MOTO GUZZI 700 cc Twin V-7 Riders Manual

~

MOTOGUZZI

rider's handbook

~

MOTO

GUZZI

FACTORY

AND

OFFICES:

Meodello dItI

urio

(Como)

VI,

ElNnue'-

V.

Parod

i,

57

Telephones:

.¥..ndello

~I

lario

71

.112

(4

lines)

Telegram5:

MOTOGUUI • Mar'ld&llo Lorio

HEAD

OFFICE:

Vi,

Andegarl, ..

felephone:

890632

BRANCH OFFICE:

Mil,,"

Vi,

Domodossola,

17

Telephone: 311.105

Nlpl

...

Piana

MuniciplQ,

8"

Telephone: 310.581

Telegraml: MOTOGUUI _ Naples

700

cc

TWIN

v

-

7

MODEL

RIDER'S

HANDBOOK

INTRODUCTION The

purpose

of this booklet

is

to

provide

ownen

with the necessary information on

operating

and

maintaining

their

machines for

maximum efficiency.

2

This manual should

be

read very carefully

as most troubles

and

fail

urn

arising from

neglec;t

or

poor

maintenance will be avoi-

ded

if

all the instructions herein contained

are

strictly followed.

Dont

forget

thai

all

major

overhauls

and

re-

pairs

are

best carried

out

by officially ap-

pointed Mota Guzzi dealers

who

have the ne·

cessary

facilities required to competently re-

pai r your Moto GUlli.

INDEX Running

in

Controls

and

accessories

Identification

data

Igni

tion key

Tool kit

Spare

parts

Main features

Instruments

ilnd controls

Riding

instructions

Lubrication

and

genenl

milinten

.. nce

Servicing

instruct

ions .

Lubrication of engine

Oil pressure relief valve

Oil

pressure

gauge

Lubrication

of

transmission

Lubrication

of

rear

wheel drive

Lubrication of front f

ork

and

hy_

draulic

dampers

lubrication

of

bevel gears

in

steering

Lubrication of wheel bearings

Lubrication of control

cables

Lubrication

of

rear

fork bearings

C

..

rburation

Filters

and

fuel lines

Carburetor

Standard

carburetor

settings

Adjustment for idling

speed

Determining correct size of main jet

Stripping

of

carburalor

Air filter

Fuel

tank

pag. 5

• 6

•

II

•

II

•

II

•

II

•

13

•

18

•

21

• 26

• 28

• 28

• 28

• 28

• 28

• 30

• 32

• 32

• 32

• 32

• 32

• 33

• 33

• 34

•

34

•

34

• 36

•

37

•

38

• 38

3

,

Mufflers

Valve gearing

Ta.ppet ciea.rance

Valve

tim

ing

Ignition

Distr

ibutor

Spark

plugs

Ignition timing

Adjus

tment

s

Generator

belt

Clutch lever

Steering

Front

brake

lever

Rear

brake

pedal

Rear suspension units

Removal of

front

wheel

Removal

of

rear

wheel

El

eclriCilI equipme

nt

Battery

Generator

Regulator unit

Starter

motor

H

orn

Light switch,

dipper

switch

and

horn

button

Headlight

Bulbs

Tail light

Fuses

Cables

pag. 39

Running

in

•

39

•

39

• '0

· "

· "

· "

· "

•

45

•

45

•

45

•

45

•

46

· "

•

'9

• 50

• 51

•

5d

• 5d

• 55

•

55

•

55

•

56

•

56

•

56

•

56

•

56

•

56

•

56

During

the

first

1600

kms.

(1000

miles)

a

new

or

overhauled

machine

should

be used

intelligently since the efficiency,

performance,

a.nd

life

of

the engine are largely

dependant

on how

it

is

used.

The englne

should

never be allowed to reach

a high

number

of

revolutions before

it

has

had

a chance to sufficiently

warm

up.

Never ride the machine

at

the highest speeds

permitted

for each

gear

before the machine

has been

well broken in.

Should the engine speed

drop

off considerably

on an

uphill grade, a lower gear

should

be im.

mediately engaged.

In

case of overheating,

it

is

best

to

stop

the engine and allow it

to

cool

down.

Under

no

circumstances

whatever should the

Following speeds be exceeded while a machine

is

being run in.

