MOTO GUZZI ambassador V 750 User Manual

Ambassadol'

rider's

handbook

Ambassador

V

750

RIDER

' S

HANDBOOK

2

INTRODUCTION This booklet

is

intended

to

provide owners

with the necessary information on

oper

ating

and

maintaining their machines for maximum

efficiency.

The manual

should be read very carefully

as

most troubles

and

failures arising from

neglect

or

poor

maintenance will be avoided

if

all the instructions herein contained

are

strictly followed.

Don't forget that all

major

overhaul jobs

and

repairs

are

best carried

out

by officially

appointed Moto Guzzi dealers

who

have the

necessary facilities to quickly

and

competen.

tly repair

your

Moto Guzzi.

IN

D E X

Running

in

Controls and accessories

Identification

data

Tool kit

Main features

_ Engine

Frame

Instr

uments

and

controls

Ignition key

Starting

button

Ignition swit

ch

keys

Steering lock

Steering

lock keys

Dimmer switch

and

horn

button

Clutch lever

Twist grip

throttle

control

Air

lever

Gearshift lever

Front

brake

lever

Rear

brake

pedal

Riding instructions

lubrication

chart

lubrication

and

general mainte-

nance

Servicing instructions

lubrication

of

engine

Oil pressure relief valve

Oil

pressure gauge

lubrication

of transmission

lubrication

of

rear

wheel drive

lubrication

of fr

ont

fork and hy-

draulic

dampers

lubrication

of bevels in

the

stee~

ring

....

~~

p,,.

5

•

6

•

JO

•

11

•

12

•

16

•

18

•

19

•

19

•

20

•

20

•

20

•

20

•

20

•

20

•

21

•

21

•

21

•

21

•

22

•

25

•

27

•

29

•

29

•

31

•

31

•

31

•

32

•

33

•

33

3

4

Lubrication of whee! bearings

Lubrication of rear fork bearings

C(!rburation

Air filter

Fuel

tank

Fuel

taps

Mufflers

Valve

gearing

Tappet clearance

Checking

valve riming

Ignition

Distributor

Spark plugs

Checking of ignition timing

Checking

of

ignition advance by

stroboscope lamp

Adjustments

Generator

belt

Clutch

lever

Steering

Steering lock

Front brake lever

Rear brake pedal

Rear

suspension units

Removal of wheels

Front wheel

Rear wheel

Electrical equipment

Wiring diagram -

USA

model

Wiring diagram - European model

p~

ge

33

•

33

• 35

•

40

•

40

•

41

•

42

•

43

•

43

•

43

•

46

•

46

•

47

•

47

•

48

•

51

•

51

•

51

•

51

• 54

• 55

•

57

•

57

•

60

•

60

• 60

• 62

•

71

• 72

RUNNING

IN

After the

first 500 kms.

(300 miles )

Every 500 kms.

(300 mile

s)

"5iiJ

-

~

During the first 1600 kms.

(1000

miles),

a

new

or

overhauled machine ough t to

be

used

with some

intelligence as the efficiency, per-

formance, and life

of

the engine are largely

dependant on how it

is

run in.

The engine

should never be allowed to reach

a high

number

of revolutions before it has

had a chance to

warm

up sufficiently. Never

ride the machine

at

the highest permissible

speeds for each gear before the machine has

been

well broken in.

Should th eengine speed drop off considerably on an uphill grade, a lower gear should

be immediately engaged.

In

case

of

overhea-

ting,

it

is

best to st

op

and allow the engine

to

cool down.

Under no circumstances whatever

should the

following speeds be exceeded

in

the running

in

period.

Maximum permissible

speeds:

Distance: up to 800 kms.

(500

miles):

in

low gear

45

kms.

(28

miles)

in

second gear

65

kms.

(40.5

miles)

in

third gear

85

kms.

(53

mile})

in

high gear 110 kms.

(68

miles')

from

800 to 1600 kms.

(500

to 1000

miles):

in

low ge(!( 55 kms.

(34.5

miles)

in

second gear 80 kms.

(50

miles)

in

third gear 105 kms.

(65

miles)

in

high gear 135 kms.

(84

miles)

From 1600 to 3000 kms.

(1000

to 1

800

miles) the speed can

be

gradually increased

up to the maximum permissible limits.

Change the engine

oil.

Tighten all nuts and bolts.

Check valve clearance.

Check

distributor

points.

Check

oil level. Correct level

is

in betwEIen

the minimum and maximum mark on the

filler

cap

dipstick.

