查询PC33879DWB/R2供应商

Freescale Semiconductor, Inc.

MOTOROLA

SEMICONDUCTOR TECHNICAL DATA

Preliminary Information

Configurable Octal Serial Switch

with Open Load Detect Current

Disable

The 33879 device is an 8-output hardware-configurable, high-side/low-side

switch with 16-bit serial input control. Two of the outputs may be controlled

directly via microprocessor for PWM applications. The 33879 incorporates

SMARTMOS technology, with CMOS logic, bipolar/MOS analog circuitry, and

DMOS power MOSFETs. The 33879 controls various inductive, incandescent,

or LED loads by directly interfacing with a microcontroller. The circuit’s

innovative monitoring and protection features include very low standby

currents, cascade fault reporting, internal +45 V clamp voltage for low-side

configuration, -20 V high-side configuration, output-specific diagnostics, and

nc...

independent overtemperature protection.

, I

Features

or

emiconduct

• Designed to Operate 5.5 V <

• 16-Bit SPI for Control and Fault Reporting, 3.3 V/ 5.0 V Compatible

• Outputs Are Current Limited (0.5 A to 1.0 A) to Drive Incandescent

Lamps

• Output Voltage Clamp, +45 V (Low Side) and -20 V (High Side) During

Inductive Switching

• On/Off Control of Open Load Detect Current (LED Application)

• Internal Reverse Battery Protection on V

• Loss of Ground or Supply Will Not Energize Loads or Damage IC

• Maximum 5.0 µA I

•R

• Short Circuit Detect and Current Limit with Automatic Retry

• Independent Overtemperature Protection

• Motorola Now Offers Pb-Free Packaging with the Suffix EK

of 1.0 Ω at 25°C Typical

DS(ON)

PWR

V

< 26.5 V

PWR

PWR

Standby Current at 13.0 V V

PWR

Document order number: MC33879

Rev 3.0, 06/2004

33879

CONFIGURABLE OCTAL SERIAL

SWITCH WITH OPEN LOAD

DETECT CURRENT DISABLE

EK (Pb-FREE) SUFFIX

DWB SUFFIX

CASE 1437-01

32-LEAD SOICW-EP

ORDERING INFORMATION

Device

PC33879DWB/R2

PC33879EK/R2

Temperature

Range (T

-40°C to 125°C

)

A

Package

32 SOICW-EP

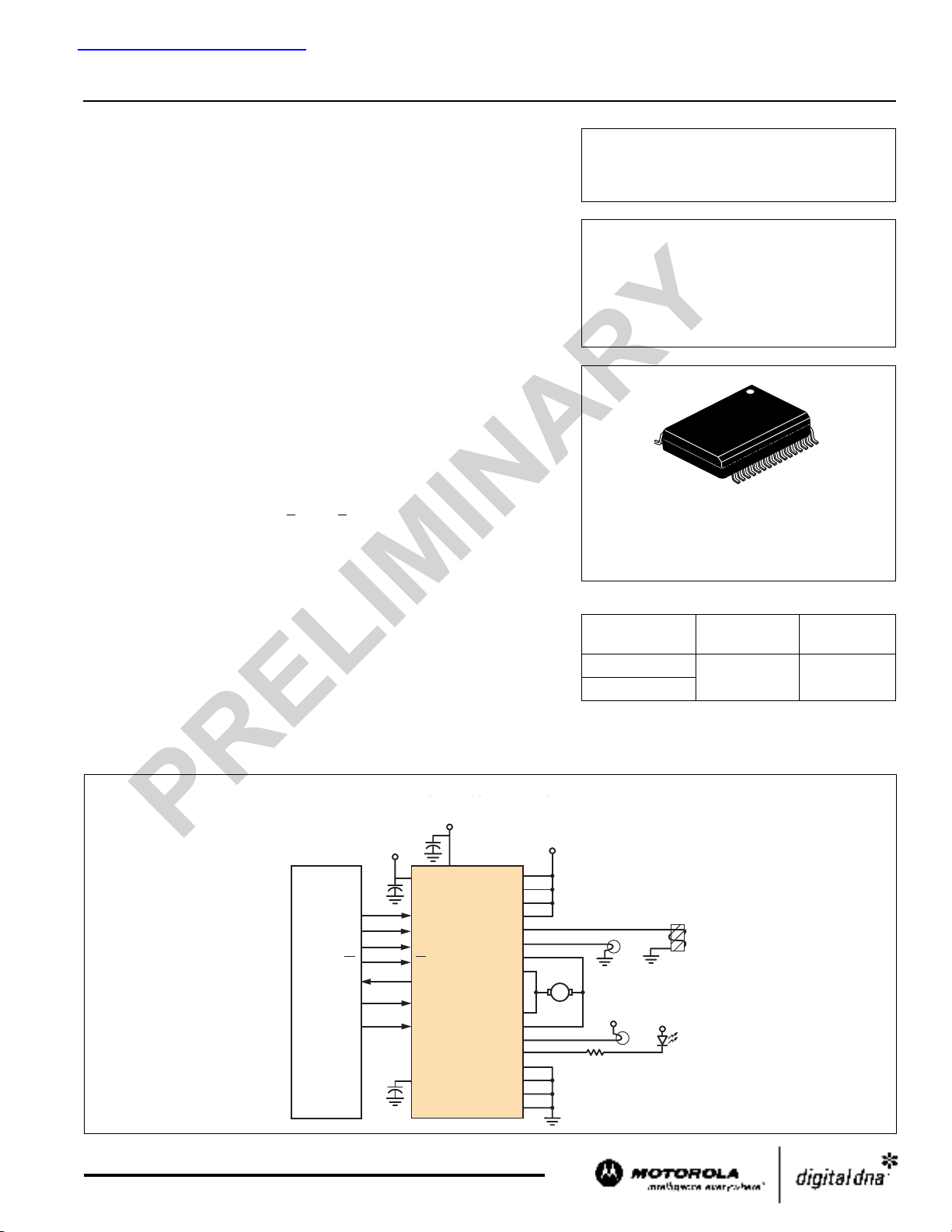

Simplified Application Diagram

33879 Simplified Application Diagram

eescale S

Fr

MCU

MOSI

SCLK

MISO

PWM1

PWM2

This document contains information on a product under development.

Motorola reserves the right to change or discontinue this product without notice.

© Motorola, Inc. 2004

For More Information On This Product,

+5.0 V

VDDV

A0

CS

EN

DI

SCLK

CS

DO

IN5

IN6

GND

Go to: www.freescale.com

V

PWR

PWR

33879

V

BAT

D1

D2

D3

D4

S1

S2

S3

S4

D5

D6

D7

D8

S5

S6

S7

S8

High-Side Drive

H-Bridge Configuration

M

Low-Side Drive

V

BAT

V

BAT

Freescale Semiconductor, Inc.

nc...

