Page 1

APPLICANT: MOTOROLA SOLUTIONS EQUIPMENT TYPE: ABZ89FC5827

109AB-5827

User Information

User Information

Tune-up and user / operational manual information are provided in the following exhibits.

EXHIBIT DESCRIPTION

D1 Tune-Up Procedure

D2 User / Operational Manual

EXHIBIT D

Page 2

APPLICANT: MOTOROLA SOLUTIONS EQUIPMENT TYPE: ABZ89FC5827

109AB-5827

User Information

Tune-Up Procedure

Aside from the 3

rd

party cavity combiners, there is no field tune-up procedure. All adjustments are software

controlled and are pre-set at the factory. Certain station operating parameters can be changed via man-machine

interface (MMI) commands, within predetermined limits. Examples include transmit / receive operating frequencies

and transmitter power level.

For information on tuning the cavity combiners, which is required only if replaced in the field, please refer to the

User / Operational Manual.

EXHIBIT D1

Page 3

APPLICANT: MOTOROLA SOLUTIONS EQUIPMENT TYPE: ABZ89FC5827

109AB-5827

User Information

Operational or User’s Manual

The manual should include instruction, installation, operator, or technical manuals with required ‘information to the

users’. This manual should include a statement that cautions the user that changes or modifications not expressly

approved by the party responsible for compliance could void the user’s authority to operate the equipment. The

manual shall include RF Hazard warning statements, if applicable.

This product is installed in restricted access locations only, thus only authorized service personnel have access to

the product. As such, a high level User’s Installation / Operating instruction manual for the product is not

published.

Content from the document “MTS LITE, MTS 2 AND MTS 4 INSTALLATION, CONFIGURATION AND

BASIC SERVICE MANUAL” (part number 6802800U74-AD, September 2014) has been included as part of this

filing package.

Due to space constraints, the full electronic version of this manual is not included in its entirety. The following

chapters have been removed from the full document as these chapters are not intended for the general ‘user’:

Chapter 3: Site Preparation

Chapter 4: Hardware Installation

Chapter 5: Interconnection and Internal Cabling

Chapter 6: Configuration and Testing

Chapter 13: MTS Troubleshooting

Upon request, published manuals will be sent to the commission and/or telecommunication certification body

(TCB). All of the descriptions, block diagrams, and schematics that are included in this filing package are current

as of the package submittal date.

EXHIBIT D2

Page 4

™

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

DIMETRA

Dimetra IP Scalable (DIPS)

Dimetra IP Compact (DIPC)/Scalable Dimetra IP (SDIP)

Dimetra IP Micro/Dimetra IP LiTE

MTS LITE, MTS 2 AND MTS

4 INSTALLATION,

CONFIGURATION AND

BASIC SERVICE MANUAL

©

2014 Motorola Solutions, Inc. All rights reserved

September 2014

*6802800U74*

6802800U74-AD

Page 5

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Page 6

Copyrights

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

The Motorola products described in this document may include copyrighted Motorola computer programs. Laws in

the United States and other countries preserve for Motorola certain exclusive rights for copyrighted computer

programs. Accordingly, any copyrighted Motorola computer programs contained in the Motorola products described

in this document may not be copied or reproduced in any manner without the express written permission of Motorola.

©

2014 Motorola Solutions, Inc. All Rights Reserved

No part of this document may be reproduced, transmitted, stored in a retrieval system, or translated into any language

or computer language, in any form or by any means, without the prior written permission of Motorola Solutions, Inc.

Furthermore, the purchase of Motorola products shall not be deemed to grant either directly or by implication,

estoppel or otherwise, any license under the copyrights, patents or patent applications of Motorola, except for the

normal non-exclusive, royalty-free license to use that arises by operation of law in the sale of a product.

Disclaimer

Please note that certain features, facilities, and capabilities described in this document may not be applicable to or

licensed for use on a particular system, or may be dependent upon the characteristics of a particular mobile subscriber

unit or configuration of certain parameters. Please refer to your Motorola contact for further information.

3 | Copyrights

Trademarks

MOTOROLA, MOTO, MOTOROLA SOLUTIONS, and the Stylized M Logo are trademarks or registered

trademarks of Motorola Trademark Holdings, LLC and are used under license. All other trademarks are the property

of their respective owners.

European Union (EU) Waste of Electrical and Electronic Equipment (WEEE)

directive

The European Union's WEEE directive requires that products sold into EU countries must have the crossed out

trash bin label on the product (or the package in some cases).

As defined by the WEEE directive, this cross-out trash bin label means that customers and end-users in EU countries

should not dispose of electronic and electrical equipment or accessories in household waste.

Customers or end-users in EU countries should contact their local equipment supplier representative or service centre

for information about the waste collection system in their country.

