Page 1

MoTeC PLM User’s Manual

Contents

Introduction ...................................................................... 3

Meter Operation................................................................ 4

PLM Connections ..........................................................................................................4

Connectors.............................................................................. 4

Analog Output ..........................................................................4

Digital inputs............................................................................ 5

Communications ...................................................................... 6

PLM Display....................................................................................................................6

Sensor Placement .........................................................................................................7

Sensor Warm-up...........................................................................................................9

Sensor Lifetime ..............................................................................................................9

Lambda.........................................................................................................................10

Engine Tuning..............................................................................................................10

Operating Tips..............................................................................................................11

PLM Setup Software.........................................................12

Computer requirements.............................................................................................12

Connecting to a PLM...................................................................................................12

Installing PLM Setup...................................................................................................12

Configurations ..............................................................................................................12

Managing Configurations.........................................................13

Changing Configurations .........................................................14

Sensor Calibration ...........................................................19

Introduction...................................................................................................................19

Calibration Methods....................................................................................................19

Use Measured Calibration Value ..............................................19

Enter Calibration Value...........................................................19

Calculate from O2 Concentration (Free Air) ...............................20

Enter Calibration Table............................................................21

PLM Communications.......................................................22

CAN Messages............................................................................................................22

Configuring Basic CAN with an ADL .........................................23

Configuring basic CAN with an M800........................................23

CAN Collect Functionality...........................................................................................24

Configuring the CAN collect master unit (PLM 1) .......................24

Configuring the CAN Collect slave units (PLM 2 to PLM

16)........................................................................................25

Page 2

MoTeC PLM User’s Manual

CAN Unit Number Display.........................................................................................26

RS232 Messages........................................................................................................27

Specifications...................................................................28

Meter....................................................................................28

Appendices ......................................................................31

Appendix A – Lambda to Air Fuel Ratio Table........................................................31

Appendix B – PLM Display Codes............................................................................32

Appendix C – PLM CAN Diagnostic Codes ............................................................33

Appendix D – PLM Connector Details......................................................................34

Appendix E – Sensor Wiring Details........................................................................36

Bosch LSU 4 Sensor ..............................................................36

NTK – UEGO Sensor..............................................................38

Appendix F – PLM to ECU Wiring Details................................................................40

Analog Output ........................................................................40

CAN......................................................................................40

Appendix G – PLM to ADL Wiring Details................................................................41

Appendix H – General CAN Bus Wiring...................................................................42

Appendix I – PC Comms Wiring...............................................................................43

Appendix J – Analog Output Wiring..........................................................................44

Appendix K – Digital Input Wiring..............................................................................46

Typical wiring for switches .......................................................46

Typical wiring for RPM measurement .......................................46

Appendix L – Glossary................................................................................................47

Appendix M – CAN Messages Format.....................................................................48

Appendix N – RS232 Message Format...................................................................53

Appendix O – Recommended CAN Collect Configuration..................................54

Appendix P – Dimensions .........................................................................................57

Copyright – Motec Pty Ltd – 2001-2005

The information in this document is subject to change without notice.

While every effort is taken to ensure correctness, no responsibility will be taken for the consequences of any

inaccuracies or omissions in this manual.

23 June, 2005

Page 3

MoTeC PLM Setup Software 3

Introduction

The M oTeC Professional Lambda Meter measures Lambda (or Air Fuel Ratio)

over a wide range of mixtures with fast response time.

The display may be set to Show Lambda, Air Fuel Ratio (for Petrol, Alcohol,

Gas, Diesel or ‘blend’ fuel), equivalence ratio or percentage oxygen.

The PLM provides a differential Analog Output Voltage proportional to Lambda

that may be connected to an Analog Meter or other measurement instrument

such as an ECU, Data Logger or dynamometer.

The PLM also supports RS232 and CAN data links to devices such as the

Motec Dash Logger or M800 ECU for transmission of sensor and diagnostic

data.

This manual covers the configuration and operation of the meter.

Page 4

4 Meter Operation

Meter Operation

PLM Connections

Connectors

The PLM has a male and a female D-9 pin connector.

See Appendix D – PLM Connector Details for a description of the PLM pinout.

Male Connector

The loom supplied with the PLM is fitted to the male PLM connector, for

connection to the sensor and to a power supply. The Power supply must

provide enough current (up to 5 Amps at start up) for both the meter and the

sensor heater element. The vehicle battery is typically the most convenient

source of power.

It is not recommended that the power and sensor loom be extended by using a

standard serial cable. These are unable to supply the current required by the

sensor heater. If an extension is made, the wire must be at least 20 gauge.

Female Connector

The female PLM connector has pins for serial connection to a PC, CAN data

bus, 2 digital inputs and the analog voltage output.

The pinout is assigned to allow direct connection to a PC with a standard

(straight through) 9 pin serial cable. Note that the PC must have a serial

communications port (normally marked COM1). A custom cable is required to

use the other features on this connector.

Analog Output

The analog output provides a voltage proportional to Lambda. The scaling of the

analog output can be changed by using the PLM Setup software to configure

the device (see Setup | Analog Output in the PLM Setup Software section).

Page 5

MoTeC Meter Operation 5

The analog output is provided as a differential voltage using two connector pins

(Analog Out+ and Analog Out -). For correct operation Analog Out- must be

connected to the ground reference on the monitoring system.

The analog output can be configured as a wide band sensor input into a MoTeC

ECU for tuning, as described below. See Appendix F – PLM to ECU Wiring

Details for wiring details.

M4/M48 ECU

PLM Configuration Output Function = ‘LA V1’ table

La = 0.000, Aout = 0.000V

La = 5.000, Aout = 5.000V

ECU Configuration Lambda Sensor Calibration = 1 (‘Narrow Band or

MoTeC AF Meter’)

M8/M800

PLM Configuration Output Function = ‘LA V1’ table

La = 0.500, Aout = 0.000V

La = 1.750, Aout = 5.000V

ECU Configuration Lambda Sensor Calibration = 39 (‘MoTeC Meter’ or

‘MoTeC AFM1 Meter’)

Digital inputs

Digital Input 1 can be enabled as a switch input or RPM input. If the input is

enabled, the PLM can be configured to operate based on the switch state

(active high or active low) or on a non-zero RPM reading. The RPM reading is

also transmitted in the CAN and RS232 data streams.

Digital Input 2 can be enabled as a switch input, and the PLM can be configured

to operate based on the switch state (active high or active low). This input can

also be configured to change the display units on the PLM display. For more

information, see Setup | Digital Inputs in the PLM Setup Software section.

The digital inputs have a 4.7k ohm pull-up resistor, and a switching threshold of

around 2.5volts.

Page 6

6 Meter Operation

Communications

RS232 Int erface

The RS232 interface is used for configuring the PLM from a PC, and for

transmitting data to third party equipment.

For configuration from a PC, the PLM can be directly connected using a

standard (straight through) 9 pin serial cable.

See Appendix I – PC Comms Wiring for details on wiring to a PC.

CAN Interface

The CAN interface is used for transmitting data to MoTeC devices such as the

ADL (Advanced Dash Logger) or M800 ECU, or to third party equipment that

supports CAN.

The CAN communications can be configured to allow one PLM unit to collect

CAN data from up to 15 other PLM units, and then retransmit the data on a

single CAN address and on the RS232 interface.

For detailed information on communications interfaces, see the PLM

Communications section.

PLM Display

Start-up Display

On powerup, the PLM displays the current firmware version (eg. 1.1.0) for one

second, followed by a unit number based on the current CAN communications

configuration.

This unit number, displayed for one second, is useful for troubleshooting

networks of multiple PLM units. See the PLM Communications section for more

detail on displayed unit numbers.

Status Display

Whenever the sensor is not in control or is warming up, a series of displayed

codes describes the current status. A description of these codes is given in

Appendix B – PLM Display Codes .

