Page 1

APPLICANT: MOTOROLA INC. EQUIPMENT TYPE: ABZ89FC5772-A

INSTRUCTION MANUALS

Due to the highly specialized application of this radio equipment, there is no ‘operational’ or ‘user’ manual.

The instruction and service manual for this base radio are available on a compact disk (CD). The title of this CD is

‘EBTS and integrated Site Controller, SYSTEM MANUALS’, the part number is 98P80800A17-0 (5/1/2002-UP).

Pertinent sections of the manual have been extracted and are included as part of this filing package in the form of

an electronic pdf document.

Upon request, published and/or printed manuals will be sent to the commission and/or telecommunication

certification body (TCB). All of the descriptions and schematics included in this filing package are current as of the

submission date.

EXHIBIT 8

Page 2

APPLICANT: MOTOROLA INC. EQUIPMENT TYPE: ABZ89FC5772-A

TUNE-UP PROCEDURE

There is no field tune-up procedure. All adjustments are software controlled and are pre-set at the factory. Certain

station operating parameters can be changed via man-machine interface (MMI) commands, within predetermined

limits. Examples include transmit / receiver operating frequencies and power level.

EXHIBIT 9

Page 3

Global Telecom Solutions Sector

ENHANCED BASE TRANSCEIVER SYSTEM (EBTS)

SYSTEM INSTALLATION AND TESTING

VOLUME 1 OF 3

© 2002 Motorola, Inc.

All Rights Reserved

Printed in U.S.A.

68P80801E35-B

ECCN 5E992

Page 4

FCC INTERFERENCE WARNING

The FCC requires that manuals pertaining to Class A computing devices must contain warnings about possible interference with local residential radio and TV reception. This

warning reads as follows:

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference when the equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

INDUSTRY OF CANADA NOTICE OF COMPLIANCE

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

COMMERCIAL WARRANTY (STANDARD)

Motorola radio communications products (the “Product”) is warranted to be free from defects in material and workmanship for a period of ONE (1) YEAR (except for crystals and

channel elements which are warranted for a period of ten (10 years) from the date of shipment. Parts including crystals and channel elements, will be replaced free of charge for

the full warranty period but the labor to replace defective parts will only be provided for One Hundred-Twenty (120) days from the date of shipment. Thereafter purchaser must

pay for the labor involved in repairing the Product or replacing the parts at the prevailing rates together with any transportation charges to or from the place where warranty

service is provided. This express warranty is extended by Motorola, 1301 E. Algonquin Road, Schaumburg, Illinois 60196 to the original end use purchaser only, and only to

those purchasing for purpose of leasing or solely for commercial, industrial, or governmental use.

THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED WHICH ARE SPECIFICALLY EXCLUDED, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL MOTOROLA BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES TO

THE FULL EXTENT SUCH MAY BE DISCLAIMED BY LAW.

In the event of a defect, malfunction or failure to conform to specifications established by Motorola, or if appropriate to specifications accepted by Motorola in writing, during the

period shown, Motorola, at its option, will either repair or replace the product or refund the purchase price thereof. Repair at Motorola's option, may include the replacement of

parts or boards with functionally equivalent reconditioned or new parts or boards. Replaced parts or boards are warranted for the balance of the original applicable warranty

period. All replaced parts or product shall become the property of Motorola.

This express commercial warranty is extended by Motorola to the original end user purchaser or lessee only and is not assignable or transferable to any other party. This is the

complete warranty for the Product manufactured by Motorola. Motorola assume no obligations or liability for additions or modifications to this warranty unless made in writing and

signed by an officer of Motorola. Unless made in a separate agreement between Motorola and the original end user purchaser, Motorola does not warrant the installation,

maintenance or service of the Products.

Motorola cannot be responsible in any way for any ancillary equipment not furnished by Motorola which is attached to or used in connection with the Product, or for operation of

the Product with any ancillary equipment, and all such equipment is expressly excluded from this warranty. Because each system which may use Product is unique, Motorola

disclaims liability for range, coverage, or operation of the system as a whole under this warranty.

This warranty does not cover:

a) Defects or damage resulting from use of the Product in other than its normal and customary manner.

b) Defects or damage from misuse, accident, water or neglect

c) Defects or damage from improper testing, operation, maintenance installation, alteration, modification, or adjusting.

d) Breakage or damage to antennas unless caused directly by defects in material workmanship.

e) A Product subjected to unauthorized Product modifications, disassemblies or repairs (including without limitation, the addition to the Product of non-Motorola supplied

equipment) which adversely affect performance of the Product or interfere with Motorola's normal warranty inspection and testing of the Product to verify any warranty claim.

f) Product which has had the serial number removed or made illegible.

g) A Product which, due to illegal to unauthorized alteration of the software/firmware in the Product, does not function in accordance with Motorola's published specifications or

the FCC type acceptance labeling in effect for the Product at the time the Product was initially distributed from Motorola.

This warranty sets forth the full extent of Motorola's responsibilities regarding the Product. Repair, replacement or refund of the purchase date, at Motorola’s option is the

exclusive remedy. IN NO EVENT SHALL MOTOROLA BE LIABLE FOR DAMAGES IN EXCESS OF THE PURCHASE PRICE OF THE PRODUCT, FOR ANY LOSS OF USE,

LOSS OR TIME, INCONVENIENCE, COMMERCIAL LOSS, LOST PROFITS OR SAVINGS OR OTHER INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGE ARISING

OUT OF THE USE OR INABILITY TO USE SUCH PRODUCT, TO THE FULL EXTENT SUCH MAY BE DISCLAIMED BY LAW.

SOFTWARE NOTICE/WARRANTY

Laws in the United States and other countries preserve for Motorola certain exclusive rights for copyrighted Motorola software such as the exclusive rights to reproduce in copies

and distribute copies of such Motorola software. Motorola software may be used in only the Product in which the software was originally embodied and such software in such

Product may not be replaced, copied, distributed, modified in any way, or used to produce any derivative thereof. No other use including without limitation alteration, modification,

reproduction, distribution, or reverse engineering of such Motorola software or exercise of rights in such Motorola software is permitted. No license is granted by implication,

estoppel or otherwise under Motorola patent rights or copyrights.

This warranty extends only to individual products: batteries are excluded, but carry their own separate limited warranty.

In order to obtain performance of this warranty, purchaser must contact its Motorola salesperson or Motorola at the address first above shown, attention Quality Assurance

Department.

This warranty applies only within the fifty (50) United States and the District of Columbia.

Page 5

About This Volume

2 System Installation

and Testing

Volume 1 of the Enhanced Base Transceiver System (EBTS) manual, System

Installation and Testing, provides the experienced service technician with an

overview of the EBTS operation and functions, and contains information on

installing and testing the 800 MHz, 900 MHz, and 1.5 GHz EBTSs and the

Multi-Sector Expansion Rack (MSER).

The EBTS has three major components:

❐ Generation 3 Site Controller (Gen 3 SC) or integrated Site Controller (iSC)

❐ Base Radios (BRs)

❐ RF Distribution System (RFDS)

The BRs are described in Volume 2, Base Radios, and RFDS are described in

Volume 3, RF Distribution Systems (RFDS). Detailed information about the Gen 3

SC is contained in the Gen 3 SC Supplement Manual, 68P880801E30 or iSC

Supplement Manual 68P1098E05 (this manual is incomplete without the Gen 3 SC

or iSC Supplement.)

The information in this manual is current as of the printing date. If changes to this

manual occur after the printing date, they will be documented and issued as

Schaumburg Manual Revisions (SMRs).

Target Audience

The target audience of this document includes field service technicians

responsible for installing, maintaining, and troubleshooting the EBTS.

In keeping with Motorola’s field replaceable unit (FRU) philosophy, this manual

provides sufficient functional information to the FRU level. Please refer to the

appropriate section of this manual for removal and replacement instructions.

Global Telecommunications Solutions

68P80801E35-A 5/1/2002 1

1301 E. Algonquin Road, Schaumburg, IL 60196

Page 6

System Installation and Testing EBTS System Manual - Vol 1

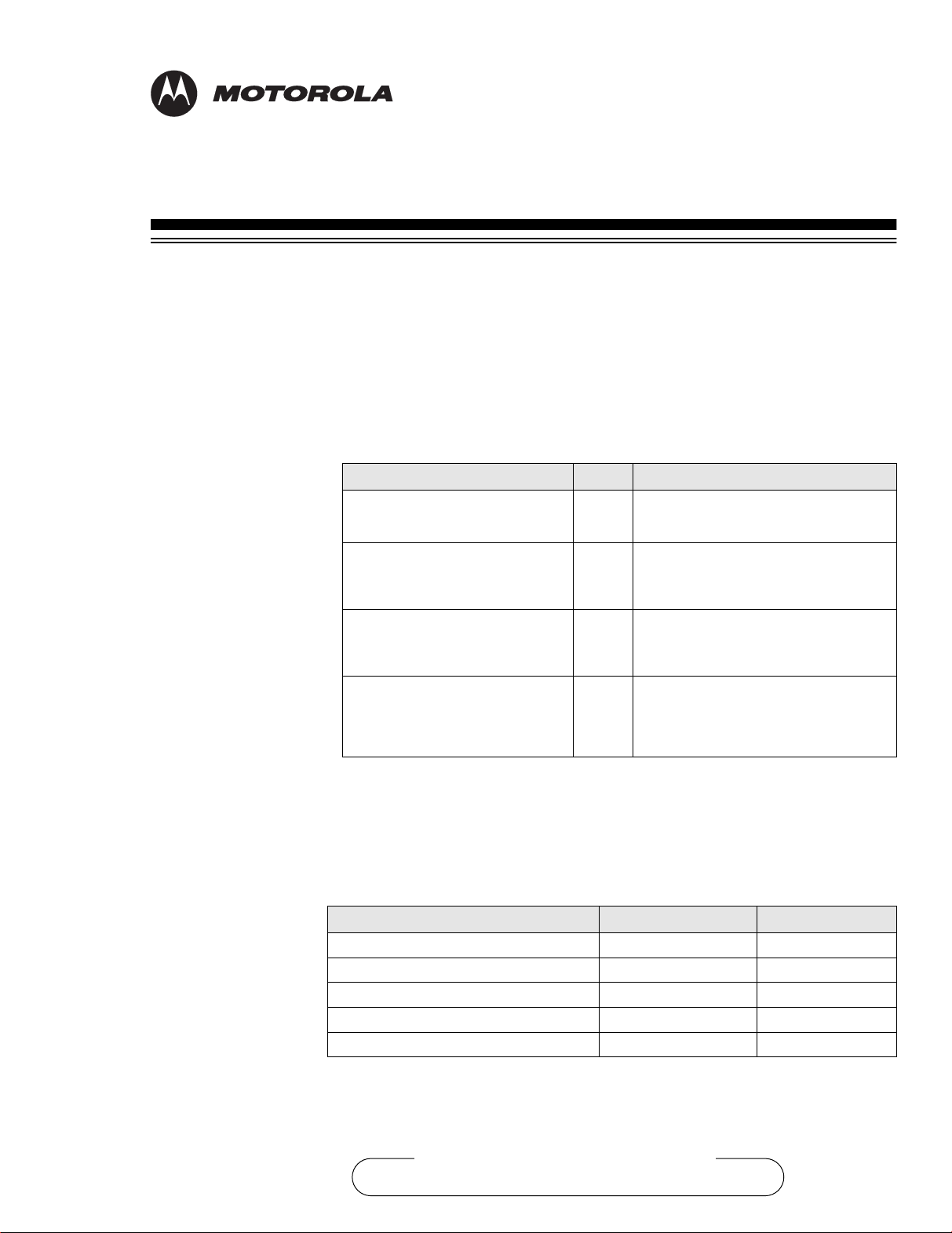

Reference Materials (MSER)

Reference Materials (MSER)

In addition to this manual, the following technical manuals are related to the

MSER and may be needed for installation or maintenance.

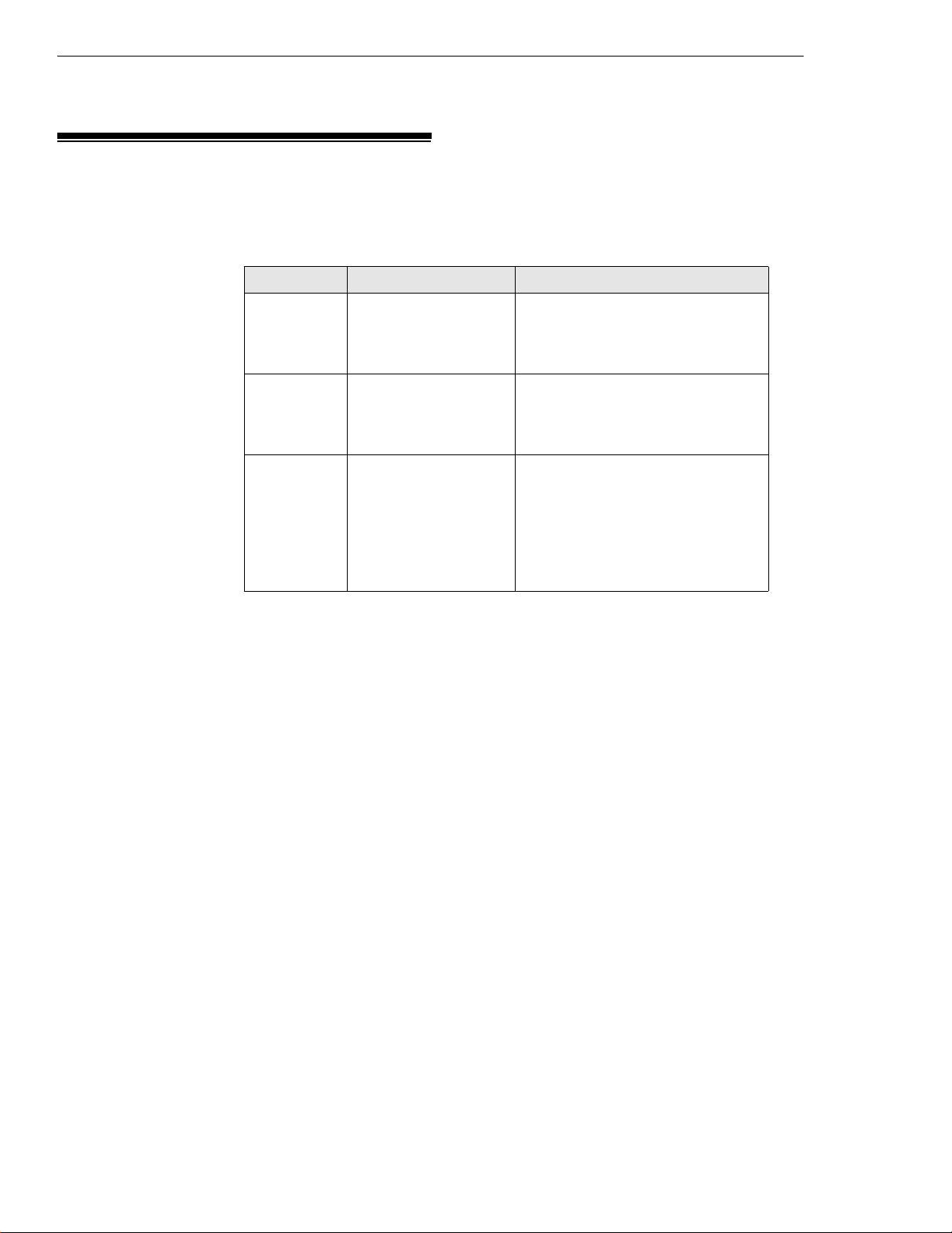

Publication Title Description

68P80801E30 Generation 3 Site

Controller (Gen 3 SC) System Manual

68P81098E05 Integrated Site Controller

(iSC) System Manual

68P81089E50 Motorola Standards and

Guidelines for

Communications Sites

Provides detailed information about the

Gen 3 SC including a description of major

subsystems, components, installation,

testing, troubleshooting, and other

information

Provides detailed information about the

iSC including a description of major

subsystems, components, installation,

testing, troubleshooting, and other

information.