5

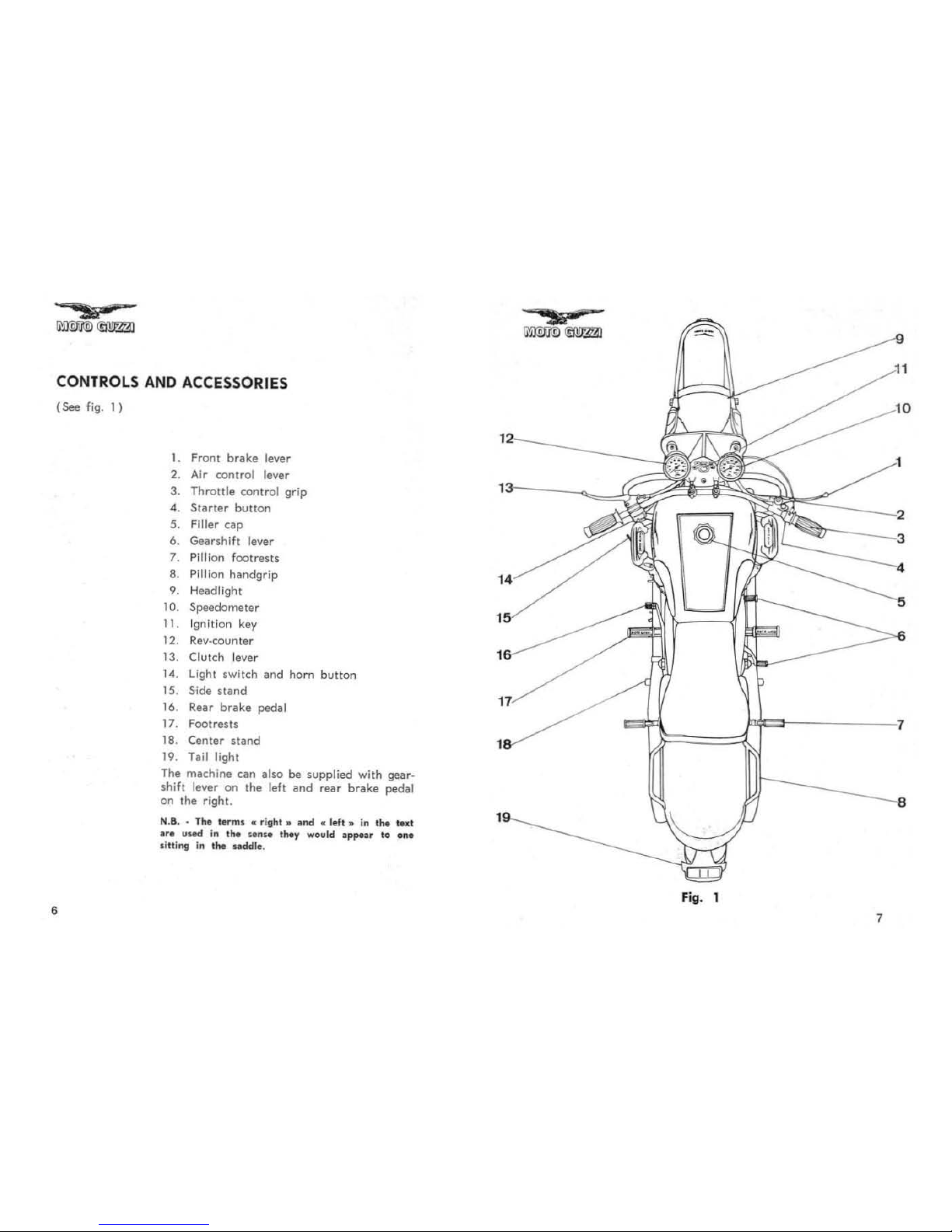

CONTROLS AND ACCESSORIES

(See

fig. I )

•

1. Front

brake

lever

2. Air control lever

3.

Throttle

control

grip

4.

Slarter

button

5. Filler

cap

6. Gearshift lever

7. Pillion footrests

8. Pillion handgrip

9. Headlight

10. Speedometer

11. Ignition key

12. Rev-counter

13.

Clutch lever

14.

light

switch

and

horn

button

15

. Side

stand

16. Rear

brake

pedal

17

. Footrests

18. Center

sland

19. Tail light

The machine can also be supplied with gearshift leve r

on

the

left

and

rear

brake

pedal!

on

the

right.

N.B, •

TIM I ...

ml

... right

" a

nd

• 1ft, ,, In

,he

lui

If.

uo.-d In 1M

.. n ..

t

...

.,

would

app-a. 10

one

IIUi",

In ,

...

udell

•.

1

tt<:"'--"

- 2

~

---

3

::-----

4

14

5

15

16

17

1

Fig

. 1

7

8

9

Identification

data

(See

fig.

4)

10

Every machine

is

identified with a serial num-

ber which

is

stamped on the frame down tube

end

on

the left hend crankcase cover.

Fig

. 4

Tool kit

(See fig.

5)

1.

Box

wrench, 19-21-22 mm.

2.

Open ended wrench, 17-19 mm.

