Page 1

Simulcast Hardware Installation Equipment Inspection and Inventory

Equipment Inspection and Inventory

Motorola recommends that an inventory of all equipment is taken with a Motorola representative to ensure

that the order is complete. Carefully inspect all equipment and accessories to verify they arrived in good

condition. Promptly report any damag e d or missing i tem s to a Motor ol a repr esentative.

Placement Recommendations

The following are recommendations for placing equipment at a site:

• Secure each rack on a firm, and level floor.

• Use the correct mounting hardware to prevent rack movement.

• Use strain relief when instal lin g and positioning cables and cords to help

ensure that no interruption of service occurs.

• Allow at least 1 m (3 ft.) of space at the front and rear of the system to allow for

proper air flow, cooling, and safe access to equipment. The system components

require an ambient air temperature of 0º C to 50º C (32º to 12 2º F).

• Locate the site racks and other equipment with enough spacing to allow access f or service.

Service personnel require access to both the front and rear of the racks.

• Locate the system in an area that is free of dust, smoke, and electrostatic discharge (ESD).

• Ground the racks according to the Sta nda rds and Guidelines for

Communication Sites (68P81089E50).

Spacing Requirements

Proper spacing of equipment is essential for ready access to equipment, ease of maintenance, and safety of

personnel. Spacing requirements have been established to meet the National Fi re Protection Associations

(NFPA) Code, and the American Society of Heating, Refrigerating, and Air Conditioning Engineers

(ASHRAE) standards. Also, adhere to any local regulations that apply to spacing requirements.

See the Standards and Guidelines for Communication Sites (68P81089E50) for

details on these space requirements.

Weight Distribution Within a Rack

To avoid hazards or damage from uneven loading of a rack, distribute the weight of equipment

evenly in the rack, and consider the limitations of equipment and cables. When possible,

mount the heaviest components in the bottom of the rack.

68P81003Y71-O November 2002 2-9

Page 2

Rack Requirements Chapter 2: Installin g the Simulcast Subsystem Hardw are

Rack Requirements

Most communications equipment is installed in a standard 48.26 cm (19-in.) EIA rack

or enclosed cabinet. Refer to the manufacturer’s instructions when installing racks or

cabinets, and installing equipment into the rack or cabinet.

Use all supplied bracing hardware when installing a rack or cabinet and secure

all equipment within a rack or cabinet.

If additional equipment needs to be installed, refer to the system design document prov ided by

the Field Engineer or consult the Motorola Field Representative.

Bonding and Grounding

Cabinets and equpment racks include a rack grounding bar (RGB) with the capacity to terminate

numerous solid or stranded 6 AWG copper ground wires, which are associated with internal metallic

or fiber optic cables and external grounding to power company equipment.

You must ground all doors of a metal cabinet by bonding the door to the main cab inet

using a 6 AWG (minimum) copper wire.

The RGB is shipped with dual-hole lugs to terminate 2 AWG ground wires. The minimum

number of dual-hole attachments is system dependent and is specified by the customer. This

bar provides electrical continuity between all bonds and ground wire with a cu rrent carrying

capacity equal to or exceeding that of a 6 AWG copper wire.

See the Standards and Guidelin es for Communication Sites (68P81089E50) for more

information on proper bonding and ground at a site.

Power Requirements

The Standards and Guidelines for Communication Sites (68P81089E5 0) defines the guid elin es

and requirements for cabinets, which house equipment that requires AC power input. Som e

of the guidelines and requirements are as follows:

• The cabinet is designed to accept 120/240 V, single-phase power with an amperage

service as required by the electronic equipment.

• Cabinets serviced by commercial power must be equipped with a nationally

recognized test laboratory (NRTL) certified power distribution panel that contains

a main circuit breaker or individual circuit breakers of the correct size as required

for the electronic equipment or specified by the customer.

2-10

• A decal showing an electrical schematic of the power wiring must be affixed

to the inside surface of the cabinet.

• All AC power equipment and electrical components must conform to National

Electrical Manufacturers Association (NEMA) and National Electrical Code

(NEC).ThesemustalsobelistedbyanNRTL.

68P81003Y71-O November 2002

Page 3

Simulcast Hardware Installation Antenna Requirements

• A surge protector, designed to protect equipment systems from surges at a 120/240 V

service and load center, must be placed on the pow er feed ahead of all individual load

center circuit breakers. This protector must be listed by an NRTL for the purpose intended.

• Selection of a surge pro tecto r is based on the susceptibility of the equipment

powered by the electrical service, with margin provided for locally generated

disturbances. See ANSI/IEEE C62.41 fo r more details.

• At least one 120 VAC, 15 A duplex convenience outlet equipped with ground fault

interrupter (GFI) protection must be provided in the electronic equipment compartment.

Table 2-2 lists the required wire gauges f or various installations. The “loop length” refers to

the combined length of the -4 8 VDC (hot) lead and the DC return lead. For example, a cabinet

installation that needs 16 feet of wire to reach the power supply rack has a total loop length

of 32 feet. For a standard installation, the equipment cabinet is located adjacent to the power

supply rack with a cable loop length l ess than 10.6 m (35 ft.).

Wire used for the cabinet power connection to the breaker panel shall not be less than 6 AWG. Total

cable loop (from the power supply rack breakers to the STR 3000 cabinet) voltage drop shall not

exceed 500 mV for the cabling of the -48 VDC (hot) lead and the DC return leads.

Some sites may require larger sizes than those noted in Table 2-2 to meet local codes. When larger cable

is u sed to run from a power source, the cable shall be “tapped down” to a smaller size fo r connection

to the STR 3000 breaker panel. In accordance with local code requirements, a properly sized electrical

box mounted on top of the STR 3000 rack cabinet or commercial tap cover is the point where the cable

size transition should take place. The site planner will specify the details of the transition.

When a “tapped down” connection is used, the total voltage drop between the “tapped

down” section and the main loop should not exceed 500 mV.

The screws that connect the power cables to the power supply rack are not provided and must be

locally procured. Power supply rack breaker panel screw size is 3/8-16 x 3/4.

Table 2- 2 Power Connection Wire Gauge

Loop Length

15.3 m (50 ft.) or less

15.3to24.4m(50to80ft.)

24.4 to 36.6 m (80 to 120 ft.)

Antenna Requirements

All antenna feed line installations are to be made through a metal antenna entry plate that

is external to the site building. S e e the Standards and Guidelines for Communication Sites

(68P81089E50) for details on the requirements for antenna feed lines.

RF Antenna at the Co-Located Site

6AWG

4AWG

2AWG

Wire Gauge

Maximum Outer Diameter

of Cable

10.2 mm (0.40 in.)

10.2 mm (0.40 in.)

10.2 mm (0.40 in.)

The RF antenna provides a link between the prime and remote sites without introducing overload,

desensitivity, and intermodulation at a co-located site. You may need to install a fixed attenuator to the

antenna feed line at the site. The values for these attenuators can vary from site to site.