6802800U74-AD | September 2014 | Send Feedback

Page 7

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Page 8

5 | CMM Labeling and Disclosure Table

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

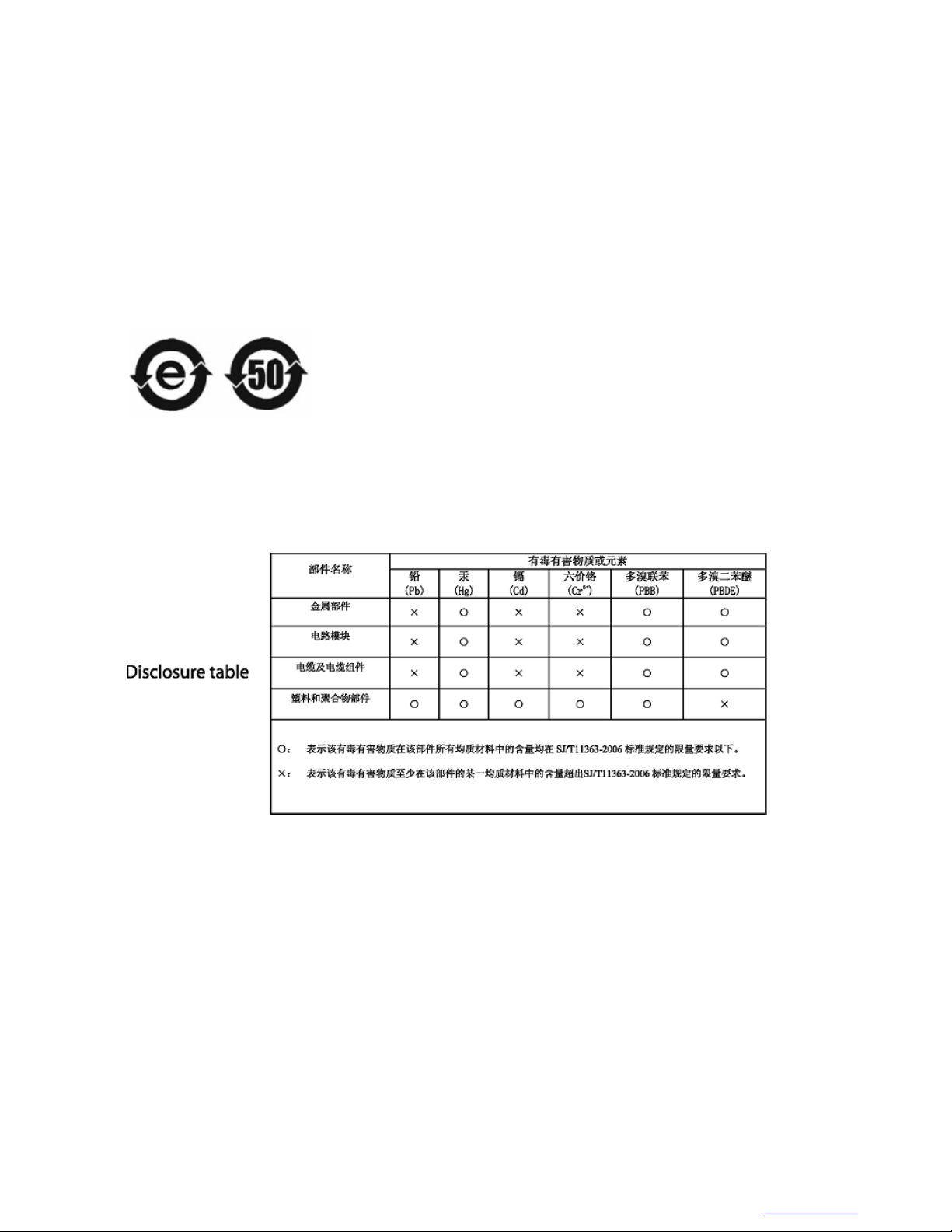

CMM Labeling and Disclosure Table

The People’s Republic of China requires that our products comply with China Management Methods (CMM)

environmental regulations. (China Management Methods refers to the Regulation Management Methods for

Controlling Pollution by Electronic Information Products.) Two items are used to demonstrate compliance; the Label

and the Disclosure Table.

The label is placed in a customer visible position on the product. The first of the following examples means that the

product contains no hazardous substances; the second means that the product contains hazardous substances, and has

an Environmental Friendly Use Period (EFUP) of fifty years.

The Environmental Friendly Use Period (EFUP) is the period (in years) during which the Toxic and Hazardous

Substances (T&HS) contained in the Electronic Information Product (EIP) will not leak or mutate causing

environmental pollution, or bodily injury from the use of the EIP.

The Disclosure Table, printed in simplified Chinese, is included with each customer order. An example of a

Disclosure Table (in Chinese) follows:

6802800U74-AD | September 2014 | Send Feedback

Page 9

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Page 10

7 | Service Information

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Service Information

Government Technical Support (GTS), EA Solutions Support Centre

The Government Technical Support (GTS), EA Solutions Support Centre provides a remote Technical Support

Service to help customers resolve technical issues and quickly restore networks and systems. This team of highly

skilled professionals is available to customers with current service agreements in place that include the Technical

Support Service. The EA GTS technical experts may be accessed through the EMEA Integrated Call Center either

electronically or using the telephone numbers listed below. If you are unsure whether your current service agreement

entitles you to benefit from this service, or if you would like more information about the Technical Support Service,

contact your local customer support or account manager for further information.

Contact Details

Email: essc@motorolasolutions.com

Table 1: List of Telephone Numbers

Country In Country Number to Dial

AUSTRIA 01206091087

DENMARK 043682114

FRANCE 0157323434

GERMANY 06950070204

ITALY 0291483230

LITHUANIA 880 030 828

NETHERLANDS 0202061404

NORWAY 24159815

PORTUGAL 0217616160

RUSSIA 810 800 228 41044

(Alternative 810 800 120 1011)

SAUDI ARABIA 800 844 5345

SOUTH AFRICA 0800981900

SPAIN 0912754787

UNITED KINGDOM 02030 277499

All Other Countries +44 2030 277499

European Systems Component Centre (ESCC)

The European Systems Component Centre provides a repair service for infrastructure equipment. Customers requiring

repair service should contact the Customer Information Desk to obtain a Return Material Authorization number. The

equipment should then be shipped to the following address unless advised otherwise.