Maximum permissible

speed:

Distance

covered:

Up

to

800

kms.

(500

miles) :

in

low gear

in

second

gear

in

third

gear

45

(28

miles)

65

(40.5

miles)

85

(53

miles)

in

high

gear

110 (68

miles)

From

800

to

1600

kms.

(500

to

1000

miles)

:

in

low gear

55

(34.5

miles)

in

second gear

80

(50

miles)

in

third

gear

IDS

(65

miles)

in

high gear 135

(84

miles)

From

1600 to

3000

kms.

(1000

to

1800

miles) :

Gradually increase the speed

up

to

the ma-

ximum

permissible limit.

5

After the

first

500

kms

.

(

300

miles )

Ev

ery

500 kms.

(

300

miles)

Change the engine oil.

Tighten all nvts

and

bolts.

Check valve clearance.

Check

distributor

contacts gap.

Check oil level. Correct level

is

in

between

the

minimum

and

maximum

mark

on the

Filler

cap

dipstick.

CONTROLS AND ACCESSORIES

(See fig.

I)

,

I Front

brake

lever

2

Air control lever

3

Throttle control grip

4 Fuel filler cap

5

Gearshift lever

6

Pillion footrests

7 Pillion handgrip

8

Headlight

9

Speedometer

and

lighted indicators

JO

Key

type ignition switch

II

Clutch lever

J2

Dipper switch

il

nd horn

button

J3

Side stilnd

14 Reilr brilke pedill

IS

Footrests

16 Center

stand

17 Tail lamp

N.B. _ The te

rm,

.. right

It

an

d " le

fl

It

in the

lui

a

..

Ul

ed

in

11M

o.e

nH

th

ey would op

pea

r to

On

e

l illing

in

the .... ddl

e.

fig . 1

7

•

•

. !

•

•

.>

-

-

-

•

~

~

~

"

N

..,

..

;;:

..

;;:

8

9

Fig. 4

10

IDENTIFICATION

DATA

(See

fig.

4)

