Battery:

With Ultra-High Cap. NiCd: 25.19oz. (693gm)

With Li-Ion:

With Ultra-High Cap. NiMH: 23.45oz. (644gm)

With Extended- Cap. NiMH: 24.04oz. (682gm)

14.10oz. (383gm)

20.41oz. (583gm)

Channel Spacing:

12.5/25 kHz

Specifications subject to change without notice

v

Page 8

or

or

or

or

or

or

SPECIFICATIONS FOR UHF RADIOS

All specifications are per Telecommunications Industries Association TIA-603 unless otherwise noted

GENERAL

FCC Designation: AZ489FT4828

Temperature Range:

Operating:

Storage:

Power Supply: Nickel-Cadmium Battery (NiCd)

Nickel-Metal-Hydride Battery (NiMH)

Lithium-Ion Battery (Li-Ion)

Battery Voltage:

Nominal:

Range:

Transmit Current Drain (Typical): 2000mA

Receive Current Drain (Rated Audio): 240mA

Standby Current Drain:

Recommended Battery:

Ultra-HIgh-Capacity NiCd:

Extended-Capacity NiMH:

Li-Ion:

Ultra–High-Capacity NiCd FM: NTN8295_*

Ultra–High-Capacity NiMH FM: NTN8299_*

Optional FM (Factory Mutual) Battery:

* FM Intrinsically Safe: Class I, II, III, Division 1,

Groups C, D,E, F, and G. FM Non-incendive:

Class 1, Division 2, Groups A, B, C, and D.

–30°C to +60°C

–40°C to +85°C

7.5 Volts

6 to 9 Volts

80mA

NTN8294_

NTN8293_

NTN8610_

RECEIVER TRANSMITTER

Frequency Range:

Bandwidth:

Quieting Sensitivity (20dBQ):

Usable Sensitivity

(12dB SINAD):

Intermodulation:

Selectivity (typical)

(25/30kHz Channel):

(12.5kHz Channel):

Spurious Rejection:

Frequency Stability

(–30+60°C; 25°C reference):

Rated Audio:

FM Hum and Noise (typical):

Distortion (At Rated Audio):

450-520MHz

70MHz

0.35µV (typical)

0.20µV (typical)

–78dB (typical)

–78dB

–70dB

–80dB

±.0002%

500mW

25kHz –48dB

12.5kHz –43dB

1.5% Typical

RF Power:

450-520MHz: 1 Watt/5 Watts

Frequency Range: 450-520MHz

Frequency Stability (typical)

(–30 to +60°C; 25°C ref.): ±.0002%

Emission (Conducted and Radiated): –75dBc

FM Hum and Noise (typical)

(Companion Receiver): 25kHz –48dB

12.5kHz –42dB

Distortion: 2% Typical

Modulation Limiting: 25kHz chnls ±5.0kHz

12.5kHz chnls ±2.5kHz

Emissions Designators:

20K0F1E, 16K0F3E, 11K0F3E,

8K10F1D, and 8K10F1E

Dimensions (H x W x D)

Note: 2.44" = width at PTT; 2.34" = width at

bottom; 1.83" = depth at speaker; 0.97" =

depth at keypad

Less Battery:

6.58" x 2.44" x 1.83"/6.58" x 2.34" x 0.97"

(167.13mm x 61.90mm x 46.42mm/

167.13mm x 59.49mm x 24.56mm)

With Battery:

6.58" x 2.44" x 1.83"/6.58" x 2.34" x 1.65"

(167.13mm x 61.90mm x 46.42mm/

167.13mm x 59.49mm x 41.97mm)

Weight: (w/Helical Antenna)

Less Battery:

With Ultra-High Cap. NiCd: 25.19oz. (693gm)

With Li-Ion:

With Ultra-High Cap. NiMH: 23.45oz. (644gm)

With Extended- Cap. NiMH: 24.04oz. (682gm)

14.10oz. (383gm)

20.41oz. (583gm)

Channel Spacing: 12.5/25 kHz

Specifications subject to change without notice

Page 9

GLOSSARY

A/D Analog-to-Digital converter; converts an instantaneous dc voltage

level to a corresponding digital value.

ABACUS IC Custom integrated circuit providing a digital receiver IF backend.

ADDAG Analog-to-Digital/Digital-to-Analog Glue IC

APCO Association of Public Safety Communication Officers

CODEC Coder/Decoder IC for analog-to-digital and digital-to-analog

conversion.

D/A Digital-to-Analog converter; converts a digital value to a

corresponding dc voltage value.

DTMF Dual-Tone Multi-Frequency

DPL Digital Private-Line™

DSP Digital Signal Processor; microcontroller specifically tailored for

signal processing computations. In this case refers specifically to

Motorola DSP56603.

DSPS IC Digital Signal Processor Support IC. Generates processor clocks

and provides peripheral functions for the DSP.

Firmware Software or a software/hardware combination of computer

programs and data, with a fixed logic configuration stored in a

read-only memory; information can not be altered or

reprogrammed.

FGU Frequency Generation Unit

FLASHport™ A Motorola term that describes the ability of a radio to change

memory. Every FLASHport radio contains a FLASHport EEPROM

memory chip that can be software written and rewritten to, again

and again.

Host Motorola HC12A4 microcontrol unit U204 (see MCU).

Host Port Parallel memory mapped interface consisting of eight registers in

the DSP56603.

IC Integrated Circuit

IMBE Improved Multi-Band Excitation: a sub-band, voice encoding

algorithm used in ASTRO digital voice.

MCU MicroControl Unit

MDC Motorola Digital Communications

Page 10

MISO Master In Slave Out; used by the slave device to send data to the

master device.

MOSI Master Out Slave In; used by the master device to send data to the

slave device.

OMPAC Over-Molded Pad-Array Carrier; a Motorola custom IC package,

distinguished by the presence of solder balls on the bottom pads.

Open

Architecture A controller configuration that utilizes a microprocessor with

extended ROM and RAM.

PC Board Printed Circuit board

PCIC Power Control IC

PL Private-Line® tone squelch; a continuous sub-audible tone that is

transmitted along with the carrier.

PLL Phase-Locked Loop; a circuit in which an oscillator is kept in phase

with a reference, usually after passing through a frequency divider.

PTT Push-To-Talk; the switch located on the left side of the radio

which, when pressed, causes the radio to transmit.

Registers Short-term data-storage circuits within the microcontrol unit or

programmable logic IC.

Repeater Remote transmit/receive facility that re-transmits received signals

in order to improve communications coverage.

RESET Reset line; an input to the microcontroller that restarts execution.

