Motec MVCD1000-x, MVCD1001-x, MC7180N, MD3071A, MD3071A-V Installation Instructions Manual

Mobile Vicinity Scout (MVS)

Installation instructions

2

Mobile Vicinity Scout (MVS)

Installation instructions

IA_MVS-EN

05.2018

Rev. 02

Original instruction

Manufacturer:

Motec GmbH

Oberweyerer Straße 21

65589 Hadamar-Steinbach

GERMANY

Phone: +49 6433 9145-0

Fax: +49 6433 9145-45

motec.info@ametek.com

www.motec-cameras.com

© Copyright 2018 by Motec GmbH

Subject to change without notice.

The document is protected by copyright. It supports the user in the safe and efficient use of the product.

Reprints, translations and reproductions in whatsoever form, including extracts, require written consent from the publisher.

3

Table of contents

1 About these instructions ................................................................................................................................. 7

1.1 Contact .................................................................................................................................................................... 7

1.2 Design features ....................................................................................................................................................... 7

1.3 Target group for these instructions ........................................................................................................................ 7

1.4 Other applicable documents .................................................................................................................................. 8

1.5 Declaration of conformity ....................................................................................................................................... 8

1.6 Guarantee ............................................................................................................................................................... 8

2 Safety ............................................................................................................................................................. 9

2.1 Introduction ............................................................................................................................................................ 9

2.2 Intended use ........................................................................................................................................................... 9

2.3 Non-intended use ................................................................................................................................................... 9

2.4 Predictable misuse .................................................................................................................................................. 9

2.5 Remaining risks ..................................................................................................................................................... 10

2.6 Display of warnings ............................................................................................................................................... 10

2.7 Safety and warning labels on the system components ........................................................................................ 11

2.8 Obligations of operator and target group ............................................................................................................ 11

2.9 Wear personal protective gear ............................................................................................................................. 11

3 System description ........................................................................................................................................ 12

3.1 Package contents .................................................................................................................................................. 13

3.1.1 MVS system .................................................................................................................................................. 13

3.1.2 Service kit ...................................................................................................................................................... 13

3.2 Type signs ............................................................................................................................................................. 14

3.3 Technical Data ...................................................................................................................................................... 14

3.4 Components .......................................................................................................................................................... 14

3.4.1 Video control unit ......................................................................................................................................... 14

3.4.2 Camera .......................................................................................................................................................... 14

3.4.3 Monitor ......................................................................................................................................................... 15

3.4.4 Operator control unit .................................................................................................................................... 15

4 Installation .................................................................................................................................................... 16

4.1 Selecting the best possible installation location .................................................................................................. 16

4.2 Installation of the MVCD control unit ................................................................................................................... 17

4.3 Installation of monitor .......................................................................................................................................... 17

4.4 Laying cables ......................................................................................................................................................... 17

4.4.1 Preparing for laying....................................................................................................................................... 17

4.4.2 Laying cables ................................................................................................................................................. 17

4.5 Electrical connections ........................................................................................................................................... 18

4.5.1 Power supply ................................................................................................................................................ 18

4.5.2 Cameras ........................................................................................................................................................ 18

4.5.3 Monitor ......................................................................................................................................................... 18

4.5.4 MBE1000 operator control unit .................................................................................................................... 18

4.5.5 Control leads/CAN bus connector ................................................................................................................ 18

4.5.6 Connection digram ....................................................................................................................................... 19

5 Operation ..................................................................................................................................................... 20

4

5.1 Switching on the system ....................................................................................................................................... 20

5.1.1 Menu overview ............................................................................................................................................. 21

5

6 Getting started .............................................................................................................................................. 22

6.1 Language selection ............................................................................................................................................... 22

6.2 Basic set 270° or 360° ........................................................................................................................................... 22

6.3 Basic setting of the image mode .......................................................................................................................... 23

6.4 Stitching or Blending basic setting ........................................................................................................................ 23

6.5 Calibration............................................................................................................................................................. 24

6.5.1 Basic setting Calibration marker size ............................................................................................................ 24

6.5.2 Laying out the calibration markers ............................................................................................................... 24

6.5.3 Aligning the 360° system .............................................................................................................................. 25

6.5.4 Aligning the 270° system .............................................................................................................................. 25

6.5.5 Check the position of the calibration markers ............................................................................................. 26

6.5.6 Enter the effective dimensions ..................................................................................................................... 26

6.5.7 Requirements for the calibration ................................................................................................................. 27

6.5.8 Semi-automatic calibration .......................................................................................................................... 27

6.6 Saving the settings ................................................................................................................................................ 28

