Page 1

Motoman NX 100 Controller

Data Transmission

Function Manual

Part Number: 152388-1CD

Revision: 0

Motoman, Incorporated

805 Liberty Lane

West Carrollton, OH 45449

TEL: (937) 847-6200

FAX: (937) 847-6277

24-Hour Service Hotline: (937) 847-3200

Page 2

The information contained within this document is the proprietary property of Motoman, Inc., and may not be

copied, reproduced or transmitted to other parties without the expressed written authorization of Motoman,

©2006 by MOTOMAN

Because we are constantly improving our products, we reserve the right to change specifications without

notice. MOTOMAN is a registered trademark of YASKAWA Electric Manufacturing.

Inc.

All Rights Reserved

Page 3

Data Transmission

152388-1

Chapter 1

Introduction

1.1 About This Document

This manual provides information for the Data Transmission function and contains the following sections:

CHAPTER 1 - INTRODUCTION

Provides general information about the structure of this manual, a list of reference documents, and

customer service information.

CHAPTER 2 - SAFETY

This section provides information regarding the safe use and operation of Motoman products.

CHAPTER 3 - DATA TRANSMISSION INSTRUCTIONS

Provides detailed information for the Data Transmission function.

1.2 Reference to Other Documentation

For additional information refer to the following:

• NX100 Controller Manual (P/N 149201-1)

• Concurrent I/O Manual (P/N 149230-1)

• Operator’s Manual for your application

• Vendor manuals for system components not manufactured by Motoman

1.3 Customer Service Information

If you are in need of technical assistance, contact the Motoman service staff at (937) 847-3200. Please have

the following information ready before you call:

• Robot Type (IA20)

• Application Type (welding, handling, etc.)

• Robot Serial Number (located on back side of robot arm)

• Robot Sales Order Number (located on back of controller)

Final page 1

Page 4

Function Manual

Chapter 1 Introduction

Notes

page 2 Final

Page 5

Data Transmission

152388-1

Chapter 2

Safety

2.1 Introduction

It is the purchaser’s responsibility to ensure that all local, county, state,

and national codes, regulations, rules, or laws relating to safety and safe

operating conditions for each installation are met and followed.

We suggest that you obtain and review a copy of the ANSI/RIA National Safety Standard for

Industrial Robots and Robot Systems. This information can be obtained from the Robotic Industries

Association by requesting ANSI/RIA R15.06-1999. The address is as follows:

Robotic Industries Association

900 Victors Way

P.O. Box 3724

Ann Arbor, Michigan 48106

TEL: (734) 994-6088

FAX: (734) 994-3338

INTERNET: www.roboticsonline.com

Ultimately, the best safeguard is trained personnel. The user is responsible for providing personnel

who are adequately trained to operate, program, and maintain the robot cell. The robot must not be

operated by personnel who have not been trained!

We recommend that all personnel who intend to operate, program, repair, or use the robot system be

trained in an approved Motoman training course and become familiar with the proper operation of the

system.

Final page 3

Page 6

Function Manual

Chapter 2 Safety

This safety section addresses the following:

• Standard Conventions (Section 2.2)

• General Safeguarding Tips (Section 2.3)

• Mechanical Safety Devices (Section 2.4)

• Installation Safety (Section 2.5)

• Programming, Operation, and Maintenance Safety (Section 2.6)

2.2 Standard Conventions

This manual includes the following alerts – in descending order of severity – that are essential to the

safety of personnel and equipment. As you read this manual, pay close attention to these alerts to

insure safety when installing, operating, programming, and maintaining this equipment.

DANGER!

Information appearing in a DANGER concerns the protection of personnel from the immediate

and imminent hazards that, if not avoided, will result in immediate, serious personal injury or

loss of life in addition to equipment damage.

WARNING!

Information appearing in a WARNING concerns the protection of personnel and equipment from

potential hazards that can result in personal injury or loss of life in addition to equipment

damage.

CAUTION!

Information appearing in a CAUTION concerns the protection of personnel and equipment,

software, and data from hazards that can result in minor personal injury or equipment damage.

Note: Information appearing in a Note provides additional information which is helpful in understanding the item being

explained.

page 4 Final

Page 7

Data Transmission

152388-1

2.3 General Safeguarding Tips

All operators, programmers, plant and tooling engineers, maintenance personnel, supervisors, and

anyone working near the robot must become familiar with the operation of this equipment. All

personnel involved with the operation of the equipment must understand potential dangers of

operation. General safeguarding tips are as follows:

• Improper operation can result in personal injury and/or damage to the equipment. Only

trained personnel familiar with the operation of this robot, the operator's manuals, the system

equipment, and options and accessories should be permitted to operate this robot system.

• Do not enter the robot cell while it is in automatic operation. Programmers must have the

teach pendant when they enter the robot cell.

• Improper connections can damage the robot. All connections must be made within the

standard voltage and current ratings of the robot I/O (Inputs and Outputs).

• The robot must be placed in Emergency Stop (E-STOP) mode whenever it is not in use.

• In accordance with ANSI/RIA R15.06-1999, section 4.2.5, Sources of Energy, use

lockout/tagout procedures during equipment maintenance. Refer also to Section 1910.147

(29CFR, Part 1910), Occupational Safety and Health Standards for General Industry

(OSHA).

2.4 Mechanical Safety Devices

The safe operation of the robot, positioner, auxiliary equipment, and system is ultimately the user's

responsibility. The conditions under which the equipment will be operated safely should be reviewed

by the user. The user must be aware of the various national codes, ANSI/RIA R15.06-1999 safety

standards, and other local codes that may pertain to the installation and use of industrial equipment.

Additional safety measures for personnel and equipment may be required depending on system

installation, operation, and/or location. The following safety equipment is provided as standard:

• Safety fences and barriers

• Light curtains and/or safety mats

• Door interlocks

• Emergency stop palm buttons located on operator station, robot controller, and

programming pendant

Check all safety equipment frequently for proper operation. Repair or replace any non-functioning

safety equipment immediately.

Final page 5

Page 8

Function Manual

Chapter 2 Safety

2.5 Installation Safety

Safe installation is essential for protection of people and equipment. The following suggestions are

intended to supplement, but not replace, existing federal, local, and state laws and regulations.

Additional safety measures for personnel and equipment may be required depending on system

installation, operation, and/or location. Installation tips are as follows:

• Be sure that only qualified personnel familiar with national codes, local codes, and

ANSI/RIA R15.06-1999 safety standards are permitted to install the equipment.

• Identify the work envelope of each robot with floor markings, signs, and barriers.

• Position all controllers outside the robot work envelope.

• Whenever possible, install safety fences to protect against unauthorized entry into the work

envelope.

• Eliminate areas where personnel might get trapped between a moving robot and other

equipment (pinch points).

• Provide sufficient room inside the workcell to permit safe teaching and maintenance

procedures.

2.6 Programming, Operation, and Maintenance Safety

All operators, programmers, plant and tooling engineers, maintenance personnel, supervisors, and

anyone working near the robot must become familiar with the operation of this equipment. Improper

operation can result in personal injury and/or damage to the equipment. Only trained personnel

familiar with the operation, manuals, electrical design, and equipment interconnections of this robot

should be permitted to program, operate, and maintain the system. All personnel involved with the

operation of the equipment must understand potential dangers of operation.

• Inspect the robot and work envelope to be sure no potentially hazardous conditions exist. Be

sure the area is clean and free of water, oil, debris, etc.

• Be sure that all safeguards are in place. Check all safety equipment for proper operation.

Repair or replace any non-functioning safety equipment immediately.

• Do not enter the robot cell while it is in automatic operation. Be sure that only the person

holding the programming pendant enters the workcell.

• Check the E-STOP button on the programming pendant for proper operation before

programming. The robot must be placed in Emergency Stop (E-STOP) mode whenever it is

not in use.

• Back up all programs and jobs onto suitable media before program changes are made. To

avoid loss of information, programs, or jobs, a backup must always be made before any

service procedures are done and before any changes are made to options, accessories, or

equipment.

page 6 Final

Page 9

Data Transmission

152388-1

• Any modifications to PART 1, System Section, of the robot controller concurrent I/O

program can cause severe personal injury or death, as well as damage to the robot! Do not

make any modifications to PART 1, System Section. Making any changes without the written

permission of Motoman will VOID YOUR WARRANTY!

• Some operations require standard passwords and some require special passwords. Special

passwords are for Motoman use only. YOUR WARRANTY WILL BE VOID if you use

these special passwords.

• The robot controller allows modifications of PART 2, User Section, of the concurrent I/O

program and modifications to controller parameters for maximum robot performance. Great

care must be taken when making these modifications. All modifications made to the

controller will change the way the robot operates and can cause severe personal injury or

death, as well as damage the robot and other parts of the system. Double-check all

modifications under every mode of robot operation to ensure that you have not created

hazards or dangerous situations.

• Check and test any new or modified program at low speed for at least one full cycle.

• This equipment has multiple sources of electrical supply. Electrical interconnections are

made between the controller and other equipment. Disconnect and lockout/tagout all

electrical circuits before making any modifications or connections.

• Do not perform any maintenance procedures before reading and understanding the proper

procedures in the appropriate manual.

• Use proper replacement parts.

• Improper connections can damage the robot. All connections must be made within the

standard voltage and current ratings of the robot I/O (Inputs and Outputs).

Final page 7

Page 10

Function Manual

Chapter 2 Safety

Notes

page 8 Final

Page 11

YASKAWA

NX100 OPTIONS

INSTRUCTIONS

FOR DATA TRANSMISSION FUNCTION

Upon receipt of the product and prior to initial operation, read these instructions thoroughly, and retain

for future reference.

MOTOMAN INSTRUCTIONS

MOTOMAN-!!! INSTRUCTIONS

NX100 INSTRUCTIONS

NX100 OPERATOR’S MANUAL

NX100 MAINTENANCE MANUAL

The NX100 operator’s manuals above correspond to specific usage.

Be sure to use the appropriate manual.

YASKAWA

MANUAL NO. RE-CKI-A445

Page 12

MANDATORY

• This manual explains the data transmission function of the NX100 system. Read this manual carefully and be sure to understand its contents

before handling the NX100.

• General items related to safety are listed in the Section 1: Safety of the

NX100 Instructions. To ensure correct and safe operation, carefully

read the NX100 Instructions before reading this manual.

CAUTION

• Some drawings in this manual are shown with the protective covers or

shields removed for clarity. Be sure all covers and shields are replaced

before operating this product.

• The drawings and photos in this manual are representative examples

and differences may exist between them and the delivered product.

• YASKAWA may modify this model without notice when necessary due to

product improvements, modifications, or changes in specifications. If

such modification is made, the manual number will also be revised.

• If your copy of the manual is damaged or lost, contact a YASKAWA representative to order a new copy. The representatives are listed on the

back cover. Be sure to tell the representative the manual number listed

on the front cover.

• YASKAWA is not responsible for incidents arising from unauthorized

modification of its products. Unauthorized modification voids your product’s warranty.

ii

Page 13

Notes for Safe Operation

Read this manual carefully before installation, operation, maintenance, or inspection of the

NX100.

In this manual, the Notes for Safe Operation are classified as “WARNING”, “CAUTION”,

“MANDATORY”, or ”PROHIBITED”.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

CAUTION

could result in death or serious injury to personnel.

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury to personnel and damage to equipment. It may also be used to alert against unsafe

practices.

MANDATORY

PROHIBITED

Even items described as “CAUTION” may result in a serious accident in some situations. At

any rate, be sure to follow these important items.

NOTE

To ensure safe and efficient operation at all times, be sure to follow all instructions, even if

not designated as “CAUTION” and “WARNING”.

Always be sure to follow explicitly the items listed under this

heading.

Must never be performed.

iii

Page 14

WARNING

• Before operating the manipulator, check that servo power is turned OFF

when the emergency stop buttons on the front door of the NX100 and

programming pendant are pressed.

When the servo power is turned OFF, the SERVO ON LED on the programming pendant is turned OFF.

Injury or damage to machinery may result if the emergency stop circuit cannot stop the

manipulator during an emergency. The manipulator should not be used if the emergency

stop buttons do not function.

Emergency Stop Button

• Once the emergency stop button is released, clear the cell of all items

which could interfere with the operation of the manipulator. Then turn

the servo power ON

Injury may result from unintentional or unexpected manipulator motion.

TURN

Release of Emergency Stop

• Observe the following precautions when performing teaching operations

within the P-point maximum envelope of the manipulator:

- View the manipulator from the front whenever possible.

- Always follow the predetermined operating procedure.

- Ensure that you have a safe place to retreat in case of emergency.

