Motorline professional MC50SE Installation Manual

MC50SE

USER/INSTALLER MANUAL

EN

1 2

24V

v7.0

REV. 04/2019

. CONTENT

INDEX

. SAFETY INSTRUCTIONS

STANDARDS TO FOLLOW

. THE CONTROL BOARD

TECHNICAL SPECIFICATIONS

PROGRAMMING PRE-RECOMENDATIONS

. INSTALLATION

ESSENTIAL STEPS FOR INSTALLATION

TRANSMITTERS

"P" MENU FUNCTIONS

"E" MENU FUNCTIONS

. PROGRAMMING P

P0AUTOMATIC PROGRAMMING

P1SETTING THE DECELERATION TIME

P2SETTING STRENGTH AND SENSITIVITY

P4PAUSE TIME

P5PHOTOCELLS PROGRAMMING

P6STOP

P7OPERATING LOGIC

P8FLASHING LIGHT

P9DISTANCE PROGRAMMING

. PROGRAMMING E

E0PRESENT MAN

E1SOFT START

E2COURTESY LIGHT TIME

E3FOLLOW ME

E6DECELERATION SPEED

E7MANEUVERS COUNTER

E8RESET RESTORE FACTORY VALUES

E9RGB FLASHING LIGHT

. DISPLAY

DISPLAY INDICATIONS

2A

2B

3A

4A

4B

5A

5B

6A

6B

7A

7B

8A

8B

9A

9B

10A

10B

11A

11B

12A

12B

13A

13B

14A

14B

. COMPONENTS TEST

TEST SCHEME

INPUTS TEST

. TROUBLESHOOTING

INSTRUCTIONS FOR FINAL CONSUMERS/ TECHNICIANS

. CONNECTION SCHEME

CONTROL BOARD CONNECTIONS

15A

15B

16

17

PT

221

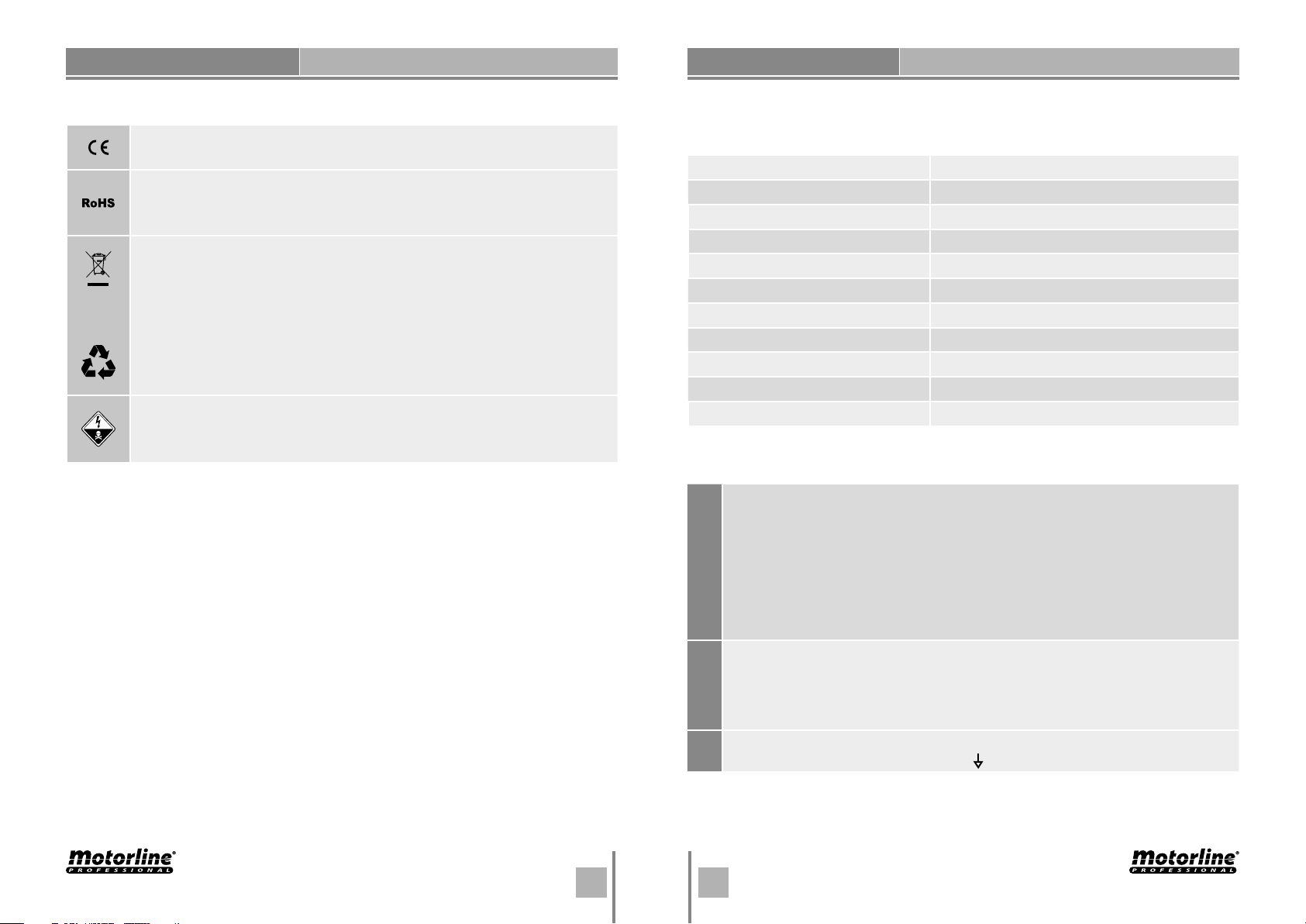

. SAFETY INSTRUCTIONS

STANDARDS TO FOLLOW

. THE CONTROL BOARD

TECHNICAL SPECIFICATIONS

ATTENTION:

This product is certified in accordance with European Community (EC) safety standards.

This product complies with Directive 2011/65/EU of the European Parliament and of the

Council, of 8 June 2011, on the restriction of the use of certain hazardous substances in

electrical and electronic equipment.

(Applicable in countries with recycling systems).

This marking on the product or literature indicates that the product and electronic

accessories (eg. Charger, USB cable, electronic material, controls, etc.) should not be

disposed of as other household waste at the end of its useful life. To avoid possible harm

to the environment or human health resulting from the uncontrolled disposal of waste,

separate these items from other types of waste and recycle them responsibly to promote the

sustainable reuse of material resources. Home users should contact the dealer where they

purchased this product or the National Environment Agency for details on where and how