7 Advanced features ........................................................................................................................................ 29

7.1 Blending zones ...................................................................................................................................................... 29

7.1.1 Stitching ........................................................................................................................................................ 29

7.1.2 Blending ........................................................................................................................................................ 30

7.2 Manual calibration ................................................................................................................................................ 31

7.3 Control lines .......................................................................................................................................................... 33

7.3.1 Introduction .................................................................................................................................................. 33

7.3.2 Requirements ............................................................................................................................................... 33

7.3.3 Configuration ................................................................................................................................................ 34

7.4 Static overlays ....................................................................................................................................................... 35

7.4.1 Introduction .................................................................................................................................................. 35

7.4.2 Configuration ................................................................................................................................................ 35

7.4.3 Delete Overlays ............................................................................................................................................. 37

7.5 Adjusting the vehicle image contour .................................................................................................................... 38

7.5.1 Configuration ................................................................................................................................................ 38

7.5.2 Creating a customised vehicle image ........................................................................................................... 39

7.6 Connecting ultrasonic sensors .............................................................................................................................. 42

7.6.1 Introduction .................................................................................................................................................. 42

7.6.2 Connection and configuration ...................................................................................................................... 43

7.6.3 Configuration ................................................................................................................................................ 43

7.6.4 Editing/deleting sensors ............................................................................................................................... 44

7.6.5 Overlays ........................................................................................................................................................ 45

8 Operating mode ............................................................................................................................................ 46

9 Fault fixing .................................................................................................................................................... 47

9.1 Hardware .............................................................................................................................................................. 47

9.2 Malfunctions during the initial start-up ............................................................................................................... 48

9.3 Malfunctions during operation ............................................................................................................................. 49

9.4 Ultrasonic sensors ................................................................................................................................................. 51

10 Maintenance ................................................................................................................................................. 52

10.1 Cleaning the monitor ............................................................................................................................................ 52

10.2 Cleaning the camera lenses .................................................................................................................................. 52

11 Disposal and environmental protection ......................................................................................................... 52

6

11.1 Disposal of packaging ........................................................................................................................................... 52

11.2 Disposal of the products ....................................................................................................................................... 52

12 Index ............................................................................................................................................................ 53

7

1 About these instructions

Thank you for your confidence in Motec products!

• We develop and manufacture our products with the

greatest of care.

• Our products are constantly being developed; Motec

GmbH reserves the right to make changes to system

components without prior notification.

• If operated in terms with the product’s intended use,

these installation instructions help you to use the

product safely.

• These installation instructions apply only to the product

indicated on the cover sheet.

• We reserve the right to make changes to these

installation instructions based on technical

advancements.

• These installation instructions are part of the scope of

delivery.

• These installation instructions are valid starting from

the date of transport to final disposal. Compliance is

mandatory.

• Therefore, always keep the instalation instructions in a

legible condition and store it in the cockpit. Pass on the

document if you sell the product.

• The operating company must ensure that the

installation instructions are read and understood by all

persons before starting to work on the product.

• The chapter on safety gives an overview about all the

important aspects of safety to ensure optimum

protection of personnel and safe, trouble-free operation

of the product.

• The manufacturer cannot be held liable for damage

resulting from non-compliance with these installation

instructions.

• For all questions on set-up guidelines and interface

documentation, please contact the vehicle

manufacturer directly.

1.1 Contact

If you have any questions about the product, its

commissioning or operation or if the products does not

meet your expectations, please do not hesitate to contact

us.

Motec GmbH

Service

Oberweyerer Str. 21

65589 Hadamar-Steinbach

GERMANY

Phone:

+49 6433 9145-9888

Fax:

+49 6433 9145-9877

E-mail:

motec.service@ametek.com

Internet:

www.motec-cameras.com

1.2 Design features

Various elements of the operating instructions have fixed

design features.

Text

Normal body text

•

Bullet points

1.

Steps

This is the general hazard symbol.

It warns of hazards to life or potential injury.

PLEASE NOTE

The words PLEASE NOTE indicate further information

on the device or its use.

1.3 Target group for these instructions

These installation instructions are aimed at the personnel

of the manufacturers or personnel trained by the

manufacturer and charged with the installation of the

product.

The installation and electrical connection must always be

carried out by appropriately qualified personnel!

8

1.4 Other applicable documents

Compliance with the following applicable documentation

is mandatory:

• Setup guidelines and applicable standards.

• Technical specifications of the vehicle and setup

manufacturer.

• Datasheets and operating instructions for system

components.