RF PA Radio Frequency Power Amplifier

RSS Radio Service Software

RPT/TA RePeaTer/Talk-Around

RX DATA Recovered digital data line.

Signal Qualifier Mode An operating mode whereby the radio is muted but still continues

to analyze receive data to determine RX signal type.

SCI IN Serial Communication Interface INput line

Softpot Software potentiometer; a computer-adjustable electronic

attenuator.

Software Computer programs, procedures, rules, documentation, and data

pertaining to the operation of a system.

SPI Serial Peripheral Interface; how the microcontroller communicates

to modules and ICs through the CLOCK and DATA lines.

Page 11

Squelch Muting of audio circuits when received signal levels fall below a

pre-determined value.

SRAM Static-RAM chip used for volatile, program/data memory.

SSI Synchronous Serial Interface on the DSP56603 to the CODEC,

DSPS IC, and ADDAG.

Standby Mode An operating mode whereby the radio is muted but still continues

to monitor data.

System Select The act of selecting the desired operating system with the system-

select switch (also, the name given to this switch).

TOT Time-Out Timer; a timer that limits the length of a transmission.

TSOP Thin Small-Outline Package

UART Universal Asynchronous Receiver Transmitter.

µC Microcontrol unit (see MCU).

VCO Voltage-Controlled Oscillator; an oscillator whereby the frequency

of oscillation can be varied by changing a control voltage.

VCOB IC Voltage-Controlled Oscillator Buffer IC

Vocoder VOice enCODER; the DSP-based system for digitally processing

the analog signals, includes the capabilities of performing voice

compression algorithms or voice encoding.

VOCON VOcoder/CONtroller board

VSWR Voltage Standing Wave Ratio

Page 12

Safety Information

R

Safe And Efficient Operation Of Motorola Two-Way Radios

For information regarding radio use in hazardous areas, please refer to the Factory Mutual (FM) approval manual

supplement that is included with radio models that offer this capability.

Exposure To Radio Frequency Energy

National and International Standards and Guidelines

Your Motorola Two-Way Radio, which generates and radiates radio frequency (RF) electromagnetic energy (EME), is

designed to comply with the following National and International Standards and Guidelines regarding exposure of

human beings to radio frequency electromagnetic energy:

• Federal Communications Commission Report and Order No. FCC 96-326 (August 1996)

• American National Standards Institute (C95.1 - 1992)

• National Council on Radiation Protection and Measurements (NCRP - 1986)

• International Commission on Non-Ionizing Radiation Protection (ICNRP - 1986)

• European Committee for Electrotechnical Standardisation (CENELEC):

• ENV. 50166-1

1995 E

• ENV. 50166-2

1995 E

• Proceedings of

SC211/8 1996

To assure optimal radio performance and that human exposure to radio frequency electromagnetic energy is within

the guidelines set forth in the above standards, always adhere to the following procedures:

Human Exposure to Electromagnetic Fields Low Frequency (0Hz to 10kHz)

Human Exposure to Electromagnetic Fields High Frequency (10kHz to 300GHz)

Safety Considerations for Human Exposure to E.M.F.s from Mobile Telecommunications

Equipment (M.T.E.) in the Frequency Range 30MHz - 6 GHz (E.M.F. - Electromagnetic

Fields)

Portable Radio Operation and EME Exposure

• When transmitting with a portable radio, hold the radio in a vertical position with its microphone

1 to 2 inches (2.5 to 5 centimeters) away from your mouth. Keep the antenna at least 1 inch (2.5

centimeters) from your head and body.

• If you wear a portable two-way radio on your body, ensure that the antenna is at least 1 inch (2.5

centimeters) from your body when transmitting.

MAN WITH

Electromagnetic Interference/Compatibility

Note

Nearly every electronic device is susceptible to electromagnetic interference (EMI) if inadequately

shielded, designed, or otherwise configured for electromagnetic compatibility.

• To avoid electromagnetic interference and/or compatibility conflicts, turn off your radio in any facility where

posted notices instruct you to do so. Hospitals or health care facilities may be using equipment that is sensitive

to external RF energy.

• When instructed to do so, turn off your radio when on board an aircraft. Any use of a radio must be in accordance

with airline regulations or crew instructions.

Page 13

Operational Warnings

!

C a u t i o n

!

Vehicles With an Air Bag

Do not place a portable radio in the area over an air bag or in the air bag deployment area. Air bags inflate with great

force. If a portable radio is placed in the air bag deployment area and the air bag inflates, the radio may be propelled

with great force and cause serious injury to occupants of the vehicle.

Potentially Explosive Atmospheres

Turn off your two-way radio when you are in any area with a potentially explosive atmosphere, unless it is a radio

type especially qualified for use in such areas (for example, Factory Mutual or CENELEC approved). Sparks in a

potentially explosive atmosphere can cause an explosion or fire resulting in bodily injury or even death.

Batteries

Do not replace or recharge batteries in a potentially explosive atmosphere. Battery contact sparking may occur while

installing or removing batteries and may cause an explosion.

Blasting Caps and Blasting Areas

To avoid possible interference with blasting operations, turn off your radio when you are near electrical blasting caps,

in a blasting area, or in areas posted: “Turn off two-way radio.” Obey all signs and instructions.

!

W A R N I N G

Note

The areas with potentially explosive atmospheres referred to above include fueling areas such as: below

decks on boats; fuel or chemical transfer or storage facilities; areas where the air contains chemicals or

particles, such as grain, dust, or metal powders; and any other area where you would normally be advised

to turn off a vehicle engine. Areas with potentially explosive atmospheres are often but not always

posted.

Operational Cautions

Antennas

• Do not use any portable two-way radio that has a damaged antenna. If a damaged antenna comes into contact

with your skin, a minor burn can result.

• Make sure you have the correct antenna installed for your radio’s frequency band. Ask your dealer for details.

Batteries

All batteries can cause property damage and/or bodily injury such as burns if a conductive material such as jewelry,

keys, or beaded chains touch exposed terminals. The conductive material may complete an electrical circuit (short

circuit) and become quite hot. Exercise care in handling any charged battery, particularly when placing it inside a

pocket, purse, or other container with metal objects.

Battery Information

Charging Batteries

This product is powered by a nickel-cadmium (Ni-Cd), nickel-metal-hydride (NiMH), or lithium-ion rechargeable

battery. Charge the battery before use to ensure optimum capacity and performance. The battery was designed

specifically to be used with a Motorola charger. Charging in non-Motorola equipment may lead to battery damage

and void the battery warranty.