, I

or

emiconduct

eescale S

V

DD

__

CS

SCLK

DI

DO

EN

IN5

IN6

~50 µA

~110 kΩ

~50 µA

~50 µA

SPI and

Interface

Logic

SPI Bit 0

Enable

SPI Bit 4

IN5

Internal

Bias

Power Supply

Charge

Pump

, POR, SLEEP

OV

Typical of all 8 output drivers

TLIM

Gate

Drive

Control

Current

Limit

+

–

+

–

Open/Short

Comparator

TLIM

Gate

Drive

Control

Current

Limit

+

–

+

–

Open/Short

Comparator

~3.5 V Open/Short

Threshold

Overvoltage

Shutdown/POR

Sleep State

–

+

–

+

~3.5 V Open/Short

Threshold

Open

Load

Detect

Current

~80 µA

Open

Load

Detect

Current

~80 µA

V

PWR

GND

D1

D2

D3

D4

D7

D8

S1

S2

S3

S4

S7

S8

D5

D6

S5

S6

Drain

Outputs

Source

Outputs

Drain

Outputs

Source

Outputs

Fr

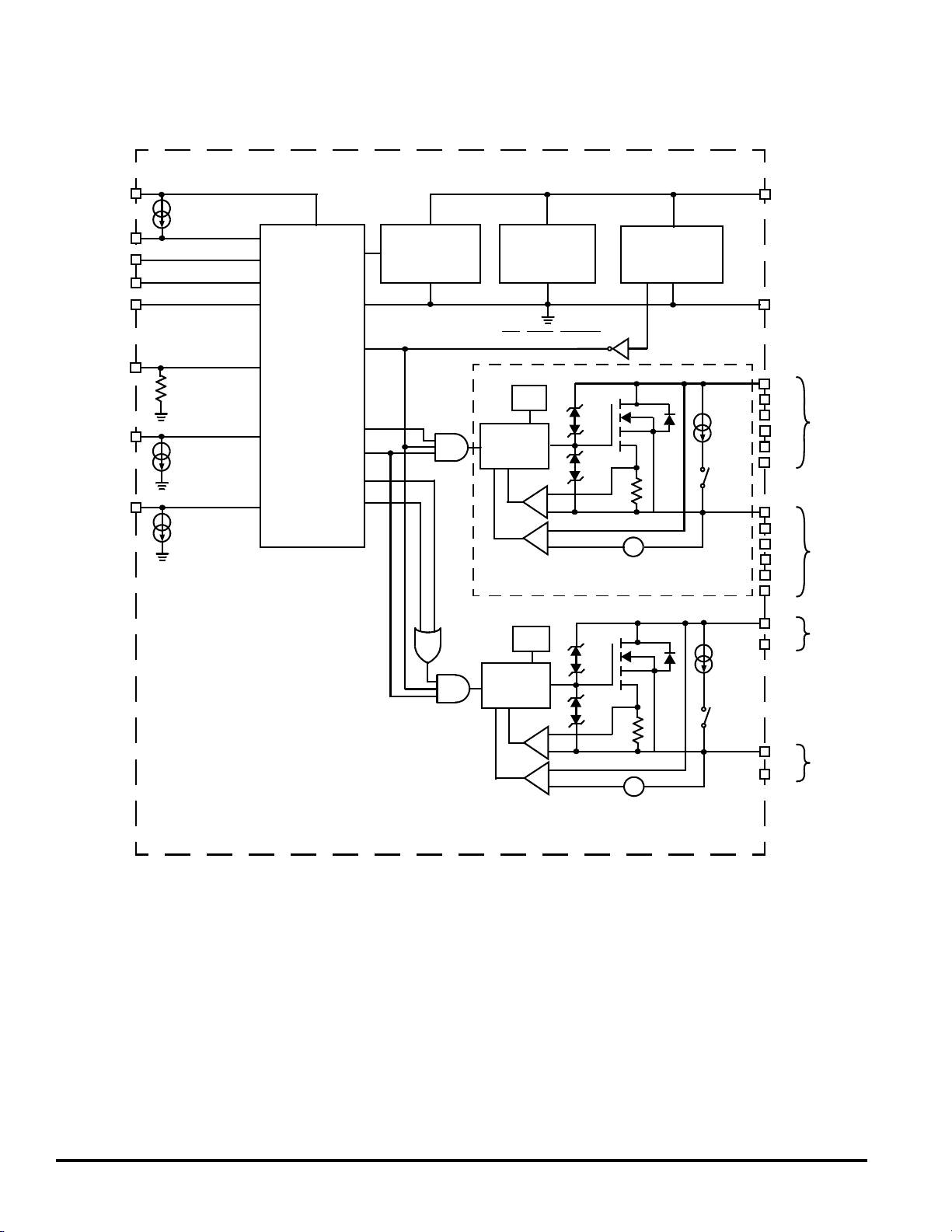

Figure 1. 33879 Simplified Internal Block Diagram

33879 MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA

2

For More Information On This Product,

Go to: www.freescale.com

Freescale Semiconductor, Inc.

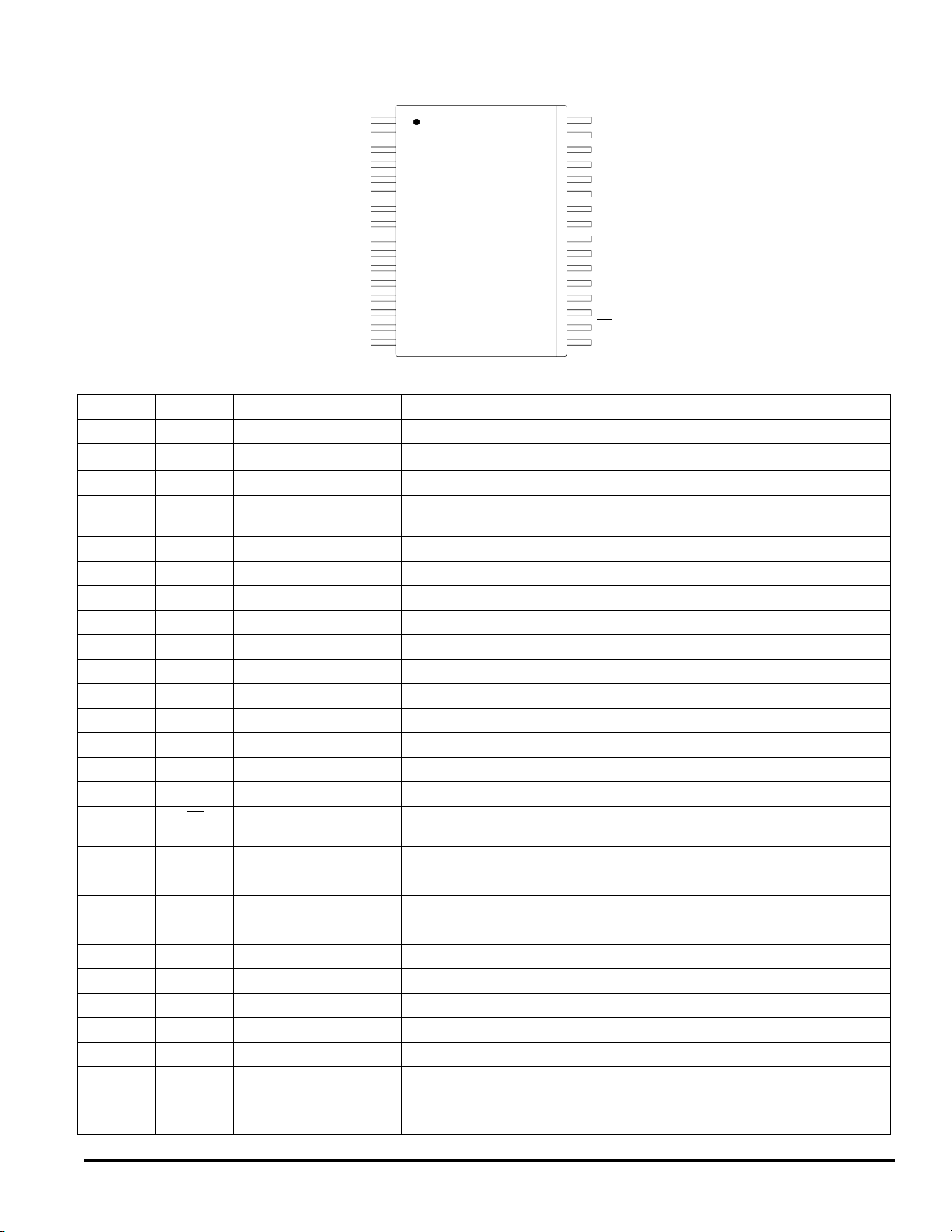

PIN FUNCTION DESCRIPTION

Pin Pin Name Formal Name Definition

nc...

, I

or

emiconduct

1GND

2V

3S8

4, 8, 9, 24,

25, 30

5D8

6S2

7D2

10 S1

11 D1

12 D6

13 S6

14 IN6

15 EN

16 SCLK

17 DI

18

NC

CS

eescale S

Fr

19 IN5

20 S5

21 D5

22 D3

23 S3

26 D4

27 S4

28 D7

29 S7

31 V

32 DO

PWR

DD

GND

V

DD

S8

NC

D8

S2

D2

NC

NC

S1

D1

D6

S6

IN6

EN

SCLK

Ground Digital ground.

Logic Supply Voltage Logic supply for SPI interface. With VDD low the device will be in sleep mode.

Source Output 8 Output eight MOSFET source pins.

Not Connected No internal connection to this pin.

Drain Output 8 Output eight MOSFETdrain pin.

Source Output 2 Output two MOSFET source pin.

Drain Output 2 Output two MOSFET drain pin.

Source Output 1 Output one MOSFET source pin.

Drain Output 1 Output one MOSFET drain pin.

Drain Output 6 Output six MOSFET drain pin.

Source Output 6 Output six MOSFET source pin.

Command Input 6 PWM direct control input pin for output 6. IN6 is “OR” with SPI bit.

Enable Input IC Enable. Active high. With EN low, the device is in sleep mode.

SPI Clock SPI control clock input pin.

Serial Data Input SPI control data input pin from MCU to the 33879. Logic [1] activates output.

SPI Chip Select SPI control chip select input pin from MCU to the 33879. Logic [0] allows data to be

Command Input 5 PWM direct control input pin for output 5. IN5 is “OR” with SPI bit.

Source Output 5 Output five MOSFET source pin.

Drain Output 5 Output five MOSFET drain pin.

Drain Output 3 Output three MOSFET drain pin.

Source Output 3 Output three MOSFET source pin.

Drain Output 4 Output four MOSFET drain pin.

Source Output 4 Output four MOSFET source pin.

Drain Output 7 Output seven MOSFET drain pin.

Source Output 7 Output seven MOSFET source pin.

Battery Input Power supply pin to the 33879. V

Serial Data Output SPI control data output pin from the 33879 to the MCU. DO=0 no fault, DO=1 specific

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

transferred in.

output has fault.

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

DO

V

PWR

NC

S7

D7

S4

D4

NC

NC

S3

D3

D5

S5

IN5

CS

DI

has internal reverse battery protection.

PWR

MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA 33879

For More Information On This Product,

Go to: www.freescale.com

3

Freescale Semiconductor, Inc.

