Page 1

Yasnac MRC Controller

January 20, 1995

MAN

ArcWorld 6000

Operator's Manual

Part Number 132340-7

TEL: 513-847-6200 FAX: 513-847-6277

24-HOUR SERVICE HOTLINE: 513-847-3200

The information contained within this document is the proprietary property of Motoman, Inc., and

may not be copied, reproduced or transmitted to other parties without the expressed written

MOTO

805 Liberty Lane

West Carrollton, OH 45449

authorization of Motoman, Inc.

Page 2

All Rights Reserved

Because we are constantly improving our products, we reserve the right to change specifications without

notice. YASNAC and MOTOMAN are registered trademarks of YASKAWA Electric Manufacturing.

Page 3

TABLE OF CONTENTS

Section Page

1.0 INTRODUCTION............................................................................................ 1

1.1 ABOUT THIS DOCUMENT............................................................... 1

1.2 SYSTEM OVERVIEW.......................................................................... 1

1.2.1 System Layout..................................................................... 3

1.2.2 Optional Equipment.............................................................. 3

1.3 REFERENCE TO OTHER DOCUMENTATION ................................... 4

1.4 CUSTOMER SERVICE INFORMATION ............................................. 4

2.0 SAFETY.......................................................................................................... 5

2.1 STANDARD CONVENTIONS............................................................. 6

2.2 GENERAL SAFEGUARDING TIPS..................................................... 7

2.3 MECHANICAL SAFETY DEVICES ...................................................... 7

2.4 INSTALLATION SAFETY.................................................................... 8

2.5 PROGRAMMING SAFETY ................................................................ 8

2.6 OPERATION SAFETY ........................................................................ 9

2.7 MAINTENANCE SAFETY................................................................. 10

3.0 DESCRIPTION OF EQUIPMENT................................................................. 11

3.1 K-SERIES ROBOT DESCRIPTION.................................................. 11

3.2 MRC CONTROLLER........................................................................ 11

3.2.1 Servo Power..................................................................... 12

3.2.2 Mode Select...................................................................... 13

3.2.3 Cycle Select...................................................................... 13

3.2.4 Emergency Stop................................................................ 13

3.2.5 Alarm / Error.................................................................... 13

3.2.6 Hold.................................................................................. 13

3.2.7 Start................................................................................. 13

3.2.8 Playback Box Sub-Panel.................................................... 13

3.3 PROGRAMMING PENDANT.......................................................... 14

3.3.1 Display.............................................................................. 15

3.3.2 Robot Speed Indicators...................................................... 15

3.3.3 Emergency Stop................................................................ 15

3.3.4 Keypad.............................................................................. 15

3.3.5 Servo Power..................................................................... 15

Page 4

3.4 MRM2-SERIES POSITIONER......................................................... 15

3.4.1 Part / Fixture Rating......................................................... 16

3.4.2 Swing Diameter................................................................. 16

3.4.3 Temperature Operating Range........................................... 16

Page 5

3.4.4 Humidity............................................................................ 16

3.4.5 Shock Rating..................................................................... 16

3.4.6 Sweep Speed ..................................................................... 17

3.4.7 Servo Head Stock Speed.................................................... 17

3.4.8 Air Requirements.............................................................. 17

3.4.9 Electrical Requirements..................................................... 17

3.4.10 Welding Current Rating..................................................... 17

3.4.11 Locking Pins...................................................................... 17

3.4.12 Arc Shield......................................................................... 18

3.5 OP-STATION.................................................................................. 18

3.5.1 Emergency Stop................................................................ 18

3.5.2 Hold.................................................................................. 18

3.5.3 Cycle Start....................................................................... 19

3.5.4 Station Ready.................................................................... 19

3.5.5 Alarm............................................................................... 19

3.5.6 Servo On.......................................................................... 19

3.5.7 Positioner Auto / Manual................................................... 19

3.5.8 Master Job Start .............................................................. 19

3.5.9 Operator Station Enable / Disable...................................... 19

3.5.10 Reset................................................................................ 20

3.6 WELDING POWER SOURCE........................................................... 20

3.6.1 Main Power...................................................................... 20

3.6.2 Volt / Amp Settings............................................................ 20

3.6.3 Terminal Connectors......................................................... 20

3.6.4 Local / Remote Operation................................................... 20

3.6.5 Feeder Control Receptacles............................................... 21

3.6.6 Circuit Breakers............................................................... 22

3.6.7 AC Receptacles................................................................. 22

3.7 WELDING EQUIPMENT.................................................................. 22

3.7.1 PWF4 Wire Feeder............................................................ 22

3.7.2 Universal Welding Interface (UWI)................................... 22

3.7.3 MIG Torch....................................................................... 22

3.7.4 RAM Breakaway Mount.................................................... 23

3.8 SAFETY EQUIPMENT ..................................................................... 23

3.8.1 Arc Screens...................................................................... 23

3.8.2 Fencing............................................................................. 23

3.8.3 Interlocks......................................................................... 24

3.8.4 Safety Mats...................................................................... 24

3.8.5 Emergency Stops............................................................... 24

4.0 OPERATION................................................................................................ 25

4.1 OPERATION................................................................................... 25

Page 6

4.1.1 Start Up........................................................................... 25

4.1.2 Loading / Unloading Procedures......................................... 26

4.1.3 Fault Recovery.................................................................. 26

Page 7

4.1.4 E-STOP Recovery............................................................. 26

4.1.5 Shock Sensor Recovery..................................................... 27

4.1.6 Shut Down........................................................................ 29

4.2 ALARMS AND ERRORS.................................................................. 29

4.2.1 Error Messages................................................................ 29

4.2.2 Minor Alarms................................................................... 29

4.2.3 Major Alarms................................................................... 30

4.3 PROGRAMMING............................................................................ 30

4.3.1 Cube Assignment............................................................... 30

4.3.2 Sweeping Positioner to Side A............................................ 31

4.3.3 Sweeping Positioner to Side B............................................ 31

4.3.4 Rotating Headstock........................................................... 32

4.3.5 Programming.................................................................... 32

4.3.6 I/O Assignment................................................................. 34

4.4 SAMPLE JOBS................................................................................ 35

4.4.1 Master Job (No Group Axes)............................................ 35

4.4.2 Sweep to A Job (R1 + S1).................................................. 36

4.4.3 Sweep to B Job................................................................. 38

4.4.4 Weld Side A Job (Multiple Weld Jobs)................................ 39

4.4.5 Weld Side A Job (Single Weld Job)..................................... 39

4.4.6 Weld Side B Job................................................................ 40

4.4.7 Clean Job (R1 Job)............................................................ 41

5.0 MAINTENANCE ........................................................................................... 42

5.1 PERIODIC MAINTENANCE............................................................ 42

5.2 SPARE PARTS LIST......................................................................... 43

5.3 FUSE AND CIRCUIT BREAKER PROTECTION............................... 44

APPX. A RISK ASSESSMENT.......................................................................... A-1

APPX. B SYSTEM OUTLINE ............................................................................ B-1

APPX. C ELECTRICAL DRAWINGS.................................................................. C-1

APPX. D MECHANICAL DRAWINGS.............................................................. D-1

INDEX ......................................................................................................... Index 1

