Motorbench MCLV-2, MCHV-3, MCHV-2 User Manual

Dashboard

/ …

/ motorBench 2.25 Release

Created by Fernando Garibaldi, last modified by Jason Sachs 4 minutes ago

motorBench User's Guide

Introduction

Recommended Reading

Hardware Setup

MCLV-2

MCHV-2 and MCHV-3

Sample motorBench Projects

Operating Instructions

Getting started

Configuration

Motor Import and Export

Importing a motor

Exporting a motor

Motor parameter measurement

Common types of motor parameter measurement errors and reasons they can occur

Autotuning

Managing Errors in Autotuning

How to identify autotuning errors

Common types of autotuning errors and reasons they can occur

How to report specific failure details to Microchip for assistance

Customize

Position and velocity estimator selection

Advanced parameters

Normalized parameters

Advice

Additional information

Generate Code

Managing Errors in Code Generation

How to identify code generation errors

Common types of code generation errors and reasons they can occur

How to report specific failure details to Microchip for assistance

Building Code

Running the Application Framework

MCLV-2

MCHV-2 and MCHV-3

Real-Time Diagnostics

Troubleshooting Issues with some motors

Appendix

Motor parameter measurement - Calibration load specifications

Introduction

This document describes how to setup hardware, configure, and operate motorBench® Development Suite as well as aid in troubleshooting issues with motors. For information on

installing motorBench please refer to the motorBench Release Notes. This document does not advise how to use the resulting generated code. Please refer to the MCAF User's Guide for

additional information.

Recommended Reading

This user's guide refers to motorBench operation only. Other useful documents are listed below:

MPLAB® Code Configurator v3.xx User's Guide

MCAF User's Guide

Hardware Setup

The following sections outline the hardware setup of MCLV-2, MCHV-2, and MCHV-3.

MCLV-2

Hardware setup: MCLV-2

This section provides detailed steps that will help you setup your hardware to work with the motorBench® Development Suite:

