Page 1

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Operational or User’s Manual

The manual should include instruction, installation, operator, or technical manuals with required ‘information to the

users’. This manual should include a statement that cautions the user that changes or modifications not expressly

approved by the party responsible for compliance could void the user’s authority to operate the equipment. The

manual shall include RF Hazard warning statements, if applicable.

The instruction and service manual for this base radio are not published at this time. However, draft copy of

available manual information has been assembled and has been included as part of this filing package.

Upon request, published manuals will be sent to the commission and/or telecommunication certification body

(TCB) as soon as they become available. All of the descriptions, block diagrams, and schematics that are included

in this filing package are current as of the package submittal date.

EXHIBIT DESCRIPTION

D1-1 Manual Front Matter (Draft)

D1-2 Specifications (Draft)

D1-3 Field Replaceable Units and Orderable Parts (Draft)

D1-4 Tune-Up Procedure (Draft)

D1-5 Racking Configurations (Draft)

D1-6 Functional Description / Operation of Modules (Draft)

EXHIBIT D

Page 2

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Manual Front Matter (Draft)

EXHIBIT D1-1

Page 3

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Manual Front Matter (Draft, Continued)

EXHIBIT D1-1

Page 4

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Manual Front Matter (Draft, Continued)

EXHIBIT D1-1

Page 5

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Manual Front Matter (Draft, Continued)

EXHIBIT D1-1

Page 6

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Specifications (Draft)

General Performance

Model T2003

Number of Channels 16

Frequency Generation Synthesized

H x W x D 5.25" x 19" x 16.5" (133x483x419mm)

Weight 40 lbs (19 kg)

Power Requirements

AC: 85-264 VAC, 47-63 Hz Standy 0.6A, Rated Power 5.4A @ 117 VAC

DC: 21.6 - 32 Volts DC Standy 1A, Rated Power 13A @ 28 VDC

Temperature Range -30 to 60 °C (-22 to 140 °F)

Input / Output Impedance 50 ohms

Antenna Connectors Tx / Rx N-Type

Modes of Operation Half-Duplex / Duplex

Frequency Bands 403 - 470 MHz

Internal Frequency Stability 1.5 PPM

External Reference Capable Yes

Channel Spacing 12.5 kHz, 25 kHz

Transmitter

Frequency Range 406.1-470 MHz

Rated Output Power 25 - 100 Watts, Variable

Intermodulation Attenuation 40 dB

Adjacent Channel Power -80 dBc (25 kHz) / -60 dBc (12.5 kHz)

Wideband Noise (1 MHz) -152 dBc/Hz

Rated System Deviation 5 kHz (25 kHz) / 2.5 kHz (12.5 kHz)

Audio Distortion <3%

FM Hum and Noise 50 dB (25 kHz) / 45 dB (12.5 kHz)

Spurious Harmonic Emissions

Attenuation

85 dB

FCC Type Acceptance

FCC Identifier: Frequency Range Type Power Output

ABZ89FC4827 406.1-470 MHz Transmitter Variable 25-100 W

ABZ89FR4828 406.1-470 MHz Receiver N/A

EXHIBIT D1-2

Page 7

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Field Replaceable Units and Orderable Parts (Draft)

Motorola provides the following approved accessories to improve the productivity of your base station / repeater.

For a list of Motorola-approved accessories, visit the following web site:

http://www.motorola.com/governmentandenterprise

.

MOTOTRBO MTR3000 Ordering Guideline

Model Description

T3000 MTR3000 Base Station/Repeater

X340MT UHF 100W Power (403–470 MHz)

X540MT UHF 100W Power (470–524 MHz)

X182UL Duplexer, UHF 403–435 MHz

X182UM Duplexer, UHF 435–470 MHz

X182UN Duplexer, UHF 470–494 MHz

X182UH Duplexer, UHF 494–512 MHz

X265UL Preselector, UHF 380–435 MHz

X265UM Preselector, UHF 435–470 MHz

X265UH Preselector, UHF 470–524 MHz

X676UL Dual Circulator, UHF (403–470 MHz)

X676UH Dual Circulator, UHF (470–524 MHz)

X371BA Antenna Relay

Note: Antenna Relay is not compatible if ordering X182, Duplexer

X189AA Power Cable, Europe

X162AD Power Cable, UK

X191AD Power Cable, Australia

CA01520AA Power Cable, DC

U178AB Cabinet Mount Hardware

X153BA Rack Mount Hardware

X347AF Manual Install and User CD

X244AF Auxiliary System Cable

X244AG Community Base Station/Repeater Panel Cable

X244AH Phone Patch Cable

C540AD System Connector Cable

XA00032AA 12 inch Ethernet Cable

CLN8665A 6 feet High speed USB cable

HKLN4439_ MTR3000 Capacity Plus Software Upgrade

Customer Replaceable Power Cables for Standalone Base Radio

Part Number Description

TRN7663A Power Cable, North America

TRN7755A Power Cable, Continental Europe

TTN5049A Power Cable, UK / Ireland

TTN5103A Power Cable, Australia

EXHIBIT D1-3

Page 8

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Field Replaceable Units and Orderable Parts (Draft) (Continued)

MOTOTRBO MTR3000 Field Replaceable Units

Model Description

DLN6701_ 100W PA, UHF 403–470 MHz

DLN6702_ 100W PA, UHF 470–524 MHz

DLN6703_ Exciter, UHF 403–470 MHz

DLN6704_ Exciter, UHF 450–524 MHz

DLN6705_ Receiver, UHF 403–470 MHz

DLN6706_ Receiver, UHF 450–524 MHz

DLN6707_ AC/DC Power Supply

DLN6719_ Station Control TCXO

CLN8629 MOTOTRBO MTR3000 Installation and User CD

X347AF Manual Install and User CD

Note The Manual Install and User CD contains:

• MOTOTRBO MTR3000 Installation and User Manual (Including MTR2000 to MTR3000 MOTOTRBO

Upgrade Kit)

• MOTOTRBO MTR3000 Basic Service Manual

Microphones/Speakers

Model Description

GMMN4063 Noise Cancelling Mic

0185180U01 Cable For External Speaker

HSN1006 Speaker

Miscellaneous Accessories

Model Description

RRX4025 ISB50LNC2 Bulkhead Arrestor 125-100

RRX4032 T-1 ISB50 Series Round Member Mount

RRX4021 Lightening / Surge Arrestor

RRX4034 Lightening / Surge Arrestor (110/220V AC Line Surge Protector)

TRN4589 Dual Line Suppressor

3083908X02 Cable, Field System Adapter

CLN1317* Antenna Relay

CLN1316** Antenna Relay For Preselector

Note

(*) Includes Antenna Relay and required cables for stations without X265, Preselector