3.

Open ended wrench, 10·11 mm.

4. Tappet adjusting wrench

5.

Box

wrench, 8-9

mm.

6. Allen

key

(5

hex)

7.

Box

wrench, 10·14 mm.

8. Universal pliers

9. Adjustable wrench

10. Screwdriver

11. Ring wrench, 27 mm.

12. Rear

damper

adjusting wrench

13.

Tool

bag

Fig.

5

11

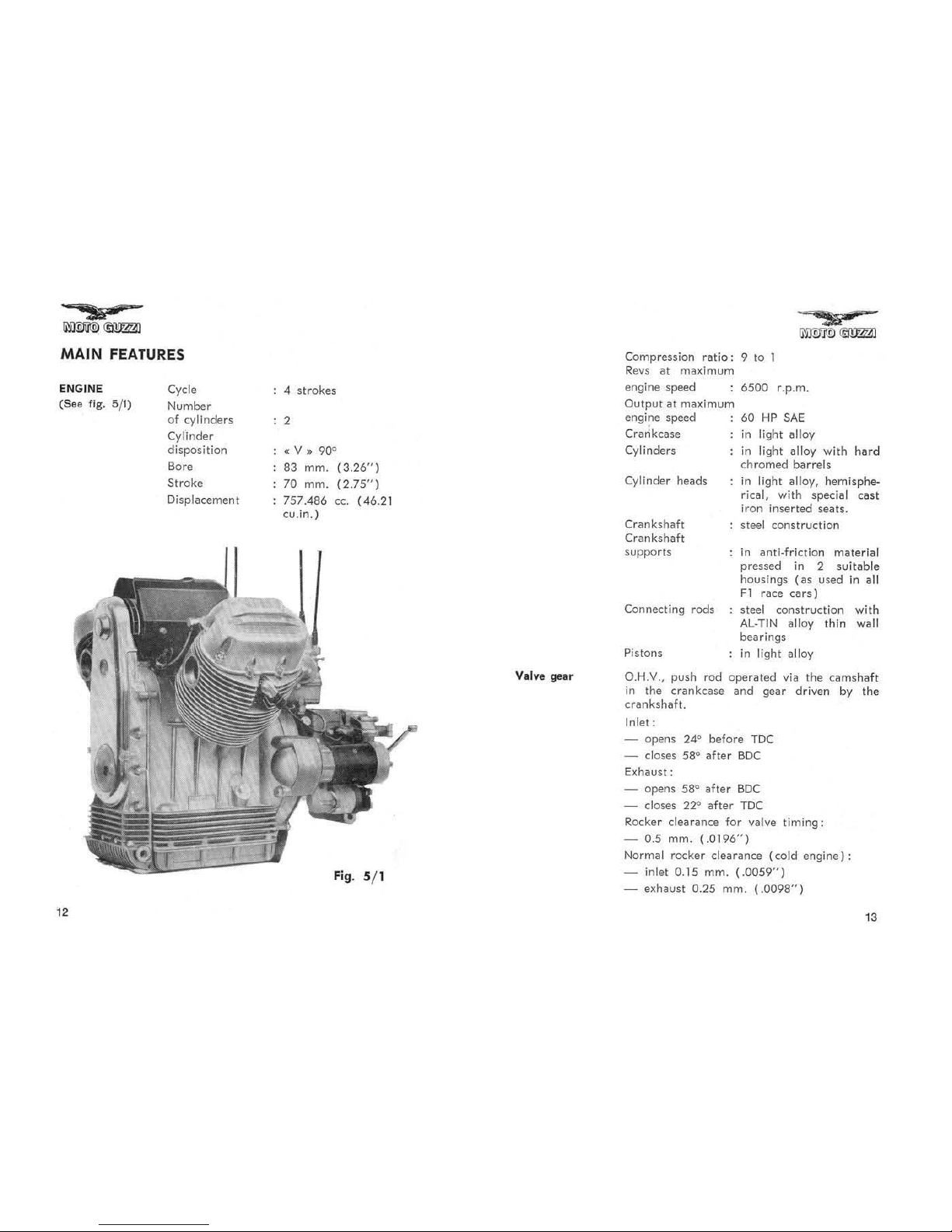

MAIN

FEATURES

ENGINE

(Sea

fig.

5/1)

12

Cycle

Number

of cyli nders

Cylinder

dispo

sition

Bore

Stroke

Displa~emenl

4

strokes

,

«v,. 90"

83

mm

.

(3.26")

70

mm.

(2.75

" )

757.486

ce.

( 46.21

cll.in.)

Fig

. 5/ 1

Valve gear

Compression

ratio:

9 to 1

Re

vs

at

maximum

engine speed 6500 r.p.m.