Note

The battery should be at about 77°F (25°C) (room temperature), whenever possible. Charging a cold battery (below

50° F [10°C]) may result in leakage of electrolyte and ultimately in failure of the battery. Charging a hot battery (above

104°F [40°C]) results in reduced discharge capacity, affecting the performance of the radio. Motorola rapid-rate battery

chargers contain a temperature-sensing circuit to ensure that batteries are charged within the temperature limits

stated above.

When charging a battery attached to a radio, turn the radio off to ensure a full charge.

Page 14

Recycling of Nickel-Cadmium Batteries

Nickel-cadmium (Ni-Cd) rechargeable batteries can be recycled. However, recycling facilities may not be available in

all areas. Under various U.S. state laws and the laws of several other countries, Ni-Cd batteries must be recycled or

disposed of properly and cannot be disposed of in landfills or incinerators.

Contact your local waste management agency for specific requirements and information in your area.

Motorola fully endorses and encourages the recycling of Ni-Cd batteries. In the U.S. and Canada, Motorola

participates in the nationwide Rechargeable Battery Recycling Corporation (RBRC) program for Ni-Cd battery

collection and recycling. Many retailers and dealers participate in this program.

For the location of the drop-off facility closest to you, access RBRC's Internet website at www.rbrc.com or call 1-8008-BATTERY. This internet site and telephone number also provide other useful information concerning recycling

options for consumers, businesses, and governmental agencies.

Intrinsically Safe Radio Information

FMRC Approved Equipment

Anyone intending to use a radio in a location where hazardous concentrations of flammable materials exist

(hazardous atmosphere) is advised to become familiar with the subject of intrinsic safety and with the National

Electric Code NFPA 70 (National Fire Protection Association) Article 500 (hazardous [classified] locations).

An Approval Guide, issued by Factory Mutual Research Corporation (FMRC), lists manufacturers and the products

approved by FMRC for use in such locations. FMRC has also issued a voluntary approval standard for repair service

(“Class Number 3605”).

FMRC Approval labels are attached to the radio to identify the unit as being FM Approved for specified hazardous

atmospheres. This label specifies the hazardous Class/Division/Group along with the part number of the battery that

must be used. Depending on the design of the portable unit, this FM label can be found on the back or the bottom

of the radio housing. The FM Approval mark is shown below:

FM

APPROVED

WARNINGS

• Do not operate radio communications equipment in a hazardous atmosphere unless it is a type

especially qualified (for example, FMRC Approved) for such use. An explosion or fire may result.

• Do not operate an FMRC Approved Product in a hazardous atmosphere if it has been physically

damaged (for example, cracked housing). An explosion or fire may result.

• Do not replace or charge batteries in a hazardous atmosphere. Contact sparking may occur while

installing or removing batteries and cause an explosion or fire.

• Do not replace or change accessories in a hazardous atmosphere. Contact sparking may occur while

installing or removing accessories and cause an explosion or fire.

• Do not operate an FMRC Approved Product unit in a hazardous location with the accessory contacts

exposed. Keep the connector cover in place when accessories are not used.

• Turn a radio off before removing or installing a battery or accessory.

• Do not disassemble an FMRC Approved Product unit in any way that exposes the internal electrical

circuits of the unit.

Radios must ship from the Motorola manufacturing facility with the hazardous atmosphere capability and FM

Approval labeling. Radios will not be “upgraded” to this capability and labeled in the field.

W A R N I N G

!

!

A modification changes the unit’s hardware from its original design configuration. Modifications can only be made

by the original product manufacturer at one of its FMRC-audited manufacturing facilities.

Page 15

WARNINGS

!

W A R N I N G

!

• Failure to use an FMRC Approved Product unit with an FMRC Approved battery or FMRC Approved

accessories specifically approved for that product may result in the dangerously unsafe condition of

an unapproved radio combination being used in a hazardous location.

• Unauthorized or incorrect modification of an FMRC Approved Product unit will negate the Approval

rating of the product.

Repair of FMRC Approved Products

REPAIRS FOR MOTOROLA PRODUCTS WITH FMRC APPROVAL ARE THE RESPONSIBILITY OF THE USER.

Y ou should not repair or relabel any Motorola- manufactured communication equipment bearing the FMRC Approval

label (“FMRC Approved Product”) unless you are familiar with the current FMRC Approval standard for repairs and

service (“Class Number 3605”).

You may want to consider using a repair facility that operates under 3605 repair service approval.

WARNINGS

• Incorrect repair or relabeling of any FMRC Approved Product unit could adversely affect the

Approval rating of the unit.

• Use of a radio that is not intrinsically safe in a hazardous atmosphere could result in serious injury

or death.

FMRC’s Approval Standard Class Number 3605 is subject to change at any time without notice to you, so you may

want to obtain a current copy of 3605 from FMRC. Per the December 1994 publication of 3605, some key definitions

and service requirements are as follows:

Repair

A repair constitutes something done internally to the unit that would bring it back to its original condition—

Approved by FMRC. A repair should be done in an FMRC Approved facility.

Items not considered as repairs are those in which an action is performed on a unit which does not require the outer

casing of the unit to be opened in a manner which exposes the internal electrical circuits of the unit. Y ou do not have

to be an FMRC Approved Repair Facility to perform these actions.

Relabeling

The repair facility shall have a method by which the replacement of FMRC Approval labels are controlled to ensure

that any relabeling is limited to units that were originally shipped from the Manufacturer with an FM Approval label

in place. FMRC Approval labels shall not be stocked by the repair facility. An FMRC Approval label shall be ordered

from the original manufacturer, as needed, to repair a specific unit. Replacement labels may be obtained and applied

by the repair facility, provided there is satisfactory evidence that the unit being relabeled was originally an FMRC

Approved unit. Verification may include, but is not limited to: a unit with a damaged Approval label, a unit with a

defective housing displaying an Approval label, or a customer invoice indicating the serial number of the unit and

purchase of an FMRC Approved model.

!

!

W A R N I N G

Do Not Substitute Options or Accessories

The Motorola communications equipment certified by Factory Mutual is tested as a system and consists of the FM

Approved portable, FM Approved battery, and FM Approved accessories or options, or both. This FM Approved

portable and battery combination must be strictly observed. There must be no substitution of items, even if the

substitute has been previously Approved with a different Motorola communications equipment unit. Approved

configurations are listed in the FM Approval Guide published by FMRC, or in the product FM Supplement. This FM

Supplement is shipped from the manufacturer with the FM Approved radio and battery combination. The Approval

Guide, or the Approval Standard Class Number 3605 document for repairs and service, can be ordered directly from

Factory Mutual Research Corporation located in Norwood, Massachusetts.