Page 8

LIST OF FIGURES

Figure Page

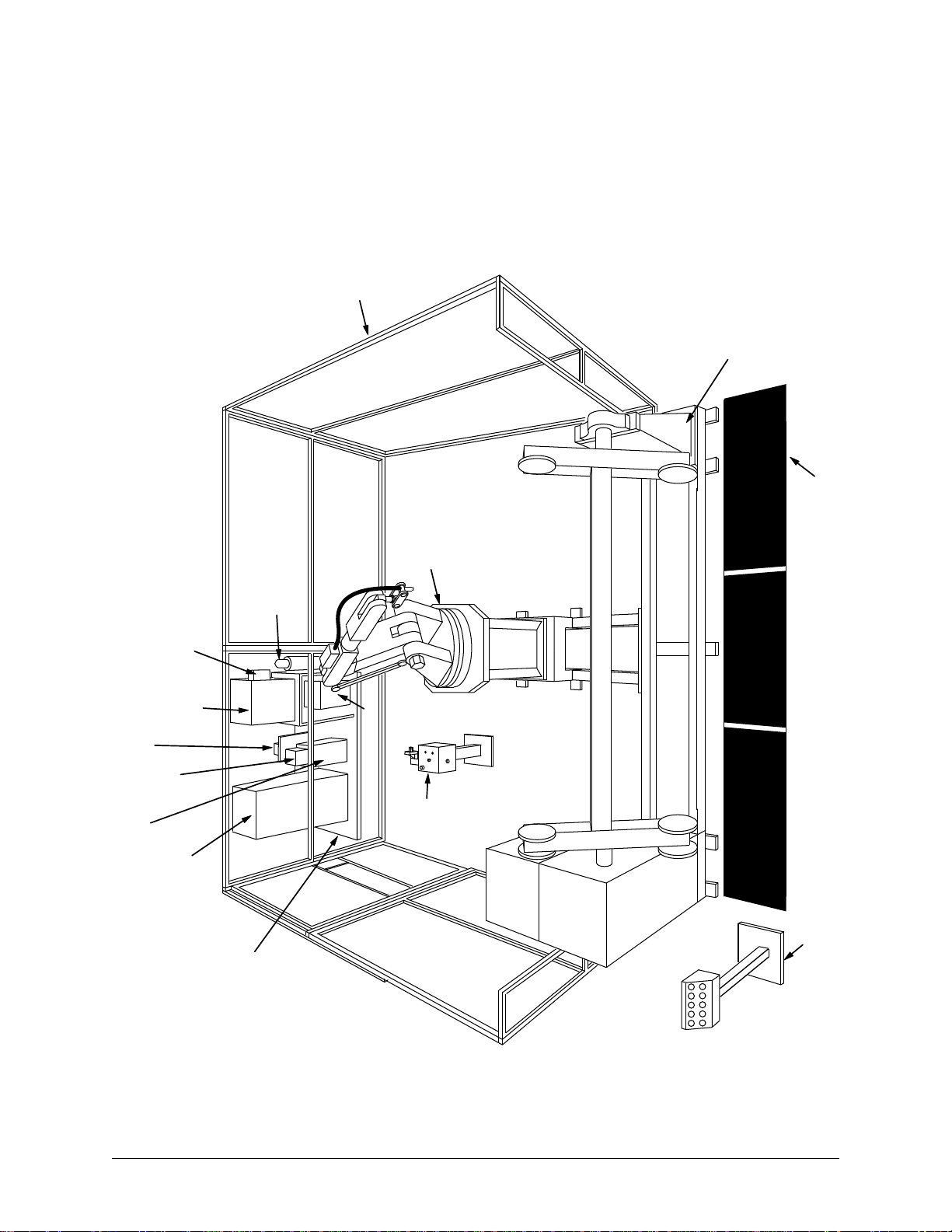

Figure 1-1 System Layout...................................................................................... 2

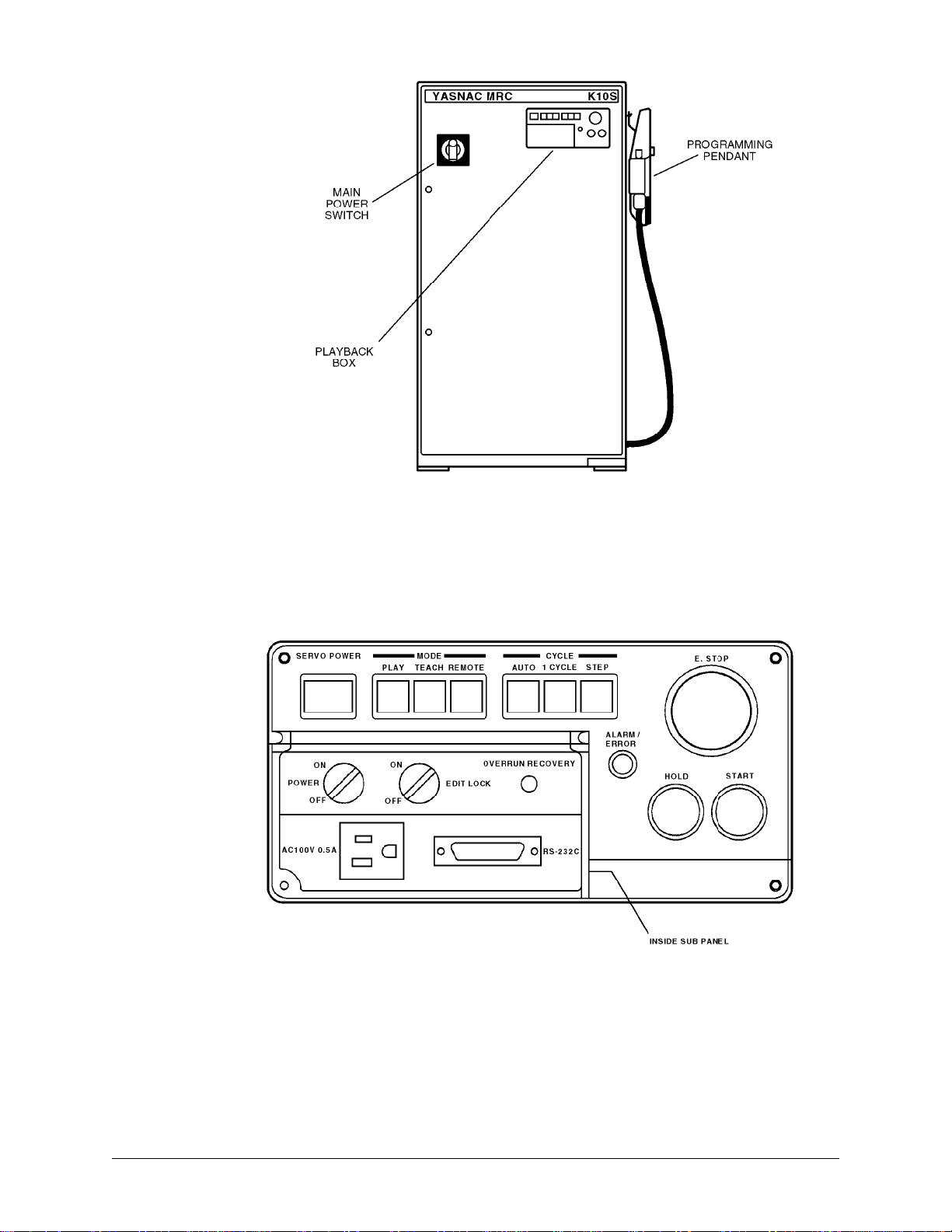

Figure 3-1 MRC Controller................................................................................. 12

Figure 3-2 MRC Playback Box............................................................................ 12

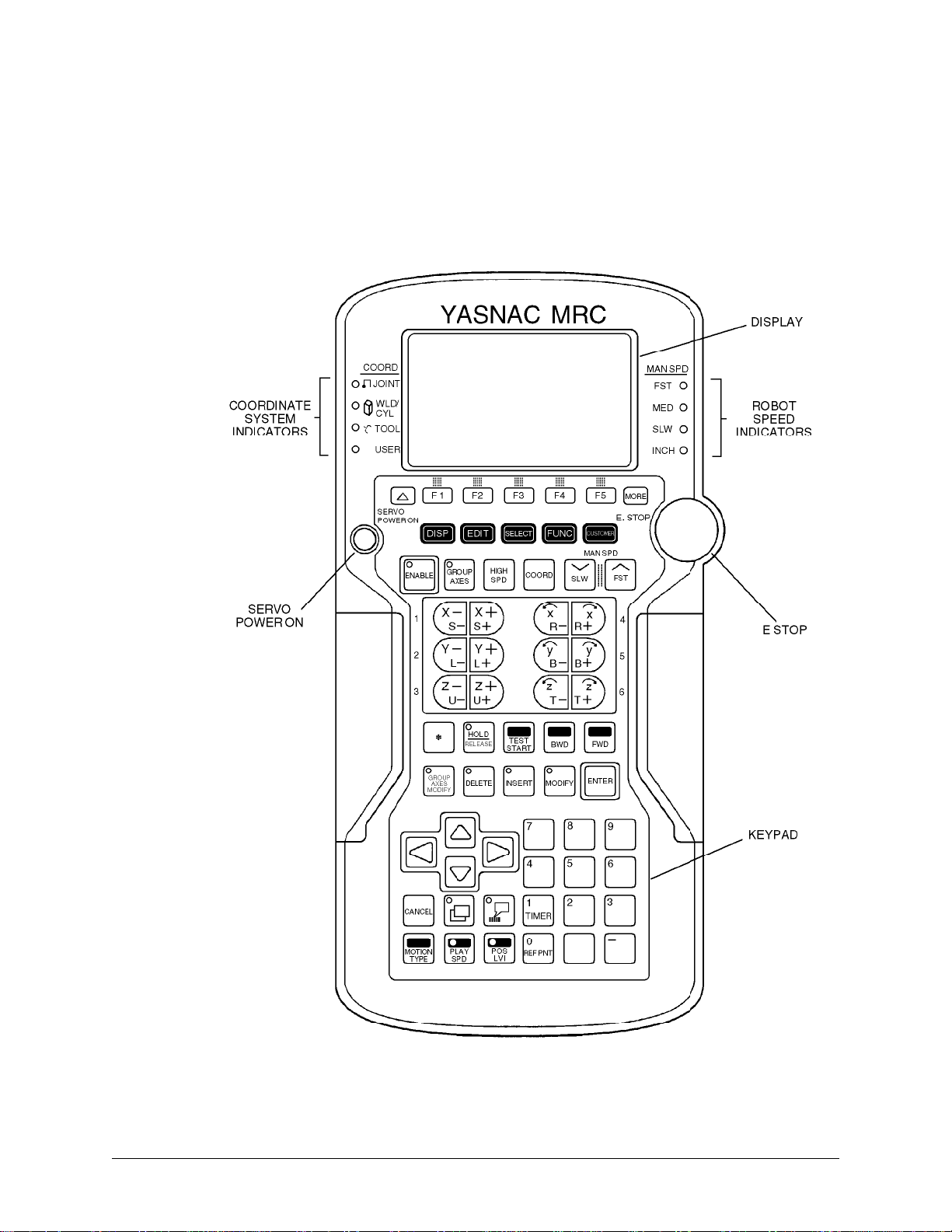

Figure 3-3 Programming Pendant........................................................................ 14

Figure 3-4 Operator Control Panel (Op-Station)................................................. 18

Figure 3-5 Excel-Arc Controls............................................................................ 21

Figure 4-1 Shock Sensor Override...................................................................... 28

LIST OF TABLES

Table Page

Table 5-1 Periodic Maintenance.......................................................................... 42

Table 5-2 Spare Parts........................................................................................ 43

Table 5-3 Excel-Arc 6045 CV Fuses and Circuit Breakers.................................. 44

Table 5-4 MRC Cabinet Fuses and Circuit Breakers............................................ 44

Table 5-5 Universal Welding Interface (UWI) Fuses and Circuit Breakers........... 46

Table 5-6 COMARC III Fuses and Circuit Breakers............................................ 46

Page 9

ArcWorld 6000 Operator's Manual Page 1 MOTOMAN

1.0 INTRODUCTION

The ArcWorld 6000 is part of the ArcWorld family of standardized arc welding

solutions. It is a fully integrated welding system, and is supported from wire to

weld by Motoman, Inc.