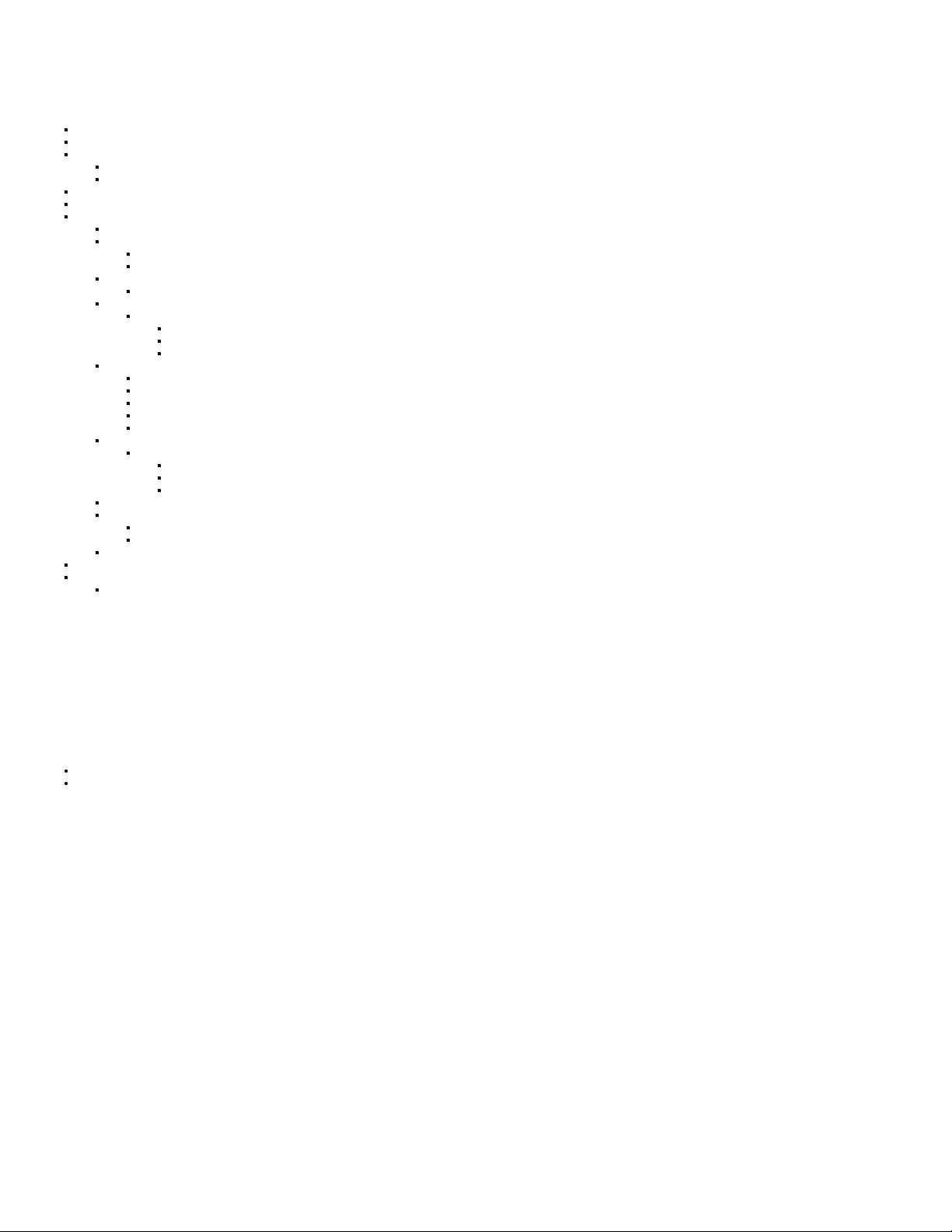

1. MCLV-2 board comes pre-installed out of the box with dsPIC33EP256MC506 Internal Op Amp Motor Control PIM (MA330031); replace this PIM with

the dsPIC33EP256MC506 External Op Amp PIM (MA330031-2) or dsPIC33CK256MP508 External Op Amp PIM (MA330041-1) specified above.

2. Make sure that the dsPIC33EP256MC506 External Op Amp PIM is populated with a silicon mask rev-A8 or later. To verify this, read out the device revision from MPLAB X and

verify that the Device ID revision is equal to or greater than 0x4008.