they can take these items for environmentally safe recycling. Business users should contact

their vendor and check the terms and conditions of the purchase agreement. This product

and its electronic accessories should not be mixed with other commercial waste.

This marking indicates that the product and electronic accessories (eg. charger, USB cable,

electronic material, controls, etc.) are susceptible to electric shock by direct or indirect contact

with electricity. Be cautious when handling the product and observe all safety procedures in this

manual.

• It is important for your safety that these instructions are followed.

• Keep these instructions in a safe place for future reference.

• The ELECTROCELOS S.A. is not responsible for the improper use of the product, or other use than that for which

it was designed.

• The ELECTROCELOS S.A. is not responsible if safety standards were not taken into account when installing the

equipment, or for any deformation that may occur.

• The ELECTROCELOS S.A. is not responsible for insecurity and malfunction of the product when used with

components that were not sold by the them.

• This product was designed and manufactured strictly for the use indicated in this manual.

• This control board is not appropriate for inflammable or explosive environments.

• Any other use not expressly indicated may damage the product and/or can cause physical and property damages,

and will void the warranty.

• Do not make any changes to the automation components and/or their accessories.

• Control board for indoor use with 230V connection.

• Keep remote controls away from children, to prevent the automated system from being activated involuntarily.

• The customer shall not, under any circumstances, attempt to repair or tune the automatism. Must call qualified

technician only.

• The installer must have certified professional knowledge at the level of mechanical assemblies in doors and

gates and control board programmation. He should also be able to perform electrical connections in compliance

with all applicable regulations.

• The installer should inform the customer how to handle the product in an emergency and provide him the

manual.