Page 7

MoTeC Meter Operation 7

If the PLM loses control of the sensor at any point, then the sensor warm-up

process is repeated and these codes are displayed again.

Sensor Readings

The displayed format of sensor readings can be configured to select the display

units, decimal places, update rates and filtering. For more information, see

Setup | Display in the PLM Setup Software section.

If the reading is too large to be displayed using the configured settings, the

display will only show ‘- -‘.

Backlighting

The backlight intensity is configurable from 0% to 100%.

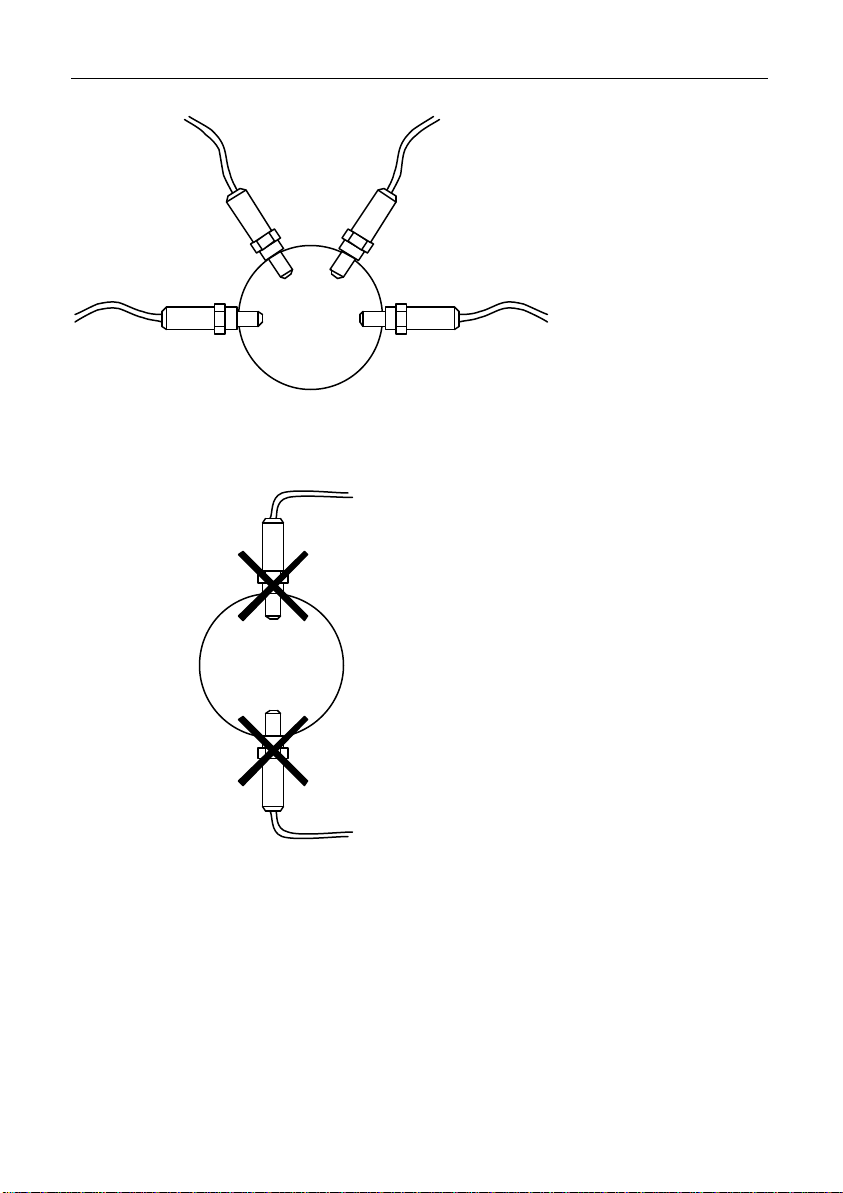

Sensor Placement

The sensor should be fitted to the exhaust system with the sensor tip protruding

into the exhaust gas flow. The sensor placement should be on an angle of

between 10 and 90 degrees to the vertical, with the tip of the sensor pointing

down. This is to ensure that no condensed water builds up between the sensor

case and the sensor ceramic. It should not be placed vertically due to excess

heat soak in this position.

It is recommended that where possible the sensor be placed at least 1m from

the exhaust ports to avoid excessive heat and at least 1m from the open end of

the exhaust system to avoid incorrect readings due to outside oxygen. This is

however not mandatory, and where necessary for shorter exhaust systems the

sensor should be placed closer to the engine.

The placement of the sensor should be away from the flame front coming out of

the cylinder head and away from areas where one cylinder may have more

affect than another.

Page 8

8 Meter Operation

Correct sensor placement

Incorrect sensor placement

Page 9

MoTeC Meter Operation 9

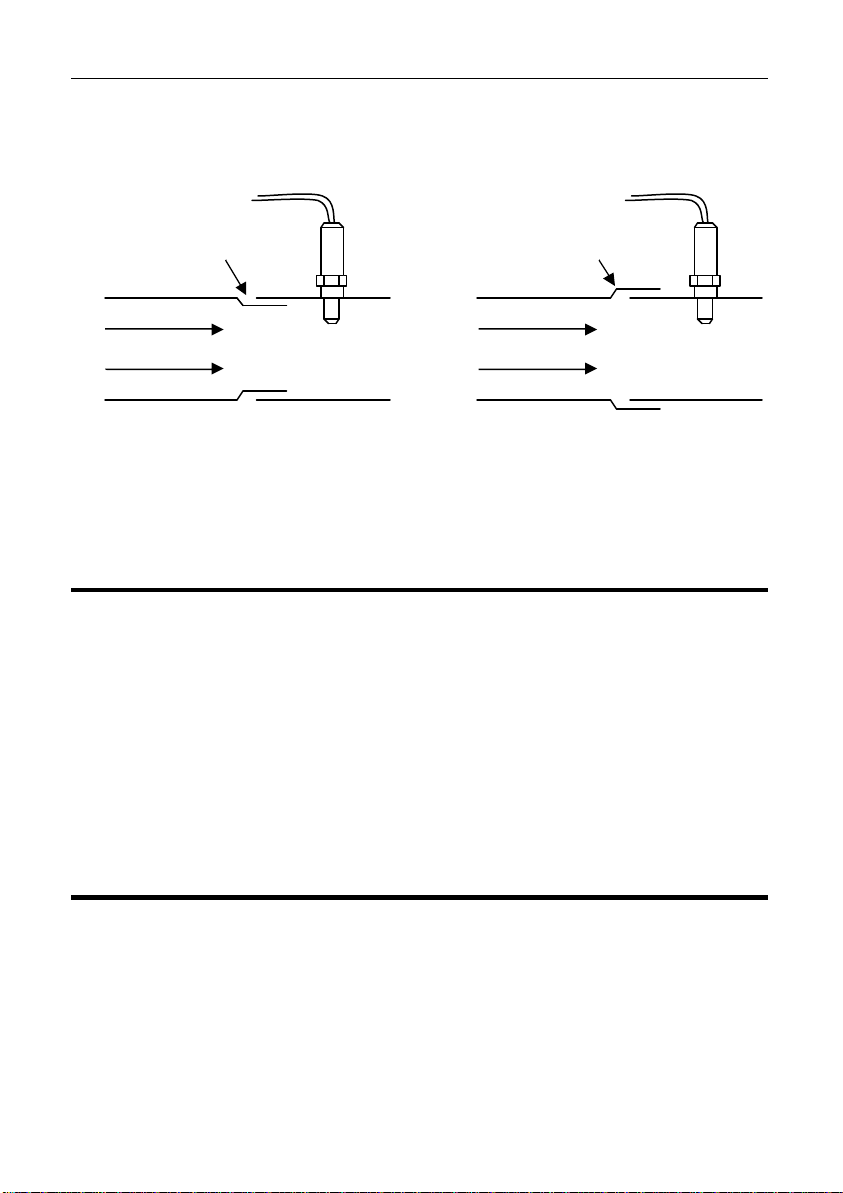

Exhaust slip joint design to avoid incorrect lambda readings

Introduced a

ir No air i

ntroduced

Exhaust slip joints should be avoided near sensor placement as some designs

allow air to enter. Slip joints can be reversed to make them better for use near

sensors.