68P81003Y71-O November 2002 2-11

Page 4

Transmit Antenna on the STR 3000 Simulcast Base Radio Rack Chapter 2: Installin g the Simulcast Subsystem Hardw are

Transmit Antenna on the STR 3000 Simulcast Base Radio Rack

One transmit cavity combiner can support up to 12 base radios per transmit antenna. It is possible to

combine the base radios into as few as two cabinets, if they are adjacent. To increase system reliability

and eliminate a single point of failure, use a minimum of two transmit antennas per site.

GPS Requirements

A simulcast subsystem uses two Global Positioning System (GPS) anten nas to provide a certain degree

of redundan c y in case one an tenn a is damaged or inadvertently shadowing. Mount the two antennas at

least 3.05 m (10 ft.) apart with an unrestricted aerial view down to within 10˚ of the horizon in all

directions. The antennas must also be mounted high enough to clear the peak of th e site roof.

Defining the Correct View for the Location

The hemispheric location of the site also affects installation of the GPS antennas. For systems in th e

northern hemisphere, mount the antennas to maintain a clear view of the southern sky. For systems in

the southern hemisphere, mount the antennas to maintain a clear view of the northern sky.

Avoiding Obstructions

Be careful to avoid adjacent structures (such as trees and buildings), which can obstruct the GPS

antennas with their w ide and soli d profiles. Mount the antennas to clear these types of obstructions.

However, an adjacent antenna tower that protrudes into the required view at a prime or remote site does

not obstruct the view and only has a minimal effect on reception from the GPS satellite.

Isolate the GPS antennas from any RF interference by mounting the antennas at least

12˚ hor izo ntal ly from other transmitting antennas.

GPS Antenna Line Loss

The maximum allowable line attenuation between the antenna and the TRAK 9100 GPS receiver is 10 dB.

This 10 dB figure includes a 4 dB margin for attenuation from foliage. So, in an installation in which there

is interference from foliage, allow for 6 dB line loss and 4 dB foliage attenuation . Installations in which

the antenn a has an unobstructed view of the sky may have a maximum line attenuation of 10 dB.

In a typical installation using 0.5-in. low density foam coaxial cable, the length of the cable run

should never exceed 45.72 m (150 ft.). This is sufficient for m ost installations.

When considering the use of larger cables, calculate the cable len gth s allowing 4.5 dB of loss at 1.5 GHz.

The remaining 1.5 dB of attenuation is provided by interior site cabling and connectors.

For more information on installation of the GPS antenna, see "Installing the Global

Positioning Satellite Antenna" on page 3-26.

2-12

68P81003Y71-O November 2002

Page 5

Simulcast Hardware Installation Environmental Requirements

Environmental R equirements

One of t he major considerations in designing a site is how to maintain an environment in which the

equipment can operate efficiently. A properly designed heating, ventilation, and air co nditio ning (HVAC)

system provides the proper environmental conditions for the communications equipment.

Each manufacturer specifies an operating or ambient temperature for their equipment.

These t wo terms for temperature are de fined:

• Operating temperature refers to the temperature within the equipment case with

the equipment operating at a given capacity or load.

• Ambient temperature refers to the environmental temperature as typically measured

152 cm (5 ft.) above the floor in the center of an adjacent aisle.

For the specific environmental requirements for the equipment in a simulcast sub sy stem, see:

• Chapter 3,"Installing t he Prime Site (10Base-2)."

• Chapter 4,"Installin g the Prime Site (10Base-T)."

• Chapter 5,"Installing the Digital Simulcast Rem ote Site (10Base-2)."

• Chapter 6,"Installing the Digital Simulcast Remote Site (10Base-T)."

Expansion Considerations

Expansion cabinets or racks allow equipment to be added to a site. Each type of equipment has its

own specific cabinet or rack for installing additional devices. For example, install an expansion rack

to add STR 3000 Simulcast Base Radios to a site in the digital simulcast subsystem.

Each expansion cabinet or rack has its own requirements for installation. Detailed

information fo r expansions appear in "Installing the Expansion Cabinets" on page 5-10

and "Installing the Expansion Cabinets" on page 6-11.

Electrostatic Discharge

Electronic components, such as circuit boards and m em ory modules, can be extrem ely sensitive

to electrostatic disch arge (ESD). Motorola recommends that an antistatic w rist strap and a

conductive foam pa d be used when installing or upgrading the system.

If an ESD station is not available, wear an antistatic wrist strap. Wrap the strap around the wrist and

attach the ground end (usually a piece of copper foil or an alligator clip) to an electrical ground. An

electrical ground can be a piece of metal that literally runs into the ground (su c h as an unpainted

metal pipe) or the metal part of a grounded electrical appliance. An appliance is grounded if it

has a three-prong p lug and is plugged into a three-prong grounded outlet.

68P81003Y71-O November 2002 2-13

Page 6

FCC Requirements Chapter 2: In stalling the Simulcast Subsystem Hardware

Do not use a computer as a ground, because it is not plugged in during installation.

FCC Requirements

Radio frequency (RF) transmitters installed at sites within the United States must be in

compliance with the following FCC regulations:

• Only persons holding a general class commercial radio telephone operator’s license

or non-licensed persons working under the immed iate supervision of licensed

operators can make adjustments to radio transm itters.

• The power input to t he final RF stage shall not exceed the maximum power

specified on the current station authorization.

• The frequency of the transmitter must be checked during initial installation of

the transmitter, when replacing modules, or when making adjustments that affect

the carrier frequency or modulation characteristics.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection a gainst

harmful interference when the equipment is operated in a commercial en viron men t.

This equipm ent generates, uses, and can radiate radio frequency energy. If not installed properly and

used in accordance w ith the instruction manuals, the equipment may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user is required to correct the interference.

Electromagnetic Safety Requirements

2-14

This section describes information you need to know about working near electromagnetic energy.

68P81003Y71-O November 2002

Page 7

Simulcast Hardware Installation OSHA Related Safety Requirements

OSHA Related Safety Requirements

The United States Department of Labor, through the provisions of the Occupational Safety and Health

Act (OSHA ) of 1970, has established an electromagnetic energy safety standard that applies to the use

of this equipment. Proper use of this equipment will result in exposure below the OSHA limit.

Human Exposure Compliance for RF Energy

STR 3000 Simulcast Base Radios are designed to generate and radiate RF energy by means of

an external antenna. When terminated into a non-radiating RF load, the base radio equipment

is certified to comply with Federal Communications Commission (FCC) regulations pertaining

to human exposure of RF radiation in accordance with the FCC Rules P art 1 section 1.1310 as

published in title 47 code of federal regulations and procedures established in TIA/EIA TSB92, Report

on EME Evaluation for RF Cabinet E missions Under FCC MPE Guidelines.

Compliance to FCC regulations of the final installation should be assessed and take into account

site specific characteristics, such as type and location of antennas, as well as site accessibility of

occupational p erson nel (controlled environment) and general public ( unco ntrolled environment). This

equipment should only be installed and maintained by trained technicians. Licensees of the FCC

using this equipment are responsible for ensuring that its installation and operation comply with FCC

regulations Part 1 section 1.1310 as published in title 47 code of federal regulations.