Ignition key

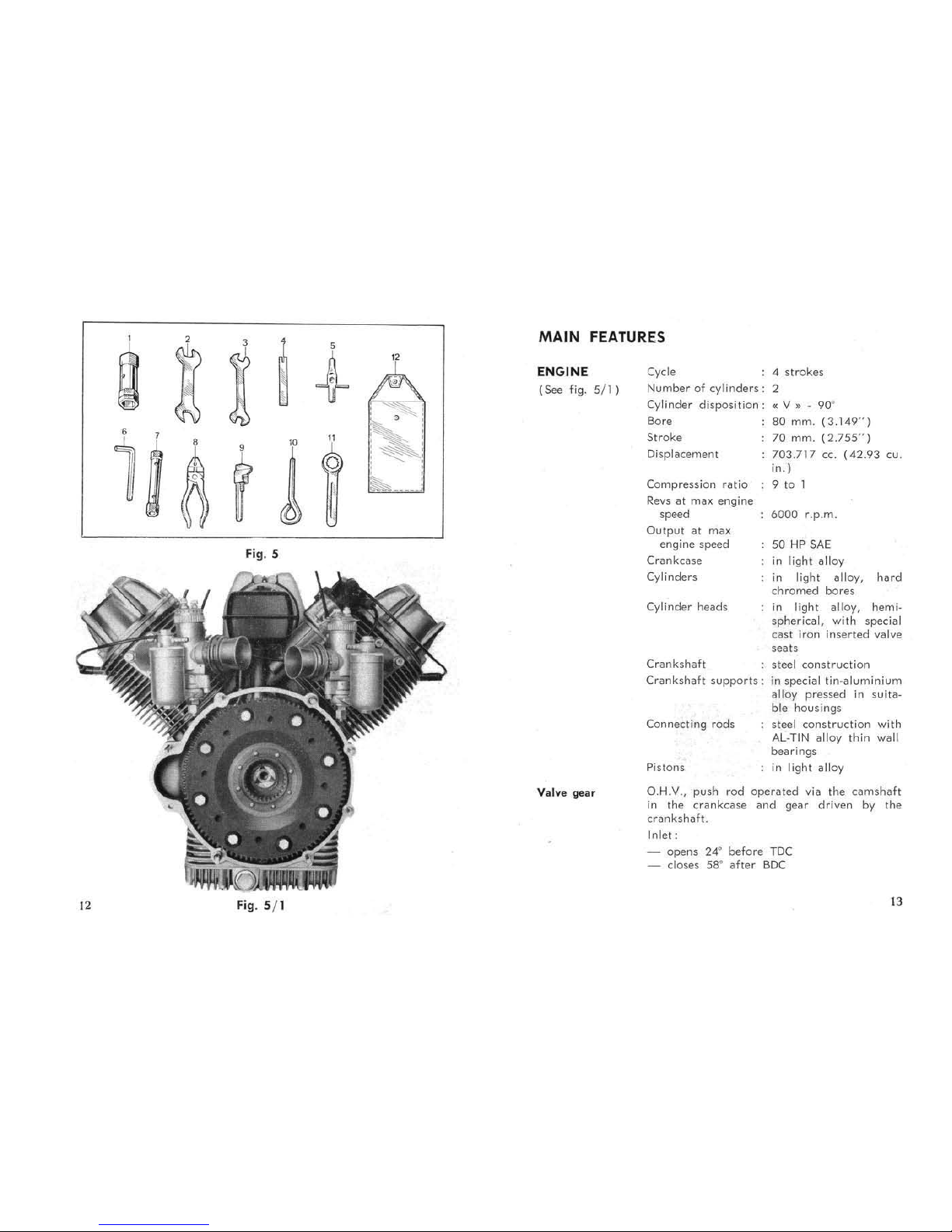

TOOL KIT

(See

fig.

5)

SpOU

$ pllTt$

Every

machine

is

identified with ill serial

num

ber

which

is

stamped

on the frame down

lube

and

on the left

hand

crankcase

cover.

An

ignition

key and

II

duplicllte

are

supplied

with each machine, The

number

should

be

recorded.

In

case of

lou,

the

key

number

should

be

reported

10

your dealer.

1

~

So)!.

wrench, 19/21/ 22

mm

.

2

Open

ended

wrench, 17/ 19

mm.

3

Open

ended

wrench, 10/

11

mm.

4

Tappel

adjus

ting wrench

5

Box wr

ench,

8/9

Mm.

6

Allen key

(5

hex)

7

Box

wrench, 10/1 4 Mm.

,

Universal

pliers

9

Adjustable

wrench

10

Screwdriver

11

Ring wrench, 27

Mm.

12

- Tool bag

If

replaceme

nts

are

required

be

sure

thaI

genuine

Moto

GUlzi

paru

iJre

used.

Failure

to do so will absolve the Manufllctvrer fr

om

all guarantee liabilities.

"

Fi

g. 5

12

Fig

. 5/ 1

MAIN

FEATURES

ENGINE

(See

fig.

5/1)

Valva gear

Cycle 4

strokes

Number

of

cylinders

: 2

Cylinder

disposition:

«V

• . 90"

Bore

80

mm.

(3.149")

Stroke

Displacement

70

mm.

(2.755")

703.717

CCo

(42.93

cu.

in.)

Compression

ratio

9

to

1

Revs

at

max engine

speed 6000 r .p.m.

Output

at

max

engine

speed

50

HP

SAE

Crankcase

Cylinders

Cylinder heads

in

light alloy

in

light

alloy,

hard

chromed bores

in

light

alloy, hemi-

spherical,

with

special

cast

iron

inserted

valve

seats

Crankshaft

steel

construc

tion

Crankshaft

supports: in

special

lin-aluminium

Conne<:ting

rods

Pistons

alloy

pressed

in

suita-

ble housings

steel

construction

with

AL·TIN

alloy

thin

wall

bearings

in light

alloy

O.H.V.,

push

rod

operated

via

the

camshaft

in the crankCi,lse

and

gear

driven

by

the

cr.,nkshaft.

Inlet;

opens

24'

before

TDC

- closes 58"

.,fter

SDC

13

Carburation

Lubrication

Cooling

Ignitio

n

14

Exhaust :

-

opens

58· after

BDC

- closes 22·

after

TOC

Rocker clearam:e for valve

timing:

- 0,5 mm.