A useful reference for the installation of

fixed network equipment. This manual

provides guidelines and procedures to

ensure the quality of Motorola radio

equipment installation, integration,

optimization, and maintenance. Field

service personnel should be familiar with

the guidelines and procedures contained

in this publication.

Motorola Literature Distribution Center

To order printed copies of the publications listed above, please contact:

Motorola Literature Distribution Center

1313 E. Algonquin Road

Schaumburg, Illinois 60196

Phone: 800-442-4210

iDEN Online

This manual is available from iDEN online (http://AccessSecure.mot.com). iDEN

online is a secured web site that provides Motorola customers with critical

information about iDEN subscriber and infrastructure.

Some of the features of this web site include:

❐ Quick reference to the iDEN organization, answers to frequently asked

questions, and definitions to iDEN acronyms.

❐ Product training information; including course descriptions, prerequisites,

training planning tools, schedules, pricing, and registration information.

❐ New product announcements and marketing bulletins.

❐ System product performance and customer satisfaction.

To request an account for iDEN online, please call 847-576-9541.

2 68P80801H35-B 5/1/2002

Page 7

EBTS System Manual - Vol 1 System Installation and Testing

Reference Materials (MSER)

Maintenance Philosophy

The EBTS has been designed using a Field Replaceable Unit (FRU) maintenance

concept. To minimize system down time, faulty FRUs may be quickly and easily

replaced with replacement FRUs. This helps to restore normal system operation

quickly.

Due to the high percentage of surface mount components and multi-layer circuit

boards, field repair is discouraged. Faulty or suspect FRUs should be returned to

the Motorola Customer Support Center for further troubleshooting and repair.

Each FRU has a bar code label attached to its front panel. This label identifies a

sequential serial number for the FRU. Log this number whenever contacting the

Motorola Customer Support Center. For complete information on ordering

replacement FRUs, or instructions on how to return faulty FRUs for repair,

contact:

Nippon Motorola LTD. OR Motorola Customer Support Center

Tokyo Service Center 1311 East Algonquin Road

044-366-8860 Schaumburg, Illinois 60196

(800) 448-3245 or (847) 576-7300

Technical Support Service

Motorola provides technical support services for installation, optimization, and

maintenance of its fixed network equipment. Before calling the Motorola

Customer Support Center, please note the following information:

❐ Where the system is located

❐ The date the system was put into service

❐ A brief description of problem

❐ Any other unusual circumstances

68P80801H35-B 5/1/2002 3

Page 8

System Installation and Testing EBTS System Manual - Vol 1

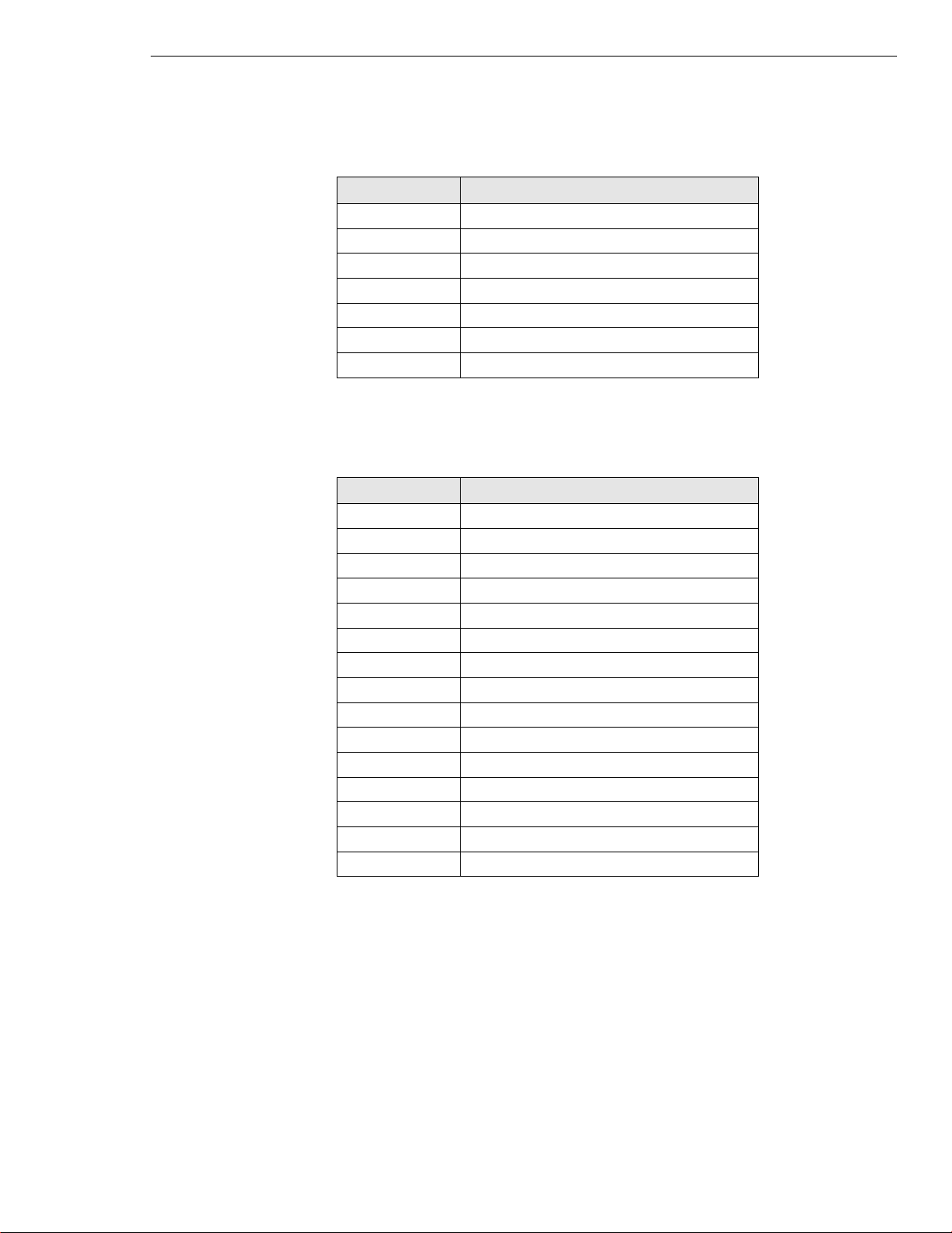

Available Field Replaceable Units

Available Field Replaceable Units

The items listed in the following tables are available as FRUs. The listings are

divided into the following FRU categories:

❐ System General – FRUs that can be used throughout any system

❐ Single Channel Base Radio- FRU used within a Single Channel Base

Radio.

❐ 800 MHz QUAD Channel Base Radio- FRU used within a QUAD

Channel Base Radio.

❐ 900 MHz QUAD Channel Base Radio- FRU used within a QUAD

Channel Base Radio.

❐ Generation 2 Base Radio- FRU used within a Generation 2 Base Radio

❐ Base Radio – FRU used within a Base Radio

❐ GEN 4 Duplexed RFDS – FRUs used within, or exclusively used with,

the following:

❍ An RF Cabinet equipped with an 800 MHz GEN 4 Duplexed RFDS

❍ An Expansion RF Cabinet utilizing GEN 4 Duplexed assemblies

❍ A Single Rack, Redundant Controller (SRRC) and/or Single Rack,

Single Controller (SRSC) EBTS and associated expansion cabinets

❐ Cavity Combining RFDS – FRUs used within, or exclusively used with,

an 800 MHz Cavity Combining RFDS

❐ 900 MHz Duplexed RFDS – FRUs used within, or exclusively used

with, an 900 MHz Duplexed RFDS

❐ 900 MHz QUAD RFDS- FRUs used within, or exclusively with, a 900

MHz QUAD RFDS

❐ Hybrid Expansion RFDS – FRUs used within a Hybrid Expansion

RFDS

❐ Site Controller Hardware – FRUs used for site control and alarm

monitoring

4 68P80801H35-B 5/1/2002

Page 9

EBTS System Manual - Vol 1 System Installation and Testing

Available Field Replaceable Units

System General FRUs

P/N Description

TLN3348 Open Rack - 43 Rack Units

TLN3349 Solid Door - 43 Rack Units

TLN3350 Door Louvered - 43 Rack Units

TLN3351 Cover Flat Top Louvered

TLN3352 Cover Base

TLN3353 Base Stationary

55-82097V01 Lock, Standard

Single Channel Base Radio FRUs

P/N Description

CLN1282 Integrated Base Radio Chassis

CLN1283 Integrated Receiver Module, 800 MHz

CLN1355 Power Amplifier, 60 Watt, 900 MHz

CLN1356 Integrated Receiver Module, 900 MHz

CLN1357 Exciter Module, 900 MHz

TLF2020 Power Amplifier, 40 Watt, 800 MHz

TLN3334 Base Radio Controller

TLN3335 Power Amplifier, 70 Watt, 800 MHz

TLN3337 Exciter Module, 800 MHz

TLN3338 DC Power Supply Module

TLN3425 Base Radio Controller (DCMA), 1500 MHz

TLN3426 Power Amplifier, 40 Watt, 1500 MHz

TLN3427 Receiver Module, 1500 MHz

TLN3428 Exciter Module, 1500 MHz

TLN3429 AC Power Supply Module (DCMA)

68P80801H35-B 5/1/2002 5

Page 10

System Installation and Testing EBTS System Manual - Vol 1

Available Field Replaceable Units

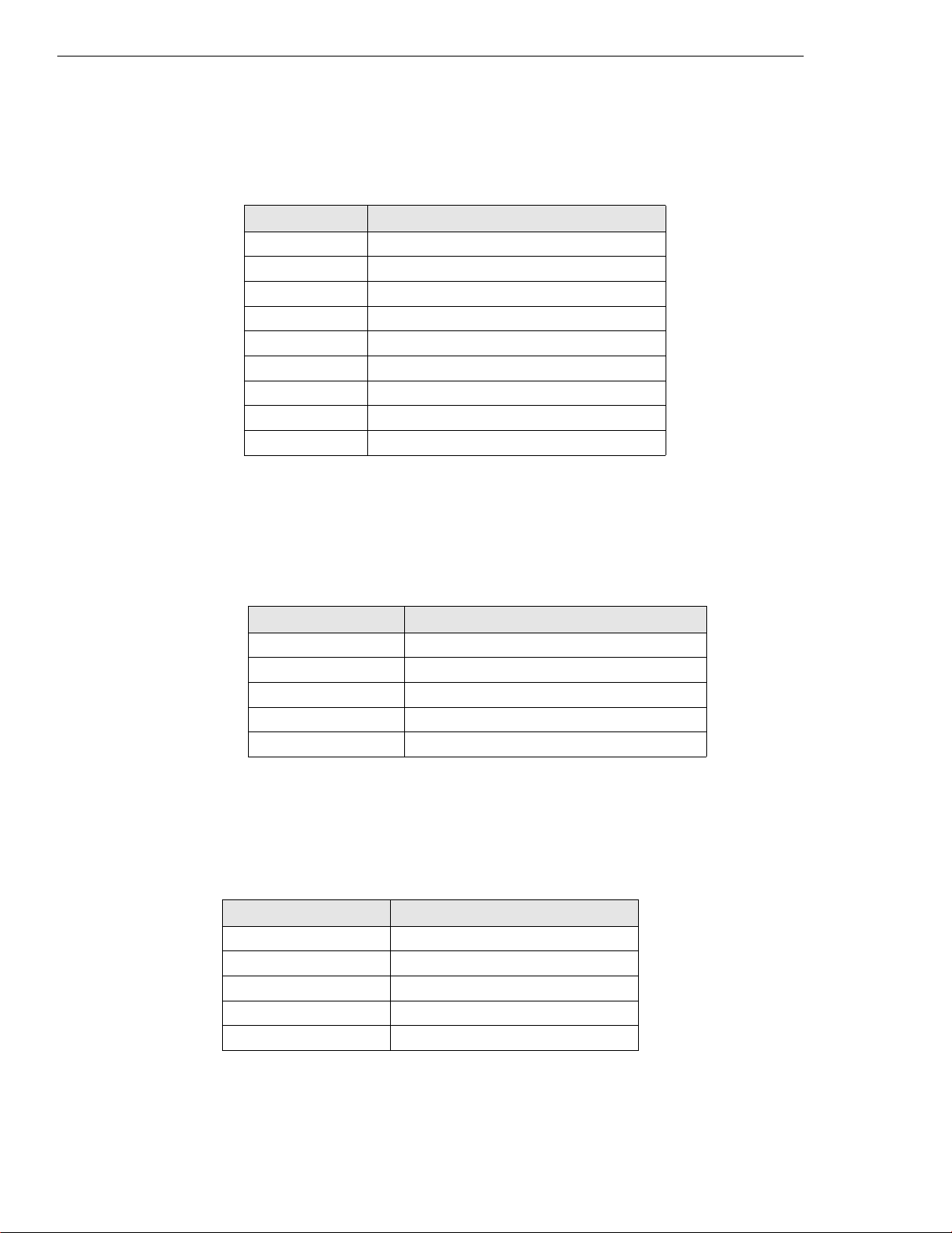

Generation 2 FRUs

P/N Description

CLN1282 Integrated Base Radio Chassis

CLN1283 Integrated Receiver Module, 800 MHz

TLF2020 Power Amplifier, 40 Watt, 800 MHz

DLN6446 Enhanced Base Radio Controller

TLN3335 Power Amplifier, 70 Watt, 800 MHz

DLN1204 Low Noise Exciter

TLN3337 Exciter Module, 800 MHz

TLN3338 DC Power Supply Module

TLN3429 AC Power Supply Module (DCMA)