Improper or unintended manipulator operation may result in injury.

• Confirm that no person is present in the P-point maximum envelope of

the manipulator and that you are in a safe location before:

- Turning ON the NX100 power

- Moving the manipulator with the programming pendant

- Running the system in the check mode

- Performing automatic operations

Injury may result if anyone enters the P-point maximum envelope of the manipulator during operation. Always press an emergency stop button immediately if there is a problem.

The emergency stop buttons are located on the right of the front door of the NX100 and

the programming pendant.

iv

Page 15

CAUTION

• Perform the following inspection procedures prior to conducting manipulator teaching. If problems are found, repair them immediately, and be

sure that all other necessary processing has been performed.

-Check for problems in manipulator movement.

-Check for damage to insulation and sheathing of external wires.

• Always return the programming pendant to the hook on the NX100 cabinet after use.

The programming pendant can be damaged if it is left in the manipulator’s work area, on

the floor, or near fixtures.

• Read and understand the Explanation of the Warning Labels in the

NX100 Instructions before operating the manipulator.

Definition of Terms Used Often in This Manual

The MOTOMAN manipulator is the YASKAWA industrial robot product.

The manipulator usually consists of the controller, the programming pendant, and supply

cables.

In this manual, the equipment is designated as follows.

Equipment Manual Designation

NX100 Controller NX100

NX100 Programming Pendant Programming Pendant

Cable between the manipulator and the controller Manipulator Cable

v

Page 16

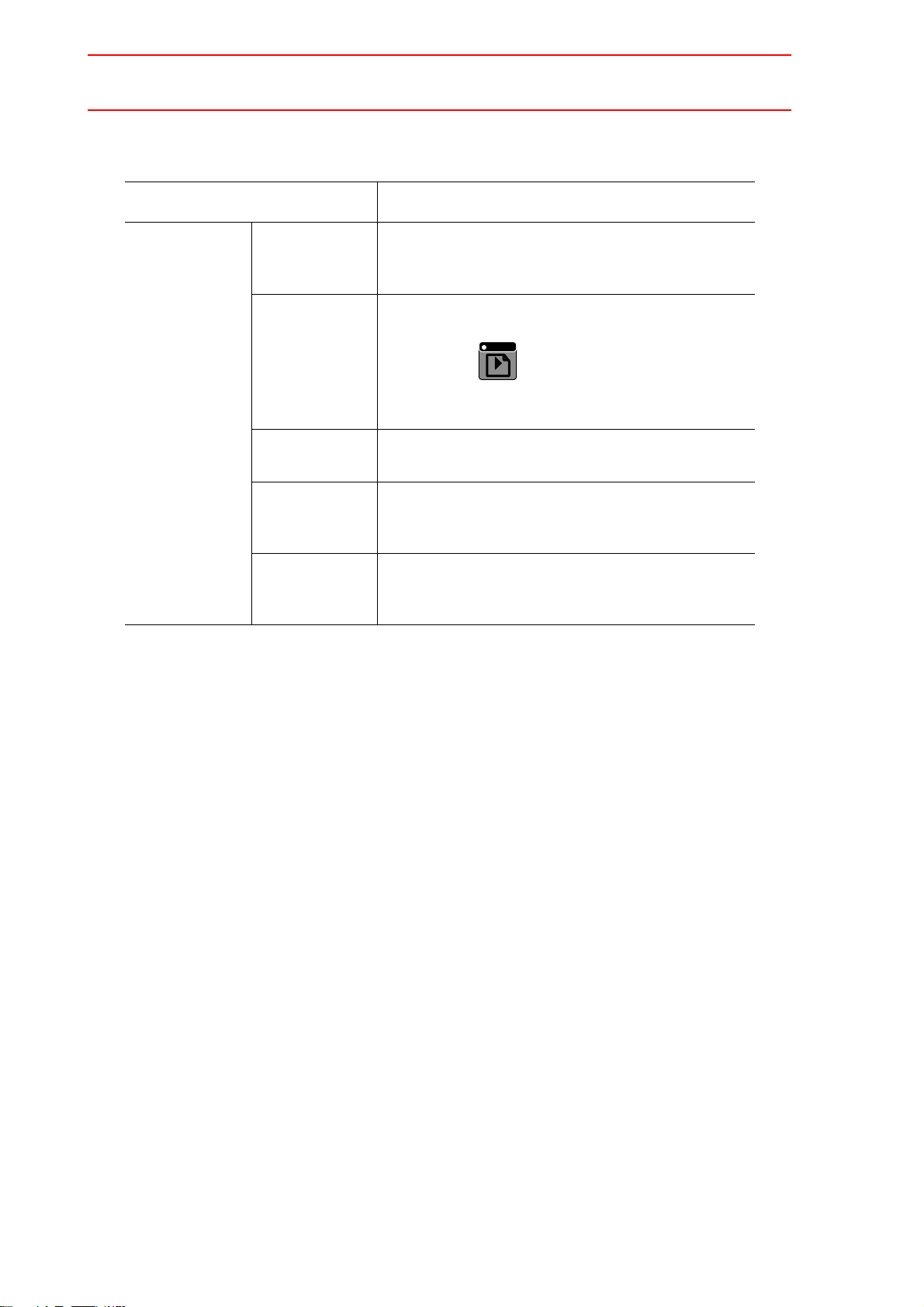

Descriptions of the programming pendant keys, buttons, and displays are shown as follows:

Equipment Manual Designation

Programming

Pendant

Character Keys The keys which have characters printed on them are

denoted with [ ].

ex. [ENTER]

Symbol Keys The keys which have a symbol printed on them are

not denoted with [ ] but depicted with a small picture.

GO BACK

ex. page key

PAGE

The cursor key is an exception, and a picture is not

shown.

Axis Keys

Numeric Keys

Keys pressed

simultaneously

“Axis Keys” and “Numeric Keys” are generic names

for the keys for axis operation and number input.

When two keys are to be pressed simultaneously,

the keys are shown with a “+” sign between them,

ex. [SHIFT]+[COORD]

Displays The menu displayed in the programming pendant is

denoted with { }.

ex. {JOB}

Description of the Operation Procedure

In the explanation of the operation procedure, the expression "Select • • • " means that the

cursor is moved to the object item and the SELECT key is pressed.

vi

Page 17

1 Outline

1.1 DCI Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Stand-alone Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.3 Host Control Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

2 For Using Data Transmission Function

2.1 Remote Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1.1 Remote Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1.2 Command Remote Valid/Invalid . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.1.3 Display in Command Remote Mode . . . . . . . . . . . . . . . . . . . . .2-3

2.2 Serial I/F Port Assignment . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.3 Parallel Operation of NX100 . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.3.1 No Multiple-operation of DCI, Stand-alone, and Host Control

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.3.2 File Access and Editing for a Single Target. . . . . . . . . . . . . . . .2-6

2.4 Differences from MRC/XRC . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.4.1 Multiport Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.4.2 Group Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.4.3 Coordinated Operation and Independent Operation . . . . . . . . .2-7

2.4.4 Condition Data and System Data . . . . . . . . . . . . . . . . . . . . . . .2-7

2.5 Transmission Specifications . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.5.1 Basic Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.5.2 Transmission Control Characters . . . . . . . . . . . . . . . . . . . . . . .2-8

2.5.3 Transmission Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.5.4 Error Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2.5.5 Character Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2.5.6 Data Link Establishment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2.5.7 Configuration of Heading and Text . . . . . . . . . . . . . . . . . . . . .2-11

2.5.8 Transmission Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

" Transmission Control Monitoring Timer. . . . . . . . . . . . . . . .2-11

" Transmission Control Resending Sequence . . . . . . . . . . . .2-12

2.5.9 Connection of D-SUB Connector Pins. . . . . . . . . . . . . . . . . . .2-13

2.5.10 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

3 DCI Function

3.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Commands for Job Transmission . . . . . . . . . . . . . . . . . . .3-1

3.2.1 LOADJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

" Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

" Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.2.2 SAVEJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

vii

Page 18

" Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

" Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.3 DELETEJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

" Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

" Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.4 SWAIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

" Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

" Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3 Commands for Variable Transmission . . . . . . . . . . . . . . 3-4

3.3.1 LOADV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

" Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

" Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.2 SAVEV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

" Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

" Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Registering DCI Instruction . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.5 Concurrent Tasks from Multiple Jobs . . . . . . . . . . . . . . . 3-7

3.6 DCI Parallel Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

" Parallel Execution Using NWAIT . . . . . . . . . . . . . . . . . . . . . 3-8

" Parallel Execution Using PSTART (Optional). . . . . . . . . . . . 3-9

3.7 Transmission Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.7.1 Job Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

" Saving Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

" Loading Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.7.2 Variable Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

" Saving Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

" Loading Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.8 Axis Data Transmission Format . . . . . . . . . . . . . . . . . . . 3-14

3.9 Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

4 Stand-alone Function

4.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Operation Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3.1 Selecting External Memory Unit . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3.2 Save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

" Saving Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

" Saving File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.3.3 Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

" Loading Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

" Loading File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3.4 Job Selection Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

" Single Selection Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

" Related Selection Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

viii

Page 19

" Switching Selection Mode . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.3.5 Selecting Job and Data File. . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

" EACH Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

" BATCH Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.4 Transmission Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

5 Host Control Function

5.1 File Data Transmission Function. . . . . . . . . . . . . . . . . . . .5-1

5.1.1 Transmission Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

" Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

" Save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.1.2 Data Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.2 Robot Control Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.2.1 Command Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.2.2 List of Interlock for Commands of Host Control Function . . . . .5-5

5.2.3 Command that Handle Axis Data . . . . . . . . . . . . . . . . . . . . . . .5-7

5.2.4 Response to MOV-type Command . . . . . . . . . . . . . . . . . . . . . .5-7

5.2.5 Status Read Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

" Read/Monitor Command . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

" Read/Data Access System Commands . . . . . . . . . . . . . . .5-13

5.2.6 System Control Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

" Operation System Commands . . . . . . . . . . . . . . . . . . . . . .5-17

" Start-up System Commands . . . . . . . . . . . . . . . . . . . . . . . .5-22

" Editing System Commands . . . . . . . . . . . . . . . . . . . . . . . .5-26

" Job Selection System Commands . . . . . . . . . . . . . . . . . . .5-30

5.2.7 I/O Read/Write Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-31

" Transmission Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

" Read-out of I/O Signal Status . . . . . . . . . . . . . . . . . . . . . . .5-32

" Write-in of I/O Signal Status . . . . . . . . . . . . . . . . . . . . . . . .5-33

5.3 Commands for Multi-control Group and

5.4 Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-37

5.5 Interpreter Message List . . . . . . . . . . . . . . . . . . . . . . . . . . .5-38

6 Data List

6.1 Header Number List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 Parameter List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Independent Control Functions

