Motor Company Warehouse SDS30OC400V10, SDS15OC400V10, SDS45OC400V10, SDS22OC400V10, SDS185OC400V10 User Manual

...

Open Chassis Star-Delta Starter User Guide

(7.5kW~9

0

kW)

V2

.

0.1

SDS Open Chassis Star-Delta Starter User Guide

Contents

1 Safety information ................................................................................ 1

2 Technical Data ...................................................................................... 2

3 Supply & Motor Connections & Circuit Diagrams ............................... 5

4 Control Connections & Operation ....................................................... 8

www.motorcontrolwarehouse.co.uk

Copyright © Motor Control Warehouse October 2017

Revision V2.0.0

Open Chassis Star-Delta Starter User Guide

P a g e | 1

1

Safety information

Safety Information

This chapter provides very important information so that you can use the SDS Open Chassis Star-Delta Starter

safely, prevent injury or death, or damage to equipment. Please read this information thoroughly and make

sure you observe all the safety information shown below and elsewhere in this manual. Please make this User

Guide available for the end user.

Safety symbols

• The SDS Open Chassis Star-Delta Starter should ONLY be installed, commissioned and maintained by

qualified and competent personnel.

• The OC SDS must be installed to the latest IEE wiring regulations taking into account local

regulations.

• Dangerous voltages are present when the input power supply is connected to the OC SDS. Before

attempting any work on the OC SDS or motor, isolate and lock off the input power supply. Prove

dead using a voltage tester. The voltage tester itself should be proved immediately before and after

testing using a proving unit with a low power output.

• The OC SDS backplate must be connected to system ground using the earth terminals. The size of

the earth conductor and earth loop impedance must comply with national and local electrical

regulations.

• The SDS is a non-field repairable unit. Contact the supplier of the SDS.

• The mains supply and control supply to the OC SDS must be protected by suitable rated

fuses/MCBs.

• All machinery, in which this OC SDS is used, within the European Union, must comply with directive

98/37/EC, Safety of Machinery.

• Do not install the OC SDS in an explosive environment.

• The motor must be used within the manufacturers guidelines.

• Do not allow conductive material to enter the components within the OC SDS, e.g. from drilling

during installation.

Danger of electrical shock which can cause injury or death, or damage to equipment

Danger

:

Warning:

Potential hazard, other than electrical, that can cause physical injury or damage to equipment

