Page 1

4/10/2021 2013 Buick Verano • MotoLogic

https://www.motologic.com/car/2013_buick_verano_3779/article/50d8772d512f03e4187788c432470fdb?returnPath=%2Fcar%2F2013_buick_verano_

…

Report a problem with this article

DTC P0010, P0013, or P2088-P2091

Applies to:

2.4L (LEA)

Diagnostic Instructions

Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

Review Strategy Based Diagnosis for an overview of the diagnostic approach.

Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC P0010

Intake Camshaft Position Actuator Solenoid Valve Control Circuit

DTC P0013

Exhaust Camshaft Position Actuator Solenoid Valve Control Circuit

DTC P2088

Intake Camshaft Position (CMP) Actuator Solenoid Control Circuit Low Voltage

DTC P2089

Intake Camshaft Position (CMP) Actuator Solenoid Control Circuit High Voltage

DTC P2090

Exhaust Camshaft Position (CMP) Actuator Solenoid Control Circuit Low Voltage

DTC P2091

Exhaust Camshaft Position (CMP) Actuator Solenoid Control Circuit High Voltage

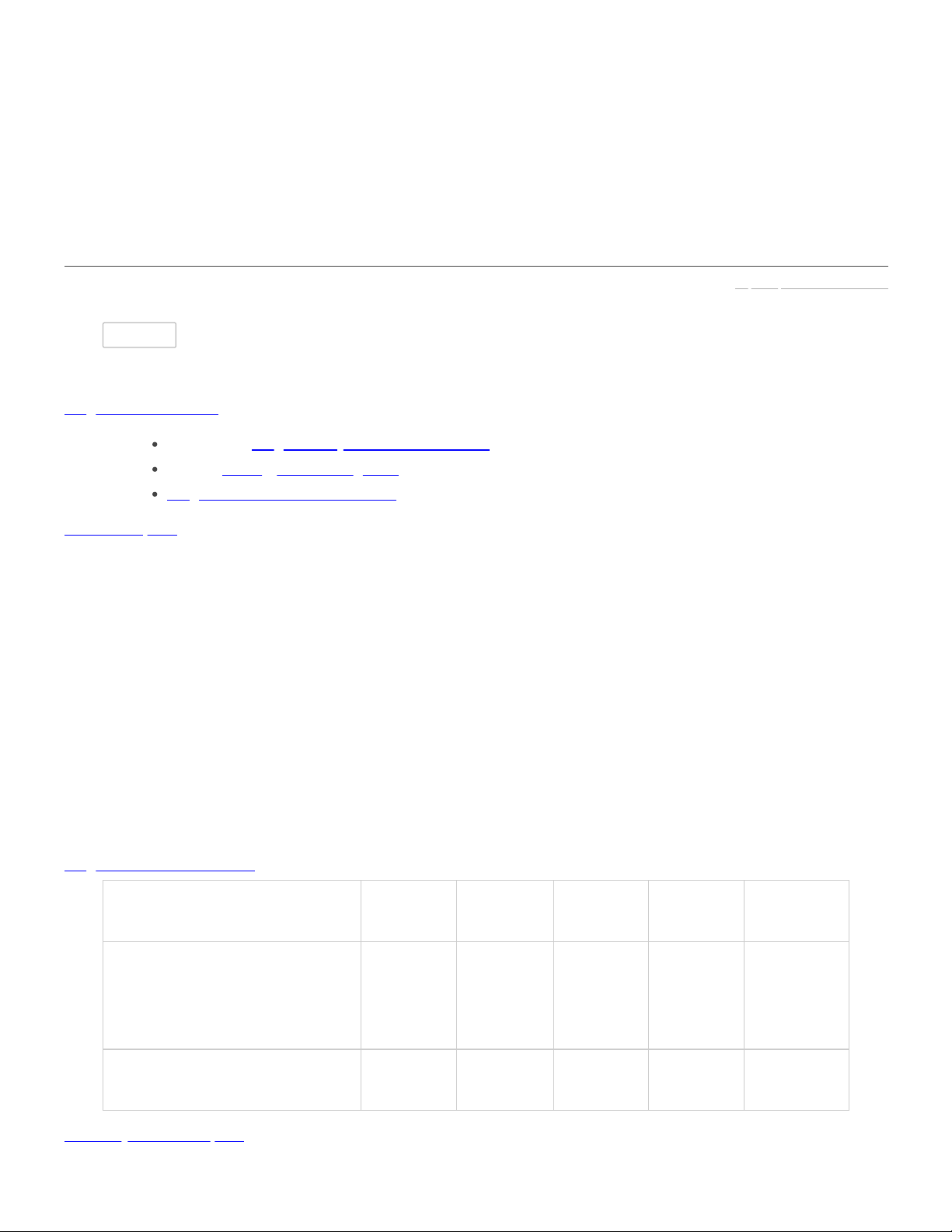

Diagnostic Fault Information

Circuit

Short to

Ground

High

Resistance Open

Short to

Voltage

Signal

Performance

Camshaft Position Actuator

Solenoid Valve High Control

P0010,

P0013,

P2088,

P2090

P0010,

P0013

P0010,

P0013

P0010,

P0013,

P2089,

P2091

P0011,

P0014

Camshaft Position Actuator

Solenoid Valve Low Reference

—

P0010,

P0013

P0010,

P0013

— —

Circuit/System Description

1/5

Page 2

4/10/2021 2013 Buick Verano • MotoLogic

https://www.motologic.com/car/2013_buick_verano_3779/article/50d8772d512f03e4187788c432470fdb?returnPath=%2Fcar%2F2013_buick_verano_

…

The camshaft position actuator system enables the engine control module (ECM) to change the timing of the

camshafts while the engine is operating. The camshaft position actuator solenoid valve signal from the ECM is

pulse width modulated (PWM). The ECM controls the camshaft position actuator solenoid valve duty cycle by

controlling the amount of solenoid valve On time. The camshaft position actuator solenoid valve controls the

advance or the retard of each camshaft. The camshaft position actuator solenoid valve controls the oil flow that

applies the pressure to advance or retard the camshafts.

The ECM controls the camshaft position actuator solenoid valve by suppling a 12 V pulse width modulated (PWM)

