Motoman DA20C, DA20, NX100 Manipulator Manual

Motoman NX100 Controller

DA20C

Manipulator Manual

Part Number: 151528-1CD

Revision 0

Motoman, Incorporated

805 Liberty Lane

West Carrollton, OH 45449

TEL: (937) 847-6200

FAX: (937) 847-6277

24-Hour Service Hotline: (937) 847-3200

COMPLETE OUR ONLINE SURVEY

Motoman is committed to total customer satisfaction! Please give us your feedback on the technical manuals you

received with your Motoman robotic solution.

To participate, go to the following website:

http://www.motoman.com/forms/techpubs.asp

The information contained within this document is the proprietary property of Motoman, Inc., and may not be

copied, reproduced or transmitted to other parties without the expressed written authorization of Motoman,

©2007 by MOTOMAN

Because we are constantly improving our products, we reserve the right to change specifications without

notice. MOTOMAN is a registered trademark of YASKAWA Electric Manufacturing.

Inc.

All Rights Reserved

DA20C

151528-1

Chapter 1

Introduction

1.1 About This Document

This manual provides information for the DA20C Manipulator and contains the following sections:

CHAPTER 1 - INTRODUCTION

Provides general information about the structure of this manual, a list of reference documents, and

customer service information.

CHAPTER 2 - SAFETY

This section provides information regarding the safe use and operation of Motoman products.

CHAPTER 3 - DA20C INSTRUCTIONS

Provides detailed information for the DA20C Manipulator.

1.2 Reference to Other Documentation

For additional information refer to the following:

• NX100 Controller Manual (P/N 149201-1)

• Concurrent I/O Manual (P/N 149230-1)

• Operator’s Manual for your application

• Vendor manuals for system components not manufactured by Motoman

1.3 Customer Service Information

If you are in need of technical assistance, contact the Motoman service staff at (937) 847-3200. Please have

the following information ready before you call:

• Robot Type (DA20C, HP50, etc.)

• Application Type (handling, welding, etc.)

• Robot Serial Number (located on back side of robot arm)

• Robot Sales Order Number (located on back of controller)

Final page 1

Manipulator Manual

Chapter 1 Introduction

Notes

page 2 Final

DA20C

151528-1

Chapter 2

Safety

2.1 Introduction

It is the purchaser’s responsibility to ensure that all local, county, state,

and national codes, regulations, rules, or laws relating to safety and safe

operating conditions for each installation are met and followed.

We suggest that you obtain and review a copy of the ANSI/RIA National Safety Standard for

Industrial Robots and Robot Systems. This information can be obtained from the Robotic Industries

Association by requesting ANSI/RIA R15.06-1999. The address is as follows:

Robotic Industries Association

900 Victors Way

P.O. Box 3724

Ann Arbor, Michigan 48106

TEL: (734) 994-6088

FAX: (734) 994-3338

INTERNET: www.roboticsonline.com

Ultimately, the best safeguard is trained personnel. The user is responsible for providing personnel

who are adequately trained to operate, program, and maintain the robot cell. The robot must not be

operated by personnel who have not been trained!

We recommend that all personnel who intend to operate, program, repair, or use the robot system be

trained in an approved Motoman training course and become familiar with the proper operation of the

system.

Final page 3

Manipulator Manual

Chapter 2 Safety

This safety section addresses the following:

• Standard Conventions (Section 2.2)

• General Safeguarding Tips (Section 2.3)

• Mechanical Safety Devices (Section 2.4)

• Installation Safety (Section 2.5)

• Programming, Operation, and Maintenance Safety (Section 2.6)

2.2 Standard Conventions

This manual includes the following alerts – in descending order of severity – that are essential to the

safety of personnel and equipment. As you read this manual, pay close attention to these alerts to

insure safety when installing, operating, programming, and maintaining this equipment.

DANGER!

Information appearing in a DANGER concerns the protection of personnel from the immediate

and imminent hazards that, if not avoided, will result in immediate, serious personal injury or

loss of life in addition to equipment damage.

WARNING!

Information appearing in a WARNING concerns the protection of personnel and equipment from

potential hazards that can result in personal injury or loss of life in addition to equipment

damage.

CAUTION!

Information appearing in a CAUTION concerns the protection of personnel and equipment,

software, and data from hazards that can result in minor personal injury or equipment damage.