(**) Includes Antenna Relay and required cables for stations that include X265, Preselector

CKN1039* Preselector Cable Kit

CKN1040** Preselector Cable For Antenna Relay

Note

(*) Order this cable for stations without X371, Antenna Relay

(**) Order this cable for stations with X371, Antenna Relay

Cabinets/Racks and Hardware

Model Description

THN6700 12 inch Indoor Cabinet

THN6701 30 inch Indoor Cabinet

THN6702 46 inch Indoor Cabinet

THN6752 30 inch Modular Rack (16 RK U)

THN6753 45 inch Modular Rack (24 RK U)

THN6754 52 inch Modular Rack (27 RK U)

THN6788_ Slides Motorola Cabinet

CLN6833_ Slides Non-Motorola Cabinet

CLN6679_ Rack Mount Hardware

EXHIBIT D1-3

Page 9

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Tune-Up Procedure (Draft)

See the following manual excerpts (Chapter 9 and Chapter 12 of MOTOTRBO MTR3000 Base Station /

Repeater, Basic Service Manual) for instruction on performing the field digital upgrade, operational verification,

and programming / tuning.

Adjustments are software controlled and are pre-set at the factory. Certain station operating parameters can be

changed using Customer Programming Software (CPS), within predetermined limits. Examples include transmit /

receiver operating frequencies and transmitter power level.

After the base station / repeater and ancillary equipment have been mechanically installed, properly cabled, and

power applied, the equipment must then be optimized; that is, before placing the base station / repeater in

operation. The cable required is a standard “USB A to B” cable. Optimization is performed through the Customer

Programming Software (CPS), kit number RVN5115.

After the base station / repeater is operational, the base station / repeater’s codeplug data must be copied to a

PC- compatible computer.

Optimization involves the following tasks:

1. Reading the base station / repeater codeplug from the base station / repeater (this ensures a match between

the base station / repeater serial number (resident in the codeplug) and the serial number (part of the

customized base station / repeater codeplug data) that is written back to the base station / repeater (see task

5).

2. Customizing the base station / repeater codeplug and saving the data to the base station / repeater.

3. Aligning the base station / repeater for:

- Modulation Limit

- Speaker Level

- Station Reference

- MTR2000 PA Calibration

- Receiver Squelch Adjust

4. Performing post-optimization procedures.

5. Writing the customized codeplug to the base station / repeater codeplug.

For details on these tasks, refer to the Customer Programming Software (CPS) Online Help.

EXHIBIT D1-4

Page 10

Chapter 9 MTR2000 MOTOTRBO Digital Upgrade

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

9.1 Overview

The MTR3000 platform supports a digital upgrade kit which allow customers with fielded analog

MTR2000 radios to upgrade the station control module (SCM), Receiver and Exciter modules and

migrate their radio to a digital MOTOTRBO product. These modules are not assembled together

when it is shipped.

An "upgraded Base Station/Repeater" is comprised of a new front bezel, new Exciter module, new

Receiver module, new SCM module, and utilizing the remaining components from the MTR2000

Base Station/Repeater (BR). Existing peripherals that are being utilized for the MTR2000 BR can

retrofit the MTR3000 BR once it is upgraded. There is no need to purchase a new Duplexer, Base

Station/Repeater Preselector, External Dual Circulator or Antenna Relay.

The MTR2000 MOTOTRBO Digital Upgrade allows a MTR2000 customer to migrate from analog to

digital. The available digital systems are:

• MOTOTRBO (2 slot TDMA digital over the air DMR standard)

• MOTOTRBO Connect Plus

• Capacity Plus

• IP Site Connect

The features that are upgradeable from MTR2000 are:

• Air Interface/Conventional – Analog Conventional

• Station Operation – Base Station Analog, Repeater Analog

• Channel Configuration – Half Duplex, Full Duplex

• Air Interface/Trunked – Analog Trunking (LTR and Passport)

• Frequency – UHF 403–470 MHz

• Transmitter Capability – 75/100 W Capability

• Hardware Peripheral Compatibility – Base Station/Repeater Preselectors, Duplexer, External

Dual Circulator/Isolator Tray, Antenna Relay, External Frequency Reference, Angus Battery

Charger

The information below is an overview for installing the station and ancillary equipment.

• Unpacking and inspecting the equipment

• Mechanically install the equipment at the site

• Make necessary electrical and cabling connections:

-Audio

-GPIO

- Ethernet

• Perform Alignment

• Perform Configuration

• Perform a post-install functional checkout test to verify installation

Note

For the correct procedure in handling static-sensitive parts, refer to Section 13.4 on page

13-2.

Page 11

9-2 MTR2000 MOTOTRBO Digital Upgrade: Unpacking

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

Note

Currently, the MTR2000 MOTOTRBO Digital Upgrade is limited to the high power (100W)

UHF BR. Additionally, once the upgrade is performed, the wireline and Auxiliary I/O board

functionality will no longer be supported.

9.2 Unpacking

This section describes the procedures to unpack the new front bezel, new SCM module, new Exciter

and Receiver modules from the packaging prior to installing them.

To avoid damage to the parts, be sure to observe proper electrostatic

discharge precautions when modules are removed from the station.

9.2.1 Equipment Unpacking and Inspection

9.2.1.1 Introduction

The new front bezel, new Exciter module, new Receiver module and new SCM module may be

shipped by either air freight or electronic van (as specified by customer), except where noted.

Thoroughly inspect the equipment as soon as possible after delivery. If any part of the equipment is

damaged during transit, immediately report the extent of the damage to the transportation company

and to Motorola.

9.2.1.2 Unpacking Equipment

The new front bezel, new Exciter Module, new Receiver Module and new Station Control Module are

packed in four separate boxes which are packed together in a common box. The individual boxes

are cushioned between corrugated cardboard in a common box.