Output at

mi)Kimum

engine speed

Crankcase

Cylinders

Cylinder

heads

Crankshaft

Crankshaft

supports

Conne<:ting rods

Pistons

60

HP

5AE

in

ligh t

alloy

in light alloy

with

hard

chr

omed barrels

in

light

alloy,

hemisphe-

rical, with special cast

iron

inserted

seats.

steel construction

in

anti·friction

mate

rial

pressed

in 2

suitable

housings

(as

used

in all

Fl

race car

s)

steel construction with

AL·TIN alloy

thin wall

bearings

in

light

alloy

O.H.v., push

rod

operated

via

the

camshaf

t

in

the crankcase

and

gear driven by

the

crankshaft.

Inlet:

- opens 24

<>

before

Toe

- closes

58

<>

after

BOC

E)(haust:

- opens

58" after

BDC

- closes 22'"

after

TDC

Rocker clearance for valve

timing:

-

0.5

mm.

(.0196")

Normal rocker clearance

(co

ld

engine):

inlet

0.15

mm.

(.0059")

- e)(haust

0.25

mm.

(.0098")

Lubrication

Cooling

Ignilion

14

2 DeIl'Orto

carburetors

type

VHB

29

CD

(right)

and

VHB

29

CS

(left)

both gravity

fed

from

the

tank.

Standard carburetor

$etting

Ch

oke

29

mm.

Throttle

slide

60

- Atomizer

265

- Main jet 1

45

- Pilot jet

45

-

Starter

atomizer

80

With needle SV9 set

at

second notch from

top:

idling screw open I

and

112

turns

for

the

left

carburetor

and I and

3

n

.

2

turns

for the right

carburetor.

With needle SV5 third notch from

top:

idling screw open

1

1f~

to 2

turns

for the

left

carburetor

and

2.2112

turns

for the right

carburetor.

Air intake provided with

dry fil

ler

.

Pressure, by gear

pump

driven by

the

crank-

shaft.

Oil

strainer

in

crankcase.

No

rmal lubrication

pressure

3.8·4.2

kgs/sq.

cm.

(54

to

60

Ibs sq.in.) controlled by relief

villive.

Electrically controlled oil

pressure

gauge.

By

air. Cylinder

and

cylinder head deeply

finned.

By

battery

with

automatic

advance distri-

butor.

Initial

advance:

10".

Automatic advillnce: 28".

Ignition

timing 38" full advance.

Starting

Exh

aust system

TRANSMISSION

Clutch

Gear box

Se<o

ndary

drive

Contact

breaker

gap:

0.42-0.48 mm.

(.016"-

.0IS·').

Spark

plug:

n. 225

in

Bosch-Marelli scale o r

equivalent_

Plugs

point

gap:

0.6 mm.

(.023")

Ignitioo coil.

Electric

starter

with

electromagnetic ratchet

control.

Ring

gear

bolted

on

flwheel.

Operated

by

sta

rter

button.

Dual exhaust pipes

and

mufflers.

Twin driven plates, d ry

type, locillted on the

flywheel.

Controlled by lever

on left

hand-

lebar.

Four speeds, frontal engagement.

Conslllnt

mesh gears. Cush drive incorporated.

Separate case bolted

on

crankcllsfI, ope

rated

by

rocker pedal on

the

right side of

the

machine.

Engine gear-box

ratio:

Inlernal gear

ratios:

-

Low

gear

-

Serond

gear

- Third gear .

- High gear

to 1.375

(16-22)

to 2.230

(13·29)

to

1.333

(18·24)

to 0.954

(22·21)

to 0.750

(24-18)

By

constant speed double joint

cardan

shaft

lllyshaft

bevel gears-rear wheel

ratio:

Overall gear

ralios:

-

Low

gear .

-

Serond gear

- Third gear

- High

gear

_

4.375

(8-35)

to 13.4

15

to

8.0

18

10

5.738

to

4.511

15

ijljW1!l

®m

FRAME

Suspension

Wheels

Tires

Tire

pressure

Brakes

Overall

dimensions

and weight

16

Duplex cradle, tubular structure.

Telescopic front fork incorporating hydrauli c

dampers.

Rear swinging fork with externally adjustable

springs.

18)(3

rims, front and rear.

4.00)(18 front and rear, block type (high

speed).

Front

tire:

solo

p<lssenger !

with

1.5 kgs/sq.cm. =

21

p.s.i.

Rear

tire:

solo

with passenger

1.8 kgs/sq.cm. = 25 p.s.i.

2.0 kgs/sq.cm. = 28 p.s.i.

N.S ..

The

~bove

recommendat ion is for

norm

at

riding (

uui

sing

spee

d ).

If

using

the

machi

ne

~

t

co n. lant high

speed

Or

On

motorw

l y" , the

~

bov

e

pr

euure.

should

be incr

eao

ed

by 0 .2 kg

./lq.cm

.