Whether a given installation meets FCC limits for human exposure to radio frequency radiation

may depend not only on this equipment, but also on whether the “environments” being assessed are

being affected by radio frequency fields from other equipment, the effects of w hich may add to the

level of ex posure. Acco rd ingly, the overall exposure may be affected by radio frequency generating

facilities that exist at the time the licensee’s equipment is being installed or even by equipm ent

installed later. Therefore, the effect of any such facilities must be considered in site selection and

in determining whether a particular installation meets the FCC requirements.

FCC OET Bulletin 65 provides materials to assist in making determinations if a giv en facility is

compliant w ith the human exposure to RF radiation limits. Determining the compliance of transmitter

sites of v arious complexities may be accomplished by means of computational methods.

In general, observe the following guidelines when working in or around radio transmitter sites:

• Ensure that all p ersonnel have electromagnetic energy awareness training.

• Ensure that all personnel entering th e site are authorized.

• Obey all posted signs.

• Assume all antennas are active.

• Beforeworkingonantennas,notifyowners and disable appropriate transmitters.

• Maintain minimum of 1 m (3 ft.) clearance from all antennas.

• Do not stop in front of antennas.

• Use personal RF monitors while working near antennas.

• Never operate transmitters without shields during norm a l operation.

• Do not operate base station antennas in equipment rooms.

68P81003Y71-O November 2002 2-15

Page 8

Installing the STR 3000 Base Radio Rack Chapter 5: Installin g the Digital Simulcast Remote Site (10Base-2)

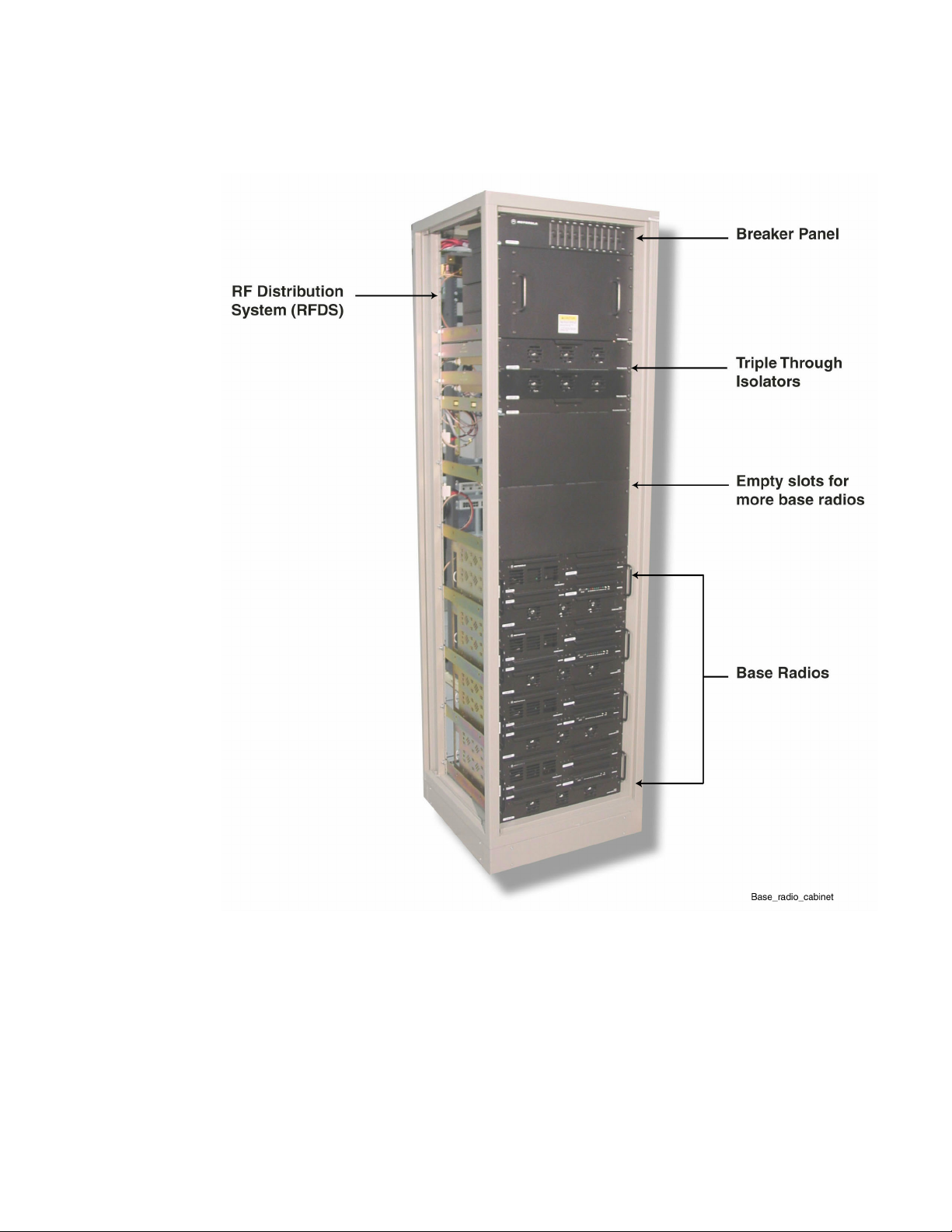

Installing the STR 3000 Base Radio Rack

The STR 3000 Base Radio rack contains the R F channels and related components for a simulcast remote site.

The cables shipped with your system were sized for a specific racking

configuration. Swapping equipment within racks or from one rack to another can

put excessive strain on cables and cause cable failures. Do not install additional

equipment or devices into the rack as this may have a negative effect on the

thermal performance of the equipment and result in reduced safety or reliability.

Overview of the STR 3000 Base Radio Rack

The STR 3000 Base Radio is the RF portion of the 800 MHz, digital-only, simulcast remote

site infrastructure. The STR 3000 rack includes from one to six base radios, multicouplers,

combiner, isolator, junction panel, circuit breaker panel, and cabling in a single rack. This rack

provides the transmit and receive capabilities for the remote site.

The STR 3000 rack forwards digital voice and control packets from the comparator to the transmitter

and forwards digital voice and control packets from the receiver to the comparator.

Figure 5-2 shows the STR 3000 Base Radio rack with four base radios.

5-4

68P81003Y71-O November 2002

Page 9

Simulcast Hardware Installation STR 3000 Rack Modules

Figure 5-2 STR 3000 Base Radio Rack with Four Base Radios

STR 3000 Rack Modules

Table 5-1 lists the hardware modules that comprise the STR 3000 rack.

68P81003Y71-O November 2002 5-5

Page 10

Base Radio Modules Chapter 5: Installing the Digital Simulcast Remote Site (10Base-2)

Table 5-1 STR 3000 Rack Modules

Module Description

Breaker panel Provides on/off control and electrical overload protection to each module within the cabinet.

Cavity combiner Acts as a band-pass filter, combines two to six transmit signals and places them on a s ingle antenna

port. The minimum channel spacing of the cavity combiner is 150 kHz.