5.3.1 Commands for Multi-control Group . . . . . . . . . . . . . . . . . . . . .5-35

5.3.2 Commands for Independent Control Function. . . . . . . . . . . . .5-36

ix

. . . . . . . . . . . . . . . . . . . .5-35

Page 20

7 Comparison of Data Transmission Functions

8 Remote Function Setting

x

Page 21

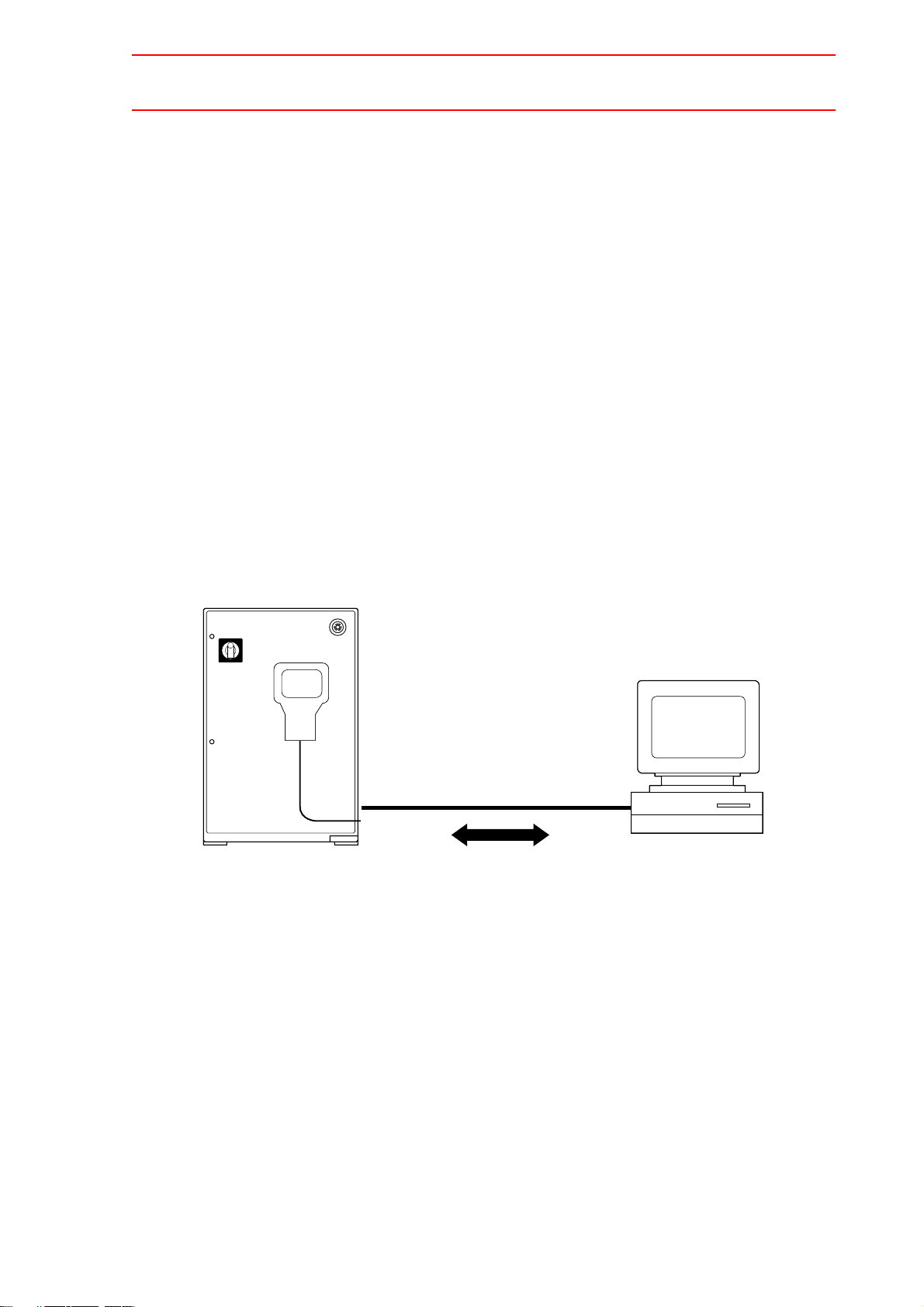

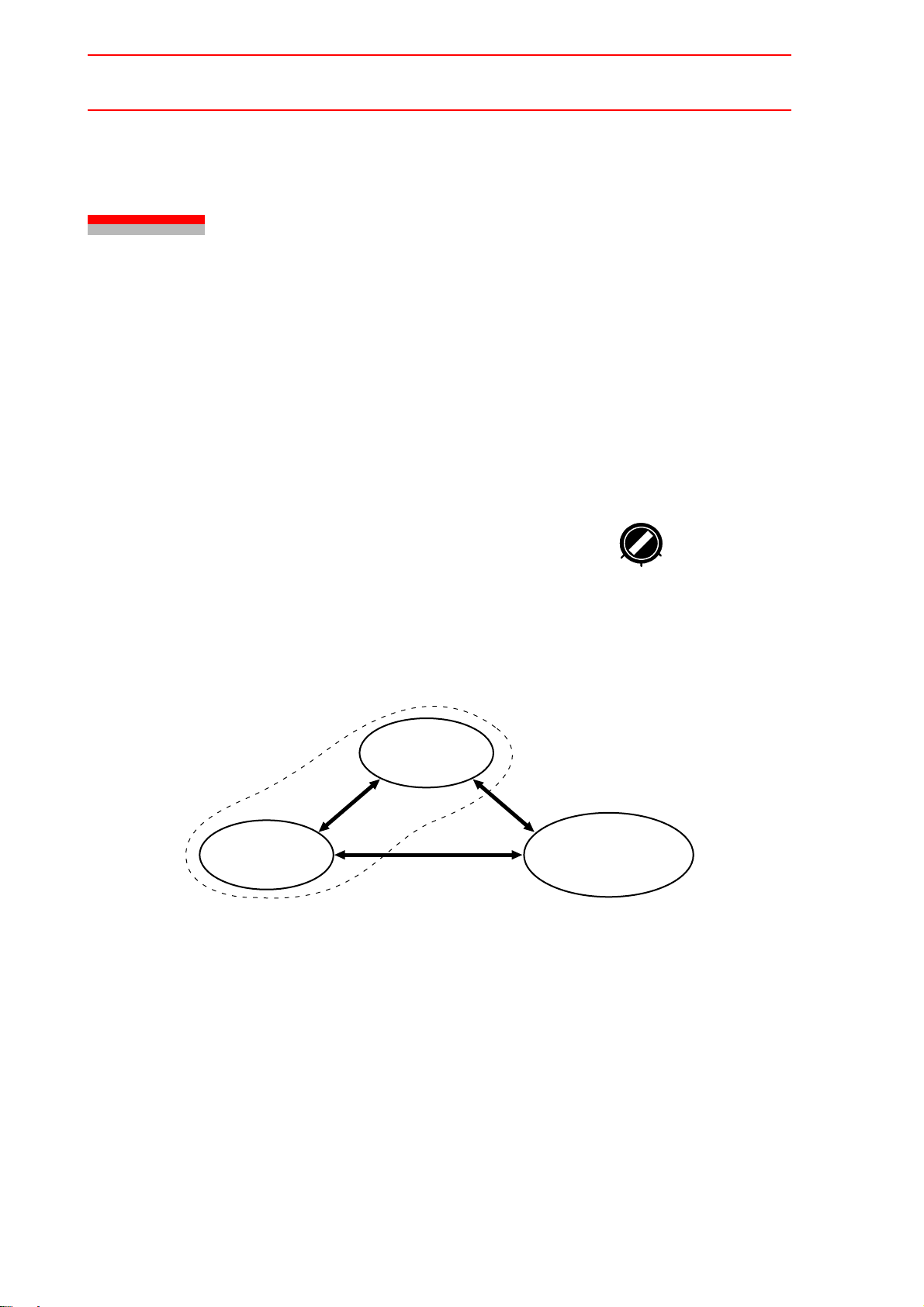

1 Outline

The data transmission function is for communication with a host computer such as a personal

computer in BSC complying protocol.

The data transmission function adopts a serial transmission line and standard protocol, making easy connection to a host computer.

The data transmission function is not only for transmission of job but also for controlling robot

system by a host computer using a set of commands.

The robot commands in the ASCII code command format are easy to use and helpful for a

quick development of necessary software to be run on the host computer.

The data transmission function is divided into the following three functions.

• DCI (Data Communication by Instruction)

• Stand-alone function

• Host control function

NX100

Host computer

(personal computer, etc.)

Data transmission

1-1

Page 22

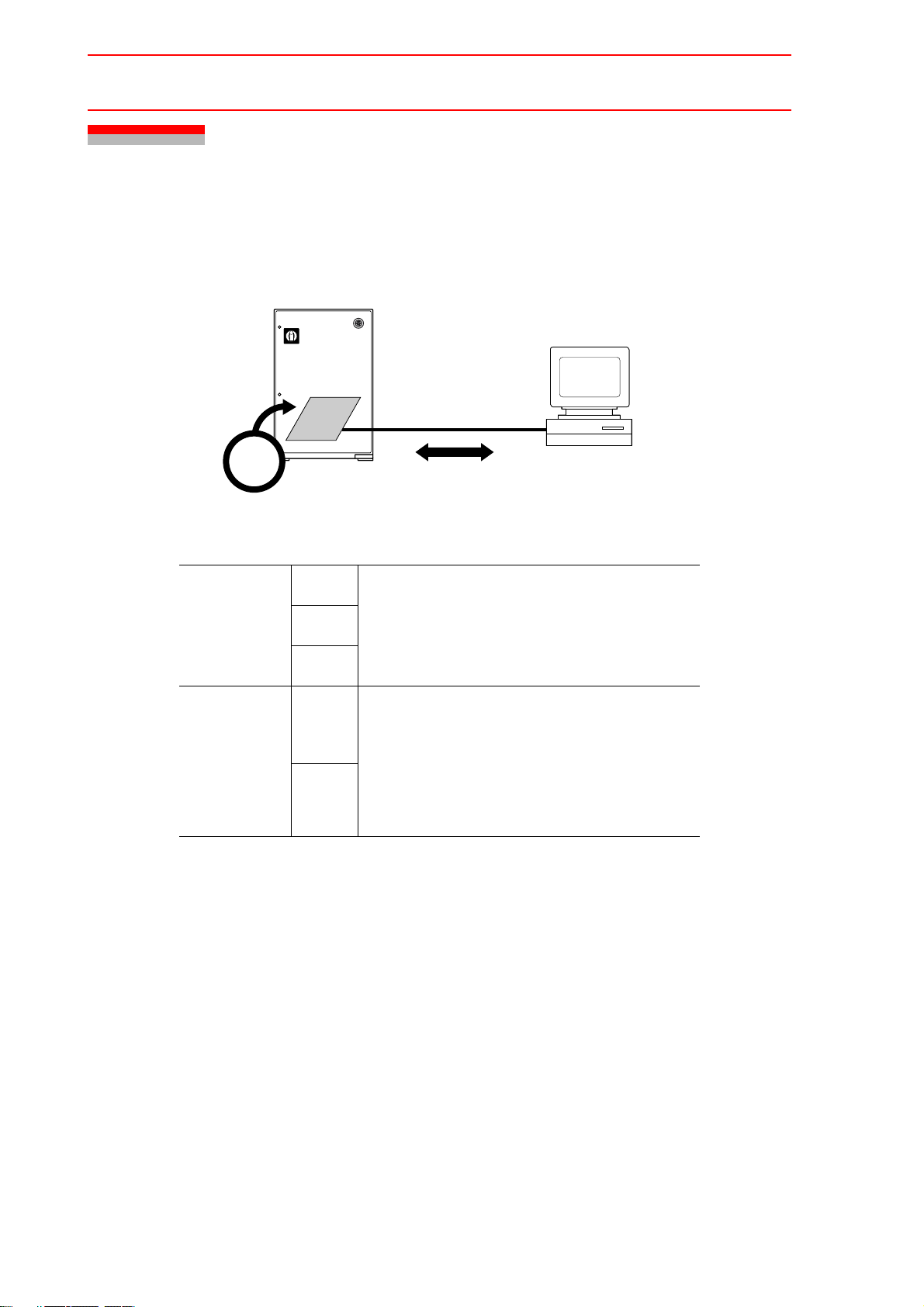

1.1 DCI Function

1.1 DCI Function

The DCI function executes instructions described in a job to perform data transmission with a

host computer. This function loads and saves jobs and variables.

NX100

Host computer

(personal computer, etc.)

Job

Execute

Job

Transmission

Variab le

Transmission

Load

Save

Delete

Load

Save

DCI Function

Job can be transmitted in either mode.