Exhaust flow

Sensor Warm -up

The internal heater in the LSU or NTK sensor is powerful enough to allow

accurate measurement when gas temperature is at room temperature. The

Bosch LSU will take ~20seconds to heat up, while the NTK ~30 seconds before

reading.

The maximum continuous operating temperature of the sensors is 850 degrees,

and sensors should not be used for a prolonged period at temperatures higher

than this. The sensor can be heated to 930 degrees for a short period (not

exceeding 10 minutes), but the accuracy may be reduced.

Sensor Lifetime

The sensor life time is dependant on the type of fuel being used and the volume

of gas flow over the sensor. The sens or can also be contaminated by exhaust

manifold sealants, so Exhaust Gas Sensor friendly sealants should be used.

Leaded fuel will reduce the sensor lifetime substantially due to lead

contamination of the sensor element. Typically, for high performance engines

the sensor should last at least 500 Hrs in unleaded fuel and 50 Hrs in leaded

fuel. Longer lifetimes can be expected for less demanding applications.

Page 10

10 Meter Operation

At the end of its life the sensor becomes slow to respond and does not read

rich properly. The NTK and LSU are designed to be accurate for 50,000km of

operation in a road car, so the above figures are a conservative estimate.

Sensor lifetime will be reduced by contaminants such as lead, silicon, oil, etc.

Thermal cycling will also age the sensor more rapidly, along with exposure to

exhaust fumes without any heating control active (ie: not connected to the

PLM). Regular performance of the Free Air Calibration will maintain the

accuracy of the sensor over its lifetime.

Sensor Temperature

It is important to ensure that the sensor is not overheated due to incorrect

placement in the exhaust as this significantly reduces the sensor life. The

sensor impedance (Zp) is measured by the PLM, and this is a reasonable

indication of sensor temperature. Zp should be approximately 80 Ohms in

normal operation. If Zp is less than 60 the sensor is being overheated by the

exhaust and the sensor life will be reduced.

Lambda

Lambda gives a measure of Air Fuel Ratio that is independent of the type of fuel

being used.

Lambda 1.0 corresponds to the stoichiometric ratio i.e. when there is no excess

fuel and no excess air.

Lambda > 1.0 => Excess Air (Lean)

Lambda < 1.0 => Excess Fuel (Rich)

Lambda may be directly converted to Air Fuel Ratio for a specific fuel using a

multiplication factor. The PLM will display Air Fuel Ratio by loading the

appropriate configuration into one of the output tables. For more information,

see Setup | Display in the PLM Setup Software section.

A table to convert Lambda to Air Fuel Ratio for various fuels is given in Appendix

A – Lambda to Air Fuel Ratio Table.

Engine Tuning

The desired Air Fuel Ratio (or Lambda) is dependant on the tuning objective i.e.

Power, Economy or Emissions. Normally at full load the engine is tuned for

Page 11

MoTeC Meter Operation 11

maximum power and at light loads the engine is tuned for emissions or

economy.

The following table gives a guide to the required Lambda values for different

tuning objectives.

Objective Lambda

Power 0.84 to 0.90

Economy 1.05

Emissions 1.00

Note: The exact requirements for a specific engine and fuel must be found by

experimentation.

Note: On Turbo Engines extra fuel may be desirable to reduce exhaust

temperatures and help avoid knock.

Note If the vehicle is fitted with a catalytic converter extra fuel may be required

to ensure the catalyst does not overheat when not operating at Lambda

1.00

Operating Tips

If the Engine misfires for any reason, including an over-rich mixture, the Meter

may falsely read Lean. This is due to excess air being present in the exhaust

gasses which is caused by incomplete combustion when the engine misfires.

Other areas that can give misleading readings include at high RPM, closed

throttle when the mixture won’t burn completely. Following overrun fuel cut the

sensor will become saturated with oxygen and can take up to several seconds

to resume accurate readings. Engine misfires include hitting the rev-limiter, be it

a fuel or ignition cut or a combination of both, and can give a similar result with

time being required to purge the sensor of excess oxygen or fuel.

Engines with high overlap camshafts running at low speed may pump air

through the engine resulting in a false lean reading, therefore the meter may

need to read leaner than would otherwise be expected.

Page 12

12 PLM Setup Software

PLM Setup Software

The PLM Setup Software allows a PLM unit to be configured from a PC for a

particular target application. A new PLM unit must be configured before its initial

use in order to specify sensor type, display units etc. This section covers the

basic configuration of the PLM. Advanced functions are also covered in the PLM

Communications and Sensor Calibration sections.

Computer requirements

The PLM setup software runs under Windows 95, 98, ME, NT4, 2000 or XP

operating systems. The minimum recommended PC specification is a Pentium

90 with 16MB RAM and a serial port.

Connecting to a PLM

The PLM connects to the PC with a standard (straight -through) serial

communication cable from the PC serial port to the 9pin Female PLM

connector. During PC operations (sending or retrieving), the PLM should be

powered using the sensor loom.

Installing PLM Setup

The PLM Setup software can be installed either from the MoTeC Resource CD

supplied with the PLM, or from the MoTeC website (software.motec.com.au)

To start the program after installation, click on Start à Programs à MoTeC à

PLM Setup à PLM Setup

Configurations

The PLM configuration determines exactly how a unit will operates. The PLM

Setup software allows changes to be made to a configuration to change PLM

characteristics such as the sensor type, display units, analog output scaling,

backlight intensity etc.

Page 13

MoTeC PLM Setup Software 13

Standard configuration templates for most common preferences are included

with the software.

Managing Configurations

When the PLM Setup software is started, a configuration file needs to loaded

before changes can be made, or before a configuration can be sent to the PLM.

This configuration can either be loaded from a file on disk, retrieved from the

PLM (using the serial cable), or created as a new configuration.

A loaded configuration can be saved to a file on disk, and then sent to the PLM

(using the serial cable). A modified configuration must be sent to the PLM for it

to take effect.

Creating a new configuration

To create a new configuration, select File | New from the main menu, and

choose a template to base the new configuration on.

Loading an existing configuration from disk

To open an existing configuration file, select File | Open from the main menu

and select the desired file. The most recently used files may be opened from

the list of files at the bottom of the File menu.

Retrieving an existing configuration from a PLM

To retrieve a configuration from a PLM, select Online | Get Configuration from

the main menu. To specify the serial port used for the connection to the PLM,

select Options | Communications Port from the main menu. The PC must be

connected to the powered PLM using the serial port specified.

It is advisable to retrieve the initial configuration from the PLM and save this

before making modifi cations.

Saving a configuration to disk

After a configuration has been created or modified it should be saved with a

meaningful name by selecting File | Save or File | Save As from the main menu.

Sending a configuration to a PLM

To send a configuration to a PLM, select Online | Send Configuration from the

main menu. To specify the serial port used for the connection to the PLM,

Page 14

14 PLM Setup Software

select Options | Communications Port from the main menu. The PC must be

connected to the powered PLM using the serial port specified.

When a configuration file is sent to the PLM, any changes are automatically

saved to the current configuration file on the PC.

Changing Configurations

Once an existing configuration file has been opened or retrieved, or a new

configuration has been created, the configuration may be modified by choosing

the options under the Setup menu.