Triple isolator Allows RF to pass from the power amplifier to the combiner and a n tenn a while redirecting any

reflected energy from the antenna system away from the power amp and into a 50 ohm load.

Receive multicoupler (RMC) Supplies a port that takes the signal from the RX antenna and distributes the appropriate

information to each base radio in its rack.

Base radio Handles the transmit and receive functions for the rack through separate modules.

The cavity combiner, triple-through isolator, and receive multicoupler comprise

the Radio Frequency Distribution System (RFDS).

Base Radio M

Table 5-2 Base Radio Modules

-48 V DC powe

Exciter Provides the transmitter and modulatio n functions for t he base radio in conjunction with

Power amplifier (PA) Provides the transmitter functi ons for the base radio in conjunction with th e exciter.

Base radi

Receiver Provides the back end receive function.

o controller

odules

The base radio consists of different modules that handle the transmit and receive functions

for the rack. Table 5-2 lists these modules.

Module Description

r supply

Figure 5-3 shows the layout for t he base radio modules.

Converts th

the power a

The PA acce

signal f or transmission via the RF output connector.

Provides

e -48 VDC input to the voltages required by the other base radio modules.

mplifier.

pts the low-level modulated RF signal from the exciter and amplifies the

signal processing and operational control for other b ase radio modules.

5-6

68P81003Y71-O November 2002

Page 11

Simulcast Hardware Installation Installing the STR 3000 Base Radio Rack

Figure 5-3 Layout of the Base Radio Modules

Installing the STR 3000 Base Radio Rack

The STR 3000 Base Radio Rack is shipped in a cabinet. To install this STR 3000 cabinet, prepare

the site and bolt the rack to the floor in t he location indicated on the site design drawings.

Placement of the Rack

Always use two or more persons and appropriate lifting equipment

whenever moving an STR 3000 rack. A fully configured rack weighs

approximately 360 kg (800 lbs). Death, serious personal injury, or

equipment damage can result if the rack tips over.

General suggestions for placing the rack are as follows:

• Secure the rack on a firm and level floor. Use the correct mounting hardware

to eliminate component movement.

• Use strain relief when installing and positioning cables and cords t o ensure

that no interruption of service occurs.

• Locate the STR 3000 cabinet where it can be serviced easily. Service people

require access to the front and the rear of the system.

• Locate the STR 3000 cabinet in an area that is free of dust, smoke, and debris.

• Maintain proper grounding and electrostatic discharge (ESD) precautions.

68P81003Y71-O November 2002 5-7

Page 12

Installing the Rack Chapter 5: Installing the Digital Simulcast Remote Site (10Base-2)

• Maintain p ro per climate and heating, ventilation, and air conditioning (HVAC) controls.

The base radio and combiner unit weight exceeds 32 kg (70 lbs) and requires

two people to lift when removing the unit from the rack. To avoid injury,

fully support a unit when it is free from the mounting rails.

Installing the Rack

Perform Procedure 5-1 to install the STR 3000 rack.

Procedure 5-1 How to Install the STR 3000 Rack

1

2

3

4 Check to ens

5

Place the rack carefully in the designated area where it will be installed at the

remote site. See the site plan for the correct location.

Bolt the rack to the floor using the correct hardware for the type of installati on.

See the Standards a nd Guidelines for Communication Sites (6 8P81089E50) for

details on a rack installation.

Verify proper grounding of the rack.

ure all of the boards are properly seated in the site controller chassis.

Boards may have loo sen ed during shipping.

Connect power connections to the STR 3000 rack.

See "Connecting Power to the STR 3000 Rack" o n page 5-9 for more information .

Connecting the STR 3000 Rack to Ground

Connect each cabinet frame to the site master ground bar using a single dedicated 2 AWG ground w ire.

The site ground wire should drop into the top of each cabinet and be connected to the designated

grounding stud located at the junction panel at the top rear of the cabinet. Single hole lugs

(1.27 cm (0.5-in.) diameter) are used for these grounding connections.

Never use a bare or damaged wire for the connection of chassis ground or other

electrical wiring to prevent damage to equipment or potential injury to personnel.

5-8

68P81003Y71-O November 2002

Page 13

Simulcast Hardware Installation Connecting Power to the STR 3000 Rack

Do NOT daisy-chain multiple equipment cabinet grounds using a single ground

wire. Doing so increases the overall inductance of the ground wire w hich can

distribute surge energy among the cabinets instead of to the master ground bar.

See Standards an d Guidelines for Communications Sites (68P81089E50) for detailed

information on grounding the rack.

Connecting Power to the STR 3000 Rack

The STR 3000 rack requires a -48 VDC, which is provided by the DC power distribution.

Figure 5-4 shows the typical connections fo r power to the STR 3000 rack.

Figure 5-4 Typical Power Connections for the STR 3000 Rack

Determining Power Connection Wire Size

Wire size recommendations contained herein reflect Motorola engineering requirements for

proper system operation. Local regulations should be adhered to and will supe rsede any

other specifications in this manual, where applicable.

Donotusewiresmallerthan16mm2CSA(5AWG).Cableloopvoltagedrop

must not exceed 500 mV for cabling of the -48 VDC and DC return leads.

68P81003Y71-O November 2002 5-9

Page 14

Installing the Expansion Cabinets Chapter 5: Installing the Digital Simulcast Remote Site (10Base-2)

For a standard installation, the equipment cabinet is located adjacent to the power supply

equipment with a cable loop length less than 10.67 m (35 ft.).

The “loop length” refers to the combined length of the -48 VDC lead and the DC return lead.

For example, a cabinet which needs 4 .87 m (16 ft.) of wire between the power supply equipment

and equipment cabinets has a total loop length of 9.75 m (32 ft.).

Table 5-3 lists the required wire sizes for various installations.

Table 5-3 Power Connections Wire Size

Loop Length

15.2m(50ft.) orless 16mm

2

CSA (5 AWG)

15.2 - 24.8 m (50 - 80 ft.) 25 mm2CSA (4 AWG)

24.8 - 36.6 m (80 - 120 ft.) 35 mm2CSA (2 AWG)

Installing the Expansion Cabinets

If an expansion cabinet is required, the expansion cabinet must be located to the right of the prime cabinet

e Figure 5-5). The two cavity combiners are connected to their respective side of the phasing harness.

(Se

The phasing harness bracket for the transmit combiner is mounted to the expansion rack. The power

monitor unit (PMU) is connected to the post filter, which is connected to the top of the phasing harness.

Wire Size

5-10

68P81003Y71-O November 2002

Page 15

Simulcast Hardware Installation Installing the Expansion Cabinets

Figure 5-5 Placement of Expansion Cabinets

68P81003Y71-O November 2002 5-11

Page 16

Cabling the STR 3000 Base Radio Rack Chapter 5: Installing the Digital Simulcast Remote Site (10Base-2)

Cabling the STR 3000 Base Radio Rack

The components of the STR 3000 Base Radio rack are shipped as one unit and do not require separate

cabling during the initial installation. For more information on how to cable each component within

the rack, see Volume 8, Field Replaceable Units and Entities (68P81004Y55).