The MC50SE is a monophasic control board com a control system via incorporated rádio,

developed for the automation of sectional door.

• Power supply 230V AC 50-60Hz

• Lightbulb’s output 230V AC 50Hz 100W max.

• RGB Lightbulb’s output 24V DC 100mA max.

• Motor’s output 230V AC 50-60Hz 1000 W max.

• Auxiliary accessories output 24V DC 8 W max.

• Security and BT transmitters 24V DC

• Working temperature -10°C to + 55°C

• Incorporated Radio Receptor 433,92 Mhz

• OP Transmitters 12bits or Rolling Code

• Maximum Memory Capacity 100 (full opening)

• Control board Dimensions 105x130 mm.

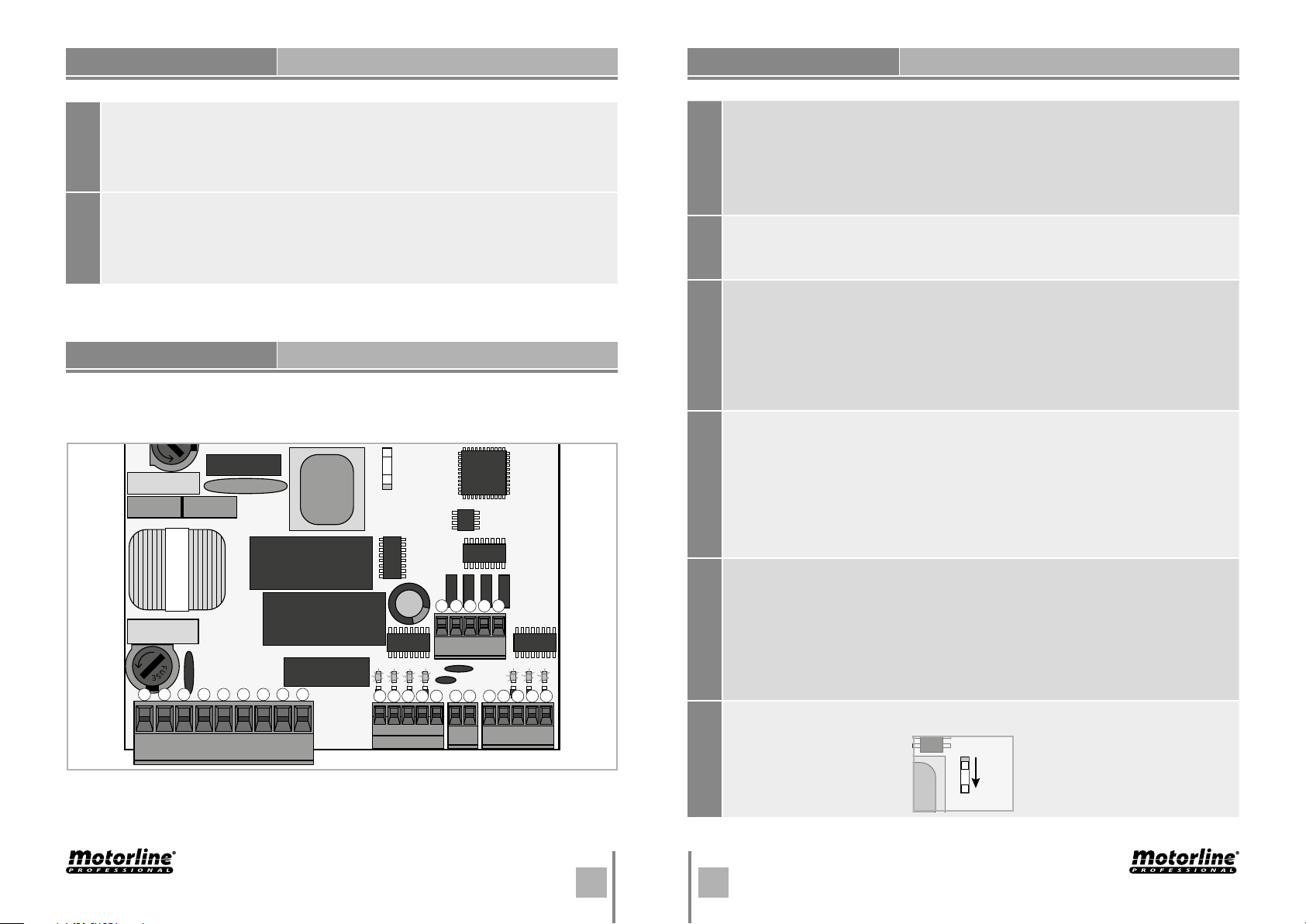

• CONNECTOR’S DESCRIPTION

01 • Grounding

02 • Grounding

03 • 230V Line Input (phase)

04 • 230V Line Input (neutral)

05 • 230V Motor’s Output – Opening

CN1

06 • 230V Motor’s Output – Common

07 • 230V Motor’s Output - Closing

08 • AC 230V Lightbulb Output

09 • AC 230V Lightbulb Output

01 • Close Push Button input

02 • Open Push Button input

03 • Motor’s opening limit-switch input (OPEN)

CN2

04 • Motor’s closing limit-switch input (CLOSE)

05 • Common

01 • 24V DC 200mA max power supply 24V

CN3

02 • 24V DC 200mA max power supply ( )

3A 3B2A 2B

ENEN

. THE CONTROL BOARD

TECHNICAL SPECIFICATIONS

. THE CONTROL BOARD

PROGRAMMING PRE-RECOMENDATIONS

01 • Safety Edge

02 • Photocells

03 • Encoder (not used)

CN4CN5

04 • Encoder (not used)

05 • Common

01 • +24V DC Auxiliary Power Supply for LED RGB flashing light

02 • Y output

03 • R output

04 • G output

05 • B output

. THE CONTROL BOARD

PROGRAMMING PRE-RECOMENDATIONS

To enhance knowledge about the control board operation, before proceeding to the

setup, give special attention to the instructions that follow.

Dipper

LS • LED lit when the close push button is active

LO • LED lit when the open push button is active

F0 • LED off when the opening limit switch is active

FC • LED off when the closing limit switch is active

LEDS

ST • LED off when STOP is active (when P6 is active)

LE • LED off when photocells are active (when P5 is active)

