Page 1

PDM

Power Distribution Modules

USER MANUAL

Page 2

MoTeC PDM User Manual

Contents

Introduction ........................................................................ 1

Features ................................................................................................... 1

System Overview ..................................................................................... 2

Installation .......................................................................... 3

Mounting .................................................................................................. 3

Wiring ....................................................................................................... 4

Battery Positive ............................................................................. 4

Battery Negative ............................................................................ 5

CAN Wiring .................................................................................... 5

Input Wiring .............................................................................................. 5

Output Wiring ........................................................................................... 6

Output Devices ........................................................................................ 6

Windscreen Wipers ....................................................................... 6

Solenoids ..................................................................................... 10

Electronic Devices ....................................................................... 11

PDM Manager Software Installation ...................................................... 12

Configuration .................................................................... 14

Configuration File .................................................................................. 14

Channels ................................................................................................ 15

Configuration Tree ................................................................................. 16

Global Setup ................................................................................ 16

Input Pins..................................................................................... 17

CAN Inputs .................................................................................. 18

CAN Output ................................................................................. 19

Functions ..................................................................................... 20

Output Pins .................................................................................. 21

CAN Keypads .............................................................................. 26

Operation .......................................................................... 27

CAN Bus Bitrate .......................................................................... 27

Sending and Retrieving Configuration Files ................................ 27

Checking Operation ..................................................................... 27

Serial Number ............................................................................. 28

Firmware Versions and Updating ................................................ 28

Password Protection ................................................................... 29

Page 3

PDM User Manual

Standby Mode........................................................................................ 29

Appendices ....................................................................... 30

Specifications ......................................................................................... 30

CAN Input Channel Examples ............................................................... 32

Fuse Characteristics .............................................................................. 34

Connectors and Pinout .......................................................................... 35

PDM16 ......................................................................................... 35

PDM32 ......................................................................................... 36

PDM15 ......................................................................................... 38

PDM30 ......................................................................................... 39

Mounting Dimensions ............................................................................ 40

PDM16 ......................................................................................... 40

PDM32 ......................................................................................... 41

PDM15 and PDM30 .................................................................... 42

Wiring ..................................................................................................... 43

Wire Specification ........................................................................ 43

UTC Wiring for PC Connection ................................................... 44

CAN Bus Wiring Requirements ................................................... 44

CAN Output Messages .......................................................................... 46

Windows Keyboard Shortcuts ............................................................... 52

Glossary ................................................................................................. 56

Copyright 2014 – MoTeC Pty Ltd

The information in this document is subject to change without notice.

While every effort is taken to ensure correctness, no responsibility will be taken for the

consequences of any inaccuracies or omissions in this manual.

PN 63029 V3.3, February 2014

Page 4

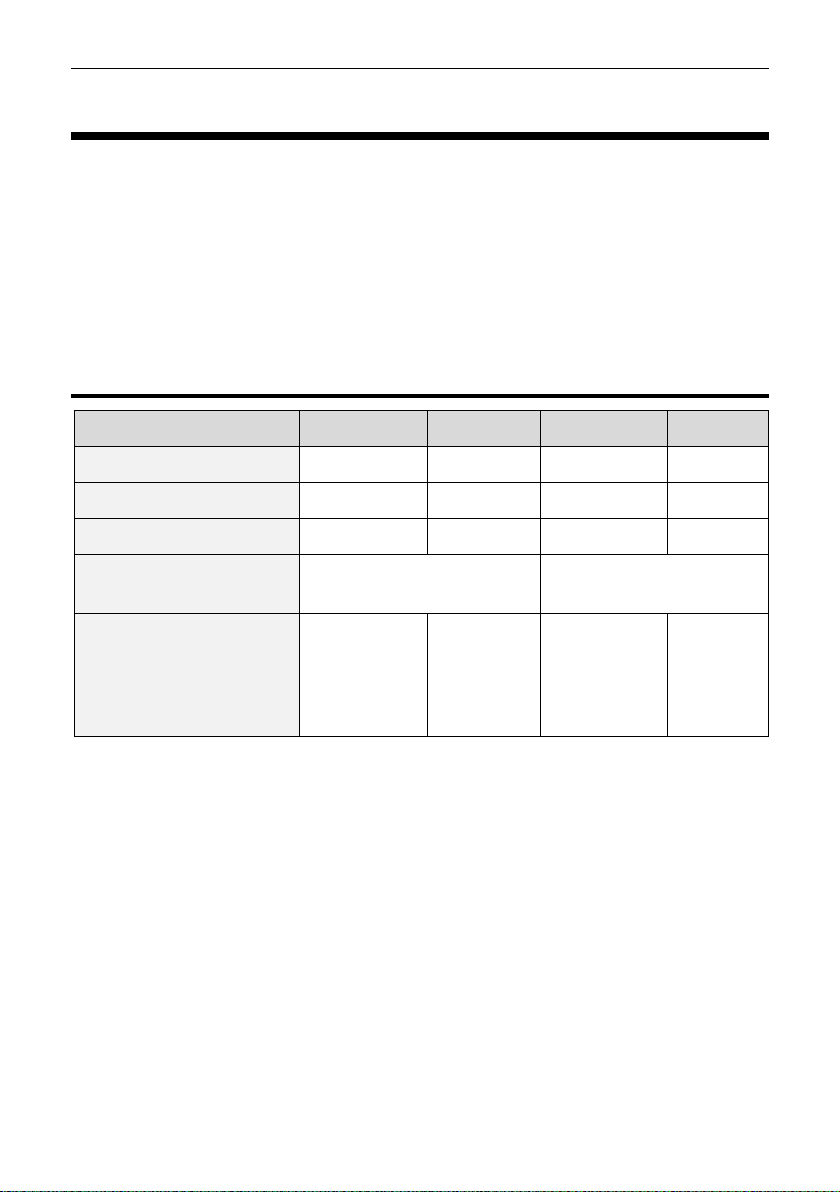

MoTeC Introduction 1

PDM16

PDM32

PDM15

PDM30

Inputs

12

23

16

16

8 Amp Outputs

8

24 7 22

20 Amp Outputs

8 8 8

8

Connectors

Autosport

Waterproof connectors

M6 stud

Case size

Length

Width

Height

130 mm

60 mm

28 mm

180 mm

60 mm

28 mm

107 mm

133 mm

39 mm

107 mm

133 mm

39 mm

Introduction

The PDMs replace conventional relays, fuses and circuit breakers by

providing electronically switched power to the various electrical systems in the

vehicle, including motors, lamps, ECUs and data systems. This simplifies

wiring and switch requirements, while increasing reliability.

There are four PDM versions: PDM16, PDM32, PDM15 and PDM30.

Throughout this manual all versions will be referred to as the PDM except

where details specific to a particular version are discussed.

Features

Each output is over-current, short circuit and thermal overload protected

Outputs are programmable in 1 A steps

Outputs are controllable via a combination of switch inputs, CAN

messages and logic functions

Switch inputs are ranging from 0 to 51 V, resolution 0.2 V

Performing up to 200 logic operations using operators like Flash, Pulse,

Set/Reset, Hysteresis, Toggle, And, Or, Less than, Greater than, Not equal

to, Equal to, True, False etc.

