Page 1

Process Black

White

White/Black MOTION PRO, INC. LOGO

Motion Pro, Inc.

867 American Street

San Carlos, CA 94070

Tel 650.594.9600 Fax 650.594.9610

www.motionpro.com

instructions

Belt tension GauGe P/n 08-0350

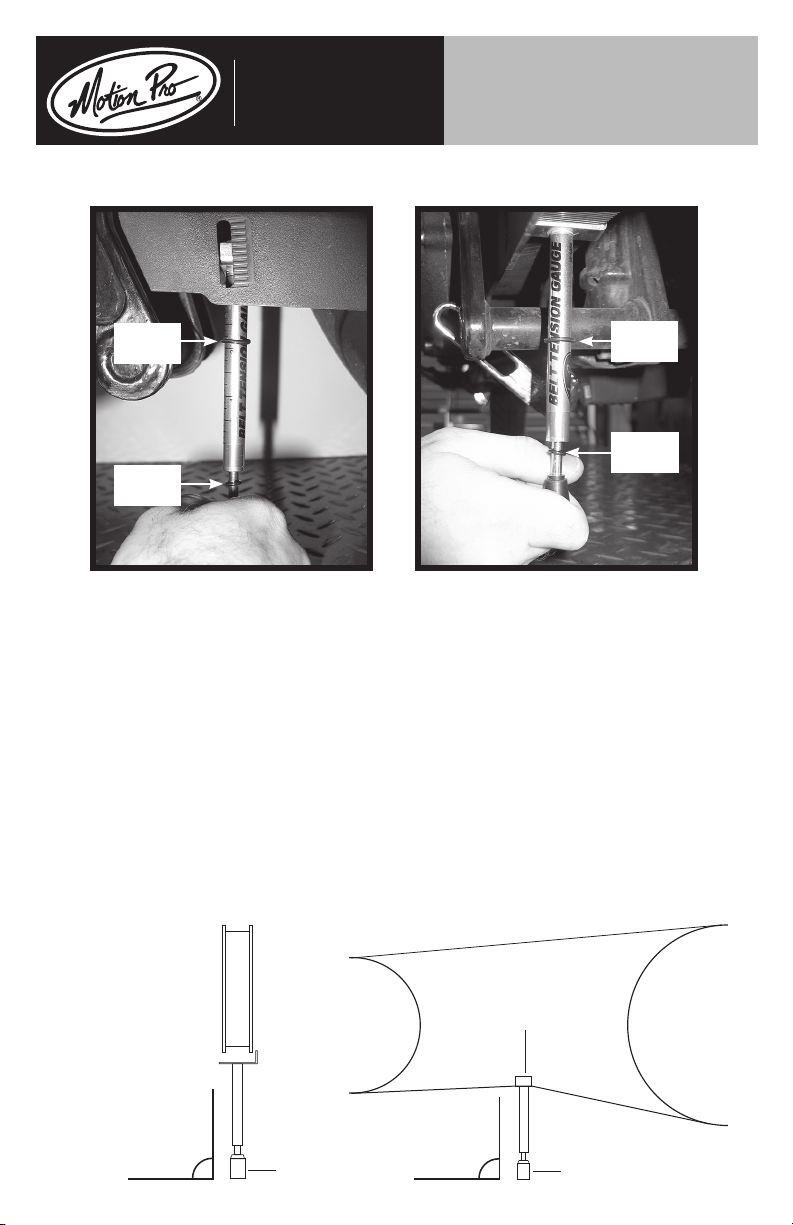

Large

O-ring

Large

O-ring

smaLL

O-ring

smaLL

O-ring

This tool is designed for use as an aid in properly adjusting belt tension on most motorcycles equipped

with a secondary drive belt; always refer to your service manual for the location to check your belt and

proper belt tension specication.

1. Position the small O-ring on the tool directly over the 10 lbs. mark on the shaft.

2. Position the U-shaped belt cradle against the lower bottom strand of the belt. Making sure the tool is

perpendicular to the belt.

3. Push upward on the rubber bumper until the small O-ring just touches the bottom of the tool body;

this means 10 lbs. has been applied to the belt, If your model does not have a method of determining the

amount of belt deection you can use the large O-ring and graduated scale on the body to calculate the

amount of belt deection. With the U-shaped belt cradle against the lower bottom strand of the belt nd a

reference point on the bike to align the large O-ring with and record the reading on the graduated scale.

After pushing upward on the rubber bumper until the small O-ring just touches the bottom of the tool body

align the large O-ring with the same reference point on the bike and record the reading on the graduated

scale. The difference between the initial reading and the nal reading is the belt deection at 10 lbs. force.

Always refer to the service manual for specic specications for the model being serviced.

note: Belt Tension

Gauge must remain

at a 90˚ angle to get

an accurate reading.

I08-0350

90˚

Rubber Bumper

90˚

Belt Cradle

Rubber Bumper

12/2011

Loading...

Loading...