3. Install the External Op Amp Configuration matrix board that comes with the MCLV-2 board into J14

4. Update the jumpers JP1-JP2-JP3 to Curr position and JP4-JP5 to UART position as shown below:

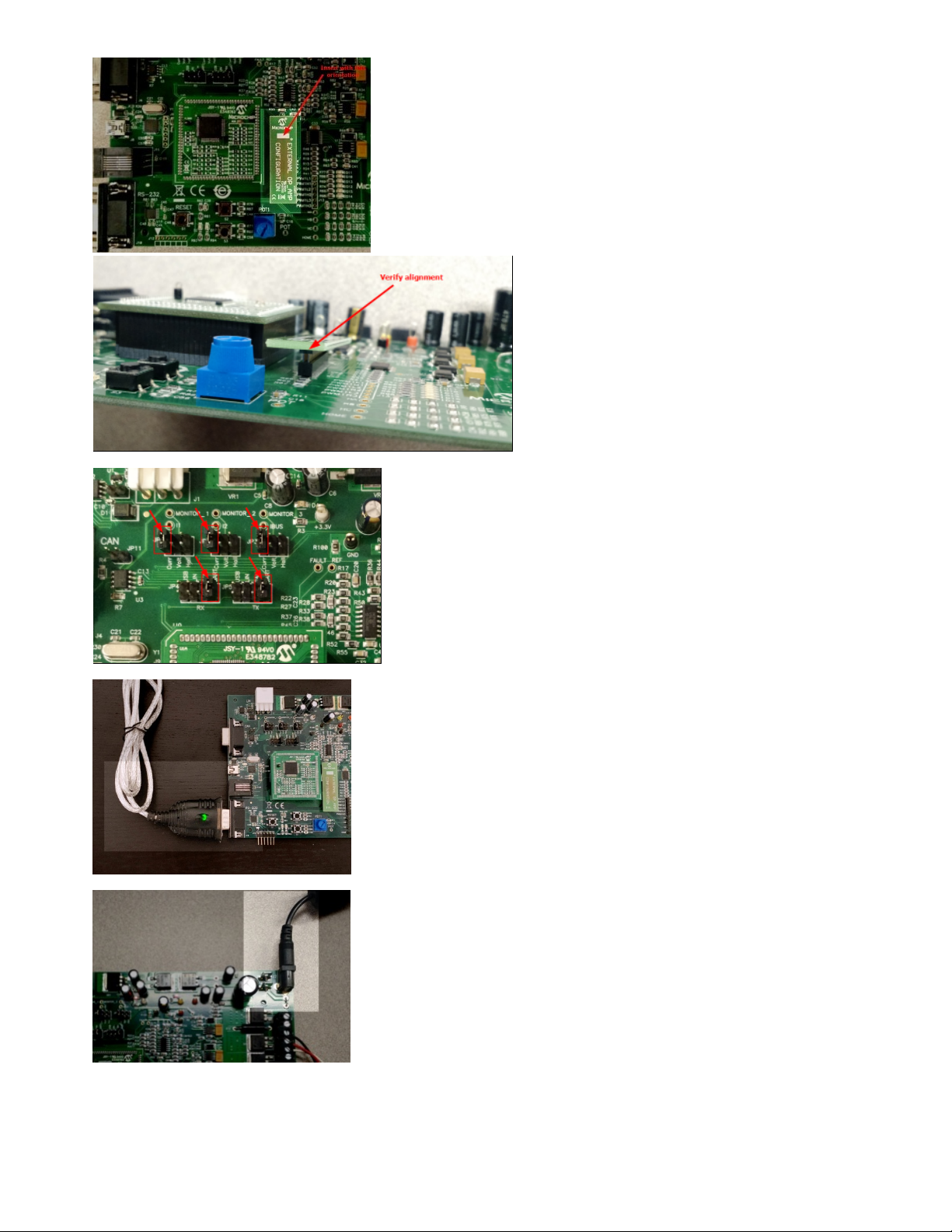

5. Connect the USB-to-logic-level-UART converter cable into J10 of MCLV-2 board and one of the USB ports on your PC:

6. Plug in the 24V power supply barrel connector into J2 of MCLV-2 board and then plug in the power supply into the mains outlet:

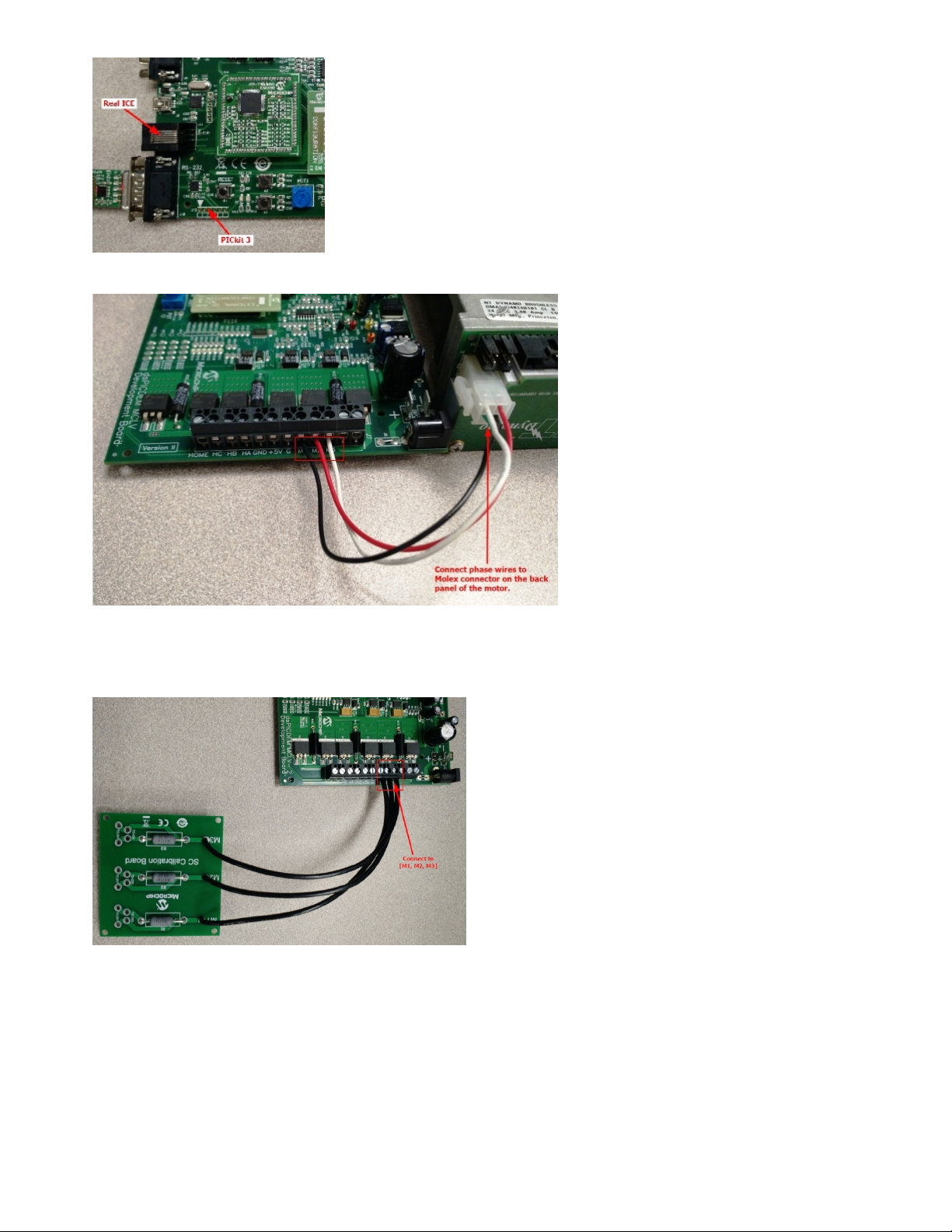

7. Connect your Real ICE / ICD3 / PICkit3 to one of the USB ports on your PC

8. Connect the Real ICE / ICD3 to J11 of MCLV-2 board. If you are using PICkit 3, then connect it to J12 of this board.

9. Connect the [black, red, white] phase wires of the 24V BLDC motor to [M1, M2, M3] terminals of J7 connector on the MCLV-2 board. (Sequence / order of this

connection is not important if the direction of rotation does not matter.) You may leave the green color phase wire unconnected or connect it to the G terminal of J7 connector on

the MCLV-2 board. Then, plug in the other end with a Molex connector to the 24V BLDC motor.

10. Keep the motor on a stable surface and use a clamp (if available) to secure the motor from jumping around. (If using a metal C-clamp, make sure there is a thin shim of rubber,

cloth, wood, or other mechanically-compliant material between the clamp and the motor, to avoid deforming the motor housing.) Alternatively, you can also place the motor on a

rubber mat. Also, do not disturb the motor or hold its shaft while motor parameter measurement is running.