( 2.8 p

.•.

i.

J.

Twin leading shoes front brake operated by

hand lever

on

the right handlebar.

Large rear

brake

opera t

ed

on left hand side

of machine.

Wheelbase

1.470 mts. (about 57.8"

Length

2.245 mts.

{about

88.3"'

Width

0.830 mts.

(about

32.6"

Height

(

dry)

1.070

mts.

(about 42.1"

Minimum ground

clearance 0.150 mts.

(abou t

5.9"

Curb weight

228

kgs.

(about

502 Ibs.)

Performance

Maximum permissible speeds and gradie nts

climbable

in

each gear, solo riding.

Low

gear:

62

kms/h

( 38.5

m.p.h.)

climbing ability:

90%

Second

gear:

104.250

kms/h

(64

.6 m.p.h .

climbing ability:

40%

Third

gear:

145.250

kms/h

(89.2

m.p.h . )

climbing ability:

20%

High

gear:

185.276

kms/h

(liS

m.p.h . )

climbing ability:

8%

Fuel consumption Measured according to

CUNA

standards:

37 m.p.g. (US).

Fuel .

Hld

oil

Fuel

tank:

22.5 liters

(5.84

US

gls.) inclu-

ca

pacities ding about 4 liters reserve

(about 1 US

gl.).

Petrol 98

NO

(Regular

octane) -Sump

3 liters

(31j-l

quarts)

Shell Super Motor Oil 100 -

Transmission

0.750 liters

(1 % pints)

Shell

Spirax 90 E.P. -

Re<lr

wheel drive 0.300 liters

(5/8

pints) Shell Spirax 90

E.P.

- Front fork

dampers

0.160 liters = 5.4 oz

US

Shell Tel-

lux 33.

17

,.....

IID:!li\!)