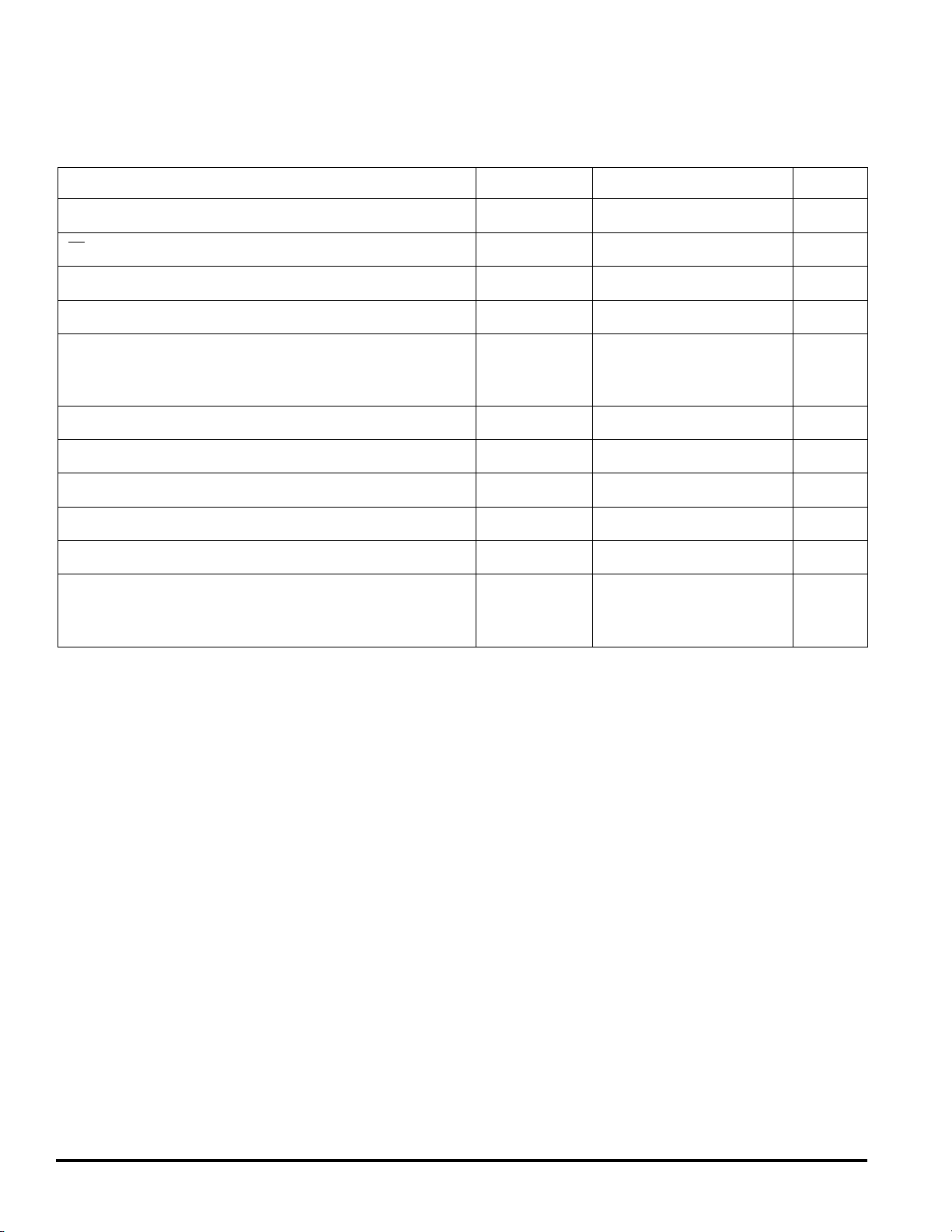

MAXIMUM RATINGS

All voltages are with respect to ground unless otherwise noted.

Rating Symbol Value Unit

Supply Voltage (Note 1) V

V

DD

CS, DI, DO, SCLK, IN5, IN6, and EN (Note 1) – -0.3 to 7.0 V

V

Supply Voltage (Note 1) V

PWR

Output Clamp Energy (Note 2) E

ESD Voltage

Human Body Model (Note 3)

Machine Model (Note 4)

Storage Temperature T

DD

PWR

CLAMP

V

ESD1

V

ESD2

STG

-0.3 to 7.0 V

-16 to 40 V

50 mJ

±2000

±200

-55 to 150

nc...

Operating Case Temperature T

C

-40 to 125

, I

Operating Junction Temperature T

or

Maximum Junction Temperature T

Power Dissipation (Note 5) P

Thermal Resistance

Junction-to-Ambient

Between the Die and the Exposed Die Pad

Notes

1. Exceeding these limits may cause malfunction or permanent damage to the device.

emiconduct

2. Maximum output clamp energy capability at 150

3. ESD1 testing is performed in accordance with the Human Body Model (C

4. ESD2 testing is performed in accordance with the Machine Model (C

5. Maximum power dissipation at T

= 25°C with no heatsink used.

A

°C junction temperature using single non-repetitive pulse method with I = 350 mA.

ZAP

= 200 pF, R

ZAP

J

J

D

R

JA

θ

R

JC

θ

= 100 pF, R

ZAP

= 1500 Ω).

ZAP

= 0 Ω).

-40 to 150

-40 to 150

1.7 W

71

1.2

DC

DC

DC

V

°C

°C

°C

°C

°C/W

eescale S

Fr

33879 MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA

4

For More Information On This Product,

Go to: www.freescale.com

Freescale Semiconductor, Inc.

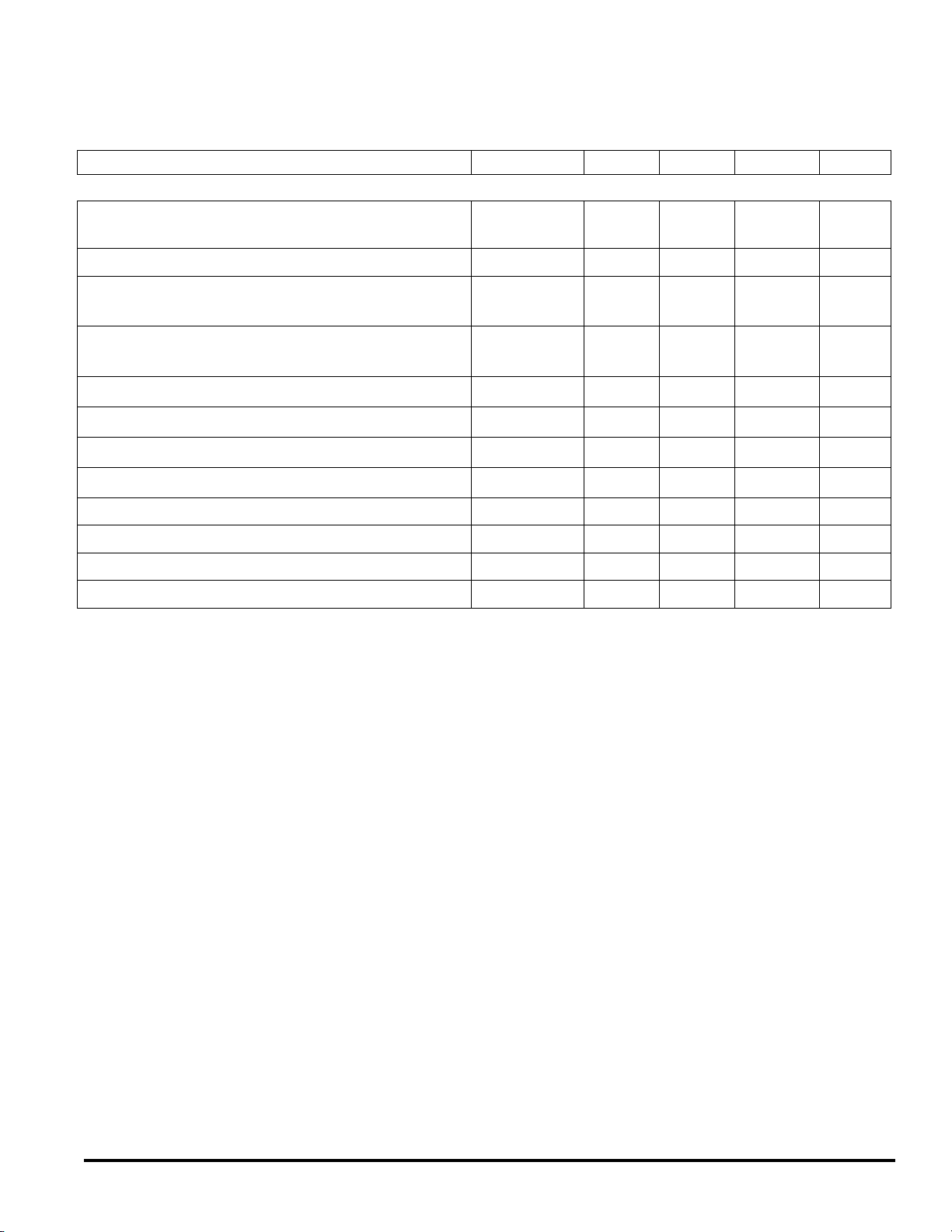

STATIC ELECTRICAL CHARACTERISTICS

Characteristics noted under conditions of 3.1 V ≤ V

Where applicable, typical values reflect the parameter’s approximate average value with V

Characteristic Symbol Min Typ Max Unit

POWER INPUT

Supply Voltage Range

Fully Operational

≤ 5.5 V, 5.5 V ≤ V

DD

V

PWR(fo)

≤ 18 V, -40°C ≤ TC ≤ 125°C unless otherwise noted.

PWR

5.5 – 26.5

= 13 V, TA = 25°C.

PWR

V

nc...