From the rack, make the following connections to the system:

• "Connecting the Ethernet Cables" on page 5-12

• "Connecting the Transmit Cables" on page 5-13

• "Connecting the Receive Cables" on page 5-14

• "Connecting the V.24 Cabling" on page 5-16

• "Connecting Cables for a Co-Located Rem ote Site" on page 5-17

Connecting the Ethernet Cables

Table 5-4 lists the Ether net connections from the STR 3000 rack to the system.

Table 5- 4 Ether net Connections from the STR 3000 Rack

From STR 3000 Rack

Port

Ethernet Ou t port

on the junction

panel in the f

cabinet

Ethernet Out

port on the

junction panel

in succeeding

cabinets

Ethernet Ou t port

on the junc

panel in the last

cabinet

irst

tion

Connector

Typ e

BNC

BNC

BNC with 50 ohm

terminati

on

Both ends of the Ethernet cabling for a rack must be terminated.

Port1onHub

Ethernet out on

preceding panel

Terminator on

Ethernet O

Destination Device

Port

ut

Connector

Typ e

RJ45

RJ45

BNC

Description

Ethernet LAN connection

Ethernet LAN connection

LAN termination

5-12

68P81003Y71-O November 2002

Page 17

Simulcast Hardware Installation Connecting the Transmit Cables

The DLN1269A base radio controller module can be configured for both 10Base-2

and 10Base-T operation. The site m ust be all 10Base-2 or all 10Base-T. You

cannot m ix configurations within a site.

Connecting the Transmit Cables

Table 5-5 lists the transmit connections from the STR 3000 rack to the system.

For more detail on internal cabling, see Volume 8, Field Replaceable Units

and Entities (68P81004Y55).

Table 5-5 Connectio ns for the Transmit Cables

From STR 3000 Rack

Port

Transmit an

tenna

gure 5-6 s ho ws the transmit cabling layout for a six-channel STR 3000 Base Radio rack.

Fi

Connector

Type

7/16 DIN N Ty

pe

Destination

Port

Antenna

Device

Connector

Type

7/16 DIN N Ty

pe

Transmit ou

the transmit antenna.

Description

tput from the STR 3000 to

68P81003Y71-O November 2002 5-13

Page 18

Connecting the Receive Cables Chapter 5: Installing the Digital Simulcast Remote Site (10Base-2)

Figure 5-6 Transmit Cabling in the STR 3000 Rack

Connecting the Receive Cables

Table 5-6 lists the receive connections from the system into the STR 3000 rack.

5-14

68P81003Y71-O November 2002

Page 19

Simulcast Hardware Installation Connecting the Receive Cables

Table 5-6 Connections for the Receive Cables

From STR 3000 Rack

Port

Rx In (Signal IN

on figure)

Figure 5-7 shows the receive cable connections for the STR 3000 rack.

Fig

Destination Device

Connector

Type

Port

Connector

Type

Description

7/16 DIN N Type Receive antenna 7/16 DIN N Type Receives antenna input into the

STR 3000 rack

ure 5-7 Receive Cabling in the STR 3000 Rack

68P81003Y71-O November 2002 5-15

Page 20

Connecting the V.24 Cabling Chapter 5: Installing th e Digital Simulc ast Remote Site (10Base-2 )

Connecting the V.24 Cabling

Table 5-7 lists the V.24 audio connections for the STR 3000 rack.

Table 5-7 V.24 Cable Connections

From STR 3000 Rack

Port

Port PNL 1

Port PNL 2

Port PNL 3

Port PNL 4

Port PNL 5

Port PNL 6

Figure 5-8 shows the V.24 cabling layout for a six-channel STR 3000 rack.

Destination De

Connector

Typ e

Port

RJ45 (V.24) Channel Bank 1

SRU Port 1

RJ45 (V.24) Channel Bank 1,

SRU Port 2

RJ45 (V.24) Channel Bank 1,

SRU Port 3

RJ45 (V.24) Channel Bank 1,

SRU Port 4

RJ45 (V.24) Channel Bank 1,

SRU Port 5

RJ45 (V.24) Channel Bank 1,

SRU Port 6

vice

Connector

Typ e

,

RJ45 (V.24) Connection to

the prime site.

RJ45 (V.24) Connection to the prime site.

RJ45 (V.24) Connection to the prime site.

RJ45 (V.24) Connection to the prime site.

RJ45 (V.24) Connection to the prime site.

RJ45 (V.24) Connection to the prime site.

Description

5-16

68P81003Y71-O November 2002

Page 21

Simulcast Hardware Installation Connecting Cables for a Co-Located Remote Site

Figure 5-8 V.24 Cabling in the STR 3000 Rack

Connecting Cables for a C o-Located Remote Site

A co-located remote site is installed along with the prime site or very near to i t. This allows the co-located

remote site to connect directly into the prime site and use the same network structures.

Connect the cables listed in Table 5- 8 from the STR 3000 rack at a co-located remote site:

• Ethernet cables

• Transmit cables

• Receive cables

68P81003Y71-O November 2002 5-17

Page 22

Powering Up the STR 3 00 0 Base Radio Chapter 5: Installing the Digital Simulc ast Remote Site (10Base-2)

Table 5- 8 Cabling Connections from the STR 3000 Rack at a Co-Located Remote Site

From STR 3000 Rack

Port

Ethernet In port

on junction pa

in the first cabinet

Ethernet In port on

the junction panel

of succeeding

cabinets

Last cabinet BNC with 50 ohm

Top of cabinet 7/16 DIN N Type Transmit antenna 7/16 DIN N Type Transmit output from the base radio to

Top of cabi

nel

net

Connection

Typ e

BNC

BNC

termination

7/16 DIN N T

Both ends o

Port1onHub

Ethernet out on

panel

Terminator on

Ethernet Out

ype

Receive an

f the Ethernet cabling run must be terminated.

Destination Device

Port

tenna

Connectoin

BNC

BNC

BNC with 50 ohm

termination

7/16 DIN N T

Typ e

Ethernet LAN connection

Ethernet LAN connection

Ethernet LAN connection

the transmit antenna

ype

Receive an

STR 3000 rack

Description

tenna input into the

Powering

Press the ON/OFF switch on the front of the power supply to apply power to the base radio. As

the radio

Table 5-9 lists the LEDs, their correspondin g functions, and the indications provided by various blinking states.

Up the STR 3000 Base Radio

powers up, the LEDs on the front panel display the following activity:

• All LEDs initially blink.

• The SlnD LED blinks, indicating the software is initializing.