C!I!m

INSTRUMENTS AND CONTROLS

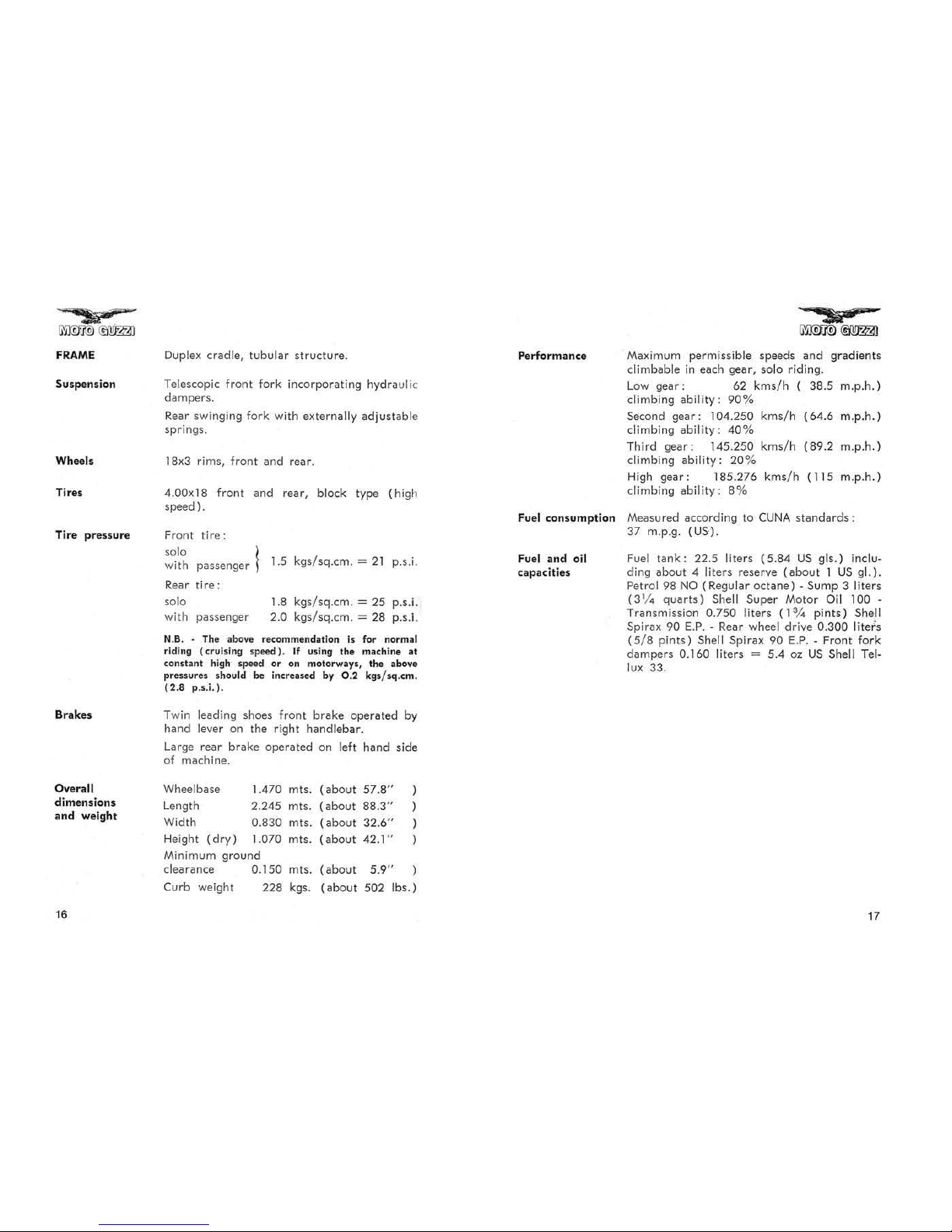

Instrument

panel

(See

fig.

6)

,.

1.

Speedometer.

2.

Town

driving

light

(green),

3.

Red

warning

light

indicating

insufficient

fl

ow

of

current

from

generator

for bal-

tery charge. Should

go

out

when the en-

gine has reached

it

certa

in number

of

revolutions.

4. Orange. This

is

the

neutral

indicato r light.

Is

nOI

lighted when

IIny

gear

is

engaged.

S.

Red

warning

light. Oil

pressure

gauge.

Will go

out

when o

il

pressure

for normal

engine operation

is

sufficient.

6.

Rev

olutio

n counter.

Fig

. 6

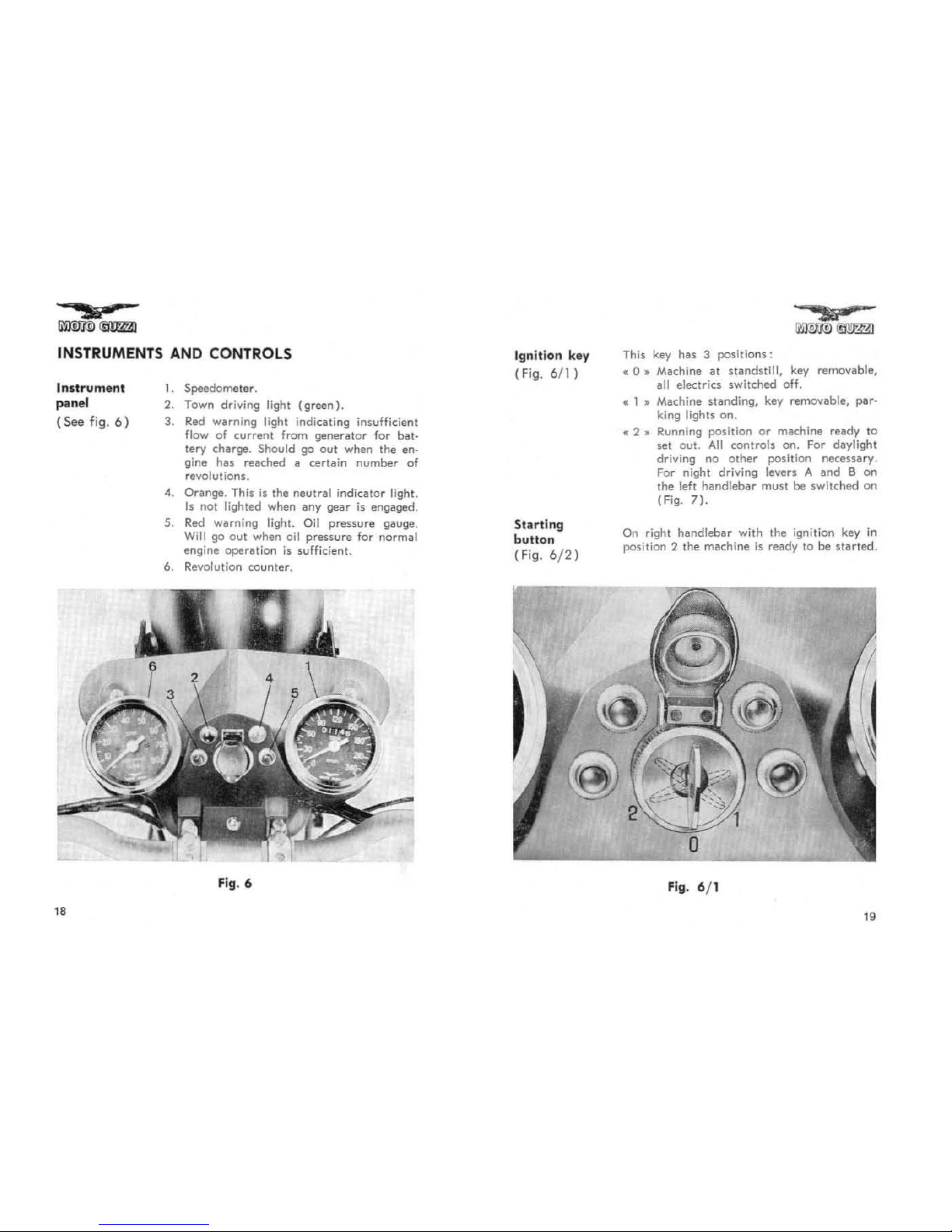

Ignition key

(Fig.