• Motec System Bus (MSB 2.0) specification for systems

with CAN communication to the vehicle.

1.5 Declaration of conformity

• As the initial vendor within Europe, we have conducted

an evaluation of conformity for our products in

accordance with EU directives and legal regulations

based on the requirements of the relevant "harmonised

standards".

• You will find the CE mark on the product and also on

the accompanying product documentation.

• We will be happy to provide you with a separate EC

Declaration of Conformity upon request.

1.6 Guarantee

• Please report any guarantee claims to your supplier or

service partner immediately after you discover the fault

or error.

• The guarantee shall be invalidated in all cases in which

no liability claims can be asserted.

• If the system is used improperly or incorrectly, no

liability can be accepted for any damage caused.

• In case of use outside the EU, the user is required to

comply with relevant national requirements.

• If modifications are made to the device, compliance

with the requirements of conformity is no longer

ensured and the warranty becomes void.

• No liability is accepted for damage or malfunctions

which are caused as described below:

• Failure to comply with the instructions.

• Unauthorised modifications to the system.

• Operating errors.

• Failure to carry out maintenance.

• The system must only be repaired, maintained and

configured by qualified personnel in conjunction with

Motec.

• In the event of a fault, contact the supplier or service

partner immediately if it cannot be remedied.

• The information, diagrams and descriptions in these

instructions cannot be used to derive requests to

modify existing supplied systems and components.

• The information in these instructions describes the

characteristics of the product without guaranteeing

them.

• The information, data and instructions set out in these

instructions was up-to-date at the time of printing.

• If using external components such as on-board sat-nav

systems or multi-functional displays, liability claims are

invalidated.

• Motec accepts no liability for different page ratios,

vehicle-related restrictions and related display formats.

For more information, please consult the relevant

operating and installation instructions.

9

2 Safety

2.1 Introduction

This chapter gives an overview of all important safety

aspects to protect personnel, for safe and trouble-free use

of the product from installation through to disposal.

• Failure to comply with the instructions and safety

instructions set out in this manual can lead to

significant risks of personal injury or damage to the

product.

• The product has been designed based on the state-ofthe-art and recognised technical safety guidelines and

standards. The product is safe to use.

2.2 Intended use

• The Motec MVS System is a driver assistance system

can only be operated with a its system limits.

• The device provides the driver with a 270°/360° allround view from a bird's-eye perspective. Images

provided by the wide angle cameras that are installed

on both sides, the front and rear of the

vehicle/machinery capture the surroundings.

In order to obtain the desired images, the MVS System

must be installed and operated compliant with these

operating instructions.

The driver/operator shall be responsible for the safe

operation of the vehicle at all times. This obligation

applies in particular if personnel remain in the danger

zone of the vehicle/machinery.

2.3 Non-intended use

Any use of other than that described in the

Chapter"Intended use" on page 9and any use beyond that

shall be deemed non-intended.

• The manufacturer accepts no liability for damage

caused as a result. The risk is borne solely by the

user/operating company.

• It is prohibited to change the system in any shape or

form.

• It is prohibited to operate the system by bypassing the

safety devices.

• It is prohibited to use components which are defect and

therefore jeopardise the safety of the system!

• The Motec MVS is not suitable for the protection of

persons in the sense of the applicable standards and

guidelines for machines and vehicles (Machinery

Directive 2006/42 / EU, DIN EN ISO 13849 and ISO

26262).

2.4 Predictable misuse

The following points describe predictable misuse of the

product:

• Work or operation carried out by unskilled or

insufficiently skilled personnel.

• Improper installation.

• Failure to comply with operational data and

maintenance intervals.

• Operation without or with damaged components, which

are intended for the safety of the persons and the

system.

10

2.5 Remaining risks

Folge

Remaining risks can occur under the following

circumstances:

• If the system is not used as intended, if the system is

modified or altered improperly.

• If the system is operated improperly by untrained or

unskilled personnel.

• If the system is cleaned, serviced or maintained

improperly and/or if non-compliant with scheduled

service intervals.

The following remaining risks should also be taken into

consideration:

• Electrical current during installation or cleaning can

lead to injury or death. Work on the electrical system

must only be carried out by qualified electricians while

the system is disconnected!

• Working in close quarters poses the risk of bumps and

crush injuries and cuts from sharp corners and edges.

• Improper handling can damage the bodywork,

components or cables.

• Welding work may not be carried out on tank

components!

• Failure to comply with the installation guidelines and

technical specifications of the vehicle and

manufacturer.

• Tree branches or other objects above the cameras are

not recorded! In this case, the use of the rear-view

mirrors or the assistance of a banksman is mandatory!