800 MHz QUAD Channel Base Radio FRUs

P/N Description

CLN1496 800 MHz QUAD Receiver

CLN1497 800 MHz QUAD Exciter/Base Radio Controller

CLN1498 800 MHz QUAD DC Power Supply

CLN1499 800 MHz QUAD Power Amplifier

DLN1200 800 MHZ QUAD Base Radio Chassis

900 MHz QUAD Channel Base Radio FRUs

P/N Description

DLN1201 900 MHz QUAD Receiver

DLN1203 900 MHz QUAD Exciter/BR Controller

CLN1498 900 MHz QUAD DC Power Supply

DLN1202 900 MHz QUAD Power Amplifier

DLN1200 900 MHz QUAD Base Radio Chassis

6 68P80801H35-B 5/1/2002

Page 11

EBTS System Manual - Vol 1 System Installation and Testing

Available Field Replaceable Units

GEN 4 Duplexed RFDS FRUs

800 MHz QUAD

P/N

CLN1349 Power Supply

CLN1350 Triple 2-Way Combiner Deck w/o Isolators

CLN1351

(NOTE 1)

CLN1353 Dual 3-Way Combiner Deck w/ Isolators

CLN1362 4-Way Rx Low Noise Amplifier/

CLN1363 6-Way Rx Low Noise Amplifier/

CLN1366A Triple Through w/Isolators

CLN1401 Alarm Board

CLN1402 I/O Board

CLN1403 Duplexed TTA Field Retrofit Kit

CLN1405 Duplexed TTA Alarm Module

CLN1481 Dual 2-Way Combiner Deck w/ Isolators

NOTES:

1. This item associated with expansion.

Triple 2-Way Combiner Deck w/o Isolators

Multicoupler Subassembly

Multicoupler Subassembly

Description 900 MHz QUAD

P/N

DLN1206

Cavity Combining RFDS FRUs

P/N Description

CKN1010 Rx Cavity Expansion Hardware: Main to Expansion Cabinet

TLF1900 Low Gain Amplifier Receiver Tray

TLF1980 Tx RF Transfer Switch for 800 MHz Cavity PCCH

TLG1002 Tx RF Transfer Switch for 1500 MHz Cavity PCCH

TLN3392 DC Low-Noise Amplifier Power Supply and Alarm Tray

TLN3393 DC Injector RF Distribution

TLN3394 Power Monitor Assembly

TTF1540 Isolator/Load Assembly

TTF1560 Cavity Combiner Channels 3 & 4

TTF1570 Cavity Combiner Channel 5

68P80801H35-B 5/1/2002 7

Page 12

System Installation and Testing EBTS System Manual - Vol 1

Available Field Replaceable Units

900 MHz QUAD Duplexed RFDS FRUs

P/N Description

See Note 1 Triple 2-Way Combiner Deck w/o Isolators

CLN1382 DC & Alarm Expansion Tray

DLN1205 RX Preselector

DLN1206 Three-Branch Rx Multicoupler Tray w/ 4-Way

LNAs

See Note 1 900 MHz Duplexer

See Note 1 800/900 MHz Diplexer

NOTE: 1- Refer to iDEN Price Book for FRU details

Hybrid Expansion RFDS

P/N Description

CLN1285 Hybrid/Coupler Expansion Load Assembly

CLN1313 Duplexed Retrofit 3 Branch TTA, V03

CLN1314 Duplexed Retrofit 3 Branch TTA, V01

CLN1315 Duplexed Retrofit 3 Branch TTA, V06

CLN1325 Hybrid Expansion Receive Cabling, Primary Rack

TFF1090 Bandpass Transmit Filter

TLF1990 Primary Isolator

TLF2000 Secondary Isolator

TLN3358 Duplexed RF Expansion Tray (Non-5th Channel)

TLN3439 Duplexed RF Expansion Tray (5th Channel)

8 68P80801H35-B 5/1/2002

Page 13

EBTS System Manual - Vol 1 System Installation and Testing

Available Field Replaceable Units

Site Control Hardware

P/N Description

DLN1103 GEN 3 Site Controller

DLN1107 Environmental Alarm System

DPN1007 Gen3 SC Power Supply

68P80801H35-B 5/1/2002 9

Page 14

System Installation and Testing EBTS System Manual - Vol 1

General Safety Information

General Safety Information

The following general safety precautions must be observed during all phases of

operation, service, and repair of the equipment described in this manual. The

safety precautions listed below represent warnings of certain dangers of which

we are aware. You should follow these warnings and all other safety precautions

necessary for the safe operation of the equipment in your operating environment.

Read and follow all warning notices and instructions marked on the product or

included in this manual before installing, servicing or operating the equipment.

Retain these safety instructions for future reference. Also, all applicable safety

procedures, such as Occupational, Safety, and Health Administration (OSHA)

requirements, National Electrical Code (NEC) requirements, local code

requirements, safe working practices, and good judgement must be used by

personnel.

Refer to appropriate section of the product service manual for additional

pertinent safety information.

Because of the danger of introducing additional hazards, do not install substitute

parts or perform any unauthorized modifications of equipment.

Identify maintenance actions that require two people to perform the repair. Two

people are required when:

A repair has the risk of injury that would require on person to perform first

aid or call for emergency support. An example would be work around high

voltage sources. A second person may be required to remove power and call

for emergency aid if an accident occurs to the first person.

Use the National Institute of Occupational Safety and Health (NIOSH) listing

equation to determine whether a one or two person lift is required when a

system component must be removed and replaced in its rack.

If troubleshooting the equipment while power is applied, be aware of the live

circuits.

DO NOT operate the transmitter of any radio unless all RF connectors are secure

and all connectors are properly terminated.

All equipment must be properly grounded in accordance with Motorola Standards

and Guidelines for Communication Sites “R56” (6881089E50) and specified

installation instructions for safe operation. Slots and openings in the cabinet are

provided for ventillation. To ensure reliable operation of the product and protect

it from overheating, these slots and openings must not be blocked or covered.

Only a qualified technician familiar with similar electronic equipment should

service equipment.

Some equipment components can become extremely hot during operation. Turn

off all power to the equipment and wait until sufficiently cool before touching.

10 68P80801H35-B 5/1/2002

Page 15

EBTS System Manual - Vol 1 System Installation and Testing

General Safety Information

Human Exposure Compliance

This equipment is designed to generate and radiate radio frequency (RF) energy

by means of an external antenna. When terminated into a non-radiating RF load,

the base station equipment is certified to comply with Federal Communications

Commission (FCC) regulations pertaining to human exposure to RF radiation in

accordance with the FCC Rules Part 1 section 1.1310 as published in title 47 code

of federal regulations and procedures established in TIA/EIA TSB92, Report on

EME Evaluation for RF Cabinet Emissions Under FCC MPE Guidelines,

Compliance to FCC regulations of the final installation should be assessed and

take into account site specific characteristics such as type and location of

antennas, as well as site accessibility of occupational personnel (controlled

environment) and the general public (uncontrolled environment). This equipment

should only be installed and maintained by trained technicians. Licensees of the

FCC using this equipment are responsible for insuring that its installation and

operation comply with FCC regulations Part 1 section 1.1310 as published in title

47 code of federal regulations.

Whether a given installation meets FCC limits for human exposure to radio

frequency radiation may depend not only on this equipment but also on whether

the “environments” being assessed are being affected by radio frequency fields

from other equipment, the effects of which may add to the level of exposure.

Accordingly, the overall exposure may be affected by radio frequency generating

facilities that exist at the time the licensee’s equipment is being installed or even

by equipment installed later. Therefore, the effects of any such facilities must be

considered in site selection and in determining whether a particular installation

meets the FCC requirements.

FCC OET Bulletin 65 provides materials to assist in making determinations if a

given facility is compliant with the human exposure to RF radiation limits.

Determining the compliance of transmitter sites of various complexities may be

accomplished by means of computational methods. For more complex sites direct

measurement of power density may be more expedient. Additional information

on the topic of electromagnetic exposure is contained in the Motorola Standards and

Guidelines for Communications Sites publication. Persons responsible for

installation of this equipment are urged to consult the listed reference material to

assist in determining whether a given installation complies with the applicable

limits.

In general the following guidelines should be observed when working in or

around radio transmitter sites:

- All personnel should have electromagnetic energy awareness training.

- All personnel entering the site must be authorized.

- Obey all posted signs.

- Assume all antennas are active.

- Before working on antennas, notify owners and disable appropriate

transmitters.

- Maintain minimum 3 feet clearance from all antennas.

- Do not stop in front of antennas.

- Use personal RF monitors while working near antennas.

- Never operate transmitters without shields during normal operation.

- Do not operate base station antennas in equipment rooms.

68P80801H35-B 5/1/2002 11

Page 16

System Installation and Testing EBTS System Manual - Vol 1

General Safety Information

For installations outside of the U.S., consult with the applicable governing body

and standards for RF energy human exposure requirements and take necessary

steps for compliance with local regulations.

References:

TIA/EIA TSB92 “Report on EME Evaluation for RF Cabinet Emissions Under

FCC MPE Guidelines”, Global Engineering Documents: http://globl.ihs.com/

FCC OET Bulletin 65 “Evaluating Compliance with FCC Guidelines for Human

Exposure to Radiofrequency Electromagnetic Fields”; http://www.fcc.gov/oet/

rfsaftey/

Motorola Standards and Guidelines for Communications Sites, Motorola manual

68P81089E50

IEEE Recommended Practice for the Measure of Potentially Hazardous

Electromagnetic Fields-- RF and Microwave, IEEE Std. C95.3-1991, Publication

Sales, 445 Hoes Lane, P.O. Box 1331, Piscattaway, NJ 08855-1331

IEEE Standard for Safety Levels with Respect to Human Exposure to Radio

Frequency Electromagnetic Fields, 3 kHz to 300 Iscattaway, NY 08855-1331GHz,

IEEE C95.1-1991, Publication Sales, 445 Hoes Lane, P.O. Box 1331

12 68P80801H35-B 5/1/2002

Page 17

Global Telecom Solutions Sector

ENHANCED BASE TRANSCEIVER SYSTEM (EBTS)

VOLUME 2 OF 3

BASE RADIOS

© 2002 Motorola, Inc.

All Rights Reserved

Printed in U.S.A.

68P80801E35-B

ECCN 5E992

Page 18

About This Volume

Base Radios

Volume 2 of the Enhanced Base Transceiver System (EBTS) manual, Base Radios,

provides the experienced service technician with an overview of the EBTS

operation and functions, and contains information regarding the 800 MHz,

900 MHz, 1500 MHz Single Channel and 800 MHz and 900 MHz QUAD Channel

Channel base radios.

The EBTS System has three major components:

❐ Generation 3 Site Controller (Gen 3 SC) or an integrated Site Controller (iSC)

❐ Base Radios (BRs)

❐ RF Distribution System (RFDS)

Installation and testing is described in Volume 1, System Installation and Testing,

and RFDS are described in Volume 3, RF Distribution Systems (RFDS). Detailed

information about the Gen 3 SC is contained in the Gen 3 SC Supplement Manual,

68P80801E30. Detailed information about the iSC is contained in the iSC

Supplement Manual, 68P81098E05

The information in this manual is current as of the printing date. If changes to

this manual occur after the printing date, they will be documented and issued as

Schaumburg Manual Revisions (SMRs).

Target Audience

The target audience of this document includes field service technicians

responsible for installing, maintaining, and troubleshooting the EBTS.

In keeping with Motorola’s field replaceable unit (FRU) philosophy, this manual

provides sufficient functional information to the FRU level. Please refer to the

appropriate section of this manual for removal and replacement instructions.

Global Telecommunications Solutions Sector

68P80801E35-B 5/1/2002 1

1301 E. Algonquin Road, Schaumburg, IL 60196

Page 19

Base Radios EBTS System Manual - Vol 2

Maintenance Philosophy

The EBTS has been designed using a Field Replaceable Unit (FRU) maintenance

concept. To minimize system down time, faulty FRUs may be quickly and easily

replaced with replacement FRUs. This helps to restore normal system operation

quickly.

Due to the high percentage of surface mount components and multi-layer circuit

boards, field repair is discouraged. Faulty or suspect FRUs should be returned to

the Motorola Customer Support Center for further troubleshooting and repair.

Each FRU has a bar code label attached to its front panel. This label identifies a

sequential serial number for the FRU. Log this number whenever contacting the

Motorola Customer Support Center. For complete information on ordering

replacement FRUs, or instructions on how to return faulty FRUs for repair,

contact:

Nippon Motorola LTD. OR Motorola Customer Support Center

Tokyo Service Center 1311 East Algonquin Road

044-366-8860 Schaumburg, Illinois 60196

(800) 448-3245 or (847) 576-7300

Technical Support Service

Motorola provides technical support services for installation, optimization, and

maintenance of its fixed network equipment. Before calling the Motorola

Customer Support Center, please note the following information:

❐ Where the system is located.

❐ The date the system was put into service.

❐ A brief description of problem.

❐ Any other unusual circumstances.

2 68P80801E35-B 5/1/2002

Page 20

Overview

Base Radio

This chapter provides an overview of the 800/900/1500 MHz Legacy,

800 MHz Generation 2 Single Channel, 800 MHz and 900 MHz QUAD

Channel Base Radios (BRs) along with technical information. The

section topics are listed and described in Table 1.