11. While running the Board Calibration within motor parameter measurement feature in motorBench® Development Suite, you will need to use a calibration load of three

equal-value resistors connected in place of the 24V BLDC motor. Please refer to the Appendix section of this document for more information on the calibration load. Once you

have the calibration load on hand, you can start by stripping off the insulation on the wires coming from the M1, M2 and M3 terminals of the Calibration load. Then connect

these wires into M1, M2, M3 terminals of the J7 connector on the MCLV-2 board.

MCHV-2 and MCHV-3

Hardware setup: MCHV-2 and MCHV-3

Hardware setup: MCHV-2 and MCHV-3

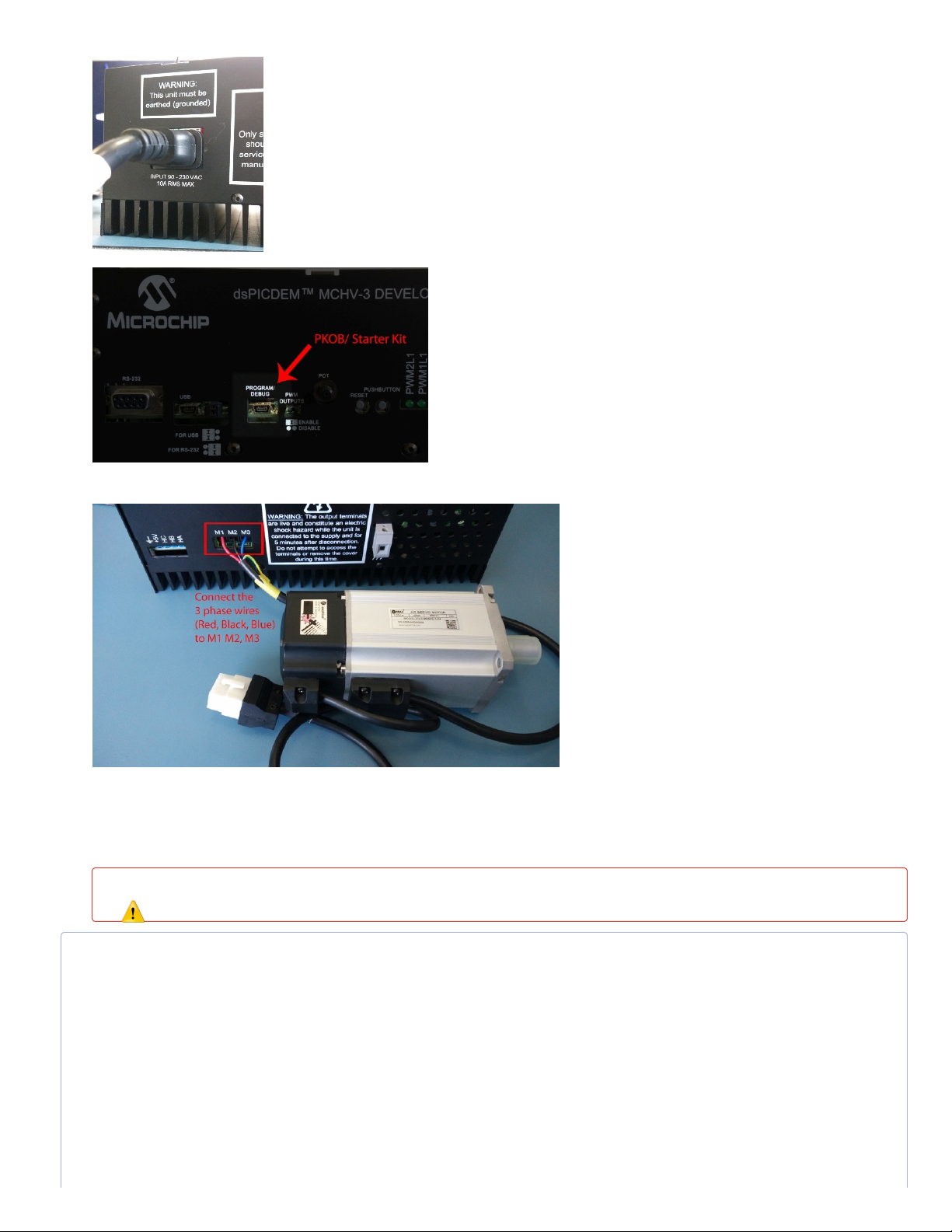

This section provides detailed steps that will help you setup your hardware to work with the motorBench® Development Suite: Although the setup is similar for MCHV-2 or MCHV-3,