, I

or

emiconduct

Supply Current I

Sleep State Supply Current

V

or EN ≤ 0.8 V, V

DD

Sleep State Supply Current

EN ≤ 0.8 V, V

Overvoltage Shutdown Threshold Voltage V

V

PWR

V

Overvoltage Shutdown Hysteresis Voltage V

PWR

V

Undervoltage Shutdown Threshold Voltage V

PWR

Undervoltage Shutdown Hysteresis Voltage V

V

PWR

Logic Supply Voltage V

Logic Supply Current I

Logic Supply Sleep State Threshold Voltage V

Logic Supply Sleep State Hysteresis (Note 6) V

Notes

6. This parameter is guaranteed by design but is not production tested.

= 5.5 V

DD

PWR

= 13 V

PWR(OV-hys)

PWR(

PWR(on)

I

PWR(ss)

I

VDD(

ss)

PWR(

OV)

PWR(

UV)

UV-hys)

DD

DD

DD(SS)

DD(SS-hys)

–1424mA

µA

–2.05.0

µA

–2.05.0

27 28.5 32 V

0.2 1.5 2.5 V

3.0 4.0 5.0 V

300 500 700 mV

3.1 – 5.5 V

250 400 700 µA

0.8 2.5 3.0 V

0.3 – 1.5 V

eescale S

Fr

MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA 33879

For More Information On This Product,

Go to: www.freescale.com

5

Freescale Semiconductor, Inc.

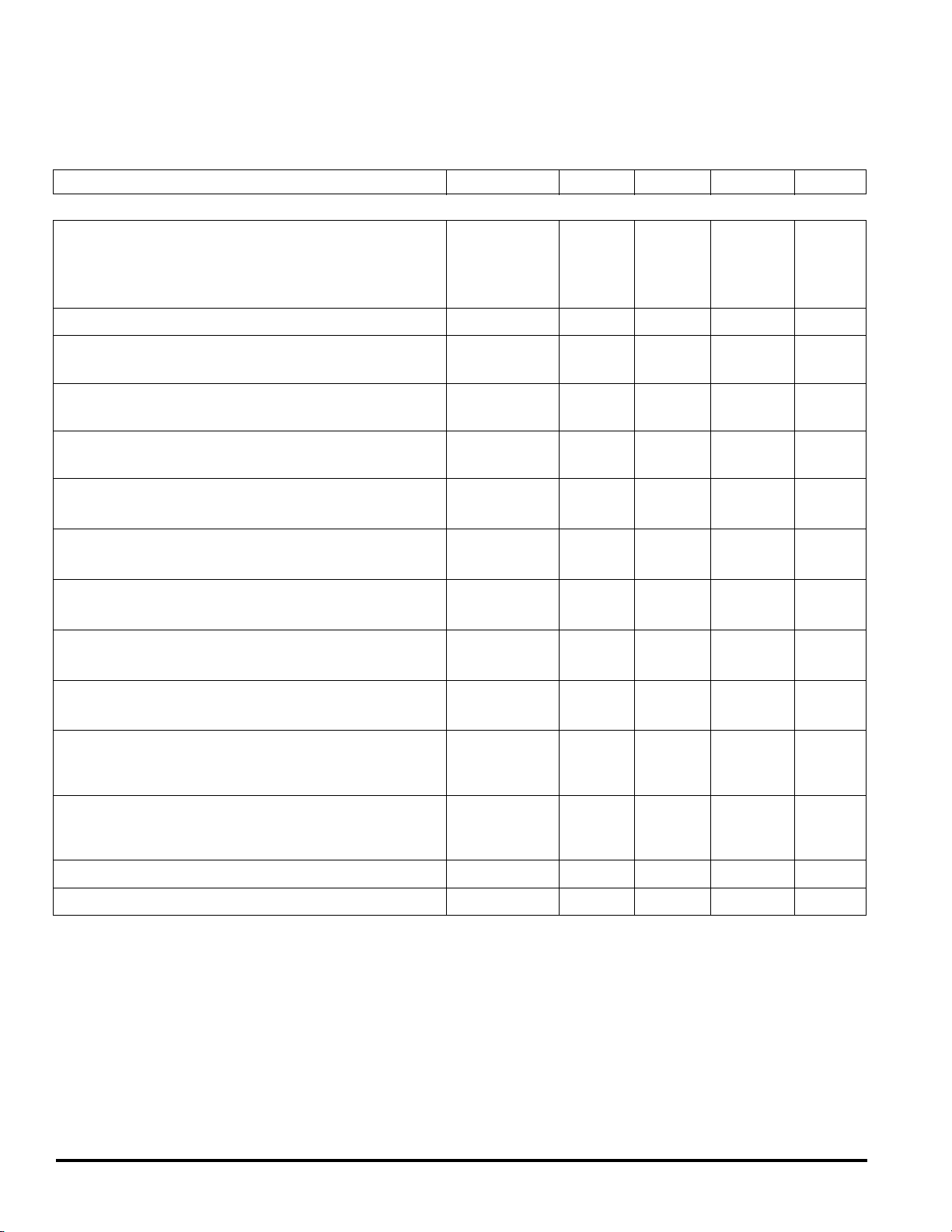

STATIC ELECTRICAL CHARACTERISTICS (continued)

Characteristics noted under conditions of 3.1 V ≤ V

≤ 5.5 V, 5.5 V ≤ V

DD

≤ 18 V, -40°C ≤ TC ≤ 125°C unless otherwise noted.

PWR

Where applicable, typical values reflect the parameter’s approximate average value with V

Characteristic Symbol Min Typ Max Unit

POWER OUTPUT

Drain-to-Source ON Resistance

I

= 0.350 A, TJ = 125°C, V

OUT

= 0.350 A, TJ = 25°C, V

I

OUT

= 0.350 A, TJ = -40°C, V

I

OUT

PWR

PWR

PWR

= 13 V

= 13 V

= 13 V

R

DS (ON)

–

–

–

= 13 V, TA = 25°C.

PWR

–

1.0

–

1.4

Ω

–

–

Output Self Limiting Current High-Side and Low-Side Configurations I

Output Fault Detection Voltage Threshold (Note 7)

Outputs Programmed OFF

Output Fault Detection Current @ Threshold, High-Side Configuration

Outputs Programmed OFF

nc...

Output Fault Detection Current @ Threshold, Low-Side Configuration

Outputs Programmed OFF

, I

Output OFF Open Load Detection Current, High-Side Configuration

or

V

= 16 V, V

Drain

Output OFF Open Load Detection Current, Low-Side Configuration

= 16 V, V

V

Drain

Output Clamp Voltage Low-Side Drive

I

= 10 mA

D

Output Clamp Voltage High-Side Drive

= -10 mA

I

S

emiconduct

Output Leakage Current High-Side and Low-Side Configurations

= 0 V, V

V

DD

Output Leakage Current Low-Side Configuration

= 5.0 V, V

V

DD

Open Load Detection Current Disabled

Output Leakage Current High-Side Configuration

V

= 5.0 V, V

eescale S

Fr

DD

Open Load Detection Current Disabled

Overtemperature Shutdown (Note 8) T

Overtemperature Shutdown Hysteresis (Note 8) T

Notes

7. Output fault detection thresholds with outputs programmed OFF. Output fault detect thresholds are the same for output open and shorts.

8. This parameter is guaranteed by design but is not production tested.

Drain

= 0 V, Outputs Programmed OFF

Source

= 0 V, Outputs Programmed OFF

Source

= 16 V, V

= 16 V, V

Drain

= 16 V, V

Drain

Source

Source

Source

= 0 V

= 0 V,

= 0 V,

OUT(LIM)

V

OUT(flt-th)

I

OUT(flt-th)

I

OUT(flt-th)

I

OCO

I

OCO

V

OC(LSD)

V

OC(HSD)

I

OUT(LKG)

I

OUT(LKG)

I

OUT(LKG)

LIM

LIM(hys)

0.5 – 1.0 A

2.5 3.5 4.2

35 55 70

20 30 50

65 100 160

40 75 135

40 45 55

-15 -20 -25

––7.0

–– 5

––20

155 – 185

5.0 10 15

µA

µA

µA

µA

µA

µA

µA

°C

°C

V

V

V

33879 MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA

6

For More Information On This Product,

Go to: www.freescale.com

Freescale Semiconductor, Inc.