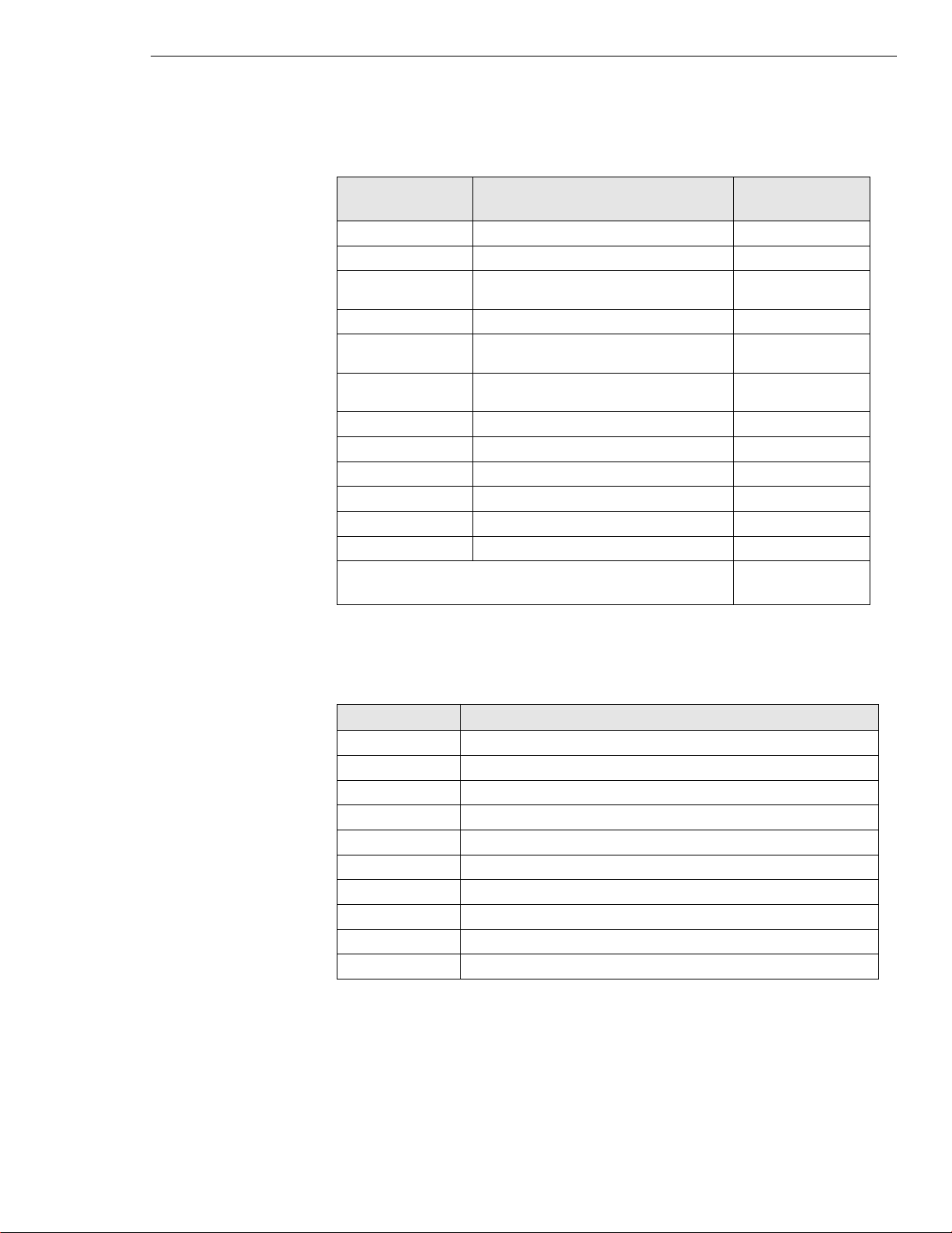

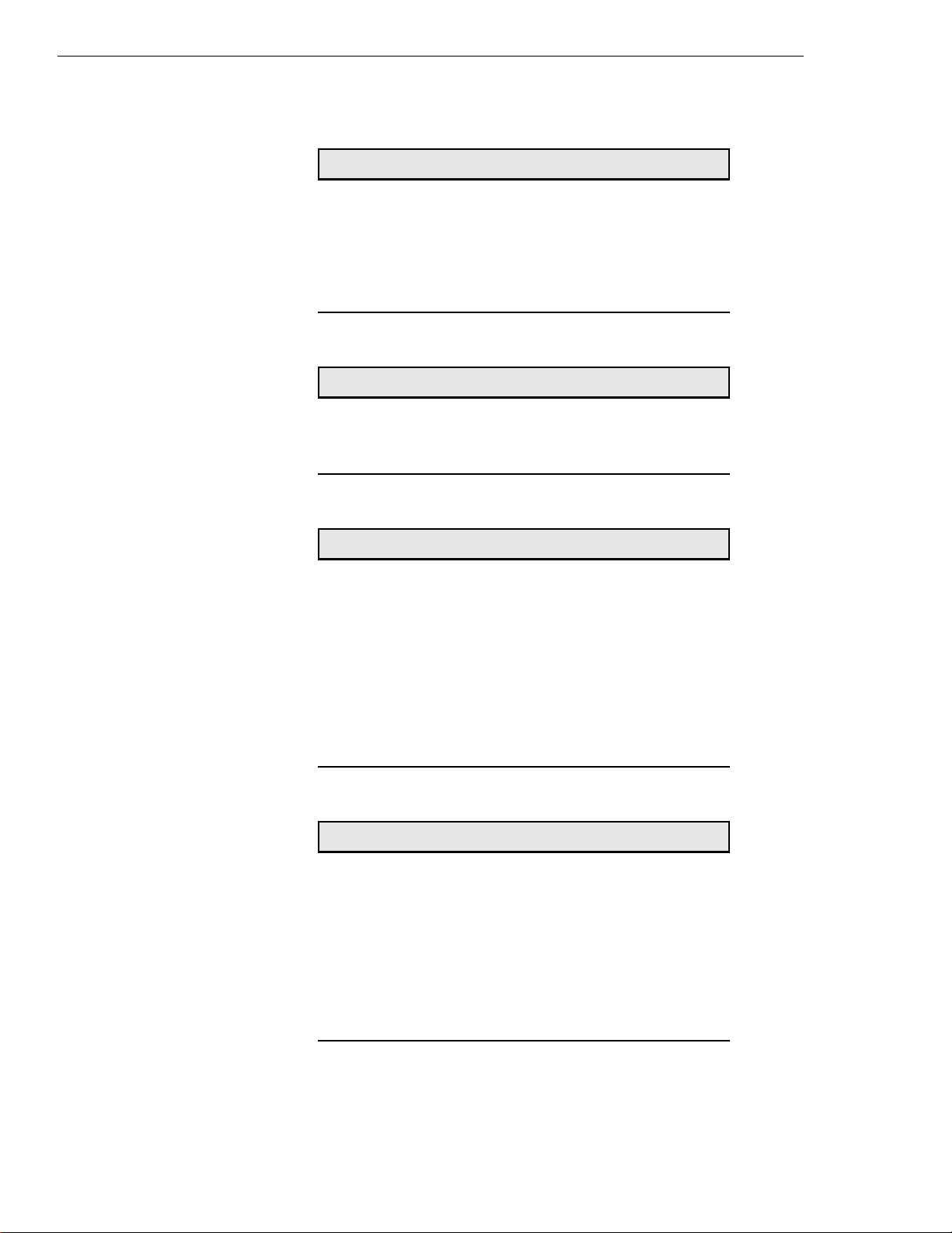

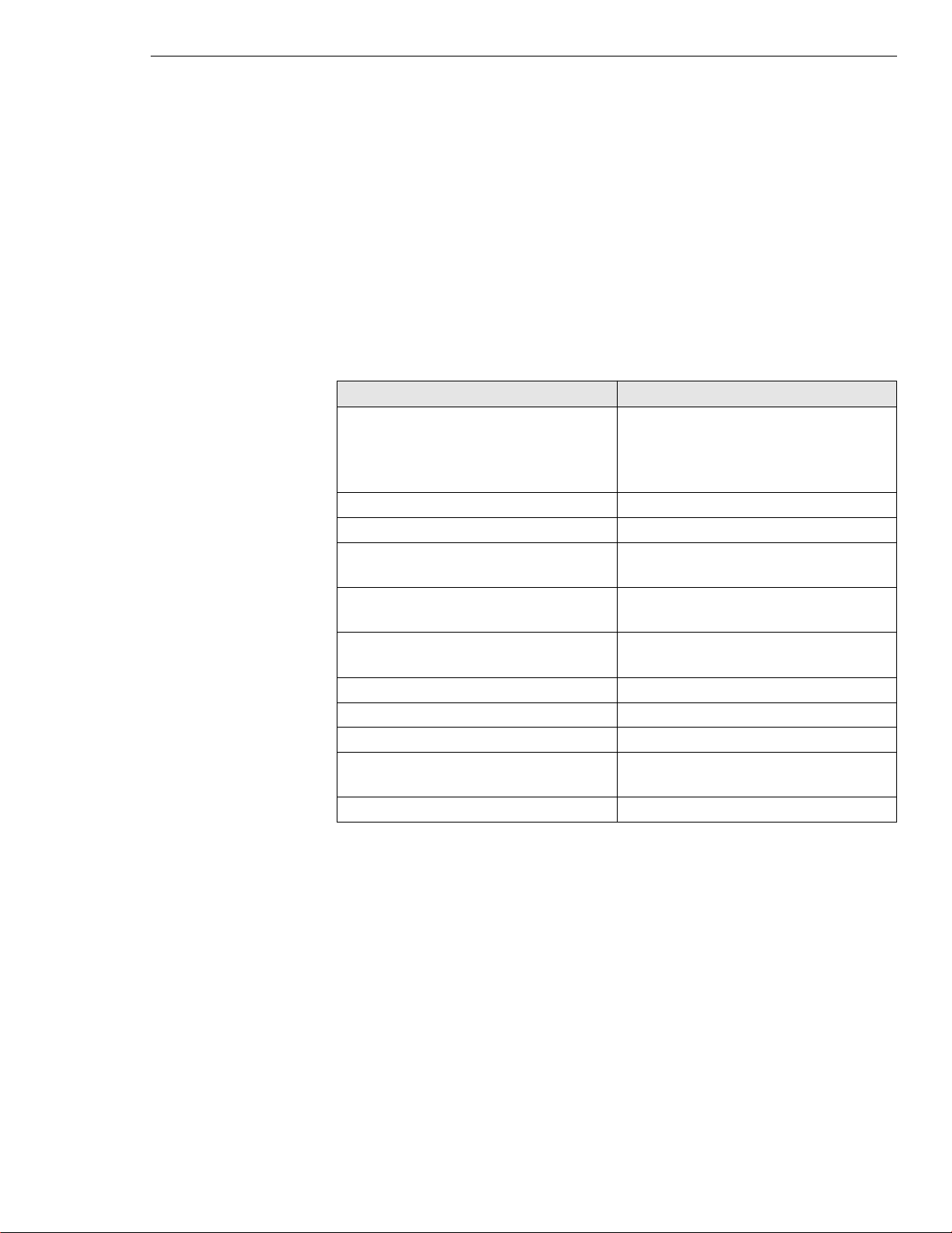

Section Page Description

Generation 2 Single Channel 800

MHz Base Radio Overview

QUAD Channel 900 MHz Base Radio

Overview

QUAD Channel 800 MHz Base Radio

Overview

Legacy Single Carrier 800 MHz Base

Radio Overview

3 Describes Controls and Indications,

Theory of Operation, and Specifications for

the 800 MHz Generation 2 Base Radio.

11 Provides information on the 900 MHz

QUAD Channel Base Radio’s Controls and

Indications, Specifications and Theory of

Operation.

16 Provides information on the 800 MHz

QUAD Channel Base Radio’s Controls and

Indications, Specifications and Theory of

Operation.

21 This section provides information on the

Legacy Single Channel 800/900/1500MHz

Base Radio including Controls and

Indications, Specifications and Theory of

Operation.

FRU Number to Kit Number Cross Reference

Table 1

68P80801E35-B 5/1/2002 1

FRU Number to Kit Number Cross Reference

Description FRU Number Kit Number

Single Channel 800/900/1500 MHz BRC TLN3334 CLN1469

Single Channel BRC (MCI) TLN3425 CLN1472

Enhanced Base Radio Controller DLN6446 CLN1653

900 MHz QUAD Channel BRC DLN1203 CLF6242

800 MHz QUAD Channel BRC CLN1497 CLF1560

Global Telecommunications Solutions Sector

1301 E. Algonquin Road, Schaumburg, IL 60196

Page 21

Base Radio EBTS System Manual - Vol 2

NOTE

The Single Carrier Base Radio section covers the

800 MHz, 900 MHz and 1500 MHz Legacy and

800 MHz Generation 2 versions of the Base

Radio (BR). Information is presented generally

for all models. Information that is model

specific noted in the text.

NOTE

For Generation 2 BR, both the 800 MHz Exciter and

the 800 MHz Low Noise Exciter modules are

supported subject to Table 2 on page 4.

NOTE

For QUAD Channel 800 MHz BR use, all Single

Carrier BR modules have undergone redesign.

Therefore, Single Carrier BR modules are

incompatible with the QUAD Channel 800 MHz BR.

QUAD Channel 800 MHz BR modules are

incompatible with the Single Carrier BR.

Do not attempt to insert QUAD Channel 800 MHz BR

modules into a Single Carrier BR or Single Carrier BR

modules into a QUAD Channel 800 MHz BR.

NOTE

For QUAD Channel 900 MHz BR use, all Single

Carrier BR modules are incompatable with the 900

MHz QUAD Channel BR. 900 MHz QUAD Channel

BR modules are incompatable with the Single Carrier

BR.

Do not attempt to insert QUAD Channel 900 MHz BR

modules into a Single Carrier BR or Single Carrier BR

modules into a QUAD Channel 900 MHz BR.

2 68P80801E35-B 5/1/2002

Page 22

EBTS System Manual - Vol 2 Base Radio

Generation 2 Single Channel 800 MHz Base Radio Overview

Generation 2 Single Channel 800 MHz Base Radio Overview

The BR provides reliable digital RF communication capabilities in a compact

software-controlled design. Increased channel capacity is provided through voice

compression techniques and Time Division Multiplexing (TDM).