Page 16

Notes

Page 17

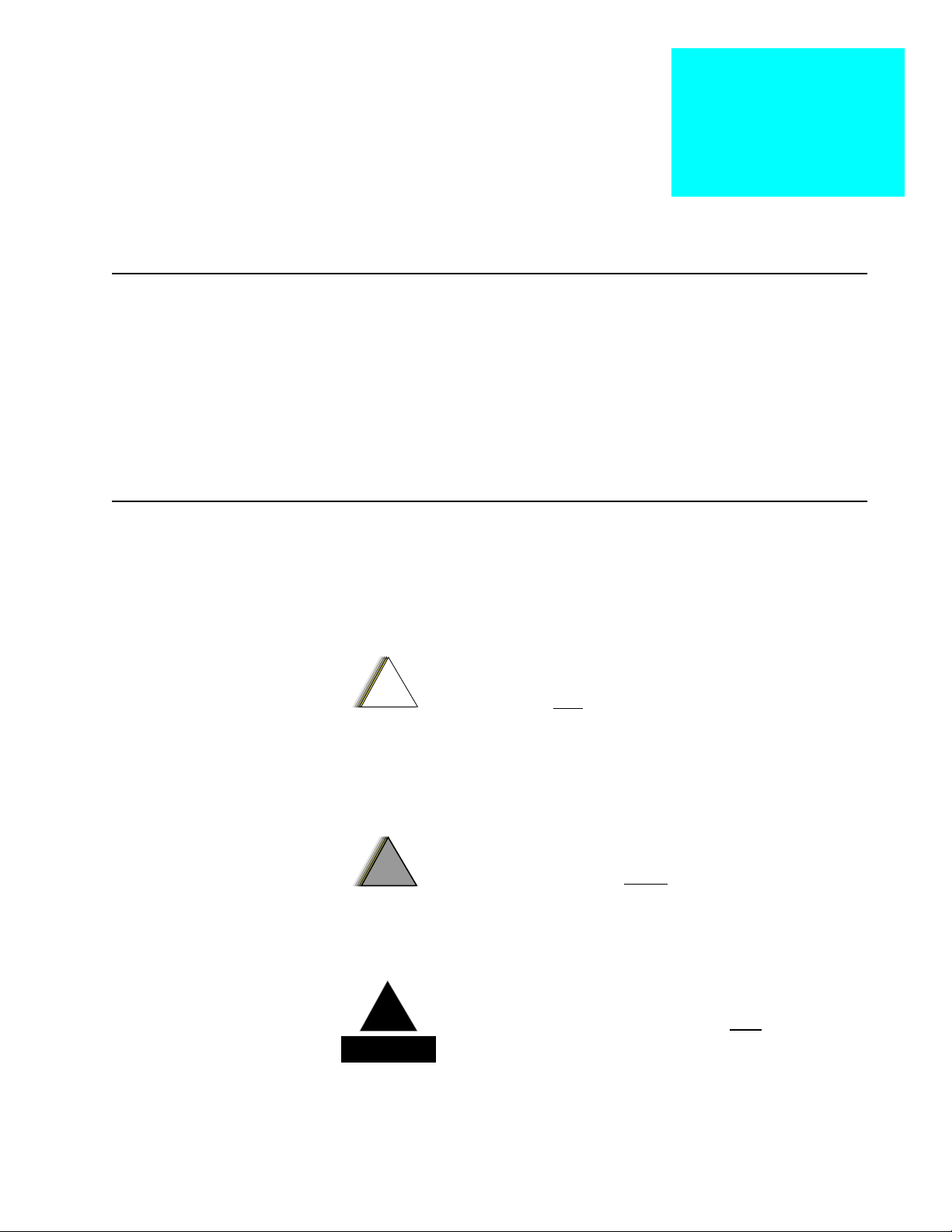

Introduction

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or injury.

!

W A R N I N G

!

DANGER indicates an imminently hazardous

situation which, if not avoided, will

result in

death or injury.

D A N G E R

!

1

General This manual covers information needed for level one troubleshooting. Level

one troubleshooting consists of radio programming, radio alignment, knobs

replacement, and installation and removal of antenna, belt clip, battery, and

universal connector cover.

Included in this manual are radio specifications for the VHF and UHF

frequency bands, a general description of XTS 3500 models, recommended

test equipment, service aids, radio alignment procedures, general

maintenance recommendations, and procedures for basic assembly and

disassembly.

Notations Used

in This Manual

Throughout the text in this publication, you will notice the use of warnings,

cautions, and notes. These notations are used to emphasize that safety hazards

exist, and care must be taken and observed.

NOTE: An operational procedure, practice, or condition, etc.,

which is essential to emphasize.

CAUTION indicates a potentially hazardous situation which,

!

C a u t i o n

if not avoided, may result in equipment damage.

Page 18

Radio

Description

Feature Model I Model II Model III

The ASTRO Digital XTS 3500 radios are among the most sophisticated twoway radios available. The radios are available in the VHF and UHF R2 bands.

One of the newest in a long line of quality Motorola products, the ASTRO

Digital XTS 3500 radio provides improved voice quality across more coverage

area. The digital process, called “embedded signalling,” intermixes system

signalling information with digital voice, resulting in improved system

reliability , and the capability of supporting a multitude of advanced features.

Such features add up to better, more cost-effective two-way radio

communications.

ASTRO Digital XTS 3500 radios are available in three basic models. Table 1

describes their basic features.

Table 1 ASTRO XTS 3500 Basic Features

Display None LCD

4 lines/

12 characters per line

Keypad None 3 x 2 button 3 x 6 button

Channel Capability 48 255 255

Dialing from Prestored List No Yes Yes

Programmable Softkeys No Yes Yes

12 characters per line

LCD

4 lines/

FLASHport The ASTRO Digital XTS 3500 radio utilizes Motorola’s revolutionary

FLASHport technology. FLASHport makes it possible to add software that

drives the radio’s capabilities both at the time of purchase and later on.

Previously, changing a radio’s features and capabilities meant significant

modifications, or buying a new radio. But now , similar to how a computer can

be loaded with different software, the radio’s features and capabilities can be

upgraded with FLASHport software.

Page 19

Basic Maintenance

The effects of certain chemicals and their vapors can

have harmful results on certain plastics. Aerosol

sprays, tuner cleaners, and other chemicals should

be avoided.

!