Note: Information appearing in a Note provides additional information which is helpful in understanding the item being

explained.

page 4 Final

DA20C

151528-1

2.3 General Safeguarding Tips

All operators, programmers, plant and tooling engineers, maintenance personnel, supervisors, and

anyone working near the robot must become familiar with the operation of this equipment. All

personnel involved with the operation of the equipment must understand potential dangers of

operation. General safeguarding tips are as follows:

• Improper operation can result in personal injury and/or damage to the equipment. Only

trained personnel familiar with the operation of this robot, the operator's manuals, the system

equipment, and options and accessories should be permitted to operate this robot system.

• Do not enter the robot cell while it is in automatic operation. Programmers must have the

teach pendant when they enter the robot cell.

• Improper connections can damage the robot. All connections must be made within the

standard voltage and current ratings of the robot I/O (Inputs and Outputs).

• The robot must be placed in Emergency Stop (E-STOP) mode whenever it is not in use.

• In accordance with ANSI/RIA R15.06-1999, section 4.2.5, Sources of Energy, use

lockout/tagout procedures during equipment maintenance. Refer also to Section 1910.147

(29CFR, Part 1910), Occupational Safety and Health Standards for General Industry

(OSHA).

2.4 Mechanical Safety Devices

The safe operation of the robot, positioner, auxiliary equipment, and system is ultimately the user's

responsibility. The conditions under which the equipment will be operated safely should be reviewed

by the user. The user must be aware of the various national codes, ANSI/RIA R15.06-1999 safety

standards, and other local codes that may pertain to the installation and use of industrial equipment.

Additional safety measures for personnel and equipment may be required depending on system

installation, operation, and/or location. The following safety equipment is provided as standard:

• Safety fences and barriers

• Light curtains and/or safety mats

• Door interlocks

• Emergency stop palm buttons located on operator station, robot controller, and

programming pendant

Check all safety equipment frequently for proper operation. Repair or replace any non-functioning

safety equipment immediately.

Final page 5

Manipulator Manual

Chapter 2 Safety

2.5 Installation Safety

Safe installation is essential for protection of people and equipment. The following suggestions are

intended to supplement, but not replace, existing federal, local, and state laws and regulations.

Additional safety measures for personnel and equipment may be required depending on system

installation, operation, and/or location. Installation tips are as follows:

• Be sure that only qualified personnel familiar with national codes, local codes, and

ANSI/RIA R15.06-1999 safety standards are permitted to install the equipment.

• Identify the work envelope of each robot with floor markings, signs, and barriers.

• Position all controllers outside the robot work envelope.

• Whenever possible, install safety fences to protect against unauthorized entry into the work

envelope.

• Eliminate areas where personnel might get trapped between a moving robot and other

equipment (pinch points).

• Provide sufficient room inside the workcell to permit safe teaching and maintenance

procedures.

2.6 Programming, Operation, and Maintenance Safety

All operators, programmers, plant and tooling engineers, maintenance personnel, supervisors, and

anyone working near the robot must become familiar with the operation of this equipment. Improper

operation can result in personal injury and/or damage to the equipment. Only trained personnel

familiar with the operation, manuals, electrical design, and equipment interconnections of this robot

should be permitted to program, operate, and maintain the system. All personnel involved with the

operation of the equipment must understand potential dangers of operation.

• Inspect the robot and work envelope to be sure no potentially hazardous conditions exist. Be

sure the area is clean and free of water, oil, debris, etc.

• Be sure that all safeguards are in place. Check all safety equipment for proper operation.

Repair or replace any non-functioning safety equipment immediately.

• Do not enter the robot cell while it is in automatic operation. Be sure that only the person

holding the programming pendant enters the workcell.

• Check the E-STOP button on the programming pendant for proper operation before

programming. The robot must be placed in Emergency Stop (E-STOP) mode whenever it is

not in use.

• Back up all programs and jobs onto suitable media before program changes are made. To

avoid loss of information, programs, or jobs, a backup must always be made before any

service procedures are done and before any changes are made to options, accessories, or

equipment.

page 6 Final

DA20C

151528-1

• Any modifications to PART 1, System Section, of the robot controller concurrent I/O

program can cause severe personal injury or death, as well as damage to the robot! Do not

make any modifications to PART 1, System Section. Making any changes without the written

permission of Motoman will VOID YOUR WARRANTY!