6/1)

Starting

button

(F;9. 6/

2)

This key has 3

positions:

«

0"

Machine at

standstill,

key removable.

i!l1I

electrics switched off.

c I

11

Machine standing, key removable, par-

king

lighls

on.

• 2 " Running

position

or

machine ready

10

set out.

All

controls on. For daylight

driving no

other

position ne<:essary.

For night driving levers A and B

on

the left handlebar must be switched

on

(Fig.

7).

On right handlebar with the ignition key

in

position 2 the machine

is

ready to

be

started.

Fig. 6/ 1

19

Ignition switch

keys

Steering lock

(Fig. 22/

1)

Steering lock

keys

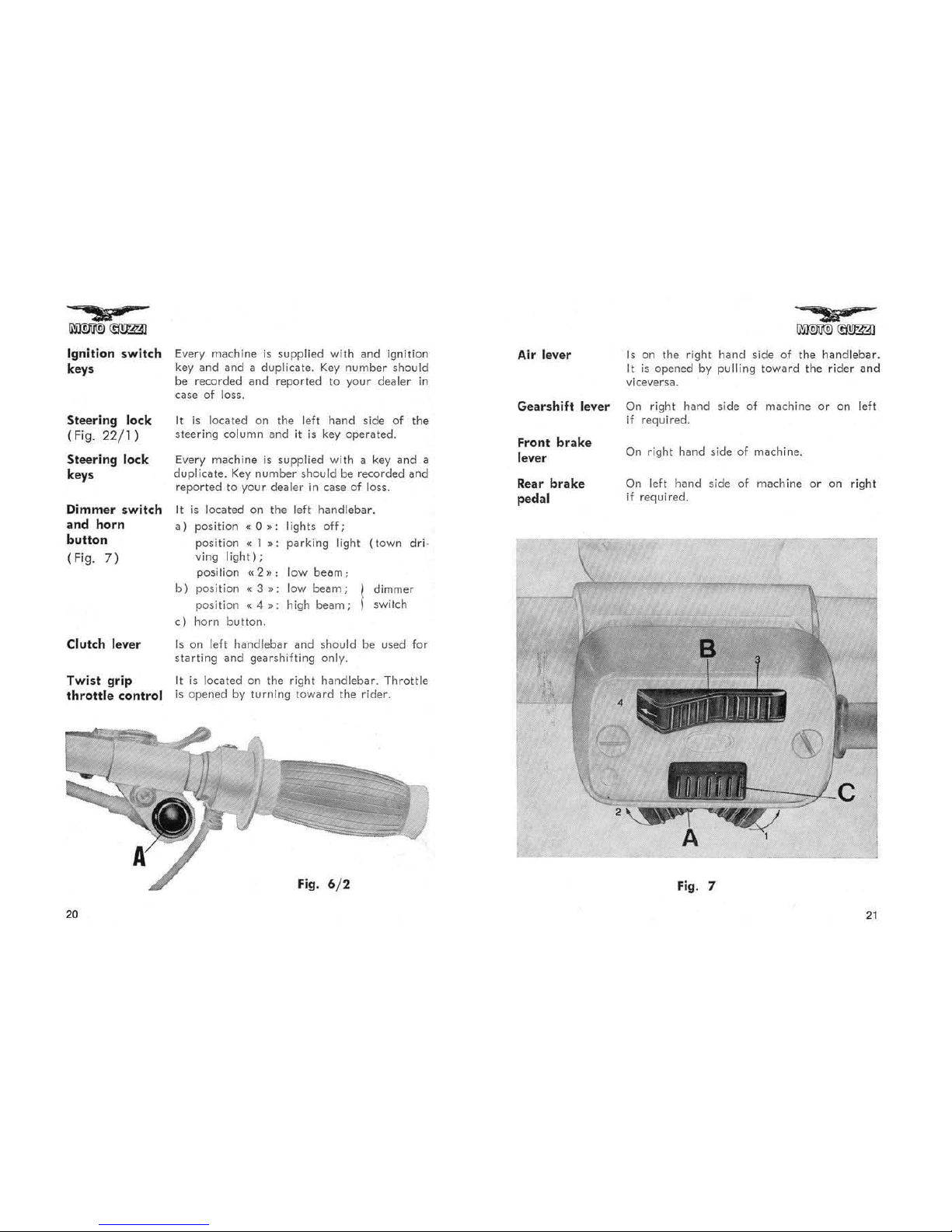

Dimmer

swit

ch

and

horn

button

(Fig.