C a u t i o n

2

Introduction

to This Section

Preventive

Maintenance

Inspection Check that the external surfaces of the radio are clean, and that all external

Cleaning The following procedures describe the recommended cleaning agents and the

This section of the manual describes preventive maintenance and handling

precautions. Each of these topics provides information vital to the successful

operation and maintenance of your radio.

The ASTRO Digital XTS 3500 radios do not require a scheduled preventive

maintenance program; however, periodic visual inspection and cleaning is

recommended.

controls and switches are functional. A detailed inspection of the interior

electronic circuitry is not needed.

methods to be used when cleaning the external surfaces of the radio. External

surfaces include the housing assembly and battery case. These surfaces should

be cleaned whenever a periodic visual inspection reveals the presence of

smudges, grease, and/or grime.

The only recommended agent for cleaning the external radio surfaces is a 0.5%

solution of a mild dishwashing detergent, such as JOY®, in water.

Cleaning External

Plastic Surfaces

The detergent-water solution should be applied sparingly with a stiff, nonmetallic, short-bristled brush to work all loose dirt away from the radio. A soft,

absorbent, lintless cloth or tissue should be used to remove the solution and

dry the radio. Make sure that no water remains entrapped near the connectors,

cracks, or crevices.

Page 20

Handling

Precautions

Complementary metal-oxide semiconductor (CMOS) devices, and other hightechnology devices, are used in this family of radios. While the attributes of

these devices are many , their characteristics make them susceptible to damage

by electrostatic discharge (ESD) or high-voltage charges. Damage can be latent,

resulting in failures occurring weeks or months later. Therefore, special

precautions must be taken to prevent device damage during disassembly,

troubleshooting, and repair. Handling precautions are mandatory for this

radio, and are especially important in low-humidity conditions.

Page 21

Recommended Test

Equipment and Service Aids 3

Recommended

Test

Equipment

Motorola

Model Number

R2600 Series Communications

Fluke 8012 Digital Multimeter Recommended for ac/dc voltage

R1150_* Code Synthesizer Injection of audio and digital

R1377_* AC Voltmeter 1mV to 300V, 10-Megohm

R1094_ Dual-Trace

The list of equipment contained in Table 2 includes all of the standard test

equipment required for servicing two-way portable radios, as well as several

unique items designed specifically for servicing this family of radios. The

“Characteristics” column is included so that equivalent equipment may be

substituted; however, when no information is provided in this column, the

specific Motorola model listed is either a unique item or no substitution is

recommended.

Table 2 Recommended Test Equipment

Description Characteristics Application

System Analyzer

Oscilloscope

This monitor will substitute

for items with an asterisk (*).

input impedance

20MHz bandwidth 5mV to

5V/division

Frequency/deviation meter and

signal generator for wide-range

troubleshooting and alignment.

and current measurements

signalling codes

Audio voltage measurements

Waveform measurements

S1350_*

ST1213_ (VHF)*

ST1223_ (UHF)*

R1065_ Load Resistor 10-watt Broadband For use with wattmeter

S1339_ RF Millivolt Meter 100µV to 3V RF RF-level measurements

R1013_* SINAD Meter Receiver sensitivity measurements

S1347_ or S1348_

(programmable)

Wattmeter

Plug-In Element

RF Dummy Load

DC Power Supply 0-20Vdc, 0-5 Amps

50-ohm, ±5% accuracy

10 watts, maximum

0-1000MHz, 300W

current limited

Transmitter power output

measurements

Bench supply for 7.5Vdc

Service Aids Refer to T able 3, “Service Aids,” for a listing and description of the service aids

designed specifically for servicing this family of radios. These kits and/or parts

are available from the Motorola Parts Division offices listed in the

“Replacement Parts Ordering” section located on the inside back cover of this

manual. While all of these items are available from Motorola, most are

standard shop equipment items, and any equivalent item capable of the same

performance may be substituted for the item listed.

Page 22

Table 3 Service Aids

Motorola Part

Number

RKN-4035_ RIB/Radio/Test Set Cable Connects radio to RTX-4005B Test Box and RIB.

REX-4424_ Battery Eliminator Interconnects radio to power supply.

RLN-4460_, or

RTX-4005_, or both

RTX-4005_ and

RPX-4665_

Field Modification Kit

RLN-1015_ or

RLN-4008_

01-80357A57 Wall-Mounted Power Supply Used to supply power to the RIB (120 Vac).

01-80358A56 Wall-Mounted Power Supply Used to supply power to the RIB (220 Vac).

30-80369B71 or

30-80369B72

30-80390B48 or

30-80390B49

RVN-4170_ Radio Service Software Software on 3-1/2 in. floppy disks.

Portable Test Set Enables connection to the universal connector.

Radio Interface Box Enables communications between the radio and the

Computer Interface Cables

for RIB RLN4008_

Computer Interface Cables

for Smart RIB RLN1015_

Description Application

Allows switching for radio testing.

computer's serial communications adapter.

Use B72 for 9-pin serial ports. All other models use B71

(25 pins). Connects the computer's serial

communications adaptor to the RIB.

Use B49 for 9-pin serial ports. All other models use B48

(25 pins). Connects the computer's serial

communications adaptor to the RIB.

58-80348B33 SMA to BNC Adaptor Adapts radio’s antenna port to BNC cabling of test

equipment.

Field

Programming

This family of radios can be aligned and programmed in the field. This requires

specific equipment and special instructions. Refer to the applicable “Radio

Service Software User's Guide” for complete field programming information.

Equipment

Page 23

Performance Checks

4

Introduction

to This Section

This section covers performance checks used to verify the radio meets

published specifications. The recommended test equipment listed in the

previous section approaches the accuracy of the manufacturing equipment,

with a few exceptions. Accuracy of the equipment must be maintained in

compliance with the manufacturer’s recommended calibration schedule.

Checks should be performed if radio performance degradation is suspected.

Setup Supply voltage can be connected from the battery eliminator. The equipment

required for alignment procedures is connected as shown in the “Radio

Alignment Test Setup” diagram (page 15, Figure 1).

Initial equipment control settings should be as indicated in the following

table, and should hold for all alignment procedures except as noted in T able 4.

Table 4 Initial Equipment Control Settings

System Analyzer Test Set Power Supply

Monitor Mode: Pwr Mon Spkr Set: A Voltage: 7.5Vdc

RF Attn: –70dB Spkr/Load: Speaker DC On/Standby: Standby

AM, CW, FM: FM PTT: OFF (center) Volt Range: 10Vdc

Display Radio

Test Mode

Entering Display

Radio Test Mode

O'scope Source: Mod

O'scope Horiz: 10mSec/Div

O'scope Vert: 2.5kHz/Div

O'scope Trig: Auto

Monitor Image: Hi

Monitor BW: Nar

Monitor Squelch: Mid CW

Monitor Vol: 1/4 CW

1. Turn the radio on.

2. Within 10 seconds after “SS

times in succession.