• The higher an object from the ground, the more this

object is displayed on the monitor as bending outward.

This representation, which is not true to scale, must be

taken into account by the driver.

• The display in the monitor is true to scale only on the

footprint of the vehicle and only in the undistorted

mode.

• The image quality decreases with corresponding

environmental conditions: In this case, a banksman

must be available during the manoeuvring of the

vehicle.

• However, the reality may slightly deviate from this

composed image. Objects outside the image cones are

not captured.

2.6 Display of warnings

In these instructions, warnings are shown in the form of

warning pictograms. The warnings must be observed in

order to avoid accidents, injury or damage to property.

The warnings are introduced by keywords which express

the extent of the risk.

The following key words and symbols are used within these

instructions.

This is the general hazard symbol.

It warns of hazards to life or potential injury.

DANGER

The keyword DANGER is used for an immediate risk.

Failure to observe will lead to serious injury or death.

WARNING

The keyword WARNING is used for a potential risk.

Failure to observe could lead to serious injury or death.

CAUTION

The keyword CAUTION is used for a potential risk.

Failure to observe could lead to minor to moderate

injuries.

CAREFUL

The keyword CAREFUL indicates possible damage to

property. Failure to observe could lead to damage to the

product.

11

2.7 Safety and warning labels on the system

components

Information and symbols, such as safety labels and signs,

attached to the system components must be observed.

These safety labels and signs must not be removed and

must be kept in legible at all times.

2.8 Obligations of operator and target group

• Never operate or continue to operate system

components with safety-relevant faults.

• Prior to their use, check all system components for

obvious damage and observe their functions in order to

detect potential faults.

• Defects that are detrimental to safety must be rectified

before the system is placed in operation again.

Otherwise, the system must not be used!

• The correct installation and proper operation of the

system must be monitored by the operating company.

• The operator must ensure that the installer, the

electrician and the user have read and understood the

instructions.

• The operator and user are therefore responsible for

ensuring correct use of the system.

• Prior to driving, the driver must proceed with a visual

inspection and a functional test before using the

system.

• Before the installation of the system components and

during their operation, compliance with the applicable

manufacturer's information and safety instructions of

the vehicle is mandatory.

• When using the system, compliance with the

recommended installation guidelines and

manufacturer's interface documentation is mandatory.

2.9 Wear personal protective gear

• When working on the system components or on the

vehicle, the necessary personal protective equipment

must be worn.

• Failure to wear personal protective gear can lead to

serious injury or death.

• Make sure that there are no unauthorised personnel in

the hazardous area.

• For further information, the operator provides the

current, locally relevant guidelines for the occupational

safety and accident prevention.

12

3 System description

The Mobile Vicinity Scout (MVS) is a camera system

designed especially for utility vehicles. It provides the driver

with a clear, seamless 270° or 360° view around his

vehicle.

The MVS system is used for heavy-duty and commercial

vehicles, which are utilised in the construction industry,

municipal transport and goods traffic, agricultural industry

and logistics.

Fig. 1: Top view (example)

Camera system

The system generates one image of one vehicle side,

using 3 cameras (270° system) or 4 cameras (360°

system). These individual images are processed to

generate a top view. The top view provides a seamless

panoramic view around the area close to the vehicle. This

view increases the safety during manoeuvring.

• During calibration, the system crops the displayed

image to the area near the vehicle.

• Objects in the detection area of the cameras and within

the calibration range are displayed.

• Inserting a customer-specific vehicle image to ensure a

display that is accurate to the contour of the vehicle.

• Display of individual static overlays for the

representation of danger areas, swivel ranges or

support points.

• The open interfaces allow a comprehensive integration

into the vehicle's electronic system and interconnection

with currently installed systems.

Additional camera in the 270° system

An additional camera (e.g., a rear-view camera) can be

connected to the 270° system. The camera image can be

selected via the control inputs or the CAN bus.

Additional sensors

As an option, up to 12 ultrasonic sensors can be connected

to the system in conjunction with the optional MVCU1300-1

control unit.

Objects detected by the ultrasonic sensors are displayed

as coloured dynamic overlays in the top view.

A (pre) warning of objects outside the field of view of the

cameras is possible via the ultrasonic sensors if the

detection range of the ultrasonic sensors is greater than

the calibration range of the cameras shown.

13

3.1 Package contents

1. Verify that all listed components are available for your

system according to the following tables.

2. Based on the information provided on the type plates of

the components, ensure that the type of the

components matches the applicable operating

instructions.

3. Check whether the corresponding operating

instructions or data sheets are available for all

components.

