Page 1

Motion Pro Suspension Bearing Tool P/N 08-0294

The Motion Pro Suspension Bearing Tool is designed to remove and install the bearings in the swing arm and

linkage pivots. The examples and tool tips shown below will help you in servicing your machine.

Section 1. Swing Arm Bearings

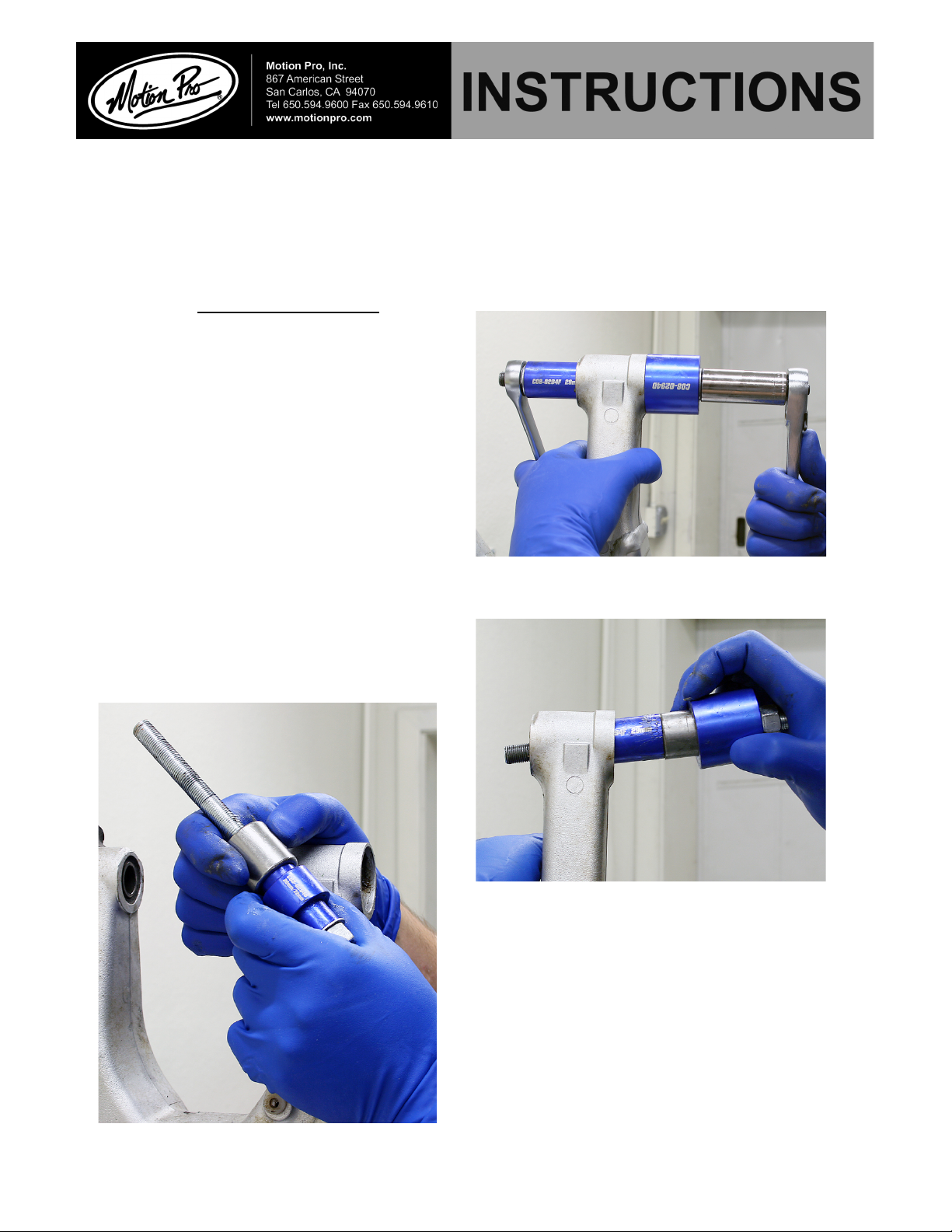

Fig 1

Fig 2

d. Clean all bearing surfaces and inspect for

damage.

e. Pack new bearings with a liberal amount of high

quality bearing grease. Apply a thin layer of grease

on the inside of the swingarm bearing surface.

This will help to prevent the new bearing from

galling during installation.

f. Install bearing onto the corresponding bearing

driver as shown in fig 3. The bearing driver will

hold the loose needles in place during installation.

a. Remove swingarm, seals, retaining

rings, and spacers. Make absolutely sure

that there are no internal circlips that may

be hidden under the grease.

b. Select the correct size driver for your

bearing and assemble the puller as shown

in Fig1.

c. Make sure as you start to tighten

the assembly that the bearing cup

(C08-0294D) is centered on the swingarm.

Pull the bearing through the swingarm

and into the bearing cup as shown in

Fig 2.