• Some operations require standard passwords and some require special passwords. Special

passwords are for Motoman use only. YOUR WARRANTY WILL BE VOID if you use

these special passwords.

• The robot controller allows modifications of PART 2, User Section, of the concurrent I/O

program and modifications to controller parameters for maximum robot performance. Great

care must be taken when making these modifications. All modifications made to the

controller will change the way the robot operates and can cause severe personal injury or

death, as well as damage the robot and other parts of the system. Double-check all

modifications under every mode of robot operation to ensure that you have not created

hazards or dangerous situations.

• Check and test any new or modified program at low speed for at least one full cycle.

• This equipment has multiple sources of electrical supply. Electrical interconnections are

made between the controller and other equipment. Disconnect and lockout/tagout all

electrical circuits before making any modifications or connections.

• Do not perform any maintenance procedures before reading and understanding the proper

procedures in the appropriate manual.

• Use proper replacement parts.

• Improper connections can damage the robot. All connections must be made within the

standard voltage and current ratings of the robot I/O (Inputs and Outputs).

Final page 7

Manipulator Manual

Chapter 2 Safety

Notes

page 8 Final

YASKAWA

1/59

MOTOMAN-DA20

INSTRUCTIONS

TYPE: YR-DA20-A00 (STANDARD SPECIFICATION)

Upon receipt of the product and prior to initial operation, read these instructions thoroughly, and retain

for future reference.

MOTOMAN INSTRUCTIONS

MOTOMAN-DA20 INSTRUCTIONS

NX100 INSTRUCTIONS

NX100 OPERA TOR’S MANUAL

NX100 MAINTENACE MANUAL

The NX100 operator’s manual above corresponds to specific usage.

Be sure to use the appropriate manual.

YASKAWA

MANUAL NO.

HW0483402

HW0483402

2/59

MANDATORY

• This instruction manual explains operating instructions and maintenance procedures primarily for MOTOMAN-DA20.

• General items related to safety are listed in Section 1: Safety of the

NX100 Instructions. To ensure correct and safe operation, carefully

read the NX100 instructions before reading this manual.

CAUTION

• Some drawings in this manual are shown with the protective covers or

shields removed for clarity. Be sure all covers and shields are replaced

before operating this product.

• The drawings and photos in this manual are representative examples

and differences may exist between them and the delivered product.

• Y ASKAWA may modify this model without notice when necessary due to

product improvements, modifications, or changes in specifications. If

such modification is made, the manual number will also be revised.

• If your copy of the manual is damaged or lost, contact a YASKAWA representative to order a new copy. The representatives are listed on the

back cov er. Be sure to tell the representative the manual number listed

on the front cover.

• YASKAWA is not responsible for incidents arising from unauthorized

modification of its products. Unauthorized modification voids your product’s warranty.

ii

HW0483402

HW0483402

3/59

Notes for Safe Operation

Read this manual carefully before installation, operation, maintenance, or inspection of the

NX100.

In this manual, the Notes for Safe Operation are classified as “WARNING”, “CAUTION”,

“MANDATORY”, or “PROHIBITED”.

Indicates a potentially hazardous situation wh ich, if not avo id ed ,

WARNING

CAUTION

could result in death or serious injury to personnel.

Indicates a potentially hazardous situation wh ich, if not avo id ed ,

could result in minor or moderate injury to personnel and damage to equipment. It may also be used to alert against unsafe

practices.

MANDATORY

PROHIBITED

Even items described as “CAUTION” may result in a serious accident in some situations. At

any rate, be sure to follow these important items.

NOTE

To ensure safe and efficient operation at all times, be sure to follow all instructions, even if

not designated as “CAUTION” and “WARNING”.

Always be sure to follow explicitly the items listed under this

heading.