• Single job

• Related job

• Byte type global variables

• Integer type global variables

• Double precision type global variables

• Real number type global variables

• Position type global variables

(Robot axes, base axes, station axes)

1-2

Page 23

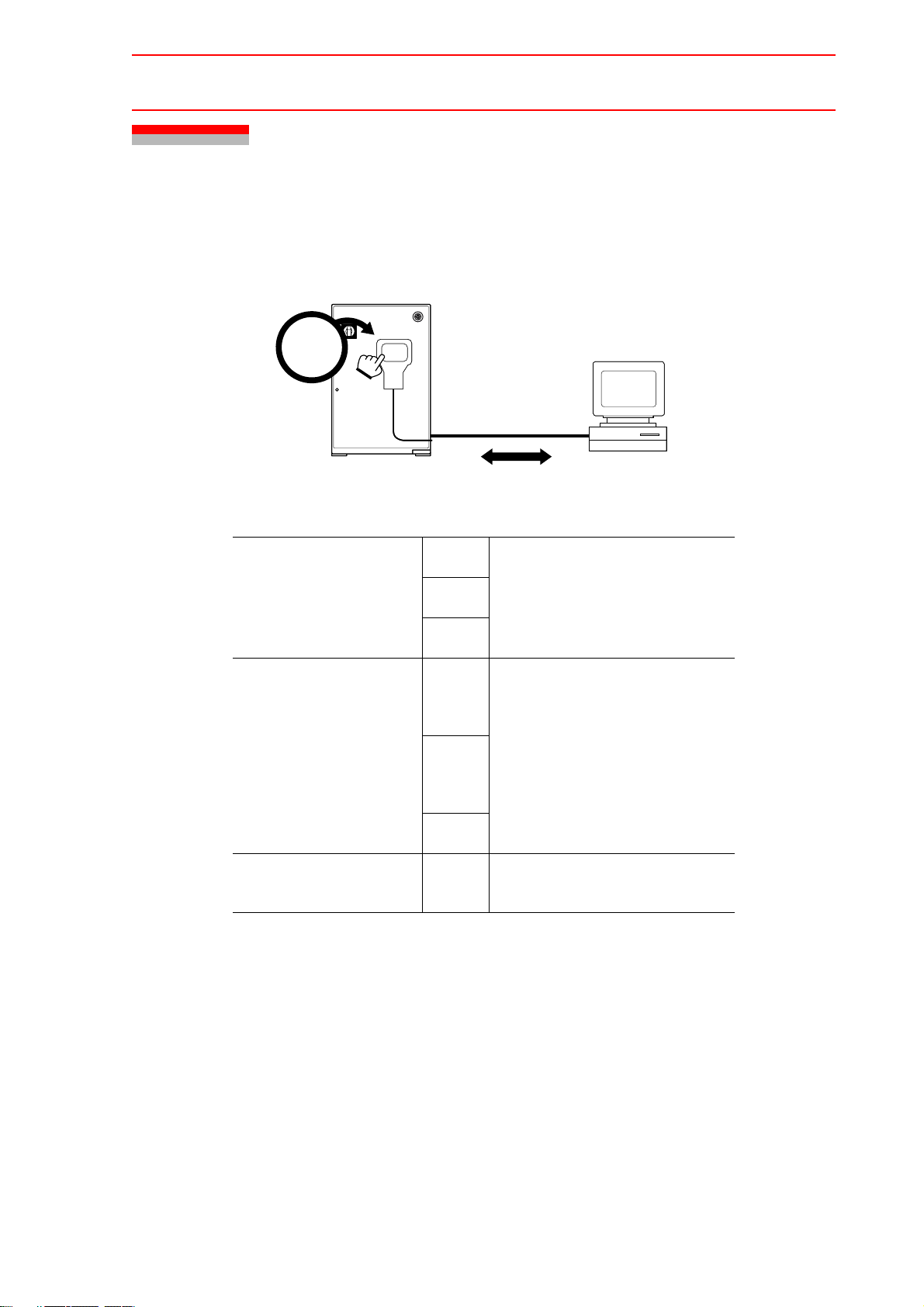

1.2 Stand-alone Function

1.2 Stand-alone Function

The stand-alone function is for data transmission with host computer by operation on the programming pendant. This function loads and saves jobs and condition data.

NX100

Operation

Job Transmission

Condition Data/

General Data

Transmission

Stand-alone Function

Load

Save

Verify

Load

Save

Job can be transmitted in either

mode.

• Single job

• Related job

• Tool data

• Weaving data

• User coordinate data

• Welding data

• Variable data

Host computer

(personal computer, etc.)

System Information

Transmission

Verify

Save

• System information

• Alarm history

1-3

Page 24

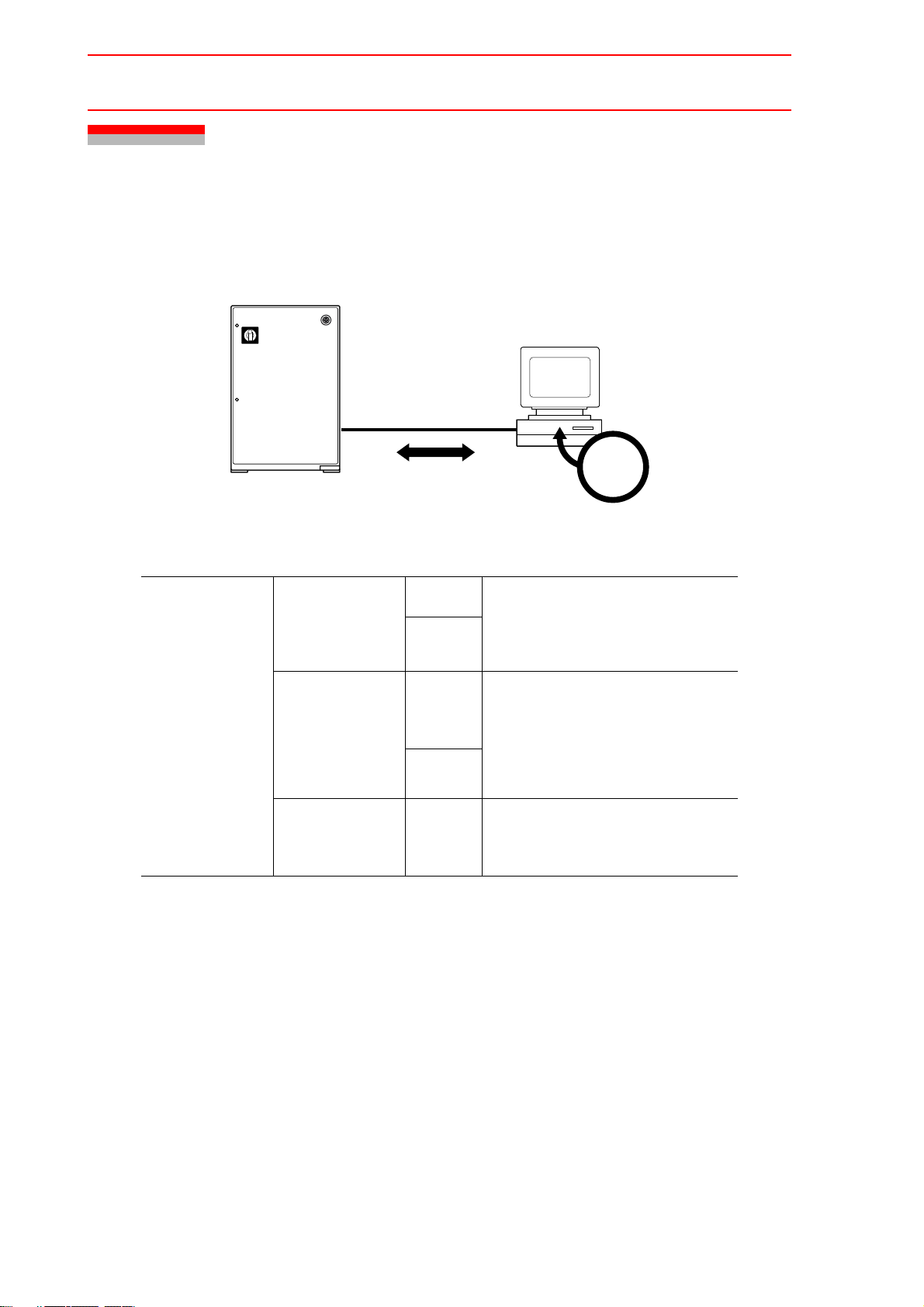

1.3 Host Control Function

1.3 Host Control Function

The host control function is for loading and saving jobs, reading robot status, and controlling

the system by sending a command from a host computer.

NX100

Host computer

(personal computer, etc.)

Operation

File Data

Transmission

Function

Host Control Function

Job

Transmission

Condition Data/

General Data

Transmission

System

Information

Transmission

Load

Save

Load

Save

Save

Jobs can be transmitted in either

mode :

• Single job

• Related job

• Tool data

• Weaving data

• User coordinate data

• Welding data

• Variable data

• System information

• Alarm history

1-4

Page 25

Host Control Function

Status Reading

1.3 Host Control Function

• Read of error and alarm codes

• Read of current position in a joint coordinate

system

• Read of current position in a specified Carte-

sian coordinate system

• Read of mode, cycle, motion, alarm error

and servo status

• Read of current job name, line No. and step

No.

• Read of all job names or related job names

• Monitoring completion of manipulator opera-

tion

• Read of specified user coordinate data

• Read of control group and task selected sta-

tus

• Read of variable data

Robot Control

Function

System Control

• Start, hold

• Reset, cancel

• Job deletion

• Master job setup

• Job, line No. and step No. setup

• Mode and cycle selection

• Servo power supply ON/OFF

• Programming pendant interlock setup/

release

• Message display

• Joint motion and linear motion to a specified

Cartesian coordinate system

• Linear motion by increments in a specified

coordinate system

• Joint motion and linear motion to a specified

joint coordinate system

• Conversion/reverse conversion of related

job of a specified job (Relative job function is

necessary)

• Write of specified user coordinate data

• Change of control group

• Change of task to be controlled

• Write of variable data

1-5

Page 26

2.1 Remote Mode

2 For Using Data Transmission Function

2.1 Remote Mode

The data transmission function can be used with NX100 in remote mode.

2.1.1 Remote Mode

To use the data transmission function, set NX100 to remote mode.

In remote mode, the operation is ordered from a host computer ; whereas in local mode, teach

mode, and play mode, the programming pendant is used for operating the system.

To switch to the remote mode or the local mode, either

• Set the mode key on the programming pendant to [REMOTE] .

REMOTE

PLAY

TEACH

The remote mode has two sub-modes ; “I/O remote enable” and “Command remote enable”.

Which sub-mode takes effect in remote mode is set in the pseudo input display. Refer to Section 8 “Remote Function Setting”.

Teach mode

Local mode

Remote mode

Play mode

!I/O remote enable

!Command remote enable

2-1

Page 27

2.1 Remote Mode

Operation-site Mode Operation-site Condition to Enable the Operation

Local Mode Programming pendant The remote lamp is OFF, or “INHIBIT PP/

PANEL” in the pseudo input display is set to

invalid.

Remote Mode

I/O remote enable

External I/O control board

The remote lamp is ON, and “INHBIT IO” in

the pseudo input display is set invalid.

Command remote

enable

In remote mode, usually operations of the programming pendant or the playback panel is

NOTE

disabled, but they can be also enabled. To enable all operations, refer to Section 8

“Remote Function Setting”. To selectively enable some of the operations, set the parameter S2C182. For details, refer to Section 6.2 “Parameter List”.

External computer

The remote lamp is ON, and “CMD

REMOTE SEL” in the pseudo input display is

set valid.

In remote mode, operations on the programming pendant are valid except the operationrelated entries. This holds true in “I/O remote enable” and “Command remote enable” submodes. The concept is based on the conventional I/O control introduced to command control.

Note that the edit-related operations cannot be entered from more than one operating device.

In “Command remote enable” submode, to enable command remote controls only, issue the

HLOCK command. When the HLOCK command is ON, operations on the programming pendant are valid only hold and emergency stop. Also the following I/O operations are disabled :

selection between remote mode and local mode, external start, external servo ON, cycle

selection, I/O prohibit, P.P/PANEL prohibit, and master job call. Other I/O operations are valid.