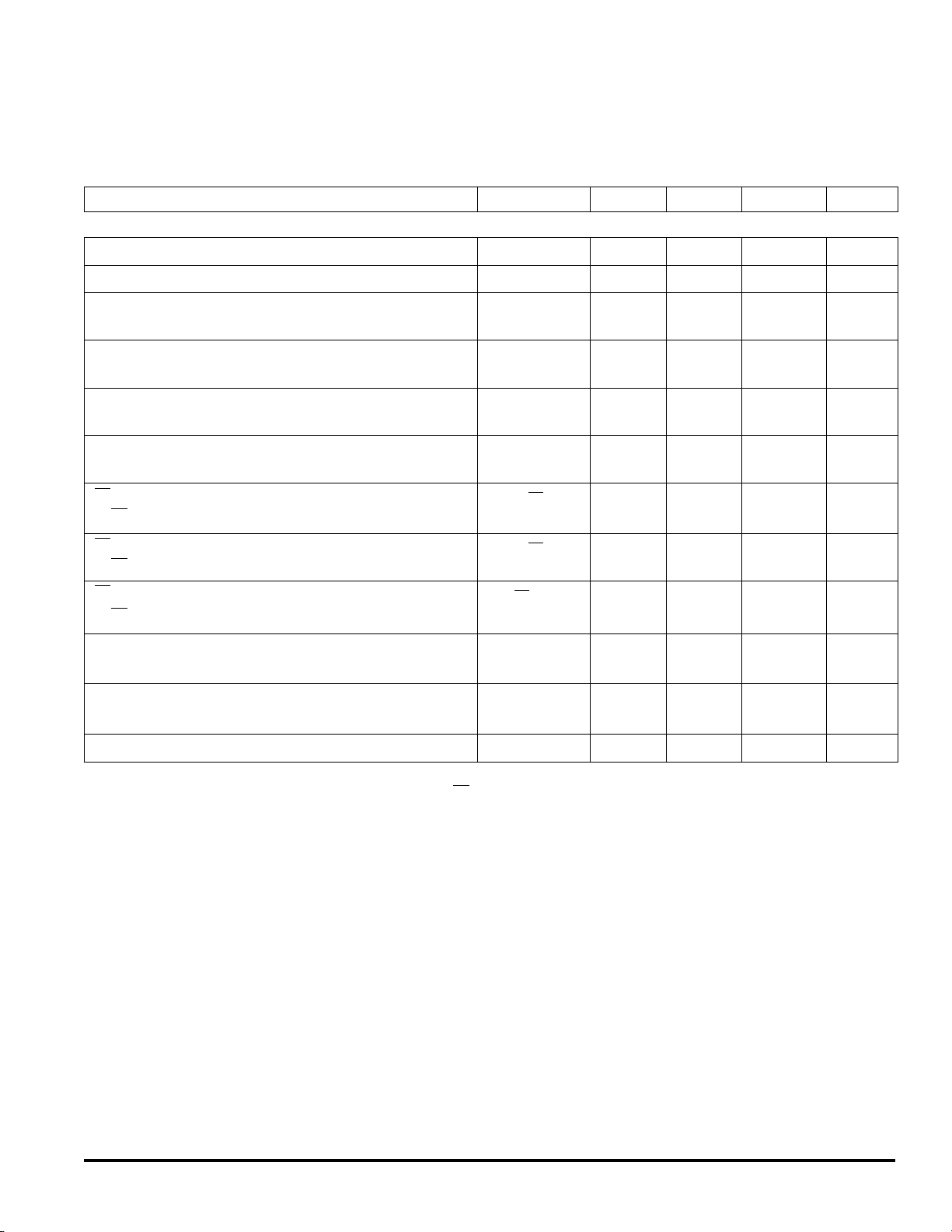

STATIC ELECTRICAL CHARACTERISTICS (continued)

Characteristics noted under conditions of 3.1 V ≤ V

≤ 5.5 V, 5.5 V ≤ V

DD

≤ 18 V, -40°C ≤ TC ≤ 125°C, unless otherwise noted.

PWR

Typical values, where applicable, reflect the parameter’s approximate average value with V

Characteristic Symbol Min Typ Max Unit

DIGITAL INTERFACE

Input Logic High-Voltage Thresholds (Note 9) V

Input Logic Low-Voltage Thresholds (Note 9) V

IN5, IN6, EN Input Logic Current

IN5, IN6, EN = 0 V

I

IN5, IIN6, IEN

IH

IL

0.7 x V

GND - 0.3 – 0.2 x V

-10 – 10

= 13 V, TA = 25°C

PWR

DD

–V

+ 0.3 V

DD

DD

V

µA

nc...

, I

or

emiconduct

eescale S

IN5, IN6 Pull-Down Current

0.8 V to 5.0 V

EN Pull-Down Current

EN = 5.0 V

SCLK, DI Input, Tri-State DO Output

0 V to 5.0 V

CS Input Current

CS = V

DD

CS Pull-Up Current

CS = 0 V

CS Leakage Current to V

CS = 5.0 V, V

DO High-State Output Voltage

I

DO-HIGH

DO Low-State Output Voltage

I

DO-LOW

Input Capacitance on SCLK, DI, Tri-State DO, IN5, IN6, EN (Note 10) C

Notes

9. Upper and lower logic threshold voltage levels apply to DI,

10. This parameter is guaranteed by design but not production tested.

DD

= -1.6 mA

= 1.6 mA

= 0 V

DD

CS, SCLK, IN5, IN6, and EN.

I

I

SCK, IDI, ITriDO

V

IN5, IIN6,

I

EN

I

CS

I

CS

I

CS(LKG)

DOHIGH

V

DOLOW

IN

30 45 100

30 45 100

-10 – 10

-10 – 10

-30 – -100

––10

VDD - 0.4 – V

––0.4

– – 20 pF

DD

µA

µA

µA

µA

µA

µA

V

V

Fr

MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA 33879

For More Information On This Product,

Go to: www.freescale.com

7

Freescale Semiconductor, Inc.

DYNAMIC ELECTRICAL CHARACTERISTICS

Characteristics noted under conditions of 3.1 V ≤ V

≤ 5.5 V, 5.5 V ≤ V

DD

≤ 18 V, -40°C ≤ TC ≤ 125°C unless otherwise noted.

PWR

Where applicable, typical values reflect the parameter’s approximate average value with V

Characteristic Symbol Min Typ Max Units

POWER OUTPUT TIMING

= 13 V, TA = 25°C.

PWR

Output Slew Rate Low-Side Configuration (Note 11)

R

= 620 Ω, CL = 200 pF

LOAD

Output Slew Rate Low-Side Configuration (Note 11)

R

= 620 Ω, CL = 200 pF

LOAD

Output Rise Time High-Side Configuration (Note 11)

R

= 620 Ω, CL = 200 pF

LOAD

Output Fall Time High-Side Configuration (Note 11)

nc...

, I

Output Turn ON Delay Time, High-Side and Low-Side Configuration

(Note 12)

or

Output Turn OFF Delay Time, High-Side and Low-Side Configuration

(Note 12)

Output Fault Delay Time (Note 13)

Power-ON Reset Delay

Low-State Duration on V

emiconduct

Notes

11. Output slew rate respectively measured across a 620 Ω resistive load at 10 to 90 percent and 90 to 10 percent voltage points. C

12. Output turn ON and OFF delay time measured from 50 percent rising edge of

13. Duration of fault before fault bit is set. Duration between access times must be greater than 300 µs to read faults.

= 620 Ω, CL = 200 pF

R

LOAD

Delay Time Required from Rising Edge of EN and V

or EN for Reset

DD

or EN ≤ 0.2 V

V

DD

is connected from Drain or Source output to Ground.

to SPI Active

DD

t

SR(

)

rise

t

SR(

)

fall

t

SR(

rise

t

SR(

)

fall

t

DLY(on)

t

DLY(

off)

t

FAULT

t

POR

t

RESET

CS to the beginning of the 10 and 90 percent transition points.

0.1 0.5 1.0

0.1 0.5 1.0

)

0.1 0.3 1.0

0.1 0.3 1.0

1.0 15 50

1.0 30 100

100 – 300 µs

100 – –

100 – –

V/µs

V/µs

V/µs

V/µs

µs

µs

µs

µs

Capacitor

L

eescale S

Fr

33879 MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA

8

For More Information On This Product,

Go to: www.freescale.com

Freescale Semiconductor, Inc.

DYNAMIC ELECTRICAL CHARACTERISTICS (continued)

Characteristics noted under conditions of 3.1 V ≤ V

Where applicable, typical values reflect the parameter’s approximate average value with V

Characteristic Symbol Min Typ Max Units

DIGITAL INTERFACE TIMING (Note 14)

≤ 5.5 V, 5.5 V ≤ V

DD

≤ 18 V, -40°C ≤ TC ≤ 125°C unless otherwise noted.

PWR

= 13 V, TA = 25°C.

PWR

nc...

, I

or

emiconduct

Recommended Frequency of SPI Operation (Note 14) f

Falling Edge of

Falling Edge of SCLK to Rising Edge of

DI to Falling Edge of SCLK (Required Setup Time) t

Falling Edge of SCLK to DI (Required Hold Time) t

DI,

CS, SCLK Signal Rise Time (Note 15)

DI,

CS, SCLK Signal Fall Time (Note 15)

Time from Falling Edge of

Time from Rising Edge of

Time from Rising Edge of SCLK to DO Data Valid (Note 18) t

Notes

14. This parameter is guaranteed by design. Production test equipment uses 4.16 MHz, 5.5V/3.1V SPI interface.

15. Rise and Fall time of incoming DI,

16. Time required for output status data to be available for use at DO pin.

17. Time required for output status data to be terminated at DO pin

18. Time required to obtain valid data out from DO following the rise of SCLK.

CS to Rising Edge of SCLK (Required Setup Time) t

CS (Required Setup Time) t

CS to DO Low Impedance (Note 16) t

CS to DO High Impedance (Note 17) t

CS, and SCLK signals suggested for design consideration to prevent the occurrence of double pulsing.

SPI

LEAD

LAG

DI(su)

DI(HOLD)

t

(DI)

r

t

(DI)

f

DO(EN)

DO(DIS)

VALID

–4.0 – MHz

100 – – ns

50 – – ns

16 – – ns

20 – – ns

–5.0 – ns

–5.0 – ns

– – 55 ns

– – 55 ns

–2555 ns

eescale S

Fr

MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA 33879

For More Information On This Product,

Go to: www.freescale.com

9

Freescale Semiconductor, Inc.

Timing Diagrams

CS

SCLK

DI

DO

0.2 V

DD

t

lead

0.7 V

DD

0.2 V

DD

0.7 V

DD

0.2 V

DD

t

DO(en)

0.7 V

DD

0.2 V

DD

nc...