Performing functions such as flashing indicator lights and controlling

thermo fans and fuel pumps

Using logic functions to selectively turn off systems during low battery

voltage or engine starting, reducing drain on the battery

Page 5

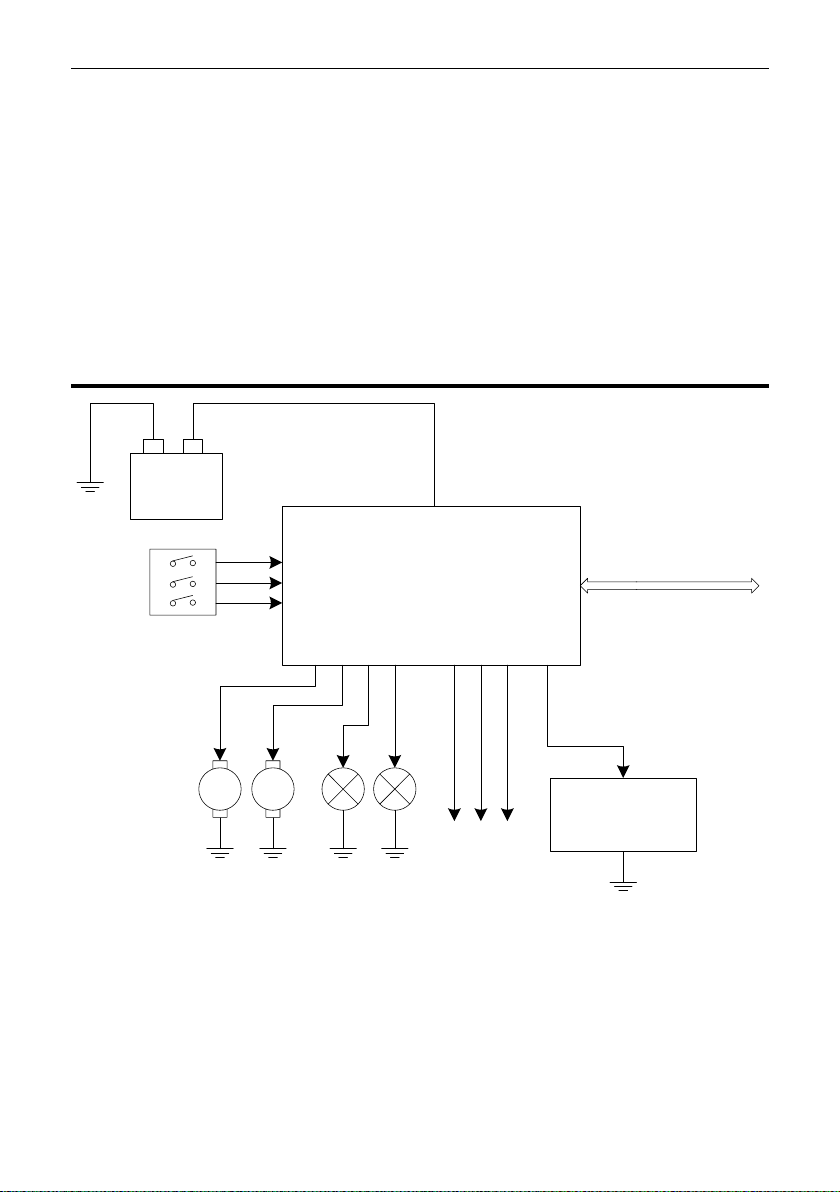

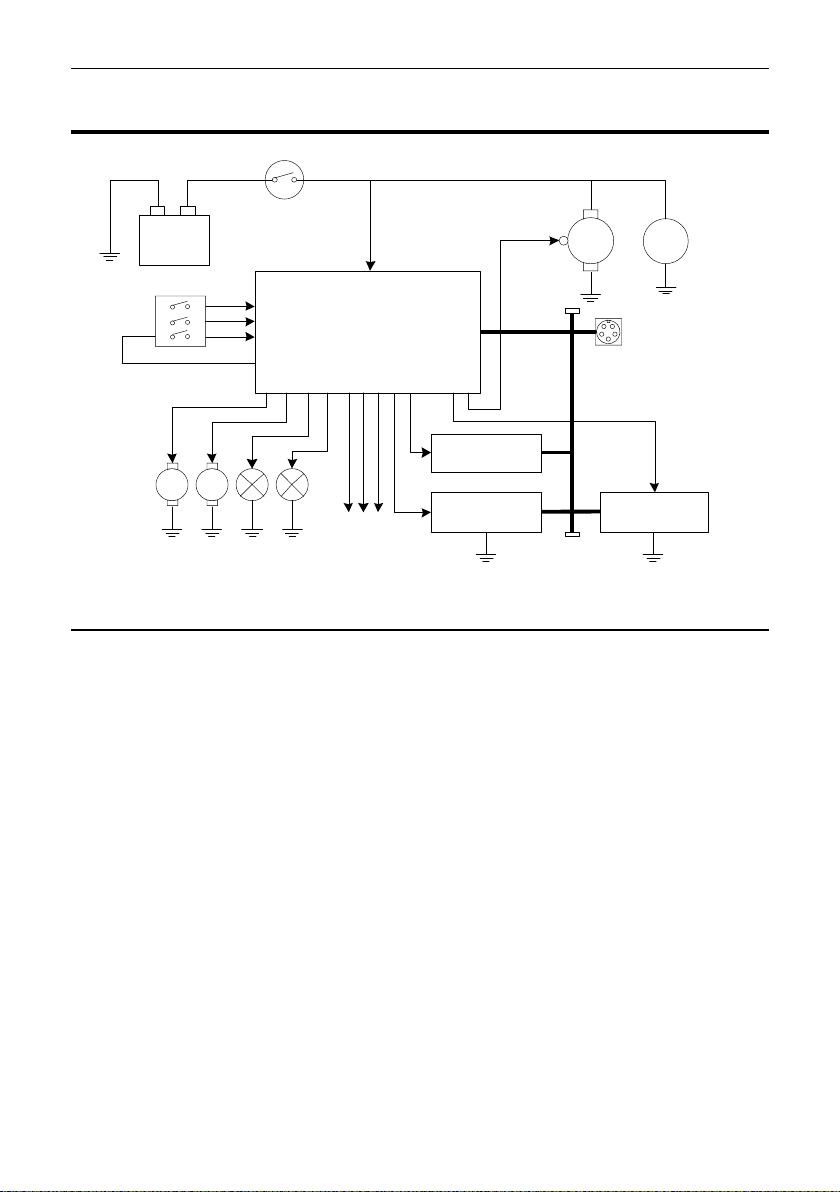

2 Introduction

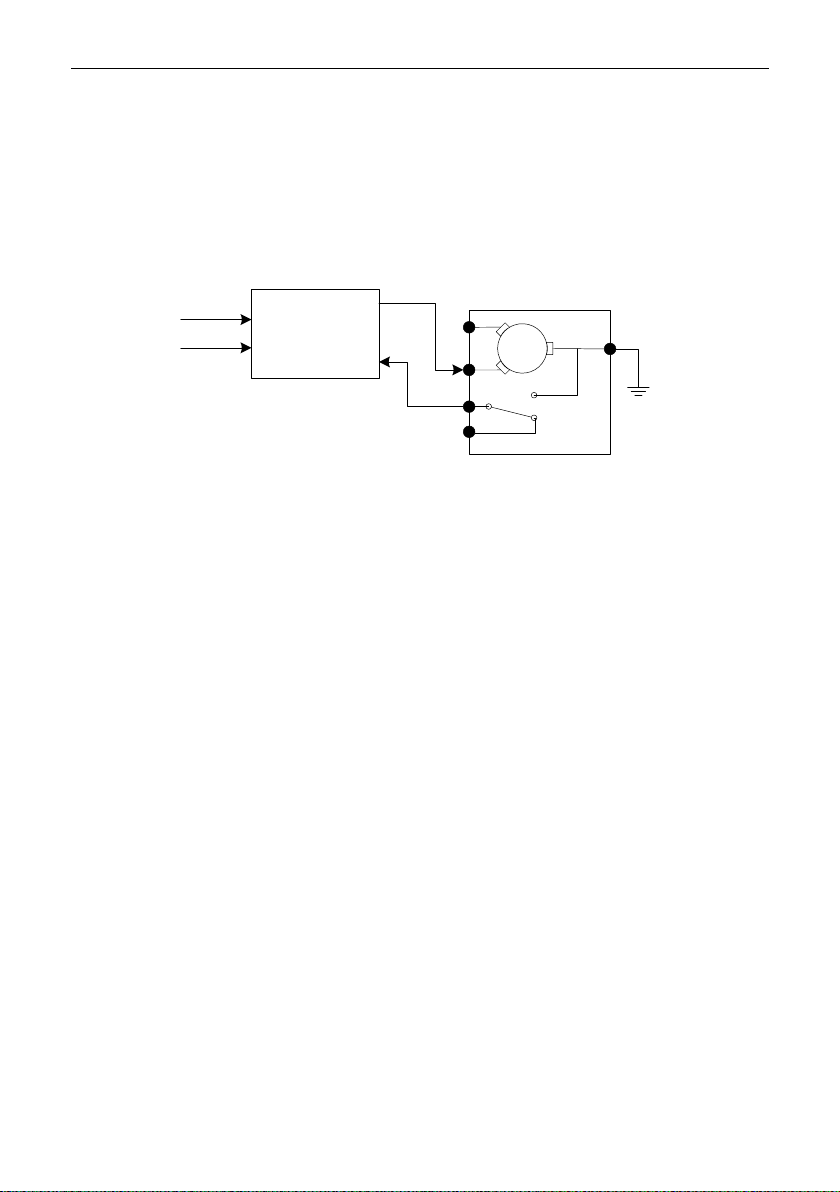

PDM

MM

Switches

Motors

CAN bus

Other

Devices

Lights

Outputs

Battery Input

CAN

Inputs

ECU

Battery

–

+

Providing full diagnostic information, including output currents and

voltages, input voltages, and error status

Transmitting diagnostic information via CAN to a display or data logging

device or monitoring directly on a PC

Protected against unauthorised access by a password feature.

Accessories

MoTeC UTC (USB to CAN adaptor) #61059

(Note: PDMs are not compatible with MoTeC CAN cable)

System Overview

Page 6

MoTeC Installation 3

Installation

Mounting

When mounting the PDM take into account that the PDM may get very hot

during operation.

Ensure the PDM is mounted in a well ventilated area and not against a hot

surface. For case dimensions see Mounting Dimensions.

The internal temperature is highly dependent on ambient temperature and

also on the total load current—a higher current will cause a higher

temperature.

Tip: The internal temperature can be checked in PDM Manager (see

Operation) or transmitted via CAN to be logged. Allow for sufficient time

for the temperature to stabilise. This may take 30 minutes or more.

If the internal temperature of the PDM exceeds the specified maximum values

(see Specifications), cooling may be achieved by one or more of the following:

relocating the PDM to a cooler mounting position

increasing air circulation around the PDM case

ducting cool air over the PDM case

fitting a heatsink to the back surface of the PDM case

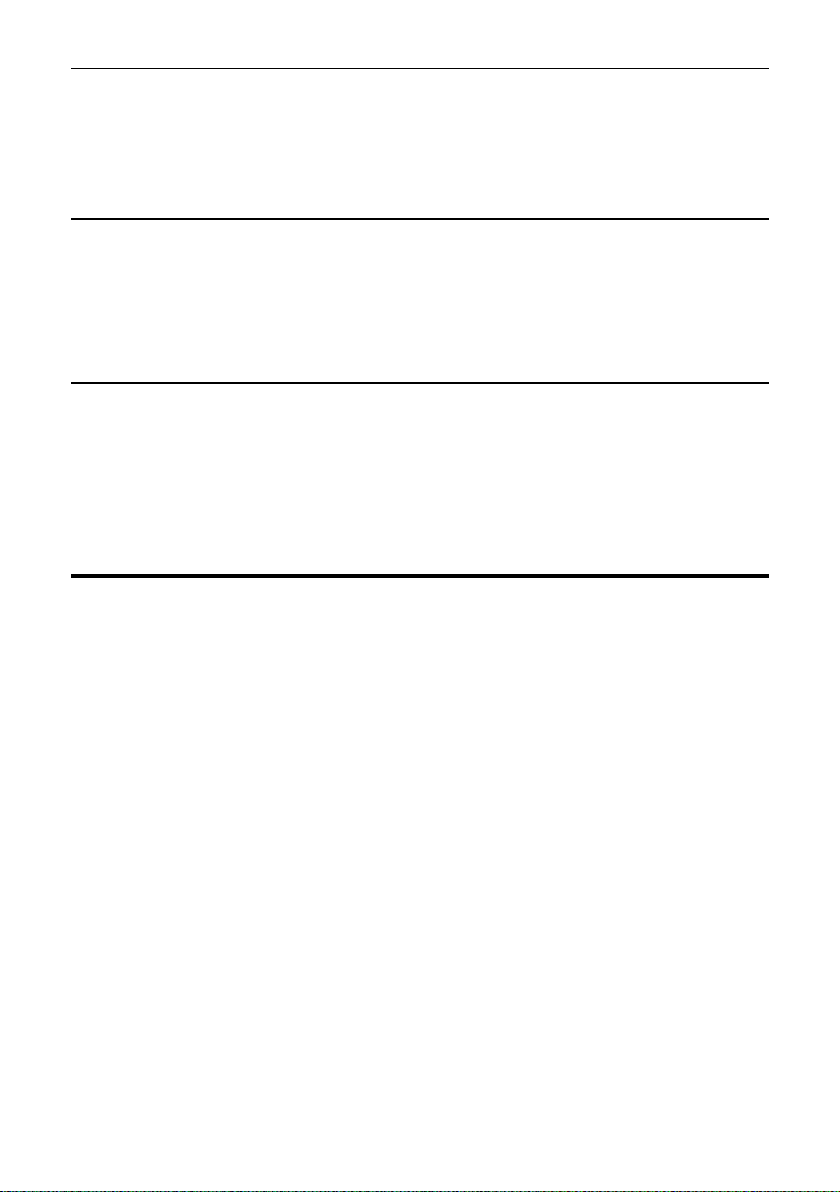

Page 7

4 Installation

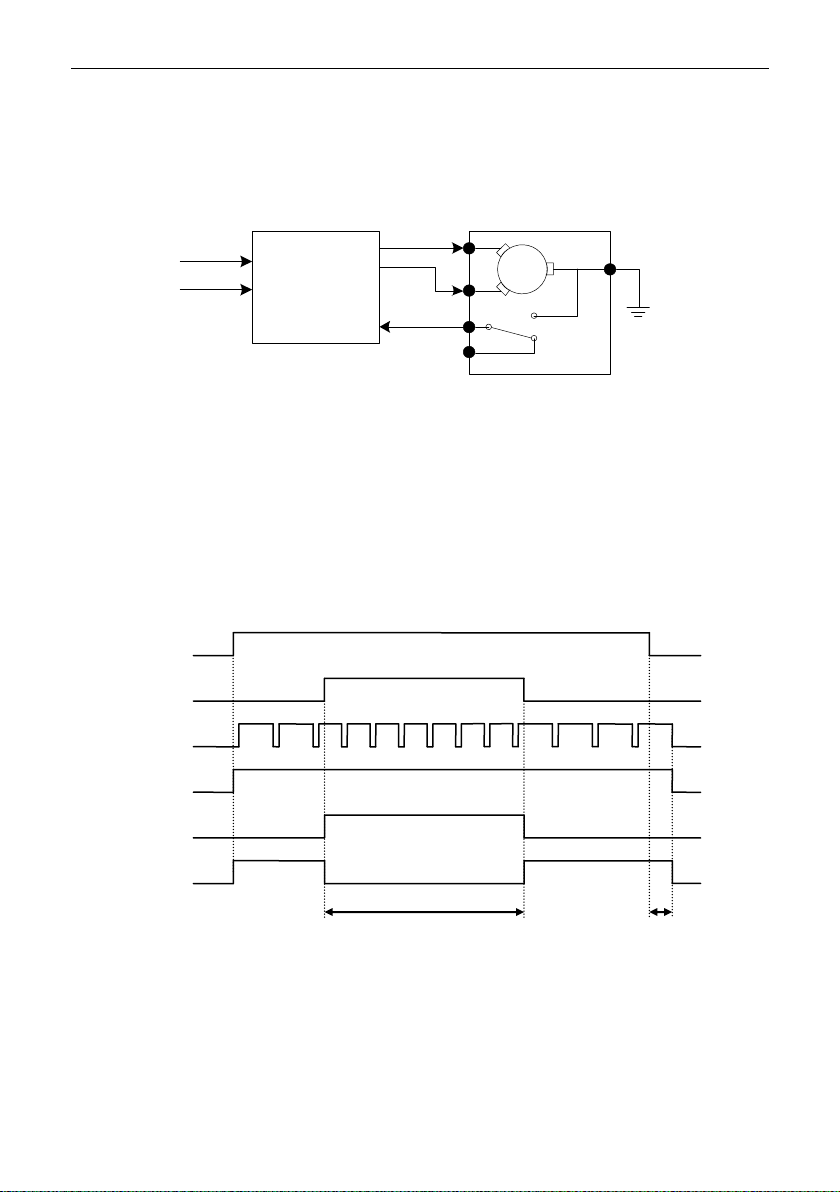

Other

Devices

PDM

A

MM

Switches

M

Motors

CAN Bus

Alternator

Lights

Starter

Motor

Outputs

Battery Input

Battery

CAN

Inputs

Isolator

Data LoggerECU

CAN Connector

for UTC

0 V

–

+

Keypad

Wiring

Battery Positive

Battery positive is supplied to the PDM via the single pin connector to suit wire

sizes 16 mm2 (6#) or 25 mm2 (4#).

The PDM16 and PDM32 use an Autosport connector, PDM15 and PDM30

use a 6 mm eyelet to suit the wire size.

The wire gauge should be chosen according to the wire temperature limit and

acceptable voltage drop. Tefzel wire must not exceed 150 °C.

The temperature of the wire is affected by the ambient temperature, air

circulation, current, wire gauge, the temperature of any surrounding wires and

the covering sheath.

See Wire Specification and Connectors and Pinout for details.

Battery Isolator Switch

Battery positive must generally be connected via an isolator switch or relay.

The isolator must isolate the battery from all devices in the vehicle including

the PDM, starter motor and alternator. The isolator must be rated to handle

the starter motor current.

When the battery is isolated, the engine may continue to run due to power

supplied by the alternator. To avoid this, the isolator switch should have a

secondary switch that is connected to a shutdown input on the ECU.

Page 8

MoTeC Installation 5

If the ECU does not have a shutdown input, the switch can be connected to a

PDM input. The PDM can then turn off power to the ignition system or the

ECU, which will cause the engine to stop.

Battery Negative

Both of the Batt– pins should be wired to battery negative via 20# wire.

These pins normally only carry the very low operating current, however during

a load dump they carry the load dump current which may be 50 ampere or

higher.

CAN Wiring

The PDM communicates over CAN with other devices connected to the same

CAN bus. The CAN bus must be wired according to CAN Bus Wiring

Requirements.

The PC also communicates to the PDM via the CAN bus. See Connecting the

PDM to a PC.

Input Wiring

The PDM Switch Inputs are intended for use with a switch that is directly

wired between a PDM input pin and a PDM 0 V pin. Each input has an

internal 10 kilo-ohm pull-up resistor to Batt+.

If it is required to connect a switch that is wired to another system in the

vehicle, ensure that the voltage levels are set appropriately as there may be

ground voltage variations between devices.

Tip: If standby current is important, wire the switches so that they are

normally open during standby. This will reduce the standby current.

Input Switch Connected to Battery

When an input is driven from a device that switches to battery, the switch

should if possible, be rearranged so that it switches to 0 V.

If the signal comes from an electronic device such as an ECU that has an

output that can only switch to battery (e.g. a signal that indicates when to turn

the fuel pump on), this might not be possible. In this case an external pulldown resistor is required. The resistor should be 1500 ohm 0.25 watt and

should be connected between the input pin and the 0 V pin.

The input trigger levels should be set to 4 V and 5 V to guarantee correct

triggering for all possible battery voltages.

Page 9

6 Installation

PDM

Park

Switch

Home

M

S

F

OEM

controller

Control

Switches

Output

Output Wiring

All outputs are high side type outputs; they switch Batt+ to the output pin.

They all have hardware thermal overload protection, fault logic and overcurrent logic.

Paralleled Outputs

Two or more output pins can be connected in parallel to increase current

capacity. Outputs that are connected in parallel must all be of the same type;

either all 8 Amp or all 20 Amp outputs.

Wire Gauges

The wire gauge must be chosen to suit the current consumed by the

connected device and to ensure that the voltage drop is acceptable. On long

runs it may be necessary to use a heavier gauge wire to minimise voltage

drop.

The wire gauge must also be compatible with the connector pin; using a

smaller than recommended wire gauge may result in a poor crimp.

Suitable wire gauges are 24# to 20# for the 8 Amp outputs and 20# to 16# for

the 20 Amp outputs. See Wiring for details.

Output Devices

Windscreen Wipers

The PDM can drive windscreen wiper motors; however the PDM cannot be

connected to both the fast and slow motor windings at the same time. The

voltage generated by the slow winding during fast operation will cause braking

of the motor and possible damage to the PDM.

A wiper unit can be wired in a number of ways. The following schematics are

shown for 'common-ground' wiper units. For 'common-positive' wiper units the

schematics must be adjusted accordingly.

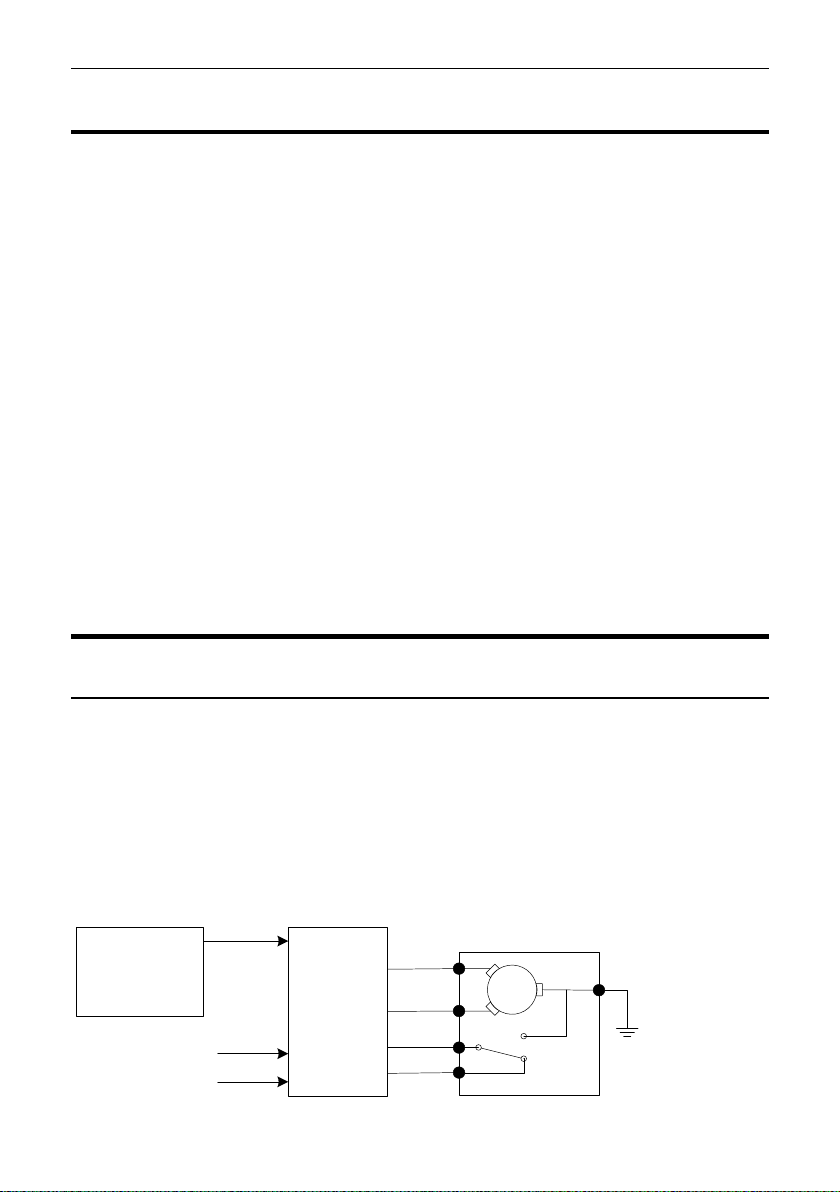

1. OEM Controller Method

Page 10

MoTeC Installation 7

PDM

c

Off

On

Fast

Slow

Park

Switch

Home

M

S

F

Output

PDM

Off

On

Fast

Slow

Relay

Park

Switch

Home

M

S

F

Control

Switches

Output

Output

The wiper unit can be wired using an OEM wiper controller with the PDM

supplying the power only.

The OEM controller performs the intermittent and motor braking functions.

2. Two Switch Method

The wiper unit can be wired in a simple two switch arrangement; one switch

for power and the other to select fast or slow. The PDM supplies power only.

Wiper motor braking is performed by the combination of the park switch and

the on/off switch.

This arrangement cannot perform intermittent operation since the wiper will

not park if the PDM simply removes power.

The switches must be able to handle the wiper motor current (typically

4 ampere).

3. Relay Method

The two switch method can be modified for intermittent operation by replacing

the on/off switch with a relay. The PDM controls the relay to perform the

intermittent function. This requires two PDM outputs; one to supply power and

the other to control the relay.

Motor braking is performed by the combination of the park switch and the

relay switch.

The PDM must be configured with the appropriate logic to perform on/off and

intermittent operation based on the state of the control switches.

Page 11

8 Installation

PDM

Park

Switch

Home

M

S

F

Input

Output 9

Control

Switches

Slow operation can be achieved using the switch or using intermittent

operation to give a similar effect which avoids the need for a high current

switch.

The fast/slow switch and on/off relay must handle the wiper motor current

(typically 4 ampere). The control switches can be low current types since they

only connect to PDM inputs.