2-2

Page 28

2.1 Remote Mode

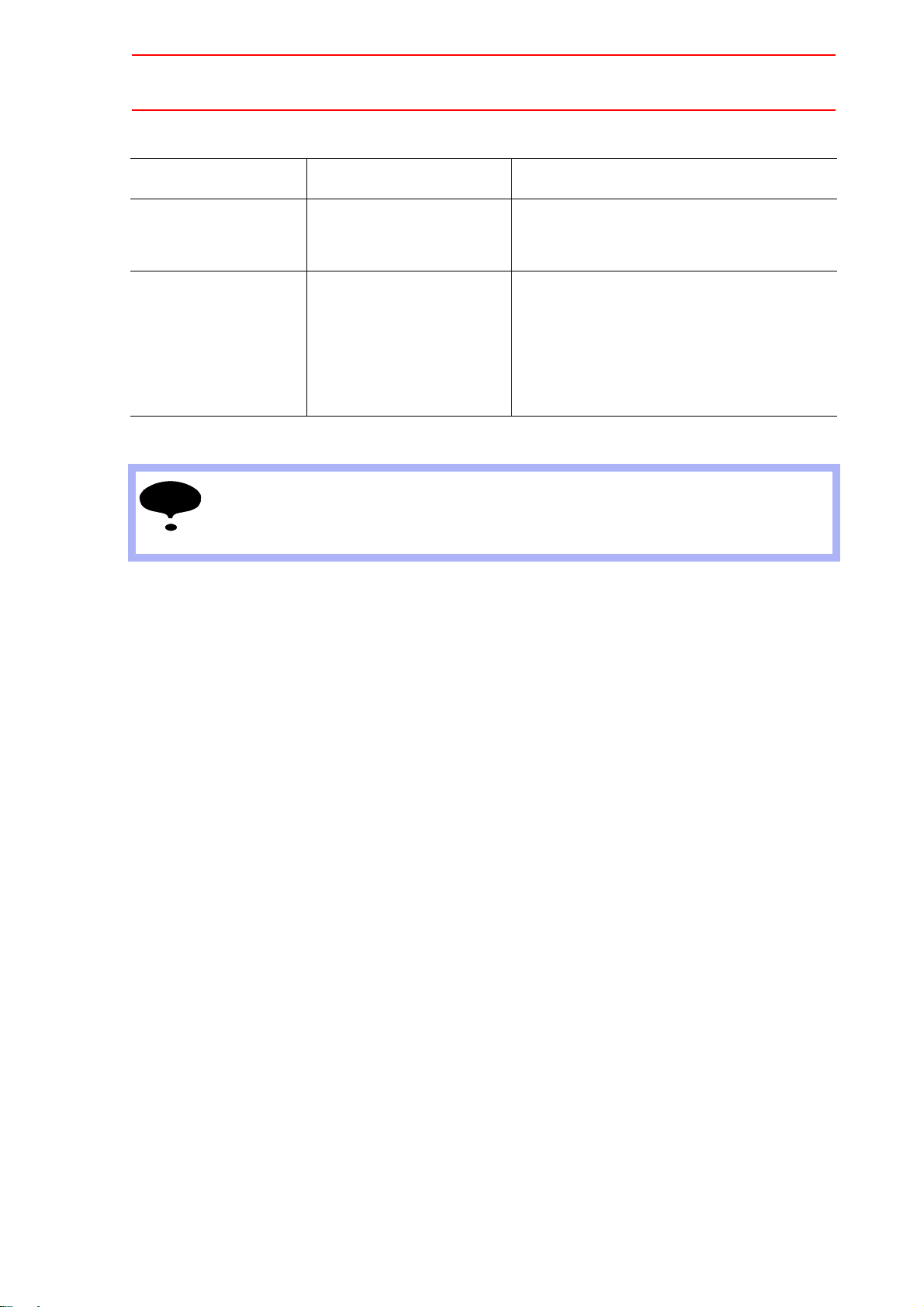

2.1.2 Command Remote Valid/Invalid

Availability of each function of data transmission differs depending on the command remote

setting (Enabled / Disabled).

When the command remote is set invalid, the read/monitor system commands (hereinafter

called read-only function) in the host control function in addition to the DCI function and standalone function can be used. For the details of read/monitor system commands, refer to Section 5.2.2 “List of Interlock for Commands of Host Control Function”..

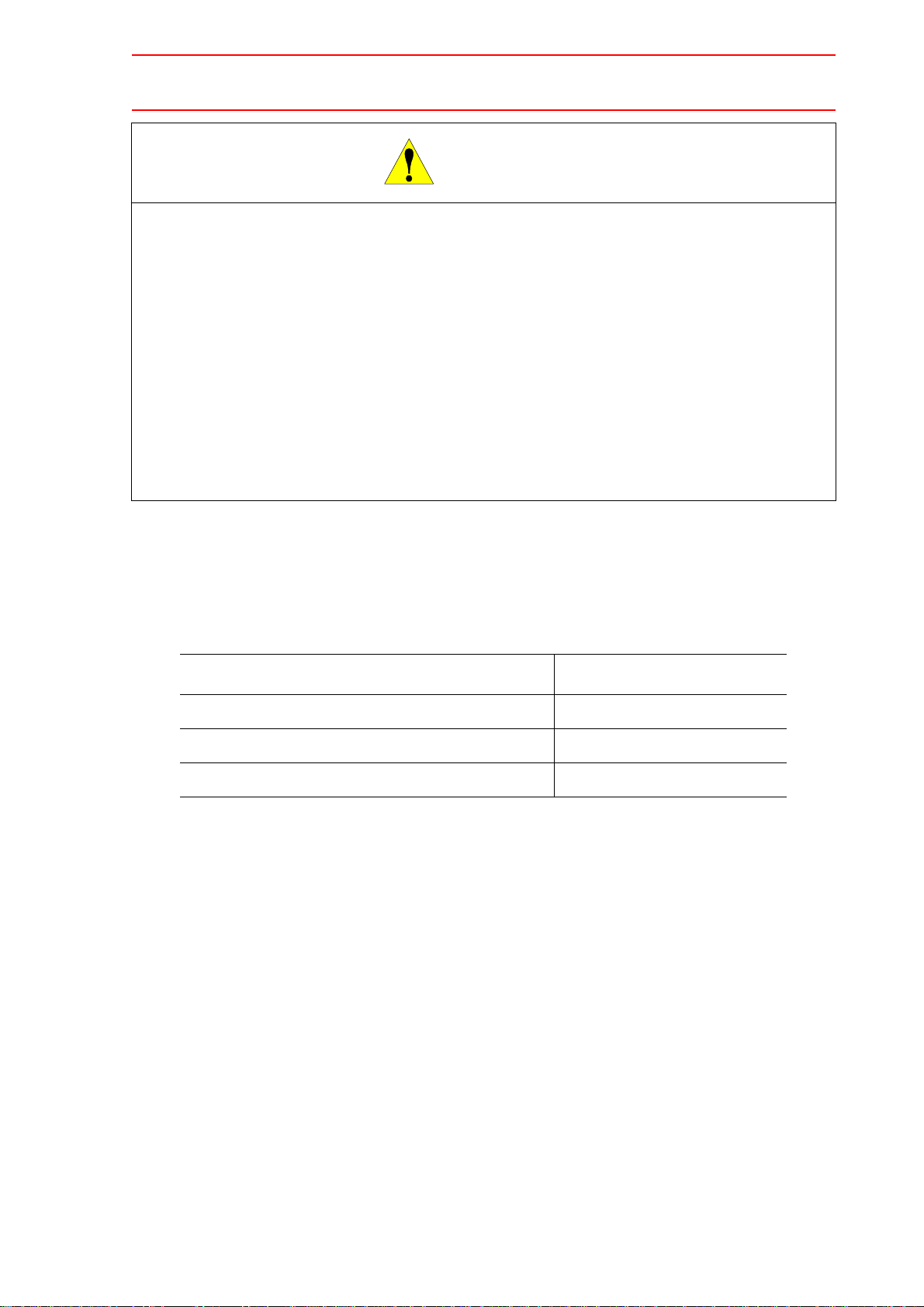

Command Remote Setting Function Availability

Invalid DCI function available

Stand-alone function available

Host control function (only read-only function) available

Valid Host control function (all commands) available

To validate the read-only function in the above host control function, set the parameter RS005

to “1”. When the command remote is validated by pressing [REMOTE] with the read-only

function valid, the command remote status is entered so that all commands can be used.

When the command remote is invalidated by pressing [REMOTE] again, the read-only function becomes validated again.

Parameter Contents and Set Value

BSC port function specification when the command

RS005

remote is invalidated

0 : DCI or stand-alone function

1 : Read-only function in host control

Initial

Value

0

2.1.3 Display in Command Remote Mode

Even in command remote enabled submode, it is not necessary to call the command remote

display because operations from NX100 is available. To call the command remote display,

select “REMOTE” from “I/O” under the top menu.

This display is used in common with the I/O remote mode display.

The message in the remote display changes according to the remote function selection.

(Refer to Chapter 8 “Remote Function Setting”.)

2-3

Page 29

REMOTE

IO and Command mode

CURR

PREV

DISP

2.2 Serial I/F Port Assignment

EDIT DISPLAY UTILITYDATA

A message shown in

the table below is displayed.

Main Menu

ShortCut

Remote Select Status

I/O

Remote

Command

Remote

Message Remarks

×דRemote mode not specified” Same when the remote lamp

is OFF.

# × “I/O mode” Only when the remote lamp

is ON.

× # “Command mode”

# # “I/O and Command mode”

Read-only Function

Valid

“Remote mode not specified” “CURR” and “PREV” are dis-

played.

# : Valid, × : Invalid

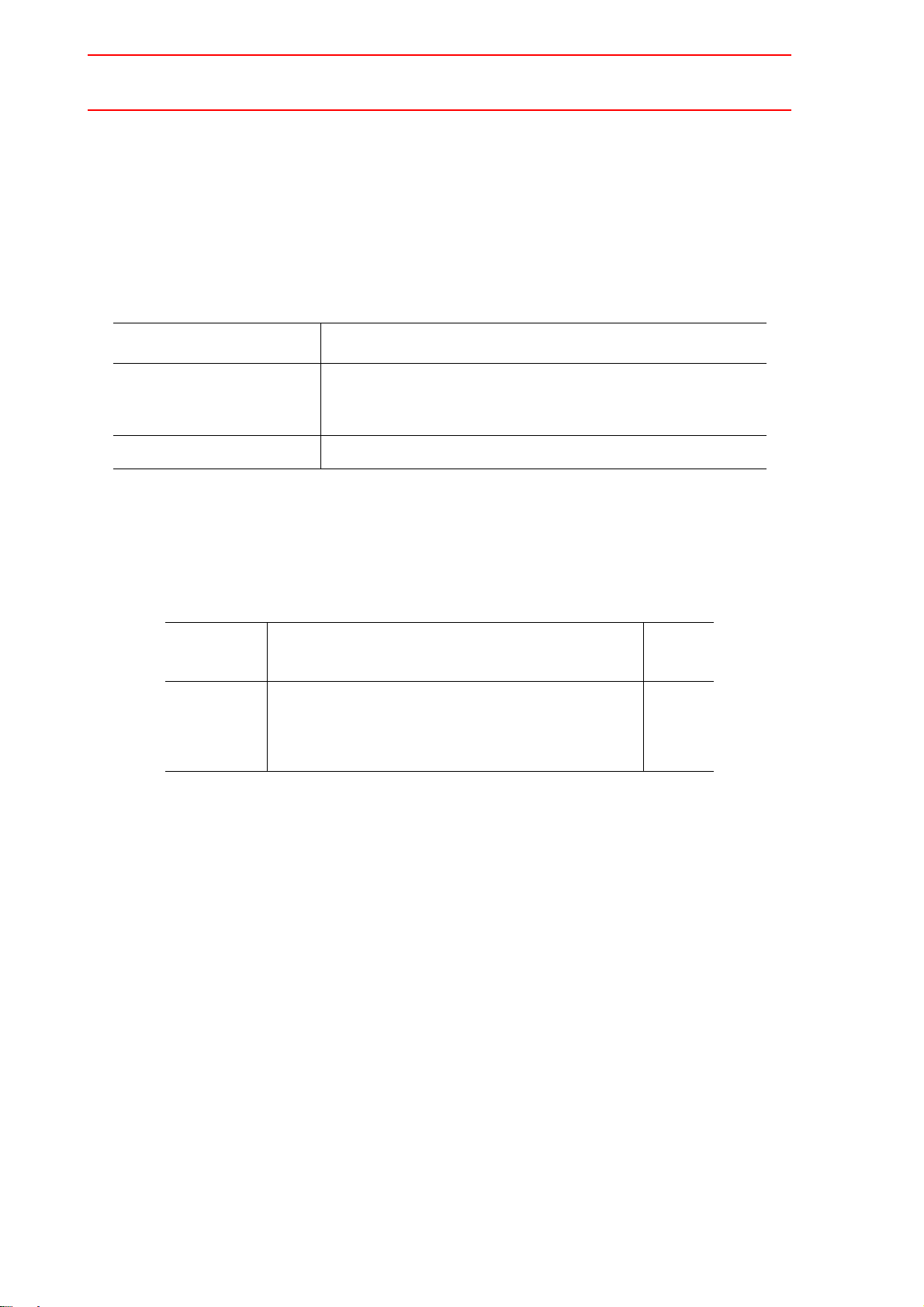

2.2 Serial I/F Port Assignment

The NX100 has one serial interface port. The FC1 protocol and the BSC complying protocol

(for data transmission function : option) can be assigned to the port to communicate with

external devices.

A change in assignment can be made only in local mode.