, I

or

VDD = 5.0 V

33879

SCLK

Under

Te st

emiconduct

NOTE: CL represents the total capacitance of the test

fixture and probe.

t

DI(su)tDI(hold)

MSB in

t

valid

MSB out LSB out

Figure 2. SPI Timing Diagram

SCLK

0.7 V

t

r(DI)

DD

< 50 ns

50%

DO

C

= 200 pF

L

DO

(Low-to-High)

DO

(High-to-Low)

0.2 V

0.7 V

DD

DD

t

r(DO)

t

lag

t

DO(dis)

t

f(DI)

< 50 ns

3.3/5.0 V

0.2 V

DD

0 V

t

valid

0.7 V

0.2 V

DD

DD

V

OH

V

OL

V

OH

V

OL

Figure 3. Valid Data Delay Time and Valid Time Test Circuit

eescale S

t

f(CS)

Fr

CS

0.2 V

DD

DO

(Tri-State to Low)

DO

(Tri-State to High)

<50 ns

t

t

Figure 4. Valid Data Delay Time and Valid Time Waveforms

t

r(CS)

<50 ns

90%

10%

DO(en)

90%

DO(en)

90%

10%

0.7 V

t

DO(dis)

t

DD

10%

DO(dis)

3.3/5.0 V

0 V

V

Tri-State

V

V

V

Tri-State

OL

OH

Figure 5. Enable and Disable Time Waveforms

33879 MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA

10

For More Information On This Product,

Go to: www.freescale.com

Freescale Semiconductor, Inc.

Typical Electrical Characteristics

nc...

, I

or

emiconduct

eescale S

Fr

20

V

@ 18 V

PWR

19

Pin (mA)

18

PWR

17

16

15

Current into V

14

PWR

I

7

14

V

6

12

Pin (µA)

Pin (uA)

5

10

PWR

PWR

4

8

3

6

2

4

Current into V

1

Current into V

2

PWR

I

PWR

I

Figure 7. Sleep State I

140

120

Pin (µA)

100

TA = 25°C

PWR

80

0 25 50 100 125-40 75-25

T

Ambient Temperature (°C)

A,

Figure 6. I

Sleep State I

@ 13 V

PWR

0 25 50 100 125-40 75-25

0 25 50 100 125-40 75-25

T

Ambient Temperature (°C)

A,

T

Ambient Temperature

vs. Temperature

PWR

versus Temperature

PWR

vs. Temperature

PWR

1.4

1.2

1.0

(Ω)

0.8

0.6

DS(ON)

R

0.4

Figure 9. R

1.4

1.2

1.0

0.8

(Ω)

0.6

DS(ON)

R

0.4

0.2

0

V

@ 13 V

PWR

High Side Drive

0 25 50 100 125-40 75-25

T

Ambient Temperature (°C)

A,

vs. Temperature at 350 mA

DS(ON)

TA = 25°C

High Side Drive

5 10152025

(V)

V

PWR

Figure 10. R

DS(ON)

vs. V

PWR

at 350 mA

60

40

Current into V

20

PWR

I

0

MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA 33879

510152025

V

PWR

Figure 8. Sleep State I

PWR

vs. V

PWR

For More Information On This Product,

11

Go to: www.freescale.com

Freescale Semiconductor, Inc.

Typical Electrical Characteristics (continued)

140

V

@ 16 V

80

60

40

20

PWR

0 25 50 100 125-40 75-25

T

Ambient Temperature (°C)

A,

120

100

Open Load (µA)

OCO,

I

nc...

Figure 11. Open Load Detection Current at Threshold Figure 12. Open Load Detection Threshold vs.

, I

5.0

TA = 25°C

Open Load Detect Enabled

4.5

4.0

3.5

3.0

Open Load Threshold (V)

2.5

,

2.0

OUT(flt-th)

V

0

5 10152025

T

Ambient Temperature (°C)

A,

Temperature

or

emiconduct

eescale S

Fr

33879 MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA

12

For More Information On This Product,

Go to: www.freescale.com

Freescale Semiconductor, Inc.

SYSTEM/APPLICATION INFORMATION

FUNCTIONAL PIN DESCRIPTION

CS

Pin

The system MCU selects the 33879 with which to

communicate through the use of the chip select

low on

CS enables the data output (DO) driver and allows data

to be transferred from the MCU to the 33879 and vice versa.

Data clocked into the 33879 is acted upon on the rising edge of

CS.

To avoid any spurious data, it is essential the high-to-low

transition of the CS signal occur only when SPI clock (SCLK) is

in a logic low state.

SCLK Pin

nc...

, I

or

The SCLK pin clocks the internal shift registers of the 33879.

The serial data input (DI) pin is latched into the input shift

register on the falling edge of the SCLK. The serial data output

(DO) pin shifts data out of the shift register on the rising edge of

the SCLK signal. False clocking of the shift register must be

avoided to ensure validity of data. It is essential that the SCLK

pin be in a logic low state when the

For this reason, it is recommended the SCLK pin is commanded

to a logic low state when the device is not accessed (

high state). With

SCLK and DI are ignored and the DO output is tri-state.

CS in a logic high state, signals present on

CS pin makes any transition.

DI Pin

emiconduct

eescale S

Fr

The DI pin is used for serial instruction data input. DI

information is latched into the input register on the falling edge

of SCLK. A logic high state present on DI will program a specific

output on. The specific output will turn on with the rising edge of

the

CS signal. Conversely, a logic low state present on the DI

pin will program the output off. The specific output will turn off

with the rising edge of the

outputs and Open Load Detection Current on or off, send the DI

data beginning with the Open Load Detection Current bits,

followed by output eight, output seven, and so on to output one.

For each falling edge of the SCLK while

bit instruction (on or off) is loaded into the shift register per the

data bit DI state. Sixteen bits of entered information is required

to fill the input shift register.

CS signal. To program the eight

CS is logic low, a data

DO Pin

The DO pin is the output from the shift register. The DO pin

remains tri-state until the

on the 33879 device are reported as logic [1] through the DO

data pin. Regardless of the configuration of the driver, open

loads and shorted loads are reported as logic [1]. Conversely,

normal operating outputs with non-faulted loads are reported as

logic [0]. Outputs programmed with Open Load Detection

Current disabled will report logic [0] in the off state. The first

eight positive transitions of SCLK will report logic [0] followed by

the status of the eight output drivers. The DI / DO shifting of data

CS pin is in a logic low state. All faults

CS pin. Logic

CS in logic

follows a first-in, first-out protocol with both input and output

words transferring the most significant bit (MSB) first.

EN Pin

The EN pin on the 33879 enables the device. With the EN pin

high, output drivers may be activated and open/short fault

detection performed and reported. With the EN pin low, all

outputs become inactive, Open Load Detection Current is

disabled, and the device enters sleep mode. The 33879 will

perform Power-ON Reset on rising edge of the enable signal.

IN5 and IN6 Pins

The IN5 and IN6 command inputs allow outputs five and six

to be used in PWM applications. The IN5 and IN6 pins are

OR-ed with the Serial Peripheral Interface (SPI) command input

bits. For SPI control of outputs five and six, the IN5 and IN6 pins

should be grounded or held low by the microprocessor. When

using IN5 or IN6 to PWM the output, the control SPI bit must be

logic [0]. Maximum PWM frequency for each output is 2.0 kHz.

VDD Pin

The VDD input pin is used to determine logic levels on the

microprocessor interface (SPI) pins. Current from VDD is used

to drive DO output and the pull-up current for CS. VDD must be

applied for normal mode operation. The 33879 device will

perform Power-ON Reset with the application of V

V

Pin

PWR

The V

33879 IC. The V

All internal logic current is provided from the V

33879 will perform Power-ON Reset with the application of

V

PWR.

pin is battery input and Power-ON Reset to the

PWR

pin has internal reverse battery protection.

PWR

PWR

DD.

pin. The

D1–D8 Pins

The D1 to D8 pins are the open-drain outputs of the 33879.

For high-side drive configurations, the drain pins are connected

to battery supply. In low-side drive configurations, the drain pins

are connected to the low side of the load. All outputs may be

configured individually as desired. When configured as low-side

drive, the 33879 limits the positive inductive transient to 45 V.

S1–S8 Pins

The S1 to S8 pins are the source outputs of the 33879. For

high-side drive configurations, the source pins are connected

directly to the load. In low-side drive configurations, the source

is connected to ground. All outputs may be configured

individually as desired. When high-side drive is used, the 33879

will limit the negative inductive transient to negative 20 V.

MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA 33879

For More Information On This Product,

13

Go to: www.freescale.com

Freescale Semiconductor, Inc.

MCU INTERFACE DESCRIPTION

Introduction

The 33879 is an 8-output hardware-configurable power

switch with 16-bit serial control. A simplified block diagram of

the 33879 is shown in Figure 1

The 33879 device uses high-efficiency up-drain power

DMOS output transistors exhibiting low drain-to-source ON

resistance (R

= 1.0 Ω at 25°C typical) and dense CMOS

DS(ON)

control logic. All outputs have independent voltage clamps to

provide fast inductive turn-off and transient protection.

In operation, the 33879 functions as an 8-output serial switch

serving as a MCU bus expander and buffer with fault

management and fault reporting features. In doing so, the

device directly relieves the MCU of the fault management

functions. This device directly interfaces to an MCU using a SPI

for control and diagnostic readout. Figure 13

nc...

basic SPI configuration between an MCU and one 33879.