Page 12

MTR2000 MOTOTRBO Digital Upgrade: Unpacking 9-3

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

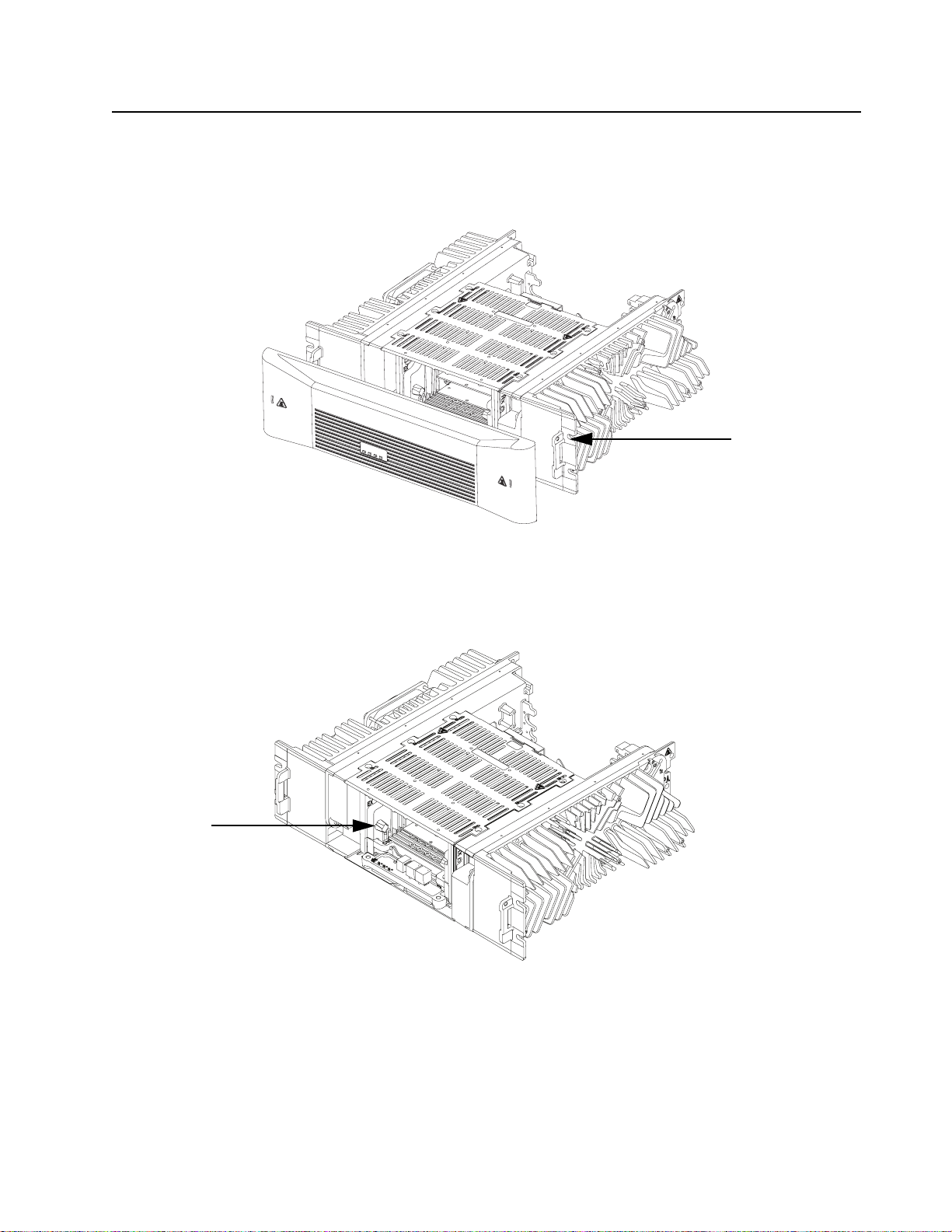

9.2.1.3 Analog to Digital Migration Path – Removal and Replacement

1. Remove the MTR2000 station front bezel from its chassis locking clip by carefully pulling the

bezel forward (Refer to Figure 9-1).

Chassis locking clip

Cast knob

Figure 9-1. Removing Front Bezel

2. Disconnect the Exciter-to-PA Coaxial Cable and Rx Input Cable (Refer to Figure 9-2). By

disconnecting the cables, the Exciter Module, Receiver Module, Station Control Module

(SCM) are accessible.

Figure 9-2. Removing RF cable

3. Remove the two screws securing the Transceiver (SCM, Exciter, and Receiver modules) to

the bottom plate. Pull forward on the cast knobs, carefully slide the assembly out of the

station (Refer to Figure 9-3) and place it aside.

Page 13

9-4 MTR2000 MOTOTRBO Digital Upgrade: Unpacking

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

Figure 9-3. Removing two screws securing the Transceiver Assembly

4. Remove the Wireline and Auxiliary I/O Card(s) (if any are installed) as the card(s) will not be

supported in an upgraded MTR2000.

5. Secure the new Station Control Module (SCM), Exciter and Receiver Modules using the eight

screws (Refer to Figure 9-4) supplied with the MTR2000 MOTOTRBO Digital Upgrade kit to

form the new Transceiver Assembly.

6. Slide the new Transceiver Assembly into the MTR2000 station (along the guide rails) to mate

with the connector on the backplane.

Figure 9-4. Putting together new SCM, Exciter and Receiver

Page 14

MTR2000 MOTOTRBO Digital Upgrade: New Connections 9-5

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

7. Secure the Transceiver Assembly to the bottom plate by fastening the screws in Step 3

(Refer to Figure 9-3).

8. Reconnect the Exciter-to-PA Coaxial Cable and Rx Input Cable.

9.3 New Connections

After the station equipment has been mechanically installed, connections must be made. This

involves making the following new connections to:

• J7 Backplane Connector to support the following analog third party boxes (If applicable)

- Community Repeater Panel

- Tone Remote Controller (Console Connection)

- LTR Trunking Controller

- Passport (NTS) Controller

- Phone Patch

- Deskset

• Ethernet to support the following MOTOTRBO features

- IP Site Connect (Multi Site)

- RDAC

- Connect Plus

- Capacity Plus

Note

1. It is not recommended to perform a digital upgrade and use the upgraded station in

analog mode as certain analog functionality will be lost. Refer to Product Planner for

details.

2. 14.2VDC power (Pin 20) and GPIO_9 (Pin 5) are not supported on an upgraded

MTR2000 J7 backplane connector. If 12VDC power is required on an upgraded

MTR2000, then it must be obtained from Pin32 of connector J5.

9.3.1 AUX Connector

The location of the AUX connector is located at the station rear panel. The following cables are the

reference cables used for this connector:

• Auxiliary System Cable, Part no. X244AG

• System Connector Cable, Part no. C540AD

9.3.2 System Connector

For details on the system connectors, refer to Chapter 6 : MTR3000 Backplane.

9.3.3 Telephone Line Connections

For details on the telephone line connections, refer to Chapter 6 : MTR3000 Backplane.

9.3.4 Station Maintenance Connections

Table 9-1 on page 9-6 provides a description of the maintenance connections located on the front of

the Station Control Module.

Page 15

9-6 MTR2000 MOTOTRBO Digital Upgrade: Operational Verification

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

Table 9-1. Station Maintenance Connections on the SCM

Connector Name Function Details

5/10 MHz External

Reference (J3008)

Service Speaker (J3010)

Microphone (J3000)

1

For alignment and for

receipt of external

reference.