• After ab

power is on and the V.24 link is established.

out 10 seconds, the V.24 and ON LEDs stay green, indicating that the

5-18

68P81003Y71-O November 2002

Page 23

Simulcast Hardware Installation Status Priorities for Multifunction LEDs

Table 5-9 LED Status Indicators on the Base Radio

LED Name

Station

Operational

(ON)

Station Failure

(Fail)

Service/Tx Inhibit

(SVC)

Control

(CTL)

Rx Active

(Rx)

PA Full/PA Low

(PA)

Station Disable

(StnD)

V. 2 4 L i n k

(V24)

Color Solid

Green

Red FRU failure • Ext Ref Failure

Yellow N/A Service SVC Tx Inh N/A

Green

Green

Green

Red

Green

All N/A N/A N/A

Control Ch Failsoft N/A

Rx Active Illegal Rx N/A N/A

PA Active N/A N/A N/A

FLASH

V24 Link V24 Fail N/A N/A

Blinks Once per

Second

• Rx Tx Unlock

N/A N/A N/A

Blinks Twice

per Second

Config N/A

Blinks off 1/4

ISP Rx

Solid Then

Second

Status Priorities for Multifunction LEDs

Some LEDs p erform multiple functions for the base radio. Table 5-10 lists these LEDs

and the order in which status indications are handled.

Table 5- 1 0 Status Priority for Multifunction LEDs

Multifunction LED

Fail • FRU failure

• External reference failure and unlock

• Base radio operational mode

SVC

StnD

• Transmitter inhibited

• Base radio operational mode

• Software download

• PA inhibited

• Receiver inhibited

General Operating Specifications

This section provides specifications for the STR 3000 rack, base radio, RFDS,

transmitter, receiver, and receiver multicoupler.

Priority of Status

(Highest to Lowest)

68P81003Y71-O November 2002 5-19

Page 24

Operating Specifications for the Base Radio Chapter 5: Installing th e Digital Simulc ast Remote Site (10Base-2 )

Table 5-11 lists the operating specifications for an S TR 3000 rack.

Table 5-11 General Operating Specifications for the STR 3000 Rack

Specification

Number of Channels

Number of Cabinets

Cabinet Height 211 cm (83 in.) (48 RU)

Footprint ( W x D) 60 x 60 cm (24 x 24 in.)

SystemWeight 361kg(795lb)

Power Requirements -48 VDC (43-60 VDC)

Temperature Range

Power Co nsum ption Typical: 2,700 W

Antenna Connectors

erating Specifications for the Base Radio

Op

Table 5-12 lists the operating specifications for the base rad io.

1-6

1

0to50˚ C(32to+122˚ F)

Maximum: 3,200 W

Transmitter: DIN 7/16 Female

Receiver: N-Female

Value or Range

5-20

68P81003Y71-O November 2002

Page 25

Simulcast Hardware Installation Operating Specifications for the Transmitter

Table 5- 1 2 Operating Specifications for the Base Radio

Specification

Dimensions Height: 22.2 cm (8.75 in.) (5 RU)

Width: 48.3 cm (19 in.)

Depth: 41.9 cm (16.5 in.)

Weight 33 kg (73 lb)

Operating Temperature Range 0 to 50˚ C(32to+122˚ F)

Power Requirements -48 VDC (41-60 VDC)

Power Dissipation 530 W (typical)

640 W (maximum)

Heat Dissipation 2,160 Btu maximum for 1 base radio 12,240 Btu

maximum for 6 base radios

See Table 5-17 for average heat dissipation for each base

radio.

Rack Spacing • Designed for mounting in an EIA /T IA standard 19-in.

(48.26 cm) rack

• Minimum of 15.24 cm (6 in.) between the cabinet

and the wall

• With doors, minimum of 53.34 cm (21 in.) is required

to open the back door.

Value or Range

Because of weight considerations, the

installation should allow access to the rear

of the unit.

perating Specifications for the Transmitter

O

Table 5-13 lists the operating specifications for a transmitter.

68P81003Y71-O November 2002 5-21

Page 26

Simulcast Hardware Installation Installing the TRAK 9 1 00 Simu lcast Site Referen ce

Table 5- 1 8 Operating Specifications for the Tower Top Amplifier

Installing the TRAK 9100 Simulcast S ite Reference

e T RAK 9100 provides a composite 5 Mpps and 1 pps signal u sed for timing at a remo te site. This

Th

section describes how the TRAK 9100 simulcast site reference is installed at a remote site.

Overview of the TRAK 9100 Simulcast Site Reference

imulcast system uses signals fr om the Navstar Global Positioning Satellite (GP S) system to

As

synchronize the audio from multiple transmitters. A GPS receiver needs to receive the 1 pps signal

from at least four satellites before it can establish its exact geographical location.

The T RA K 9100 uses the satellite signal to derive a high-precision 1 pps signal used in the simulcast

ystem for time launching. By launching signals at exactly the same time from multiple sites, destru ctiv e

s

interference of the transmitted signals in overlap areas is minimized. In addition to controlling the

launch, the use of GPS allows for variance in delay of the distribution network (T1/E1).

The TRAK 9100 simulcast site reference provides 1 pps and 5 Mpps reference signals

or the following com ponents at a remote site:

f

• Base radios

• Remote site channel bank

Remote site hub

•

igure 5-9 shows the modules and con nections on the front view of the simulcast site reference.

F

68P81003Y71-O November 2002 5-25

Page 27

Hardware Modules in the TRAK 9100 Simulcast Site Reference Chapter 5: Installing the Digital Simulcast Remote Site (10Base-2)

Figure 5-9 Front View of the TRAK 9100 Simulcast Site Reference

Hardware Modules in the TRAK 9100 Simulcast Site Reference

Table 5-19 lists the modules that comprise the TRAK 9100 sim ulcast site reference.

Table 5-19 TRAK 9100 Simulcast Site Reference Modules

Module Description

Antenna

GPS Receiver (A1) This module contains a crystal oscillator and generates the 1 pps

GPS Receiver (A2) A second oscillator is included for redundancy. (Module A2 does

Power Supply Converts A C input to DC voltages used by all other TRAK 9100

Frequency Distribution

Module

Fault Sense Un it Detects system failures and provides control, alarm, and status

See "Installing the GPS Antenna" on page 5-27.

and 5 Mpps reference signals based on received GPS tim ing signals.

not include a front-panel cooling fan like Module A1.)

modules.

Outputs the 1 pps and 5 Mpps reference signals along with

composite signal.

information.

Installing the TRAK 9100 Simulcast Site Reference in the Rack

5-26

The TRAK 9100 simulcast site reference is installed in an EIA/TIA 19-in. (48.26 cm) rack.

68P81003Y71-O November 2002

Page 28

Simulcast Hardware Installation Grounding the Chassis

Grounding the Chassis

Connect the grou nding cable to the ground lug . The ground lug is a screw on the back of

the power supply located to the left of the AC power receptacles.

Use 6 AWG wire and the appropriate lug connected to chassis ground through to the RGB.

Wiring for Power

The two AC outlets on the rear of the panel provide power to all of the modules in the TRAK 9100.

Installing an Expansion Rack

See "Installing TRAK 9200 Simulcast Site Reference for Expansion" on page 5-31.

Installing the GPS Antenna

The GPS antenna feeds the TRAK 9100 simulcast site reference, which provides a 5 Mpps/1 pps signal (5

Mpps signal at 1 pps repetition rate) to the base radios and other com ponents at the remote site. This

signal establishes timing functions for the transmit and receive frequencies for the base radios.