4. Verify all components before use and check for obvious

defects.

5. Report any damage or other defects immediately to

your supplier/service partner.

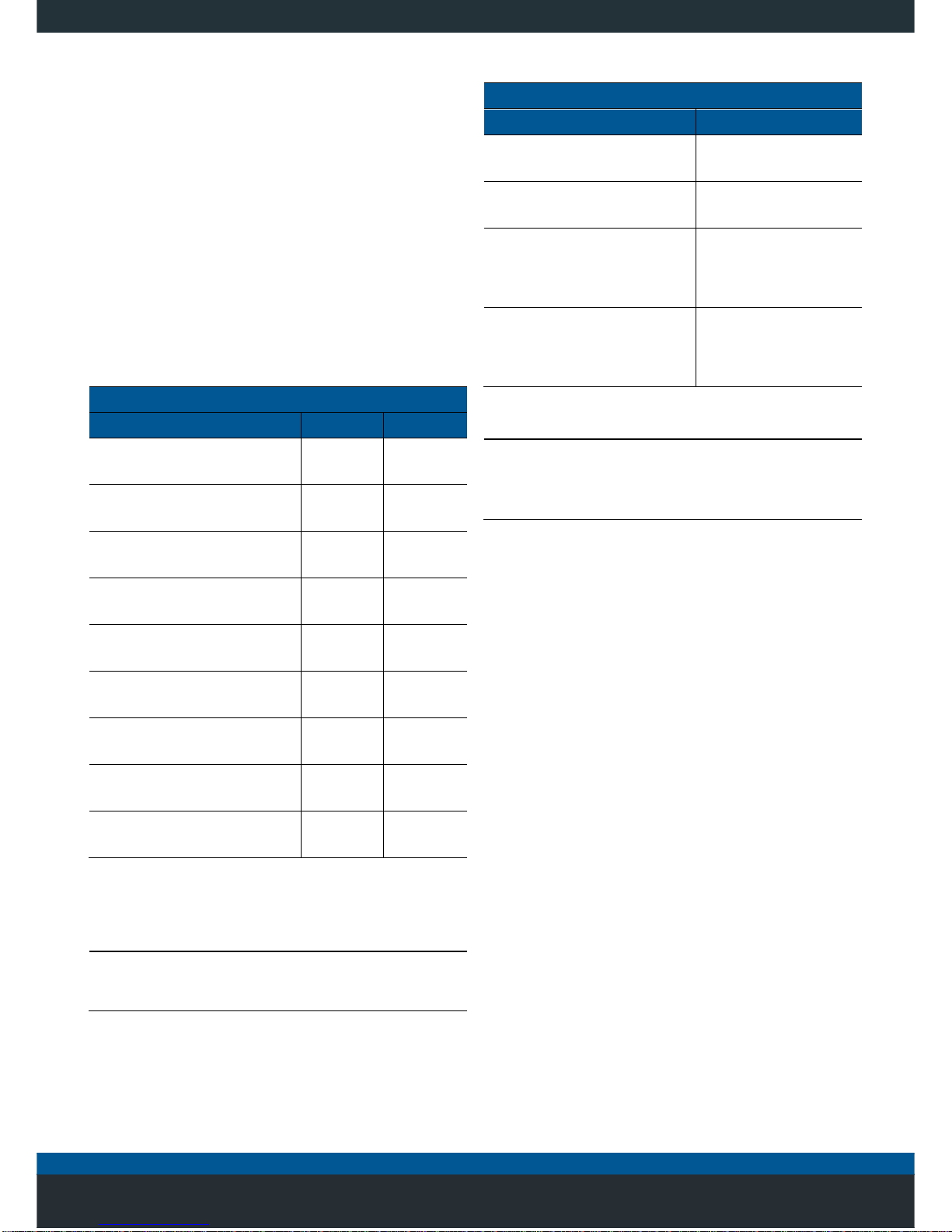

3.1.1 MVS system

MVS scope of delivery

Component

360°

270°

Video control unit

MVCD1000-x / MVCD1001-x

1x

1x

Wide angle camera

MC7180N

4x

3x

Heavy-duty monitor

MD3071A-V

1x1)

1x1)

Heavy-duty monitor

MD3071A

—

1x

MK723 connection cable

Power supply

1x

1x

MK772 connection cable

Control lead (for MVCD1000-x)

1x

1x

MK798 connection cable

CAN cable (for MVCD1001-x)

1x

1x

MK722 connection cable

Monitor

1x

1x

Connection cable MKS

Camera

4x

3x

1) optional, either MD3071A-V or MD3071A.