The ArcWorld 6000 features a Motoman arc welding robot and MRC controller

with menu-driven arc welding application software, complete welding package,

180˚ reciprocating positioner, operator interface, and total safety environment.

1.1 ABOUT THIS DOCUMENT

This manual provides operation instructions for the ArcWorld 6000 system. In

addition to this introduction, the manual includes the following sections:

• Section 2: Safety

• Section 3: Description of Equipment

• Section 4: Operation

• Section 5: Maintenance

• Appendices

The Safety Section of the manual provides information regarding the safe use and

operation of the ArcWorld 6000 system.

Section 3 of this manual provides a detailed description of the major components of

the ArcWorld system. This section includes a table of component specifications.

The Operation Section of the manual provides instructions to operate the ArcWorld

system. In this section, we describe the various operator controls and indicators.

We also provide procedures for start-up, loading, normal operation, fault recovery,

and shut-down. Finally, the section contains a number of sample robot programs.

In the Maintenance Section, you will find a table listing periodic maintenance

requirements for the ArcWorld 6000 cell. This section includes detailed

instructions to perform specific maintenance tasks. It also includes a list of

recommended spare parts.

Appendix A is a Risk Assessment document. The remaining appendices to this

manual contain a full set of reference drawings.

1.2 SYSTEM OVERVIEW

The ArcWorld 6000 provides a complete arc welding solution in a standardized

configuration. The system is designed around a Motoman arc welding robot and

includes a complete welding package. A dual ferris-wheel positioner allows an

Page 10

ArcWorld 6000 Operator's Manual Page 2 MOTOMAN

operator to prepare and set up parts on one side while the robots weld on the other

side. The cell provides a full complement of safety features designed to protect

both personnel and equipment.

Assembled

Fence

Robot

Auxiliary

Equipment

Common Base

Operator

Station

Positioner

Gas Bottle

(customer supplied)

Safety Mats

MRC

Cabinet

Water

Circulator

Disconnect

Disconnect

Transformer

Com-Arc

Welding

Power

Source

Torch

Tender

Page 11

ArcWorld 6000 Operator's Manual Page 3 MOTOMAN

Figure 1-1 System Layout

Page 12

ArcWorld 6000 Operator's Manual Page 4 MOTOMAN

1.2.1 System Layout

The illustration in Figure 1-1 shows the system layout for the ArcWorld 6000 cell.

The ArcWorld 6000 includes the following major components:

• Motoman robot manipulator and MRC controller

• MRM2 series dual ferris-wheel positioner

• Master operator station

• Welding equipment, including the following:

• Excel-Arc welding power source

• Torch (water-cooled or air-cooled)

• Wire feeder

• Welding interface

• Torch breakaway

• Safety equipment, including the following:

• Safety fencing with arc curtains

• Interlocked safety mats

• Interlocked cell door

• Positioner arc screen

The MRC controller and welding power source share a common base. Additional

auxiliary components, such as the COMARC unit and water circulator, can be

located on this base as well. The robotic cell is fully enclosed by safety fencing and

an interlocking door. Safety mats prevent positioner cycling while anyone stands in

front of the positioner. All operator controls, including those on the MRC and

welding power supply, are accessible from outside of the robotic enclosure.

1.2.2 Optional Equipment

The following optional equipment is available for use with the ArcWorld 6000:

• Torch tender

• Wire cutter

• COMARC III

• Heavy duty positioners

• Stationary tables

Page 13

ArcWorld 6000 Operator's Manual Page 5 MOTOMAN

1.3 REFERENCE TO OTHER DOCUMENTATION

For additional information refer to the following:

• Motoman K10 MRC Manipulator Manual (Part Number 132330-7)

• Motoman K6 MRC Manipulator Manual (Part Number 132330-4)

• Motoman MRC Operator's Manual for Arc Welding (Part Number 132332-1)

• Motoman MRC User Functions Manual (Part Number 132331-1)

• Motoman ArcWorld 6000 Installation Manual (Part Number 132341-7)

• Motoman RM2-250SE2 Manual (Part Number TT-503.8)

• Motoman RM2-500SE2 Manual (Part Number TT-504.2)

• Additional vendor's manuals

1.4 CUSTOMER SERVICE INFORMATION

If you are in need of technical assistance, contact the Motoman service staff at

(513) 847-3200. Have the following information ready before you call:

• Robot Type (K3, K6, K10, etc.)

• Robot Serial Number (located on the back side of the robot arm)

• Application Type (palletizing, welding, handling, etc.)

• Robot Sales Order Number (located on back side of robot and MRC controller)

Page 14

ArcWorld 6000 Operator's Manual Page 6 MOTOMAN

2.0 SAFETY

It is the purchaser's responsibility to ensure that all local, county, state, and national

codes, regulations, rules, or laws relating to safety and safe operating conditions for

each installation are met and followed.

We suggest that you obtain and review a copy of the ANSI/RIA National Safety

Standard for Industrial Robots and Robot Systems. This information can be

obtained from the Robotic Industries Association by requesting ANSI/RIA

R15.06. The address is as follows:

Robotic Industries Association

900 Victors Way

P.O. Box 3724

Ann Arbor, Michigan 48106

TEL: 313/994-6088

FAX: 313/994-3338

Ultimately, the best safeguard is trained personnel. The user is responsible for

providing personnel who are adequately trained to operate, program, and maintain

the robot cell. The robot must not be operated by personnel who have not

been trained!

We recommend that all personnel who intend to operate, program, repair, or use

the robot system be trained in an approved Motoman training course and become

familiar with the proper operation of the system.

This safety section addresses the following:

• Standard Conventions (see Section 2.1)

• General Cautions and Warnings (see Section 2.2)

• Mechanical Safety Devices (see Section 2.3)

• Installation Safety (see Section 2.4)

• Programming Safety (see Section 2.5)

• Operation Safety (see Section 2.6)

• Maintenance Safety (see Section 2.7)

Page 15

ArcWorld 6000 Operator's Manual Page 7 MOTOMAN

2.1 STANDARD CONVENTIONS

This manual includes information essential to the safety of personnel and

equipment. As you read through this manual, be alert to the four signal words:

• DANGER

• WARNING

• CAUTION

• NOTE

Pay particular attention to the information provided under these headings which are

defined below (in descending order of severity).

➪

DANGER!

Information appearing under the DANGER caption concerns the

protection of personnel from the immediate and imminent

hazards that, if not avoided, will result in immediate, serious

personal injury or loss of life in addition to equipment damage.

➪

WARNING!

Information appearing under the WARNING caption concerns the

protection of personnel and equipment from potential hazards

that can result in personal injury or loss of life in addition to

equipment damage.

➪

CAUTION!

Information appearing under the CAUTION caption concerns the

protection of equipment, software, and data from hazards that

can result in minor personal injury or equipment damage.

NOTE: Information appearing in a NOTE caption provides additional information which is helpful in

understanding the item being explained.

Page 16

ArcWorld 6000 Operator's Manual Page 8 MOTOMAN

2.2 GENERAL SAFEGUARDING TIPS

All operators, programmers, plant and tooling engineers, maintenance

personnel, supervisors, and anyone working near the robot must become

familiar with the operation of this equipment. All personnel involved with the

operation of the equipment must understand potential dangers of operation.

General safeguarding tips are as follows:

• Improper operation can damage the equipment. Only trained personnel familiar

with the operation of this robot, the operator's manuals, the system equipment,

and options and accessories should be permitted to operate this robot system.

• Do not enter the robot cell while it is in operation. Place the robot in

Emergency Stop (E-Stop) mode and ensure that all motion has stopped before

entering the cell.

• Improper connections can damage the robot. All connections must be made

within the standard voltage and current ratings of the robot I/O (Inputs and

Outputs).

• The robot must be placed in Emergency Stop (E-Stop) mode whenever it is not

in use.

2.3 MECHANICAL SAFETY DEVICES

The safe operation of the robot, positioner, auxiliary equipment, and system is

ultimately the user's responsibility. The conditions under which the equipment will

be operated safely should be reviewed by the user. The user must be aware of the

various national codes, RIA safety recommendations, and other local codes that

may pertain to the installation and use of industrial equipment. Additional safety

measures for personnel and equipment may be required depending on system

installation, operation, and/or location. The following safety measures are available:

• Safety fences and barriers

• Light curtains

• Door interlocks

• Safety mats

• Floor markings

• Warning lights

Check all safety equipment frequently for proper operation. Repair or replace any

non-functioning safety equipment immediately.

Page 17

ArcWorld 6000 Operator's Manual Page 9 MOTOMAN

2.4 INSTALLATION SAFETY

Safe installation is essential for protection of people and equipment. The user must

be aware of the various national codes, RIA safety recommendations, and other

local codes that may pertain to the installation and use of industrial equipment.

Additional safety measures for personnel and equipment may be required

depending on system installation, operation, and/or location. The following

suggestions are intended to supplement, but not replace, existing federal, local, and

state laws and regulations.