Must never be performed.

iii

HW0483402

HW0483402

4/59

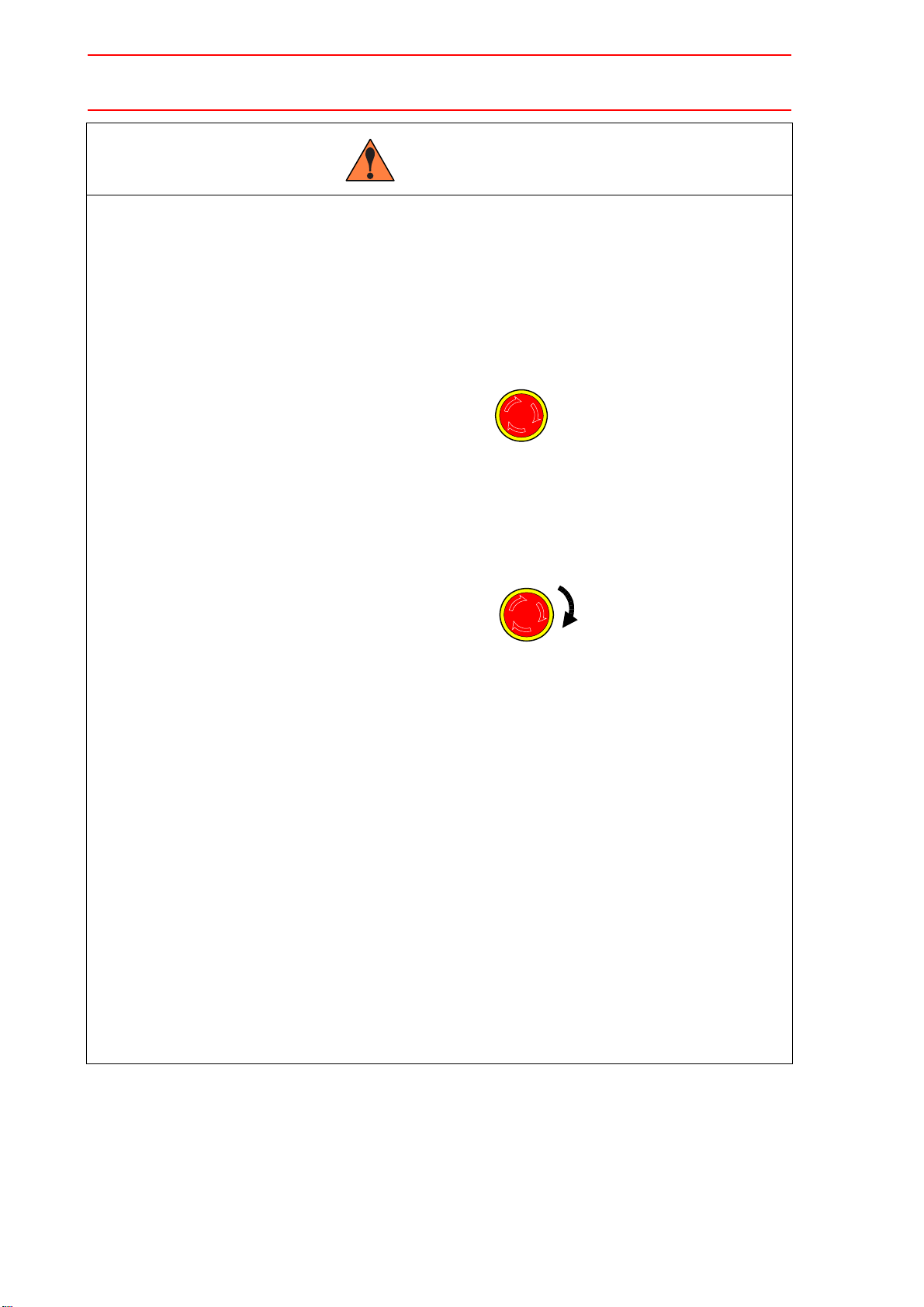

WARNING

• Before operating the manipulator , c heck tha t servo power is turned OFF

when the emergency stop buttons on the front door of the NX100 and

programming pendant are pressed.

When the servo power is turned OFF, the SERVO ON LED on the programming pendant is turned OFF.

Injury or damage to machinery may result if the emergency stop circuit cannot stop the

manipulator during an emergency. The manipulator should not be used if the emergency

stop buttons do not function.

Emergency Stop Button

• Once the emergency stop button is released, clear the cell of all items

which could interfere with the operation of the manipulator. Then turn

ON the servo power.

Injury may result from unintentional or unexpected manipulator motion.