Perform Procedure 5-2 to install the GPS antenna.

Procedure 5 -2 How to Install the GPS Antennas

1 Mount the GPS

the horizon in all directions.

2

3 Isolate the

4

Mount the antennas high enough to clear the peak of the site roof using the

following guidelines:

• For systems in the northern hemisphere, mount the GPS antennas so that a

clear view of the southern sky is maintained.

• For systems in the southern hemisphere, mount the GPS antennas so t hat a

clear view of the northern sky is maintained.

distance of at least 3.66 m (12 ft.) horizontally from the other antennas.

Mount the GPS antennas to clear obstructions and provide a clear path.

antenna with an unrestricted aerial down view to within 10˚ of

GPS antennas from RF interference by mounting the antennas at a

Adjacent structures (such as trees or buildings) are considered

obstructions due to their wide and solid profiles.

Adjacent antenna towers at the RF site which protrude into the

required view (but have a minimal effect on GPS satellite reception

due to their narrow, largely open profiles) are not considered

obstructions.

68P81003Y71-O November 2002 5-27

Page 29

GPS Antenna Line Loss Chapter 5: Installin g the Digital Simulcast Remote Site (10Base-2)

The simulcast system will not operate properly if the GPS receiver is not locked onto at

least four GPS satellites. The four satellites are used to establish a three-dimensional

fix (latitude, longitude, and altitude) for the site.

The TRAK 9100 will free-run for a time period defined by configuration settings. However,

after the specified period whil e still operating without the GPS satellite sig nals, the simulcast

system will not operate. The GPS antennas must be properly positioned, and the cables and

connectors m ust be properly maintained to ensure operation of the simulcast system.

If the TRA K 9100 is powered down, the simulcast system will not operate properly until

the GPS receiver has locked onto the signals from at least four GPS satellites. This

process takes approximately 13 to 25 minutes to complete.

GPS Antenna Line Loss

Cutting the cable below a recommended minimum length can

cause problems with signal strength overload. Refer to Appendix

E in the TRAK 9100 Reference book.

The maximum allowable line attenuation between the antenna and the TRAK 9100 is 6 dB . This

includes a 4 dB m argin fo r attenuation fro m foliage. Installations in which the antenna has an

unobstructed view of the sky may have a maximum line attenuation of 10 dB.

In a typical installation using 0.5-in., low density foam coaxial cab le, the length of th e cab le run

should never exceed 45.72 m (150 ft). This is sufficient for most installations.

When considering the use of larger cables, calculate the cable len gth s allowing 4.5 dB of loss at 1.5 GHz.

The remaining 1.5 dB of attenuation is provided by interior site cabling and connectors.

GPS Antenna Operating Specifications

Table 5-20 lists the operating specifications for the GPS antenna.

Table 5-20 Operating Specifications for the GPS Antenna

Specification

Physical Dimensions Diameter: 8.89 cm (3.5 in.)

Height: 10.16 cm (4.0 cm)

Value or Range

Weight 0.32 kg (0.7 lb ) (excluding mast)

Operating Temperature -40º to +85º C (-40º to 185º F)

5-28 68P81003Y71-O November 2002

Page 30

Simulcast Hardware Installation ALARM INDICATION (NO LOCK O N GPS SIG NAL )

ALARM INDICATION (NO LOCK ON GPS SIGNAL)

A system alarm indicates w hen the GPS signal cannot be located and that the

antenna may need to be repositioned.

Cabling the TRAK 9100 Simulcast Site Reference

All output signal connections interfacing to the network are made via the rear panel. The connections are:

• Two power supply (AC or DC) connectors

• Two GPS antenna N-type connectors

• An RJ45 connector for 10Base-T to distribute Coordinated Universal Time

(UTC) through Network Time Protocol (NTP)

• An RJ45 connector for Alarm (relay contacts) reporting

• A DB9 connector for Time of Day (TOD) output

• An RS232 DB9 connector for d iagn ostics (VT100)

• An IEEE-488 connector for digital distribution unit (DDU) TRAK 9200

• 24 BNC connectors for:

• 1 pps

• 5Mpps

• 1 pps + 5 Mpps composite signals, framed 1.544/2.048 Mbps TTL, and IRIG-B (or 10

MHz if desired) outp uts depending on the type of modules plugged at the front panel.

All cables are connected between the BNC T-adapters, which are mounted

to the appropriate module connector.

The cabinet is equipped with cables (index no. 2) and T-adapters for connection to six base

radios regardless of BR complement. Unu sed T-adapters are left unconnected.

Unless the cabinet is to be used with other RF cabinets, 5 MHz/1 pps OUT

connector must be terminated with a 5 0 ohm terminator.

Table 5-21 lists all of the cables from the front connection s on the TRAK 9100 simulcast site reference.

Table 5-22 lists the cables from the connections on the back of the TR AK 9100.

68P81003Y71-O November 2002 5-29

Page 31

Powering Up the TRAK 9100 Simulcast Site Reference Chapter 5: Installing the Digital Simulc ast Remote Site (10Base-2)

Table 5- 2 1 Cabling from the Front Connections on the TRAK 9100 Simulcast Site Reference

From TRAK 9100 Destination Device

Port

Connector

Typ e

Port

Connector

Typ e

Description

AC Inpu t A IEC 320

AC Inpu t B IEC 320

Ethernet IN

Ethernet IN

Table 5- 2 2 Cabling from the Rear Connections on the TRAK 9100 Simulcast Site Reference

From TRAK 9100 Destination Device

Port

10Base-T 10Base-T

RS232 I/O

Reference Output 24-pin D Digital

RJ45

RS-232

Connector

Typ e

J45)

(R

RS232 MOSCAD N FM 2

Power O ut let

Power O ut let

Port 6 on the

Remote Si te L

switch

Port 2 on the

MOSCAD NFM

Port

mote Site

Re

LANSwi Port 5

Port 2

istribution Unit

D

(DDU) (where

used)

Power AC Power

Power AC Power

RJ45

AN

RS-232

Connector

Typ e

10Base-T

J45)

(R

RS232

Path for the NTP data

Path for diagnostic information to

MOSCAD

Description

P information

NT

Diagnostic information routed to

MOSCAD

Output to DDU

Powering Up the TRAK 9100 Simulcast Site Reference

The TRAK 9100 has the following three power outputs:

• +5 VDC

• +15 VDC

• -15 VDC

All three outputs have an LED indicator that turns green after the TRAK 9100 powers

up. Figure 5-10 show s the power supply LEDs.

5-30

68P81003Y71-O November 2002

Page 32

Simulcast Hardware Installation Operating and Environmental Specifica tions

Figure 5-10 Power Supply Module with LED Indicators

Operating and Environmental Specifications

Table 5-23 lists the operating a n d environmental specifications for the TRAK 9100 simulcast site reference.

Table 5- 2 3 TRAK 9100 Operating and Environmental Specifications

Specification

Physical Dimensions Height: 13.34 cm (5.25 in.) (3U)

Width: 48.26 cm (19 in.)