• Ensure that only trained personnel familiar with the operation of this robot, the

operator's manuals, the system equipment, and options and accessories are

permitted to operate this robot system.

• Identify the work envelope of each robot with floor markings, signs, and

barriers.

• Position all controllers outside the robot work envelope.

• Whenever possible, install safety fences to protect against unauthorized entry

into the work envelope.

• Eliminate areas where personnel might get trapped between a moving robot and

other equipment (pinch points).

• Provide sufficient room inside the workcell to permit safe teaching and

maintenance procedures.

2.5 PROGRAMMING SAFETY

All operators, programmers, plant and tooling engineers, maintenance personnel,

supervisors, and anyone working near the robot must become familiar with the

operation of this equipment. All personnel involved with the operation of the

equipment must understand potential dangers of operation. General safeguarding

tips are as follows:

• Any modifications to ladder nodes, parts 1 and 2 of the controller PLC can

cause severe personal injury or death, as well as damage to the robot! Do not

make any modifications to the ladder. Making any changes without the written

permission of Motoman will VOID YOUR WARRANTY!

• Some operations require standard passwords and some require special

passwords. Special passwords are for Motoman use only. YOUR

WARRANTY WILL BE VOID if you use these special passwords.

• Back up all programs and jobs onto a floppy disk whenever program changes

are made. To avoid loss of information, programs, or jobs, a backup must

always be made before any service procedures are done and before any changes

are made to options, accessories, or equipment.

• The concurrent I/O (Input and Output) function allows the customer to modify

the internal ladder inputs and outputs for maximum robot performance. Great

Page 18

ArcWorld 6000 Operator's Manual Page 10 MOTOMAN

care must be taken when making these modifications. Double-check all

modifications under every mode of robot operation to ensure that you have not

created hazards or dangerous situations that may damage the robot or other

parts of the system.

• Improper operation can damage the equipment. Only trained personnel familiar

with the operation, manuals, electrical design, and equipment interconnections

of this robot should be permitted to operate the system.

• Inspect the robot and work envelope to ensure no potentially hazardous

conditions exist. Be sure the area is clean and free of water, oil, debris, etc.

• Ensure that all safeguards are in place.

• Check the E-STOP button on the teach pendant for proper operation before

programming.

• Keep the teach pendant with you when you enter the workcell.

• Ensure that only the person holding the teach pendant enters the workcell.

• Test any new or modified program at low speed for at least one full cycle.

2.6 OPERATION SAFETY

All operators, programmers, plant and tooling engineers, maintenance personnel,

supervisors, and anyone working near the robot must become familiar with the

operation of this equipment. All personnel involved with the operation of the

equipment must understand potential dangers of operation. General safeguarding

tips are as follows:

• Check all safety equipment for proper operation. Repair or replace any nonfunctioning safety equipment immediately.

• Inspect the robot and work envelope to ensure no potentially hazardous

conditions exist. Be sure the area is clean and free of water, oil, debris, etc.

• Ensure that all safeguards are in place.

• Improper operation can damage the equipment. Only trained personnel familiar

with the operation, manuals, electrical design, and equipment interconnections

of this robot should be permitted to operate the system.

• Do not enter the robot cell while it is in operation. Place the robot in

Emergency Stop (E-Stop) mode and ensure that all motion has stopped before

entering the cell.

• The robot must be placed in Emergency Stop (E-Stop) mode whenever it is not

in use.

• This equipment has multiple sources of electrical supply. Electrical

interconnections are made between the controller, external servo box, and other

equipment. Disconnect and lockout/tagout all electrical circuits before making

any modifications or connections.

• All modifications made to the controller will change the way the robot operates

and can cause severe personal injury or death, as well as damage the robot.

Page 19

ArcWorld 6000 Operator's Manual Page 11 MOTOMAN

This includes controller parameters; ladder nodes, parts 1 and 2; and I/O (Input

and Output) modifications. Check and test all changes at slow speed.

Page 20

ArcWorld 6000 Operator's Manual Page 12 MOTOMAN

2.7 MAINTENANCE SAFETY

All operators, programmers, plant and tooling engineers, maintenance personnel,

supervisors, and anyone working near the robot must become familiar with the

operation of this equipment. All personnel involved with the operation of the

equipment must understand potential dangers of operation. General safeguarding

tips are as follows:

• Do not perform any maintenance procedures before reading and understanding

the proper procedures in the appropriate manual.

• Check all safety equipment for proper operation. Repair or replace any nonfunctioning safety equipment immediately.

• Improper operation can damage the equipment. Only trained personnel familiar

with the operation, manuals, electrical design, and equipment interconnections

of this robot should be permitted to operate the system.

• Back up all your programs and jobs onto a floppy disk whenever program

changes are made. A backup must always be made before any servicing or

changes are made to options, accessories, or equipment to avoid loss of

information, programs, or jobs.

• Do not enter the robot cell while it is in operation. Place the robot in

Emergency Stop (E-Stop) mode and ensure that all motion has stopped before

entering the cell.

• The robot must be placed in Emergency Stop (E-Stop) mode whenever it is not

in use.

• Ensure all safeguards are in place.

• Use proper replacement parts.

• This equipment has multiple sources of electrical supply. Electrical

interconnections are made between the controller, external servo box, and other

equipment. Disconnect and lockout/tagout all electrical circuits before making

any modifications or connections.

• All modifications made to the controller will change the way the robot operates

and can cause severe personal injury or death, as well as damage the robot.

This includes controller parameters; ladder nodes, parts 1 and 2; and I/O (Input

and Output) modifications. Check and test all changes at slow speed.

• Improper connections can damage the robot. All connections must be made

within the standard voltage and current ratings of the robot I/O (Inputs and

Outputs).

Page 21

ArcWorld 6000 Operator's Manual Page 13 MOTOMAN

3.0 DESCRIPTION OF EQUIPMENT

3.1 K-SERIES ROBOT DESCRIPTION

The standard ArcWorld 6000 uses either a Motoman K6 or K10 robot

manipulator. The Motoman K6 and K10 robots and YASNAC MRC Controller

represent state-of-the-art technology in robotics today. The six-axis K6 robots have

a payload of 6 kg (13.2 lbs). They feature a 1,322 mm (52.01 in.) reach and have a

relative positioning accuracy of ± 0.1 mm (0.004 in.). The six-axis K10 robots

have a payload of 10 kg (22 lbs). They feature a 1,555 mm (61.2 in.) reach and

have a relative positioning accuracy of ± 0.1 mm (0.004 in.).

Each robot can reach below its own base as well as behind itself. These robots can

also be mounted in floor, wall, or ceiling configurations with few hardware

modifications. The Motoman K-Series robots have been constructed for ease of

maintenance, utilizing brushless AC servo motors with absolute positioning

encoders. All motors are readily accessible. A combination of capacitance and

lithium batteries in both the robot encoder assemblies and in the Motoman

YASNAC MRC controller protects program position data for up to one year. The

replacement life for the lithium battery is approximately three years.

3.2 MRC CONTROLLER

The MRC controller (Figure 3-1) coordinates the operation of the ArcWorld

system. It provides the following control functions:

• User interface

• Main logic functions

• Input / output control

• Servo control

• Numeric processing

• Variable data memory

• Program and constant data memory

• Analog welding command functions

• Welding interface

• Power distribution

The MRC controls the movement of the manipulators, processes input and output

signals, controls the operation of the welding power supply, and provides the

signals to operate the welding system. It maintains variable data and performs the

numeric processing to convert to and from different coordinate systems.

Page 22

ArcWorld 6000 Operator's Manual Page 14 MOTOMAN

Figure 3-1 MRC Controller

The playback box (Figure 3-2) on the MRC has the primary system controls. The

following paragraphs describe the MRC controls.

Figure 3-2 MRC Playback Box

3.2.1 Servo Power

The SERVO POWER pushbutton switch turns on the robot servo power. An

indicator lamp in the switch lights when servo power is on.

Page 23

ArcWorld 6000 Operator's Manual Page 15 MOTOMAN

3.2.2 Mode Select

The Mode Select pushbutton switches (PLAY, TEACH, and REMOTE) set the

robot's mode of operation. Indicator lamps in the Mode Select switches light to

show the current mode of operation. Refer to your MRC Operator's Manual for

more information.

3.2.3 Cycle Select

The Cycle Select pushbutton switches (AUTO, 1-CYCLE, and STEP) set the

operating method for playback operations. Indicator lamps in the Cycle Select

switches light to show the selected playback method. Refer to your MRC

Operator's Manual for more information.

3.2.4 Emergency Stop

The E. STOP button is connected to the system emergency stop circuit.

Interrupting the E-Stop circuit causes the robot to go into the E-Stop condition.

Pressing the E. STOP pushbutton immediately turns off servo power.

3.2.5 Alarm / Error

The ALARM / ERROR indicator lights whenever an alarm or error condition

occurs. After you reset the alarm or error condition, the indicator lamp goes off.

3.2.6 Hold

The HOLD button is a normally closed, momentarily actuated switch. Pressing the

HOLD button stops the operation of the manipulator. The Hold state is active only

while the switch is held down. The indicator lamp lights whenever the robot is in a

Hold state. Refer to your MRC Operator's Manual for more information.

3.2.7 Start

Pressing the START button causes the manipulator playback operation to start.

The indicator lamp lights during playback.

3.2.8 Playback Box Sub-Panel

The playback box has an inside sub-panel that contains additional user controls.

Refer to your MRC Operator's Manual for more information.