3. The radio will show a series of displays that will give information

regarding various version numbers and subscriber specific information.

The displays are described in Table 5 on page 8.

SSeeeellllffff TTTTeeeesssstttt

” is complete, press Side button 3 five

Current: 2.5Amps

Page 24

Table 5 Front-Panel Access Test-Mode Displays

Name of Display Description Appears

SSEEEERRRRVVVVIIIICCCCEEEE

“SS

Host Software Version The version of host firmware is displayed. Always.

DSP Software Version The version of DSP firmware is displayed. Always.

EMC Secure Version Version of the encryption hardware. When the radio is secure equipped.

Encryption Type 1 Type of encryption being used. When the radio is secure equipped.

Encryption Type 2 Type of encryption being used. When the radio is secure equipped.

” The literal string indicates the radio has entered

test mode.

Always.

Model Number The radio’s model number as programmed in the

codeplug.

Serial Number The radio’s serial number as programmed in the

codeplug.

ROM Size The memory capacity of the host FLASH part. Always.

FLASHcode The FLASH codes as programmed in the codeplug. Always.

Note: All displays are temporary and will expire without any user intervention. If information is longer than the

physical length of the radio’s display, the information will wrap around to the next display. After the last

display, “RR

RRFFFF TTTTEEEESSSSTTTT

” will be displayed.

Always.

Always.

4a. Press Side Button 1 to stop the displays and put the radio into the

Control Top and Keypad test mode (display radio). The test mode menu

CCHHHH TTTTEEEESSSSTTTT

“CC

” will be displayed. Go to the “Control Top and Keypad Test

Mode (Display Radio)” section.

NOTE: Each press of Side Button 1 will toggle between “CC

RRFFFF TTTTEEEESSSSTTTT

and “RR

.”

CCHHHH TTTTEEEESSSSTTTT

”

OR

4b. Press the Top Programmable Button (Emergency button) to stop the

displays and put the radio into the RF test mode (display radio). The test

mode menu “11

11 CCCCSSSSQQQQ

.” will be displayed, indicating test frequency 1,

Carrier SQuelch mode. Go to the “RF Test Mode (Display Radio)” section.

RF Test Mode

(Display Radio)

When the ASTRO Digital XTS 3500 radio is operating in its normal environment,

the radio's microcomputer controls the RF channel selection, transmitter key-up,

and receiver muting, according to the customer codeplug configuration.

However, when the unit is on the bench for testing, alignment, or repair , it must

be removed from its normal environment via a special routine, called TEST

MODE or “air test.”

1. Each additional press of Side Button 3 will advance to the next test

channel. (Refer to Table 6.)

2. Pressing Side Button 2 will scroll through and access test environments

as shown in Table 7.

NOTE: Transmit into a load when keying a radio under test.

Page 25

Table 6 Test Frequencies

Test Channel VHF UHF Band 2

TX #1 136.025 450.025

RX #1 136.075 450.075

TX #2 142.125 465.225

RX #2 142.075 465.275

TX #3 154.225 475.125

RX #3 154.275 475.275

TX #4 160.125 484.975

RX #4 160.175 485.025

TX #5 168.075 500.275

RX #5 168.125 500.225

TX #6 173.975 511.975

RX #6 173.925 511.925

TX #7 177.975 519.975

RX #7 177.925 519.925

Table 7 Test Environments

Control Top

and Keypad

Test Mode

(Display Radio)

No. of

Beeps

11 AST ASTRO RX: none

12 USQ Carrier

Display Description Function

1 CSQ Carrier

Squelch

3 TPL Tone

Private-Line

9 SEC Secure*** RX: auto-coded clear

Unsquelch

RX: unsquelch if carrier detected

TX: mic audio

RX: unsquelch if carrier and

tone (192.8 Hz) detected

TX: mic audio + tone (192.8 Hz)

TX: with key present—encrypted audio

with key absent—constant unsquelch

TX: 1200Hz tone **

RX: unsquelch always

TX: mic audio

** All deviation values are based on deviation tuning of this mode

*** On radios equipped with secure option

This test mode is used to verify proper operation of all radio buttons and

switches if a failure is suspected.

1. Press and hold the Top Programmable Button; all segments on the

display will light, and the LED on the control top will illuminate a red

color.

2. Release the Top Programmable Button; “33

33////0000

” appears, which indicates

that the Top Programmable Button is in the open condition.

3. Press the Top Programmable Button again; “33

33////1111

” appears, which

indicates that the Top Programmable Button is in the closed condition.

4. Rotate the Mode/Zone Selector Switch; “44

44////0000

” through “44

44////11115555

” appears,

which indicates that the selector switch is in mode/zone position 1

through 16.

Page 26

5. Rotate the Two-Position Concentric Switch; “66

665555////0000

” and “66

665555////1111

” appear.

6. Cycle through the Three-Position Programmable Switch; “66

667777////1111

“66

,” and “66

7. Rotate the Volume Control; “22

8. Press Side Button 1; “99

9. Press Side Button 2; “99

10. Press Side Button 3; “99

11. Press the PTT Switch; “11

12. Keypad Checks:

Model III Only—

- Press 0, “44

- Press 1, “44

- Press 2, “55

- Press 3, “55

- Press 4, “55

- Press 5, “55

- Press 6, “55

- Press 7, “55

667777////2222

” appear.

996666////1111

” appears; release, “99

997777////1111

”appears; release, “99

998888////1111

”appears; release, “99

11////1111

” appears; release, “11

448888////1111

” appears; release, “44

449999////1111

” appears; release, “44

550000////1111

” appears; release, “55

551111////1111

” appears; release, “55

552222////1111

” appears; release, “55

553333////1111

” appears; release, “55

554444////1111

” appears; release, “55

555555////1111

” appears; release, “55

22////0000

” through “22

448888////0000

449999////0000

550000////0000

551111////0000

552222////0000

553333////0000

554444////0000

555555////0000

22////222255555555

996666////0000

” appears.

997777////0000

” appears.

998888////0000

” appears.

11////0000

” appears.

” appears.

” appears.

” appears.

” appears.

” appears.

” appears.

” appears.

” appears.

” appear.