Motorola GmbH, European Systems Component Centre, Am Borsigturm 130,13507 Berlin, Germany

Contact Details

• E-Mail: escc.admin@motorolasolutions.com

6802800U74-AD

| September 2014 |

Send Feedback

Page 11

8 | Service Information

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

• Telephone: +49 (0) 30 66861404

• Telefax: +49 (0) 30 66861426

• Monday – Friday 08:00 am to 06:00 pm (CET)

Parts Identification and Ordering

Request for help in identification of non-referenced spare parts should be directed to the Customer Care Organization

of Motorola’s local area representation. Orders for replacement parts, kits, and assemblies should be placed directly

on Motorola’s local distribution organization or through the Extranet site Motorola Online at https://

emeaonline.motorolasolutions.com.

Updated Versions of Manuals

Verify the current version of the manual at our Extranet site, Motorola Online: https://

emeaonline.motorolasolutions.com.

Your Input

Send questions and comments regarding user documentation to documentation@motorolasolutions.com

We welcome your feedback on this and other Motorola manuals. To take a short, confidential survey on Motorola

Customer Documentation, go to docsurvey.motorolasolutions.com

device to access the survey.

or scan the following QR code with your mobile

Send Feedback | September 2014 | 6802800U74-AD

Page 12

Document History

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Version Description Date

6802800U74–A Initial Edition July 2006

6802800U74–B Minor changes Aug. 2006

6802800U74–C Table 4–4 updated Aug. 2006

Table 4–5 updated and note inserted

Table 5–6 updated

6802800U74–D Service Cable and Connector Box Description section updated Oct. 2006

6802800U74–E Updates throughout the manual Feb. 2007

9 | Document History

6802800U74–F Expansion Cabinet updates throughout the manual, and addi-

tion of Expansion Options chapter.

6802800U74–G 800 MHz updates throughout the manual. Nov. 2007

6802800U74–H BTS Q108 SPU updates, including the addition of redundant

power connector on the Site Controller.

6802800U74–J

6802800U74–K

6802800U74–L

• Regulatory CE Labeling Compliance updated

• MTS 4 Outdoor Enclosure on page 403 added

• Added info about Base Radio dekey when Standby SC is

powered on.

• Added info about frequencies in receiver band that can

cause high bit error rate to occur

• Updated FRU number for RX Splitter

Updated MTS site link configuration info in Table 8–9

•

• Updated RF cabling/Connections for MTS 4 with two

TX/RX antennas and up to one additional RX antenna (Table 5–13 and Figure 5–12)

• Revision to FRU numbers for MTS fan and Hybrid

Combiner

• Other minor updates

• Updated manual with TEDS compatibility.

• Updates to the Power Supply Unit (PSU) DC Input Power.

• Other minor updates throughout the manual.

Aug. 2007

Mar. 2008

June 2008

Dec. 2008

Apr. 2009

6802800U74–M

6802800U74–N

6802800U74–P Updated the following sections: July 2010

• Ethernet Site Link Cabling hardware installation informa-

• Ethernet Site Link cabling and interconnection added.

• Configuring Ethernet Site Link added.

• Ethernet Site Link Retro-fit kit and configurations added.

• Added section MTS LVD Kit Installation to Hardware In-

June 2009

tion added.

Sep. 2009

stallation chapter.

Table continued…

6802800U74-AD | September 2014 | Send Feedback

Page 13

10 | Document History

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Version Description Date

• 260 MHz additions throughout the manual.

• Updated information on LVD Kit Installation

• Updated MTS 4 Duplexer FB diagram

Updated procedure How to configure E1 links

•

• other minor updates

6802800U74–R Added non-duplexed MTS 2 configurations Sep. 2010

6802800U74–T Added MTS LiTE Dec. 2010

6802800U74–U

6802800U74–V

6802800U74–W Updated the following:

• Added Procedure How to Upgrade the ATCC Firmware

• Updated Procedure How to Replace Site Controller Lithium

Battery

• Added section Tuning the MTCC in a BTS in Tetra Applica-

tion Mode on page 256

• Removed reference to obsolete item (surge arrestor for an

MTS4 in 450 MHz band for TX/RX and/or RX antennas)

• Added warning not to key the base station without a proper

load

• Added New part numbers for duplexer and preselector (supplied by Fingu, replaces Power Wave)

• General Defect Fixing

• MMI Commands and MTS Modes of Operation on page

203

• Table 41: RF Cabling/Connections for MTS LiTE with One

TX and One RX ant. No Diversity on page 162

• Service Cable and Connector Box Description on page 207

• Setting Base Radio IP on page 217

Station Verification Procedures on page 220

• Added Configuring the Base Radio VSWR on page 220

• Configuring the Base Radio Receiver on page 217

• XHUB Controller – Front Panel Indicators (LED) on page

282

• XHUB Controller – Front Panel Connectors on page 284

• Troubleshooting: General Check of a Site Controller File

on page 318

• Added Ethernet Site Link on page 328.

• Base Radio Alarms on page 333

• Miscellaneous Troubleshooting on page 355

• Field Replaceable Units (FRUs) on page 405

June 2011

Mar. 2012

May 2012

Restoration content moved to the respective Backup And Re-

store Including FRU/FRE manuals (for Dimetra IP Scalable

and Dimetra IP Compact systems) or Service Manual (for Dimetra IP Micro system).