1

Output to Power Voice

speaker

Local Microphone Input Use local microphone type GMMN4063 or

Note 1. Only work in analog mode.

9.4 Operational Verification

After the station equipment has been mechanically installed and all electrical connections have been

made, replace the new MTR3000 station front bezel by inserting one of the front bezel locking clip

into corresponding latch on the station housing, and carefully pressing the bezel on the opposite side

until the second locking clip snaps into place.

Achieved automatically and does not require

configuration in the CPS. This is a 50 Ω input that is

compatible with a 2Vpp (min) to 5Vpp (max) sine or

square wave.

Adjustable between 0 to 500 mV across 50 kΩ

@60% system deviation. Audio signal appears

between Pins 3 and 4 on the connector. Must use

speaker type HSN1006 via adapter cable Part.No.

0185180U01.

equivalent. Modulation sensitivity for 60% system

deviation is typically 56 mV rms.

9.4.1 Applying Power

Before applying power to the station, make sure all modules are securely seated in the appropriate

connectors on the backplane and that all RF cables are securely connected.

Plug in the AC line cord that supplies power to the station Power Supply, or switch on the DCbreaker to a station with a DC power source to the Power Supply.

9.4.2 Alignment and Configuration

After the station and ancillary equipment have been mechanically installed, properly cabled, and

power applied, the equipment must be optimized before placing the station in operation. Align with

the Tuner application followed by configuration with the CPS application.

Note

1. The BR will be locked after alignment with the Tuner application. To unlock it, the

codeplug must be read and then written to by the CPS application.

2. The BR reference must be aligned as shown in Section 13.3.3 on page 13-2, before the

BR is placed on the air.

9.4.3 Optimizing Tasks

Refer to Chapter 12 : MTR3000 Programming and Tuning for optimizing tasks.

Page 16

MTR2000 MOTOTRBO Digital Upgrade: Operational Verification 9-7

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

9.4.4 Verifying Radio Operation

Refer to Chapter 11 : MTR3000 Performance Check or Testing for procedures to verify Exciter and

Receiver circuitry operation.

9.4.5 Verifying Proper Operation

For details in this section, refer to Table 1-9 on page 1-12.

Page 17

Chapter 12 MTR3000 Programming and Tuning

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

12.1 Introduction

This chapter provides an overview of the MOTOTRBO Customer Programming Software (CPS) for

the MTR3000 and MTR2000 MOTOTRBO Digital Upgrade, as well as the MOTOTRBO Tuner

application for use on Windows XP

TM

Edition

32 bit and 64 bit operating system.

TM

, Windows Vista Home PremiumTM or Windows Vista Business

Note

Refer to the appropriate program on-line help files for the programming procedures.

12.2 Customer Programming Software Setup

The Customer Programming Software setup, shown in Figure 12-1 is used to program the base

station/repeater. Refer to Figure 12-2 and Figure 12-3 for the actual connectors on the front and rear

panels of the base station/repeater.

Note

Refer to the appropriate program on-line help files for the programming procedures.

Computer USB ports can be sensitive to Electronic Discharge. Employ

proper ESD practices (wrist strap, grounding, etc.) and do not touch

exposed contacts on cables when connected to a computer.

Station

Rear Panel

AUX (J7)

Front Panel

120 / 240 VAC

28 VDC

Figure 12-1. Customer Programming Software Setup from Rear Accessory Connector

AC

DC

Tx Port

(N-type Female)

Rx Port

(N-type Female)

Either One or Both

USB

Computer

Standard Type “A” to Type “B” USB cable

USB

Page 18

12-2 MTR3000 Programming and Tuning: Customer Programming Software Setup

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

USB port

Figure 12-2. Front view (without front bezel) of MTR3000 Base Station/Repeater

Tx port

DC connector

Rx port

AC connector

Figure 12-3. Rear view of MTR3000 Base Station/Repeater

Page 19

MTR3000 Programming and Tuning: Base Station/Repeater Tuning Setup 12-3

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

12.3 Base Station/Repeater Tuning Setup

A personal computer (PC), Windows TM operating system, and the MOTOTRBO Tuner application

are required to tune the Station. To perform the tuning procedures, the base station/repeater must

be connected to the PC and test equipment setup as shown in Figure 12-4.

Station

Front Panel

Computer

Either One or Both

120 / 240 VAC

28 VDC

Rear Panel

AUX (J7)

AC

DC

Wattmeter

Service Monitor

or Counter

Transmit

20 dB Pad

Tx Port

(N-type Female)

USB

Standard Type “A” to Type “B” USB cable

Figure 12-4. Base Station/Repeater Tuning Equipment Setup

12.4 Tuning Setup (MTR2000 MOTOTRBO Digital Upgrade)

Note

12.4.1 MTR2000 Calibration Coefficient Entry

This feature is used to allow entry of the transmitter (Tx) output power coefficients of an MTR2000

Power Amplifier (PA) into the MTR3000 tuning codeplug.

Since an upgraded MTR2000 Base Station/Repeater does not have its PA upgraded, its PA

calibration coefficients must be entered into the tuning codeplug, as the non-upgraded MTR2000 PA

does not have an Electrically Erasable Programmable Read-only Memory (EEPROM). The

calibration coefficients, which exist on a sticker on the face plate, consist of two 7 digit hexadecimal

numbers and two 6 digit hexadecimal numbers. The sticker itself is created and applied at the factory

in which the PA was calibrated.

12.4.1.1 Tuning Procedure

Section 12.4 only applies to an upgraded MTR2000.

USB

1. Power the Station from either an AC or DC source.

2. Launch the MOTOTRBO Tuner application on the computer.

Page 20

12-4 MTR3000 Programming and Tuning: Tuning Setup (MTR2000 MOTOTRBO Digital Upgrade)

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

Figure 12-5. Tx Menu tree (Tuning Procedure)

3. Select “Power” under the Tx menu in the tree view (Refer to Figure 12-5).

4. Click the “Read” button in the Tuner to read the current code values from the radio’s tuning

codeplug.

- If the returned codeplug values match the PA calibration sticker values, click the directory

tree to exit from the “Power” menu, or click the “Write” button to save the tuned power

values into the radio’s codeplug.

- If the retuned codeplug values do not match the PA calibration sticker value, proceed to

Step 5 below. Otherwise, proceed to Step 9 to exit.