TURN

Release of Emergency Stop

• Observe the following precautions when performing teaching operations

within the working envelope of the manipulator:

- View the manipulator from the front whenever possible.

- Always follow the predetermined operating procedure.

- Ensure that you have a safe place to retreat in case of emergency.

Improper or unintended manipulator operation may result in injury.

• Confirm that no persons are present in the manipulator’s work envelope

and that you are in a safe location before:

- Turning ON the NX100 power.

- Moving the manipulator with the programming pendant.

- Running check operations.

- Performing automatic operations.

Injury may result if anyone enters the working envelope of the manipulator during operation. Always press an emergency stop button immediately if there is a problem. The

emergency stop button is located on the right of the front door of the NX100 and the programming pendant.

iv

HW0483402

HW0483402

5/59

CAUTION

• Perform the following inspection procedures prior to conducting manipulator teaching. If problems are found, repair them immediately , and be

sure that all other necessary processing has been performed.

-Check for problems in manipulator movement.

-Check for damage to insulation and sheathing of external wires.

• Always return the programming pendant to the hook on the NX100 cabinet after use.

The programming pendant can be damaged if it is left in the manipulator’s work area, on

the floor, or near fixtures.

• Read and understand the Explanation of the Warning Labels in the

NX100 instructions before operating the manipulator.

Definition of Terms Used Often in This Manual

The MOTOMAN manipulator is the YASKAWA industrial robot product.

The manipulator usually consists of the controller, the programming pendant, and manipulator

cables.

In this manual, the equipment is designated as follows:

Equipment Manual Designation

NX100 controller NX100

NX100 programming pendant Programming pendant

Cable between the manipulator and the controller Manipulator cable

v

HW0483402

HW0483402

6/59

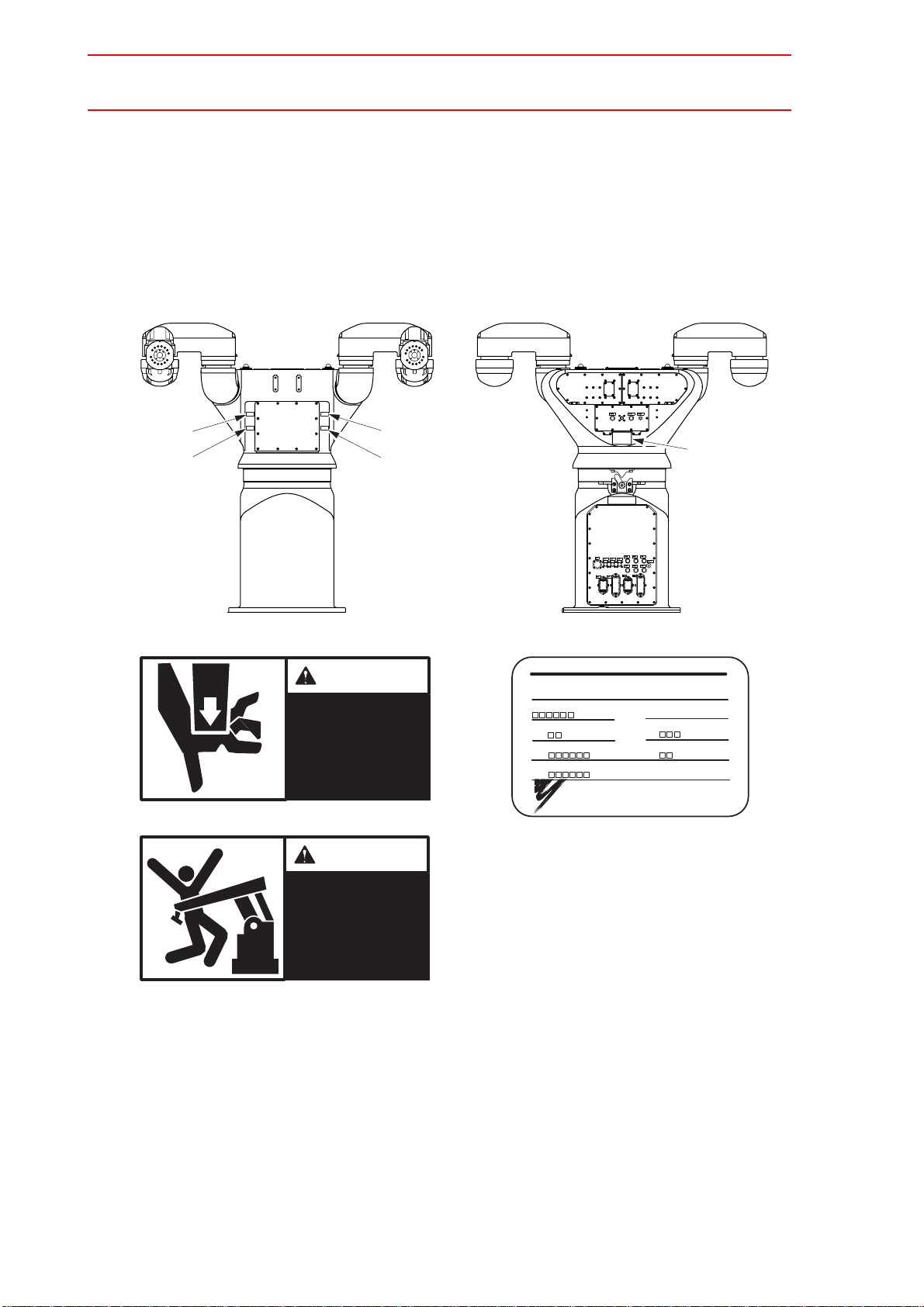

Explanation of Warning Labels

The following warning labels are attached to the manipulator.

Always follow the warnings on the labels.

Also, an identification label with important information is placed on the body of the manipulator. Prior to operating the manipulator, confirm the contents.

Warning label A

Warning label B

Warning Label A:

Warning Label B:

Warning label A

Warning label B

WARNING

Moving parts

may cause

injury

WARNING

Nameplate:

MOTOMAN

TYPE

PAYLOAD

ORDER NO.

SERIAL NO.

YASKAWA ELECTRIC CORPORAION JAPAN

Nameplate

kg

MASS

DATE

kg

Do not enter

robot

work area.

vi

HW0483402

HW0483402

7/59

1 Product Confirmation

1.1 Contents Confirmation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Order Number Confirmation . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 Transporting

2.1 Transporting Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Using a Crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1.2 Using a Forklift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.2 Shipping Bolts and Brackets. . . . . . . . . . . . . . . . . . . . . . . 2-4

3 Installation

3.1 Installation of the Safeguarding . . . . . . . . . . . . . . . . . . . . 3-2

3.2 Mounting Procedures for Manipulator Base . . . . . . . . 3-2

3.2.1 Mounting Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.3 Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

4 Wiring

4.1 Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Manipulator Cable Connection. . . . . . . . . . . . . . . . . . . . . 4-2

4.2.1 Connection to the Manipulator. . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.2.2 Connection to the NX100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

5 Basic Specifications

5.1 Basic Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Part Names and Working Axes . . . . . . . . . . . . . . . . . . . . 5-2

5.3 Manipulator Base Dimensions . . . . . . . . . . . . . . . . . . . . . 5-3

5.4 Dimensions and P-Point Maximum Envelope . . . . . . 5-4

5.5 Alterable Operating Range . . . . . . . . . . . . . . . . . . . . . . . . 5-5

6 Allowable Load for Wrist Axis and Wrist Flange

6.1 Allowable Wrist Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Wrist Flange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

vii

HW0483402

8/59

7 System Application

7.1 Peripheral Equipment Mounts . . . . . . . . . . . . . . . . . . . . . .7-1

7.2 Internal User I/O Wiring Harness and Air Line . . . . . .7-2

8 Electrical Equipment Specification

8.1 Internal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

9 Maintenance and Inspection

9.1 Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.2 Notes on Maintenance Procedures. . . . . . . . . . . . . . . . .9-5

9.2.1 Battery Pack Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.2.2 Batteries in NX100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.2.3 Grease Replenishment/Exchange for Rotation-Axis

Speed Reducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Grease Replenishment (Refer to " Fig. 23 Grease

Inlet and Grease Exhaust Port for the Rotation-Axis

Speed Reducer ".) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Grease Exchange (Refer to " Fig. 23 Grease Inlet

and Grease Exhaust Port for the Rotation-Axis Speed

Reducer ".) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.2.4 Grease Replenishment for S-, L-, U-, R-, B-, T-axis