4. Direct Method

The wiper unit can be wired directly to the PDM as long as it is only connected

to one output.

In this method the park switch is wired directly to a PDM input so the park

logic must be configured in the PDM.

This method requires the use of Output 9 which performs motor braking. The

PDM performs motor braking by momentarily shorting the output to ground

when the output turns off.

The PDM must be configured with the appropriate logic to perform on/off and

intermittent operation based on the state of the control switches.

Slow operation can be achieved using a switch between the fast and slow

windings as used in the other methods or intermittent operation can be used

to wipe less frequently.

The control switches can be low current types since they only connect to PDM

inputs.

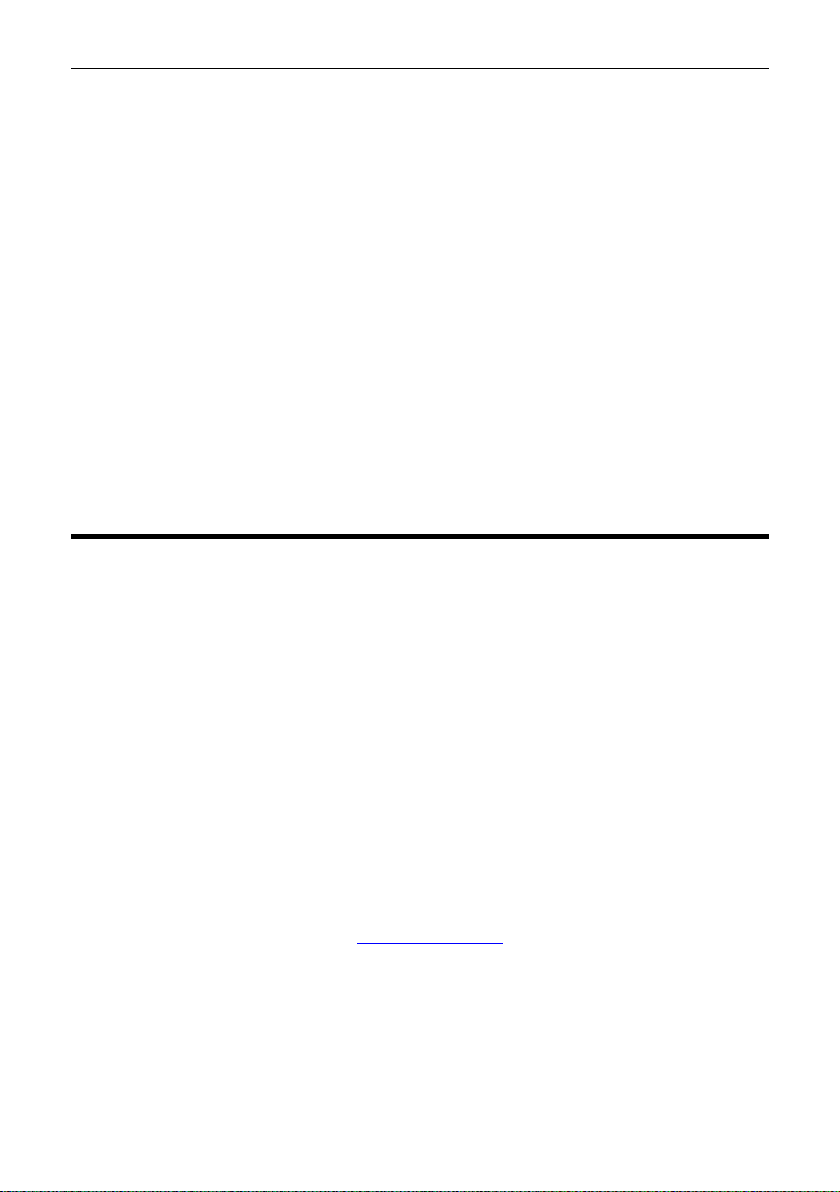

5. Direct Method with Linked Channels – PDM Version 2

Hardware

The PDM Version 2 hardware has additional functionality to simplify

windscreen wiper motor control.

This method requires the use of Output 9 which provides special wiper

functionality:

- Output 9 is isolated whenever the user nominated linked high speed

wiper output is turned on. This protects Output 9 from the high voltage

generated by the slow winding, and also prevents Output 9 from

Page 12

MoTeC Installation 9

PDM

Park

Switch

Home

M

S

F

Output 9

Output x

Control

Switches

Input

Wiper slow

input

Wiper fast

input

Wiper park

switch input

Wiper slow

condition

Out 9 (slow

winding)

Out x (High

Winding)

Out 9 held off while

linked output is on

Parking

braking the motor when the high speed winding is turned on. The

linked high speed wiper output can be configured in the Output 9

settings.

- Output 9 performs motor braking by momentarily shorting the output

to ground when the output turns off.

The PDM must be configured with the appropriate logic to perform on/off,

speed selection, intermittent operation and wiper parking based on the state

of the control switches and park switch input.

The diagram below shows an example sequence of wiper operations. The

wiper slow condition is setup to operate the slow winding when the wiper

switch is on, or when the wiper is not parked. When the linked fast winding

output is on, Output 9 is held off even though the condition driving output 9 is

still true.

Consider when implementing wiper control logic:

- The condition for the slow winding output (Output 9) can remain true

- The wiper should always be parked from the slow winding output

even when the fast winding output is on.

(Output 9) so that motor braking can be used.

Page 13

10 Installation

- Set the High Time and Low Time to 0.00s in the park switch input pin

configuration so that the wiper is parked as soon as possible after

reaching the park position.

An sample configuration for this method is included with PDM Manager.

Note: Version 2 hardware is indicated by the symbol 2 next to the engraved

serial number on the PDM case.

Solenoids

The current drawn by a normal single coil solenoid ramps up from zero to its

steady state value over a period of time. The time taken to do this depends on

the inductance and resistance of the solenoid but is normally very short (less

than 0.1 second). This has no effect on the PDM.

A solenoid will generate a voltage spike when turned off; this is clamped and

absorbed by the PDM. The amount of energy absorbed by the PDM depends

on the inductance and current in the solenoid. The PDM is capable of

absorbing the energy of most normal solenoids in a vehicle.

Two Stage Solenoids

Some solenoids have two windings; one is used to turn the solenoid on, the

other is used to hold it on once it has switched. This ensures optimum turn on

characteristics with minimum holding current.

The current drawn by the turn on winding may be higher than the current

drawn by the holding winding. Ensure the Output Load is well clear of 100%

during turn on and during holding.

Starter Solenoids

In many cases it is possible to run starter solenoids from a single 20 Amp

output even though they typically draw more than 20 ampere (possibly as

much as 40 ampere).

The Over-Current Shutdown feature allows excess current for a period of

time. This feature will shut down the output after about 10 to 20 seconds of

cranking. See the Over-Current Shutdown section for details.

The wire can be rated for 20 ampere, also ensuring that the starter motor

does not overheat during excess cranking. A larger wire gauge might be

required if the voltage drop is not acceptable.

Alternatively two 20 Amp outputs may be paralleled allowing cranking for any

period of time (subject to overheating of the starter motor).

Page 14

MoTeC Installation 11

Electronic Devices

The PDM can supply power to electronic devices such as engine

management systems, data acquisition systems, radios etc.

Many electronic devices will have a short inrush current. The PDM will largely

ignore this due to the Output Load filtering. See the Over-Current Shutdown

section for details.

The PDM provides reverse battery protection and load dump clamping to

protect itself and the connected devices.

Ignition Systems

Inductive Ignition Systems

Most inductive ignition systems draw a peak current of about 8 ampere,

some draw as much as 20 ampere; however the average current is much

lower.

In most cases inductive ignition systems can be connected to an 8 Amp

output however the Output Load current must be checked to ensure it

stays well clear of 100%.

The average current will increase with increasing RPM so the Output Load

should be checked at maximum RPM.

CDI Ignition Systems

CDI ignition systems can draw peak currents of as much as 50 ampere. It

is recommended that all CDI ignition systems are connected to a 20 Amp

output.

The average current will increase with increasing RPM so the Output Load

should be checked at maximum RPM.

Engine Management Systems

The current drawn by an engine management system will depend on the type

of loads it is connected to and the operating conditions.

Fuel injectors draw current in pulses. The maximum average current drawn by

the fuel injectors is when they are at maximum duty cycle.

For servo devices such as Drive by Wire motors maximum current is drawn

when making large transitions.

Check that the Output Load is clear of 100% under worst case operating

conditions, i.e. when the injectors are operating at maximum duty cycle, servo

devices are making large transitions and any auxiliary loads are drawing

maximum current.

Page 15

12 Installation

CAN Keypads

The CAN Keypads continuously communicate with the PDM which will

prevent the PDM from entering its low power standby mode.

Options for powering the keypads include:

- Configuring the PDM to always power the keypads.

This allows buttons on the keypads to be used for master startup

functions, but the PDM would never enter standby mode.

To minimize battery drain, the isolator would need to be turned off (eg.

during vehicle transport or storage)

- Wiring a master switch or ignition key input to the PDM.

All outputs (including the keypad power) would be configured to turn

off when the master switch or key is turned off.

This allows the PDM to enter standby mode, minimizing battery drain.

PDM Manager Software Installation

The PDM Manager software is used to:

Change the PDM configuration

Monitor the PDM operation including the output currents and

diagnostics

Test the outputs by manually turning them off and on

Set and unlock security password

Update the firmware

PC Requirements

PDM Manager runs under Windows XP or Vista operating systems. The

minimum recommended PC specification is a Pentium 90 with 16 MB RAM

and a USB port.

Installing PDM Manager Software

Go to the MoTeC website at www.motec.com and navigate to

downloads/software/latestreleases/PDM Manager software

OR Locate PDM Manager software on the MoTeC Resource Disc

Save the selected file in your preferred location (for example desktop)

When downloading is finished, double click on the file and select run

Follow the instructions on the InstallShield Wizard

Page 16

MoTeC Installation 13

To start the program after installation, click

Start > All Programs > MoTeC > PDM Manager

Updating PDM Manager Software

Software updates are available to give access to the latest features.

Download the latest software version from the website and follow the software

installation instructions to update to the new version.

To update the associated firmware in the device select Update Firmware from

the Online menu. For more information refer to Operation.

Connecting the PDM to a PC

The PC communicates with the PDM via the CAN bus.

The connection to the CAN bus is via USB through a MoTeC UTC.

To connect through a UTC, a mating connector for the UTC must be wired to

the PDM's CAN bus.

Refer to UTC Wiring for PC Connection and CAN Bus Wiring Requirements

for more information.

The PC must connect to the PDM at the configured PDM CAN bitrate. Refer

to the Operation section for details about CAN bitrate configuration.

Note: The MoTeC CAN cable (#61021) cannot be used with the PDM.

Page 17

14 Configuration

Configuration

The PDM requires various settings to be configured such as the maximum

current settings for the outputs and the circumstances in which to turn the

outputs on.

The configuration settings are stored in a configuration file on the PC.

Changes to the PDM configuration are performed ‘Offline’, i.e. without the PC

communicating with the PDM. The changes are saved in the configuration file

on the PC. The file must be sent to the PDM before the changes take effect.

See Operation.