Parameter Contents and Set Value

Standard port protocol specification

0 : NON

RS000

1 : System reserved

2 : BSC LIKE (Data transmission

function

3 : FC1

2-4

Initial

Value

2

Page 30

2.2 Serial I/F Port Assignment

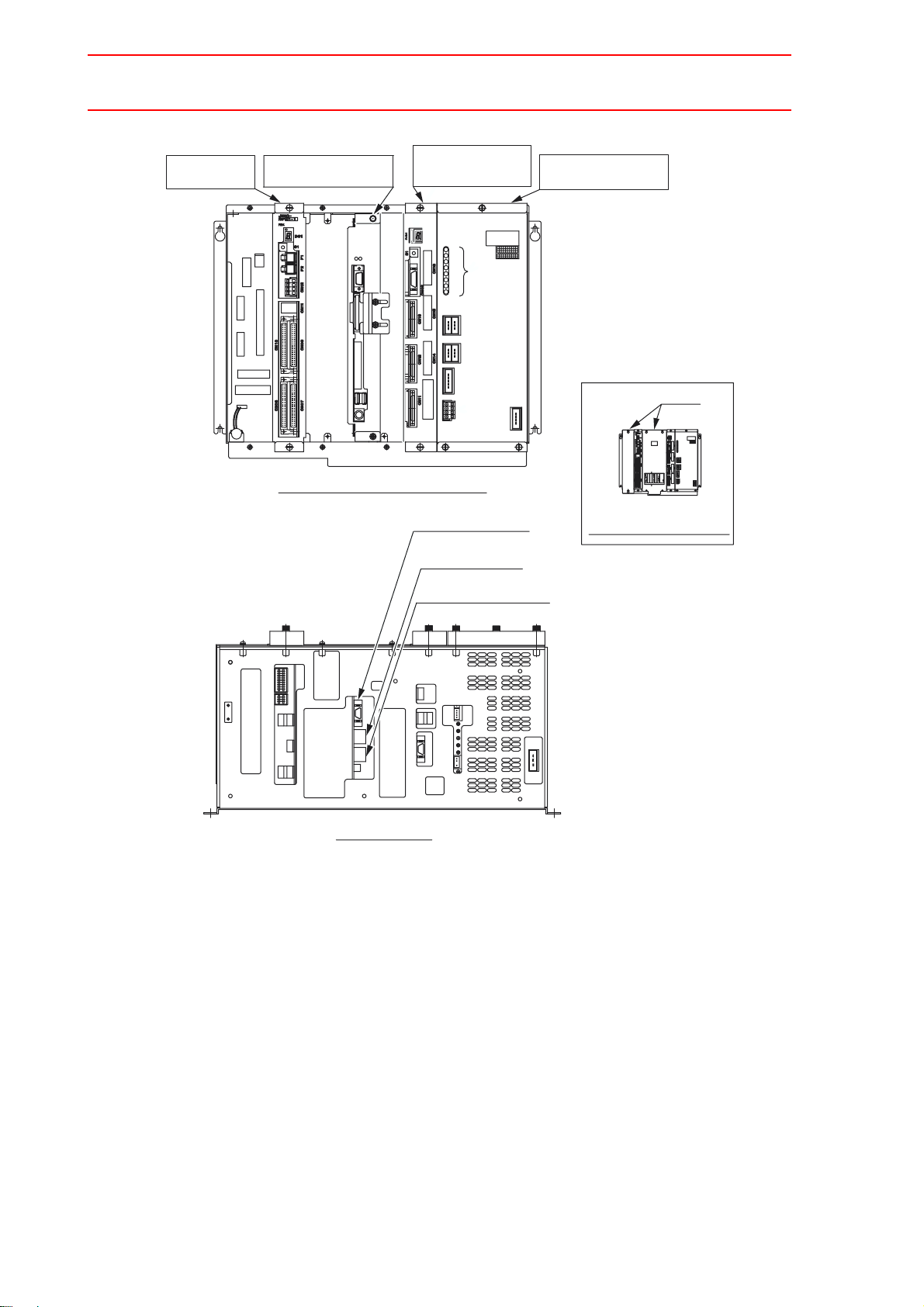

TYPE JANCD-NCP01

Robot I/F Unit

JZNC-NIF01

CNBAT

Control Circuit Board

JANCD-NCP01

CPU

TYPE JANCD-NCP01

TYPE JANCD-NCP01

DATE

REV

LED

0

CNSP1

CNTU

CNRI

CNM

CNRO

CNFAN

ATX

1

VIDEO

IDE

USB1(L)

USB1(R)

PS2

Front View (without the cover)

Major Axes Control

Circuit Board

SGDR-AXA01A

SUPPLY

POWER

CPS-NX1

No.

DATE

Fuji

Co.,Ltd.

JAPAN

Electric

080910

03040506

07

01

02

181920

13141516

17

11

SOURCE

+5VSB

PON

+5V

+24V

OTHER

FAN

OHT

CN05

(+24V1)

CN04

(+24V2)

(REMOTE)

12

282930

23242526

27

21

22

GFEDC

BA

KJH

SRQPN

ML

VUT

CN03

(TU)

CN02

200-240V AC

CN01

(AC IN)

INPUT

50/60Hz

3A

Serial port interface

(RS-232C I/F)

(LAN2)

Ethernet function

(LAN1)

Programming Pendant

Control Circuit Board

CPS-420F

Cover

Front View

(with the cover supplied)

Bottom View

CPU Unit Configuration (JZNC-NRK 01!-!)

2-5

Page 31

2.3 Parallel Operation of NX100

2.3 Parallel Operation of NX100

The NX100 is capable of parallel processing. For instance, it can check signals with programming pendant while saving files to YASNAC FC2, or can edit files with the programming pendant while monitoring operation status by the host control function.

The parallel operation has the following restrictions. When an operation against these restrictions is made, a warning message is displayed.

Operation Warning

YASNAC FC2

Stand-alone

Programming pendant

DCI Alarm

Host control Interpreter message

Error message for 3 seconds

(or error message)

2.3.1 No Multiple-operation of DCI, Stand-alone, and Host Control Functions

All DCI, stand-alone, and host control use BSC LIKE protocol and the same port, therefore

these functions cannot be performed by parallel processing.

Warning message : Serial port not defined

Warning message : Serial port being used

Warning message : Protocol being used

2.3.2 File Access and Editing for a Single Target

Access to a single target file is available. Parallel processing of reads from two or more

sources is impossible.

During access to a file for other function, the HLOCK command of the host control function

cannot be issued.

Key operations are ignored while the HLOCK command is ON.

Warning message : Data accessed with other functions

2-6

Page 32

2.4 Differences from MRC/XRC

2.4 Differences from MRC/XRC

The data transmission function in NX100 is intended to reuse basically the user applications

with succession to the data transmission of MRC/XRC.

There are some differences resulted from functional differences between the MRC/XRC and

the NX100.

2.4.1 Multiport Processing

The XRC is not applicable for multiport processing.

2.4.2 Group Axes

The control group information used for the CGROUP and RGROUP commands in the host

control function differs depending on the number of manipulators.

2.4.3 Coordinated Operation and Independent Operation

Up to 8 tasks (6 tasks for XRC) can be changed by the CTASK command. No command

related to coordinated operation is available.

2.4.4 Condition Data and System Data

Condition data and system data have different file name in option function, accordingly their

communication header differ.

2-7

Page 33

2.5 Transmission Specifications

2.5 Transmission Specifications

This section explains the transmission specifications for the data transmission.

2.5.1 Basic Specifications

Interface Complies to RS-232C (RS/CS method)

Transmission Speed

Transmission Mode

Synchronization

system

Protocol

Transmission Code

Error Check

Response Method

9600 bps

Half-duplex transmission system (point-topoint)

Asynchronous (stop bit 1 *

BSC LIKE

ASCII, shift JIS

8-bit data length *

Even parity *

Nontransparent

BCC

ACK alternating response

1

1

1

*1 Can be changed by transmission parameter setting

2.5.2 Transmission Control Characters

)

The transmission control characters are shown in the table below.

Transmission Control Characters and Codes

Control

Character

DLE

SOH

STX

ETX

EOT

ENQ

NAK

ETB

ACK0

ACK1

Code

(hexadecimal)

10

01

02

03

04

05

15

17

10, 30

10, 31

Meanings of Control Character

Data Link Escape

Start of Heading

Start of Text

End of Text

End of Transmission

Enquiry

Negative Acknowledgment

End of Text Block

Even Affirmative Acknowledgment

Odd Affirmative Acknowledgment

2-8

Page 34

2.5 Transmission Specifications

2.5.3 Transmission Format

The transmission format is as follows.

S

HEADING

O

H

S

O

HEADING

H

S

T

X

S

T

X

E

N

Q

E

O

T

TEXT

TEXT

S

T

X

S

T

X

TEXT

TEXT

E

T

B

E

T

X

BCC

BCC

E

BCC

T

B

E

T

BCC

X

N

A

K

ACK0

ACK1

2-9

Page 35

2.5 Transmission Specifications

2.5.4 Error Control System

The error control is performed by a check sum of all the characters from SOH or STX to ETB

or ETX.

The check sum is calculated as shown below.

<Example>

E

BCC

T

X

+

0000 0001 1101 1011

0000 0101

0000 0000

0011 0110

1010 1100

1111 0001

0000 0011

S

TEXT

T

X

• Start of calculation : Calculation is started when SOH or STX used as the block start

sequence appears. These block start sequence are not included in

the sum. As for a STX led by a SOH, STX is included in the sum.

• End of calculation : Calculation is ended when ETB or ETX used as the block end

sequence appears, with the ETB or ETX included in the sum.

2.5.5 Character Configuration

The character configuration is as follows.

Start bit

b1 b2 b3 b4 b5 b6 b7 b8 bp

2.5.6 Data Link Establishment

A data link is established by responding ACK0 to ENQ.

Stop bit

Parity bit

2-10

Page 36

2.5 Transmission Specifications

2.5.7 Configuration of Heading and Text

The configuration of heading and text is as follows.

Heading 6 characters fixed Max. 256 characters

S

O

H

S

T

X

Subcode No.

, (comma)

Header No.

TEXT BCC

E

T

B

2.5.8 Transmission Parameters

" Transmission Control Monitoring Timer

Two timers are provided for transmission control monitoring. Both are transmission parameters so that their settings can be changed for each system.

Timer A : Sequence monitoring timer. Serves as protection against invalid or no response.

Recommended value is 3 sec.

Timer B : Text reception monitoring timer. Serves as protection against no response of text

end character. Recommended value is 20 sec.

Timer B

Timer B

NX100

ACK0

ACK1

ENQ

Data

EOT

Host

computer

Timer A

Timer A

NX100

ENQ

Data

EOT

Host

computer

ACK0

ACK1

2-11

Page 37

2.5 Transmission Specifications

" Transmission Control Resending Sequence

Two constants below are related to the transmission control resending sequence. Both are

transmission parameters like the transmission control monitoring timers, whose settings can

be changed for each system.

Retry 1 : Number of resendings of a sequence character at an invalid or no response

at all. Recommended value is 10 times.

Retry 2 : Number of resendings of a text at a block check error (reception of NAK).

Recommended value is 3 times.

Parameter Contents and Set Value

RS030 Number of data bits 7 : 7 (bit)

8 : 8 (bit)

RS031 Number of stop bits 0 : 1 (bit)

1 : 1.5

2 : 2

RS032 Parity specification 0 : No specification

1 : Odd parity

2 : Even parity

RS033 Transmission speed specification 1 : 150 (baud rate)

2 : 300

3 : 600

4 : 1200

5 : 2400

6 : 4800

7 : 9600

8 : 19200

RS034 Timer A Sequence monitoring timer

Serves as protection against invalid or no response

Unit : 0.1 sec. (Setting range : 0 to 100)

Initial

Value

8

0

2

7

30

RS035 Timer B Text reception monitoring timer

Serves as protection against no response of text end character

Unit : 0.1 sec. (Setting range : 0 to 255)

RS036 Retry 1 Number of resendings of a sequence character at an invalid or

no response (Setting range : 0 to 30)

RS037 Retry 2 Number of resendings of a text at a block check error (reception

of NAK). (Setting range : 0 to 10)

RS038 Block check method 0 : Check sum 0

2-12

200

10

3

Page 38

2.5 Transmission Specifications

2.5.9 Connection of D-SUB Connector Pins

The connection of D-SUB connector pins is shown below.

NCP01 board (D-SUB9P)

NX100

Carrier detect

1

CD

Data receive

2

RD

Data send

3

SD

Data terminal ready

4

ER

Grounding for signal

5

SG

Request to send

7

RS

Sending enabled

8

CS

Protective grounding

9

FG

2.5.10 Connection

Since the system is “null-modem”, connect the pins as shown below.

XCP01 board

Host Computer

3

SD

2

RD

7

RS

8

CS

5

SG

NX100

2

3

5

7

8

9

RD

SD

SG

RS

CS

FG

• Connect “RS” of the NX100 to “CS” of a host computer. This prevents data overrun when

reception processing speed of the NX100 cannot catch up with data sending from the

host computer. In other words, “RS” signal from the NX100 controls start-hold of data

transmission from the host computer. The sending interface controller must be capable of

coping with CS input displacement in units of a single byte.

• The NX100 sends data when the “CS” signal is ON.

2-13

Page 39

3.1 Outline

3 DCI Function

3.1 Outline

The data communication by instruction (DCI) function loads, saves jobs and variables according to an instruction that executes data transmission with a host computer. The DCI function

is classified as follows.