(.0196")

Normal rocker clearance

(cold

engine)

:

in

let

0.1

mm.

(.00393")

- exhaust 0.2 mm.

(.00787")

Both

carburetors

are gravity fed

from the

tank.

Carburetor

Make:

type Dell"Orto

5.5.1.

(ringht and

left)

Pressure,

by

gear

pump

driven by the crank-

shaft.

Oil

strainer

in

crankcase.

Normal lubricating

pressure

2.5 - 3

kgs./sp.

crn.

(35.6·

42.7

Ibs/sp.in.)

(Controlled by relief valve)

Electrically controlled oil

pressure

gauge.

By

air

. Cylinder

and

cylinder heads deeply

finned.

8y

battery

with

automatic

advance Marelli di-

stributor

type 5 123

A.

Inilial

advance: 10·.

Automatic

advance:

28°.

Ignition

timing 38" full advance.

Contact

breaker

gap:

0.42-0.48 mm.

(

.016-.018").

Spark

plug : n. 225

in

Bosch-Marelli scale

or

equivalent.

Exhau

st

system

TRANSMISSION

Clutch

Gear

box

Seconda

ry

drive

at

rear

wheel

Plugs point gap : .6 mm. (.

023")

.

Ignition

coil: Marelli

BE

220

O.

Marelli

stuter

MT

40 H

(12 V-.7 HP) with

electromagnetic ratchet control. Ring gear

bolted on

flywheel.

Dual

e~haust

pipes

and

mufflers.

Twin driven plates,

dry

type, located

in

the

flywheel. Controlled by lever on left handlebar.

Four speeds, frontal engagement. Constant

mesh gears. Cush drive spring

incorpor<Hed.

Separate case bolted on crilnkcase,

operated

by rocker

pedal

on

the right hand side of the

machine.

Engine-gearbox

ratio:

I to 1.352

( 17-23)

Internal gear

ratios:

Low

gear

'0

1.812 ( 16-29)

Second gear

w

1.25

(20-25)

Third gear w

0.956

(23-22)

High gear

'0

0.730

(26-19

)

By

homokinetic double joint

cardan

shaft.

Bevel layshafl gear-wheel

ratio:

4.625

(8·37)

Overall gear ralios :