PLEASE NOTE

The connection cables are available in different lengths.

The applicable length must be specified when ordering

the system.

3.1.2 Service kit

Delivery scope of Service kit

Component

Quantity

Operator control unit

MBE1000

1x

Ethernet cable

MK773

1x

Calibration targets 1.5 x

1.5 m

PF400, set includes

8 calibration targets

1x

Y-cable CAN-Bus

Only for configuration of the

system if optional ultrasonic

sensors are connected

1x (optional)

PLEASE NOTE

The service kit is only required for the initial start-up and

configuring the MVS system.

The service kit can be used to configure multiple MVS

systems.

14

3.2 Type signs

Fig. 2: System components type sign (example)

1 Match code

2 Article number

3 Serial number

4 Power supply

5 Power consumption

6 Manufacturer’s

address

7 CE mark

8 FCC approval

9 ECE test mark with

approval number

The type signs on the system components correspond to

the example shown above. All information and symbols are

not always available.

Fig. 3: Cable ifentification (example)

1 Match code

2 Article number

3 Batch identification (week of production/year)

A shrink tube is used to attach the cable identification to

ensure, it cannot be lost.

3.3 Technical Data

PLEASE NOTE

For detailed information on the technical data of the

components, please refer to the relevant data sheets.

To download the data sheets of the components go to

http://www.motec-cameras.com/.

3.4 Components

3.4.1 Video control unit

Fig. 4: MVCD1000-x / MVCD1001-x

The video control unit processes the images delivered by

the cameras to a 360° or 270° panoramic view.

The video control unit is available in two versions

depending on the vehicle connection:

MVCD1000-x

Digital control signals are used to connect to the vehicle.

MVCD1001-x

A CAN bus is used to connect to the vehicle.

3.4.2 Camera

Fig. 5: MC7180N

The MC7180N wide angle camera is used for the

270°/360° bird’s eye view system.

The 180° view angle and the small design enable

adaptation to very different vehicle and visibility situations.

•

270° systems use three cameras.

•

360° systems use four cameras.

The cameras are connected to the video control unit via the

MKS cable and are supplied with voltage by the video

control unit.

15

3.4.3 Monitor

Fig. 6: MD3071A

Fig. 7: MD3071A-V

The 7'' monitor displays the image calculated by the video

control unit.

Depending on the system configuration, the monitor is

available in two models:

System

Monitor

360° or 270°

system

MD3071A-V

Vertical monitor alignment (portrait

format)

270° system

MD3071A

Horizontal monitor alignment

(landscape format)

3.4.4 Operator control unit

Fig. 8: MBE1000 operator control unit

The MBE1000 operator control unit is only required for the

initial start-up and configuring the MVS system.

The operator control unit is connected to the CAN 2 port of

the video control unit.

16

4 Installation

4.1 Selecting the best possible installation

location

Due to the large number of possible vehicle dimensions

and designs, observation of the general notes on the

optimal positioning is highly recommended.