Courtesy light or flashing light:

08 and 09 • This output allows connection of a courtesy light or a flashing light

CN1

(see P8 in page 9B).

Limit switches:

03 and 04 • The control board needs a opening and closing limit-switches

connection (both in NC). Triggering any limit-switch will make the immediate

stoppage of the movement.

CN2

The limit-switch thriggering is visible on the display. OP (opening limit switch

activated) and CL (opening limit switch activated).

It is mandatory the use of limit switches.

Safety circuits:

01 • This input allows connection of STOP device. The device could be activeted

or desactiveted in the P6 menu (page 8B).

02 • This input allows connection of photocells. The device operates according

CN4

to programming set in the P5 menu (page 8A)

Shunt application is not necessary.

04 • It allows the connection of a pushbutton of singular botton for up and

down of the door.

01 • Auxiliary output for flashing light or 24V DC LED.

2

1

3

4

5

Open collector for the management of auxiliary functions:

02 • The y output is activated in the initial 2 seconds of the movement to control

the second capacitor.

CN5

LSLOFOLAFC

2

1

3

6

4

5

8

7

9

1

2

3

4

CN5

5

LE PU

11

22

3

4

5

03 • The R output is activated in intermittent mode, only in closing phase.

04 • The G output is activated in intermittent mode, only in opening phase.

05 • The B output is activated in intermittent mode, only in pause time

.

The dipper indicates the motor's power rating. Put the dipper in this position.

24V

CN1

CN2 CN3 CN4

Dipper

4A 4B

3A 3B

ENEN

. INSTALLATION

ESSENTIAL STEPS FOR INSTALLATION

. INSTALLATION

TRANSMITTERS

The installation process assumes that the gate has already limit switches

plates installed. For more information consult the motor's manual.

01 • Make the connections of all the accessories according to the connection scheme

(page 17).

02 • Connect the control board to a 230V power supply (3 and 4 - CN1 terminals).