Page 24

ArcWorld 6000 Operator's Manual Page 16 MOTOMAN

3.3 PROGRAMMING PENDANT

A programming pendant (Figure 3-3) provides the primary user interface with the

system. The pendant has a 12-line LCD display and keypad. The system uses the

INFORM II robot language and a menu driven interface to simplify operator

interaction with the robot. By using the pendant, the operator can teach robot

motion, and perform programming, editing, maintenance, and diagnostic functions.

Figure 3-3 Programming Pendant

Page 25

ArcWorld 6000 Operator's Manual Page 17 MOTOMAN

3.3.1 Display

The programming pendant has a 12-line LCD display. The display provides status

information, system messages and prompts, and a graphic work area. Refer to

your MRC Operator's Manual for more information.

3.3.2 Robot Speed Indicators

The MAN SPD indicators light to show the selected robot manipulator speed.

3.3.3 Emergency Stop

The E. STOP button is connected to the system emergency stop circuit.

Interrupting the E-Stop circuit causes the robot to go into the E-Stop condition.

Pressing the E. STOP pushbutton immediately turns off servo power.

3.3.4 Keypad

The user keypad on the programming pendant serves as an input device. The keys

are grouped into different functional sections to simplify operator use. For more

information, refer to your MRC Operator's Manual.

3.3.5 Servo Power

The SERVO POWER pushbutton switch turns on the robot servo power. An

indicator lamp in the switch lights when servo power is on.

3.3.6 Coordinate System Indicators

The COORD indicators light to show the currently active coordinate system.

3.4 MRM2-SERIES POSITIONER

The ArcWorld 6000 cell uses one of two different reciprocating positioners: the

MRM2-550 or the MRM2-1100. The MRM2-Series positioners are AC servo

controlled by the master robot to provide coordinated motion while welding or

between welds. The standard distance between the headstock and tailstock

faceplates on the MRM2-550 positioner is 2.6 meters (approximately 102"). The

standard distance between the headstock and tailstock faceplates on the MRM21100 positioner is 3.0 meters (approximately 118").

The load side of the positioner is fixed for loading and unloading parts. The

patented servo motor design of this ferris-wheel type positioner is used to sweep

the positioner workstations into and out of the robot envelope.

Page 26

ArcWorld 6000 Operator's Manual Page 18 MOTOMAN

A fixture frame is typically mounted between the headstock and tailstock faceplates.

Fixtures are either mounted on or integrated to these frames for positioning and

clamping of production parts. Pneumatic and electrical signals can be run to the

fixtures if required. Depending on part size(s) and weight(s), single, multiple, or a

combination of parts can be mounted to the fixture frame to provide a highly

flexible system.

3.4.1 Part / Fixture Rating

The combined weight of the part(s) and fixture(s) on each side of the MRM2-550

reciprocating positioner is 550 pounds (1100 pounds total). The maximum offset

load for the MRM2-550 is 375 pounds. The positioner will not sweep if the load

on one side is more than 375 pounds heavier than the load on the other side.

The combined weight of the part(s) and fixture(s) on each side of the MRM2-1100

reciprocating positioner is 1100 pounds (2200 pounds total). The maximum offset

load for the MRM2-1100 is 639 pounds. The positioner will not sweep if the load

on one side is more than 639 pounds heavier than the load on the other side.

3.4.2 Swing Diameter

The maximum swing diameter for a part on the MRM2-550 positioner is 0.98

meters (approximately 37.4"). The maximum swing diameter for a part on the

MRM2-1100 positioner is 1.1 meters (approximately 43.3").

3.4.3 Temperature Operating Range

40 - 110˚ Fahrenheit.

3.4.4 Humidity

Non-condensing 10 - 90% relative humidity.

NOTE: In high humidity areas, the tooling plate may rust or corrode. Surface protection should be

used.

3.4.5 Shock Rating

Less than 0.5 G.

Page 27

ArcWorld 6000 Operator's Manual Page 19 MOTOMAN

3.4.6 Sweep Speed

Torque Time

MRM2-550 1000 N.m 4 sec

MRM2-1100 2000 N.m 5 sec

3.4.7 Servo Head Stock Speed

Torque Speed

MRM2-550 1050 N.m 0 - 16.8 rpm

MRM2-1100 1050 N.m 0 - 16.8 rpm

3.4.8 Air Requirements

80 psi minimum.

3.4.9 Electrical Requirements

The MRC controller supplies the electrical power required to operate the 180˚

reciprocating positioners. These requirements consists of a 24 VDC interface

circuit, and a 208 VAC, 6.2 amp circuit for the MRM2-550 motor and drive, or a

208 VAC, 9.0 amp circuit for the MRM2-1100 motor and drive.

3.4.10 Welding Current Rating

The MRM2 positioners have a welding current capacity of 700 amperes at 100%

duty cycle. The welding ground system consists of a spring loaded copper brush

that contacts a large ring mounted behind the surface of the faceplate. The ground

cable to the welding power source is connected to the ground stud located on the

right side of the positioner base when facing the back of the ArcWorld 6000 cell.

3.4.11 Locking Pins

The MRM2-1100 positioner has sweep lock drive pins and fixture locking pins for

positioner Side A and Side B. There are two of each on the MRM2-1100. The

sweep lock pins keep the sweep axis from turning while the servo advances and

withdraws. The fixture locking pins are spring loaded, so when the servo

withdraws, the pins engage. This keeps the headstock from turning when the servo

motor retracts.

Page 28

ArcWorld 6000 Operator's Manual Page 20 MOTOMAN

3.4.12 Arc Shield

The MRM2 positioners are provided with a sheet metal screen for arc radiation

protection between the operator loading zone and the welding zone. Do not operate

this equipment unless the arc shield is in place.

3.5 OP-STATION

The operator control station (Figure 3-4) includes a NEMA enclosure on a standalone pedestal. The following paragraphs describe each of the Op-station controls.

ALARM

RESET

ROBOT HOLD

MASTER JOB

START

MOTOMAN

STATION READY

POSITIONER

AUTO/MAN

SERVO ON

ESTOP

OPERATOR STATION

ENABLE/DISABLE

WARNING!

CYCLE START

CYCLE START

3.5.1 Emergency Stop

Figure 3-4 Operator Control Panel (Op-Station)

The operator station E-STOP, the robot E-STOP, the air pressure switch, the

sliding door interlocks, and the ArcWorld 6000 safety mats are connected in series

in the Emergency Stop circuit. If the E-Stop circuit is interrupted, the robots and

the MRM2 positioner go into the E-Stop condition. The operator station E-STOP

light comes on when the E-STOP button is pressed. In the E-Stop condition,

power to the positioner interface is removed. This stops the positioner sweep.

Page 29

ArcWorld 6000 Operator's Manual Page 21 MOTOMAN

3.5.2 Hold

The operator station HOLD button is a normally closed pushbutton and is

connected to the MRC to cause the robots to go into the Hold condition when the

button is pressed.

3.5.3 Cycle Start

The palm buttons in the operator station use an anti tie-down technique for robot

input. The anti tie-down timer is set for 10 seconds. Holding the palm buttons

down for more than 10 seconds, causes the timer to time out and prevents the input

from reaching the robot. The CYCLE START buttons are connected to robot Input

#1.

3.5.4 Station Ready

The STATION READY lamp is interlocked with the robot CUBE #1 output. The

robot Output #1 turns on the STATION READY lamp.

3.5.5 Alarm

The ALARM lamp is connected to the robot Alarm Occurrence output. The

ALARM lamp turns on when one of the robots encounters a major or minor alarm

condition. The ALARM lamp also lights when the positioner is not reset.

3.5.6 Servo On

The SERVO ON pushbutton is connected to the robot Servo On input. The robot

servo motors will turn on when the SERVO ON pushbutton is pressed and an EStop condition does not exist.

3.5.7 Positioner Auto / Manual

The POSITIONER AUTO / MANUAL selector switch is used to select Automatic

or Manual Mode for the MRM2 positioner. The selector switch is connected to

robot Input #2. When the selector switch is in the Automatic position, the robots

process the part after the positioner sweeps. In Manual Mode, the robot does not

process the part after the positioner sweeps. This function is dependent on the

structure of the master job.

3.5.8 Master Job Start

The MASTER JOB START pushbutton is connected to the robot external start

input. The robot will start the current active job when pressed if the robot is in Play

Mode and the servo motors are on.

Page 30

ArcWorld 6000 Operator's Manual Page 22 MOTOMAN

3.5.9 Operator Station Enable / Disable

The OPERATOR STATION ENABLE / DISABLE selector switch is used to

transfer primary control of the ArcWorld cell from the MRC to the Op-Station.

The REMOTE MODE button on the MRC playback box lights when the opstation is enabled. Most programming pendant functions are disabled.

3.5.10 Reset

The RESET pushbutton is connected to the robot alarm reset input. Any alarm or

error condition will be cleared when this button is pressed. In addition, the RESET

pushbutton and the RIGHT CYCLE START pushbuttons are interlocked and,

when pressed simultaneously, enable the MRM2 positioner if the robot servo

motors are on. The positioner needs to be enabled at initial power up, or after an

emergency stop or shock sensor condition.

3.6 WELDING POWER SOURCE

The Excel-Arc power source (Figure 3-5) is a constant voltage transformer-rectifier

type welding machine. It provides volt-current characteristic curves that are

essentially flat. This power source can be used with most MIG applications from

thin sheet metal to heavy gauge plate.

3.6.1 Main Power

The Input Power Switch (7) turns on the main power to the Excel-Arc unit. The

main power must be on before any other section of the power source can operate.

The pilot light (1) illuminates when main power is on.