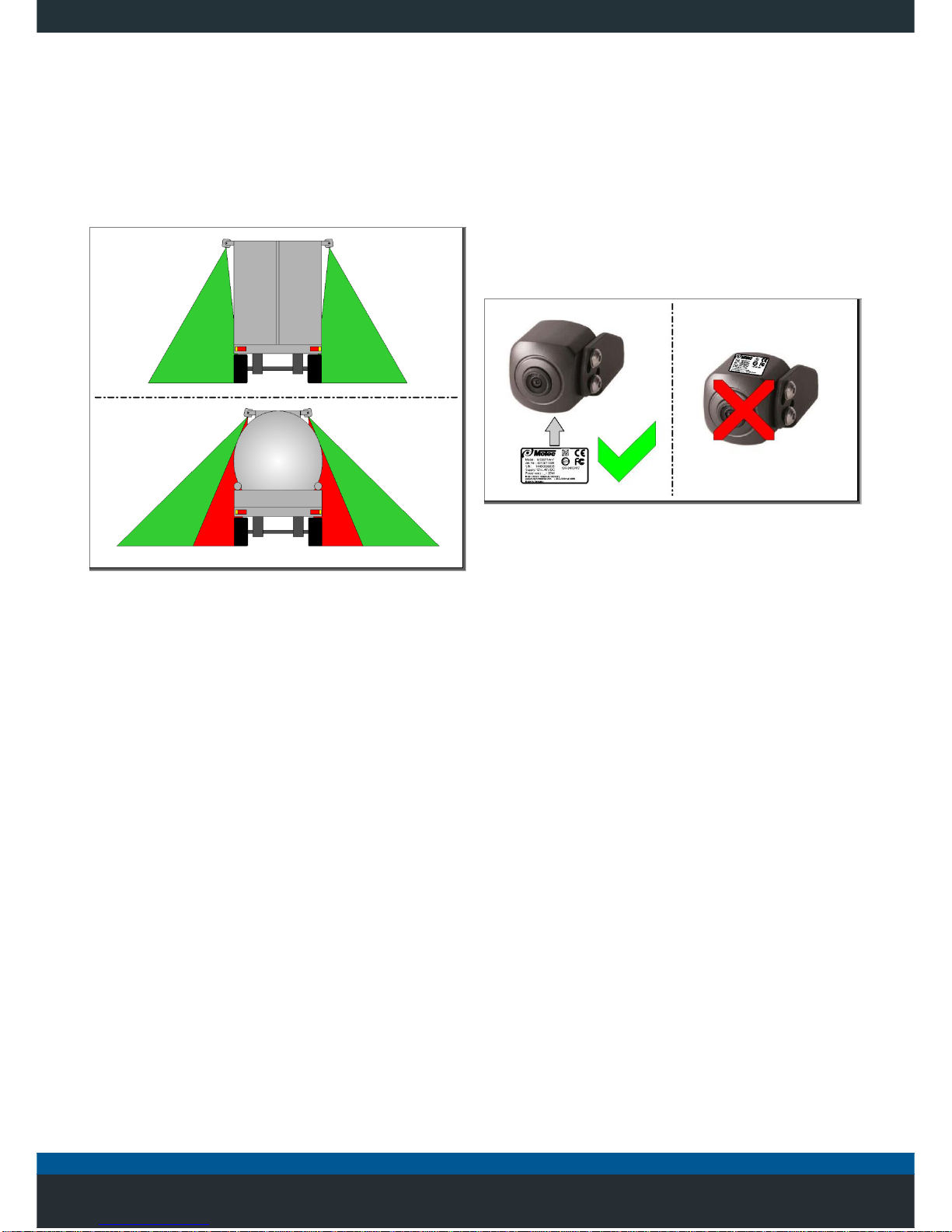

Fig. 9: Camera positions and blind spots

• Keep in mind that convex panels or added

structures may restrict the view.

• In this case, the area immediately next to the

vehicle will not be captured completely, see red

zones Fig. 9.

• Within the context of legal and technical options, it

is possible to use brackets in order to mount the

cameras in order to enlarge the viewing field.

Also observe the following instructions for selecting the

mounting position:

• Position the cameras as high as possible and in the

centre of the relevant side of the vehicle after the

calibration.