Depth: 38.1 cm (15 in.)

Weight Approximately 11.34 kg (25 lb) with all modules installed

Operating Temperature –30˚ to +60˚ C(-22˚ to 140˚ F) with a rate of change <2˚

C/minute (<3.5˚ F/minute)

Power Requirements 100 to 240 VAC ± 10%, 48-63 Hz single-phase

Heat Dissipation 120 W at power-up, tapers to approxim ately 80 W within

15 minutes of power-up at 25˚ C(77˚ F)

Value or R

ange

Installing TRAK 9200 Simulcast Site Reference for Expansion

The TRAK 9200 is the optional e x pansion chassis which adds simulcast s ite reference ports.

It provides 56 ports, arranged in four rows of 14 ports each.

68P81003Y71-O November 2002 5-31

Page 33

Overview of the TRAK 9200 Simulcast Site Reference Chapter 5: Installing th e Digital Simulc ast Remote Site (10Base-2 )

Overview of the TRAK 9 200 Simulcast Site Reference

The TRAK 9200 simulcast site reference differs from the TRAK 9100 simulcast site reference with

respect to two modules: the power supply and the term ination/fault logic unit.

The power supply has only one output (5 VDC). So the indicators differ from those referen ced in "Po w ering

Up the TRAK 9100 Sim ulcast Site Reference" on page 5-30. There are only two indicators, as follows:

• Green, indicating the 5 VDC power supply is operating properly.

• Red, indicating a fault with the power supply.

The fault logic unit serves the same function as the fault sense unit in the TRAK 9 100 .

Figure 5-11 shows the rear view of the TRAK 9200.

Figure 5-11 Rear View of TRAK 9200

Cabling the TRAK 9200 Simulcast Site Reference

Table 5-24 lists the cabling for the TRAK 9200 simulcast site reference expansion.

5-32

68P81003Y71-O November 2002

Page 34

Simulcast Hardware Installation Operating Spe cifications

Operating Specifications

Table 5-30 lists the operating and environmental specifications for the r emote site hub.

Table 5- 3 0 Remote Site Hub Operating and Environmental Specifications

Specification

Physical Dimensions Height: 4.32 cm (1.7 in.) (1 RU)

Width: 44.1 cm (17.4 in.)

Depth: 17.0 cm (6.7 in.)

Weight 2.1kg(4.6lb)

Operating Temperature 0˚ to 50˚ C(32˚ to 122˚ F)

Power Requirements 85-244 VAC 50/60 Hz 1 20 W

Heat Dissipation 103 Btu/Hour

Value or Range

Installing the Simulcast Remote Site Router

e remote site router routes network managem ent traffic from a simulcast remote site to the prime site.

Th

verview of the Simulcast Remote Site Router

O

The simulcast remote site router routes network management information from the remote

ite to the prime site through the High Speed Unit (HSU) card.

s

igure 5-20 and Figu re 5-21 respectively show the fron t and rear views of the simulcast remote site router.

F

Figure 5-20 Front View of the Simulcast Remote Site Router

68P81003Y71-O November 2002 5-43

Page 35

Installing the Simulcast Remote Site Router Chapter 5: Installing the Digital Simulcast Remote Site (10Base-2)

Figure 5-21 Rear View of the Simulcast Remote Site Router

Installing the Simulcast Remote Site Router

This section describes how to install the simulcast remote site router.

Grounding the Chassis

Some network topolo gies require a grounding stud, which is separate from the AC ground

on the chassis of the networking eq uipment. If this type of grou nding is required for the

topology, perform Procedure 5-6 to connect the chassis ground.

Procedure 5-6 How to Connect a Chassis Ground

1 Term in ate o

2

3

Using a grounding screw, attach the lug to the rear of the chassis.

Terminate the other end of the wire on a permanently connected protective grounding conductor

or RGB.

ne end of a len gth of minimum 6 AWG wire with a compression lug.

Wiring for Power

Power is provided to the simulcast remote site router by connecting a power cable to

the power receptacle on the rear of the unit.

Cabling the Simulcast Remote Site Router

Table 5-31 lists the cable connections from the simulcast remote site router.

5-44

68P81003Y71-O November 2002

Page 36

Simulcast Hardware Installation Powering Up the Simulcast Remote Site Router

Table 5-31 Cable Connections from the Simulcast Remote Site Router

From Remote Site Router

1

Connector

Type

Remote Site Hub

Remote Site

Switch

AN

Channel Bank 60-pin FlexW

not used

not used

nal, Serial

Attach the p ower cable to the power receptacle.

Port

LAN 1 RJ45

LAN 2 RJ45

Serial 3 60-pin FlexW

Serial 4 60-pin FlexWAN Channel Bank 60-pin FlexWAN Ethernet connection between the hub

WAN 5 RJ 45

WAN 6 RJ 45

Console RS232/DB9 Console/Termi-

owering Up the Simulcast Remote Site Router

P

Perform Procedure 5-7 to power up the simulcast remote site router and verify that it is working.

Procedure 5-7 How to Power Up the Simulcast Remote Site Router

Destination Device

Port

Port

Connector

RJ45

RJ45

RJ45

RJ45

RS232/DB9 Communications connection between

Type

Description

Ethernet connection only for co-located

Ethernet connection between the hub

and the prime site switch

AN

Ethernet con

and the channel bank

and the channel bank

not used

not used

the router a

nection between the hub

nd a console or terminal

2

3

4

The power-up process takes a few seconds. When the process has successfully completed, the

LEDs on the fro nt panel should be on o r off, as described in Table 5-32.

Plug the power cable into the AC outlet.

Turn the power switch to the ON position.

Verify that the power LED is on.

68P81003Y71-O November 2002 5-45

Page 37

Operating Specifications Chapter 5: Installin g the Digital Simulcast Remote Site (10Base-2)

Table 5-32 LED Status at Successfu l Startup

LED

LAN

Link

Active On or blinking

Fault Off

FlexWAN SERIAL

Link

Active

Fault Off

SYSTEM

Status

Fwd Off or blink

Power/Fault

Run On

Load Off

Test

On

On

On

All off

ing

Green

Off

Status

Operating Specifications

Table 5-33 lists the oper a tin g specifications for the simulcast r emote site router.

Table 5-33 Simulcast Remote Router Operating Specifications

Specification

Physical Dimen sions Height: 4.32 cm (1.7 in.) (1 RU)

Weight 4.54 kg (10 lb)

Power Requirements

Heat Dissipation

Temperature

Relative Humidity Operating: 10% - 90% noncondensing

alue or Range

V

Width: 43.94 cm (17.3 in.)

Depth: 30.48 cm (12.0 in.)

120 W

137 Btu

Operating: 5˚ to 40˚ C(41˚ to 104˚ F)

Non-Operating: -40˚ to 75˚ C(-40˚ to 167˚ F)

Non-Operating: 10% - 90% noncondensing

5-46 68P81003Y71-O November 2002

Loading...

Loading...