3.6.2 Volt / Amp Settings

The Welding Voltage / Amperes Control (2) adjusts the welding output and open

circuit voltage. The Volt / Amp Meter and Switch (3) display either DC voltage or

DC current depending on the position of the switch. Refer to your Excel-Arc

manual for additional information.

3.6.3 Terminal Connectors

The two terminals on the front of the Excel-Arc power source serve as connection

points for the welding leads. The Positive Terminal (4) connects positive welding

lead (to the wire feeder). The Negative Terminal (5) connects to the negative

welding lead (to the positioner).

Page 31

ArcWorld 6000 Operator's Manual Page 23 MOTOMAN

3.6.4 Local / Remote Operation

The Local / Remote Output Control Selector Switch (6) sets the mode of operation

for the power source. For ArcWorld applications this switch should be set to

REMOTE. Refer to your Excel-Arc manual for additional information.

Figure 3-5 Excel-Arc Controls

Page 32

ArcWorld 6000 Operator's Manual Page 24 MOTOMAN

3.6.5 Feeder Control Receptacles

The Feeder Control Receptacle Panel (8) located in the back of the power source

provides connectors for use with remote voltage control applications. For

ArcWorld applications, the MRC connects to the 19-pin connector.

3.6.6 Circuit Breakers

The Excel-Arc power source uses two 10 amp circuit breakers (9 and 10). One

circuit breaker protects the 24 volt circuit, the other protects the 115 volt circuit.

3.6.7 AC Receptacles

The Excel-Arc unit has two standard 115 V AC Receptacles (11). These provide

auxiliary power at a maximum current of 10 amps. For applications using the

water-cooled torch, the water circulator plugs into one of these receptacles.

3.7 WELDING EQUIPMENT

In addition to the Excel-Arc power sources, the ArcWorld 6000 system provides a

complete complement of arc welding equipment. In its standard configuration, the

ArcWorld system includes the following:

• PWF-600 wire feeder

• UWI welding interface

• Either an air cooled or water cooled MIG torch

• Torch breakaway mount

3.7.1 PWF4 Wire Feeder

The PWF4 wire feeder mounts on the robot arm. This 4-roll wire feeder provides

reliable wire feeding at rates up to 750 IPM. An integral gas valve provides fast

gas response time. The PWF4 feeder has an inch forward button to help simplify

set-up and reduce change-over time. The PWF4 wire feeder uses interchangeable

feed rolls to accommodate different types and sizes of wire.

3.7.2 Universal Welding Interface (UWI)

The UWI interface provides microprocessor control to the wire feeder and power

source. It scales the signals from the MRC to the appropriate levels required for

control of the welding components. It also provides isolation of the power source

analog signals.

Page 33

ArcWorld 6000 Operator's Manual Page 25 MOTOMAN

3.7.3 MIG Torch

The ArcWorld 6000 uses either an air-cooled or water-cooled robotic/automatic

MIG torch. These are heavy-duty torches designed for quick replacement while

requiring minimum robot reprogramming. The MIG torch mounts on the end of

the robot wrist. For applications that use the water-cooled torch, the ArcWorld

6000 includes a suitable water circulator kit.

3.7.4 RAM Breakaway Mount

A Motoman RAM torch breakaway mount protects the robot, workpiece, fixture,

and positioner. It provides multi-directional impact detection, including Z-axis

collisions. The torch breakaway causes the robot to stop immediately upon impact.

Keyed joints assure accurate re-alignment of components.

3.8 SAFETY EQUIPMENT

The ArcWorld 6000 system incorporates a host of safety equipment. When all

standard safety precautions are taken, the safety equipment helps to ensure safe

operation of the robotic cell. The ANSI/RIA R15.06 Robot Safety Standard

stipulates the user is responsible for safeguarding.

Users are responsible for

determining whether the provided safeguards are adequate for plant

conditions. Users must also ensure that safeguards are maintained in

working order.

The ArcWorld 6000 safety features include the following:

• Arc screens

• Safety fencing

• Dual interlocking cell door

• Interlocked safety mats

• Emergency stop (E-STOP) buttons

3.8.1 Arc Screens

Two separate arc screens are used on the ArcWorld 6000. The first is a metal arc

screen on the turntable positioner. This screen blocks arc radiation and sparks from

the welding operation. The material used to cover the safety fencing of the entire

robotic cell acts as the second arc screen. This material reduces the amount of ultraviolet radiation that escapes from the robotic cell.

Page 34

ArcWorld 6000 Operator's Manual Page 26 MOTOMAN

➪

WARNING!

Although this screen blocks dangerous arc radiation, you should

not look directly at the arc during operation without protective

eyewear!

3.8.2 Fencing

The safety fencing provided with the ArcWorld 6000 encloses the entire robotic

cell. It forms a physical barrier to prevent entry into the robot envelope.

3.8.3 Interlocks

Dual safety interlocks on the cell entrance door prevent entry into the cell during

operation. The interlocks consist of a pull plug and magnetic door switch.

Opening the cell door with the robot in Play causes an E-Stop and shuts down the

entire system.

3.8.4 Safety Mats

The safety mat provided with the ArcWorld 6000 helps prevent serious injury to

anyone entering the positioner area during the sweeping process. If a person steps

on this mat when the positioner is in motion, an E-Stop occurs causing the entire

system to shut down.

3.8.5 Emergency Stops

In addition to the interlocking devices described above, the ArcWorld 6000 has

strategically placed emergency stops (E-STOPS). These are operator actuated

devices that, when activated, immediately cause the system to shut down. The

following is a list of their locations:

• The MRC control panel has one E-STOP button.

• The MRC programming pendant has one E-STOP button.

• The positioner operator station has one E-STOP button.

In addition, the following conditions also cause an emergency stop:

• Opening the cell door while the robot is in Play mode.

• Stepping on the safety mat while the positioner is sweeping.

• Loss of air system pressure.

• Activating the shock sensor.

Page 35

ArcWorld 6000 Operator's Manual Page 27 MOTOMAN

4.0 OPERATION

This section provides operation instructions for the ArcWorld 6000 system.

Operation procedures include the following:

• System start up

• Part set up

• Normal operation

• Fault recovery

• System shut down

We have included several sample programs. The listed programs demonstrate the

proper format and instruction sequences for different operations. You can use

these programs as guidelines when creating programs for your specific

applications.

4.1 OPERATION

The ArcWorld 6000 is a fully integrated robotic MIG welding cell. The robot

welds on one side of the 180˚ reciprocating positioner, while the operator loads

parts on the opposite side. Once the robot is finished with its process, it return to

the safe position. The operator can then initiate the positioner sweep enabling the

robot to start welding on the next part.

The safety door interlocks prevent anyone from entering the cell while the robot is

in Play Mode. If anyone steps on the safety mats in front of the part loading area

during the positioner sweep, an E-Stop occurs.

4.1.1 Start Up

To start up the ArcWorld 6000 from a power off condition, proceed as follows:

1. Turn on the MRC disconnect.

2. Turn on the power source disconnect.

3. Set the INPUT POWER switch on the welding power source to ON. The pilot

light should glow.

4. Set the Main Power switch on the MRC to ON.

5. Open the regulator valve on the welding gas supply.

6. Make sure that the enclosure door is closed and the safety plug is connected.

7. Press the TEACH MODE button on the MRC playback box. The indicator

lamp in the switch should light.

Page 36

ArcWorld 6000 Operator's Manual Page 28 MOTOMAN

8. Press the SERVO POWER button on the MRC playback box. The indicator

lamp in the switch should light.

9. Press the RESET button and the right CYCLE START button on the operator

station at the same time to initialize the positioner. The ALARM lamp goes off.

10. Use the programming pendant to move the robot to the starting position

(CUBE 1 position).

11. Call up the master job.

12. Press the PLAY MODE button on the MRC playback box, and then press the

AUTO CYCLE button. The indicator lamps in the switches should light.

13. Set the OPERATOR STATION ENABLE / DISABLE switch to the

ENABLE position.

14. Press the MASTER JOB START button on the operator station.

15. Wait for the STATION READY indicator to light.

The ArcWorld 6000 Cell is now ready for operation.

4.1.2 Loading / Unloading Procedures

The following is the typical sequence of operations for the ArcWorld 6000 Cell

after startup:

1. Load production parts on the fixtures located on the operator side of the MRM2

positioner.

2. Step off the safety mats and wait for the STATION READY indicator to light.

3. Press both CYCLE START palm buttons on the operator station to sweep the

positioner. This places the unwelded parts in the robot work envelope.

4. After the positioner sweeps, the robot begins the welding sequence on the parts.

Coordinated motion capabilities allow programming to rotate the parts on the

positioner, and weld or move the robot between welds at the same time.

5. Unload the welded parts from the fixture on the operator side.

6. Repeat Steps 1 through 5 to continue production.

4.1.3 Fault Recovery

Under varying conditions an alarm or error can occur. Clearing an alarm or error

condition may require different operator intervention depending on the nature of the

alarm or error. In some cases, simply resetting the robot and restarting the

operation is sufficient. In other instances, you must first remedy the condition

causing the alarm or error. Refer to paragraph 4.2, Alarms and Errors.

4.1.4 E-STOP Recovery

An E-Stop can occur under one of the following conditions:

Page 37

ArcWorld 6000 Operator's Manual Page 29 MOTOMAN

• Pressing the E-STOP button on the operator station, the programming pendant,

or the MRC terminal.

• Opening the sliding door on the robot enclosure or removing the safety plug

when the robot is not in Teach Mode.