Configuration File

From the File menu the following options are available:

New: creates a new configuration file

Open: selects an existing configuration file

Right-click the configuration file to Rename, Delete, Send to a disk etc.

Close: closes the current configuration file

Save: after a new configuration has been defined, it should be saved with

a meaningful name

Save as: can be used to create a copy of an existing configuration file by

giving it a new name

Check Channels: verifies that all channels are correctly generated

Exit: exits the program

To create a new configuration file

On the File menu, click New.

Select the PDM type and enter the Serial Number

The serial number can be found on the PDM label

This will open the Configuration Tree panel and the Channels panel.

Tips:

The most recently used files appear at the bottom of the File menu.

This is often the easiest way to open an existing file.

When changing the PDM type all configured inputs and outputs settings

will be transferred to the relevant pin number in the new PDM type.

Configuration files can be password protected, preventing unauthorised

retrieving and sending of configuration files.

Page 18

MoTeC Configuration 15

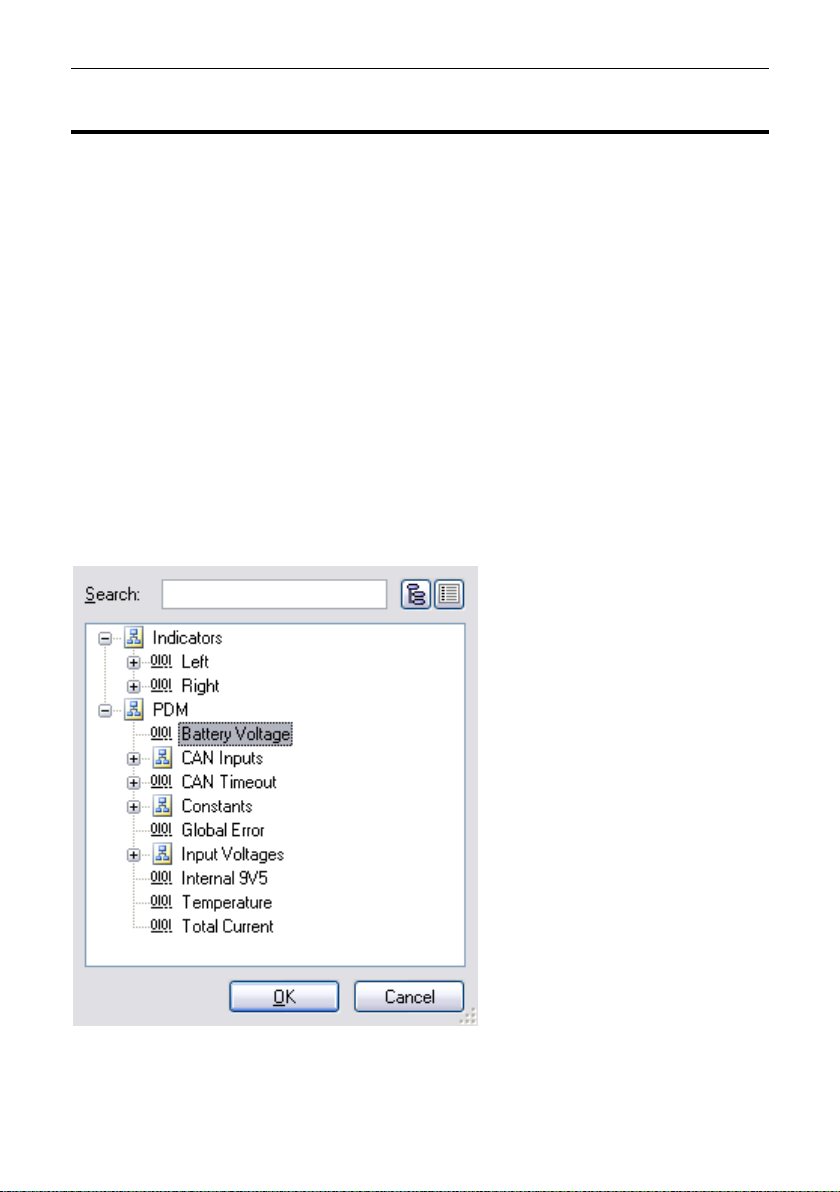

Channels

Channels are used to link the various systems within the PDM configuration.

For example: The input pin system generates two channels for each

configured input pin. Depending on the state of the input pin the input channel

value will be zero or one.

The channel can be selected to directly control a particular output. It can also

be used as an input to a Condition. This is a complex logic function that

combines a number of channels to create a new channel. This new channel

can then be used to control an output, or as an input to another condition.

Each channel can only be generated once, but may be used by multiple

outputs and conditions.

Channel Names

Each channel has a name to identify it. By including a dot between parts of

the channel name, channels are arranged in a tree structure.

For example: Indicators.Left and Indicators.Right would appear as Left and

Right under a node called Indicators.

The use of a dot between parts of the channel name is optional. The channel

list will be a simple flat list rather than a tree structure if it is not used.

Page 19

16 Configuration

To rename a channel globally

Right-click on the channel name in the Channels window and click

Rename.

This will rename the channel where it is generated as well as in all the

places where it is used.

Configuration Tree

The Configuration Tree is used to configure the Global Setup, Input Pins,

CAN Inputs, Conditions, CAN Outputs, Keypad buttons and Output Pins.

The input and output pins will be numbered according to the PDM type

selected.

Global Setup

The Global Setup in the configuration tree is used to

Enter the PDM type and serial number

Configure the CAN addresses and timeout periods for incoming CAN

messages

Configure Master Retry and Master Shutdown channels for output pins

Configure Keypad settings for CAN keypads

PDM Type and Serial Number

The PDM type (PDM32, PDM16 etc.) and serial number must be configured

correctly before a new configuration file can be sent to a PDM.

A configuration can only be sent to the matching PDM to ensure the correct

configuration of PDMs in applications with multiple PDMs.

Output Pins Master Retry

The Master Retry feature turns all outputs that are in error back on. If there is

still a fault on a particular output, this output will go into error again and will go

through the normal retry sequence.

To initiate a Master Retry by pressing a button

Wire a button to a switch input

Use the channel generated by this input as the trigger channel for the

Master Retry.

Page 20

MoTeC Configuration 17

Output Pins Master Shutdown

The Master Shutdown feature turns off all outputs that are configured for

Master Shutdown, while a user configured channel is true.

Any PDM channel can be used as the Master Shutdown channel.

Each output pin can be individually configured to support or ignore the Master

Shutdown channel.

Keypads

Up to four MoTeC CAN keypads can be configured to work with the PDM.

The global keypad setup configures the overall keypad settings. Individual

keypad buttons are configured under the Keypads in the Configuration Tree.

The Keypad Name is a description of the keypad (eg. “Main Keypad”).

The Keypad Type determines how many buttons will be shown in the keypad

button configuration.

The keypad Node ID and CAN Addresses must match the settings

programmed into the keypad. Keypads are supplied by MoTeC preprogrammed with default settings for Keypad 1. The Restore Defaults button

will select the default settings for the particular keypad.

The Brightness Control settings allow the keypad backlight and LED

brightness to be set to a specified level. An alternate brightness level and

condition can be specified to allow day/night operation.

Input Pins

Configuration of an input will create a Status and a Voltage channel. Both

channels can be used in a condition or to directly control an output. They are

transmitted via CAN.

To configure an Input Pin

In the Configuration Tree, select Input Pins

Double click the input to setup

Type a channel name and select settings as required

The trigger voltages are fully programmable. The recommended trigger

voltages are approximately 3.5 V for the low threshold and 4.2 V for the high

threshold. The high threshold should be set below 6 V to ensure detection of a

high level signal when the battery voltage is low.

To avoid switch bounce and/or to delay recognition when the switch changes

state, the inputs also have programmable trigger times. A trigger time of 0.1

second will normally reject switch bounce.

Page 21

18 Configuration

Channel Name

Description

CAN Output

InputName

Input Status

0 = Off

1 = On

Yes

InputName.Voltage

Voltage on the input

Resolution 0.2 V

Yes

CAN Inputs

The PDM can receive CAN messages allowing the outputs to be controlled by

other devices.

The PDM can be configured to receive CAN messages on up to seven

different CAN addresses in the standard or extended address ranges. The

CAN addresses and message timeout periods are configured in Global Setup

in the Configuration Tree.

To configure a CAN input

In the Configuration Tree, select CAN Inputs

On the Edit menu, click Add

Type a channel name and select settings as required

Channel extraction

Channels are extracted from the CAN messages by specifying the CAN

message and a byte offset within the message. Optional bit masking, byte

swapping and dividing operations can be performed on the received channel,

depending on the data size (8bit, 16bit signed or 16bit unsigned).

8 Bit Values

An 8bit value is specified with a byte offset and an 8bit mask. To use the

entire 8bit value, set the mask to FF (hex).

16 Bit Signed Values

A 16bit signed value is specified with a byte offset (the first byte of the

value within the CAN message), an optional byte swap, and a divisor (1 to

255). The resulting channel will be an 8 bit value with a range of 0 to 255.

The PDM treats the received value as a signed 16 bit value (i.e. -32768 to

32767). Negative values are clamped to 0. If the value after division is

greater than 255 then the result value will be clamped to 255.

Page 22

MoTeC Configuration 19

16 Bit Unsigned Values

A 16bit unsigned value is specified with a byte offset (the first byte of the

value within the CAN message), an optional byte swap, a 16bit mask, and

a divisor (1 to 255). The resulting channel will be an 8 bit value with a

range of 0 to 255.

The PDM treats the received value as an unsigned 16 bit value (i.e. 0 to

65535). If the value after division is greater than 255 then the result value

will be clamped to 255.

Examples of the different types of CAN channel extraction are included in the

Appendices.

Timeout values

If the CAN message is not received for a period exceeding its timeout period,

the corresponding timeout channel will be set to TRUE. Each CAN input

channel can be configured to hold its previous value or go to a specific value

while the corresponding CAN message is timed out.

Tip: The timeout channel can be used in a condition.

Initial values

If the channel is configured to hold the previous value when the CAN

message times out then the channel will be set to zero on start-up. The

channel stay zero until a matching CAN message is received.

If the channel is configured to use a specific value when the CAN message

times out then the channel will be set to this value on start-up. The channel

stay at the timeout value until a matching CAN message is received.

The PDM CAN bitrate is user configurable. All devices on the CAN bus must

be set to the same speed. Refer to the Operation section for details about

CAN bitrate configuration.

CAN Output

The PDM can transmit a set of fixed standard messages, and up to four user

defined messages on the CAN bus. CAN messages are configured in Can

Outputs in the Configuration Tree.

The receiving device can use the messages for diagnostic purposes

(particularly useful if the values are logged in a logging device), to show an

alarm on a display, or to activate a feature in another device depending on the

value of a PDM input switch.

Page 23

20 Configuration

The PDM CAN bitrate is user configurable. All devices on the CAN bus must

be set to the same speed. Refer to the Operation section for details about

CAN bitrate configuration.

Standard Messages

The sets of fixed messages to be sent from the PDM are configured in

Standard Messages. Messages sets can be individually enabled and a base

CAN address is configurable.

Most MoTeC logging devices have CAN communications templates available

to receive these messages.