667777////0000

,”

Non-Display

Radio Test

Mode

- Press 8, “55

- Press 9, “55

- Press *, “55

- Press #, “55

All Display Models—

- Press <, “11

- Press O, “11

- Press >, “11

- Press the left-hand M key on the top row of keys, “11

release, “11

- Press the center N key, “11

- Press the right-hand M key, “11

appears.

556666////1111

557777////1111

558888////1111

559999////1111

1122228888////1111

1122229999////1111

1133330000////1111

1133331111////0000

” appears; release, “55

” appears; release, “55

” appears; release, “55

” appears; release, “55

” appears; release, “11

” appears; release, “11

” appears; release, “11

” appears.

1133332222////1111

556666////0000

” appears.

557777////0000

” appears.

558888////0000

” appears.

559999////0000

” appears.

1122228888////0000

” appears.

1122229999////0000

” appears.

1133330000////0000

” appears.

” appears; release, “11

1133333333////1111

” appears; release, “11

1133332222////0000

1133331111////1111

1133333333////0000

” appears;

” appears.

”

Entering NonDisplay Radio

Test Mode

1. Turn the radio on.

2. Within 10 seconds after the top green LED turns off, press Side button 3

five times in succession.

Page 27

ppyp

mode (non-display radio). Go to the “Control T op and Keypad Test Mode

(Non-Display Radio)” section.

NOTE: Each press of Side Button 1 will toggle between Control

Top and Keypad test mode (non-display radio) and RF test

mode (non-display radio).

OR

3b. Press the Top Programmable Button (Emergency button) to stop the

displays and put the radio into the RF test mode (non-display radio). Go

to the “RF Test Mode (Non-Display Radio)” section.

RF Test Mode

(Non-Display

Radio)

Control Top

and Keypad

Test Mode

(Non-Display

Radio)

When the ASTRO Digital XTS 3500 radio is operating in its normal environment,

the radio's microcomputer controls the RF channel selection, transmitter key-up,

and receiver muting, according to the customer codeplug configuration.

However, when the unit is on the bench for testing, alignment, or repair , it must

be removed from its normal environment via a special routine, called TEST

MODE or “air test.”

1. Each additional press of Side Button 3 will advance to the next test

channel. (Refer to Table 6.) The channel number is represented by the

number of beeps emitted by the radio after the button press (for example,

five beeps indicates channel 5).

2. Pressing Side Button 2 will scroll through and access test environments

as shown in Table 7. The test environment is represented by the number

of beeps emitted by the radio after the button press (for example, 11

beeps indicate AST).

NOTE: Transmit into a load when keying a radio under test.

This test mode is used to verify proper operation of all radio buttons and

switches if a failure is suspected.

1. Press and hold the Top Programmable Button; the LED on the control

top lights red, and the radio beeps.

2. Release the Top Programmable Button; the radio beeps again.

3. Press the Top Programmable Button again; the radio beeps, indicating

that the Top Programmable Button is in the closed condition.

4. Rotate the Two-Position Concentric Switch; the radio beeps in each

switch position.

5. Rotate the Mode/Zone Selector Switch; the radio beeps in each switch

position.

6. Cycle through the Three-Position Programmable Switch; the radio

beeps in each switch position.

7. Rotate the Volume Control; the radio beeps at each new volume setting.

8. Press Side Button 1; the radio beeps.

9. Press Side Button 2; the radio beeps.

10. Press Side Button 3; the radio beeps.

Page 28

Table 8 Receiver Performance Checks

Test Name System Analyzer Radio Test Set Comments

Reference

Frequency

Rated Audio Mode: GEN

Distortion As above, except to

Sensitivity

(SINAD)

Noise Squelch

Threshold (only

radios with

conventional

system need to

be tested)

Mode: PWR MON 4th

channel test frequency❖

Monitor: Frequency error.

Input at RF In/Out

Output level: 1.0mV RF

4th channel test

frequency❖

Mod: 1kHz tone at 3kHz

deviation

Monitor: DVM: ac Volts

distortion

As above, except SINAD;

lower the RF level for 12dB

SINAD

RF level set to 1mV RF As above PTT to OFF (center);

As above, except change

frequency to a

conventional system. Raise

RF level from zero until

radio unsquelches.

TEST MODE, 4

CSQ output at

antenna

TEST MODE, 4

CSQ

As above As above Distortion < 3.0%

As above PTT to OFF (center) RF input to be <

Out of TEST

MODE; select

a conventional

system

PTT to continuous

(during the

performance check)

PTT to OFF (center);

meter selector to Audio

PA

meter selection to

Audio PA; spkr/load to

speaker

As above Unsquelch to

Frequency error to

be ≤ ±1.0kHz

Set volume control

to 3.74Vrms

0.35µV

Set volume control

to 3.74Vrms

occur at < 0.25µV.

Preferred SINAD =

5-8dB

❖ See Table 7

Page 29

Table 9 Transmitter Performance Checks

Test Name System Analyzer Radio Test Set Comments

Reference

Frequency

Power RF As above As above,

Voice

Modulation

Voice

Modulation

(internal)

PL Modulation (radios

with conventional, clear

mode, coded

squelch operation only)

Mode: PWR MON 4th

channel test frequency❖

Monitor: Frequency

error. Input at RF In/Out

Mode: PWR MON 4th

channel test frequency❖

atten to –70, input to RF

In/Out.

Monitor: DVM, ac Volts.

Set 1kHz Mod Out level

for 0.025Vrms at test set,

80mVrms at ac/dc test set

jack

Mode: PWR MON 4th

channel test frequency❖

atten to –70, input to RF

In/Out

Change frequency to a

conventional transmit

frequency

TEST MODE,

4 CSQ

4 CSQ

As above,

4 CSQ

TEST MODE,

4 CSQ, output

at antenna

Conventional

coded squelch

personality

(clear mode

operation) 4

TPL

PTT to continuous

(during the

performance check).

As above Refer to Maintenance

As above, meter

selector to mic

Remove modulation

input

As above Deviation: ≥ 500Hz but ≤

Frequency error to be ≤

±1.0kHz.

Specifications page in

front of manual.

Deviation: ≥ 4.1kHz but ≤

5.0kHz

Press PTT switch on radio.

Say “four” loudly into the

radio mic. Measure

deviation: ≥ 4.1kHz but ≤

5.0kHz

1000Hz

Talkaround

Modulation

(radios with

conventional,

clear mode,

talk-around

operation

only)

Talkaround

Modulation

(radios with

conventional,

secure mode,

talkaround

operation

only)

❖ See Table 7

Change frequency to

conventional talk-around

frequency.

Mode: PWR MON

deviation, attenuation to

–70, input to RF In/Out.