• Stepping on the safety mat when the MRM2 positioner is sweeping.

• Activation of the shock sensor, indicating a robot crash.

• Loss of air system pressure.

To restart the ArcWorld 6000 Cell after an E-Stop condition occurs, follow the

procedure below.

1. To clear the E-Stop condition, do any of the following actions that apply:

• Release the E-STOP button on the operator station, the programming

pendant, or the MRC playback box.

• Close the sliding door and connect the safety plug.

• Step off the safety mat.

• Clear the Shock Sensor condition (refer to paragraph 4.1.5).

• Restore operating air pressure.

2. Press the SERVO ON button on the operator station.

➪

CAUTION!

Make sure the robots are in a clear position to continue motion.

A crash may occur if the robots cannot clear the part or fixtures

when they resume motion.

3. Press the RESET button and the right CYCLE START button on the operator

station to initialize the system.

4. Press the MASTER JOB START button on the operator station.

The ArcWorld 6000 Cell will continue its operation.

4.1.5 Shock Sensor Recovery

The ArcWorld welding package includes a RAM breakaway torch mount. This

mount is designed to protect the torch from damage in case of a crash. A slight

deflection of the torch activates a SHOCK SENSOR error. A more severe crash

separates the torch mount from the robot arm. The SHOCK SENSOR error is

factory set to an E-Stop condition.

To override the shock sensor, do the following:

1. Disconnect the shock sensor plug from the connector at the front of the wire

feeder (see Figure 4-1).

Page 38

ArcWorld 6000 Operator's Manual Page 30 MOTOMAN

2. Connect the shock sensor jumper (Motoman P/N 132601-1) to the connector at

the front of the wire feeder.

3. Press the RESET and right CYCLE START buttons on the operator's station at

the same time.

4. Use the programming pendant to operate the manipulator out of the impact

position.

5. Re-attach the sections of the torch breakaway mount if the impact caused them

to separate.

Feeder

Housing

Shock Sensor

Cord

Torch

Assembly

Breakaway

Shock

Sensor Plug

Shock Sensor

Jumper

Figure 4-1 Shock Sensor Override

To resume operation after clearing the Shock Sensor condition, proceed as follows:

1. Disconnect the shock sensor jumper from the connector at the front of the wire

feeder (see Figure 4-1).

➪

CAUTION!

You must remove the shock sensor jumper during normal

operation. Failure to do so can result in equipment damage.

2. Connect the shock sensor plug to the connector at the front of the wire feeder.

3. Close the interlocked enclosure doors.

4. Press the SERVO ON button on the MRC or programming pendant.

Page 39

ArcWorld 6000 Operator's Manual Page 31 MOTOMAN

5. Press the RESET and right CYCLE START buttons on the operator's station at

the same time. This initializes the positioner.

➪

CAUTION!

You may need to move the robot to recover from a crash. To avoid

another crash, make sure that the robot has a clear path to the

next step.

6. Press the MASTER JOB START button.

4.1.6 Shut Down

Use the following procedure to shut down the ArcWorld 6000 Cell after operation

is complete:

1. Make sure the robot is in the starting position (CUBE 1 position).

2. To turn off the robot servo motors, press the E-STOP button on either the

operator station, programming pendant, or MRC playback box.

3. Press the TEACH MODE button on the MRC playback box.

4. Set the MRC Main Power switch to the OFF position.

5. Turn off the MRC disconnect.

6. Set the INPUT POWER switch on the welding power source to the OFF

position.

7. Turn off the power source disconnect.

8. Close the regulator valve on the welding gas supply.

The ArcWorld 6000 Cell is now shut down.

4.2 ALARMS AND ERRORS

Alarms and errors will cause the program to stop. There are three levels of alarms

and errors: Error Messages, Minor Alarms, and Major Alarms.

For more detailed information about alarm recovery, refer to your Motoman MRC

Manipulator Manual.

4.2.1 Error Messages

These are simple errors such as pressing the START button when the robot is not

in Play mode, or enabling the programming pendant without the servo power being

live.

Page 40

ArcWorld 6000 Operator's Manual Page 32 MOTOMAN

Errors like these are cleared by pressing the CANCEL or ENABLE button on the

programming pendant.

4.2.2 Minor Alarms

Minor alarms are usually programming errors. Minor alarms might occur if a

circle has been programmed with fewer than three circular points, etc.

These alarms are cleared by pressing one of the following:

• RELEASE soft key on the programming pendant

• RESET button on the operator's station

• ENABLE button on the programming pendant twice

4.2.3 Major Alarms

Major alarms are hardware failures. Major alarms might occur because of a servo

tracking error or an abnormal speed associated with crashes.

To clear these alarms, you must turn off the controller and then turn it on again.

4.3 PROGRAMMING

The MRM2 positioner with its programmable axis offers a high degree of

programming flexibility. The robot can be programmed to weld a part with the

headstock stationary, or the robot and headstock can move simultaneously to weld

a part while turning.

You can program the robots independently (R1 job), the station axis independently

(S1 job), or robot and station axis together (R1 + S1). You must select the axis

combination when teaching the job initially. We recommend programming the

robot and station axis together (R1 + S1 jobs) to reduce the risk of interference.

➭

WARNING!

The positioner axis operates as another robot axis and has the

potential of hazardous motion.

➭

CAUTION

If the robot is working on a part and the headstock is not turning,

DO NOT assume that the headstock will not turn. The robot is

Page 41

ArcWorld 6000 Operator's Manual Page 33 MOTOMAN

executing programmed steps which could index the headstock at

any time.

NOTE: The ArcWorld 6000 robot S-axis is restricted by hard stops on the robot base and internal soft

stops. Do not change.

4.3.1 Cube Assignment

The system uses the Cube #1 Output as an interlock for sweeping. This is a

software zone around the tool center point (TCP). It should be defined with the

robot clear of the positioner sweep motion. The Cube #1 Output can be viewed in

diagnostics under Specified Outputs. To assign the K6 or K10 robot manipulator

position to Cube #1, refer to your MRC User Functions and Operator's Manuals.

Page 42

ArcWorld 6000 Operator's Manual Page 34 MOTOMAN

4.3.2 Sweeping Positioner to Side A

NOTE: Before sweeping, make sure the weight of parts and fixturing is approximately equal on Sides

A and B of the positioner. (Refer to paragraph 3.4.1.)

NOTE: Before sweeping at first power up, make sure the correct job has been loaded.

To sweep the Motoman MRM2 positioner to Side A:

1. Press the SERVO ON button on the operator station.

2. Make sure that the robot is in Cube #1 with the headstock in sweep position

(marks on headstock lined up, refer to your positioner manual).

3. Press the PLAY MODE button on the MRC playback box. The indicator lamp

in the switch should light.

4. If this is the first power up, or an E-Stop recovery, press the RESET button

and right CYCLE START button.

5. Press the MASTER JOB START button.

6. Press the CYCLE START palm buttons. The drive unit disengages the

headstock and engages the sweep axis.

7. The sweep axis locking pin retracts and the MRC moves the external sweep

axis (S1) 180˚ to align Side A.

8. The sweep locking pin engages.

9. The drive unit engages Side A.

When the positioner sweeps into position at Side A, the drive unit engages the

headstock. IN #9 turns off. Side B faces towards the operator, and IN #10, FIX. B

LOCK ON, turns on.

4.3.3 Sweeping Positioner to Side B

To sweep the Motoman MRM2 positioner to Side B:

1. Press the SERVO ON button on the operator station.

2. Make sure that the robots are in Cube #1 with the headstock in sweep position

(marks on headstock lined up, refer to your positioner manual).

3. Press the PLAY MODE button on the MRC playback box. The indicator lamp

in the switch should light.

4. If this is the first power up, or an E-Stop recovery, press the RESET button

and right CYCLE START button.

5. Press the MASTER JOB START button.

6. Press the CYCLE START palm buttons. The drive unit disengages the

headstock and engages the sweep axis.

Page 43

ArcWorld 6000 Operator's Manual Page 35 MOTOMAN

7. The sweep axis locking pin retracts and the MRC moves the external sweep

axis (S1) 180˚ to align Side B.

8. The sweep locking pin engages.

9. The drive unit engages Side B.

When the positioner sweeps into position at Side B, the drive unit engages the

headstock. IN #10 turns off. Side A faces towards the operator, and IN #9, FIX.

A LOCK ON, turns on.

4.3.4 Rotating Headstock

To rotate the Motoman MRM2 headstock:

1. Enable the programming pendant.

2. Press the GROUP AXES key and make sure the key LED lights.

3. Press the X+ or X- keys to move the headstock. Jog speed is set on the

programming pendant.

NOTE: The GROUP AXES key must be turned off to move the robots with the motion keys.

4.3.5 Programming

You can program three types of moves:

• Rotation of the positioner during air cut moves.

• Robot motion with positioner stationary.

• Rotation of the positioner during welding.

The job you create may consist of a combination of the above. The first two types

of moves assume a robot plus station group axis specification (R1 + S1). The last

type of move is called station synchronous and should be programmed with a

station plus robot group axis specification (S1 + R1).

Rotating the Positioner During Air Cut Moves

1. Teach the robot to the desired position.

2. Rotate the positioner to the desired position.

a. Press the GROUP AXES button on the programming pendant so LED is

on.

b. Press MAN SPEED button to select the desired axis speed while teaching.

c. Press the first set of motion keys, +X or -X, to move the axis in the desired

direction.

3. Record the step after designating the motion type and playback speed.

Page 44

ArcWorld 6000 Operator's Manual Page 36 MOTOMAN

4. Check the path with the STEP FWD/BWD keys. The position for the robot or

positioner may have to be altered to prevent torch interference.