Setup | Sensor

Sensor:

The sensor type used with the PLM (NTK, Bosch LSU 4 or Bosch LSU

4.2) must be specified before a configuration can be sent to a PLM. It is

important to select the correct sensor type to prevent damage to the

sensor and ensure correct lambda measurements.

Calibration:

There are several options available for choosing the calibration method of

the sensor being used.

The default option, ‘Use measured calibration value’ allows the PLM to

determine the factory sensor calibration and can be used in most cases.

If the calibration value of the sensor is known then it can be entered by

selecting the option ‘Enter calibration value’. This value is engraved on

sensors supplied by MoTeC as an equivalent resistor calibration value.

Either of these two options will be sufficient in nearly all situations. The

more advanced calibration methods (‘Calculate from O2 concentration’

and ‘Enter calibration table’) are des cribed in the section Sensor

Calibration.

Heater Control:

This parameter allows the heater voltage to be set when using an NTK

sensor. For most situations this can be left at the default value of 10.5

volts. A value of 12 – 12.5 volts will give better results during cold start or

warm-up calibrations or during extensive periods of overrun fuel cut where

the sensor may become too cold for accurate measurement. Running the

Page 15

MoTeC PLM Setup Software 15

heater at a sustained voltage above 10.5 volts will reduce the sensor

lifetime.

Sensor Timeout:

The option to ignore sensor errors is only recommended for very

specialised applications where extreme changes in lambda may cause a

short loss of sensor control. Enabling this option will disable the default

PLM behaviour of shutting down the sensor for a timeout period when

control is lost. This timeout is to protect the sensor as loss of control can

indicate a wiring fault.

Setup | Display

Output Tables:

The Output Table Setup dialog is displayed when the Output Tables

button is clicked. The Output Tables are used by the PLM to calculate

the displayed value. The PLM stores two tables that can be configured

with different calibrations for displaying lambda, air fuel ratio or

equivalence ratio.

In addition to a lambda calibration, there are a number of pre-defined

calibrations for air fuel ratio for different fuels. To display one of these, the

calibration must be loaded by clicking on the ‘Load’ button and choosing

the appropriate calibration from the list displayed.

Advanced users can generate their own calibration tables using the Ipn

(normalised sensor pump cell current) value measured by the meter.

These user calibrations can be saved for re-use by clicking the ‘Save As’

button.

Output to Display:

The default PLM display value can be selected as the result from one of

the two tables that are specified under the Output Tables setup.

Display Decimals Table 1 / Table 2:

This is the number of decimals used to display the values from Table 1

and Table 2 in the Output Tables setup. The display decimals are

specified for both tables as the PLM can be configured to swap the

display between the two tables using a digital input.

Normal use would be to 2 decimal places for lambda.

Page 16

16 PLM Setup Software

Display Update Rate:

The update rate of the displayed value can be from 1 to 10 times per

second.

Filter Time:

The display data can be filtered so that it is more stable and easier to

read. This filtering is independent of the update rate. The filter time can

be specified in 0.1second units from 0 to 25 seconds.

Backlight Intensity:

Backlight intensity is configurable from 0 to 100%

Setup | Digital Inputs

Device Activation:

If digital inputs are not used for PLM activation, the ‘Run always ’ option

should be selected. The remaining four options allow the PLM to be

activated either while a digital input (1 or 2) remains active, or after a

digital input (1 or 2) first becomes active.

If one of digital input device activation modes is selected, the

corresponding digital input mode must be configured as Active Low,

Active High or Measure RPM. This allows the PLM to be configured to

operate only when measuring RPM, or when a switch is set.

Input 1 Mode:

‘Off’ – digital input 1 is disabled

‘Active High’ – digital input 1 is active when the input voltage is high

‘Active Low’ – digital input 1 is active when the input voltage is low

‘Measure RPM’ – digital input 1 is active when a non-zero RPM is

measured and the RPM value is transmitted in the CAN and RS232 data

streams (if configured under the communications setup).

RPM Pulses per Revolution:

If Input 1 Mode is ‘Measure RPM’ the number of pulses per engine

revolution must be specified here to calibrate the RPM measurement.

Page 17

MoTeC PLM Setup Software 17

Input 2 Mode:

‘Off’ – digital input 2 is disabled

‘Active High’ – digital input 2 is active when the input voltage is high

‘Active Low’ – digital input 2 is active when the input voltage is low

‘Display Other Output Table When Low’ – the other output table is used

for the display value while digital input 2 is low. For example, if Output to

Display (in the Setup | Display menu) is table 2, then table 1 will be

displayed while digital input 2 is low.

Setup | CAN Messages

The configuration templates included with PLM Setup are all configured to send

CAN data to a MoTeC ADL (Advanced Dash Logger) or M800 ECU by default.

The Output to Transmit parameter specifies the output table to be used for

transmitted values.

The Output Table Setup dialog is displayed when the Output Tables button is

clicked.

Note that the two tables setup in this dialog are used for displayed values,

transmitted values and analog outputs, but each function can use either table 1

or table 2.

For use with MoTeC equipment (ADL or M800), the selected table must be

setup for Lambda with 3 decimal places. Other table setups should only be

used for interfacing with third party equipment.

For basic CAN communications with an ADL, the Address parameter for

Message 1 should match the address in the PLM CAN communications

template loaded in the ADL.

If multiple PLMs (up to six units) are connected to an ADL then eac h should be

given a different address. The addresses chosen must match those of the PLM

CAN communication templates provided with Dash Manager. For example, the

ADL template ‘PLM #1 (CAN ID 460)’ requires that the Message 1 Address be

460. Note that “CAN Collect” functionality is the preferred method for

communications from more than one PLM to an ADL.

For basic CAN communications with an M800 ECU, the Address parameter for

Message 1 should be 460 for the first PLM, 461 for second PLM etc.

Only advanced users should change the other CAN message settings, or

configure Collect Master functionality. CAN Messages are covered in more

detail in the PLM Communications section.

Page 18

18 PLM Setup Software

Setup | Analog Output

Output Table:

The Output Table Setup dialog is displayed when the Output Tables

button is clicked.

Note that the two tables setup in this dialog are the same tables used for

displayed values, transmitted values and analog outputs, but each

function can use either table 1 or table 2.

Output Function:

This parameter spec ifies input to the analog output Calibration Table. The

‘Ip’ and ‘Ipn’ options are the raw and normalized sensor pump cell

currents (Ipn is normalized using the calibration method specified under

Setup | Sensor). The other options are the two tables that are specified

under the Output Tables setup.

Calibration Table:

The calibration table allows users to set the voltage output that

corresponds to the table input value. The table takes the input value and

translates it to an analog voltage (0 to 5 volts) by way of the calibration

table. The voltage is linearly interpolated between points in the table, so

at least two pairs of values must be entered in the table.

Once created, calibration tables can be saved (using the Save As

button), and reloaded (using the Load button) for use in other

configurations.

Default Output:

The analog output voltage is set to the Default Output voltage if the PLM

is not active or if the analog output is disabled.

Page 19

MoTeC Sensor Calibration 19

Sensor Calibration

Introduction

The NTK and Bosch lambda sensors are factory calibrated with a trimming

resistor embedded in the sensor connector. This resistor value can be read by

the PLM and used to calibrate the sensor readings for a new sensor.

As sensors age their calibration changes. To maintain accurate readings, the

PLM allows comparison of the measured O2 concentration in air against that of

the pure O2 reference in the sensor itself to calculate a new calibration.

Sensor calibration values in the PLM Setup software are expressed as either an

equivalent calibrat ion resistor value, or as a gain factor. It is recommended that

all applications that require sensor calibration values to be measured and

recorded (such as workshops using multiple sensors) should use the gain factor

calibration number rather than the equivalent resistor. Support for equivalent

resistor calibration values is included for backwards compatibility with previous

PLM software.

Calibration Methods

There are four calibration methods available under the Setup | Sensor menu.