5. Enter the upper left code from the PA calibration sticker to Code 1.

6. Enter the upper right code from the PA calibration sticker to Code 2.

7. Enter the lower left code from the PA calibration sticker to Code 3.

8. Enter the lower right code from the PA calibration sticker to Code 4.

9. Click the “Write” button to save the tuned power values into the radio’s codeplug.

10. Exit from the Tuner application to reset the radio. After reset, the radio will be locked.

11. To unlock the radio, launch the CPS. Read the codeplug, then write to the codeplug.

- CPS can be used to configure the codeplug prior to the write procedure (e.g. setting up

frequency)

12. Alignment is complete.

Page 21

MTR3000 Programming and Tuning: Modulation Limit Alignment 12-5

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

12.4.1.2 Verification or Test Procedure for High Power

1. Power the Station from either an AC or DC source.

2. Connect the radio’s Tx antenna port, through an attenuation pad and calibrate the path loss,

to the Communication Analyzer.

3. Via the CPS, program the radio with all user frequencies supported by the BR in analog

mode.

4. Enter the test frequency into the Communication Analyzer and set the analyzer in power

meter mode.

5. Connect a Mic to the RJ45 connector at the front panel.

6. Press the PTT button on the Mic.

7. Measure the transmit power.

8. If the measured transmit power is not within the original MTR2000 specifications range, the

PA must be replaced as it cannot be calibrated in the field.

9. Repeat Step 4 to Step 7 for the remaining frequencies.

12.5 Modulation Limit Alignment

This feature is to set the modulation limit of the radio for MTR3000 and MTR2000 MOTOTRBO

Digital Upgrade.

Note

A modulation limit alignment is not needed if the radio is used in repeat mode. This is

always the case when the radio is in digital mode.

12.5.1 Tuning Procedure (with no Tx Data and no PL)

Note

1. Under the “Accessories” menu within the CPS, if the “Audio Type” is set to “Rx & Tx

Filtered Squelch” and the “Analog Accessory Emphasis” is set to “De & Pre”, then a

modulation limite alignment is not needed. In this configuration, the modulation limit is

always set to 92% RSD by the station software.

2. If data or PL signaling is applied to Pin 13 of the J7 connector, proceed to Section 12.5.3

on page 12-7.

1. Connect the radio’s antenna port to the attenuation pad, if necessary, before connecting to

the Communication Analyzer.

2. Power the Station from either an AC or DC source.

3. Apply a 1 kHz signal at 1.2Vrms to Pin 1 of the J7 backplane connector.

- Signal ground is Pin 9 of the J7 backplane connector.

4. Launch the Tuner application and click the “Read” button to read the softpot values.

Page 22

12-6 MTR3000 Programming and Tuning: Modulation Limit Alignment

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

5. Select “Modulation Limit” under the Tx menu in the tree view (Refer to Figure 12-6).

Figure 12-6. Tx Menu tree (Tuning Procedure with no Tx data)

6. Enter the tuning frequency into the Communication Analyzer (the value displayed on the

Tuner GUI).

7. Click the “PTT Toggle” button within the Tuner environment to key up the radio.

8. Adjust the softpot value until the maximum deviation is 92% of the rated system deviation

(RSD). This will be tested in a 12.5 kHz channel spacing, so 92% of 2.5 kHz is 2.3 kHz.

Note

Set the modulation limit to 92% so that any additional deviation incurred by the transmitter

VCOs over temperature is compensated for.

Channel Spacing RSD 92% of RSD Tolerance

12.5 kHz 2.5 kHz 2.3 kHz +0Hz / -50Hz

9. Click the “PTT Toggle” button within the Tuner environment to de-key the radio.

10. Click “Write” to save the new tuned softpot value into the radio’s codeplug.

12.5.2 Verification (with no Tx Data and no PL)

1. Connect the radio’s antenna port to the attenuation pad, if necessary, before connecting to

the Communication Analyzer.

2. Power the Station from either an AC or DC source.

3. Via CPS, program the radio with any frequency within the specified range of the BR under

test, and set the radio for low power and disable the repeat path.

4. Apply a 1 kHz signal at 1.2Vrms to Pin 1 of the J7 backplane connector.

- Signal ground is Pin 9 of the J7 backplane connector.

5. Key up the radio and measure the deviation

- Key the radio by grounding Pin 2 of the J7 backplane connector.

- CPS must have Pin 2 configured as an active low with the PTT function.

Page 23

MTR3000 Programming and Tuning: Modulation Limit Alignment 12-7

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

6. De-key the radio.

The deviation shall meet the limits shown in the table below.

Relative

Channel Spacing

Standard

Deviation

92% of RSD Tolerance

(RSD)

12.5 kHz 2.5 kHz 2.3 kHz +0Hz / -50Hz

20.0 kHz 4.0 kHz 3.68 kHz +0Hz / -80Hz

25.0 kHz 5.0 kHz 4.6 kHz +0Hz / -100Hz

Note The BR will be factory-tuned in accordance to the above procedure and specification.

12.5.3 Tuning Procedure (with Tx Data or PL)

1. Connect the radio’s antenna port to the attenuation pad, if necessary, before connecting to

the Communication Analyzer.

2. Turn on the Station using an AC or DC source.

3. Click the “Read” button on the Tuner application to read the radio’s softpot values.

4. Select “Modulation Limit” under the Tx menu in the tree view.

5. Enter the tuning frequency into the Communication Analyzer (the value displayed by the

Tuner application).

6. Click the “PTT Toggle” button within the Tuner environment to key up the radio.

7. Apply a 1 kHz signal at 1.2Vrms to Pin 22 of the J7 backplane connector.

- Signal ground is Pin 9 of the J7 backplane connector.

- If the manufacturer of the third party controller specifies that the Tx Audio is not to be pre-

emphasized, use Pin 1 instead of Pin 22.

8. Adjust the Modulation Limit softpot to a value that limits the maximum deviation to “X”% RSD,

where “X” is equal to “92% RSD” minus “Tx Data’s % RSD”.

E.g. If Tx Data deviation is equal to 17%,

9. Click the “PTT Toggle” button within the Tuner environment to de-key the radio.

X = 92% - 17% = 75% as the maximum deviation limit.

100%

%RSD

0%

With Tx Data or PL

8%

17%

75%

Figure 12-7. Example of maximum deviation limit calculation

92%

Buffer

Data or PL

Voice

Page 24

12-8 MTR3000 Programming and Tuning: Modulation Limit Alignment

Applicant: Motorola

Equipment Type: ABZ89FC4827

Exhibit D1-4

10. Click “Write” to save the newly tuned softpot value into the radio’s codeplug.

11. Alignment is complete.

Note

Note

Refer to Figure 5-2 on page 5-5 for details regarding the audio and data flow.

Set the modulation limit to 92% to compensate for any additional deviation incurred by the

transmitter VCOs over temperature.