The BR contains the five FRUs listed below:

❐ Enhanced Base Radio Controller (EBRC)

❐ Exciter or Low Noise Exciter

❐ Power Amplifier

❐ Power Supply (DC)

❐ Receiver

The modular design of the BR also offers increased shielding and provides easy

handling. All FRUs connect to the backplane through blindmate connectors.

Figure 1 shows the front view of the BR.

Figure 1

INSERT ONLY IN SLOT RX2 WITH BACKPLANE 0183625X

POWER SUPPLY

LOW NOISE EXCITER

SERVICE ACCESS

Generation 2 Base Radio (Typical)

ENHANCED CONTROL

RESETBR PS EX PA CTL R1 R2 R3

POWER AMPLIFIER

3X RECEIVER

EBTS282

101497JNM

68P80801E35-B 5/1/2002 3

Page 23

Base Radio EBTS System Manual - Vol 2

Generation 2 Single Channel 800 MHz Base Radio Overview

Generation 2 Single Channel Radio Controls and Indicators

The Power Supply and EBRC contain controls and indicators that provide a

means for monitoring various status and operating conditions of the BR, and also

aid in fault isolation. The controls and indicators for both modules are discussed

in the Power Supply and EBRC sections of this chapter.

The Power Supply contains two front panel indicators; the EBRC contains eight

front panel indicators. The Power Supply contains a power switch used to apply

power to the BR. The EBRC contains a RESET switch used to reset the BR.

Generation 2/EBRC Compatibility

Table 2

Exciter R01.00.xx- R01.03.xx SR10.0 or Greater

Exciter R01.04.xx and higher SR9.15 or Greater

Single Receiver R01.00.xx - R01.02.xx SR10.0 or Greater

Single Receiver R01.03.xx and higher SR9.15 or Greater

3X Receiver all versions SR9.15 or Greater

40W Power Amplifier all versions SR9.15 or Greater

70W Power Amplifier all versions SR9.15 or Greater

The Enhanced Base Radio Controller (EBRC) serves as the main controller for the

Base Radio. The EBRC provides signal processing and operational control for

other Base Radio modules. Figure 1 shows a top view of the EBRC module with

the cover removed. The EBRC module consists of two printed circuit boards

(EBRC board and LED display board), a slide-in housing, and associated

hardware.

❐ The EBRC is only compatible with System Software Release SR 9.15 or later.

Any system running a pre-SR 9.15 System Release must be updated to at

least SR 9.15 prior to installation.

❐ The EBRC module is compatible with Legacy Base Radios that support

multiple receiver module assemblies.

❐ The Generation 2 Base Radio is compatible with all versions of power

supplies.

EBRC Compatibility

Module Software Revision System Release

4 68P80801E35-B 5/1/2002

Page 24

EBTS System Manual - Vol 2 Base Radio

Generation 2 Single Channel 800 MHz Base Radio Overview

❐ The Generation 2 Base Radio is compatible with all 800 MHz 70W and 40W

Power Amplifiers.

❐ The EBRC module is only compatible with Legacy Exciter (containing

revision number R1.04.xx and higher) or the Low Noise Exciter.

Determining FRU and Kit Revisions

For Generation 2 BR/EBRC

These commands will return all available FRU and Kit Revision numbers. Use

these to determine installation requirements:

1. Connect one end of the RS-232 cable to the service computer.

2. Connect the other end of the RS-232 cable to the Service Access port, located

on the front panel of the EBRC module.

3. Power on the BR using the front switch on the Power Supply Module. Press

the reset button on the Control Module front panel. At the prompt, hit a

Carriage Return on the service computer to enter the test application mode.

Using the password motorola, log in to the BR.

:> login -ufield

password: motorola

field>

4. Collect revision numbers from the station by typing the

following command:

field> fv -oplatform

field>

5. If all modules return revision numbers of the format “Rxx.xx.xx”, then all

revision numbers are present. In that case, verification requires no further

action. If revision numbers return as blank, or not in the format “Rxx.xx.xx”,

contact your local Motorola representative or Technical Support.

68P80801E35-B 5/1/2002 5

Page 25

Base Radio EBTS System Manual - Vol 2

Generation 2 Single Channel 800 MHz Base Radio Overview

For Legacy Single Channel BR/BRC

1. Connect one end of the RS-232 cable to the service computer.

2. Connect the other end of the RS-232 cable to the STATUS port, located on the

front panel of the BRC.

3. Using the field password, login to the BR.

4. Collect revision numbers from the station by typing the

following commands:

BRC>dekey

BRC>test_mode

BRC>get brc_rev_no

BRC>get rx1_rev_no

BRC>get rx2_rev_no

BRC>get rx3_rev_no

BRC>get pa_rev_no

BRC>get ex_rev_no

(

if BR is 3 branch

)

BRC>

6 68P80801E35-B 5/1/2002

Page 26

EBTS System Manual - Vol 2 Base Radio

Generation 2 Single Channel 800 MHz Base Radio Overview

5. If all modules return revision numbers of the format “Rxx.xx.xx”, then all

revision numbers are present and no further action is required. Log out and

repeat steps 1 through 4 for each additional BR.

If revision numbers were returned as blank or not in the format “Rxx.xx.xx”,

contact your local Motorola representative or Technical Support.

Generation 2 Single Channel BR General Specifications

General specifications for the Generation 2 BR are listed in Table 2.

Table 3

Generation 2 BR General Specifications

Specification Value or Range

Dimensions:

Height

Width

Depth

Operating Temperature 32˚ to 104˚ F (0˚ to 40˚ C)

Storage Temperature -22˚ to 140˚ F (-30˚ to 60˚ C)

Rx Frequency Range:

800 MHz iDEN 806 - 825 MHz

Tx Frequency Range:

800 MHz iDEN 851 - 870MHz

Tx – Rx Spacing:

800 MHz iDEN 45 MHz

Channel Spacing 25 kHz

Frequency Generation Synthesized

Digital Modulation M-16QAM

Power Supply Inputs:

VDC -48 VDC (-41 - 60 VDC)

Diversity Branches Up to 3

5 EIA Rack Units (RU)

19" (482.6 mm)

16.75" (425 mm)

68P80801E35-B 5/1/2002 7

Page 27

Base Radio EBTS System Manual - Vol 2

Generation 2 Single Channel 800 MHz Base Radio Overview

Gen 2 Single Channel BR Transmit Specifications

The Generation 2 BR transmit specifications are listed in Table 4.

Table 4

Transmit Specifications

Specification Value or Range

Average Power Output:

(800 MHz) 40 W PA

(800 MHz) 70 W PA

Transmit Bit Error Rate (BER) 0.01%

Occupied Bandwidth 18.5 kHz

Frequency Stability * 1.5 ppm

RF Input Impedance 50 Ω (nom.)

FCC Designation (FCC Rule Part 90):

(800 MHz Legacy) 40 W PA

(800 MHz Legacy) 70 W PA

(800 MHz Low Noise Exciter) 40 W PA

(800 MHz Low Noise Exciter) 70 W PA

* Stability without site reference connected to station.

5 - 40 W

5- 70 W

ABZ89FC5772

ABZ89FC5763

ABZ89FC5772-A

ABZ89FC5763-A

Gen 2 Single Channel BR Receive Specifications

The receive specifications are listed in Table 5.

Table 5

Receive Specifications

Specification Value or Range

Static Sensitivity †:

800 MHz BR -108 dBm (BER = 8%)

BER Floor (BER = 0.01%) ≥ -80 dBm

IF Frequencies

1st IF (All bands):

2nd IF:

800MHz

Frequency Stability * 1.5 ppm

RF Input Impedance 50 Ω (nom.)

FCC Designation (FCC Rule Part 15):

800 MHz BR ABZ89FR5762

† Measurement referenced from single receiver input port of BR.

* Stability without site reference connected to station.

73.35 MHz (1st IF)

450 kHz (2nd IF)

8 68P80801E35-B 5/1/2002

Page 28

Base Radio EBTS System Manual - Vol 2

Generation 2 Single Channel 800 MHz Base Radio Overview

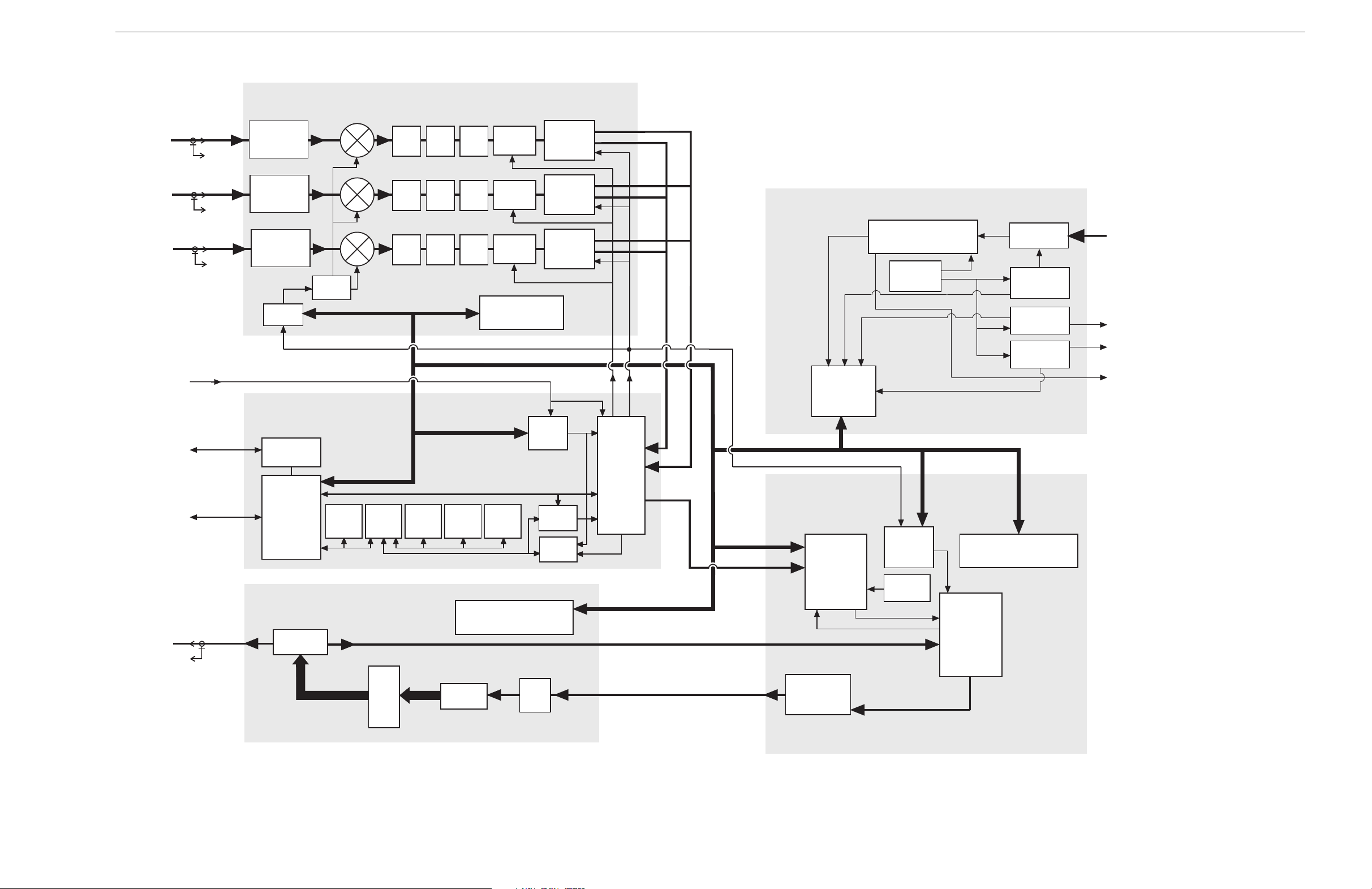

Generation2 Single Channel BR Theory of Operation

The BR operates in conjunction with other site controllers and equipment that are

properly terminated. The following description assumes such a configuration.

Figures 5 shows an overall block diagram of the BR.

Power is applied to the DC Power input located on the BR backplane. The DC

Power input is connected if -48 VDC or batteries are used in the site.

Power is applied to the BR by setting the Power Supply power switch to the ON

position. Upon power-up, the BR performs self-diagnostic tests to ensure the

integrity of the unit. These tests are primarily confined to the EBRC and include

memory and Ethernet verification routines.

After the self-diagnostic tests are complete, the BR reports any alarm conditions

present on any of its modules to the site controller via Ethernet. Alarm conditions

may also be verified locally using service computer and the STATUS port located

on the front of the EBRC.

The software resident in Flash Memory on the EBRC registers the BR with the site

controller via Ethernet. Once registered, the BR software is downloaded via

resident FLASH- or Ethernet and is executed from RAM. Operating parameters

for the BR are included in this download. This software allows the BR to perform

call processing functions.

The BR operates in a TDMA (Time Division Multiple Access) mode. This mode,

combined with voice compression techniques, provides an increased channel

capacity ratio of as much as 6 to 1. Both the receive and transmit signals of the BR

are divided into 6 individual time slots. Each receive slot has a corresponding

transmit slot; this pair of slots comprises a logical RF channel.

The BR uses diversity reception for increased coverage area and improved

quality. The Receiver module within the BR contains up to three receivers. Two

Receivers are used with two-branch diversity sites, and three Receivers are used

with three-branch diversity sites.

All Receivers within a given BR are programmed to the same receive frequency.

The signals from each receiver are fed to the EBRC where a diversity combining

algorithm is performed on the signals. The resultant signal is processed for error

correction and then sent to the site controller via Ethernet with the appropriate

control information regarding its destination.

The transmit section of the BR is comprised of two separate FRUs, the Exciter and

Power Amplifier (PA). Several PA FRUs are available, covering different

applications and power levels; these are individually discussed as applicable in

later subsections.

The Exciter processes the information to transmit from the EBRC in the proper

modulation format. This low level signal is sent to the PA where it is amplified to

the desired output power level. The PA is a continuous keyed linear amplifier. A

power control routine monitors the output power of the BR and adjusts it as

necessary to maintain the proper output level.