Danger

Warning

P a g e | 2

Open Chassis Star-Delta Starter User Guide

2

Technical Specification

Technical data

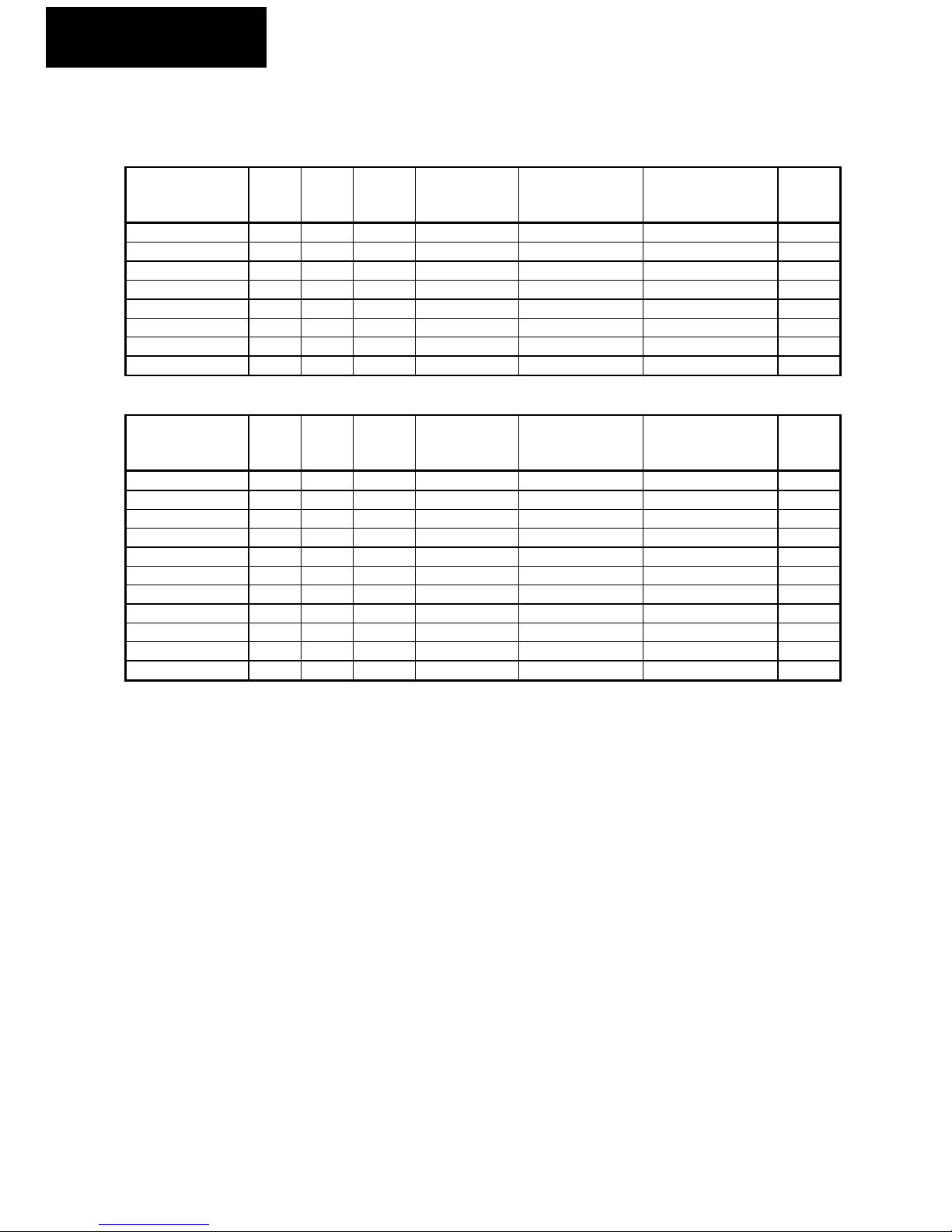

Trip Class 10

Model kW

rating

Input

phase

Input

voltage

(VAC)

Max allowed

motor current

(A)

Motor current (A)

(overload range)

Trip Class 10

Overload range

(A)

Typical

Motor

(A)

SDS075OC400V10 7.5 3 400 17 15.5 to 22 9 to 13 16

SDS11OC400V10 11 3 400 22 20 to 31 12 to 18 20

SDS15OC400V10 15 3 400 29 29 to 43 17 to 25 27

SDS185OC400V10 18.5 3 400 36 29 to 43 17 to 25 34

SDS22OC400V10 22 3 400 44 39.5 to 55 23 to 32 41

SDS30OC400V10 30 3 400 59 52 to 69 30 to 40 55

SDS37OC400V10 37 3 400 75 63 to 86 37 to 50 72

SDS45OC400V10 45 3 400 89 82 to 112 48 to 65 86

Trip Class 20

Model kW

rating

Input

phase

Input

voltage

(VAC)

Max allowed

motor current

(A)

Motor current (A)

(overload range)

Trip Class 20

Overload range

(A)

Typical

Motor

(A)

SDS075OC400V20 7.5 3 400 17 15.5 to 77 9 to 45 16

SDS11OC400V20 11 3 400 22 15.5 to 77 9 to 45 20

SDS15OC400V20 15 3 400 29 15.5 to 77 9 to 45 27

SDS185OC400V20 18.5 3 400 36 15.5 to 77 9 to 45 34

SDS22OC400V20 22 3 400 44 15.5 to 77 9 to 45 41

SDS30OC400V20 30 3 400 59 31 to 155 18 to 90 55

SDS37OC400V20 37 3 400 75 31 to 155 18 to 90 72

SDS45OC400V20 45 3 400 89 31 to 155 18 to 90 86

SDS55OC400V20 55 3 400 108 31 to 155 18 to 90 98

SDS75OC400V20 75 3 400 135 31 to 155 18 to 90 129

SDS90OC400V20 90 3 400 170 103 to 206 60 to 120 158

NOTE: The thermal overload setting is set to minimum as default. It should be adjusted to suit the motor

used.

To calculate the thermal overload setting = Actual motor nameplate current ÷ 1.7 x 1.1 (10% safety margin to

prevent spurious tripping).

NOTE: Due to the large range of the thermal overloads on the Trip Class 20 star delta starters, please make

sure the thermal overload is adjusted correctly to suit the motor.

NOTE: Starting the motor more than once every 10 minutes will alter the thermal overload tripping

characteristic by heating the current sensing elements, making the overload trip more quickly for a given

setting.