Fig 3

I08-0294A 5/2009

Page 2

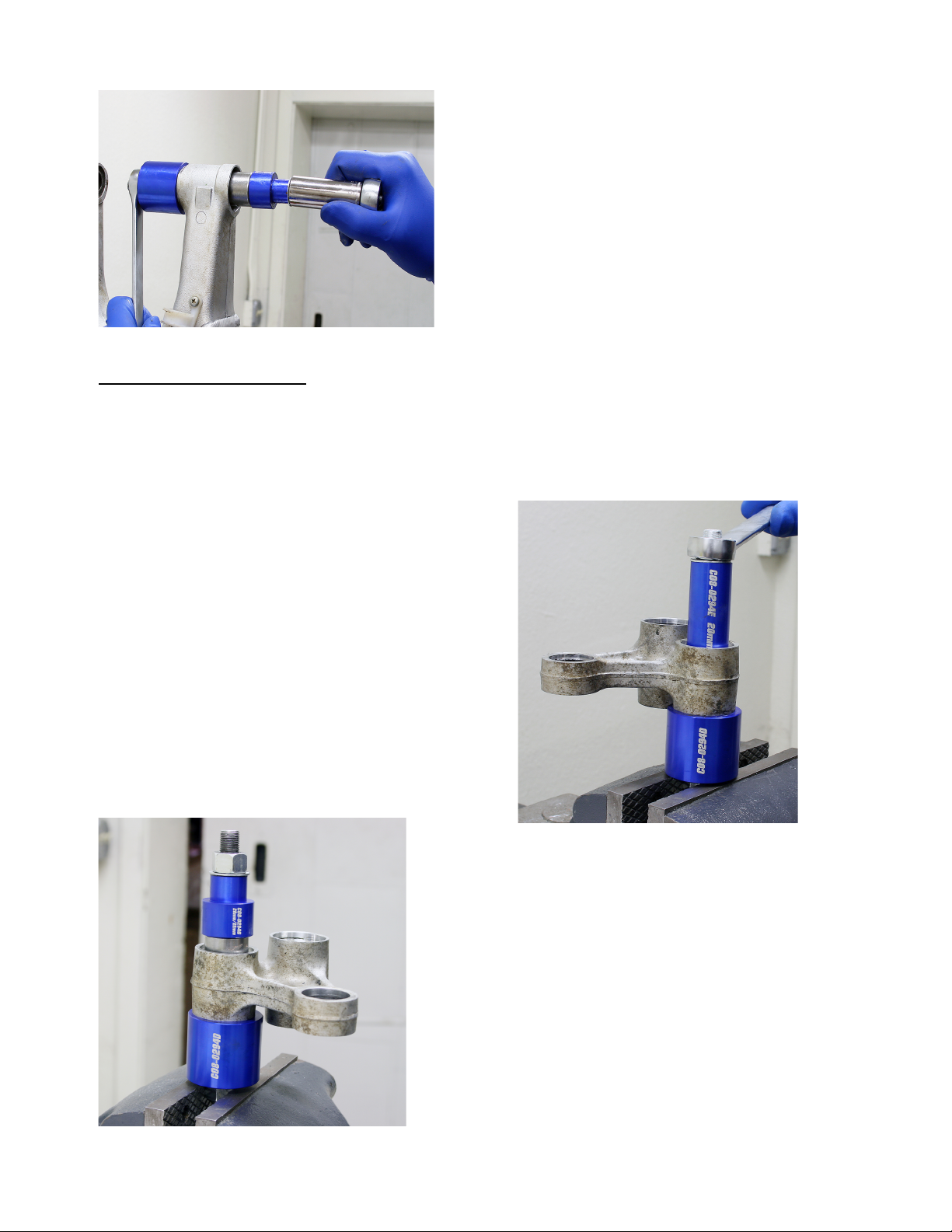

Section 2. Rocker Pivot

Every manufacturer has a slightly different suspension linkage system. The examples here are performed

on a 2006 CRF450R. Refer to your shop manual for any specific instructions or procedures that are not

covered here.

g. Assemble the bearing driver as shown in Fig 4.

Tighten screw until the driver bottoms out on the

inside bearing surface.

a. Remove all seals and inner spacers from

the rocker

b. Using the appropriate bearing remover,

assemble the tool as shown in Fig 5. If you do

not have a bench vise you can use a wrench

on both nuts.

c. Tighten the nut until the bearing is pushed

completely out of the rocker and into the

bearing cup.

d. Clean all bearing surfaces and inspect for

damage.

e. Install bearing onto the corresponding bearing

driver as shown in Fig 6. The bearing driver will hold

the loose needles in place during installation.

f. Assemble the bearing driver as shown in Fig 4.

Tighten screw until the driver bottoms out on the

inside bearing surface.

g. Reinstall all seals and bearing spacers. Be sure to

pack the new bearings with a high quality grease

before reinstalling the components onto the

motorcycle.

Fig 4

Fig 5

Fig 6

I08-0294A 5/2009

Page 3

Section 3. Connecting Link

Again, most manufacturers have a slightly

different suspension linkage system.

The examples here are performed on a 2006

CRF450R. Refer to your shop manual for

any specific instructions or procedures that

are not covered here.

a. Remove all seals and inner spacers.

b. Fully tighten the blind bearing remover on

the inner lip of the needle bearing then

assemble the tool as shown in Fig 7. Be sure

that the lip of the blind bearing remover is fully

engaged on the bearing.

c. Apply a small amount of grease onto the

threads of the puller and washer

d. Remove bearing as shown in Fig 8.

e. Clean all bearing surfaces and inspect for

damage.

f. Assemble the bearing driver as shown in Fig

9 and Fig 10. Tighten screw until the driver

bottoms out on the inside bearing surface

g. Install new greased bearing onto the bearing

driver and assemble the tool as shown in fig 9

and 10

h. Replace all seal, inner spacers, and clips.

Fig 7

Fig 8

Fig 9

Fig 10

I08-0294A 5/2009

Loading...

Loading...