signal. The ECM supplies a ground to the low reference circuit.

Conditions for Running the DTC

The ignition voltage is greater than 11 V.

The ECM has commanded the camshaft position actuator solenoid valve On.

The DTCs run continuously once the above conditions are met.

Conditions for Setting the DTC

The ECM detects that the commanded state of the driver and the actual state of the control circuit do not match for

greater than 5 s.

Action Taken When the DTC Sets

DTCs P0010, P0013 and P2088 - P2091 are type B DTCs.

Conditions for Clearing the DTC

DTCs P0010, P0013 and P2088 - P2091 are type B DTCs.

Diagnostic Aids

If the condition is intermittent, move the related harnesses and connectors, with the engine operating, while

monitoring the scan tool Circuit Test Status parameters for the component. The Circuit Test Status parameters

change from OK or Not Run to Malfunction if there is a condition with the circuit or a connection.

Reference Information

Schematic Reference

Engine Controls Schematics

Connector End View Reference

Component Connector End Views

Component View Reference

Powertrain Component Views

Description and Operation

Camshaft Actuator System Description

Electrical Information Reference

Circuit Testing

Connector Repairs

Testing for Intermittent Conditions and Poor Connections

Wiring Repairs

2/5

Page 3

4/10/2021 2013 Buick Verano • MotoLogic

https://www.motologic.com/car/2013_buick_verano_3779/article/50d8772d512f03e4187788c432470fdb?returnPath=%2Fcar%2F2013_buick_verano_

…

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

Note: If a crankshaft or camshaft position sensor DTC is set, the Camshaft Position Actuator output

control will not function.

1. Ignition On.

2. Verify DTC P0335, P0336, P0340, or P0341 is not set.

If any of the DTCs are set

If any of the DTCs are set, refer to Diagnostic Trouble Code (DTC) List - Vehicle

If none of the DTCs are set

Observe the appropriate control circuit status parameters listed below with a scan tool:

Camshaft Position Actuator Solenoid Valve Control Circuit Open test status

Camshaft Position Actuator Solenoid Valve Control Circuit High Voltage test status

Camshaft Position Actuator Solenoid Valve Control Circuit Low Voltage test status

If Malfunction is displayed

Refer to Circuit/System Testing

If Malfunction is not displayed

Engine idling at normal operating temperature.