Use Measured Calibration Value

The factory calibration resistor is measured by the PLM and used to calibrating

readings. The factory sensor plug must be present to use this calibration

method.

Enter Calibration Value

A previously measured calibration value can be entered directly as either an

equivalent calibration resistor value or as a gain factor value.

Entered calibration values are useful when sensors are calibrated using the free

air calibration (O2 concentration). The results of the free air calibration can be

recorded for a particular sensor and then entered when the sensor is used with

another PLM.

Page 20

20 Sensor Calibration

Calculate from O2 Concentration (Free Air)

This calibration method uses the known oxygen concentration of free air to

calibrate a sensor. Re-calibration using this method allows a sensor to maintain

accuracy as it ages.

To perform the free air calibration, the PLM must be powered up and connected

to a PC (with a serial cable) running the PLM Setup software. The configuration

in the PLM must match the sensor type being used for the calibration. Free air

calibration must be done in the open air – not in a workshop or dyno room

where there will be large amounts of hydrocarbons in the atmosphere.

The O2 Concentration parameter specifies the actual % concentration of

Oxygen in the at mosphere and should be entered if known. A nominal value of

20.94% is given, but the more accurately this is known for current atmospheric

conditions (temperature, pressure) the more accurate the calibration will be.

To start the calibration process, click the ‘Calibrate’ button. The following dialog

is displayed while the sensor readings stabilize.

When the sensor reading is stable the calibration can be stored by clicking the

Store button, as shown below.

The new calibration value is displayed as bot h a gain factor and an equivalent

resistor calibration. This calibration can be recorded against the sensor serial

number to allow the sensor to be used with another PLM unit by simply entering

the calibration value.

Page 21

MoTeC Sensor Calibration 21

To apply the new calibration, the PLM configuration must be saved and sent to

the PLM.

Enter Calibration Table

For advanced applications, a calibration table can be specified to calculate Ipn

(normalized sensor pump cell current) from Ip (sensor pump cell current).

At least two pairs of values must be specified in the table, and linear

interpolation is used between the points. Calibration tables may be saved and

reloaded for use in other calibrations.

Page 22

22 PLM Communications

PLM Communications

CAN Messages

The PLM can transmit up to four CAN messages containing readings and

diagnostics.

The format of these four messages is fixed (see Appendix M – CAN Messages

Format), but the following parameters can be configured by the user for each

message under the Setup | CAN Messages menu.

Address Format:

Standard address formatting is recommended for most applications.

Extended addressing should normally only be used if required for

interfacing to third party equipment , however it is supported by the ADL if

required.

Address:

The CAN address for a message is specified in hex. The recommended

address range for PLM messages is hex 460 to hex 46F.

Compound ID:

The compound ID (0 to 255) is placed in the first data byte of the CAN

message and is used to differentiate between messages sent to a single

CAN address. Multiple messages can be transmitted to a single address

by specifying different compound IDs for each message.

Message Rate:

The message rate (1,2,5,10,20 or 50 times per second) determines how

often the CAN message is transmitted.

Scaling

The scaling of the actual reading for the PLM is determined by the Output to

Transmit parameter which specifies the output table to be used for transmitted

values (eg. Lambda, O2 concentration etc.).

Page 23

MoTeC PLM Communications 23

For use with MoTeC equipment (ADL or M800), the selected table must be

setup for Lambda with 3 decimal places. Other table setups should only be

used for interfacing with third party equipment.

Configuring Basic CAN with an ADL

To connect a small number of PLM units (maximum of six) to an ADL, the ADL

must use one CAN template (PLM#1 to PLM#6) for each PLM.

The PLM units must be configured as follows to match the ADL templates.

Output To Transmit LA V1, with 3 decimal places in the table

Address Format Standard

Address As per ADL template (460 to 465)

Compound Id Message 1 = 0

Message 2 = 1

Message 3 = 2

Message 4 = 3

Message Rate Message 1 = User defined

Message 2 = User defined

Message 3 = User defined

Message 4 = User defined

Collect Master = Off

Configuring basic CAN with an M800

Up to 12 PLM units can transmit to an M800 ECU if configured as follows:

Output To Transmit LA V1, with 3 decimal places in the table

Address Format Standard

Address PLM 1 = 460

PLM 2 = 461

….

PLM 12 = 46F

Page 24

24 PLM Communications

Compound Id Message 1 = 0

Message Rate Message 1 = User defined

Message 2 = Off

Message 3 = Off

Message 4 = Off

Collect Master = Off

CAN Collect Functionality

For applications involving multiple PLM units, a single PLM can be configured to

collect calibrated lambda readings from up to 15 other PLMs on the CAN bus,

and to retransmit the 16 readings on a single CAN address. This functionality is

available in PLM firmware V1.1 and later.

Note that only the calibrated lambda reading is collected and re-transmitted. If

the CAN collect feature is used, PLM Diagnostic CAN messages may still be

turned on, but care must be taken in assigning addresses not to interfere with

messages from the other PLMs.

Configuring the CAN collect master unit (PLM 1)

Only one PLM on the CAN bus should be configured as a Collect Master.

To enable the CAN collect functionality, a base address and a message rate

must be specified in the Collect Master tab of the CAN Message Setup dialog.

Page 25

MoTeC PLM Communications 25

The base address is the address on which the collected Lambda values will be

retransmitted. This address must lie on a 16 message boundary (i.e. the

address, in hex, must end in 0). The base address also defined the addresses

of the Collect slave units that the master will monitor. The recommended

address is Hex 460.

The message rate is the rate at which the Lambda values are retransmitted on

the CAN bus to the measuring device (usually an ADL or ECU).

Messages 1 to 4 do not need to be configured on the master unit.

Output to Transmit must be LA V1, with 3 decimal places in the table setup.

The master PLM unit will briefly display “CU 1” (Collect Unit 1) on start-up after

displaying the firmware version.

If the slave PLM stops transmitting to the master PLM for 1.5 seconds then the

master PLM will retransmit a value of 0 for the missing slave.

Configuring the CAN Collect slave units (PLM 2

to PLM 16)

The Message 1 tab of the CAN Message Setup dialog must be configured as

follows:

Output To Transmit LA V1, with 3 decimal places in the table

Address Format Standard

Compound ID 00

Message Rate As required for application. This is the rate at which the

Lambda value for this unit will be sent to the master

unit.

Address Master PLM Collect Master Base Address + PLM

number – 1 (in hexadecimal)

Eg. For a master PLM base address Hex 460:

PLM 5 address would be Hex 464

PLM 12 address would be Hex 46B

Page 26

26 PLM Communications

Messages 2 to 4 are not required and should be “OFF” on the slave units.

The Collect Master message rate must be set to OFF on the slave units.

A PLM configured as a slave unit will briefly display the PLM unit number (eg “U

4” for PLM 4) on start-up after displaying the firmware version.

Appendix O – Recommended CAN Collect Configuration describes the

recommended configuration for connecting multiple PLM units to an ADL.

CAN Unit Number Display

On power-up, a PLM will display a unit number based on the current CAN

communications configuration. This unit number is displayed for one second

after the firmware version has been displayed. The unit number is useful for

trouble shooting systems containing multiple PLMs.

The unit number displayed is based on whether the unit is a Collect Master, and

on the least significant digit of the CAN address specified for CAN Message 1,

as shown below.

Display PLM Number Configuration

U 0 PLM 0 Collect Master disabled

Message 1 disabled (Message Rate = Off)

Page 27

MoTeC PLM Communications 27

CU1 PLM 1 Collect Master enabled

U1 PLM 1 Collect Master disabled

Message 1 address = xx0

U2 PLM 2 Collect Master disabled

Message 1 address = xx1

… … …

U16 PLM 16 Collect Master disabled

Message 1 address = xxF

A correctly configured network of PLMs using the CAN collect functionality

should have the unit numbers CU1, U2, U3, U4 etc.