pictures of MCHV-3 are shown in the below section

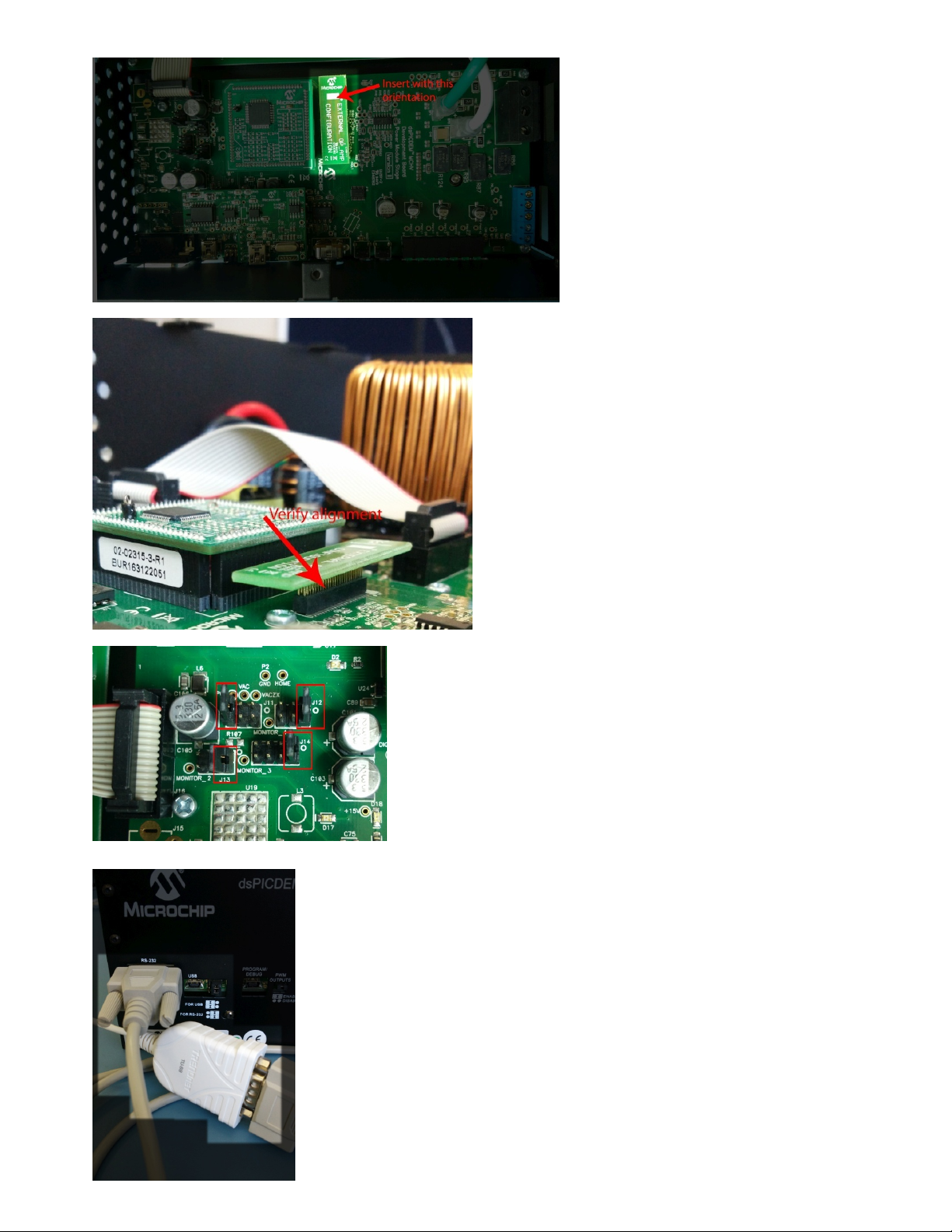

1. MCHV-3 board comes pre-installed out of the box with dsPIC33EP256MC506 Internal OpAmp Motor Control PIM (MA330031); replace this PIM with

the dsPIC33EP256MC506 External OpAmp PIM (MA330031-2) or dsPIC33CK256MP508 External OpAmp PIM (MA330041-1) specified above.

2. Make sure that the dsPIC33EP256MC506 External OpAmp PIM is populated with a silicon mask rev-A8 or later. To verify the revision of silicon, read out the device revision

from MPLAB X and make sure that the Device ID revision is equal to or greater than 0x4008.

3. Install the External OpAmp Configuration matrix board that comes with the MCHV-3 board into J4

4. Update the jumpers J12-J13-J14 to 1-2 position and J11 to 5-6 position as shown below:

5. Connect the USB-to-UART converter cable into RS232 labeled port on MCHV-3 board and one of the USB ports on your PC:

Please note that in the event of mechanical interference with the USB-to-UART cable, you may need to use an UART extension cable.

6. Plug in an appropriate ac power supply cable to MCHV-3 board and then plug in the AC power supply cable into the mains outlet:

7. Connect the provided USB cable to PROGRAM/DEBUG connector on MCHV-3 board and to one of the USB ports on your PC.

8. Connect the [red, black, blue] phase wires of the Leadshine 400W 220VAC Servo Motor (AC300025) to the [M1, M2, M3] terminals on the MCHV-3 board. (Sequence /

order of this connection is not important if the direction of rotation does not matter.) Connect the green-yellow combination color wire to the Ground terminal provided on the

MCHV-3 board.

9. Keep the motor on a stable surface and use a clamp (if available) to secure the motor from jumping around. (If using a metal C-clamp, make sure there is a thin shim of rubber,