Actuators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Grease Replenishment of Each Actuator (Refer to

" Fig. 24 Grease Inlets and Grease Exhaust Ports

for the S-, L-, U-, R-, B-, T-Axis Actuators ".) . . . . . . . . . . 9-10

9.2.5 Actuator Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Actuator Replacement

(Example of the B-Axis Replacement Procedure) . . . . . . .9-12

9.2.6 Interface Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

9.2.7 Brake Driver Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Alarm Causes and Corrective Actions . . . . . . . . . . . . . . . .9-16

HW0483402

10 Recommended Spare Parts

viii

HW0483402

HW0483402

9/59

1.1 Contents Confirmation

1 Product Confirmation

CAUTION

• Confirm that the manipulator and the NX100 have the same order number. Special care must be taken when more than one manipulator is to

be installed.

If the numbers do not match, manipulators may not perform as expected and cause injury

or damage.

1.1 Contents Confirmation

Confirm the contents of the delivery when the product arrives.

Standard delivery includes the following four items (Information for the content of optional

goods is given separately):

• Manipulator

• NX100

• Programming Pendant

• Manipulator Cables (Three cables, between manipulator and NX100)

1-1

HW0483402

HW0483402

SELECT

10/59

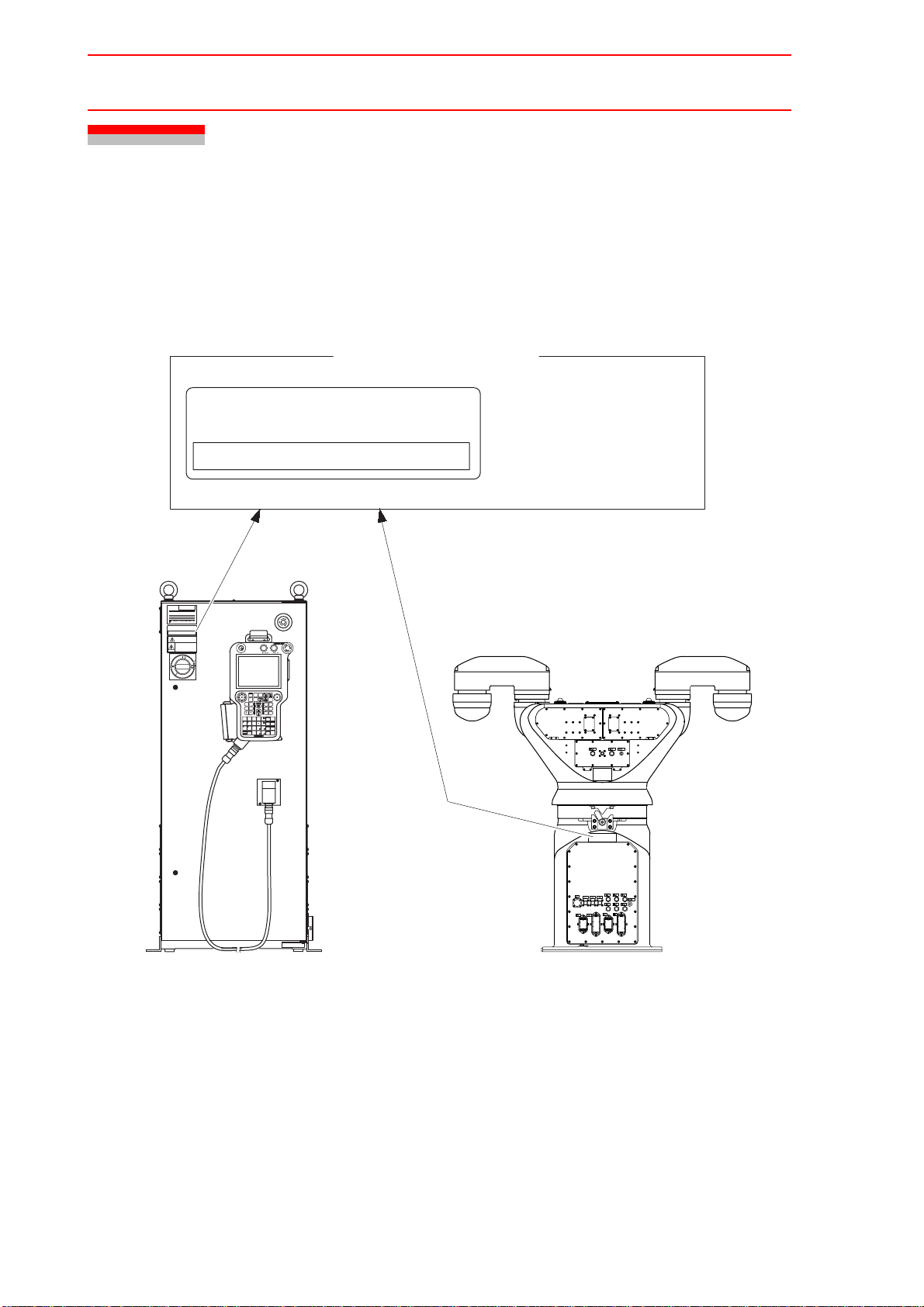

1.2 Order Number Confirmation

1.2 Order Number Confirmation

Check that the order number of the manipulator corresponds to the NX100. The order number

is located on a label as shown below.

Label (Enlarged View)

THE MANIPULATOR AND THE CONTROLLER

SHOULD HAVE SAME ORDER NUMBER.

ORDER. No.

NX100

******

TYPE

ERCR-

POWER SUPPLY

200V 50Hz

SERIAL No.

DATE

THE MANIPULATOR AND THE CONTROLLER

SHOULD HAVE SAME ORDER NUMBER.

ORDER NO.

WARNING

Do not open the door

ON

TRIPPED

OFF

RESET

kVA3PHASE220V 50/60Hz

NJ2484-1MADE IN JAPAN

NJ1529

REMOTE

G

E

R

N

E

C

M

Y

E

S

P

T

O

TEACH

PLAY

SERVO

MULTI

COORD.

DISPLAY

POWER

SWITCH

SELECT

SELECT

MAIN

SHORTCUT

ASSIST

MENU

MENU

x

X-

S-X+S+

R-xR+

yy

Y+Y-

B+B-