10 68P80801E35-B 5/1/2002

Page 29

68P80801E35-B 5/1/2002

27

EBTS System Manual - Vol 2 800/900/1500 MHz Base Radios

Base Radio Overview

POWER AMPLIFIER MODULE

TO/FROM

ETHERNET

ENHANCED

BASE RADIO CONTROLLER

MODULE

EXCITER MODULE

DC POWER SUPPLY MODULE

SERIAL BUS

TO/FROM

STATUS

PORT

(RS-232)

16.8 MHZ

5 MHZ

SPI BUS

5 MHZ

EXTERNAL

REFERENCE

FINAL

LINEAR

AMPS

SPLITTER

LINEAR

DRIVER

ADDRESS DECODE,

MEMORY, A/D CONVERTER

ADDRESS DECODE,

MEMORY, A/D CONVERTER

FROM

RFDS

(RECEIVER

ANTENNA)

#3

3X RECEIVER MODULE

MIXER

DSP BUS

LPF/

PRESELECT/

PREAMP/

IMAGE FILTER

VCO/

SYNTH

ADDRESS DECODE,

MEMORY,

A/D CONVERTER

PLL/

VCO

SPI BUS

2.1 MHZ

COMBINER

LINEAR RF

AMPLIFIER

EXCITER

IC

IF IN IF OUT

TRANLIN

IC

INPUT FILTER

BOARD

CLOCK

GENERATOR

CIRCUITRY

START-UP

INVERTER

CIRCUITRY

133 KHZ

267 KHZ

+14.2 V

INVERTER

CIRCUITRY

133 KHZ

DIAGNOSTICS

CIRCUITRY

+14.2 VDC

TO BACKPLANE

+5 VDC

TO BACKPLANE

+28 VDC

TO BACKPLANE

EXTERNAL

DC INPUT

41 - 60 VDC

RF OUT

SPI BUS

SPI BUS

SPI BUS

SPI BUS

2.1 MHZ

SPI BUS

DATA/CLOCK

DATA/CLOCK

RF IN

RF OUT

RF FEEDBACK

FEEDBACK IN

DIGITAL

ATTEN.

CIRCUIT

AGC

SPI BUS

RF IN

CUSTOM

RECEIVER

IC

EBTS284

053001JNM

TO

RFDS

(TRANSMIT

ANTENNA)

MAIN INVERTER

CIRCUITRY

+5 V

INVERTER

CIRCUITRY

FROM

RFDS

(RECEIVER

ANTENNA)

#2

MIXER

DSP BUS

LPF/

PRESELECT/

PREAMP/

IMAGE FILTER

RF IN

DIGITAL

ATTEN.

CIRCUIT

CUSTOM

RECEIVER

IC

FROM

RFDS

(RECEIVER

ANTENNA)

#1

MIXER

DSP BUS

LPF/

PRESELECT/

PREAMP/

IMAGE FILTER

RF IN

DIGITAL

ATTEN.

CIRCUIT

CUSTOM

RECEIVER

IC

BAND

PASS

FILTER

BAND

PASS

FILTER

BAND

PASS

FILTER

IF

AMP

IF

AMP

IF

AMP

BAND

PASS

FILTER

BAND

PASS

FILTER

BAND

PASS

FILTER

3-WAY

SPLITTER

NOTES:

1. 2-Branch systems must have a 50Ω load (P/N 5882106P03) installed on Antenna Port #3.

2. Set the RX_FRU_CONFIG parameter as follows:

2-Branch Systems: 12

3-Branch Systems: 123

3. Where two frequencies are given, frequency without parentheses applies to 800 MHz BR only and frequency with parentheses applies to 900 MHz BR only.

970 MHZ

(1025 MHZ)

VCO/SYNTH

FREQUENCY

DOUBLER

237 MHZ

(180.6 MHZ)

VCO

SDRAM

IO

LATCHES

EEPROMFLASHBUFFERS

HOST

µ

P

ETHERNET

INTERFACE

RECEIVE

DSP

TRANSMIT

DSP

TISIC

1PPS &

SLOT

TIMING

Figure 5

Generation 2 Single Channel 800 MHz Base Radio Functional Block Diagram

Page 30

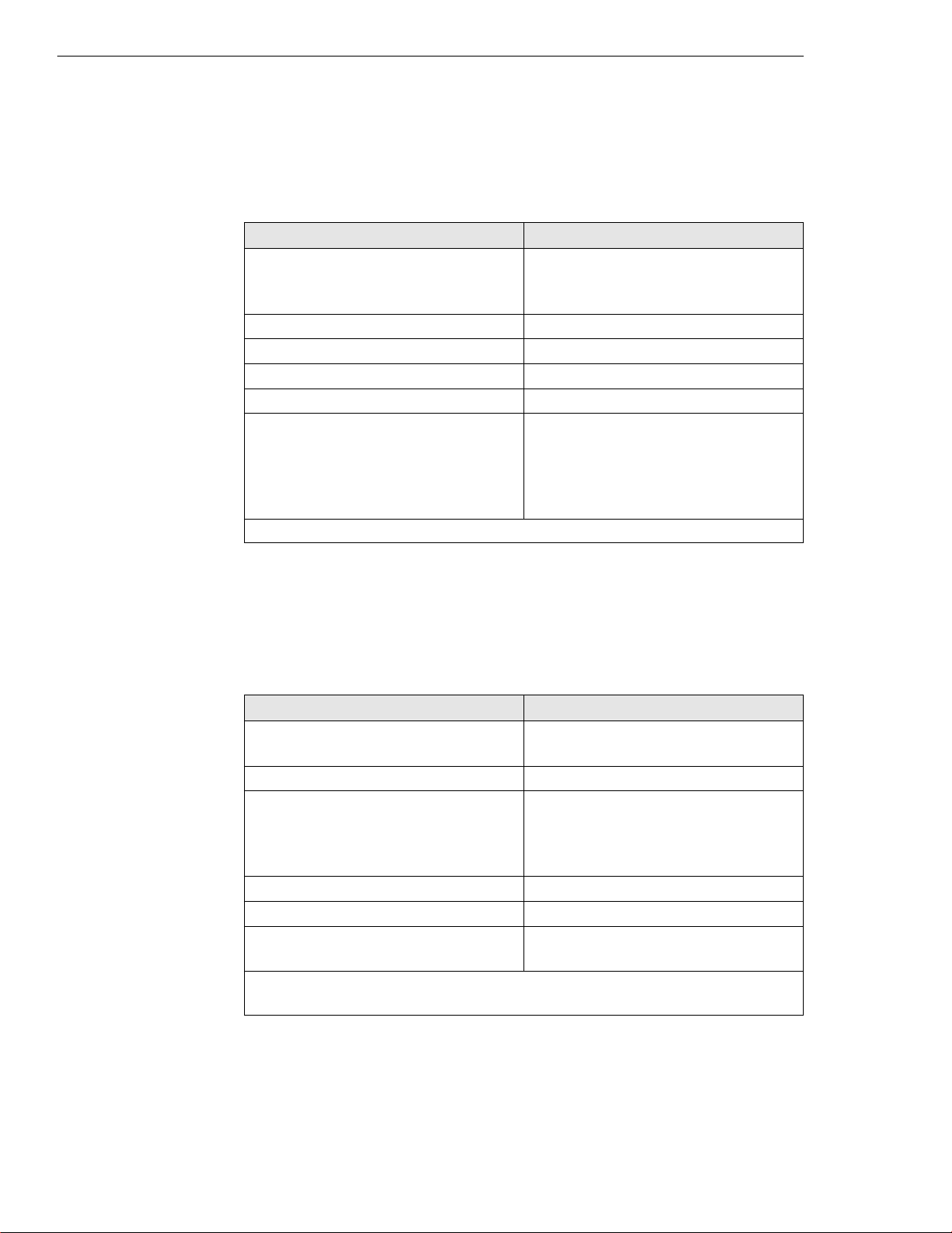

Base Radio Controllers

Overview

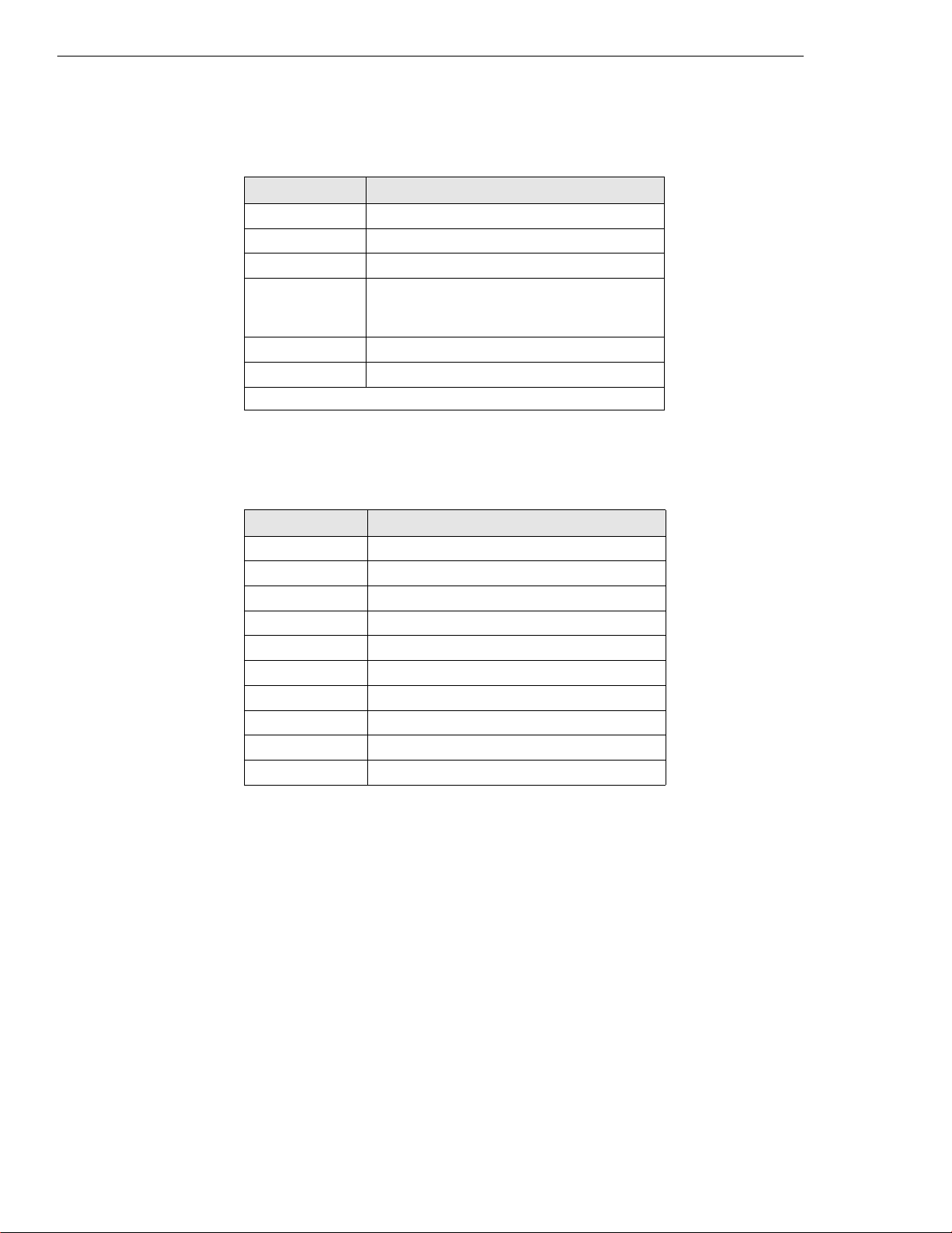

This chapter provides information on Base Radio Controllers (BRCs):

Chapter Topic Page Description

Enhanced Base Radio Controller 2 Includes information on the Enhanced Base Radio

900 MHz QUAD Channel Base Radio

Controller

800 MHz QUAD Channel Base Radio

Controller

800/900/1500 MHz Legacy Base Radio

Controller

15 Provides an 900 MHz QUAD Channel BRC Controls and

25 Provides an overview, 800 MHz QUAD Channel BRC

35 Provides an overview, outline of controls and indications as

Controller’s Controls and Indications and Theory of

Operation

Indications as well as the controller’s Theory of Operation

Controls and Indications as well as the controller’s Theory of

Operation

well as the controller’s Theory of Operation

FRU Number to Kit Number Cross Reference

Base Radio Controller (BRC) Field Replaceable Units (FRUs) are available for the

iDEN EBTS. The FRU contains the BRC kit and required packaging. Table 1

provides a cross reference between BRC FRU numbers and kit numbers.

Table 1

Description FRU Number Kit Number

Single Channel 800/900/1500 MHz Base Radio

Controller

Single Channel Base Radio Controller

(1500 MHz MCI)

Enhanced Base Radio Controller DLN6446 CLN1653

QUAD Channel 900 MHz Exciter/BR Controller DLN1203

QUAD Channel 800 MHz Exciter/BR Controller CLN1497 CLF1560

FRU Number to Kit Number Cross Reference

TLN3334 CLN1469

TLN3425 CLN1472

Global Telecommunications Solutions Sector

68P80801E35-B 5/1/2002 1

1301 E. Algonquin Road, Schaumburg, IL 60196

Page 31

Base Radio Controllers EBTS System Manual - Vol 2

Enhanced Base Radio Controller

Enhanced Base Radio Controller

Enhanced Base Radio Controller Overview

Generation 2 BR/EBRC Compatibility

Table 2

The Enhanced Base Radio Controller (EBRC) serves as the main controller for the

Base Radio. The EBRC provides signal processing and operational control for

other Base Radio modules. Figure 1 shows a top view of the EBRC with the cover

removed. The EBRC module consists of two printed circuit boards (EBRC board

and LED display board), a slide-in housing, and associated hardware.

❐ The EBRC is only compatible with System Software Release SR 9.15 or

❐ The EBRC is compatible with Legacy Base Radios that support multiple

❐ The Generation 2 Base Radio is compatible with all versions of power

EBRC Compatibility

Module Software Revision Compatible

Exciter R01.00.xx- R01.03.xx SR 10.0 or Greater

Exciter R01.04.xx and higher SR 9.15 or Greater

Single Receiver R01.00.xx - R01.02.xx SR 10.0 or Greater

Single Receiver R01.03.xx and higher SR 9.15 or Greater

3X Receiver all versions SR 9.15 or Greater

40W Power Amplifier all versions SR 9.15 or Greater

70W Power Amplifier all versions SR 9.15 or Greater

newer. Any system running a pre-SR 9.15 System Release must be updated

to at least SR 9.15 prior to installation.

receiver module assemblies.

supplies.