cloth, wood, or other mechanically-compliant material between the clamp and the motor, to avoid deforming the motor housing.) Alternatively, you can also place the motor on a

rubber mat. Also, do not disturb the motor or hold its shaft while motor parameter measurement is running.

10. While running the Board Calibration within motor parameter measurement feature in motorBench® Development Suite, you will need to use a calibration load of three

equal-value resistors connected in place of the BLDC motor. Please refer to the Appendix section of this document for more information on the calibration load. Once you have

the calibration load on hand, you can start by stripping off the insulation on the wires coming from the M1, M2 and M3 terminals of the Calibration load. Then connect these wires

into the M1, M2, M3 terminals of connector on the MCHV-3 board.

Hazard warning

Whenever connecting or disconnecting a motor or calibration load from MCHV-2/ MCHV-3 board, please disconnect the power from the MCHV-2/ MCHV-3 board. Also,

use an insulated screwdriver that is recommended for high voltage rating.

There is a known hardware design limitation with MCHV-2 and MCHV-3 boards that can cause the device on a dsPIC33EP256MC506 External Op Amp Motor Control PIM to

reset when running motors with large phase currents. This issue does not affect dsPIC33CK256MP508. If you are observing dsPIC device reset issues while using MCHV-2 or

MCHV-3 board with this PIM and with certain test motors, power down the board, unplug the AC power cable, wait until LED D13 is OFF and then make the following

modification:

Use a short length of jumper wire to connect digital ground signal to analog ground signal on the PIM. To do this, connect pins 31 and 36 on the dsPIC33EP256MC506

External Op Amp Motor Control PIM:

Loading...

Loading...