Open Chassis Star-Delta Starter User Guide

P a g e | 3

2

Technical Specification

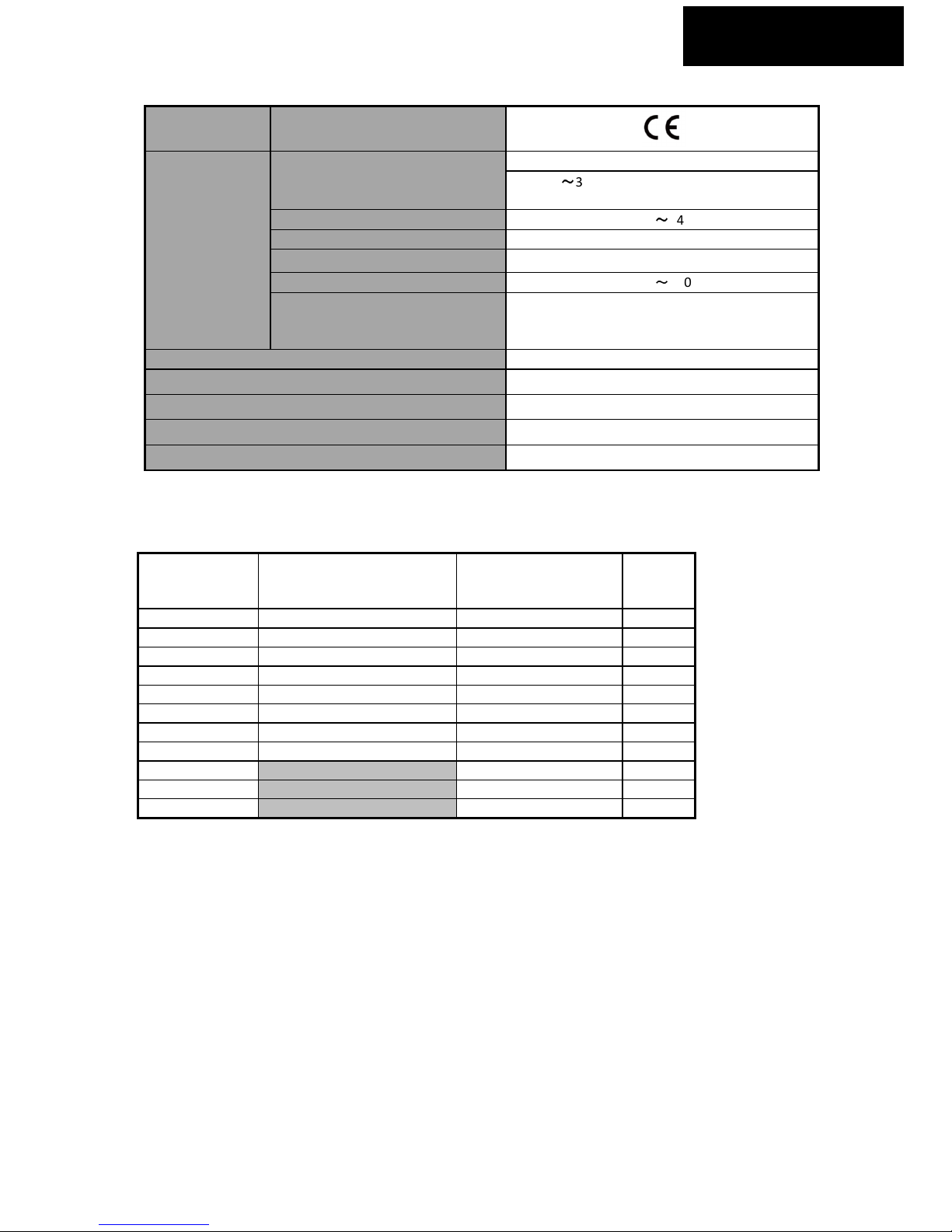

Approvals CE approval

Environment

Altitude

1000m rated

1000m~3000m, 1% rated current de-rating per

100m above 1000m

Operating Temperature

−10°C~+40°C

Max. Humidity ≤90%RH, non-condensing

Vibration ≤5.9m/s2 (0.6g)

Storage Temperature

−40°C~+70°C

Running Environment

Non-flammable, No corrosive gasses, no

contamination with electrically conductive

material

Supported Power Supply Systems TT & TN

OC SDS Enclosure IP20 (must be installed in an enclosure)

Supply frequency 50 to 60Hz

Supply voltage 3 phase 400VAC ±10%

*Contactor coil voltage 400VAC / 240VAC / 110VAC (+/-10%)

*Model dependant

OC SDS Dimensions

Model Dimensions

(H x W x D)

Trip Class 10

Dimensions

(H x W x D)

Trip Class 20

Approx.

Weight

(kg)

SDS075OC400V 170 x 180 x 170 170 x 180 x 170 2.2

SDS11OC400V 170 x 180 x 170 170 x 180 x 170 2.2

SDS15OC400V 200 x 300 x 190 200 x 300 x 190 5

SDS185OC400V 200 x 300 x 190 200 x 300 x 190 5

SDS22OC400V 200 x 300 x 190 200 x 200 x 200 5

SDS30OC400V 200 x 320 x 200 200 x 320 x 200 5

SDS37OC400V 200 x 320 x 200 200 x 320 x 200 5

SDS45OC400V 200 x 320 x 200 200 x 320 x 200 5

SDS55OC400V 200 x 320 x 200 5

SDS75OC400V 350 x 480 x 150 10

SDS90OC400V 350 x 480 x 150 10

NOTE: The above dimensions are only approximate and do not take into account the size of the thermal

overload on the trip class 20 star delta starters.

NOTE: The contactor sets between the Trip Class 10 and Trip Class 20 open chassis star delta starter may differ

hence the physical size of the trip class 20 may be larger than the equivalent trip class 10 model.

NOTE: The open chassis star delta starters are supplied pre-wired on a back plate. The starting and stopping

method will need wiring into the star delta starter. See Control Connections & Operation section of this User

Guide for example connections.

NOTE: The thermal overload is fitted into the output of the main contactor on the Trip Class 10 product. The

Trip Class 20 thermal overload is supplied as a separate module which will need to be mounted separately

from the contactors and wired into the output of the main contactor.

Loading...

Loading...