L+L-

z

+

z

-

R+

T-

T+

R-

INTER

7

8

9

SHIFT

SHIFT

WEAVING

WELD

TEST RUN

LOCK

FEED

START

START

645

ROBOT

WELD

WEAVING

AUXILIARY

NEXT

BACK

COMPLETE

RETRUCT

COMPLETE

SWITCH

1

2

3

EX-AXIS

AUXILIARY

DELETE

INSERT

CURRENT

TIMER

VOLTAGE

SWITCH

.

0

-

CABCEK

ENTER

REF.

INTER.

MODIFY

VOLTAGE

CURRENT

POINT

Check that the manipulator

and the NX100 have the

same order number.

NX100 (Front View) Manipulator (Back View)

Fig. 1 Location of Order Number Labels

1-2

HW0483402

HW0483402

11/59

2.1 Transporting Method

2 Transporting

CAUTION

• Sling applications and crane or forklift operations must be performed by

authorized personnel only.

Failure to observe this caution may result in injury or damage.

• Avoid excessive vibration or shock during transporting.

Failure to observe this caution may adversely affect the performance as the system consists of precision components.

2.1 Transporting Method

• Before transporting the manipulator, check if the eyebolts are firmly fixed to the manipu-

NOTE

2.1.1 Using a Crane

As a rule, when removing the manipulator from the package and moving it, a crane should be

used. The manipulator should be lifted using wire rope threaded through shipping bolts and

brackets. Be sure the manipulator is fixed with the shipping bolts and brackets before the

transportation, and lift it in the posture as shown in " Fig. 2 Posture for Transportation ".

lator.

• The weight of the manipulator is approximately 240 kg including the shipping bolts and

brackets. Use a wire rope strong enough to withstand the weight.

• Be sure to mount the shipping bolts and brackets to transport the manipulator shown in

" Fig. 4 Shipping Bolts and Brackets ".

The shipping bolts and brackets are designe d to transport the manipulator: do not use

them for anything other than transporting the manipulator.

• When transporting the manipulator with transportation equipment other than a crane or

forklift, make sure to avoid external force on the arm or motor unit as in the case of transportation with a crane or forklift.

2-1

HW0483402

Loading...

Loading...