6802800U74–Y

Send Feedback | September 2014 | 6802800U74-AD

Added:

Dec.2012

Table continued…

Page 14

Document History | 11

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Version Description Date

• Verifying and Tuning the Receiver RSSI Levels on page

224

Updated:

• Ethernet Site Link on page 328

• Site Controller – Front Panel Indicators (LED)

267

on page

6802800U74–AA

6802800U74–AB Updated the following:

6802800U74–AC Updated:

6802800U74–AD Added:

Added:

• Encrypted Ethernet Site Links on page 331

• Verifying Encryption Capability on page 332

Updated:

• Verifying and Tuning the Receiver RSSI Levels on page

224

• Encrypted Ethernet Site Links on page 331

• Verifying Encryption Capability on page 332

• Field Replaceable Units for MTS LiTE on page 405

• Field Replaceable Units for MTS 2 on page 407

• Field Replaceable Units for MTS 4 on page 409

• Miscellaneous Troubleshooting on page 355

• RF Cabling – MTS 4, No Diversity on page 172

• Resetting the RTC Battery Status on page 275

Updated:

Feb. 2013

Mar. 2014

July 2014

Sept. 2014

• Checking if the Site Controller Lithium Battery Needs

• Replacing the Site Controller Lithium Battery on page 276

Changing on page 276

6802800U74-AD | September 2014 | Send Feedback

Page 15

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Page 16

Contents

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Copyrights........................................................................................................................................ 3

CMM Labeling and Disclosure Table............................................................................................5

Service Information......................................................................................................................... 7

Document History............................................................................................................................9

List of Figures................................................................................................................................ 23

List of Tables.................................................................................................................................. 29

List of Processes............................................................................................................................. 33

List of Procedures.......................................................................................................................... 35

About MTS LiTE, MTS 2 and MTS 4 Installation, Configuration and Basic Service

Manual....................................................................................................................................... 37

What Is Covered In This Manual?...................................................................................................................... 37

Helpful Background Information

Related Information.............................................................................................................................................37

Icon Conventions.................................................................................................................................................38

Style Conventions................................................................................................................................................39

Regulatory CE Marking Compliance..................................................................................................................39

........................................................................................................................ 37

Contents | 13

Chapter 1: MTS Overview.................................................................................... 41

MTS Platform Description.................................................................................................................................. 41

MTS LiTE Components...................................................................................................................................... 42

MTS 2 Components............................................................................................................................................ 43

MTS 4 Components............................................................................................................................................ 45

Expansion Cabinet Components......................................................................................................................... 46

MTS Modules......................................................................................................................................................47

RF Distribution System...........................................................................................................................47

Preselector................................................................................................................................... 47

Duplexer...................................................................................................................................... 48

Post Filter.................................................................................................................................... 48

Cavity Combiners........................................................................................................................48

Hybrid Combiner.........................................................................................................................49

Rx Splitter....................................................................................................................................49

Site Controller Module............................................................................................................................49

XHUB......................................................................................................................................................49

Base Radio Module................................................................................................................................. 50

Base Radio Transceiver...............................................................................................................50

Base Radio Power Amplifier.......................................................................................................50

Power Supply Unit.................................................................................................................................. 50

Backup Battery............................................................................................................................50

Cooling Fans........................................................................................................................................... 50

Chapter 2: General Safety.....................................................................................51

General Safety Precautions................................................................................................................................. 51

Mains Safety........................................................................................................................................................52

Battery Safety......................................................................................................................................................52

Chapter 3: Site Preparation.................................................................................. 55

Page 17

14 | Contents

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Site Planning........................................................................................................................................................55

Site Survey.............................................................................................................................................. 55

Site Selection Considerations..................................................................................................................56

Cabinets Installation Considerations

MTS LiTE Cabinet Considerations.........................................................................................................56

MTS 2 Cabinet Considerations............................................................................................................... 58

MTS 4 Cabinet Considerations............................................................................................................... 59

Expansion Cabinet Considerations..........................................................................................................61

Antenna Installation Considerations................................................................................................................... 63

Network Interface Installation Considerations....................................................................................................64

MTS Installation Special Considerations............................................................................................................64

Environmental Considerations............................................................................................................................ 64

MTS Installation Electrical Requirements for MTS Site.................................................................................... 65

Applicable Codes and Practices.............................................................................................................. 65

AC and DC Power Supplies.................................................................................................................... 66

Service Current Rating................................................................................................................ 66

AC and DC Current Load............................................................................................................72

Backup Battery............................................................................................................................72

Surge Arrestors........................................................................................................................................72

Power Panel.............................................................................................................................................72

User Alarms, Control Outputs, and Door Alarm.................................................................................................73

Grounding Requirements.................................................................................................................................... 73

...................................................................................................................56

Chapter 4: Hardware Installation........................................................................ 75

Installation Overview.......................................................................................................................................... 75

Installation Personnel.............................................................................................................................. 75

Receiving the MTS Equipment............................................................................................................... 75

Installation Prerequisites..................................................................................................................................... 76

Cabinet Transportation........................................................................................................................................76

Safety Considerations..............................................................................................................................77

MTS LiTE and MTS 2 Cabinets Transportation.....................................................................................77

Moving the MTS 4 and Expansion Cabinet............................................................................................ 77

Cabinet Installation..............................................................................................................................................79

Cabinet Bracing Considerations..............................................................................................................80

Floor Mounting Instructions....................................................................................................................80

Installing the Cabinet Using the Mounting Brackets.............................................................................. 80

Installing the Cabinet Using the Mounting Plate.................................................................................... 82