, I

or

emiconduct

MC68HCxx

Microcontroller

Shift Register Shift Register

16 Bits

Receive

Buffer

Parallel

Ports

Figure 13. SPI Interface with Microcontroller

All inputs are compatible with 5.0 V and 3.3 V CMOS logic

levels and incorporate positive logic. When a SPI bit is

eescale S

programmed to a logic [0], the corresponding output will be

OFF. Conversely, when a SPI bit is programmed to logic [1] the

Fr

output being controlled will be ON. Diagnostics are treated in a

similar manner. Outputs with a fault will feed back (via DO) a

logic [1] to the microcontroller, while normal operating outputs

will provide a logic [0].

MOSI

MISO

on page 2.

DI

DO

SCLK

CS

illustrates the

33879

16 Bits

To

Logic

Figure 14

illustrates the daisy chain configuration using the

33879. Data from the MCU is clocked daisy chain through each

device while the

CS bit is commanded low by the MCU. During

each clock cycle, output status from the daisy chain is

transferred to the MCU via the Master In Slave Out (MISO) line.

On rising edge of

CS, command data stored in the input register

is then transferred to the output driver.

SCLK

Parallel Port

33879

CSSCLK SCLK

MC68HCxx

Microcontroller

with

SPI Interface

33879 33879

CS

MISO

DO DI DO DI DO DI

8 Outputs 8 Outputs 8 Outputs

MOSI

CS

Figure 14. 33879 SPI System Daisy Chain

Multiple 33879 devices can be controlled in a parallel input

fashion using the SPI. Figure 15 illustrates the control of

24 loads using three dedicated parallel MCU ports for chip

select.

DI

SCLK

DO

CS

DI

SCLK

DO

CS

DI

SCLK

DO

CS

33879

8 Outputs

33879

8 Outputs

33879

8 Outputs

MC68HCxx

Microcontroller

with

SPI Interface

Parallel

Ports

MOSI

SCLK

MISO

A

B

C

Figure 15. Parallel Input SPI Control

33879 MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA

14

For More Information On This Product,

Go to: www.freescale.com

Freescale Semiconductor, Inc.

SPI DEFINITION

On each SPI communication, a 16-bit command word is sent

to the 33879 and a 16-bit status word is received from the

33879. The MSB is sent and received first. As Table 1

the Command Register defines the position and operation the

Table 1. Command Register Definition

MSB LSB

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

ON/ OFF

ON/ OFF

Open

Load

Detect

8

0 = Bits 0 to 7, Output commanded OFF.

0 = Bits 8 to 15, Open Load Detection Current OFF.

Open

Load

Detect

7

ON/ OFF

Open

Load

Detect

6

ON/ OFF

Open

Load

Detect

5

ON/ OFF

Open

Load

Detect

4

ON/ OFF

Open

Load

Detect

3

nc...

, I

MSB LSB

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

or

00000000OUT 8

0 = Bits 0 to 7, No Fault at Output.

1 = Bits 0 to 7, Output Short-to-Battery, Short-to-GND, Open Load,

or T

.

LIM

Serial Output (DO) Pin Reports

emiconduct

eescale S

Fr

Overtemperature Fault reported by serial output (DO) pin.

Overcurrent DO pin reports short to battery/supply or overcurrent condition.

Output ON Open Load Fault Not reported.

Output OFF Open Load Fault DO pin reports output OFF open load condition only with Open Load Detection Current enabled.

DO pin will report “0” for Output OFF Open Load Fault with Open Load Detection Current disabled.

Device Shutdowns

Overvoltage Total device shutdown at V

outputs assuming the previous state upon recovery from overvoltage.

Overtemperature Only the output experiencing an overtemperature shuts down. Output assumes previous state upon

recovery from overtemperature.

33879 will perform on rising edge of

shown in Table 2, defines the previous state status of the output

shows,

driver. Table 3

which the fault is communicated to the microprocessor.

ON/ OFF

Open

Load

Detect

2

ON/ OFF

Open

Load

Detect

1

ON/ OFF

ON/ OFF

OUT 8

OUT 7

1 = Bits 0 to 7, Output commanded ON.

1 = Bits 8 to 15 Open Load Detection Current ON.

Table 2. Fault Register Definition

Status

OUT 7

Status

Bits 8 to 15 will always return “0”.

Table 3. Fault Operation

= 27 V–30 V. Resumes normal operation with proper voltage. All

PWR

CS. The Fault Register,

identifies the type of fault and the method by

ON/ OFF

OUT 6

OUT 6

Status

ON/ OFF

OUT 5

OUT 5

Status

ON/ OFF

OUT 4

OUT 4

Status

ON/ OFF

OUT 3

OUT 3

Status

ON/ OFF

OUT 2

OUT 2

Status

ON/ OFF

OUT 1

OUT 1

Status

MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA 33879

For More Information On This Product,

15

Go to: www.freescale.com

Freescale Semiconductor, Inc.

DEVICE OPERATION

Power Supply

The 33879 device has been designed with ultra-low sleep

mode currents. The device may enter sleep mode via the EN

pin or the V

current consumed by the V

Placing the 33879 in sleep mode resets the internal registers

to the Power-ON Reset state. The reset state is defined as all

outputs off and Open Load Detection Current disabled.

To place the 33879 in the sleep mode, either command all

outputs off and apply logic low to the EN input pin or remove

power from the V

device, it is recommended that all control inputs from the MCU

be low.

Paralleling of Outputs

nc...

Using MOSFETs as an output switch conveniently allows the

, I

paralleling of outputs for increased current capability. R

MOSFETs have an inherent positive temperature coefficient

or

that provides balanced current sharing between outputs without

destructive operation. This mode of operation may be desirable

in the event the application requires lower power dissipation or

the added capability of switching higher currents. Performance

of parallel operation results in a corresponding decrease in

R

DS(ON)

and the output current limits increase correspondingly.

Paralleling outputs from two or more different IC devices is

possible but not recommended.

emiconduct

Fault Logic Operation

Fault logic of the 33879 device has been greatly simplified

over other devices using SPI communications. As command

word one is being written into the shift register, a fault status

word is being simultaneously written out and received by the

MCU. Regardless of the configuration, with no outputs faulted

and Open Load Detection Current enabled, all status bits being

received by the MCU will be zero. When outputs are faulted (off

eescale S

state open circuit or on state short circuit / overtemperature), the

status bits being received by the MCU will be one. The

Fr

distinction between open circuit fault and short /

overtemperature is completed via the command word. For

example, when a zero command bit is sent and a one fault is

received in the following word, the fault is open /short-to-battery

for high-side drive or open/short-to-ground for low-side drive. In

the same manner, when a one command bit is sent and a one

fault is received in the following word, the fault is a short-toground/overtemperature for high-side drive or short-to-battery/

overtemperature for low-side drive. The timing between two

write words must be greater than 300 µs to allow adequate time

to sense and report the proper fault status.

pin. In the sleep mode (EN or VDD ≤ 0.8 V), the

DD

pin is less than 5.0 µA.

PWR

supply pin. Prior to removing VDD from the

DD

DS(ON)

while the output OFF Open Load Detection Currents

of

SPI Integrity Check

Checking the integrity of the SPI communication with the

initial power-up of the V

initial system start-up or reset, the MCU will write one 32-bit

pattern to the 33879. The first 16 bits read by the MCU will be

8 logic [0]s followed by the fault status of the outputs. The

second 16 bits will be the same bit pattern sent by the MCU. By

the MCU receiving the same bit pattern it sent, bus integrity is

confirmed. Please note the second 16-bit pattern the MCU

sends to the device is the command word and will be

transferred to the outputs with rising edge of

Important A SCLK pulse count strategy has been

implemented to ensure integrity of SPI communications. SPI

messages consisting of 16 SCLK pulses and multiples of

8 clock pulses thereafter will be acknowledged. SPI messages

consisting of other than 16 + multiples of 8 SCLK pulses will be

ignored by the device.

and EN pins is recommended. After

DD

CS.

Overtemperature Fault

Overtemperature detection and shutdown circuits are

specifically incorporated for each individual output. The

shutdown following an overtemperature condition is

independent of the system clock or any other logic signal. Each

independent output shuts down at 155

output shuts down owing to an overtemperature fault, no other

outputs are affected. The MCU recognizes the fault by a one in

the fault status register. After the 33879 device has cooled

below the switch point temperature and 15

output will activate unless told otherwise by the MCU via SPI to

shut down.

°C to 185°C. When an

°C hysteresis, the

Overvoltage Fault

An overvoltage condition on the V

device to shut down all outputs until the overvoltage condition

is removed. When the overvoltage condition is removed, the

outputs will resume their previous state. This device does not

detect an overvoltage on the V

threshold on the V

1.0 V typical hysteresis. A V

causing all outputs to be turned OFF.

Output OFF Open Load Fault

An output OFF open load fault is the detection and reporting

of an open load when the corresponding output is disabled

(input bit programmed to a logic low state). The Output OFF

Open Load fault is detected by comparing the drain-to-source

voltage of the specific MOSFET output to an internally

generated reference. Each output has one dedicated

comparator for this purpose.

pin is specified as 27 V to 30 V, with

PWR

pin. The overvoltage

DD

overvoltage detection is global,

PWR

pin will cause the

PWR

33879 MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA

16

For More Information On This Product,

Go to: www.freescale.com

Freescale Semiconductor, Inc.

An output OFF open load fault is indicated when the drain-tosource voltage is less than the output threshold voltage

(V

OUT(

load open in the OFF state when the output drain-to-source

voltage is less than V

This device has an internal 80 µA current source connected

from drain to source of the output MOSFET. The current source

may be programmed on or off via SPI. The Power-ON Reset

state for the current source is “off” and must be enabled via SPI.