7)

Clutch lever

Twist

grip

throttle

control

20

Every machine is

supplied

with

and

ignition

key

and and

a duplicate.

Key

number

should

be

recorded and

reported

to your

dealer

in

case

of

loss.

It is located on

the

left

hand

side

of

the

steering

column

and

it

is

key

operated.

Every machine is supplied with a key

and

a

duplicate.

Key

number

should

be

recorded

and

reported

to your dealer in

case

of loss.

It is located on the left

handlebar

.

a)

position

«0,,:

lights

off;

b)

0)

position

.. 1 ,,;

parking

light

(town

dri·

ving

light);

position

«2»

: low

beom;

position

«3"

:

low

beam;

dimmer

position

.. 4

,,;

high

beam;

switch

horn

button.

Is

on

left

handlebar

and

should be used for

starting

and

gearshifting

only.

It

is located

on

the right

handlebar. Throttle

is

opened

by

turning

toward

the rider.

Fig

. 6/ 2

Air lever

Gear

shift

lever

Front

brake

lever

Rear

brake

pedal

Is

on the right

hand

side

of

the

handlebar

.

It is opened

by

pulling

toward

the

rider

and

viceversa.

On

right

hand

side of machine

or

on left

if

required.

On right

hand

side

of machine.

On left

hand side

of machine o r on

right

if required.

Fig

. 7

21

RIDING INSTRUCTIONS

Engine

sta

rting

Caution

Starting a hoi

engine

22

Ensure there is

sufficient

fuel

in

the

tank

and

that

the

crankcase oil

is

at

correct

level.

Insert the ignition key and switch it on

to

position 2

(fig.

6

/1),

ensuring that the red

oil

pressure

light

and

the

orange neutral indi-

cator

lighl

are

on.

If

the engine

is

started

from cold, ensure Ih;!,

the

easy

starting

air

control

is is

opened

and

then push the

starter

button

on the right hand side

of

the

handlebar.

When the engine has

started,

release

the

starting

butlon

and

allow the engine

to

idle

for a

short time

in

the

cold season

to

give

a

chance

to

the

oil

to

warm

up

and reach

all the lubricating points. Then close

the

easy

starting

air control.

If

this

is

left open,

there

will be excessive petrol consumption

and

irregular

carburation.

Attempting to

start

the engine

in

gear can

be

very dangerous unless the clutch lever

is

kept fully dis engaged as with

the

firing

of

the

engine the machine itself may

start

off.

Even

at

very low

temperatures,

the engine

should always

start

easily, provided there

is

sufficient

thrust

from the

starter

motor

and

everything

is

in

good running

order.

If

the engine does not st

art

easily,

do

not

persist

in

many

attempts,

but

check carbu-

ration, ignition,

battery

charge,

and

tha

t the

oil

is

not too heavy.

When

starting

a hot engine there

is

no need

to close the

air

lever as this would richen

the

mixture

and

make

starting

difficult.

If

starting

a hot engine gives some difficulty,

Getting under

way and

stopping

of

machine

On

the way

it

is

well to open the

throttle

completely

before pushing

in

the

starter

bulton.

Pull the clut

ch

lever completely, engage low

gear, release the clutch slowly,

and

at

the

same time

turn

the gas on.

As

soon as the engine has picked up some

speed, close

the

gas, pull the c1ulch

and

by

downward

toe

pressure

engage second gear.

Then release the clutch rapidly

(but

not with

a

jerk)

and

turn

on

the

gas once more. Third

and

high gear

are

likewise engaged by toe

pressure.

In

normal riding conditions, all

the

tell-Iale

lights should be off, e xcept naturally the

green light when night driving

in

towns.

If

anyone

of them light up, this means

there

is

some fault

in

the

system

or

all pressure

is

insufficient.

The

maximu m speeds

in

each

gear

should never be exceeded, not even on steep downhill

grades.

Do

not forget

that

by toa

pressure

you

pass to a higher gear and by heel pressure

to

a lower gear (Fig.

9).

Before any

gear

is

engaged,

make

sure

the clutch

is

comple-

tely disengaged.

It

is

necessary

to

fully close

the gas when

yO\)

change up but it can only

be

closed partially when changing down. To

obtain fast

and

effortless gear shifts, always,

depress

the

pedal firmly

but

gently

without

stamping or jabbing vigorously

on

il.

The free position

(neutral)

is

in

between first

and

second gear.

To

locate this position it is

necessary to shift to low gear

and

then by

slight ( t

oe)

pressure

(half

stroke)

to feel for

neu

tr

al

position.

With the machine standing

still

and

the

en-

gine running,

the

transmission should always

23

Loading...

Loading...