• Job load, save and delete functions

• Variable load and save functions

NX100

Host computer

(personal computer, etc.)

Job

Execute

3.2 Commands for Job Transmission

3.2.1 LOADJ

" Function

Loads specified jobs as single or related jobs, from the external memory unit to the memory of

the NX100.

3-1

Page 40

3.2 Commands for Job Transmission

" Configuration

LOADJ

JOB:<Job name>

IG#<Input group No.>

B<Variable No.>

Unit of

loading

JBI, JBR

NWAIT

IF statement

• If the NX100 memory already contains a job having the same name as the job to be

loaded, the existing job is deleted and the new job is loaded. However, if the job to be

loaded is as follows, an alarm occurs.

• Execution starting job

• Job under execution/halting

• Job registered in job call stack

• Specify input group numbers (BCD/BIN, parity specification), and variable numbers in the

same way as for the CALL command. If the pattern input value is 0, the operation is not

executed. A variable number 0 is valid.

• Unit of loading : Select either a single job (JBI) or related jobs (JBR)

• When the NWAIT is specified, the next instruction is executed without waiting completion

of job loading.

• While a job is being loaded by the LOADJ command for which NWAIT is specified, if an

access is attempted to a job called by the CALL command or JUMP command, an alarm

occurs. If a LOADJ or SAVEJ command has already been executed, a job is loaded after

completion of the execution.

3-2

Page 41

3.2 Commands for Job Transmission

3.2.2 SAVEJ

" Function

Saves a specified job as single or related jobs, from the memory of the NX100 to the external

memory unit.

" Configuration

SAVEJ

JOB:<Job name>

IG#<Input group No.>

B<Variable No.>

Unit of saving

JBI, JBR

NWAIT

IF statement

• Specify input group numbers (BCD/BIN, parity specification), and variable numbers in the

same way as for the CALL command. If the pattern input value is 0, the operation is not

executed. A variable number 0 is valid.

• Unit of saving : Select either a single job (JBI) or related jobs (JBR).

• When the NWAIT is specified, the next command is executed without waiting completion

of job saving. When a LOADJ or SAVEJ command has already been executed, a job is

saved after completion of the execution.

3.2.3 DELETEJ

" Function

Deletes all jobs except its own job or specified jobs as single or related jobs, from the memory

of the NX100.

" Configuration

DELETEJ

Unit of

JOB:<Job name>

deleting

JBI, JBR

• Unit of deleting : Select either a single job (JBI) or related jobs (JBR).

• The following jobs cannot be deleted.

• Execution starting job

• Job under execution/halting

• Job registered in job call stack

3-3

IF

statement

Page 42

3.3 Commands for Variable Transmission

3.2.4 SWAIT

" Function

Waits for completion of loading or saving jobs or variables.

Use this command to recognize a completion of LOADJ, SAVEJ, LOADV, and SAVEV commands when a NWAIT is specified for these instructions.

" Configuration

SWAIT

3.3 Commands for Variable Transmission

3.3.1 LOADV

" Function

Loads the specified global variables from an external memory unit to the NX100 memory.

" Configuration

LOADV

Byte type global variable

Integer type global variable

Double precision type global variable

Real number type global variable

Position type (robot axis) global variable

Position type (base axis) global variable

Position type (station axis) global

variable

NWAIT

3.3.2 SAVEV

" Function

Saves the specified global variables from the NX100 memory to a external memory unit.

" Configuration

SAVEV

Byte type global variable

Integer type global variable

Double precision type global variable

Real number type global variable

Position type (robot axis) global variable

Position type (base axis) global variable

Position type (station axis) global

variable

3-4

NWAIT

Page 43

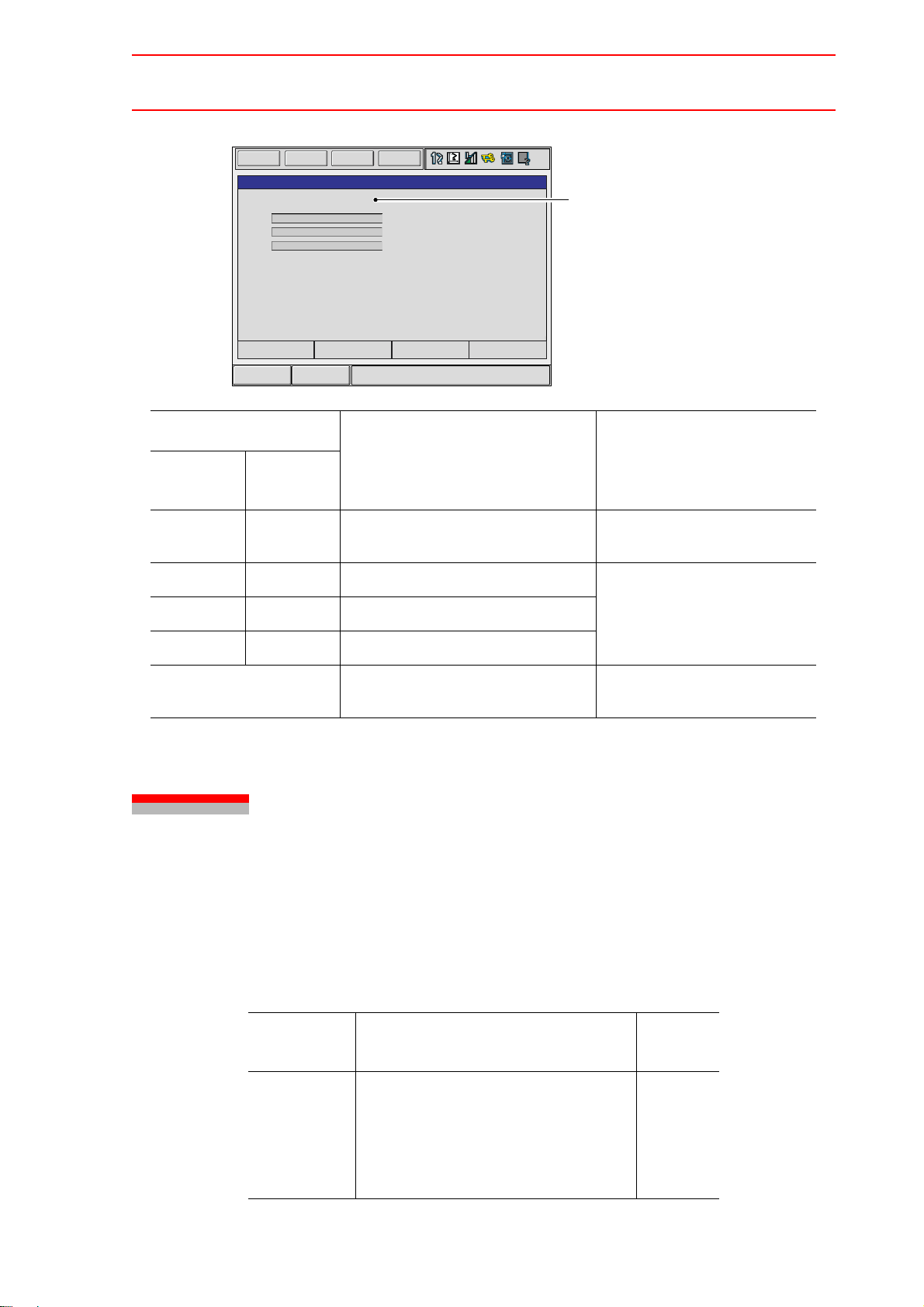

3.4 Registering DCI Instruction

CONTROL GROUP R1 TOOL 00

CO O

Operation Explanation

1 Move the cursor to the

address area.

3.4 Registering DCI Instruction

2 Move the cursor to the line

where an instruction is to be

In the job content display in teach mode, move the cursor to the

line just above the place where an instruction is to be registered.

registered in the job content

0019

MOVJ

display.

Line just above

the place where

an instruction is

to be registered

0020

0021

0022

0023

0024

0025

0026

0027

MOVL

MOVL

MOVJ

DOUT

MOVJ

MOVL

MOVL

MOVL

VJ=50.00

V=138

V=138

VJ=100.00

OT#(1) ON

VJ100.00

V=138

V=138

V=138

LOADJ

SAVEJ

LOADV

SAVEV

DELETEJ

DEVICE

MOTION

ARITH

SHIFT

OTHER

SAME

3 Press [INFORM LIST]. The instruction list dialog is displayed. The cursor moves to the

instruction list dialog while the cursor in the address area

changed to an underline.

MOVJ

MOVL

MOVL

MOVJ

DOUT

MOVJ

MOVL

MOVL

MOVL

EDIT DISPLAY

TEST

R1

VJ=50.00

V=138

V=138

VJ=100.00

OT#(1) ON

VJ100.00

V=138

V=138

V=138

ShortCut

UTILITY

STEP NO.

TOOL

015

00

IN/OUT

CONTROL

DEVICE

LOADJ

MOTION

SAVEJ

ARITH

LOADV

SHIFT

SAVEV

OTHER

DELETEJ

SAME

PRIOR

SWAIT

JOB

JOB CONTENT

JOB NAME

CONTROL GROUP

0019

0020

0021

0022

0023

0024

0025

0026

0027

LOADJ JOB:JOB JBI

Main Menu

4 Select an instruction to be reg-

istered.

The instruction where the cursor is positioned is displayed with

the previously registered additional items in the input buffer line.

JOB CONTENT

JOB NAME

CONTROL GROUP

0019

0020

0021

0022

0023

0024

0025

0026

0027

MOVJ

MOVL

MOVL

MOVJ

DOUT

MOVJ

MOVL

MOVL

MOVL

LOADV B000

TEST

VJ=50.00

V=138

V=138

VJ=100.00

OT#(1) ON

VJ100.00

V=138

V=138

V=138

STEP NO.

TOOL

R1

015

00

LOADJ

SAVEJ

LOADV

SAVEV

DELETEJ

SWAIT

IN/OUT

CONTROL

DEVICE

MOTION

ARITH

SHIFT

OTHER

SAME

PRIOR

3-5

Page 44

3.4 Registering DCI Instruction

Operation Explanation

5 Change the additional items

and variable data.

<To register items as displayed in the input buffer>

Perform operation described in the step 6 below.

<To edit any additional items>

With the cursor on the instruction to be registered, press

[SELECT]. The cursor moves to the input buffer line.

LOADV B000

• Changing a numerical value data of additional items

Move the cursor to the additional item whose numerical value is to be

changed. Pressing simultaneously [SHIFT] and the cursor key increments or decrements the value.

LOADV B000

To enter a value by pressing the number key, press [SELECT] to display the input line.

B=

LOADV

Enter a value, then press [ENTER]. The value displayed in the input

line is changed.

• Adding, changing, or deleting the additional items

To add, change or delete the additional items, select an instruction in

the input buffer line to display the detail edit display.

EDIT DISPLAY UTILITYJOB

DETAIL EDIT

LOADV

VARIABLE

NWAIT

To add an additional item, select “NOT USED” of an additional item

selection status, then display the selection dialog to select an additional

item to be added.

To delete an additional item, move the cursor to an additional item to be

deleted, then select “NOT USED” to delete.

LOADV B000

B000

UNUSED

ShortCutMain Menu

DETAIL EDIT

LOADV

VARIABLE

NWAIT

3-6

B000

NWAIT

UNUSED

Page 45

3.5 Concurrent Tasks from Multiple Jobs

Operation Explanation

5 (cont’d) • Changing the data type

To change the data type of additional item, move the cursor to the of

the additional item and press [SELECT] to select a data type.

DISPLAY UTILITY

JOB

DETAIL EDIT

LOADV

VARIABLE

NWAIT

EDIT

B000

UNUSED

B

I

O

R

P

After having added, changed or deleted the addtional items, press

[ENTER]. The detail edit display is ended and the job content display

appears.

6 Press [INSERT] and [ENTER]. The instruction displayed in the input buffer line is registered.

To register an instruction just before an END instruction, it is not

necessary to press [INSERT].

JOB CONTENT

JOB NAME

CONTROL GROUP

0020

0021

0022

0023

0024

0025

0026

0027

0028

TEST

MOVL

V=138

MOVL

V=138

LOADV

I000

MOVJ

VJ=100.00

DOUT

OT#(1) ON

MOVJ

VJ100.00

MOVL

V=138

MOVL

V=138

MOVL

V=138

STEP NO.

TOOL

R1

015

00

IN/OUT

CONTROL

DEVICE

MOTION

ARITH

SHIFT

OTHER

SAME

PRIOR

3.5 Concurrent Tasks from Multiple Jobs

As an option, commands related to DCI function can be executed from more than one job

simultaneously. The operations are explained below.