Monitor: DVM, ac volts

Set 1kHz Mod Out level

for 25mVrms at test set.

Change frequency to

conventional talk-around

frequency.

Mode: PWR MON

deviation, attenuation to

–70, input to RF In/Out.

Monitor: DVM, ac volts

Mod: 1kHz out level

for25mVrms at test set.

Conventional

talkaround

personality

(clear mode

operation)

1 CSQ

Conventional

talkaround

personality

(secure mode

operation)

1 SEC. Load

key into

radio.

As above Deviation: ≥ 4.1kHz but ≤

5.0kHz

As above Deviation: ≥ 3.7kHz but ≤

4.3kHz

Page 30

Notes

Page 31

Radio Alignment

Procedures 5

Introduction

to This Section

This section describes both receiver and transmitter radio alignment

procedures.

General A personal computer (PC) and radio service software (RSS) are required to align

the radio. Refer to the applicable RSS manual for installation and setup

procedures for the software. To perform the alignment procedures, the radio

must be connected to the PC, radio interface box (RIB), and a universal test set

as shown in Figure 1.

SYSTEM ANALYZER

OR COUNTER

WATTMETER

TX

AUDIO GENERATOR

RX

SINAD METER

AC VOLTMETER

BATTERY

ELIMINATOR

REX-4424

RTL-4224A

RADIO

SMA-BNC

58-80348B33

PROGRAM/TEST CABLE

RKN-4035_

RKN-4046A

BNC

TEST SET

TEST SET

RLN-4460_ or

RTX-4005B

RTX-4005_

30 dB PAD

TRANSMIT

30 dB PAD

RF GENERATOR

RECEIVE

SET TO APPROX. 450mV FOR Tx

AUDIO IN

MEASURE 80mV FOR Tx

COMPUTER

RIB

RIB

RLN-1015_ or

RLN-4008B

RLN-4008_

RIB POWER SUPPLY

01-80357A57 (120V)

COMPUTER INTERFACE

CABLE

30-80369B71

30-80369B71 (25 pins)

30-80369B72 (IBM "AT" ONLY)

30-80369B72 (7 pins)

DATA

BUSY

GND

Figure 1 Radio Alignment Test Setup

All service and tuning procedures are performed from the SERVICE menu,

which is selected by pressing B from the MAIN MENU. Figure 2 illustrates

how the RSS alignment SERVICE screens are organized.

Page 32

SERVICE

Do NOT switch radios in the middle of any SERVICE

procedure. Always use the EXIT key to return to the

MAIN menu screen before disconnecting the radio.

Improper exits from the SERVICE screens may leave

the radio in an improperly configured state and

result in seriously degraded radio or system

performance.

!

C a u t i o n

TRANSMITTER ALIGNMENT MENU

F2 -

B

HELPF1 -

A

REFERENCE OSCILLATOR ALIGNMENT

F2 -

B

F3 -

TRANSMIT POWER ALIGNMENT

C

F4 -

TRANSMIT DEVIATION BALANCE

D

(COMPENSATION) ALIGNMENT

F5 -

TRANSMIT DEVIATION LIMIT ALIGNMENT

E

EXIT, RETURN TO SERVICE MENUF10 -

J

F3 -

RECEIVER ALIGNMENT MENU

C

FRONT END BANDPASS FILTER ALIGNMENTF2 -

B

Figure 2 RSS Service Menu Layout

All SERVICE screens read and program the radio codeplug directly; you do

NOT have to use the RSS GET/SAVE functions to use the SERVICE menus.

The SERVICE screens introduce the concept of the “softpot,” an analog

SOFTware-controlled POTentiometer used for adjusting all transceiver

alignment controls.

Each SERVICE screen provides the capability to increase or decrease the

‘softpot’ value with the keyboard UP/DOWN arrow keys respectively. A

graphical scale is displayed indicating the minimum, maximum, and

proposed value of the softpot, as shown in Figure 3.

015

Min.

Value

Max.

Value

Figure 3 Softpot Concept

Page 33

Adjusting the softpot value sends information to the radio to increase (or

decrease) a dc voltage in the corresponding circuit. For example, pressing the

UP arrow key at the Reference Oscillator screen instructs the radio’s

microcomputer to increase the voltage across a varactor in the reference

oscillator, which increases the frequency.

In ALL cases, the softpot value is just a relative number corresponding to a

digital-to-analog (D/A) generated voltage in the radio.

Perform the following procedures in the sequence indicated.

NOTE: Some of the following screens may vary

depending upon the radio under test and the

version of radio service software you are using.

Refer to your radio service software user’s guide.

Reference

Oscillator

Alignment

Adjustment of the reference oscillator is critical for proper radio operation.

Improper adjustment will result not only in poor operation, but also in a

misaligned radio that will interfere with other users operating on adjacent

channels. For this reason, the reference oscillator should be checked every

time the radio is serviced. The frequency counter used for this procedure must

have a stability of 0.1 ppm (or better).

1. From the SERVICE MENU, press B to select the TRANSMITTER

ALIGNMENT MENU.

2. Press B again to select the REFERENCE OSCILLATOR alignment screen.

See Figure 4.

MOTOROLA Radio Service Software Use UP/DOWN Arrows To Adjust Softpot.

XTS Model: H24SDC9PW5AN

MAIN:SERVICE:TX ALIGN:REF OSC

REFERENCE OSCILLATOR

--------------------

Frequency Current Value

--------- -------------

519.975 150 New Softpot Value.....150

Transmitter..On

0 215

MIN |----+----+----+----+----+----+----+----+----+----+----+----| MAX

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

HELP TOGGLE PROGRAM EXIT

PTT VALUE

Figure 4 Reference Oscillator Alignment Screen

3. Press F to key the radio. The screen will indicate that the radio is

transmitting.

4. Measure the transmit frequency on your service monitor.

5. Use the É/Ç arrow keys to adjust the reference oscillator softpot value.

See Table 10.

Page 34

Table 10 Reference Oscillator Alignment

Band Target

VHF or UHF ±100 Hz

6. Press F again to dekey the radio.

7. Press H to program the new softpot value.

8. Press J once to return to the TRANSMITTER ALIGNMENT MENU, or

press J twice to return to the SERVICE MENU.

Transmit

Power

Alignment

NOTES:

• All power measurements are to be made at the antenna port.

• The transmitter power setting keeps the radiated power at or below

the level specified in the exclusionary clause for low power devices

of IEEE Standard C95.1-1991.

1. From the SERVICE MENU, press B to select the TRANSMITTER

ALIGNMENT MENU.