The transmitted CAN messages include Output Voltage, Output Current,

Output Load, Output Status, Input State, Internal Temperature, Battery

Voltage, Global Error, and Total Current. See CAN Output Messages in the

Appendices for details on the CAN messages.

Standard messages are transmitted at 20Hz.

User Defined Messages

Up to four user defined CAN messages to be sent from the PDM can be

configured in Message 0 to Message 3.

Up to 8 channels can be included in each CAN message, with one channel

per message byte.

The CAN address is user configurable in the standard or extended address

ranges.

User defined messages are transmitted at 50Hz.

Functions

Conditions

A condition is a complex logic function that combines a number of channels to

create a new channel. The logic operations include AND, OR, flash and many

more.

The new channel, with a value of either TRUE (1) or FALSE (0), can be used

to directly control an output or it can be used in another condition.

Counters

A counter generates an integer channel value that can be incremented or

decremented on transitions of other logic channels.

Number of Operations

There are a total of 200 logic operations available in the PDM. The number of

operations used is shown in the status line.

Page 24

MoTeC Configuration 21

Tip: A condition can also be configured in the output pin setup. In this case

the outcome of the logic function will not create a new channel but will be

directly connected to the output channel.

To configure a Condition or Counter

In the Configuration Tree, select Functions

On the Edit menu, click Add

Select the function type (Counter or Condition)

Type a channel name and select settings as required

Output Pins

All outputs are high side type outputs; they switch Batt+ to the output pin. All

outputs have hardware thermal overload protection, fault logic and overcurrent logic.

Paralleled Outputs

When two or more output pins are connected in parallel, they must be

configured to use a common channel or an identical condition to activate

them.

Note: outputs that are connected in parallel must all be of the same type;

either all 8 Amp or all 20 Amp outputs.

Output Protection

Over-Current Shutdown

An Over-Current Shutdown occurs when the Output Load exceeds 100%,

which corresponds to the maximum current setting.

The Output Load value is filtered so that it normally increases (and

decreases) slowly, modelling how the temperature of a wire responds to

the current flowing through it. The resultant characteristic is very similar to

a thermal circuit breaker which is often used in motorsport applications. It

is also similar to a slow blow fuse. See Fuse Characteristics for details.

The filtering of the load value ensures that the start-up current (inrush

current) of motors and lamps does not cause the output to shutdown

during this period. It also allows for short term overloads to occur without

the output shutting down.

A large over-current such as a short circuit will cause the Output Load

value to increase rapidly, causing the output to shutdown in a short period

of time to protect the wire and the PDM output. The filtering is set with a

time constant of 20 to 50 seconds based on the maximum current setting.

These values conservatively suit the appropriate wire gauge for the

Page 25

22 Configuration

selected current setting and are not adjustable.

Tips:

The Output Load and Output Current values are transmitted via CAN so

that they can be logged by another device. Check the logged Output

Load value to ensure it is not too close to 100% during normal

operation and during start-up.

The Output Load and Output Current values can also be monitored

using PDM Manager. See Checking Operation.

Fault Shutdown

A Fault Shutdown occurs when the output voltage is lower than expected.

This can be caused by a short circuit or thermal overload of the output.

A short circuit may cause a Fault Shutdown before the Over-Current

Shutdown occurs.

Output Settings

To configure an Output Pin

In the Configuration Tree, select Output Pins

Double click the output to setup

Type a channel name and select settings as required

Maximum Current

This sets the current at which the output will shutdown. The output current

may exceed this value for a period of time which allows for the start-up

(inrush) current of devices such as motors and lamps.

The maximum current can be set to 10 ampere on the 8 Amp outputs and

25 ampere on the 20 Amp outputs to be clear of the normal running

current, even for devices that draw the maximum specified current of 8 or

20 ampere.

Number of Retries and Retry Delay

When an Over-Current Shutdown or a Fault Shutdown occurs, the PDM

will attempt to turn the output on again if the Number of Retries is

configured. The Number of Retries determines how many times an output

will attempt to turn on again.

The Retry Delay determines how long an output remains shutdown before

it is turned on again.

The retry count for an output is reset whenever the condition driving the

output changes to FALSE and then to TRUE (i.e. when the condition

Page 26

MoTeC Configuration 23

driving the output turns off then on again).

Master Shutdown

If Master Shutdown is enabled on the output, the output will be turned off

while the Master Shutdown channel is true.

The Master Shutdown channel is configured in the Global Setup.

Stay Alive During Standby Mode

Up to four outputs can be configured to stay alive (i.e. remain turned on)

during the PDM low power standby mode.

Refer to the Standby Mode section for more information.

Linked High Speed Wiper Output (For output 9 only)

The PDM Version 2 hardware has additional functionality to simplify

windscreen wiper motor control.

Linked output control can be enabled and a linked channel can be selected

in the settings for Output 9.

If this setting is enabled then Output 9 will be held off while the linked

channel used for the high speed wiper winding is turned on.

See the Windscreen Wipers section for more detail.

Tips:

There is a Master Retry feature available in Global Setup

Ensure that the maximum current has been set appropriately by

checking that the Output Load value is less than 100% under all

operating conditions.

The wire used must be capable of carrying the current specified in the

maximum current setting. See Wire Specification.

Set the maximum current well clear of the normal operating current of

the device but within the current rating of the wire. Use a larger wire to

achieve this if necessary. For example, for a device that draws no more

than 5 ampere (except at start-up) use a wire that is rated at 8 ampere

and set the maximum current to 8 ampere to give a clear margin.

Consider the voltage drop of the wire when selecting the wire size.

Sometimes this dictates that a larger wire gauge is needed than the

current rating would suggest.

Setting the current close to the normal current of the device to try and

protect the device is unlikely to be effective and could result in an

inadvertent shutdown. The purpose of the maximum current setting is

Page 27

24 Configuration

Channel Name

Description

CAN

Output

OutputName

Output Control Status

0 = Off

1 = On (Note: the output may be off

due to Over-current Shutdown or

Fault Shutdown)

No

OutputName.Voltage

Voltage on the output

Resolution 0.2 V

Yes

OutputName.Current

Output Current in amps

Resolution 0.5 A on Outputs 1 – 8

Resolution 0.2 A on Outputs 9 – 32

Yes

OutputName.Load

Output Load. Filtered current as a

percentage of the maximum current

setting.

Resolution 1%

Yes

OutputName.Status

0 = Off

1 = On Active

2 = Over-Current Shutdown

4 = Fault Shutdown

Yes

OutputName.Status.

Active

0 = Output is off

1 = Output is on

No

OutputName.Status.

OverCurrent

0 = OK

1 = Over-Current Shutdown

No

OutputName.Status.

Fault

0 = OK

1 = Fault Shutdown

No

to protect the wire from overheating, not to protect the connected

device.

Some devices draw more current under circumstances such as high or

low battery voltage. Also, a motor will draw increased current when

under more load. Set a good margin and where possible check the

Output Load value under these varying circumstances.

Configuration of an output will create a number of channels, some of which

are transmitted via CAN. OutputName.Status channel is used for output

status information on CAN. The output should be on for any non-zero value.

Fault Indicator

When an output fault occurs the PDM sets the value of the Global Error

channel to TRUE (PDM.Global Error). A fault indicator light can be connected

Page 28

MoTeC Configuration 25

to any PDM output and configured to turn on when the Global Error channel is

TRUE.

The Global Error channel can also be transmitted via CAN to a display device

and used to show an alarm message and activate an alarm light.

Maximum Current for Typical Output Devices

Lamps

Tungsten Lamps

Typically used for tail lights, indicator lights and general lighting.

Tungsten lamps draw additional current during turn on. Typically this

peaks at about 5 times the steady state current and dies out in about 0.1

second. The PDM will largely ignore this due to the Output Load filtering.

Halogen Lamps

Halogen lamps are commonly used in headlights and are more efficient

than Tungsten lamps.

Halogen lamps have similar characteristics to Tungsten lamps.

Xenon (HID) Lamps

Xenon lamps are also used in headlights and are more efficient than

Tungsten and Halogen lamps.

Xenon lamps have a long duration inrush current that peaks at about 4

times the steady state current. The inrush current decays over a period of

about 10 seconds. This puts a high load on the PDM output during startup.

To avoid Over-Current Shutdown during start-up it may be necessary to

set a higher Maximum Current than normal particularly if the battery

voltage is low.

For example, a Xenon lamp with a steady state current of 3 ampere may

need a Maximum Current setting of 6 to 8 ampere. The wire should also

be rated at this current.

Unlike other lamps, Xenon lamps draw more current as the battery voltage

decreases. At 10 volt the lamp will draw 40% more current than at 14 volt.

For example a lamp that draws 3 ampere at 14 volt will draw 4.2 ampere at

10 volt. This must be allowed for when setting the Maximum Current.

To ensure that the Maximum Current is set appropriately, check that the

Output Load value stays safely below 100% during turn on when the

battery is at 12 volt (not charging).

Page 29

26 Configuration

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

Motors

Electric motors draw additional current during start-up. Typically the startup current is 3 to 5 times the steady state current and it dies out in less

than a second.

This start-up current is largely ignored by the PDM due to the Output Load

filtering.

The current in a motor increases with increasing load on the motor. A

motor draws maximum current when it is stalled. The Maximum Current

setting should take this into account.

A motor may draw more current as it or the device that it is connected to

ages; this should be allowed for when setting the Maximum Current.

Note: motor speed control is currently not supported.

CAN Keypads

Up to four MoTeC CAN keypads can be configured to work with the PDM. A

keypad must be enabled and configured under the Global Settings before the

individual buttons can be configured.

To use a keypad button, a channel name must be specified. This channel will

be true while the keypad button is pressed.

Each of the three LEDs on a keypad button can be controlled with a PDM

channel. The LED will be turned on while the channel is true.

A maximum of 120 keypad LEDs (across all keypads) can be configured.

Keypad button numbering is from left to right, from top to bottom.

E.g.

Page 30

MoTeC Operation 27

Operation

CAUTION: The PDM may get very hot, do not touch the PDM during

operation.

To perform any of the activities in the Online menu, the PC needs to

communicate with the PDM.

When a configuration file is open in PDM Manager, it will connect to the PDM

with the matching serial number.

If there is no file open, all connected PDMs will be displayed. PDM Manager

can be connected to a selected PDM.

CAN Bus Bitrate

The PDM can be configured to operate at CAN bit rates of 250Kbps, 500Kbps

or 1Mbps.

PDM manager includes a CAN bitrate conversion tool in the Tools > Options >

Communications menu. This tool configures the CAN bitrate and restarts the

PDM at the new rate.

Note: During the conversion process, all CAN devices must be removed from

the CAN bus except for the PDM and the UTC.

PDM Manager must be configured (in the Tools>Options>Communications

menu) to match the PDM CAN bit rate.

Sending and Retrieving Configuration Files

On the Online menu, click Send Configuration to send the currently

open configuration file to the connected PDM

On the Online menu, click Get Configuration to retrieve the current

configuration file in the connected PDM

Checking Operation

Monitor Channels

On the Online menu, click Monitor Channels

Monitor Channels shows the value of each channel in the original tree

structure.

Monitor PDM

On the Online menu, click Monitor PDM

Page 31

28 Operation

Monitor PDM shows the input-, output-, CAN input-, condition- and PDM

status channels in separate screen areas in an easy to view layout.