To achieve low sleep mode quiescent currents, the Open Load

Detection Current source of each driver is switched off when

V

DD

During output switching, especially with capacitive loads, a

false output OFF open load fault may be triggered. To prevent

this false fault from being reported, an internal fault filter of

100 µs to 300 µs is incorporated. A false fault reporting is a

function of the load impedance, R

as well as the supply voltage, V

nc...

triggers the built-in fault delay timer. The timer will time out

before the fault comparator is enabled and the fault is detected.

, I

Once the condition causing the open load fault is removed, the

or

device will resume normal operation. The open load fault,

however, will be latched in the output DO register for the MCU

to read.

) of 2.5 V to 4.0 V. Hence, the 33879 will declare the

)

flt-th

OUT(flt-th)

or EN is removed.

.

, C

DS(ON)

PWR

OUT

. The rising edge of CS

of the MOSFET,

Shorted Load Fault

A shorted load (overcurrent) fault can be caused by any

output being shorted directly to supply, or an output

experiencing a current greater than the current limit.

There are two safety circuits progressively in operation

during load short conditions that provide system protection:

emiconduct

1. The device’s output current is monitored in an analog

fashion using SENSEFET approach and current limited.

2. The device’s output thermal limit is sensed and when

attained causes only the specific faulted output to shut

down. The output will remain off until cooled. The device

will then reassert the output automatically. The cycle will

continue until fault is removed or the command bit

eescale S

Fr

instructs the output off. Shorted load faults will be

reported properly through SPI regardless of Open Load

Detection Current enable bits.

Undervoltage Shutdown

An undervoltage condition on VDD or V

shutdown of all outputs. The V

between 0.8 V and 3.0 V. V

between 3.0 V and 5.0 V. When the supplies fall below their

respective thresholds, all outputs are turned OFF. As both

supplies returns to normal levels, internal logic is reset and the

device resumes normal operation.

undervoltage threshold is

DD

undervoltage threshold is

PWR

will result in the

PWR

Output Voltage Clamp

Each output of the 33879 incorporates an internal voltage

clamp to provide fast turn-off and transient protection of each

output. Each clamp independently limits the drain-to-source

voltage to 45 V for low-side drive configurations and -20 V for

high-side drive configurations. The total energy clamped (E

can be calculated by multiplying the current area under the

current curve (I

Figure 16

Characterization of the output clamps, using a single pulse

non-repetitive method at 0.35 A, indicates the maximum energy

per output to be 50 mJ at 150°C junction temperature.

Drain-to-Source Clamp

Voltage (V

Drain Current

(I

D

Drain-to-Source ON

Voltage (V

Drain-to-Source ON

Voltage (V

Source Current

Source Clamp Voltage

(V

CL

) times the clamp voltage (VCL) (see

A

).

= 45 V)

CL

= 0.3 A)

)

DS(ON)

GND

)

DS(ON)

VS

GND

(IS = 0.3 A)

= -15 V)

Figure 16. Output Voltage Clamping

Current

Area (I

Current

Area (IA)

)

A

Drain Voltage

Clamp Energy

= IA x VCL)

(E

J

Clamp Energy

(E

= IA x VCL)

J

Source Voltage

Time

BAT

Time

)

J

SPI Configurations

The SPI configuration on the 33879 device is consistent with

other devices in the Octal Serial Switch (OSS) family. This

device may be used in serial SPI or parallel SPI with the 33298

and 33291. Different SPI configurations may be provided. For

more information, contact Motorola Analog Products Division or

local Motorola representative.

Reverse Battery

The 33879 has been designed with reverse battery

protection on the V

All outputs consist of a power MOSFET with an integral

substrate diode. During the reverse battery condition, current

will flow through the load via the substrate diode. Under this

circumstance, relays may energize and lamps will turn on.

Where load reverse battery protection is desired, a reverse

battery blocking diode must be placed in series with the load.

PWR

pin.

MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA 33879

For More Information On This Product,

17

Go to: www.freescale.com

Freescale Semiconductor, Inc.

PACKAGE DIMENSIONS

EK (Pb-FREE) SUFFIX

32-LEAD SOIC WIDE BODY EXPOSED PAD

10.3

DWB SUFFIX

PLASTIC PACKAGE

CASE 1437-01

ISSUE O

nc...

, I

or

emiconduct

eescale S

7.6

7.4

1

PIN 1 ID

BB

16

5.15

2X 16 TIPS

0.3 A

B C

A

CC

A

0.3 A B C

5.3

4.7

C

32

17

B

95

4

11.1

10.9

9

0.25

0.19

ROTATED 90 CLOCKWISE

2.65

2.35

(0.29)

(0.203)

0.38

6

0.22

0.13MCAMB

SECTION A-A

°

30X

C

L

A

32X

BASE METAL

PLATING

0.65

SEATING

PLANE

0.10

8

NOTES:

1. ALL DIMENSIONS ARE IN MILLIMETERS.

2. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

3. DATUMS B AND C TO BE DETERMINED AT THE PLANE

WHERE THE BOTTOM OF THE LEADS EXIT THE

PLASTIC BODY.

4. THIS DIMENSION DOES NOT INCLUDE MOLD FLASH,

PROTRUSION OR GATE BURRS. MOLD FLA SH,

PROTRUSION OR GATE BURRS SHALL NOT EXCEED

0.15 mm PER SIDE. THIS DIMENSION IS DETERMINED

AT THE PLANE WHERE THE BOTTOM OF THE LEADS

EXIT THE PLASTIC BODY.

5. THIS DIMENSION DOES NOT INCLUDE INTERLEAD

A

FLASH OR PROTRUSIONS. INTERLEAD FLASH AND

PROTRUSIONS SHALL NOT EXCEED 0.25 mm PER

SIDE. THIS DIMENSION IS DETERMINED AT THE

PLANE WHERE THE BOTTOM OF THE LEADS EXIT

THE PLASTIC BODY.

6. THIS DIMENSION DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DA MBAR PROTRUSION

SHALL NOT CAUSE THE LEAD WIDTH TO EXCEED 0.4

mm PER SIDE. DAMBAR CANNOT BE LOCATED ON

THE LOWER RADIUS OR THE FOOT. MINIMUM SPACE

BETWEEN PROTRUSION AND ADJACENT LEAD

SHALL NOT LESS THAN 0.07 mm.

7. EXACT SHAPE OF EACH CORNER IS OPTIONAL.

8. THESE DIMENSIONS APPLY TO THE FLAT SECTION

OF THE LEAD BETWEEN 0.1 0 mm AND 0.3 mm FROM

THE LEAD TIP.

9. THE PACKAGE TOP MAY BE SMALLER THAN THE

PACKAGE BOTTOM. THIS DIMENSION IS

DETERMINED AT THE OUTERMOST EXTREMES OF

THE PLASTIC BODY EXCLUSIVE OF MOLD FLASH, TIE

BAR BURRS, GATE BURRS AND INTER-LEAD FLASH,

BUT INCLUDING ANY M ISMATCH BETWEEN THE TOP

AND BOTTOM OF THE PLASTIC BODY.

Fr

6.4

5.7

0.3 A B C

VIEW C-C

33879 MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA

18

For More Information On This Product,

Go to: www.freescale.com

R0.08 MIN

0.25

GAUGE PLANE

°

8

°

0

°

0

MIN

0.9

0.5

SECTION B-B

0.1

0.0

Freescale Semiconductor, Inc.

NOTES

nc...

, I

or

emiconduct

eescale S

Fr

MOTOROLA ANALOG INTEGRATED CIRCUIT DEVICE DATA 33879

For More Information On This Product,

Go to: www.freescale.com

19

Freescale Semiconductor, Inc.

nc...

, I

or

emiconduct

eescale S

Fr

Information in this document is provided solely to enable system and software implementers to use Motorola products. There are no express or implied

copyright licenses granted hereunder to design or fabricate any integrated circuits or integrated circuits based on the information in this document.

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty, representation or guarantee

regarding the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product

or circuit, and specifically disclaims any and all liability, including without limitation consequential or incidental damages. “Typical” parameters which may be

provided in Motorola data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating

parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. Motorola does not convey any license

under its patent rights nor the rights of others. Motorola products are not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the Motorola product

could create a situation where personal injury or death may occur. Should Buyer purchase or use Motorola products for any such unintended or

unauthorized application, Buyer shall indemnify and hold Motorola and its officers, employees, subsidiaries, affiliates, and distributors harmless against all

claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated

with such unintended or unauthorized use, even if such claim alleges that Motorola was negligent regarding the design or manufacture of the part.

MOTOROLA and the Stylized M Logo are registered in the US Patent and Trademark Office. All other product or service names are the property of their

respective owners.

© Motorola, Inc. 2004

HOW TO REACH US:

USA/EUROPE/LOCATIONS NOT LISTED: JAPAN: Motorola Japan Ltd.; SPS, Technical Information Center

Motorola Literature Distribution 3-20-1 Minami-Azabu. Minato-ku, Tokyo 106-8573, Japan

P.O. Box 5405, Denver, Colorado 80217 81-3-3440-3569

1-800-521-6274 or 480-768-2130

ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; Silicon Harbour Centre

2 Dai King Street, Tai Po Industrial Estate, Tai Po, N.T., Hong Kong

852-26668334

HOME PAGE: http://motorola.com/semiconductors

For More Information On This Product,

Go to: www.freescale.com

MC33879

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...