12.5.4 Verification (with Tx Data or PL)

Refer to Section 12.5.2 on page 12-6 with the following exceptions:

• The same Tx data signal level determined (obtained from Step 8 in Section 12.5.3 on page 12-

7), is applied to Pin 13 during the validation process.

• Pin 22 may be used instead of Pin 1, depending on the recommendation by the manufacturer of

the third party controller.

Page 25

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Racking Configurations (Draft)

There are various equipment racking configurations available to customers. The following section depicts some of

the racking alternatives.

Floor-Mount Cabinet

The front, side and top views for all available floor-mount cabinets are shown below. Cabinet models and

hardware are shown in the following table:

Model Description

THN6700 12 inch Indoor Cabinet

THN6701 30 inch Indoor Cabinet

THN6702 46 inch Indoor Cabinet

THN6788 Motorola Cabinet Slides

CLN6833 Non-Motorola Cabinet Slides

See the installation manual for recommended equipment ventilation clearances. For improved access to the unit,

tray slides are available as shown in the table above.

EXHIBIT D1-5

Page 26

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Racking Configurations (Draft, Continued)

Modular Racks

The front, side and top views for all available floor-mount cabinets are shown below. The cabinet models and

associated description are shown in the following table:

Rack Model Description

THN6752 30 inch Modular Rack (16 RK U)

THN6753 45 inch Modular Rack (24 RK U)

THN6754 52 inch Modular Rack (27 RK U)

The side, top and bottom views for all available modular racks are shown below. The top and bottom plates are

identical, and all dimensions and clearances are common to all racks.

Recommended clearance front and rear is 91.44 cm (36 in) minimum for servicing access. Refer to Equipment

Ventilation for recommended ventilation clearances.

FRU kit CLN6679 (Rack Mount Hardware) is included with each rack model. This allows proper installation of the

MTR3000 base station / repeater within the rack’s center of gravity.

NOTE: This kit includes two rack mount standoffs and eight mounting screws.

EXHIBIT D1-5

Page 27

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Functional Description / Operation of Modules (Draft)

Base Radio Module Overview

The Motorola MTR2003 / MTR3000 Base Station / Repeater (BR) provides a modular, flexible analog and digital

station design for today's communication systems and of the future. The stations are available for use in Analog

Conventional, Digital Conventional (MOTOTRBO), LTR Trunking, Passport Trunking, MOTOTRBO Capacity Plus

Trunking, and MOTOTRBO Connect Plus Trunking configurations.

The BR can either be configured as a stand-alone base station / repeater or as a base station / repeater connected

to a back-end network, as in the case of operating in IP Site Connect mode. As a base station / repeater, it listens

on one uplink frequency, and then re-transmits on a downlink frequency thus providing the RF interface to the field

subscribers. When configured for analog station operation, the BR is designed to operate with most existing

analog systems, therefore making a smooth migration to the MOTOTRBO system.

When configured for digital operation, the BR offers additional services. The digital BR operates in TDMA mode,

which essentially divides one channel into two virtual channels using time slots; therefore the user capacity is

doubled. The BR utilizes embedded signaling to inform the field radios of the busy/idle status of each channel

(time slot), the type of traffic, and even the source and destination information.

Note: When configured in Digital Mode, the BR can only be used as a repeater.

Note: At any given time, the BR either operates as a digital repeater or as an analog repeater.

The BR is divided into functional modules that separate the frequency band specific and transmitter power specific

circuits from other circuits and has separate modules for the control interface. These modules are self contained

functional blocks with module-specific alarms. This design facilitates the field replaceable unit (FRU) concept of

field repair to maximize system uptime.

Indicators and Connections

This section describes the LED indicators and connectors provided on the base station / repeater. The set of

LEDs indicate the operational status of the base station / repeater. There are two sets of connectors for devices

external to the base station / repeater:

• One set connects to external devices to enable full operation of the base station / repeater. These are

located at the back of the base station / repeater.

• Another set connects to external devices for servicing the base station / repeater. These are located on

the Station Control Module.

LED Indicators

A set of eight LEDs is located on the base station / repeater front bezel. The position of the eight LEDs on the

front bezel is shown below. These LEDs indicate the status of the base station / repeater during normal operation.

Front Bezel LEDs and Connectors

After booting up the base station / repeater, the six LEDs (Power/Status, TX Slot 1, TX Slot 2, RX Slot 1, RX Slot 2

and the Mode LEDs) flashes in unison. The general status and condition of the MTR3000 Base Station / Repeater

can be obtained by observing the eight LED indicators on the front bezel. The following tables show the LED

symbols and their meaning and identify the information conveyed via the LED indicators.

EXHIBIT D1-6

Page 28

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Functional Description / Operation of Modules (Draft)

Front Bezel LED Indicators

External Connections - Electrical Connections for the base station / repeater external connectors and line cord are

located on the back panel and are shown below.

Location of External Connectors at Rear of Base Station / Repeater

The connection to external devices on the back panel is the J7 Auxiliary System Connector. The connector is a

25-pin connector used for connecting to an external device such as a trunking controller, tone remote adaptor, or

phone patch.

Service ports and LEDs are located on the front of the Station Control Module (SCM). The connection to external

devices on the front of the station control module is the BNC connector. The connector allows the base station /

repeater to be connected to a 5 MHz or 10 MHz external reference signal. The service ports include connectors

for:

• 5/10 MHz External Reference Signal

• Ethernet Connector

• Service Speaker Connector

• USB Connector

• Service Microphone Connector

EXHIBIT D1-6

Page 29

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Functional Description / Operation of Modules (Draft)

The locations of the connectors on the front of the station control module are shown below.

EXHIBIT D1-6

Page 30

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Functional Description / Operation of Modules (Draft)

Control Overview

The heart of the Station Control Module (SCM) is the two Texas Instruments OMAP1710 processors. Each OMAP

processor contains an ARM Host and a C55 DSP processor. One of these OMAP processor is dedicated to

Receiver DSP operations, while the other OMAP provides for all other operations, including the transmitter

functions.

The SCM controls the entire coordination of the base station/repeater functions. Specifically, the SCM provides for

the following functionalities:

• Contains and runs the preloaded base station/repeater software

• Manages inbound and outbound RF and Audio traffic

• Provides external speaker and microphone ports

• Provides an on-board USB port for local configuring, alignment and diagnostics via the following

applications:

- Customer Programming Software (CPS)

- Tuner application

- Repeater Diagnostic and Control (RDAC) software

- Online Help

• Provides an Ethernet port for IP site connectivity and remote RDAC

• Provides GPIO connectivity for third party controller interfaces

• Provides for analog base station/repeater audio connectivity

• Data and Control to the Receiver via the SPI and SSI respectively

• Data and Control to the Exciter via the SPI and SSI respectively

• Control of the PA’s set power via the SPI

• Generates the internal station reference

• Provides control of the front panel status indicators

EXHIBIT D1-6

Page 31

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Functional Description / Operation of Modules (Draft)

Receiver Overview

The Receiver Circuitry accepts receive RF signals from the site receive antenna, performs filtering and dual

conversion, and outputs a digitized receive signal to the SCM. The receiver module has an on-board preselector.