Test Outputs

On the Online menu, click Test Outputs

All outputs may be manually turned on and off in PDM Manager to check the

current levels.

To be able to test an output, it must first be configured in PDM Manager.

Serial Number

On the Online menu, click Show Serial Number

A configuration file can only be sent to the PDM with the matching serial

number.

This allows multiple PDMs to be used without special device configuration

requirements and also ensures that each PDM has the correct configuration

file.

Firmware Versions and Updating

On the Online menu, click Update Firmware

The software inside the PDM (firmware) can be updated by the user at any

time to take advantage of the latest features.

Matching Versions

The firmware version must match the version of the PDM Manager software

on the PC in order to communicate. PDM Manager will show a warning if the

versions do not match.

Tip:

To check the version of PDM Manager software, click About MoTeC PDM

Manager on the Help menu.

To check the firmware version in the PDM click Show Serial Number on

the Online menu

Matching Configuration File

Configuration files created with new software including new features can

not be used with older version of the software. If required, create backup

files before updating.

Page 32

MoTeC Operation 29

Password Protection

On the Online menu, click Set Password

The password will prevent unauthorised retrieving and sending of

configuration files.

It is not possible to update firmware if the PDM is password protected.

Standby Mode

The PDM has a low power standby mode to minimize battery drain when the

vehicle is turned off.

Up to four outputs can be configured in the Output Pin settings to stay alive

(i.e. remain turned on) during the standby mode. These outputs are intended

for powering applications where electronic devices require a continuous low

current (typically micro amps) supply to maintain settings or state.

The PDM enters the low current Standby Mode when all of the following

conditions have been true for 5 minutes:

- All outputs that do not have the “stay alive during standby mode” option

enabled are turned off

- All outputs that have the “stay alive during standby mode” option enabled

are below the allowed current limits (approximately 0.5A)

- No CAN messages have been received

- No CAN messages have been successfully transmitted

The PDM will exit the Standby Mode when any of the following conditions are

true:

- Activity is present on the CAN bus

- Any output that has the “stay alive during standby mode” option enabled

exceeds the allowed current limit (approximately 0.5A)

- Any input pin changes state

Page 33

30 Appendices

Battery voltage

30 V max, 6.5 V min

Current consumption

35 mA typical operating

5 mA typical standby

Total output current

(continuous)

PDM16

PDM32

PDM15

PDM30

100 A

120 A

80 A

100 A

Reverse battery

protection

Protection for PDM and all connected devices

Load dump transient

protection

Protection for PDM.

Also assists in protecting connected devices.

Operating temperature

110 °C max internal (100 °C recommended)

Typical 85 °C max ambient for 120 A total load (for

110 °C internal) depending on mounting, air

circulation and load distribution.

These specifications apply for a 12 V battery.

For a 24 V battery reduce specified temperatures

by 20 °C.

Weight

PDM16

PDM32

PDM15

PDM30

330 g

(0.72 lbs)

405 g

(0.89 lbs)

260 g

(0.57 lbs)

270 g

(0.59 lbs)

Length

130 mm

(5.1")

180 mm

(7.1")

107 mm

(4.2")

107 mm

(4.2")

Width

60 mm

(2.4")

60 mm

(2.4")

133 mm

(5.2")

133 mm

(5.2")

Height

28 mm

(1.1")

28 mm

(1.1")

39 mm

(1.5")

39 mm

(1.5")

Case

Machined aluminium

Magnesium

Environmental

protection

Rubber seal on lid and

connectors, conformal

coating on PCB

Conformal coating on

PCB

Appendices

Specifications

General

Page 34

MoTeC Appendices 31

Number of 20 A outputs

PDM16

PDM32

PDM15

PDM30

8 8 8 8 Maximum output current

20 A continuous, 115 A transient (typical)

Over-current shutdown

Programmable in steps of 1 A

Protection

Short circuit and thermal overload

protection

Inductive load clamp voltage

–17 V (relative to Batt–)

Maximum inductive load

energy

1.5 J (junction temperature = 150 °C, load

current = 20 A)

Number of 8 A outputs

PDM16

PDM32

PDM15

PDM30

8

24 7 22

Maximum output current

8 A continuous, 60 A transient (typical)

Over-current shutdown

Programmable in steps of 1 A

Protection

Short circuit and thermal overload

protection

Inductive load clamp voltage

Output 9: –0.7 V (relative to Batt–)

Other Outputs: –42 V (relative to Batt+)

Maximum inductive load

energy

0.3 J (junction temperature = 150 °C, load

current = 20 A)

Number of inputs

PDM16

PDM32

PDM15

PDM30

12

23

16

16

Pull-up resistor

10 kilo ohm to Batt+

Measurement

Range of 0 to 51 V, resolution 0.2 V

(8 bits)

Calibration

High and low trigger voltage, high and low

trigger times

Number of messages

4 messages, 8 bytes per message

Message rate

20 Hz

20 Amp Outputs

8 Amp Outputs

Inputs

CAN Input

CAN Output

Page 35

32 Appendices

Byte

0 1 2 3 4 5 6

7

Value (hex)

00

00

F3

21

40

00

CC

8A

Offset

Data Size

Mask

Byte 2

8bit

FF

Offset

Data Size

Mask

Byte 2

8bit

02

Offset

Data Size

Alignment

Divisor

Byte 3

16bit (signed)

Normal

100

Offset

Data Size

Alignment

Divisor

Byte 3

16bit (signed)

Swap Bytes

100

Offset

Data Size

Alignment

Divisor

Byte 2

16bit (signed)

Normal

100

Offset

Data Size

Alignment

Mask

Divisor

Byte 6

16bit (unsigned)

Swap Bytes

0FFF

25

CAN Input Channel Examples

Sample received CAN message used in examples below

Channel Extraction Examples

Resulting channel: 0xF3 masked with 0xFF = 0xF3

Resulting channel: 0xF3 masked with 0x02 = 0x02

Resulting channel: 0x2140 / 100 = 85

Resulting channel: 0x4021 / 100 = 164

Resulting channel: 0xF321 is negative (-3295) so channel is clamped to 0

Resulting channel: (0x8ACC masked with 0x0FFF) / 25 = 110

Page 36

MoTeC Appendices 33

Offset

Data Size

Alignment

Mask

Divisor

Byte 6

16bit (unsigned)

Normal

FFFF

100

Resulting channel: (0xCC8A masked with 0x0FFF) / 100 = 523 so channel is

clamped to 255

Typical CAN input channel application

A CAN message contains a 16 bit RPM value with resolution of 1 RPM.

Using a 16bit unsigned data type and a divider of 100 gives a resulting

channel with a resolution of 100 RPM. The maximum channel value of 255

will be equivalent to 25500 RPM.

The resulting channel can be used in conditions to turn outputs on when the

RPM is above or below preset limits.

Page 37

34 Appendices

Max current setting [A]

Trip time multiplier

4

76%

6

84%

8

92%

10

100%

15

120%

20

140%

Trip time versus over current multiplier at 10A

0.10

1.00

10.00

100.00

1 2 3 4 5 6 7 8 9

10

Over current multiplier

Trip time

(s)

Fuse Characteristics

Example:

For 25 A current where max current setting is 5 A:

Over current multiplier: 25 A / 5 A = 5

From Graph: Trip time (at 10 A) is approx. 1 second

From Table: Trip time multiplier (at 5 A) is approx. 80%

Trip time (at 5 A) = 1 x 80% = 0.8 seconds

Page 38

MoTeC Appendices 35

Connector A

Connector B

26 pin Autosport

1 pin Autosport

Mating connector #65040

Mating connector

#68093 (wire gauge #6 AWG)

#68094 (wire gauge #4 AWG)

Pin

Function

Pin

Function

A_A

8 A Output 9

B_1

Batt+

A_B

8 A Output 10

A_C

8 A Output 11

A_D

Digital/Switch Input 1

Connector C

A_E

Digital/Switch Input 2

8 Pin Autosport

A_F

Digital/Switch Input 3

Mating Plug: Deutsch AS616-08SN

A_G

0 V

Pin

Function

A_H

0 V C_A

20 A Output 1

A_J

CAN Low

C_B

20 A Output 2

A_K

CAN High

C_C

20 A Output 3

A_L

8 A Output 12

C_D

20 A Output 4

A_M

8 A Output 13

C_E

20 A Output 5

A_N

8 A Output 14

C_F

20 A Output 6

A_P

8 A Output 15

C_G

20 A Output 7

A_R

8 A Output 16

C_H

20 A Output 8

A_S

Digital/Switch Input 4

A_T

Digital/Switch Input 5

A_U

Digital/Switch Input 6

A_V

Digital/Switch Input 7

A_W

Digital/Switch Input 8

A_X

Digital/Switch Input 9

A_Y

Digital/Switch Input 10

A_Z

Digital/Switch Input 11

A_a

Digital/Switch Input 12

A_b

Batt–

A_c

Batt–

Connectors and Pinout

PDM16

Page 39

36 Appendices

Connector A

Connector B

37 pin Autosport

26 pin Autosport

Mating connector #68089

Mating connector #65040

Pin

Function

Pin

Function

A_1

Digital/Switch Input 1

B_A

8 A Output 9

A_2

Digital/Switch Input 2

B_B

8 A Output 10

A_3

Digital/Switch Input 3

B_C

8 A Output 11

A_4

Digital/Switch Input 4

B_D

8 A Output 12

A_5

Digital/Switch Input 5

B_E

8 A Output 13

A_6

0 V B_F

8 A Output 14

A_7

0 V B_G

8 A Output 15

A_8

0 V B_H

8 A Output 16

A_9

0 V B_J

8 A Output 17

A_10

CAN Low

B_K

8 A Output 18

A_11

CAN High

B_L

8 A Output 19

A_12

Digital/Switch Input 6

B_M

8 A Output 20

A_13

Digital/Switch Input 7

B_N

8 A Output 21

A_14

Digital/Switch Input 8

B_P

8 A Output 22

A_15

Digital/Switch Input 9

B_R

8 A Output 23

A_16

Digital/Switch Input 10

B_S

8 A Output 24

A_17

Digital/Switch Input 11

B_T

8 A Output 25

A_18

Digital/Switch Input 12

B_U

8 A Output 26

A_19

Digital/Switch Input 13

B_V

8 A Output 27

A_20

Digital/Switch Input 14

B_W

8 A Output 28

A_21

Digital/Switch Input 15

B_X

8 A Output 29

A_22

0 V B_Y

8 A Output 30

A_23

0 V B_Z

8 A Output 31

A_24

0 V B_a

8 A Output 32

A_25

0 V B_b

Batt–

A_26

Digital/Switch Input 16

B_c

Batt–

A_27

Digital/Switch Input 17

A_28

Digital/Switch Input 18

A_29

Digital/Switch Input 19

A_30

Digital/Switch Input 20

A_31

Digital/Switch Input 21

A_32

Digital/Switch Input 22

A_33

Digital/Switch Input 23

A_34

Not Connected

A_35

Not Connected

A_36

Not Connected

A_37

Not Connected

PDM32

Page 40

MoTeC Appendices 37

Connector C

1 pin Autosport

Mating connector

#68093 (wire gauge #6 AWG)