Low

gear

'0

11.330

Second gear

'0

7.816

Third gear

'0

5.977

High gear

'0

4.564

15

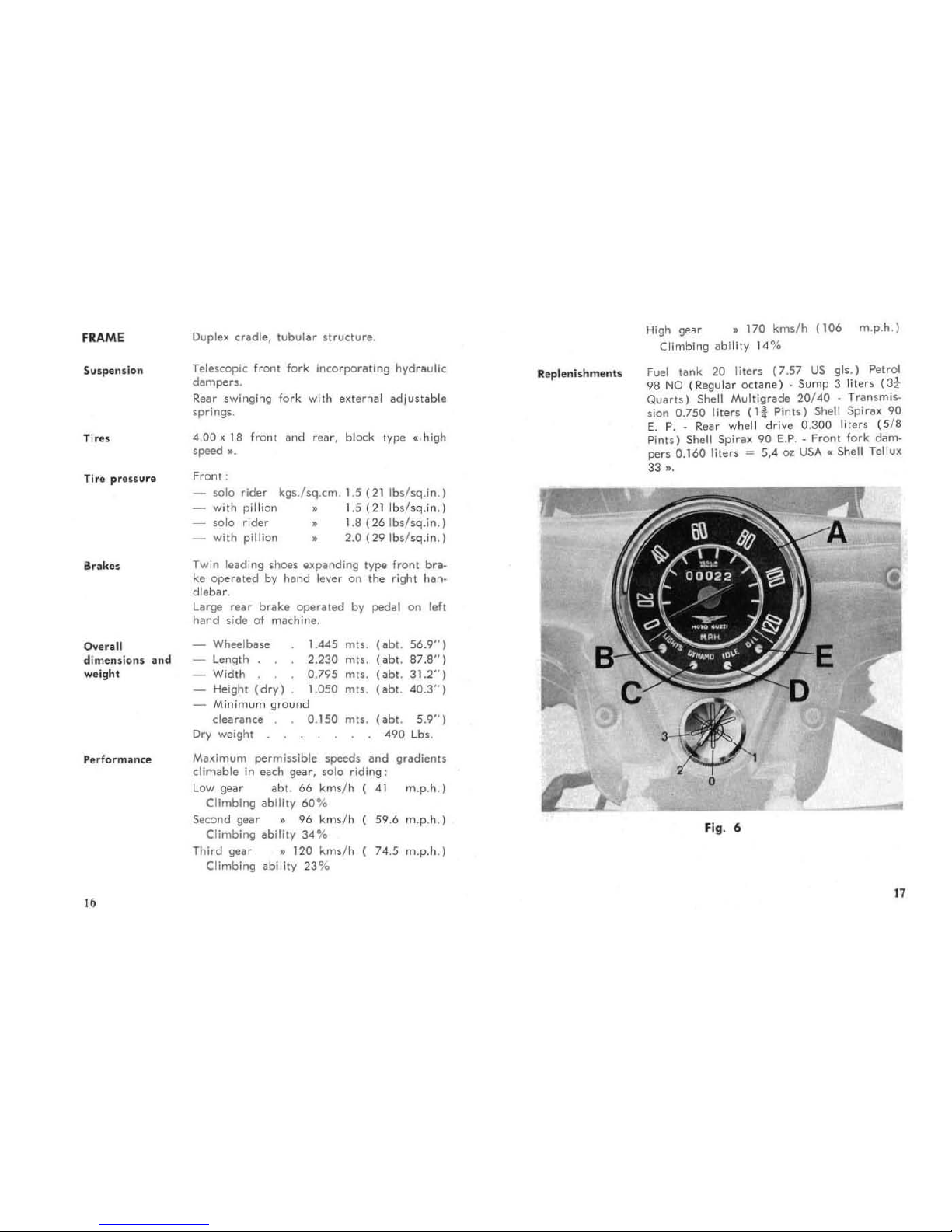

FRAME

Tires

Tire

prenure

Oyer~dl

dimensio ns and

weight

Pe

rforman

ce

16

Duplex cradle,

tubular

5!ruclure.

Telescopic front

forI<

incorporating hydraulic

dampen.

Rear swinging fork with external

adjustable

springs.

4.00 x 18 front

and

rear, block type

0:

high

speed

".

Front:

solo rider kgs./sq.cm. 1.5

(21

Ibs/sq.in.)

with pillion

..

1.5 (21

Ibs/s

q,in

.)

rolo

rider

..

1.8

(26

Ibs/sq.in.)

with pillion

..

2.0

(29Ibs/sq.in.)

Twin leading shoes eJlpanding type front

bra·

ke

operated

by

hand

lever

on

the

right han.

dlebar.

Large rellr

brake

operated

by pedal

on

leff

hand

side

of

machine.

Wheelbll5e

1.445

Length

2.230

Width 0.795

Height

(dry)

1.050

- Minimum

ground

clearance.

0.150

Dry

weight

mlS. ( ab!.

56.9")

mls.

(ab!. 87.8

" )

mts.

(ab!.

31.2")

mts.

(abl. 40.3")

mlS.

(ab!.

5.9")

.

490

Lbs.

Maximum permissible speeds

and

gradients

climable

in

each gear, solo

riding:

Low

gear ab!. 66

kms

/h

41

m.p

.h.)

Climbing ability 60%

Second gear

..

96

kms/h

59.6

m.p.h.)

Climbing ability

34%

Third gear • 120

kms/h

74.5

m.p.h.)

Climbing ability 23 %

Reple

nishmen

ts

High gear

• 170

kms/h

(106

m.p.h.)

Climbing ability 14%

Fuel

tank

20 liters

(7.57

US

gls.)

Petrol

98

NO

(Regular

octane) . Sump

3 liters

(3*

Quarts)

Shell Multigrade

20/40 . Transmh·

sion 0.750 liters

(Ii

Pints)

Shell

Spiru

90

E.

P

..

Rear whell drive

0.300

liters

(5/8

P

ints)

Shell Spirax 90 E.P

.. Fron

t fork

dam.

pen

0.160

liters

= 5,4 0%

USA

c Shell Tellux

33

•.

d

Fig

. 6

17

Loading...

Loading...