03 • Make sure that the gate movement is the same as the one shown on the display:

If the display does not match the gate's

movement, turn off the control board from

the power supply e swap the 5 and 7 wires

CLOSING OPENING

from CN1 and check if it is correct with 3

and 4 from CN2.

04 • Check is the limit switches, so that the FC LED turns off during the closure and the

LED FO turns off during the opening.

05 • Make an automatic programming - P0 menu (page 6A).

06 • If necessary, adjust the gate of the deceleration time in opening and closing - P1

menu (page 6B).

07 • Adjust the strength and sensitivity of the motor - P2 menu (page 7A).

08 • Make an automatic programming of the course again - P0 menu (page 6A).

09 • Enable or disable the use of photocells in the P5 menu (page 8A).

10 • Enable or disable the use of safety band in the P6 menu (página 8B).

11 • Program a transmitter (page 4B).

The control board is now fully configured!

Check the menus from the programming pages in case you wish to configure other

features of the plant.

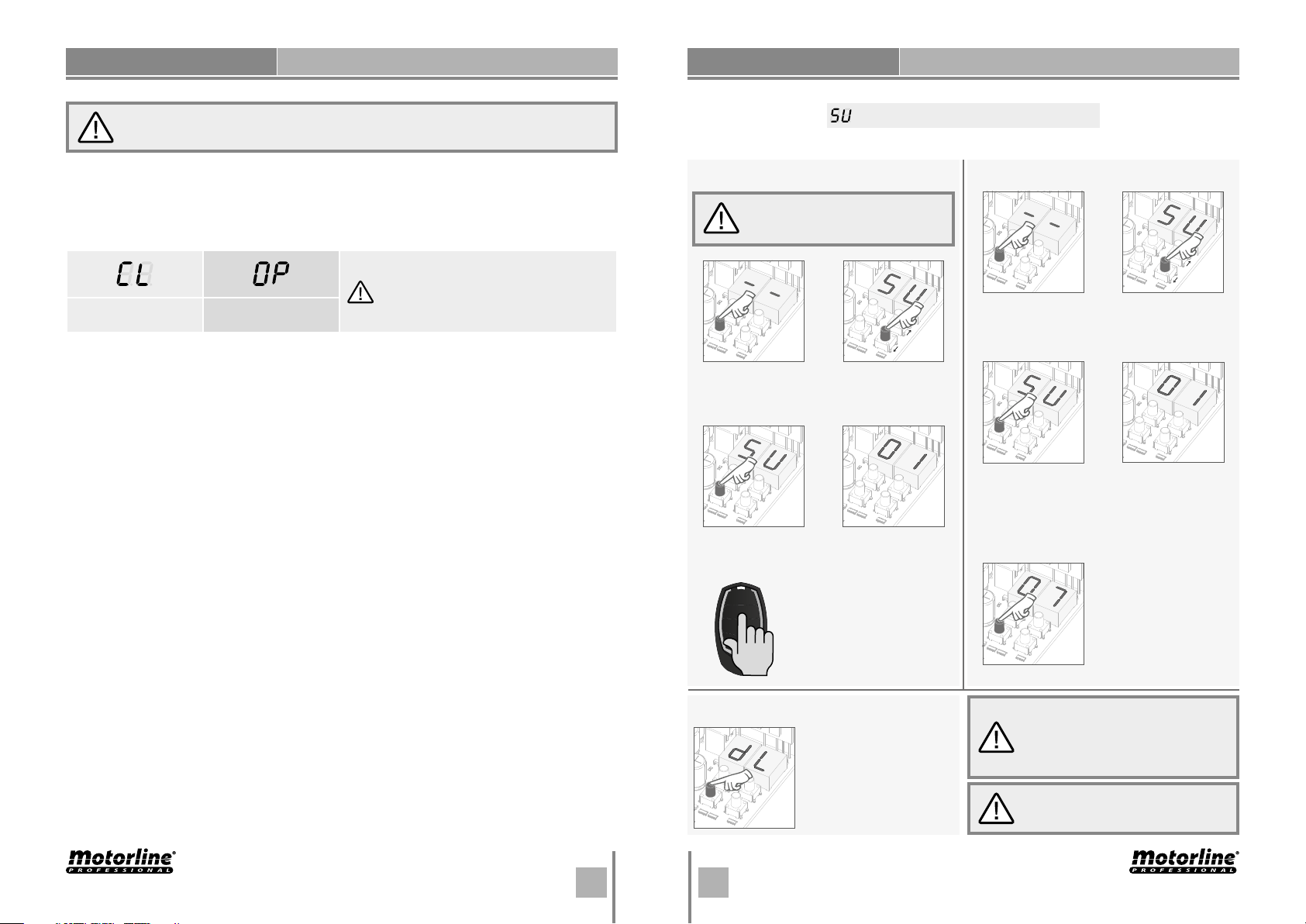

Transmitter programming for total opening.

• PROGRAMMING TRANSMITTERS

To program transmitters, you must

close the gate or turn the power

OFF and ON again.

01 • Press the

cmd button for

3sec.

03 • Press cmd

once to confirm.

05 • Press the command

button you want to program.

The display will blink and

move to the next free

location.

02 • SU appears.

04 • The first free

position appears.

• ERASE TRANSMITTERS

01 • Press the

cmd button for

3sec.

03 • Press cmd

once to confirm.

05 • Press cmd for 3sec

and the location will be

empty.

The display will show

the following location

with memorized

transmitter.

02 • SU appears.

04 • Use

to select the

transmitter

location you want

to delete.

↑↓

• ERASE ALL THE TRANSMITTERS

5A 5B4A 4B

• Whenever you save or delete a

01 • Press the

cmd button for 10sec.

02 • The display will show

dL, confirming that all

transmitters have been

erased.

transmitter, the display will show the

following location. You can add or

delete transmitters without having

to go back to point 01.

• If you do not press any key for 10

sec. the control board will return to

standby.