#68094 (wire gauge #4 AWG)

Pin

Function

C_1

Batt+

Connector D

8 pin Autosport

Mating connector #68092

Pin

Function

D_A

20 A Output 1

D_B

20 A Output 2

D_C

20 A Output 3

D_D

20 A Output 4

D_E

20 A Output 5

D_F

20 A Output 6

D_G

20 A Output 7

D_H

20 A Output 8

PDM32 continued

Page 41

38 Appendices

Connector A

Connector B

34 pin waterproof connector

26 pin waterproof connector

Mating connector #65044

Mating connector #65045

Pin

Function

Pin

Function

A_1

20 A Output 1 (with A10)

B_1

Not used

A_2

8 A Output 9

B_2

Not used

A_3

20 A Output 2 (with A12)

B_3

20 A Output 6 (with B9)

A_4

8 A Output 10

B_4

Not used

A_5

20 A Output 3 (with A14)

B_5

20 A Output 7 (with B11)

A_6

8 A Output 11

B_6

Not used

A_7

20 A Output 4 (with A16)

B_7

20 A Output 8 (with B13)

A_8

8 A Output 12

B_8

Not used

A_9

20 A Output 5 (with A17)

B_9

20 A Output 6 (with B3)

A_10

20 A Output 1 (with A1)

B_10

Not used

A_11

8 A Output 13

B_11

20 A Output 7 (with B5)

A_12

20 A Output 2 (with A3)

B_12

Not used

A_13

8 A Output 14

B_13

20 A Output 8 (with B7)

A_14

20 A Output 3 (with A5)

B_14

Not used

A_15

8 A Output 15

B_15

Digital/Switch Input 13

A_16

20 A Output 4 (with A7)

B_16

Not used

A_17

20 A Output 5 (with A9)

B_17

Digital/Switch Input 15

A_18

Not used

B_18

Battery Negative

A_19

Digital/Switch Input 2

B_19

Not used

A_20

Not used

B_20

Digital/Switch Input 11

A_21

Digital/Switch Input 4

B_21

Digital/Switch Input 12

A_22

Not used

B_22

0 V

A_23

Digital/Switch Input 7

B_23

Digital/Switch Input 14

A_24

Not used

B_24

Digital/Switch Input 16

A_25

Not used

B_25

CAN Low

A_26

Battery Negative

B_26

CAN High

A_27

Digital/Switch Input 1

A_28

0 V

A_29

Digital/Switch Input 3

A_30

Digital/Switch Input 5

Connector C

A_31

Digital/Switch Input 6

M6 stud

A_32

Digital/Switch Input 8

Mating: eyelet and M6 nut

A_33

Digital/Switch Input 9

Pin

Function

A_34

Digital/Switch Input 10

C_1

Battery +

PDM15

Page 42

MoTeC Appendices 39

Connector A

Connector B

34 pin waterproof connector

26 pin waterproof connector

Mating connector #65044

Mating connector #65045

Pin

Function

Pin

Function

A_1

20 A Output 1 (with A10)

B_1

8 A Output 21

A_2

8 A Output 9

B_2

8 A Output 22

A_3

20 A Output 2 (with A12)

B-3

20 A Output 6 (with B9)

A_4

8 A Output 10

B_4

8 A Output 23

A_5

20 A Output 3 (with A14)

B-5

20 A Output 7 (with B11)

A_6

8 A Output 11

B_6

8 A Output 24

A_7

20 A Output 4 (with A16)

B_7

20 A Output 8 (with B13)

A_8

8 A Output 12

B_8

8 A Output 25

A_9

20 A Output 5 (with A17)

B_9

20 A Output 6 (with B3)

A_10

20 A Output 1 (with A1)

B_10

8 A Output 26

A_11

8 A Output 13

B_11

20 A Output 7 (with B5)

A_12

20 A Output 2 (with A3)

B_12

8 A Output 27

A_13

8 A Output 14

B_13

20 A Output 8 (with B7)

A_14

20 A Output 3 (with A5)

B_14

8 A Output 28

A_15

8 A Output 15

B_15

Digital/Switch Input 13

A_16

20 A Output 4 (with A7)

B_16

8 A Output 29

A_17

20 A Output 5 (with A9)

B_17

Digital/Switch Input 15

A_18

8 A Output 16

B_18

Battery Negative

A_19

Digital/Switch Input 2

B_19

8 A Output 30

A_20

8 A Output 17

B_20

Digital/Switch Input 11

A_21

Digital/Switch Input 4

B_21

Digital/Switch Input 12

A_22

8 A Output 18

B_22

0 V

A_23

Digital/Switch Input 7

B_23

Digital/Switch Input 14

A_24

8 A Output 19

B_24

Digital/Switch Input 16

A_25

8 A Output 20

B_25

CAN Low

A_26

Battery Negative

B_26

CAN High

A_27

Digital/Switch Input 1

A_28

0 V

A_29

Digital/Switch Input 3

A_30

Digital/Switch Input 5

Connector C

A_31

Digital/Switch Input 6

M6 stud

A_32

Digital/Switch Input 8

Mating: eyelet and M6 nut

A_33

Digital/Switch Input 9

Pin

Function

A_34

Digital/Switch Input 10

C_1

Battery +

PDM30

Page 43

40 Appendices

Mounting Dimensions

PDM16

Page 44

MoTeC Appendices 41

PDM32

Page 45

42 Appendices

PDM15 and PDM30

Page 46

MoTeC Appendices 43

Wire

Gauge

(AWG)

Current Rating

at 80 °C ambient

[A]*

Current Rating

at 100 °C ambient

[A]*

Resistance

[ohm/m]

Resistance

[ohm/1000 ft]

24#

4.5

4

0.071

22

22# 6 5

0.045

14

20# 8 6

0.028

8.5

18#

11

9

0.018

5.5

16#

15

12

0.014

4.3

14#

22

18

0.009

2.7

6#

90‡

75‡

0.0015

0.44

4#

120‡

100‡

0.0009

0.28

2#

150‡

120‡

0.0006

0.18

Recommended Wire Gauge

Output

24# to 20#

8 Amp outputs

20# to 16#

20 Amp outputs

4# to 2#

Battery pos

Wiring

Wire Specification

M22759/16

Insulation Material: Tefzel

Conductor: Tin Plated Copper

Voltage Rating: 600 V

Maximum Temperature: 150 C

*The current ratings above are an indication only and will not apply in all

circumstances.

The actual maximum current rating is determined by the maximum allowed

temperature for the wire (150 °C).

The temperature of the wire is affected by many factors including the

temperature of adjacent wires, how the wires are bundled and covered, the

ambient temperature and the current.

‡current rating for a single wire in free air

Page 47

44 Appendices

1

2 3 4

5

9

10

11

Black

White

CAN Connector (5 pin XLR Female)

PDM

0V

CAN-LO

CAN-HI

100R Resistor

*Not essential if the wiring

length is less than 2 m (7 ft)

These wires must be twisted

Minimum one twist per 50 mm (2 in)

White

Green

Green

UTC Wiring for PC Connection

To connect to a PDM through a MoTeC UTC (USB to CAN adaptor), a mating

connector for the UTC must be wired to the PDM's CAN bus.

The UTC connects to the PC USB port with a standard USB A-B cable.

If the PDM does not connect to any other CAN device, it can be directly wired

to the CAN connector.

If the wiring length is less than 2 m (7 ft) the terminating resistor is

recommended but not essential as the UTC has a built in terminating resistor.

UTC Connector Type (5 pin XLR Female):

Deltron 716-0-0501 (Non-latching)

Neutrik NC5FDL1 (Latching)

CAN Bus Wiring Requirements

The CAN bus should consist of a twisted pair trunk with 100R (0.25 watt)

terminating resistors at each end of the trunk.

The preferred cable for the trunk is 100R data cable but twisted 22# Tefzel is

usually OK.

The maximum length of the bus is 16 m (50 ft)

CAN devices (such as MoTeC PDM, M800 etc) may be connected to the

trunk with up to 500 mm (20 in) of twisted wire.

The CAN Connector for the UTC may also be connected to the trunk with up

to 500mm (20in) of twisted wire and should be within 500mm of one end of

the trunk. If desired two CAN connectors may be used so that the UTC may

be connected to either side of the vehicle. Both connectors must be within

500mm of each end of the trunk.

Page 48

MoTeC Appendices 45

CAN-LO

CAN-HI

100R

100R

CAN-LO CAN-HI

500 mm

max

CAN-LO CAN-HI

UTC

Connector

500 mm

Max

<< CAN Bus >>

100R Terminating

Resistors at each

end of the CAN Bus

CAN-LO CAN-HI CAN-LO CAN-HI

5 4 1

These wires must be twisted

Minimum one twist per 50 mm (2 in)

CAN Device

eg M1 ECU

CAN Device

eg PDM

CAN Device

eg ADL3

0V

Short CAN Bus

If the CAN Bus is less than 2 m (7 ft) long then a single termination resistor

may be used. The resistor should be placed at the opposite end of the CAN

bus to the CAN connector.

Page 49

46 Appendices

CAN Address

Byte

Bit

Channel

Scaling

Base address

+ 0

0

4..7

Compound Id = 0

0 0 Input 1 State

0 = Inactive

1 = Active

1 0 Input 2 State

2 0 Input 3 State

3 0 Input 4 State

4 0 Input 5 State

5 0 Input 6 State

6 0 Input 7 State

7 0 Input 8 State

Base address

+ 0

0

4..7

Compound Id = 1

0 0 Input 9 State

0 = Inactive

1 = Active

1 0 Input 10 State

2 0 Input 11 State

3 0 Input 12 State

4 0 Input 13 State

5 0 Input 14 State

6 0 Input 15 State

7 0 Input 16 State

Base address

+ 0

0

4..7

Compound Id = 2

0 0 Input 17 State

0 = Inactive

1 = Active

1 0 Input 18 State

2 0 Input 19 State

3 0 Input 20 State

4 0 Input 21 State

5 0 Input 22 State

6 0 Input 23 State

Base address

+ 0

0

4..7

Compound Id = 3

1

0..7

PDM Internal

Temperature

0 to 125 = 0 °C to +125 °C

1 °C steps

2

0..7

PDM Battery

Voltage

0 to 255 = 0 V to 31 V

0.1216 V steps

3

0..7

Global Error Flag

0 = OK

1 = one or more outputs is in

either Fault or Over-Current error

4

0..7

Total Current

0 to 255 = 0 to 255 A

1 A steps

5

0..7

9.5V internal rail

voltage

0 to 255 = 0 V to 15.68 V

0.0615 V steps

Should read close to 9.5 V when

the Battery voltage is > 10.5 V

6

0..7

Reset Source

CAN Output Messages

The PDM transmits the following messages at 20 Hz.

Note: only relevant messages get transmitted for a particular PDM type

Page 50

MoTeC Appendices 47

CAN Address

Byte

Bit

Channel

Scaling

Base address

+ 1

0

0..7

Compound Id = 0

1

0..7

Output 1 Current

0 to 255 = 0 to 127.5 A

0.5 A steps

2

0..7

Output 2 Current

3

0..7

Output 3 Current

4

0..7

Output 4 Current

5

0..7

Output 5 Current

6

0..7

Output 6 Current

7

0..7