➭

WARNING!

The positioner axis operates as another robot axis and has the

potential for hazardous motion.

NOTE: The GROUP AXES button must be turned off to move the robot.

NOTE: Normally, air cut moves are taught at Joint moves. The speed for Joint moves is specified as a

percentage of maximum speed (VJ=.01 - VJ=100.00). The axis which takes the longest time

to complete the programmed motion automatically determines the speed of the system. This

might be a wrist axis, a major robot axis, or the positioner axis. Cycle times can be reduced by

changing wrist orientation, robot position, and headstock position simultaneously between

program points rather than making the moves independently. Setting the speed at 100.00 will

normally establish the quickest time between steps.

Robot Motion with the Positioner Stationary

1. Program the robot position without moving the positioner axis.

2. Set motion type and speeds in the normal fashion.

Rotation of the Positioner During Welding

The MRC controller can coordinate motion with the external axis. This requires

calibration of the headstock and robot at the time of installation. Jobs programmed

for coordinated motion must be taught as S1 + R1 jobs.

Move instructions for coordinated motion are registered using the following

format:

Coordinated

motion instruction

SMOVL=138 Slave side

(manipulator with torch)

MOVL Master side

(positioner with workpiece)

In coordinated motion instructions, an "S" prefixes the instruction to the slave side.

Page 45

ArcWorld 6000 Operator's Manual Page 37 MOTOMAN

Converting Programs from Side A to Side B

The positioner uses the external axis to sweep the positioner in addition to driving

the headstock. This results in the external axis position being 180˚ offset from the

other side. This offset amount can be determined from the difference in the

external axis pulse counts at the two sweep positions. Software can be used to

modify the position of the external axis in a job copied to run on the opposite side.

1. Determine the pulse count difference of the external axis between Side A and

Side B.

2. Set the pulse count offset amount into an EX variable.

3. Make a copy of the original job. Designate the proper side in the original and

copied job name.

4. Use the Modify Position (MODPOS) function to change the position of the

external axis in the program.

5. Step through the new program to verify the path.

4.3.6 I/O Assignment

The ArcWorld 6000 positioner and ArcWorld operator station use the following

Motoman MRC user and dedicated inputs and outputs:

MRC User Inputs

IN#1 Cycle Start interlocked with Cube #1

IN#2 Auto/Manual Selector Switch

IN#9 Fixture A Lock On

IN#10 Fixture B Lock On

IN#11 Servo Drive Return

IN#12 Servo Drive Forward

IN#13 In Position (on MRM2-550 only)

IN#13 Sweep Lock On (on MRM2-1100 only)

IN#14 Sweep Lock Off (on MRM2-1100 only)

MRC User Outputs

OUT#1 Station Ready interlocked with Cube #1

OUT#4 Wire Cutter (optional)

OUT#9 Withdraw Servo

OUT#10 Advance Servo

Page 46

ArcWorld 6000 Operator's Manual Page 38 MOTOMAN

OUT#11 Sweep Lock On (on MRM2-1100 only)

OUT#12 Sweep Lock Off (on MRM2-1100 only)

In order to sweep the positioner, the robot must be in Cube #1, and OUT#1 of the

master robot must be ON to enable the operator station.

Page 47

ArcWorld 6000 Operator's Manual Page 39 MOTOMAN

MRC Dedicated Inputs

• External Emergency Stop

• External Over Travel

• External Servo On

• External Hold

• Anti-Tie Down

• External Start

• Alarm Reset

MRC Dedicated Outputs

• Servo On

• Alarm Occurrence

• Teach Mode

• Cube #1

For more information on the Motoman MRC User and Dedicated I/O, refer to the

MRC Controller I/O Structure Manual and MRC Dedicated I/O Guidelines

Manual.

4.4 SAMPLE JOBS

The following jobs are shown as examples only. Your system may have other

features and / or options requiring program changes. Double-check your system

before running these jobs. Lines that begin with an apostrophe (') are comments

added for clarification only and do not appear in the actual program listing.

4.4.1 Master Job (No Group Axes)

Line Step Function

000 000 NOP

001 CALL JOB:SWEEPTOA IF IN#(09)=ON

002 TIMER T=0.20

003 CALL JOB:SWEEPTOB IF IN#(10)=ON

004 END

Page 48

ArcWorld 6000 Operator's Manual Page 40 MOTOMAN

4.4.2 Sweep to A Job (R1 + S1)

Lines 009 through 011, and lines 013 and 014 in the job listing below apply to the

systems using an MRM2-1100 positioner only.

Line Step Function

000 000 NOP

001 001 MOVJ P050 EX052 VJ=25.00

'Program position with robot at safe position in Cube #1 and

headstock in sweep orientation.

002 DOUT OT#(1) ON

'Turn on Station Ready lamp on operator station.

003 WAIT IN#(01)=ON

'Wait for Cycle Start palm buttons.

004 WAIT IN#(09)=ON

'Verify that locking pin on Side A is engaged.

005 DOUT OT#(10) OFF

Turn off ADVANCE SERVO.

006 DOUT OT#(09) ON

'Turn on WITHDRAW SERVO to retract drive unit.

007 WAIT IN#(11)=ON

'Wait for SERVO DRIVE RTN input indicating the drive

unit is fully retracted.

008 WAIT IN#(10)=ON

'Wait for FIX B LOCK ON input to verify that the locking

pin has engaged the headstock.

009 DOUT OT#(11) OFF

'Turn off SWEEP LOCK ON output.

010 DOUT OT#(12) ON

'Turn on SWEEP LOCK OFF output to retract the locking

pin from the sweep axis.

011 WAIT IN#(14)=ON

'Wait for SWEEP LOCK OFF input to verify the sweep

locking pin has been retracted.

012 002 MOVJ P050 EX051 VJ=25.00 CONT

'The robot moves the external axis only, until Side A lines

up with the drive unit and the sweep locking pins.

013 DOUT OT#(12) OFF

Page 49

ArcWorld 6000 Operator's Manual Page 41 MOTOMAN

'Turns off the SWEEP LOCK OFF output.

014 DOUT OT#(11) ON

'Turns on the SWEEP LOCK ON output. This is necessary

to keep the sweep axis from turning.

015 WAIT IN#(13)=ON

'Wait for SWEEP LOCK ON input to verify that pin is

engaged.

016 DOUT OT#(09) OFF

'Turn off WITHDRAW SERVO output.

017 DOUT OT#(10) ON

'Turn on ADVANCE SERVO output to send the drive unit

forward to engage the headstock.

018 WAIT IN#(12)=ON

'Wait for SERVO DRIVE FORWARD input to verify the

drive unit is fully forward.

019 WAIT IN#(09)=OFF

'Wait for FIX A LOCK ON input to go off and verify that

the headstock locking pins have been retracted.

020 DOUT OT#(1) OFF

'Turn off the STATION READY lamp.

021 JUMP JOB:A-JOBS IF IN#(02)=ON

'Jump to the job for side A. It is important to use a job

Jump and not a Call instruction. Use Input #2 as a jump

condition. The job will execute only if the operator station

selector switch is set to AUTO.

022 RET

023 END

NOTE: The sweep positions are programmed in position variables. They are factory set and should not

require editing. Care should be taken not to use these variables in other programs. You can

edit position variables from the file display.

Page 50

ArcWorld 6000 Operator's Manual Page 42 MOTOMAN

4.4.3 Sweep to B Job

Lines 008 through 010, and lines 013 and 014 in the job listing below apply to the

systems using an MRM2-1100 positioner only.

Line Step Function

000 000 NOP

001 001 MOVJ P050 EX051 VJ=25.00

002 DOUT OT#(1) ON

003 WAIT IN#(01)=ON

004 WAIT IN#(10)=ON

005 DOUT OT#(10) OFF

006 DOUT OT#(09) ON

007 WAIT IN#(11)=ON

008 DOUT OT#(11) OFF

009 DOUT OT#(12) ON

010 WAIT IN#(14)=ON

011 WAIT IN#(09)=ON

012 002 MOVJ P050 EX051 VJ=25.00

013 DOUT OT#(12) OFF

014 DOUT OT#(11) ON

015 WAIT IN#(13)=ON

016 DOUT OT#(09) OFF

017 DOUT OT#(10) ON

018 WAIT IN#(12)=ON

019 WAIT IN#(10)=OFF

020 DOUT OT#(1) OFF

021 CALL JOB:B-JOBS IF IN#(02)=ON

022 RET

023 END

Page 51

ArcWorld 6000 Operator's Manual Page 43 MOTOMAN

4.4.4 Weld Side A Job (Multiple Weld Jobs)

➪

CAUTION!

Do not attempt to run programs from Side B on Side A.

The headstock position for jobs on Side B will be 180˚ off from programs on Side

A. Refer to paragraph 4.3.5, Programming, for information on converting a Side B

job to a Side A job.

Line Step Function

000 000 NOP

001 001 MOVJ VJ=100.00 CONT

002 CALL JOB:WELD1-A

003 CALL JOB:WELD2-A

004 CALL JOB:WELD3-A

005 CALL JOB:CLEAN IF B00=6

006 002 MOVJ VJ=100.00 CONT

007 RET

008 END

4.4.5 Weld Side A Job (Single Weld Job)

Line Step Function

000 000 NOP

001 001 MOVJ VJ=100.00 CONT

002 002 MOVJ VJ=100.00 CONT

003 003 MOVJ VJ=100.00 CONT