ENEN

. INSTALLATION

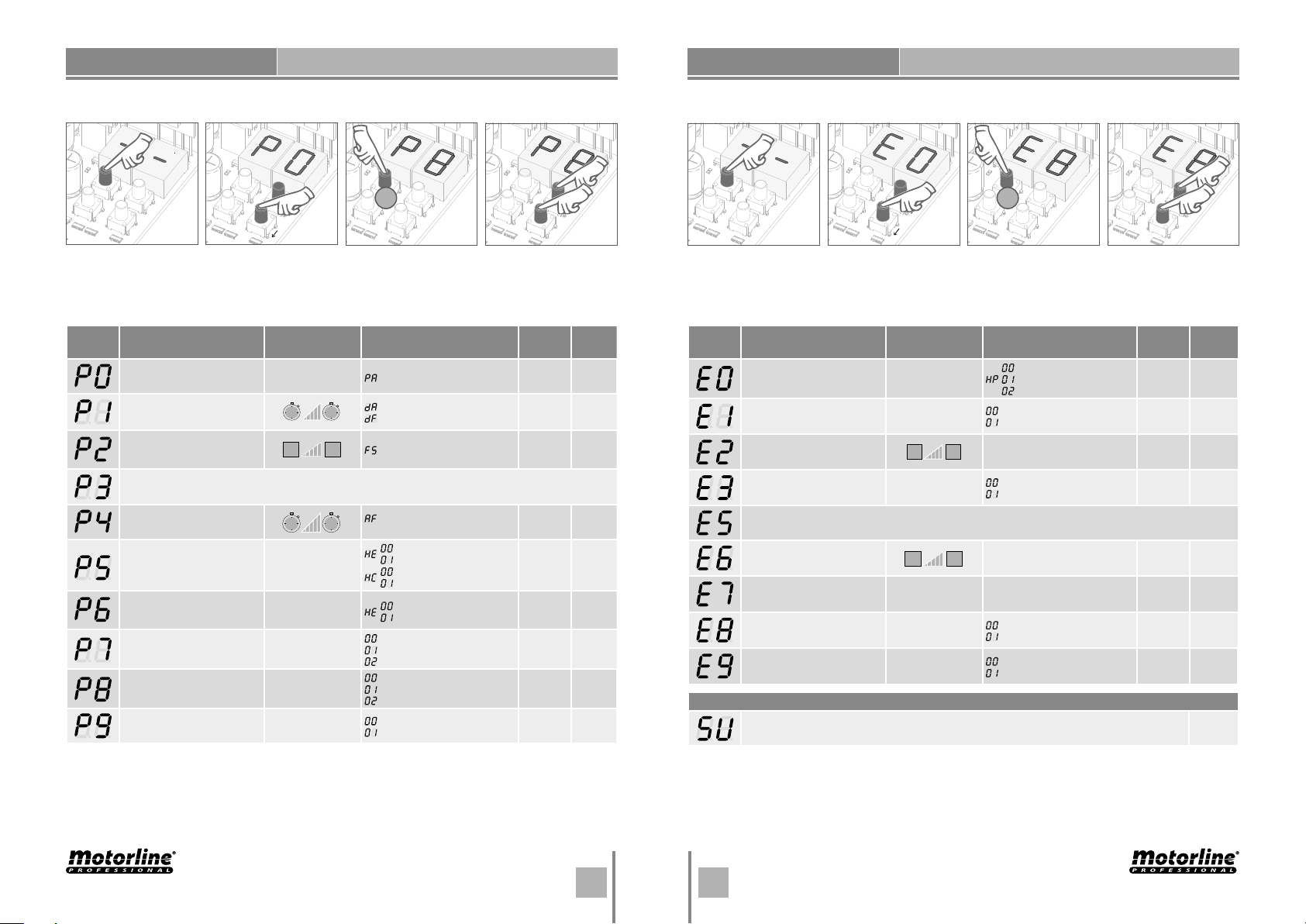

"P" MENU FUNCTIONS

. INSTALLATION

• We can only go into programming with a electrically closed gate. • We can only go into programming with a electrically closed gate.

"E" MENU FUNCTIONS

• To access the P menu

press the MENU key

for 3sec.

MENU FUNCTION

Course automatic

programming

Deceleration time

adjustment

Force and

sensibility adjustment

Pause time

Photocells programming

STOP

OperatiNG logic

Flashing light

Distance programming

• Use

↑↓

to navigate

through the menus.

MAX. MIN.

PROGRAMMABLE

0s

min. max.

1

min. max.

1s

min. max.

1x

• Press MENU when

you want to confirm

access to a menu.

-

Automatic Programming

Opening deceleration

15s

Closing deceleration

Sensibility adjustment

9

DISABLE MENU

Total closure pause time

99s

adjustment

photocells Disabled

-

-

-

-

-

photocells Activated

Photocells in closing

Photocells in opening

Security Band Disabled

Security Band Activated

Automatic mode function

Step by step mode function

Mode condominium function

Flashing (opening and closing)

Step by step mode function