The receive signal is input from the site receive antenna to the receiver module, or to an external preselector filter

(a separate assembly attached to the rear of the base station / repeater which provides highly selective bandpass

filtering). The signal is fed through a low-pass filter, varactor tuned preselector, RF amplifier and image filter to the

RF input of the first mixer. The filtered signal is mixed with an injection signal generated by the receive synthesizer

/ VCO, resulting in a first i-f (intermediate frequency) signal. The injection signal frequency is determined by

frequency programming data from the SCM via the SPI bus. The specific frequency of the first i-f depends on the

frequency band of the base station / repeater.

The first i-f signal is filtered and input to a custom receiver IC. This component contains circuitry for generating the

second injection signal, mixing down the first i-f to 2.25 MHz, amplification, and A/D (analog-to-digital) conversion

of the second i-f signal, resulting in a digitized receive signal. This signal is fed as differential data to the SCM.

The Receiver Module contains the following circuitry:

• Frequency Synthesizer Circuitry – consists a phase-locked loop and Voltage-Controlled Oscillator (VCO),

generates the first LO injection signal

• Varactor-tuned Preselector Filter – provides bandpass filtering of the station Receiver RF input

• Receiver Front End Circuitry – performs filtering, amplification, and the first down conversion of the

Receiver RF signal

• Custom Receiver IC Circuitry – consists a custom IC which performs the second down conversion,

filtering, amplification, and analog-to-digital conversion of the receive signal

• Analog to Digital Converter (ADC) Converter Circuitry – converts analog Receiver status signals to digital

format for transfer, upon request, to the SCM

• Local Power Supply Regulation – accepts +8V, +10V and +14.2V inputs and outputs +2.775V, +3.3V, +5V,

+10V, and +14.2V operating voltages

Input and Output Connections

The following shows the Receiver module input and output external connections.

EXHIBIT D1-6

Page 32

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Functional Description / Operation of Modules (Draft)

Specifications

The following table shows the specifications of MTR3000 Base Station / Repeater’s Receiver.

Parameter Specification

Frequency Ranges 403–470 MHz (UHF R1) or 450–524 MHz (UHF R2)

Electronic Bandwidth Full Bandwidth (UHF R1 and R2)

Analog Sensitivity 12 dB SINAD 0.257 μV (-118.8 dBm)

Intermodulation Rejection 85 dB

Adjacent Channel Rejection* 75 dB at 12 kHz, 80 dB at 25 kHz

Spurious and Image Response Rejection 85 dB

Intermediate Frequencies 1st: 73.35 MHz

2nd: 2.25 MHz

RF Impedance 50 Ω

Current Draw (Maximum) 0.04A from 14.2 VDC supply

0.52A from 10 VDC supply

0.11A from 8 VDC supply

EXHIBIT D1-6

Page 33

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Functional Description / Operation of Modules (Draft)

Exciter Overview

The Transmitter Circuitry comprises two modules, the Exciter Module and the Power Amplifier (PA) Module.

These modules combine to generate, modulate, and amplify the RF signal which is transmitted via the site transmit

antenna.

The Exciter Module interfaces directly to the Station Control Module (SCM), generates a modulated RF signal at

the desired transmit frequency and sends this signal to the PA for amplification. The circuitry operates as follows.

The transmit synthesizer and Voltage-Controlled Oscillator (VCO) circuitry on the Exciter Module accept frequency

programming data from the SCM via the Serial Peripheral Interface (SPI) bus, and generate an RF carrier at the

specified frequency. The VCO is directly modulated by transmit audio / data from the SCM. The resulting

modulated RF signal (at a level of approximately +12 dBm) is then fed to the PA.

The Exciter board contains the following circuitry:

• Frequency Synthesizer Circuitry – consists of a phase-locked loop and Voltage-Controlled Oscillator

(VCO), generates a modulated RF signal at the transmitter carrier frequency

• RF Isolation Switch – allows the SCM to turn on/off the Exciter RF output signal to the power amplifier

module

• Analog to Digital Converter (ADC) Converter Circuitry – converts the analog Exciter status signals to the

digital format for transfer, upon request, to the SCM

• Local Power Supply Regulation/Filtering – accepts +8V, +10V and +14.2V inputs and provides +5V, +10V,

and +12V operating voltages

Input and Output Connections - The following shows the Exciter module input and output external connections.

Specifications of Exciter Module

Parameter Specification

Frequency Ranges 403–470 MHz (UHF R1) or 450–524 MHz (UHF R2)

Electronic Bandwidth Full Bandwidth (UHF R1 and R2)

Output Power 10–14 dBm

Current Draw (Maximum) 0.04A from 14.2 VDC supply

0.15A from 10 VDC supply

0.02A from 8 VDC supply

Harmonics -20 dBc

EXHIBIT D1-6

Page 34

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Functional Description / Operation of Modules (Draft)

Power Amplifier Module Overview

The Power Amplifier (PA) is a forced convection-cooled RF power amplifier. It accepts a low-level modulated RF

signal from the Exciter Module and amplifies the signal for transmission via the site transmit antenna. The output

power is continually monitored and regulated by a feedback and control loop, with a power output control voltage

being generated by the transmitter control circuitry located on the PA Input/Output boards.

Overview of Circuitry

The Power Amplifier contains the following sub-circuits:

• Intermediate Power Amplifier (IPA) – hybrid substrate amplifier stage which accepts low-level input from

Exciter Module, amplifies the signal, and outputs a 0 W to 10 Watt RF signal

• Final Module – hybrid substrate amplifier stage which accepts output from IPA Hybrid and provides final

amplification to 100 Watts (maximum)

• Directional Coupler/Power Detector/Low Pass Filter – couples amplified RF signal to transmit antenna

connector; also generates dc voltages proportional to forward and reflected power for use in TX power

control loop; provides harmonic suppression for the station

• Single Circulator – provides isolation between Power Amplifier output and transmit antenna

• Temperature Sense Circuitry – provides variable resistance signal proportional to heat sink temperature;

signal is monitored by the PA power control circuitry

Input and Output Connections

The following shows the PA input and output external connections.