Verify the scan tool parameters listed below do not display Malfunction when commanding the appropriate scan

tool Camshaft Position Actuator from 0–20° and back to 0° with a scan tool:

Camshaft Position Actuator Solenoid Valve Control Circuit Open test status

Camshaft Position Actuator Solenoid Valve Control Circuit High Voltage test status

Camshaft Position Actuator Solenoid Valve Control Circuit Low Voltage test status

If Malfunction is displayed

Refer to Circuit/System Testing.

If Malfunction is not displayed

Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the

conditions that you observed from the Freeze Frame/Failure Records data.

Verify the DTC does not set.

If the DTC sets

Refer to Circuit/System Testing.

If the DTC does not set

All OK.

3/5

Page 4

4/10/2021 2013 Buick Verano • MotoLogic

https://www.motologic.com/car/2013_buick_verano_3779/article/50d8772d512f03e4187788c432470fdb?returnPath=%2Fcar%2F2013_buick_verano_

…

Circuit/System Testing

1. Ignition Off and all vehicle systems Off, disconnect the harness connector at the appropriate Q6 Camshaft

Position Actuator Solenoid Valve. It may take up to 2 minutes for all vehicle systems to power down.

2. Test for less than 5 Ω between the low reference circuit terminal B or 2 and ground.

If 5 Ω or greater

1. Ignition Off, disconnect the harness connector at the K20 Engine Control Module.

2. Test for less than 2 Ω in the low reference circuit end to end.

If 2 Ω or greater, repair the open/high resistance in the circuit.

If less than 2 Ω, replace the K20 Engine Control Module.

If less than 5 Ω

Ignition On.

Note: A test lamp must be used for this test. The control circuit is pulled-up to a low current voltage, 1.5–3.5 V on

the control circuit is normal.

Verify that a test lamp does not illuminate between the control circuit terminal A or 1 and ground.

If the test lamp illuminates

1. Ignition Off, disconnect the harness connector at the K20 Engine Control Module, ignition On.

2. Test for less than 1 V between the control circuit and ground.

If 1 V or greater, repair the short to voltage on the circuit.

If less than 1 V, replace the K20 Engine Control Module.

If the test lamp does not illuminate

Remove the test lamp.

Connect the DMM black lead to the control circuit terminal A or 1. Connect the DMM red lead to B+. Set the

DMM on the diode setting. Command the CMP actuator solenoid On and Off with a scan tool. The DMM should

transition from OL when commanded Off to less than 1 V when commanded On.

If the circuit voltage does not correspond to the specified values

1. Ignition Off, disconnect the harness connector at the K20 Engine Control Module.

2. Test for less than 2 Ω in the control circuit end to end.

If 2 Ω or greater, repair the open/high resistance or short to ground in the circuit

If less than 2 Ω, replace the K20 Engine Control Module.

If the circuit voltage corresponds to the specified values

Test or replace the Q6 Camshaft Position Actuator Solenoid Valve.

Component Testing

1. Ignition Off, disconnect the harness connector at the appropriate Q6 Camshaft Position Actuator Solenoid

Valve.

2. Test for 8–13 Ω between the control terminal A or 1 and the low reference circuit terminal B or 2

If not between 8-13 Ω

Replace the Q6 Camshaft Position Actuator Solenoid Valve.

4/5

Page 5

4/10/2021 2013 Buick Verano • MotoLogic

https://www.motologic.com/car/2013_buick_verano_3779/article/50d8772d512f03e4187788c432470fdb?returnPath=%2Fcar%2F2013_buick_verano_

…

If between 8-13 Ω

Test for infinite resistance between each terminal and the Q6 Camshaft Position Actuator Solenoid Valve

housing.

If not infinite resistance

Replace the Q6 Camshaft Position Actuator Solenoid Valve.

If infinite resistance

All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

Camshaft Position Actuator Solenoid Valve Replacement

Control Module References for ECM replacement, programming, and setup

5/5

Loading...

Loading...