• The DCI related commands can be executed in any job regardless of distinction among

the ordinary job, concurrent job (option), or job activated in series (option).

• Multiplexing of DCI transmission function is not supported. Therefore, it is impossible to

manipulate files on two or more external memory units (such as personal computer) connected to the NX100.

• If two or more commands related to DCI function are issued concurrently, the execution

starts after completion of processing of the currently executing command. Therefore, if a

module issues a command request while another module is executing DCI function, the

request has to wait until the ongoing processing completes.

3-7

Page 46

3.6 DCI Parallel Execution

3.6 DCI Parallel Execution

By using the function described below, the DCI instruction can be executed in parallel with

general instructions such as a move instruction and operating instruction. When this function

is used, the robot can be moved or the calculation is executed during data transmission ; this

function is effective for reduction of tact time, etc.

" Parallel Execution Using NWAIT

NOP

MOVJ VJ=50.00

MOVJ VJ=50.00

LOADJ JOB:ABC JBI NWAIT

MOVJ VJ=50.00

MOVJ VJ=50.00

SWAIT

CALL JOB:ABC

) ) )

END

$

%

&

'

(

In the above job, when the command $ is executed, loading of the host computer and the job

are executed. Normally, when NWAIT is not specified, the commands of % and after are not

executed until the job loading is completed. However, when NWAIT is specified, the commands % and & are executed sequentially during the job loading ; at execution of SWAIT

command ', the execution of command ( is waited for the job “ABC” loading is completed.

At the time of completion of job “ABC” loading, the command ( is executed to execute the

job “ABC”.

At this time, if SWAIT command is not specified before the command (, the command ( is

executed during the loading of job “ABC”, and an alarm occurs. Therefore, be sure to verify

that loading is completed before executing a job to be loaded, by using SWAIT command.

To load/save variables, be sure to input a SWAIT command before using variables to be

loaded/saved as shown below.

(Correct) (Wrong)

NOP

) ) )

LOADV B000 NWAIT

) ) )

SWAIT

SET B001 B000

NOP

) ) )

LOADV B000 NWAIT

) ) )

SET B001 B000

3-8

Page 47

3.7 Transmission Procedure

" Parallel Execution Using PSTART (Optional)

By using an independent control command (optional), DCI commands can be executed in parallel with general commands. For example, to execute the job “R1” for robot 1 is to be executed in parallel with the job “S1” for station 1 during job loading, the following procedure is

taken :

Job “R1” : Job for robot 1

Job “S1” : Job for station 1

[JOB:R1]

NOP

MOVJ VJ=50.00

MOVJ VJ=50.00

PSTART JOB:S1 SUB1

LOAD JOB:ABC

PWAIT

CALL JOB:ABC

END

When PSTART command $ is executed, the job “S1” starts execution in parallel with the job

“R1”. The job “ABC” is loaded by the command % during execution of the job “S1” ; when

loading is completed, the NX100 waits for the job “S1” to be completed by the command &.

When the execution of job “S1” is completed, the job “ABC” is executed by the command '.

$

%

&

'

[JOB:S1]

NOP

MOVJ VJ=50.00

MOVJ VJ=50.00

END

3.7 Transmission Procedure

3.7.1 Job Transmission

" Saving Procedure

The transmission from the NX100 to a host computer proceeds as follows.

NX100 → Host computer

1. The ENQ code is sent out to establish a data link.

2. After the data link is established, data are sent out to the host computer.

3. After the transmission completes, the NX100 waits for a response from the host com-

puter to verify the completion of transmission. Therefore, the host computer should

return a response.

4. The transmission is terminated upon receipt of the response from the host computer.

3-9

Page 48

3.7 Transmission Procedure

The data type is distinguished by the header number and the subcode number. Refer to the

header number list.

ENQ

ACK0

SOH 02, 001 STX File name

*1

ETB BCC

ACK1

STX

STX ETX BCCData

NX100

EOT

ACK0

ACK1

*1

File name : CR (File name does not include extension.)

ETB BCCData

SOH 90, 000 STX Data ETX BCC

*3

*2 ACK0 or ACK1

*3 Normal completion : 0000CR (ASCII code)

Abnormal completion : Integer except 0000 CR (ASCII code)

ACK0

*2

ACK

Host computer

ENQ

EOT

" Loading Procedure

The transmission from a host computer to the NX100 proceeds as follows.

Host computer → NX100

1. The ENQ code is sent out to establish a data link.

2. After the data link is established, a request to send is sent out to the host computer.

3. When the request to send is accepted, the NX100 enters receiving status, waiting for

the ENQ code from the host computer. Therefore, the host computer should send data

after the data link is established.

4. The transmission is terminated at completion of data reception from the host computer.

A request to send consists of a header number and a subcode number. Refer to the header

number list.

3-10

Page 49

3.7 Transmission Procedure

At transmission, memory capacity is checked and if received data cannot be stored, an alarm

occurs. If the transmission itself is normal, reception is continued and an alarm is displayed

after the transmission is terminated. If an error occurs during reception, the job data will not

be stored.

ENQ

ACK0

STX

*1

ETX BCC

1

*

ACK1

ENQ

Host computer

ETB BCCData

SOH 02, 051 STX File name

EOT

ACK0

SOH 02, 001 STX File name ETB BCC

NX100

ACK1

STX ETX BCCData

*2

ACK

*1

File name : CR (File name does not include extension.)

*2 ACK0 or ACK1

EOT

3-11

Page 50

3.7 Transmission Procedure

3.7.2 Variable Transmission

The variable transmission is performed in the same way as for the data as shown below.

" Saving Procedure

ENQ

ACK0

1

SOH 03,001 STX

EOT

Data

*

CR

ETX BCC

ACK1

NX100

ACK0

ACK1

" Loading Procedure

ENQ

SOH 03,051 STX

EOT

NX100

ACK0

SOH 90,000 STX Data

ETX BCC

SOH 03,001 STX

Data

ENQ

Host computer

*2

CR

ETX BCC

EOT

ACK0

ACK1

ENQ

Host computer

1

*

CR

ETX BCC

ACK1

For headers, refer to the header number list.

EOT

3-12

Page 51

3.7 Transmission Procedure

*1

Byte type global variable : +++ (0 to 255)

Integer type global variable : ± +++ (-32768 to +32767)

Double precision type global variable :

Real number type global

variable :

Position type (robot axis)

global variable :

Position type (base axis)

global variable :

± ++++++++++ (-2147483648 to 2137383647)

7 significant digits (-1.70141E+38 to +1.70141E+38)

Pulse type or XYZ type depending on the internal setting status

Pulse type

S, L, U, R, B, T (Unit : pulse)

(-999999999 to 999999999)

XYZ type

X, Y, Z, TX, TY, TZ, TYPE

d0 = 0 : Flip d0 = 1 : No flip

d2 = 0 : Up d2 = 1 : Back

Unit : degree (°), significant 2 decimal points

-9999.99 to 9999.99

Unit : mm, significant 3 decimal points

-999999.999 to 999999.999

Pulse type or XYZ type depending on the internal setting status

Pulse type

1, 2, 3 (Unit : pulse)

(-999999999 to 999999999)

Position type (station axis)

global variable :

*2

0000 or error code

The response is as follows when an error occurs in response.

SOH 90,000 STX DATA CR ETX BCC

If a stop operation (hold and emergency stop) is done during data transmission (while

jobs or variables are loaded or saved), the robot stops but the data transmission continues. In this case, the start lamp goes OFF. The restart will not be accepted until completion of the data transmission.

XYZ type

X, Y, Z (Unit : mm, significant 3 decimal points)

(-999999.999 to 999999.999)

Pulse type

1, 2, 3, 4, 5, 6 (Unit : pulse)

(-999999999 to 999999999)

3-13

Page 52

3.8 Axis Data Transmission Format

3.8 Axis Data Transmission Format

The NX100 data transmission function has the following restrictions on transmission of the

NX100 internal data.

The robot axes are fixed to a 6-axis set.

A base axis and a station axis are recognized as an external axis. Up to three base axes are

available. With station axis data added after base axis data, up to six axes can be handled.

For example, SAVEV BP005 is read as SAVEV BP005 + EX005.

If the system lacks one of the variables, only the existing one is used. If the system has both

variables but not registered, an error occurs.

The definition of the robot, base, and station axes is used as it is, free of the predetermined

axis data R1, B1, and S1.

<Example>

Transmission data of SAVEV in different system configurations are shown below.

• In a system having two base axes (X and Z) and no station axis

If BP005 is pulse type and 1st axis is 100 and 2nd axis is 200, then

SAVEV BP005 → 03, 007 100, 200, 0, 0, 0, 0

If BP005 is XYZ type and X-axis is 123.456 and Z-axis is 234.567, then

SAVEV BP005 → 03, 008 123.456, 234.567, 0,0, 0, 0

• In a system having no base axis and three station axes

If EX005 is pulse type and 1st axis is 500, 2nd axis is 600, and 3rd axis is 700

SAVES EX005 → 03, 007 500, 600, 700, 0, 0, 0

• In a system having two base axes (X and Z) and three station axes

If BP005 is pulse type, 1st axis is 100 and 2nd axis is 200, and

EX005 is pulse type, 1st axis is 500, 2nd axis is 600, and 3rd axis is 700, then

SAVEV BP005 → 03, 007 100, 200, 500, 600, 700, 0

(Same as for SAVEV EX005)

If BP005 is XYZ type, X axis is 123.456, and Z axis is 234.567, and

EX005 is pulse type, 1st axis is 500, 2nd axis is 600, and 3rd axis is 700, then

SAVEV BP005 → 03, 008 123.456, 234.567, 500, 600, 700, 0

(same as for SAVEV EX005)

3-14

Page 53

3.9 Alarm Codes

Code Message Data

3.9 Alarm Codes

4104

4105

4106

Data Contents

001

002

003

004

012

Insufficient memory capacity

Job editing prohibited

Attempted to load or delete a job being executed.

No specified job

Position data destroyed

WRONG EXECUTION OF

LOAD INST

WRONG EXECUTION OF

SAVE INST

WRONG EXECUTION OF

DELETE INST

Refer to the

table below.

013

017

019

020

023

024

090

104

111

112

113

117

118

Position variable not registered

Instruction destroyed

Invalid character in job name

Invalid character in label

Invalid character in this system

Syntax error

Control command sending/receiving error (Ethernet)

Error response from host computer

Syntax error

Error in position data

No NOP or END instruction

Format error

Invalid number of data

3-15

Page 54

3.9 Alarm Codes

Data Contents

120

122

125

126

127

128

211

212

213

214

221

222

223

Data range exceeded

Destroyed file exists

No serial port setting

This serial port already used.

This protocol already used.

File accessing in other function

System block error (Receiving EOT while waiting ACK)

System block error (Receiving EOT at starting receiving)

System block error (Receiving EOT before receiving the last block)

System block error (Receiving codes other than EOT before receiving the last block)

Sending error (Retry for NAK exceeded)

Sending error (Timeup for timer A retry)

Sending error (ACK0/ACK1 order error after retry)

231

232

233

234

235

236

237

240

241

242

243

Receiving error (Timeup for timer A while waiting ACK after ENQ, timeup for timer A while

waiting ENQ response)

Receiving error (Timeup for timer B while receiving a text)

Receiving error (Heading length is shorter than 6 characters)

Receiving error (Heading length is longer than 6 characters)

Receiving error (Header number error)

Receiving error (Text length exceeds 256 bytes)

Receiving error (Receiving other than ENQ while waiting ENQ, receiving other than control code while waiting control code, receiving other than STX, SOH, ENQ, EOT while

waiting text)

Software error

Hardware error (Overrun)

Hardware error (Parity error)

Hardware error (Framing error)

244

245

Hardware error (Sending timeup (timer A))

Hardware error (Sending timeup (timer B))

3-16

Page 55

4.1 Outline

4 Stand-alone Function

4.1 Outline

In stand-alone mode, the file data transmission function is available. By the operations on the

NX100 programming pendant, file data can be sent from the NX100 to a host computer such

as personal computer to be saved, and from a host computer to the NX100 memory to be

loaded.

Load : Transmits file data from a host computer to the NX100.

Save : Transmits file data from the NX100 to a host computer.

Verify : Verifies data between the NX100 and the host computer and informs if some parts are

not matched.

NX100

Operation

The following data can be transmitted between the NX100 and a host computer. System

information can be saved but not loaded.

• Job data

• Condition data/General data

• System information

Host computer

(personal computer, etc.)

4-1

Page 56

4.2 Operation Flow

4.2 Operation Flow