EXHIBIT D1-6

Page 35

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Functional Description / Operation of Modules (Draft)

The following table shows the specifications of MTR3000 Power Amplifier (PA).

Specifications of Power Amplifier

Parameter Specification

Operational Frequency Range 403–435 MHz (R1) or 435–470 MHz (R2)

Rated RF Output Power Range 25–100 W

Rated RF Input Power Range 9.8–14 dBm

28.6V Supply Nominal Voltage (AC Power) 28.6V (+/- 4%)

14.2V Supply Nominal Voltage 14.2V (+/- 3%)

28.6V Supply Maximum Current Draw 12.6A

14.2V Supply Maximum Current Draw 2.0A

Functional Theory of Operation

A low-level modulated RF signal (approximately +13 dBm) from the Exciter Module enters the PA Input board via a

coax cable. The signal is input to the IPA and amplified to approximately 0 to 10 W (depending on the dc power

control voltage (V_CNTL) from the PA output board). The IPA output is then fed to the Dual Device Module for

further amplification.

The output of the DDM is then transferred to the circulator and then to the harmonic filter/coupler via the PA output

board. The signal then exits from the Power Amplifier Module via an N-type coax connector.

A single circulator is built into the Power Amplifier Module to provide isolation between the PA module and the

transmit antenna.

A thermistor mounted on the PA printed circuit board outputs a variable resistance proportional to the heat sink

temperature. This signal is fed to the power control circuitry on the PA output board, which monitors the signal and

reduces the PA output power (and enables a fan) if the PA temperature exceeds set limits.

A feedback and control loop configuration is used to regulate the PA output power. The Directional Coupler

generates a dc voltage proportional to the PA Module output power. This voltage is fed to power control circuitry

on the PA output board where it is compared to reference voltages to generate a dc power control voltage. The

Station Control Module sends current and power limit signals to a D/A converter (via the SPI bus) to control the

maximum current/control voltage levels. The control voltage is fed to the IPA module where it controls the IPA

output, thus controlling the overall output from the PA Module.

Analog signals from various strategic operating points throughout the PA module are fed to an A/D converter,

which converts them to a digital signal and, upon request by the Station Control Module, outputs the signal to the

Station Control Module via the SPI bus.

For example, the directional coupler generates a dc voltage proportional to the reflected power. This signal is

converted to a digital signal and sent to the SCM. If the sense line indicates an impedance mismatch (high

VSWR), the PA is either cut back in power or shut down completely.

EXHIBIT D1-6

Page 36

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Functional Description / Operation of Modules (Draft)

Power Supply Module Overview

The Power Supply is described in this section. The information provided is sufficient to give service personnel a

functional understanding of the module, allowing maintenance and troubleshooting to the module level. Refer to

the service manual for Maintenance and Disassembly/Reassembly Procedures for detailed removal or installation

procedures for all modules in the station.

Over-current conditions on either the 28.6 VDC or 14.2 VDC outputs cause the total supply to shutdown and try to

restart. If the over-current continues to exist, the power supply will ‘hiccup’ until the overload condition is removed,

and will not be damaged by the overload. The 28.6 VDC output is protected by a primary current sense method

such that its current limit point varies depending on the load on the other outputs at the time. The trip point for the

14.2 V and 5.1 V outputs is greater than 115% of the maximum current specified for the outputs. The power

supply recovers automatically after the removal of the overload condition.

The 28.6 V and 14.2 V outputs are protected from continuous over-voltages by detection circuits that cause the

supply to shutdown and then try to restart itself. If the over-voltage condition continues to occur, the supply goes

into a ‘hiccup’ mode of shutting down and trying to restart. If the over-voltage condition is removed, the supply

automatically recovers. In addition, the 14.2 V and the 5 V outputs are protected by crowbar circuits.

An AC Fail detect signal is provided to indicate (when used with battery backup option) that the power supply is

operating from an external dc source rather than the ac mains. This signal is a TTL compatible output capable of

sinking 1 mA, and is routed to the Station Control Module. The active-low state indicates ac operation. For the

nominal 120 VAC operation, the signal is active-high impedance (indicating an ac mains failure) when the ac

voltage is less than 85 Vrms, but more than the minimum voltage that guarantees that all outputs will be in

regulation at full load. For the nominal 240 AC operation, the detect point is less than 170 Vrms but more than the

minimum ac input voltage that guarantees that all outputs be in regulation at full load.

The supply incorporates temperature sense/fan enable circuitry for controlling a 12VDC fan mounted on the

surface of the heatsink assembly. The power supply circuitry senses the internal temperature of the power supply.

When the internal temperature exceeds +60°C (± 5°C), +12 V is enabled at J1–1 to turn on the fan. The +12 V fan

supply is derived from the +14.2 V output. Power to the fan is off when the temperature is below the set limit. The

fan turns for approximately 5 seconds when power is first applied as a diagnostic indicator that the fan is

functional.

The power supply will turn off all outputs when an operational ambient temperature of +80°C (±2°C) has been

reached with the supply operating at any input within its operating input voltage range (dc and ac).

The following shows the electrical performance specifications for the power supply.

Power Supply Module AC Performance Specifications:

Parameter Value or Range

Input Voltage Range 85 VAC to 264 VAC

Operating Temperature –30° to +60° C (–22° to +140° F)

Input Frequency Range 47 to 63 Hz

Steady State Output Voltage

28.6 V @ 13 A,

14.2 V @ 8 A,

5.1 V @ 2 A

Output Power (Rated) 500 W

Output Ripple:

+28.6 VDC

+14.2 VDC

+5.1 VDC

50 mV p-p, @ 25°C (77°F)

50 mV p-p, @ 25°C (77°F)

100 mV p-p, @ 25°C (77°F)

Efficiency Greater than 75% (Full Load)

EXHIBIT D1-6

Page 37

APPLICANT: MOTOROLA EQUIPMENT TYPE: ABZ89FC4827

User / Operational Manual

Functional Description / Operation of Modules (Draft)

Power Supply Module DC Performance Specifications:

Parameter Value or Range

Input Voltage Range 21.6 - 32 VDC

Operating Temperature –30° to +60° C (–22° to +140° F)

Steady State Output Voltage

28.6 V @ 13 A, Input Voltage Dependent

14.2 V @ 8 A, Regulated

5.1 V @ 2 A, Regulated

Output Power (Rated) 500 W

Output Ripple:

+28.6 VDC

+14.2 VDC

+5.1 VDC

Input Voltage Dependent, 0-0.5V below input

50 mV p-p, @ 25°C (77°F)

100 mV p-p, @ 25°C (77°F)

Efficiency Greater than 75% (Full Load)

EXHIBIT D1-6

Loading...

Loading...