2 68P80801E35-B 5/1/2002

Page 32

EBTS System Manual - Vol 2 Base Radio Controllers

Enhanced Base Radio Controller

Determining FRU and Kit Revisions

For Generation 2 BR/EBRC

These commands will return all available FRU and Kit Revision numbers. Use

these to determine installation requirements:

1. Connect one end of the RS-232 cable to the service computer.

2. Connect the other end of the RS-232 cable to the Service Access port, located

on the front panel of the EBRC module.

3. Power on the BR using the front switch on the Power Supply Module. Press

the reset button on the Control Module front panel. At the prompt, hit a

Carriage Return on the service computer to enter the test application mode.

Using the password motorola, log in to the BR.

:> login -ufield

password: motorola

field>

4. Collect revision numbers from the station by typing the

following command:

field> fv -oplatform

field>

5. If all modules return revision numbers of the format “Rxx.xx.xx”, then all

revision numbers are present. In that case, verification requires no further

action. If revision numbers return as blank, or not in the format “Rxx.xx.xx”,

contact your local Motorola representative or Technical Support.

For Legacy Single Channel BR/BRC

1. Connect one end of the RS-232 cable to the service computer.

2. Connect the other end of the RS-232 cable to the STATUS port, located on the

front panel of the BRC.

3. Using the field password, login to the BR.

68P80801E35-B 5/1/2002 3

Page 33

Base Radio Controllers EBTS System Manual - Vol 2

Enhanced Base Radio Controller

4. Collect revision numbers from the station by typing the

following commands:

BRC>dekey

BRC>test_mode

BRC>get brc_rev_no

BRC>get rx1_rev_no

BRC>get rx2_rev_no

BRC>get rx3_rev_no

BRC>get pa_rev_no

BRC>get ex_rev_no

BRC>

5. If all modules return revision numbers of the format “Rxx.xx.xx”, then all

revision numbers are present and no further action is required. Log out and

repeat steps 1 through 4 for each additional BR.

If revision numbers were returned as blank or not in the format “Rxx.xx.xx”,

contact your local Motorola representative or Technical Support.

(

if BR is 3 branch

)

EBRC Description

The EBRC memory contains the operating software and codeplug. The software

defines BR operating parameters, such as output power and operating frequency.

The EBRC connects to the Base Radio backplane with one 96-pin Euro connector

and one blindmate RF connector. Two Torx screws secure the EBRC in the Base

Radio chassis.

Figure 1 shows a top view of the EBRC (model CLN1653) with the cover removed.

The EBRC module contains the main board, CLN7428 and LED board, CLN7208.

4 68P80801E35-B 5/1/2002

Page 34

EBTS System Manual - Vol 2 Base Radio Controllers

Enhanced Base Radio Controller

Figure 1

Enhanced Base Radio Controller, version CLN1653 (with cover removed)

68P80801E35-B 5/1/2002 5

Page 35

Base Radio Controllers EBTS System Manual - Vol 2

Enhanced Base Radio Controller

Enhanced Base Radio Controller Controls and Indicators

The EBRC monitors the functions of other Base Radio modules. The LEDs on the

front panel indicate the status of EBRC-monitored modules. The CTL LED on the

front panel light momentarily on initial BR power-up and on BR resets. Figure 2

shows the front panel of the EBRC.

Figure 2

SERVICE ACCESS

EBRC (Front View)

ENHANCED CONTROL

RESETBR PS EX PA CTL R1 R2 R3

EBTS316g

06701SJW

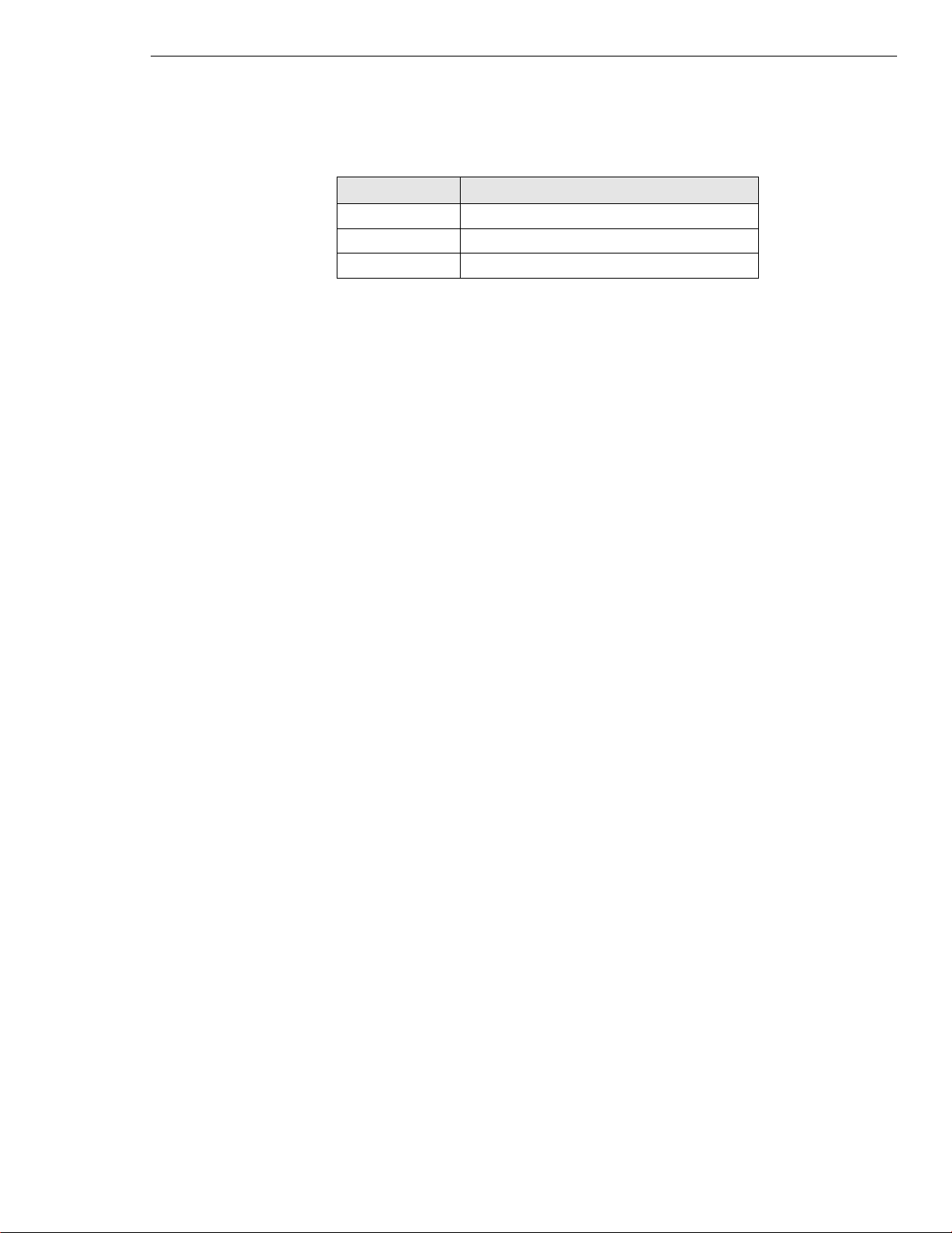

Indicators

Table 3 lists and describes the EBRC LEDs.

Table 3

EBRC Indicators

LED Color Module

Monitored

BR Green BR Solid (on) Station is keyed

PS Red Power

Supply

EX Red Exciter Solid (on) FRU failure indication - Exciter has a

PA Red Power

Amplifier

Condition Indications

Flashing (on) Station is not keyed

Off Station is out of service or power is

removed

Solid (on) FRU failure indication - Power Supply

has a major alarm and is out of service

Flashing (on) Power Supply has a minor alarm and

may be operating at reduced

performance

Off Power Supply under normal operation

(no alarms)

major alarm and is out of service

Flashing (on) Exciter has a minor alarm and may be

operating at reduced performance

Off Exciter under normal operation

(no alarms)

Solid (on) FRU failure indication - PA has a major

alarm and is out of service

Flashing (on) PA has a minor alarm and may be

operating at reduced performance

Off PA under normal operation (no

alarms)

6 68P80801E35-B 5/1/2002

Page 36

EBTS System Manual - Vol 2 Base Radio Controllers

Enhanced Base Radio Controller

Table 3

EBRC Indicators (Continued)

LED Color Module

Monitored

CTL Red Controller Solid (on) FRU failure indication - BRC has a

R1

R2

R3

Red Receiver #1,

#2, or #3

Condition Indications

major alarm and is out of service.

NOTE:

Flashing (on) BRC has a minor alarm and may be

operating at reduced performance

Off BRC under normal operation (no

alarms)

Solid (on) FRU failure indication - Receiver (#1,

#2, or #3) has a major alarm and is out

of service

Flashing (on) Receiver (#1, #2, or #3) has a minor

alarm and may be operating at

reduced performance

Off Receiver (#1, #2, or #3) under normal

operation (no alarms)

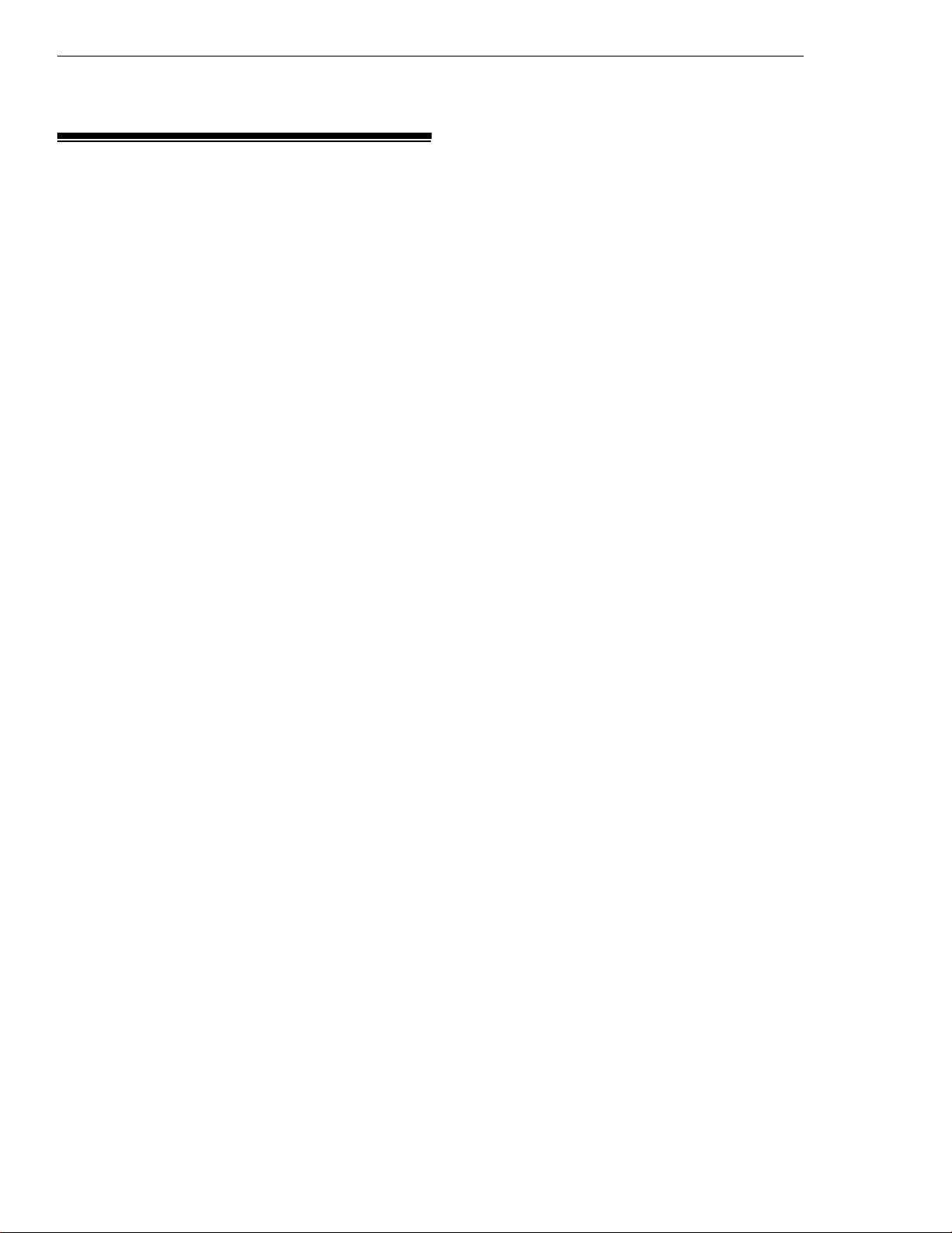

Controls

Table 4 lists the controls and descriptions.

Table 4

EBRC Controls

Control Description

RESET Switch A push-button switch used to manually reset the BR.

STATUS

connector

A 9-pin connector used for connection of a service computer, providing a

convenient means for testing and configuring.

STATUS Connector

Table 5 the pin-outs for the STATUS connector.

68P80801E35-B 5/1/2002 7

Page 37

Base Radio Controllers EBTS System Manual - Vol 2

Enhanced Base Radio Controller

Table 5

Pin-outs for the STATUS Connector

Pin-out Signal

1 not used

2 TXD

3 RXD

4 not used

5 GND

6 not used

7 not used

8 not used

9 not used

8 68P80801E35-B 5/1/2002

Page 38

EBTS System Manual - Vol 2 Base Radio Controllers

Enhanced Base Radio Controller

Enhanced Base Radio Controllers Theory of Operation

Table 6 briefly describes the EBRC circuitry. Figure 15 is a functional block

diagram of the EBRC.

Table 6

EBRC Circuitry

Circuit Description

Host Microprocessor Contains integrated circuits that comprise the central controller

of the EBRC and station

Non-Volatile Memory Consists of:

• FLASH containing the station operating software

• EEPROM containing the station codeplug data

Volatile Memory Contains SDRAM to store station software used to execute

commands.