Mounting Plate............................................................................................................................ 82

Installing the Mounting Plate...................................................................................................... 83

Securing Cabinet to a Mounting Plate.........................................................................................84

Wall Fixing..............................................................................................................................................85

Electrical Connections.........................................................................................................................................86

Grounding Connection............................................................................................................................ 86

Grounding the Equipment Cabinet..........................................................................................................88

Battery System Grounding.......................................................................................................... 89

Checking Grounding Connections.............................................................................................. 89

Power Supply Connections..................................................................................................................... 89

-48 VDC Input Power and Backup Battery Charging Connections............................................89

Connecting -48 VDC Power Source to the Equipment Cabinet................................................. 91

100–240 VAC Input Power Connections....................................................................................93

Connecting 100–240 VAC Power Source to Equipment Cabinet...............................................95

Backup Battery Sensor Connections........................................................................................... 96

Connecting the Backup Battery Sensor to the Equipment Cabinet.............................................97

MTS LVD Kit Installation.......................................................................................................... 98

Installing the MTS LVD Kit..................................................................................................... 100

Page 18

Contents | 15

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

RF Antenna Connections...................................................................................................................................102

Expansion Cabinet Connections........................................................................................................................106

TX Connections.....................................................................................................................................106

Connections between Site Controller and XHUB Controller...............................................................

Power Connection to the XHUB Controllers........................................................................................108

CAN Bus Cabling..................................................................................................................................109

RX Connection......................................................................................................................................109

GPS Connections...............................................................................................................................................110

GPS Site Reference Operation Modes.................................................................................................. 111

Tracking Criteria................................................................................................................................... 112

GPS Start Up......................................................................................................................................... 112

Remote GPS Antenna/Receiver Connection.........................................................................................113

Remote GPS Receiver Requirements........................................................................................114

Remote GPS Receiver Cabling................................................................................................. 114

GPS Antenna Connection......................................................................................................................116

GPS Antenna Line Loss............................................................................................................ 118

GPS Interference Avoidance................................................................................................................. 118

X.21, E1-120Ω Cabling.....................................................................................................................................118

Ethernet Site Link Cabling................................................................................................................................121

Ethernet Site Link Retrofit Kit.............................................................................................................. 122

Connecting Ethernet Site Link Retrofit Kit for MTS 2 (old JP)............................................... 123

Connecting Ethernet Site Link Retrofit Kit for MTS 2 (new JP)..............................................123

Connecting Ethernet Site Link Retrofit Kit for MTS 4.............................................................123

Connecting Ethernet Site Link Retrofit Kit for MTS 4 with Expansion Cabinet (old JP)........124

Connecting Ethernet Site Link Retrofit Kit for MTS 4 with Expansion Cabinet (new JP)...... 124

External Alarm Cabling.....................................................................................................................................124

Performing a Final Check-Out after Installation...............................................................................................127

Checking the Cabinet after Setup..........................................................................................................127

Powering Up the MTS...........................................................................................................................127

Recommended Installation Tools, Parts, and Test Equipment..........................................................................127

Recommended Installation Tools..........................................................................................................128

Recommended Test Equipment.............................................................................................................128

Recommended Parts..............................................................................................................................129

Recommended Torque.......................................................................................................................... 130

Mounting Screws...................................................................................................................................130

107

Chapter 5: Interconnection and Internal Cabling............................................ 135

AC/DC Power Cabling......................................................................................................................................135

AC/DC Power Cabling – MTS LiTE.................................................................................................... 135

AC/DC Power Cabling – MTS 2...........................................................................................................136

AC/DC Power Cabling – MTS 4...........................................................................................................137

AC/DC Power Cabling – Expansion Cabinet........................................................................................140

User Alarms/Controls, X.21, RGPS, and GPS Cabling.................................................................................... 141

User Alarms/Controls, X.21, RGPS, and GPS Cabling – MTS LiTE.................................................. 142

User Alarms/Controls, X.21, RGPS, and GPS Cabling – MTS 2.........................................................143

User Alarms/Controls, X.21, RGPS, and GPS Cabling –MTS 4..........................................................144

E1 and Ethernet Cabling....................................................................................................................................147

E1 and Ethernet Cabling – MTS LiTE..................................................................................................147

E1 and Ethernet Cabling – MTS 2........................................................................................................ 148

E1 and Ethernet Cabling – MTS 4........................................................................................................ 149

E1 and Ethernet Cabling – Expansion Cabinet..................................................................................... 151

Ethernet Site Link Cabling................................................................................................................................152

Ethernet Site Link Cabling – MTS LiTE.............................................................................................. 153

Ethernet Site Link Cabling – MTS 2.....................................................................................................153

Ethernet Site Link Cabling – MTS 4 with Single Site Controller.........................................................154

Page 19

16 | Contents

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Ethernet Site Link Cabling – MTS 4 with Dual Site Controller........................................................... 157

Ethernet Site Link Cabling – MTS 4 Expansion Cabinet with Single Site Controller......................... 159

Ethernet Site Link Cabling – MTS 4 Expansion Cabinet with Dual Site Controller............................