A correctly configured network of PLMs that are not using the CAN collect

functionality should have the unit numbers U1, U2, U3, U4 etc.

A correctly configured PLM that is not using CAN communication should have

the unit number U0.

RS232 Messages

The PLM transmits RS232 status messages at a rate of 20 times a second.

If the PLM is configured as a CAN Collect Master then the transmitted message

contains the Lambda values for the master PLM and up to 15 slave PLMs.

If the PLM is not configured as a CAN Collect Master the transmitted message

contains Lambda values and diagnostics for the PLM.

Appendix N – RS232 Message Format describes the format of the RS232

Messages. Note that the number of decimal places for calibrated sensor

readings depends on the selected output table in the PLM configuration.

The transmitted messages conform to the MoTeC generic data protoc ol and are

sent at 9600 baud, 8 data bit, no parity, 1 stop bit (9600, 8N1).

Page 28

28 Specifications

Specifications

Meter

Power Supply

Input Voltage Range 7 to 16Volts

Input current 60mA typical, backlight off

110mA typical, backlight on

Plus sensor heater current

Protection Reverse polarity protected

Load Dump Clamp Max 40V at 100 Amp 100msec

Sensors

Sensors 1

Compatible Types Bosch LSU 4/ Bosch LSU 4.2/ NTK UEGO

Calibration Methods Automatic using sensor’s built in calibration resistor

Manual Table Entry

Known Oxygen Environment

Calibration Constant

Type Detection Manual

Sensor Thread M18 x 1.5

Max Exhaust Temp 850 deg

Normal Temp Range 150 – 800 deg

Measurements

Lambda 0.7 to 32.0

02 0 to 22%

A/F Ratio Fuel dependant (see lambda range)

Accuracy +/- 1.5% (sensor specific)

Page 29

MoTeC Specifications 29

Sensor Heater

Outputs 1

Current Max 8 Amp

Control Bosch - Digital PID

NTK - Constant Voltage

Voltage supply to the PLM should be at least 11V for

proper operation of the sensor heater when using an

NTK UEGO sensor.

Output

Output Type Differential

Calibration User Programmable

Max Output Current 10mA (Short circuit protected)

Output Voltage Swing 0 to 4.5V relative to the negative output (when the

negative output is less than 0V and greater than

negative 4.5V (relative to Battery -) and for output

currents less than 1mA.

If the negative output is greater than 0V then the

output voltage swing will be reduced by the voltage on

the negative output (relative to Battery -)

If the negative output is connected to a floating device

such as a multimeter or other high impedance

measuring device then it will float in the range 1.25V

to 2.5V, this will reduce the output voltage swing by

2.5V to 0 to 2V. In this case connecting the negative

output to Battery - will restore the full output voltage

swing.

Negative Pin Output

Voltage Range Must be within -4.5 to +5 volts (relative to Battery -)

The negative out put has an impedance of

approximately 5kohm connected to a variable voltage

in the range 1.25V to 2.5V (relative to Battery -)

Min Positive Pin

Output Voltage -4.5V (relative to Battery -) for current less than 1mA

Page 30

30 Specifications

Max Positive Pin

Output Voltage 4.5V (relative to Battery -) for current less than 1mA

Inputs

Digital 2 x User Programmable as RPM or PLM Operate

Communications

CAN 1Mbit

RS232 9600 baud, 8 data bits, no parity, 1 stop bit (9600,

8N1)

Display

Type LCD 3.5 Digit

Digit Height 12.7mm

Lighting Green LED Back Light

Connection

Connectors 2 x 9 Pin Dsub (commonly called D9)

Environment

Temperature Range -10 to 70 Deg C

Case

Dimensions(WxHxD) 105x41x25 mm (Excluding Connector)

Weight 135grams

Page 31

MoTeC Appendices 31

Appendices

Appendix A – Lambda to Air Fuel Ratio Table

Lambda Air Fuel Ratio

Petrol Alcohol LPG Diesel

0.70 10.3 4.5 10.9 10.2

0.75 11.0 4.8 11.6 10.9

0.80 11.8 5.1 12.4 11.6

0.85 12.5 5.4 13.2 12.3

0.90 13.2 5.8 14.0 13.1

0.95 14.0 6.1 14.7 13.8

1.00 14.7 6.4 15.5 14.5

1.05 15.4 6.7 16.3 15.2

1.10 16.2 7.0 17.1 16.0

1.15 16.9 7.4 17.8 16.7

1.20 17.6 7.7 18.6 17.4

1.25 18.4 8.0 19.4 18.1

1.30 19.1 8.3 20.2 18.9

1.35 19.8 8.6 20.9 19.6

1.40 20.6 9.0 21.7 20.3

1.45 21.3 9.3 22.5 21.0

1.50 22.1 9.6 23.3 21.8

1.55 22.8 9.9 24.0 22.5

1.60 23.5 10.2 24.8 23.2

Page 32

32 Appendices

Appendix B – PLM Display Codes

Warm-up Codes

C-6 Sensor Protection Shutdown. The C-6 state is entered when the PLM

can not pump enough current into the pump cell to balance the sense cell.

When C-6 is entered pump current is turned off. The PLM will try to gain control

of the sensor (the C-1 state) every 10 seconds. If it is then unable to regain

control after 2 seconds then it will re-enter the C-6 state.

C-5 User Stop. The sensor has been turned off via a digital input

C-4 No Heater detected. This will occur if the sensor is disconnected or the

heater is open circuit – ie: the sensor is damaged. Heater circuit should be

approx 3ohms at room temp

C-3 Warm Up. The PLM is heating the sensor prior to normal operation and

waiting for sensor to warm up.

C-2 Control Initialization. Waiting to start pump current

C-1 Checking Operation. Waiting to get control of sensor cell voltage.

In normal operation the PLM will display C-3, C-2, C-1 then start reading lambda

values. The C-4 and C-6 error states will occur if a problem is detected.

Error Codes

0010 The config loaded into the PLM does not match the PLM firmware version

0011 The config stored in the PLM is corrupt (CRC failure)

0020 The factory calibration values does not match the PLM firmware version

0021 The calibration stored in the PLM is corrupt (CRC failure)

Page 33

MoTeC Appendices 33

Appendix C – PLM CAN Diagnostic Codes

These are the bit field descriptions for the diagnostic error groups that are sent

to the ADL via the CAN link.

Diagnostic Group 1

1: No Sensor

2: Sensor Hot

4: Sensor Cold

8: Sensor Faulty

32: Warm Up

64: Ref voltage out of range

Diagnostic Group 2

These codes correspond to those displayed by the PLM.

1 (C-1) - Checking Operation.

2 (C-2) - Control Initialization.

4 (C-3) - Warm Up.

8 (C-4) - No heater detected.

16 (C-5) - User Stop (sensor turned off via digital input).

32 (C-6) - Sensor Protection Shutdown.

Page 34

34 Appendices

Appendix D – PLM Connector Details

Sensor Connector - Male D9

1 Battery +12 Power (Note 2)

2 Heater +

3 Rc

4 Ip

5 Sensor Common

6 Battery 0V Power

7 Heater –

8 Vs

9 Ipr

Auxiliary Connector – Female D9

1 CAN Hi (Note 3)

2 RS232 Tx

3 RS232 Rx

4 Digital Input 1

5 Comms 0V

6 CAN Lo (Note 3)

7 Digital Input 2

8 Analog out + (Note 4)

9 Analog out – (Note 4)

Note1: Extension of Standard Sensor Loom

The length of the standard loom supplied for connection of the PLM to a sensor

is 2.5m. Longer looms are available from MoTeC by request.

It is not recommended that the loom is extended by using a standard serial

cable. These are unable to supply the current required by the sensor. If an

extension is made, the wire thickness must be at least 20 gauge.