Ethernet Interface Provides the EBRC with a 10Base2 Ethernet communication

port to network both control and compressed voice data

RS-232 Interface Provides the EBRC with an RS-232 serial interface

Digital Signal Processors Performs high-speed modulation/demodulation of

compressed audio and signaling data

TISIC Contains integrated circuits that provide timing reference

signals for the station

TX Reclock Contains integrated circuits that provide highly stable,

reclocked transmit signals and peripheral transmit logic

Station Reference Circuitry Generates the 16.8 MHz and 48 MHz reference signals used

throughout the station

Input Ports Contains 16 signal input ports that receive miscellaneous

inputs from the BR

Output Ports Contains 40 signal output ports, providing a path for sending

miscellaneous control signals to circuits throughout the BR

Remote Station Shutdown Provides software control to cycle power on the BR

MPC860 Host Microprocessor

The MPC860 host microprocessor is the main controller for the BR. The processor

operates at a 50-MHz clock speed. The processor controls Base Radio operation

according to station software in memory. Station software resides in FLASH

memory. For normal operation, the system transfers this software to non-volatile

memory. An EEPROM contains the station codeplug.

NOTE

At BR power-up, the EBRC LED indicates a major

alarm. This indication continues until BR software

achieves a predetermined state of operation.

Afterward, the software turns off the EXBRC LED.

68P80801E35-B 5/1/2002 9

Page 39

Base Radio Controllers EBTS System Manual - Vol 2

Enhanced Base Radio Controller

Serial Communication Buses

The microprocessor provides a general-purpose SMC serial management

controller bus.

The SMC serial communications bus is an asynchronous RS-232 interface with no

hardware handshake capability. The BRC front panel includes a nine-pin, D-type

connector. This connector provides a port where service personnel may connect a

service computer. Service personnel can perform programming and maintenance

tasks via Man-Machine Interface (MMI) commands. The interface between the

SMC port and the front- panel STATUS connector is via EIA-232 Bus Receivers

and Drivers.

Host Processor

The microprocessor incorporates 4k bytes of instruction cache and 4k bytes of

data cache that significantly enhance processor performance.

The microprocessor has a 32-line address bus. The processor uses this bus to

access non-volatile memory and SDRAM memory. Via memory mapping, the

processor also uses this bus to control other BRC circuitry.

The microprocessor uses its Chip Select capability to decode addresses and assert

an output signal. The eight chip-select signals select non-volatile memory,

SDRAM memory, input ports, output ports, and DSPs.

The Host processor...

❐ Provides serial communications between the Host Microprocessor and other

Base Radio modules.

❐ Provides condition signals necessary to access SDRAM.

❐ Accepts interrupt signals from EBRC circuits (such as DSPs).

❐ Organizes the interrupts, based on hardware-defined priority ranking.

❐ The Host supports several internal interrupts from its Communications

Processor Module. These interrupts allow efficient use of peripheral

interfaces.

❐ The Host supports 10 Mbps Ethernet/IEEE 802.3.

❐ Provides a 32-line data bus transfers data to and from EBRC SDRAM and

other BRC circuitry. Buffers on this data bus allow transfers to and from

non-volatile memory, general input and output ports and DSPs.

Non-Volatile Memory

Base Radio software resides in 2M x 32 bits of FLASH memory. The Host

Microprocessor addresses the FLASH memory with 20 of the host address bus’ 32

lines. The host accesses FLASH data over the 32-line host data bus. A

host-operated chip-select line provides control signals for these transactions.

The FLASH contains the operating system and application code. The system

stores application code in FLASH for fast recovery from reset conditions.

Application code transfers from network or site controllers may occur in a

10 68P80801E35-B 5/1/2002

Page 40

EBTS System Manual - Vol 2 Base Radio Controllers

Enhanced Base Radio Controller

background mode. Background mode transfers allow the station to remain

operational during new code upgrades.

The data that determines the station personality resides in a 32K x eight bit

codeplug EEPROM. The microprocessor addresses the EEPROM with 15 of the

host address bus’ 32 lines. The host accesses EEPROM data with eight of the data

bus’ 32 lines. A host-operated chip-select line provides control signals for these

transactions.

During the manufacturing process, the factory programs the codeplug’s default

data. The BRC must download field programming data from network and site

controllers. This data includes operating frequencies and output power level. The

station permits adjustment of many station parameters, but the station does not

store these adjustments. Refer to the Software Commands chapter for additional

information.

Volatile Memory

Each BRC contains 8MB x 32 bits of SDRAM. The BRC downloads station

software code into SDRAM for station use. SDRAM also provides short-term

storage for data generated and required during normal operation. SDRAM is

volatile memory. A loss of power or system reset destroys SDRAM data.

The system performs read and write operations over the Host Address and Data

buses. These operations involve column and row select lines under control of the

Host processor’s DRAM controller. The Host address bus and column row signals

sequentially refresh SDRAM memory locations.

Ethernet Interface

The Host processor’s Communications Processor Module (CPM) provides the

Local Area Network (LAN) Controller for the Ethernet Interface. The LAN

function implements the CSMA/CD access method, which supports the IEEE

802.3 10Base2 standard.

The LAN coprocessor supports all IEEE 802.3 Medium Access Control, including

the following:

❐ framing

❐ preamble generation

❐ stripping

❐ source address generation

❐ destination address checking

The PCM LAN receives commands from the CPU.

The Ethernet Serial Interface works directly with the CPM LAN to perform the

following major functions:

❐ 10 MHz transmit clock generation (obtained by dividing the 20 MHz signal

provided by on-board crystal)

❐ Manchester encoding/decoding of frames

68P80801E35-B 5/1/2002 11

Page 41

Base Radio Controllers EBTS System Manual - Vol 2

Enhanced Base Radio Controller

❐ electrical interface to the Ethernet transceiver

An isolation transformer provides high-voltage protection. The transformer also

isolates the Ethernet Serial Interface (ESI) and the transceiver. The pulse

transformer has the following characteristics:

❐ Minimum inductance of 75 µH

❐ 2000 V isolation between primary and secondary windings

❐ 1:1 Pulse Transformer

The Coaxial Transceiver Interface (CTI) is a coaxial cable line driver and receiver

for the Ethernet. CTI provides a 10Base2 connection via a coaxial connector on the

board. This device minimizes the number of external components necessary for

Ethernet operations.

A DC/DC converter provides a constant voltage of -9 Vdc for the CTI from a

3.3 Vdc source.

The CTI performs the following functions:

❐ Receives and transmits data to the Ethernet coaxial connection

❐ Reports any collision that it detects on the coaxial connection

❐ Disables the transmitter when packets are longer than the legal length

(Jabber Timer)

Digital Signal Processors

The BRC includes two Receive Digital Signal Processors (RXDSPs) and a Transmit

Digital Signal Processor (TXDSP). These DSPs and related circuitry process

compressed station transmit and receive audio or data. The related circuitry

includes the TDMA Infrastructure Support IC (TISIC) and the TISIC Interface

Circuitry. The DSPs only accept input and output signals in digitized form.

The RXDSP inputs are digitized receiver signals. The TXDSP outputs are digitized

voice audio and data (modulation signals). These signals pass from the DSP to the

Exciter portion of the EXBRC. DSPs communicate with the Microprocessor via an

eight-bit, host data bus on the host processor side. For all DSPs, interrupts drive

communication with the host.

The RXDSP operates from an external 16.8 MHz clock, provided by the local

station reference. The RXDSP internal operating clock signal is 150MHz,

produced by an internal Phase-Locked Loop (PLL).

The RXDSP accepts digitized signals from the TISIC device through the RxDSP

parallel bus. The RXDSP supports a single carrier (single 3 branch receiver) digital

data input.

The RXDSP accesses its DSP program and signal-processing algorithms in 128k

words of internal memory. The RXDSP communicates with the host bus on an

8-bit interface.

Additionally, a serial control path connects the two RXDSPs and the TXDSP. The

Synchronous Communications Interface (SCI) port facilitates this serial control

path.

12 68P80801E35-B 5/1/2002

Page 42

EBTS System Manual - Vol 2 Base Radio Controllers

Enhanced Base Radio Controller

For initialization and control purposes, the RXDSP connects to the TISIC device.

The TXDSP operates at an external clock speed of 16.8 MHz, provided by the

EBRC local station reference. The TXDSP internal operating clock is 150MHz,

produced by an internal Phase Lock Loop (PLL).

The TXDSP sends one carrier of digitized signal to the TISIC to reformat the date

before sending it to the exciter. The exciter converts the digital signal to analog.

The TXDSP contains its own, internal address and data memory. The TXDSP can

store 128k words of DSP program and data memory. An eight-bit interface

handles TXDSP-to-host bus communications.

TISIC

The TISIC controls internal DSP operations. This circuit provides the following

functions:

❐ For initialization and control, interfaces with the RXDSP via the DSP

address and data buses.

❐ Accepts a 16.8 MHz signal from Station Reference Circuitry.

❐ Accepts a 5 MHz signal, modulated with one pulse per second (1 PPS) from

the site reference.

❐ Demodulates the 1 PPS from the modulated 5 MHz signal

❐ Outputs a 1 PPS signal and a windowed version of this signal for network

timing alignment.

❐ Outputs a 2.1 MHz reference signal used by the Exciter and Receiver(s).

❐ Generates 15 ms and 7.5 ms ticks. (These ticks synchronize to the 1 PPS time

mark. The system decodes the time mark from the site reference. Then the

system routes the reference to the TXDSP and RXDSP.)

❐ Provides a 4.8 MHz reference signal. This signal is used by the Exciter to

clock data into the TRANLIN

❐ Accepts differential data from the Receiver(s) (Rx through Rx3) via the

interface circuitry.

❐ Transmits serial control data to the Receiver(s) (Rx through Rx3) via the

serial data bus.

❐ Accepts and formats differential data from the TXDSP for transmission to

the Exciter via interface circuitry.

❐ Generates the Receiver SSI (RxSSI) frame sync interrupt for the RxDSP.

Station Reference Circuitry

The Station Reference Circuitry is a phase-locked loop (PLL). This PLL consists of

a high-stability, Voltage-Controlled, Crystal Oscillator (VCXO) and a PLL IC. GPS

output from the iSC connects to the 5 MHz/1 PPS BNC connector on the BR

backplane. Wiring at this connector routes signals to EXBRC station reference

circuitry.

The PLL compares the 5 MHz reference frequency to the 16.8 MHz VCXO output.

Then the PLL generates a DC correction voltage. The PLL applies this correction

68P80801E35-B 5/1/2002 13

Page 43

Base Radio Controllers EBTS System Manual - Vol 2

Enhanced Base Radio Controller

voltage to the VCO through an analog gate. The analog gate closes when three

conditions coexist: (1) The 5 MHz tests stable. (2) The PLL IC is programmed. (3)

Two PLL oscillator and reference signal output alignments occur.

A loss in the 5MHz / 1PPS signal causes the control voltage enable switch to

open. This complex PLL control allows the BR to maintain 16.5 MHz capability

during short disconnects (of approximately one minute) of the 5 MHz / 1 PPS

signal. (For example, during 5 MHz / 1 PPS cable maintenance work.)

When the gate enables, the control voltage from the PLL can adjust the

high-stability VCXO frequency. The adjustment can achieve a stability nearly

equivalent to that of the external, 5 MHz frequency reference.

The correction voltage from the PLL continuously adjusts the VXCO frequency.

The VXCO outputs a 16.8 MHz clock signal. The circuit applies this clock signal to

the receiver, and TISIC.

The TISIC divides the 16.8 MHz signal by seven, and outputs a 2.1 MHz signal.

This output signal then becomes the 2.1 MHz reference for the Exciter and

Receiver(s).

Input Ports

One general-purpose input register provides for EBRC and station circuit input

signals. The register has 16 input ports. The Host Data Bus conveys input register

data to the Host Microprocessor. Typical inputs include 16.8 Station Reference

Circuitry status outputs and reset status outputs.

Output Ports

Two general-purpose output registers distribute control signals from the Host

Microprocessor to the BRC and station circuitry. One register has 32 output ports

and the other register has 8 output ports. Control signal distribution occurs over

the backplane. The Host Data Bus drives the output ports’ latched outputs.

Typical control signals include front-panel LED signals and SPI peripheral enable

and address lines.

Remote Station Shutdown

The EBRC contains power supply shutdown circuitry. This circuitry can send a

shutdown pulse to the Base Radio Power Supply. BRC software generates the

shutdown control pulse.

After receiving a shutdown pulse, the power supply turns off BR power. Shut

down power sources include 3.3, 5.1, 28.6 and 14.2 Vdc sources throughout the

BR. Due to charges retained by BR storage elements, power supply voltages may

not reach zero. The shutdown only assures that the host processor enters a

power-on-reset state.

A remote site uses the shutdown function to perform a hard reset of all BR

modules.

14 68P80801E35-B 5/1/2002

Page 44

68P80801E35-B 5/1/2002

51

EBTS System Manual - Vol 2 800/900/1500 MHz Base Radios

Base Radio Controller

Figure 15

Enhanced Base Radio Controller Functional Block Diagram

(Sheet 1 of 2)

Enhanced Base Radio Controller

Functional Block Diagram

Model CLN1653A

LED

CONTROL

LINES

HOST

LATCH

P0 OUT

FRONT PANEL LEDS

12

BASE

RADIO

POWER

SUPPLY

EXCITER

PA CTL RX1 RX2 R3

5MHZ_1PPS

BASE RADIO

INPUT

5MHZ

1PPS

G

A

T

I

N

G

STATION REFERENCE CIRCUITRY

SYNTHESIZER

IC / CIRCUITRY

SPI

BUS

PHASE

DETECTION/

FILTERING/

CONTROL

DISCONNECT/

CONNECT

CONTROL

STEARING

LINE

HIGH

STABILITY

VCXO

16.8 MHZ

28V

P0_OUT

REMOTE STATION

SHUTDOWN CIRCUITRY

SHUTDOWN

CIRCUITRY

SHUTDOWN

(TO POWER

SUPPLY)

Page 45

52

68P80801E35-B 5/1/2002

800/900/1500 MHz Base Radios EBTS System Manual - Vol 2

Base Radio Controller

Figure 16

Enhanced Base Radio Controller Functional Block Diagram

(Sheet 2 of 2)

EnhancedBase Radio Controller

Functional Block Diagram

Model CLN1653A

FRONT PANEL

RESET

5MHZ

1PPS

SERIAL MANAGEMENT CONTROLLER (SMC2)

2

SCC1

HOST

MICRO-

PROCESSOR

ETHERNET

SERIAL

INTERFACE

ETHERNET