RF Cabling........................................................................................................................................................ 162

RF Cabling – MTS LiTE with One TX and One RX Antenna, No Diversity...................................... 162

RF Cabling – MTS LiTE with One TX/RX Antenna........................................................................... 163

RF Cabling – MTS LiTE with One TX and Two RX Antennas...........................................................164

RF Cabling – MTS 2, No Diversity...................................................................................................... 165

RF Cabling – MTS 2 with One TX Antenna.........................................................................................166

RF Cabling – MTS 2 with One TX/RX Antenna..................................................................................168

RF Cabling – MTS 2 with Two TX/RX Antennas................................................................................170

RF Cabling – MTS 4, No Diversity...................................................................................................... 172

RF Cabling – MTS 4 with One TX/RX Antenna..................................................................................174

RF Cabling – MTS 4 with Two TX/RX Antennas................................................................................176

RF Cabling – MTS 4 with One TX Antenna.........................................................................................178

RF Cabling – Expansion Cabinet with One TX/RX Antenna...............................................................180

RF Cabling – Expansion Cabinet with Two TX/RX Antennas.............................................................184

RF Cabling – Expansion Cabinet with One TX Antenna..................................................................... 187

RF Cabling – Expansion Cabinet with Two TX Antennas................................................................... 190

CAN Bus Cabling..............................................................................................................................................193

CAN Bus Cabling – MTS LiTE ...........................................................................................................193

CAN Bus Cabling – MTS 2.................................................................................................................. 193

CAN Bus Cabling – MTS 4.................................................................................................................. 195

CAN Bus Cabling – Expansion Cabinet............................................................................................... 199

160

Chapter 6: Configuration and Testing...............................................................203

Setup and Testing Overview............................................................................................................................. 203

Preparing for Configuration and Testing...........................................................................................................203

MMI Commands and MTS Modes of Operation.................................................................................. 203

Logging on to the Site Controller Application through Serial Connection...............................204

Logging on to the Base Radio Application through Serial Connection....................................204

Logging on to the BOOT1 mode...............................................................................................205

Logging on to the Test Application...........................................................................................205

Test Equipment......................................................................................................................................206

Service Cable and Connector Box Description.....................................................................................207

Setting Up Service Terminal................................................................................................................. 209

CAN Bus Configuration....................................................................................................................................209

PSU CAN Bus Commands....................................................................................................................209

Fans CAN Bus Commands................................................................................................................... 210

DPM CAN Bus Commands.................................................................................................................. 210

ATCC CAN Bus Commands................................................................................................................ 211

Other CAN Bus Commands..................................................................................................................211

Configuring and Verifying the Site Controller..................................................................................................211

Setting Up the Site Controller............................................................................................................... 212

E1 Connection Test............................................................................................................................... 212

X.21 Connection Test............................................................................................................................212

Site Reference Check............................................................................................................................ 213

Configuring and Verifying the Base Radio.......................................................................................................213

Base Radio Startup Sequence................................................................................................................213

Base Radio Position and Receivers Selection....................................................................................... 215

Setup and Access to Base Radio Position............................................................................................. 216

Setting and Accessing Base Radio Position Using Test Application........................................216

Setting and Accessing Base Radio Position Using Boot1.........................................................217

Setting Base Radio IP............................................................................................................................217

Configuring the Base Radio Receiver ..................................................................................................217

Page 20

Contents | 17

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Corrective Actions for the Base Radio Receiver Configuration............................................... 218

Configuring the pm_config....................................................................................................... 219

Configuring the Base Radio VSWR......................................................................................................220

Station Verification Procedures

Verifying the Base Radio Software Revision............................................................................220

Upgrading the Base Radio Test Application Software (Optional)............................................220

Transmitter Verification ...........................................................................................................221

Receiver Verification................................................................................................................ 223

Displaying Base Radio Alarms................................................................................................. 226

Viewing the Transmit Spectrum (Optional)..............................................................................227

Synchronizing Non-Volatile Memory (NVM) Regions........................................................................227

.............................................................................................................220

Chapter 7: Radio Frequency Distribution System............................................229

RFDS Theory of Operation............................................................................................................................... 229

CAN Bus............................................................................................................................................... 230

RFDS Frequency Band and Bandwidth................................................................................................ 230

MTS LiTE and MTS 2 RFDS........................................................................................................................... 230

MTS LiTE and MTS 2 Filter Tray........................................................................................................ 231

MTS LiTE / MTS 2 Preselector............................................................................................................ 234

Replacing the MTS LiTE / MTS 2 Preselector......................................................................... 236

MTS LiTE / MTS 2 Duplexer............................................................................................................... 237

Replacing the MTS LiTE / MTS 2 Duplexer............................................................................239

Hybrid Combiner...................................................................................................................................241

Replacing the Hybrid Combiner................................................................................................241

MTS 4 RFDS.....................................................................................................................................................242

MTS 4 Filter Tray..................................................................................................................................242

MTS 4 Preselector.................................................................................................................................244

Replacing the MTS 4 Preselector..............................................................................................246

MTS 4 Duplexer....................................................................................................................................247

Replacing the MTS 4 Duplexer.................................................................................................249

Hybrid Combiner in MTS 4.................................................................................................................. 250

Post Filter.............................................................................................................................................. 250

Replacing the Post Filter........................................................................................................... 251

Cavity Combiner................................................................................................................................... 253

Cavity Combiner - Theory of Operation................................................................................... 254

Replacing the Cavity Combiner................................................................................................ 254

Tuning the MTCC in a BTS in Tetra Application Mode.......................................................... 256

Expansion Cabinet RFDS..................................................................................................................................257

RX Splitter.............................................................................................................................................260

Replacing the Expansion Cabinet RX Splitter.......................................................................... 261

Cavity Combiner................................................................................................................................... 262

Chapter 8: Site Controller...................................................................................263

Site Controller – Theory of Operation.............................................................................................................. 264

Site Controller – Indicators, Switches, and Connectors....................................................................................265

Site Controller – Front Panel.................................................................................................................266

Site Controller – Front Panel Indicators (LED)........................................................................ 267

Site Controller – Front Panel Switches..................................................................................... 269

Site Controller – Front Panel Connectors..................................................................................270

Site Controller Rear Panel.....................................................................................................................271

Site Controller – Rear Panel Connectors...................................................................................271

Site Controller CAN Bus...................................................................................................................................271

Updating CAN Bus TrackID Mapping List.......................................................................................... 274

Site Controller – GPS Module...........................................................................................................................275

Page 21

18 | Contents

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Site Controller – Lithium Battery......................................................................................................................275

Resetting the RTC Battery Status..........................................................................................................275

Checking if the Site Controller Lithium Battery Needs Changing.......................................................