Courtesy light

Distance PGM OFF

Distance PGM ON

STATE

• Press

↑↓

simultaneously to

exit programming.

FACTORY

VALUE

-

sec

PAGE

6A

6B

7A

7B

8A

8B

9A

9B

10A

• To access the E menu

press the MENU key

for 10sec.

MENU FUNCTION

Present Man

Soft start

Courtesy light time

Follow me

Deceleration speed

Operation counter

Reset - Restore factory settings

RGB Output

Transmitter programming for total opening.

• Use

↑↓

to navigate

through the menus.

MÁX. MIN.

PROGRAMABLE

0

min. max.

1

min. max.

1x

• Press MENU when

you want to confirm

access to a menu.

-

-

-

Deactivates present man

Activates present man

Activates present man - closing

Deactivates Soft start

Activates Soft start

Courtesy light time adjustment

99

Deactivates follow me

Activates follow me

DISABLE MENU

Deceleration speed adjustment

9

-

-

-

TRANSMITTER

Shows the number of maneuvers

Deactivated

Reset activated

Continued output

Intermittent output

STATE

• Press

↑↓

simultaneously to

exit programming.

FACTORY

VALUE

-

PAGE

10B

11A

11B

12A

12B

13A

13B

14A

B

6A 6B

5A 5B

ENEN

Loading...

Loading...