Note 2: Power Supply Current

If using a power supply other than the vehicle battery, start -up current for the

sensor is up to 5A, though operating current is much lower than this, 0.5 – 1

Amps, depending on exhaust gas temperature.

Page 35

MoTeC Appendices 35

Note 3: Wiring

See Appendix G – PLM to ADL Wiring Details for CAN wiring to an ADL

See Appendix F – PLM to ECU Wiring Details for CAN wiring to an M800 ECU

See Appendix H – General CAN Bus Wiring for recommended CAN wiring

practices

Note 4: Analog Output

Connect the “Analog out +” to the input on the measuring device.

Connect the “Analog out –“ to the 0V reference point on the measuring device.

“Analog out –“ must be connected for the measuring device to make a correct

reading.

See Appendix F – PLM to ECU Wiring Details for wiring the analog outputs to

M4/M48, M8 & M800 ECUs

Page 36

36 Appendices

6 Ip

Bosch

LSU 4

5 Heater +

4 Heater

-3

Common

BAT-

N/C

2 Vs

Heater

-

1

BAT+

BAT-Vs Ipr

PLM

Heater +

M2

Rc M1

BAT+

M3M4M5M6M7M8M9Ip

Common

Ipr

Appendix E – Sensor Wiring Details

Bosch LSU 4 Sensor

Wiring Details

Page 37

MoTeC Appendices 37

6

Ipr

Bosch

LSU 4.2

5

Common

4

Heater

- 3 Heater +

BAT-

N/C 2 Ip

Heater

-

1 BAT+ BAT- Vs

Ipr

PLM

Heater +

M2 Rc M1

BAT+

M3 M4 M5 M6 M7

M8

M9 Ip Common

Vs

Bosch LSU 4.2 Sensor

Wiring Details

Page 38

38 Appendices

NTK – UEGO Sensor

Page 39

MoTeC Appendices 39

3 Common

NTK UEGO

4 Ip

5 Vs6

BAT-

N/C7

Heater

-

Heater

-

8

BAT+

BAT-Vs Ipr

PLM

Heater +

M2

Rc

M1

BAT+

M3M4M5

M6

M7

M8M9Ip Common

Heater +

21 RcCommon

N/C

Wiring Details

Page 40

40 Appendices

F8 F9 32

Red

PLM M4/M48

La+ La

- A out

A out

-

F8 F9

24A

36A

Red

PLM M8

La+ La

- A out

A out

- 0V 10A

Appendix F – PLM to ECU Wiring Details

Analog Output

PLM wiring using the Analog Output to M4/M48/M8/M800 ECUs :

(Previously La- was shown connected to ECU 0V, this is now optional)

PLM

A out +

A out -

F8

Red

F9

Black

B25, B12 / 60, 61

B16 / 27

M800/M880

La1S or La2S

Sensor 0V

CAN

One or more PLMs may be connected to the M800 ECU via the CAN bus.

Note that the ECU version must be V3.0 or higher.

See Appendix H – General CAN Bus Wiring for details on correct wiring and

termination for CAN devices.

Page 41

MoTeC Appendices 41

Appendix G – PLM to ADL Wiring Details

One or more PLMs may be connected to the MoTeC ADL via the CAN bus.

See Appendix H – General CAN Bus Wiring for details on correct wiring and

termination for CAN devices.

Page 42

42 Appendices

CAN-LO CAN-HI

100R

CAN

-LO

CAN

-HI

500mm

Max

CAN

-LO

CAN

-HI

CAN Cable

500mm

Max

500mm

Max

CAN

-LO

CAN

-HI

CAN

-LO

CAN

-HI

5 4 3 1

Appendix H – General CAN Bus Wiring

The CAN bus should consist of a twisted pair trunk with 100R (0.25Watt)

terminating resistors at each end of the trunk.

The preferred cable for the trunk is 100R Data Cable but twisted 22# Tefzel is

usually OK.

The maximum length of the bus is 16m (50ft) including the MoTeC CAN Cable

(PC to CAN Bus Communications Cable)

CAN Devices (such as MoTeC PLM, ADL, etc) may be connected to the trunk

with up to 500mm (20in) of twisted wire.

The connector for the CAN Communications Cable may also be connected to

the trunk with up to 500mm (20in) of twisted wire and should be within 500mm

of one end of the trunk. If desired two CAN Cable connectors may be used so

that the MoTeC CAN Cable may be connected to either side of the vehicle.

Both connectors must be within 500mm of each end of the trunk.

100R Terminating

Resistors at each

end of the CAN Bus

These wires must be Twisted

Minimum one twist per 50mm (2in)

<< CAN Bus >>

Connector

0V

8V

Short CAN Bus

If the CAN Bus is less than 2m (7ft) long then a single termination resistor may

be used. The resistor should be placed at the opposite end of the CAN Bus to

the CAN Cable connector.

100R

CAN

Device

CAN

Device

CAN

Device

Page 43

MoTeC Appendices 43

PLM

0V

Standard Serial Comms cable.

only 3 wires are required.

F5

PC Serial Port

Comms 0V

5

Appendix I – PC Comms Wiring

A PC may be connected to the PLM by connecting to the 9 pin female

connector as shown below. This allows the PLM to be configured using the

PLM Configuration software.

It is also acceptable to use a standard 1:1 male to female communications

cable which connects all 9 pins.

Note that during configuration the PLM must also have power connected to it via

the PLM 9 pin male connector.

RS232 Rx

RS232 Tx

F3

F2

This will connect all 9 pins, but

3

RS232 Tx

2

RS232 Rx

Page 44

44 Appendices

F8 F9

PLM Floating

Input +

Input –

A out +

A out

-

M6

Battery

- Battery

-

F8 F9

PLM Single Ended

Input +

Input

- A out +

A out

-

M6

Ground

Ground

Battery

- Battery

-

Appendix J – Analog Output Wiring

Floating Measuring Device

When connected to a floating measuring device such as a multimeter, Aout –

should be connected to Battery – as shown to ensure that the full output voltage

swing is available. (See the specifications for details)

Measuring Device

Single Ended Input Measuring Device

A single ended measuring device has the negative input internally connected to

the devices ground pin.

Note: The Ground voltage must not be more than 4.5 volts below Battery –.

Note: If the Ground voltage is greater than the Bat tery – voltage then the PLM

output voltage swing will be reduced. (See the specifications for details)

Differential Input Measuring Device

When connected to a differential input measuring device, Aout – should be

connected to Battery– as shown to ensure that the full output voltage swing is

available. (See the specifications for details)

Measuring Device

Page 45

MoTeC Appendices 45

F8 F9

PLM

Input +

Input

–

A out +

A out

-M6

Ground

Ground

Battery

-

Battery

-

Note: Aout+ and Aout – must be within the within the input common mode range

of the measuring device. This limits the voltage difference that can be between

Battery– and Ground.

Differential Input

Page 46

46 Appendices

Dig

ital

Input

1/2

PLM

0V

Dig

ital

Input

1

PLM

0V

Signal

Sensor 0V

RPM Sensor: Must

8V sensor

Appendix K – Digital Input Wiring

Typical wiring for switches

Typical wiring for RPM measurement

be Hall Effect type

supply

Page 47

MoTeC Appendices 47

Appendix L – Glossary

CAN – Controller Area Network. High speed serial data bus common in

automotive applications

Ip – Sensor pump cell current

Ipn – Normalised Ip

Vs – Sense voltage

Page 48

48 Appendices

Appendix M – CAN Messages Format

Messages 1 to 4 can be optionally transmitted from any PLM unit.

Messages 5 to 10 are only transmitted from a PLM unit configured as a CAN

Collect Master.