Replacing the Site Controller Lithium Battery......................................................................................276

Chapter 9: XHUB Controller..............................................................................279

XHUB Controller – Theory of Operation......................................................................................................... 280

XHUB Controller – Indicators, Switches, and Connectors...............................................................................281

XHUB Controller – Front Panel............................................................................................................282

XHUB Controller – Front Panel Indicators (LED)................................................................... 282

XHUB Controller – Front Panel Switches................................................................................ 284

XHUB Controller – Front Panel Connectors............................................................................ 284

XHUB Controller – Rear Panel.............................................................................................................284

XHUB Controller – Rear Panel Connectors..............................................................................284

Replacing the XHUB Controller....................................................................................................................... 285

XHUB Controller – FRU...................................................................................................................... 285

Chapter 10: Base Radio....................................................................................... 287

Base Radio – Overview.....................................................................................................................................287

Base Radio – Theory of Operation....................................................................................................................288

Transceiver (XCVR)............................................................................................................................. 290

Power Amplifier....................................................................................................................................290

Base Radio – Indicators and Connectors...........................................................................................................291

Replacing the Base Radio..................................................................................................................................293

Electrostatic Discharge Precaution........................................................................................................293

Restoring the Base Radio...................................................................................................................... 294

Removing the Base Radio......................................................................................................... 294

Reinstalling the Base Radio...................................................................................................... 294

276

Chapter 11: Power Supply Unit..........................................................................295

Power Supply Unit (PSU) – Theory of Operation............................................................................................ 295

PSU CAN Bus Monitoring, Alarms, and Controls............................................................................... 296

Backup Battery......................................................................................................................................297

Backup Battery Charging Procedure.........................................................................................297

Fans....................................................................................................................................................... 298

Power Supply Unit (PSU) Indicators, Switches, and Connectors.....................................................................298

PSU LED Indicators..............................................................................................................................299

PSU Switch........................................................................................................................................... 300

PSU Connectors.................................................................................................................................... 301

Replacing the Power Supply Unit (PSU).......................................................................................................... 302

Removing the Power Supply Unit (PSU)..............................................................................................302

Installing the Power Supply Unit (PSU)............................................................................................... 302

Updating the Mapping List with the New PSU TrackID...................................................................... 303

Chapter 12: Cooling Fans....................................................................................305

Cooling Fans Overview.....................................................................................................................................305

Cooling Fans Theory of Operation....................................................................................................................305

PSU Fan Control................................................................................................................................... 306

Alarms and Controls Available Through PSU CAN Bus Interface...................................................... 306

Airflow.................................................................................................................................................. 307

Cooling.................................................................................................................................................. 309

Replacing the Cooling Fans.............................................................................................................................. 309

Page 22

Contents | 19

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Chapter 13: MTS Troubleshooting.................................................................... 311

Site Controller Troubleshooting........................................................................................................................311

Site Controller Fault Indications........................................................................................................... 311

LED Fault Indications

Troubleshooting Flow Chart..................................................................................................... 315

Troubleshooting: Power............................................................................................................ 315

Troubleshooting: status sc.........................................................................................................316

Troubleshooting: SC Config File.............................................................................................. 317

Troubleshooting: status bts........................................................................................................317

Troubleshooting: BRC Config Files and Code File.................................................................. 317

Troubleshooting: General Check of a Site Controller File........................................................318

MMI Fault Indications...........................................................................................................................319

Troubleshooting: GPS and Site Reference Faults..................................................................... 319

GPS Receiver Detailed Troubleshooting.................................................................................. 321

Troubleshooting Site Link Faults..............................................................................................323

Other Site Controller Symptoms........................................................................................................... 333

Base Radio / RFDS / Miscellaneous Troubleshooting......................................................................................333

Base Radio Troubleshooting................................................................................................................. 333

Base Radio Alarms....................................................................................................................333

Recommended Test Equipment.................................................................................................350

Troubleshooting Procedures......................................................................................................351

Routine Checkout......................................................................................................................351

Reported/Suspected Problems...................................................................................................352

Base Radio Fault Indications.................................................................................................................354

Miscellaneous Troubleshooting............................................................................................................ 355

........................................................................................................................... 311

Chapter 14: Technical Specifications................................................................. 357

Environmental and Standards Specifications....................................................................................................357

Environmental Specifications................................................................................................................357

Standards Specifications........................................................................................................................358

Cabinet and Module Specifications...................................................................................................................359

MTS Cabinets Frequency Range...........................................................................................................359

Dimensions of the MTS Cabinets......................................................................................................... 359

RF Specifications.................................................................................................................................. 360

Transmitter Specifications.....................................................................................................................361

Receiver Specifications......................................................................................................................... 364

Site Controller Specifications................................................................................................................366