• In the case of vehicles which are subject to

authorisation for the transport on public roads,

when the camera protrudes beyond the outer

contour of the vehicle: Mount the cameras at a

minimum height of 2 meters

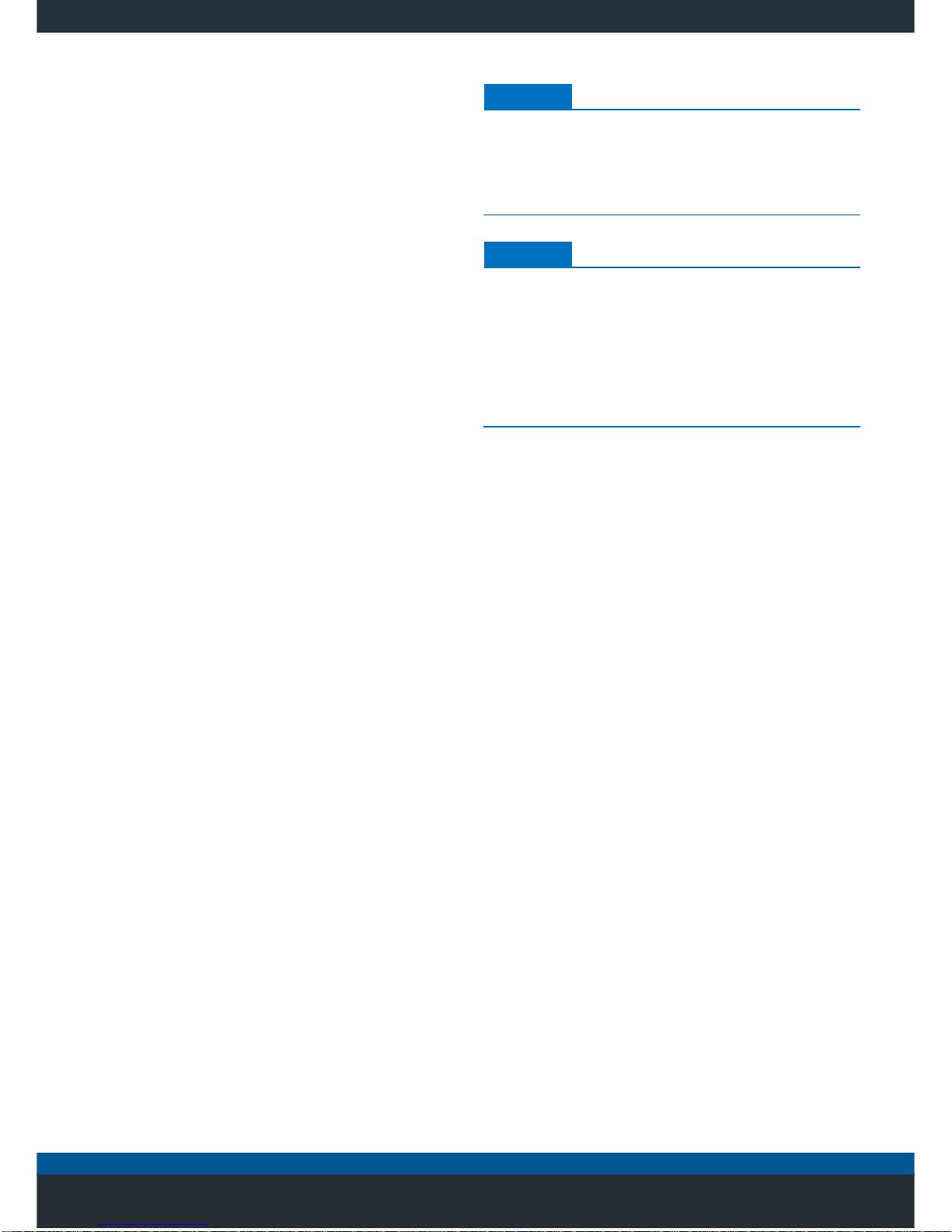

• When installing the cameras, ensure the type plate

points downwards of the vehicle.

Fig. 10: Type plate position

• Cameras that project the vehicle's contour must be

protected with suitable safety bar or cover.

• Align the cameras in order to ensure that the image

of the vehicle boundaries is captured. The area

around the vehicle must be recorded properly and

the field of view must overlap at least 3 metres.

• Avoid installation positions where add-on

components restrict the view of the road.

• Avoid installation positions subject to excessive

vibrations.

• Never install the cameras on movable attachments.

• Avoid installation positions subject to an increased

risk of contamination.

17

4.2 Installation of the MVCD control unit

• Select an installation location that is not subject to

excessive vibrations.

• Do not install the unit next to a heat source.

• If installed externally, avoid areas subject to an

increased risk of contamination.

• Ensure all plug connectors are easily accessible.

• Use the standard safety socket covers, included as a

standard, and plug them into outlets that are not being

used.

4.3 Installation of monitor

• Always install the monitor outside of the effective area

of the air bags and head impact zone; otherwise there

is a risk of severe injuries.

• Avoid installation positions that restrict the direct view.

• If possible, select an installation position that allows the

driver a direct view from the front and at the same time

provides unobstructed access to all controls.

• Ensure the mounting area is vibration-free.

• If making vehicle-specific brackets, ensure the stability

of the support and the mount is adequate.

4.4 Laying cables

CAREFUL

Damage to the vehicle’s body!

Improper and unsuitable drilling holes can damage the

bodywork and cables.

• Only drill in places without cable runs.

• ensure to protect drill holes with corrosion protection.

CAREFUL

Damage to cables!

Cables can be damaged by mechanical devices or

chemicals.

• Never paint the cable or bring in contact with solvents

of any kind.

• Never install cables near a heat source.

• Compliance with installation instructions is

mandatory.

Since the installation of the cables depends on the

respective vehicle, only general information on cable

routing can be provided.

If in doubt, consult with the vehicle manufacturer to

determine the best possible route.

4.4.1 Preparing for laying

In order to install the cables, you must drill cable glands at

this step and install cable ducts or cable conduits to protect

the cables.

1. Pilot-drill each cable feed-through and then drill the

hole to the required diameter.

2. Deburr all cable feed-through.

3. Drill holes for cable ducts.

4. Install cable ducts or cable conduits.

4.4.2 Laying cables

1. Use cable ties to secure cables and to minimize

mechanical stress

2. If the cables are too long install the cables in loops,

taking into account the minimum installation radii.

Loading...

Loading...