Message 1

Byte Name Scaling

0 Compound ID – user defined,

default 0

1:2 Calibrated Sensor Output Value –

user defined, default Lambda

3 Heater duty cycle Byte*1 = xxx%

4 Device Internal Temperature Byte*195/10-500 = xxx.xC

5 Zp (Pump cell impedance) Byte*1 = X ohm

6 Diagnostic Field 1 Sensor RUN

7 Sensor state RUN

N/A

Hi:lo*1 = x.xxxLa (Note 1)

Sensor COLD

Sensor FAULT

Sensor WARM UP

ADC Ref fault

CONTROL_WAIT

PUMP_WAIT

WARM_UP

NO_HEATER

STOP

PUMP_OFF

2

4

8

32

64

0

1

2

3

4

5

6

Page 49

MoTeC Appendices 49

Message 2

Byte Name Scaling

0 Compound ID – user defined,

default 1

1:2 Ipn (Normalised pump cell

current)

3 Vs (Sense voltage) Byte*5 = X mV

4 Vp (Pump cell voltage) Byte * 10000 / 255 – 5000 = X

5 Reserved N/A

6:7 Ip (Raw pump cell current) Hi:Lo * 1 = X µA

N/A

Hi:Lo * 1 = X µA

mV

Message 3

Byte Name Scaling

0 Compound ID – user defined,

default 2

1 Bosch calibration resistor Byte*1 = X ohm

3 NTK calibration resistor Byte*1 = x.x kohm

4 Reserved N/A

5 Reserved N/A

6 Battery Voltage Byte*1 = x.xV

7 Sensor in control

N/A

Sensor voltage within

limits

1

Sensor voltage outside

limits

0

Page 50

50 Appendices

Message 4

Byte Name Scaling

0 Compound ID – user defined,

default 3

1 Positive Analog output pin

voltage

2 Negative Analog output pin

voltage

3 Sensor type NONE

4 Reset source (Note 2) Low Voltage reset

5 Firmware Version x.xx

6:7 RPM HI:LO xxxxx RPM

N/A

Byte*1000/255–500 = x.xx V

Byte*1000/255–500 = x.xx V

NTK

BOSCH LSU4

BOSHC LSU4.2

Illegal Address reset

Illegal operation reset

Watchdog timer reset

External reset

Message 5

Byte Name Scaling

0 Compound ID = 4 N/A

1 Reserved N/A

2:3 PLM 1 (Master PLM) Calibrated Sensor Output

Value

4:5 PLM 2 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

6:7 PLM 3 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

Hi:Lo*1 = x.xxxLa

(Note 1)

(Note 1)

(Note 1)

0

1

2

3

2

8

16

32

64

Message 6

Byte Name Scaling

0 Compound ID = 5 N/A

1 Reserved N/A

2:3 PLM 4 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

4:5 PLM 5 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

6:7 PLM 6 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

Page 51

MoTeC Appendices 51

Message 7

Byte Name Scaling

0 Compound ID = 6 N/A

1 Reserved N/A

2:3 PLM 7 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

4:5 PLM 8 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

6:7 PLM 9 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

Message 8

Byte Name Scaling

0 Compound ID = 7 N/A

1 Reserved N/A

2:3 PLM 10 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

4:5 PLM 11 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

6:7 PLM 12 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

Message 9

Byte Name Scaling

0 Compound ID = 8 N/A

1 Reserved N/A

2:3 PLM 13 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

4:5 PLM 14 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

6:7 PLM 15 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

Message 10

Byte Name Scaling

0 Compound ID = 9 N/A

1 Reserved N/A

2:3 PLM 16 Calibrated Sensor Output Value Hi:Lo*1 = x.xxxLa

(Note 1)

4:7 Reserved N/A

Page 52

52 Appendices

Note 1

Calibrated Sensor Output Value is x.xxxLa when the PLM is setup to transmit

Lambda with 3 decimal places as recommended for connection to MoTeC

equipment.

Note 2

Low Voltage reset: this is the only reset code that should be seen in normal

operation

External reset: this reset code may be seen after upgrading firmware

Page 53

MoTeC Appendices 53

Appendix N – RS232 Message Format

Master PLM Message

Byte Description Value

0 Header 0 = 0x80 0x80

1 Header 1 = 0x81 0x81

2 Header 2 = 0x82 0x82

3 Data Length 32

4:5 PLM 1 (Master) Calibrated sensor reading Hi:Lo = x.xxxLa

6:7 PLM 2 Calibrated sensor reading Hi:Lo = x.xxxLa

8:9 PLM 3 Calibrated sensor reading Hi:Lo = x.xxxLa

. .

. .

32:33 PLM 15 Calibrated sensor reading Hi:Lo = x.xxxLa

34:35 PLM 16 Calibrated sensor reading Hi:Lo = x.xxxLa

36:37 Checksum Hi:Lo = 16 bit sum

of unsigned bytes 0

to 35

Non-Master PLM Message

Byte Description Value

0 Header 0 = 0x80 0x80

1 Header 1 = 0x81 0x81

2 Header 2 = 0x82 0x82

3 Data Length 8

4:5 Calibrated sensor reading Hi:Lo = x.xxxLa

6 Sensor cold status

7 Sensor faulty status

8 Sensor control state

9 Sensor in control status

10:11 RPM Hi:Lo = RPM

12:13 Checksum 16 bit sum of

unsigned bytes 0 to

11

Page 54

54 Appendices

Appendix O – Recommended CAN Collect

Configuration

The following configuration is recommended for connecting multiple PLM units

to an ADL.

Master Unit (PLM 1)

CAN Message 1 Message Rate OFF

CAN Message 2 Message Rate OFF

CAN Message 3 Message Rate OFF

CAN Message 4 Message Rate OFF

Base Address Hex 460 Collect Master

Message Rate At least 1 per second

Slave Units (PLM 2 to PLM 16)

CAN Message 1

Address Format Standard

Compound ID 00

Message Rate Same as PLM 1 Collect

Address PLM 2 = Hex 461

Master Message Rate

PLM 3 = Hex 462

PLM 4 = Hex 463

PLM 5 = Hex 464

PLM 6 = Hex 465

PLM 7 = Hex 466

PLM 8 = Hex 467

PLM 9 = Hex 468

PLM 10 = Hex 469

Page 55

MoTeC Appendices 55

PLM 11 = Hex 46A

PLM 12 = Hex 46B

PLM 13 = Hex 46C

PLM 14 = Hex 46D

PLM 15 = Hex 46E

PLM 16 = Hex 46F

CAN Message 2 Message Rate OFF

CAN Message 3 Message Rate OFF

CAN Message 4 Message Rate OFF

CAN Collect

Message Rate OFF

ADL

Use the CA N template “PLM Collect 16 Channel”, and enable (ie. tick) the

channels required. By default the template has the first 8 channels enabled.

This template places PLM values in the following channels:

ADL Channel Channel Value

Lambda – Cyl 1 PLM 1 (Master PLM) Reading

Lambda – Cyl 2 PLM 2 Reading

Lambda – Cyl 3 PLM 3 Reading

Lambda – Cyl 4 PLM 4 Reading

Lambda – Cyl 5 PLM 5 Reading

Lambda – Cyl 6 PLM 6 Reading

Lambda – Cyl 7 PLM 7 Reading

Lambda – Cyl 8 PLM 8 Reading

Lambda – Cyl 9 PLM 9 Reading

Page 56

56 Appendices

Lambda – Cyl 10 PLM 10 Reading

Lambda – Cyl 11 PLM 11 Reading

Lambda – Cyl 12 PLM 12 Reading

Lambda 1 PLM 13 Reading

Lambda 2 PLM 14 Reading

Lambda – Left Bank PLM 15 Reading

Lambda – Right Bank PLM 16 Reading

Page 57

MoTeC Appendices 57

Appendix P – Dimensions

Page 58

58 Notes

Page 59

MoTeC Notes 59

Loading...

Loading...