Internal GPS Module Input Specifications............................................................................................366

MTS LiTE / MTS 2 Duplexer Specifications....................................................................................... 366

MTS LiTE / MTS 2 Preselector Specifications.....................................................................................366

MTS 4 Duplexer Specifications............................................................................................................ 367

MTS 4 Post Filter Specifications...........................................................................................................367

MTS 4 Preselector Specifications......................................................................................................... 367

Auto Tune Cavity Combiner (ATCC) Specifications........................................................................... 368

Manual Tune Cavity Combiner (MTCC) Specifications...................................................................... 368

Hybrid Combiner Specifications...........................................................................................................368

Base Radio Specifications.....................................................................................................................369

Power Supply Unit Specifications.........................................................................................................369

XHUB Controller Specifications...........................................................................................................370

RX Splitter Specifications.....................................................................................................................370

MTS LiTE, MTS 2, and MTS 4 Connectors.........................................................................................371

Page 23

20 | Contents

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Chapter 15: Expansion Options..........................................................................373

Additional Base Radio for MTS 2.....................................................................................................................373

Cable Connections.................................................................................................................................374

Adding an Additional Base Radio to MTS 2

Installing an Additional Base Radio to MTS 2......................................................................... 378

Installing the Hybrid Combiner.................................................................................................379

Configuration.........................................................................................................................................379

Additional Module Cage for MTS 4................................................................................................................. 380

Adding an Additional Module Cage to MTS 4..................................................................................... 380

Configuration.........................................................................................................................................381

Additional Base Radio for Existing Module Cage in MTS 4............................................................................381

Cable Connections.................................................................................................................................382

Adding an Additional Base Radio to MTS 4........................................................................................ 388

Configuration.........................................................................................................................................389

Redundant Site Controller.................................................................................................................................389

Adding a Redundant Site Controller..................................................................................................... 390

Installing a Second Site Controller............................................................................................391

Configuring Redundant Site Controller................................................................................................ 392

Performing Site Controller Hardware Pre-Checks....................................................................392

Configuring Site Controller Configuration Files.......................................................................393

Configuring Ethernet Ports........................................................................................................393

Configuring Site Controller IDs................................................................................................394

Expansion from Two-Channel to Four-Channel Cavity Combiner.................................................................. 394

Cable Connections.................................................................................................................................395

Adding the Four-Channel Cavity Combiner......................................................................................... 396

Installing the Cavity Combiner into the Cabinet.......................................................................397

Configuration.........................................................................................................................................397

Hybrid Combiner Expansion.............................................................................................................................398

Installing an additional Hybrid Combiner.............................................................................................398

Configuration.........................................................................................................................................398

Expansion from MTS 2 to MTS 4 Cabinet....................................................................................................... 398

Expanding from MTS 2 to MTS 4........................................................................................................ 398

Extracting the Module Cage from MTS 2.................................................................................398

Assembling the Module Cage in the MTS 4 Cabinet................................................................400

Configuration.........................................................................................................................................401

Redundant XHUB Controller............................................................................................................................401

Adding a Redundant XHUB Controller................................................................................................ 401

Configuration.........................................................................................................................................402

........................................................................................ 377

Chapter 16: MTS 4 Outdoor Enclosure.............................................................403

Appendix A: Field Replaceable Units (FRUs).................................................... 405

Field Replaceable Units for MTS LiTE............................................................................................................ 405

Field Replaceable Units for MTS 2...................................................................................................................407

Field Replaceable Units for MTS 4...................................................................................................................409

Surge Arrestors and Suppliers...........................................................................................................................415

AC Power and E1/X.21 Interface Surge Arrestors................................................................................415

Antenna Surge Arrestors....................................................................................................................... 416

Lightning Arrestors............................................................................................................................... 416

Appendix B: Planned Maintenance Inspection (PMI).......................................417

Page 24

Contents |

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

21

Appendix C: Static Precautions and ESD Strap................................................ 419

Static Sensitive Precautions...............................................................................................................................419

ESD Wrist Strap Safety Precautions................................................................................................................. 419

Appendix D: TETRA/Dimetra Acronyms.......................................................... 423

Page 25

22 | Contents

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

Page 26

List of Figures | 23

Applicant: Motorola Solutions

Equipment Type: ABZ89FC5827 / 109AB-5827

Exhibit D2

List of Figures

Figure 1: MTS LiTE Cabinet ......................................................................................................................................... 42

Figure 2: MTS 2 Cabinet

Figure 3: MTS 4 Cabinet ................................................................................................................................................45

Figure 4: MTS Expansion Cabinet

Figure 5: MTS LiTE Cabinet Dimensions ..................................................................................................................... 57

Figure 6: Suggested MTS LiTE Site Layout ..................................................................................................................57

Figure 7: MTS 2 Cabinet Dimensions ............................................................................................................................58

Figure 8: Suggested MTS 2 Site Layout ........................................................................................................................ 59

Figure 9: MTS 4 Cabinet Dimensions ............................................................................................................................60

Figure 10: Suggested MTS 4 Site Layout ...................................................................................................................... 61

Figure 11: Expansion Cabinet Dimensions ....................................................................................................................62

Figure 12: Suggested Expansion Cabinet Site Layout ................................................................................................... 63

Figure 13: Opto-isolated Alarm Input Structure ............................................................................................................ 73

Figure 14: Lifting Point for MTS 4 and Expansion Cabinet ..........................................................................................78

Figure 15: Placing the MTS 4 and the Expansion Cabinet in the Vertical or Horizontal Position ................................79